Abstract

The difficulty of underground gas extraction in coal mines depends on the permeability of the coal body, and coal body permeability enhancement is one of the keys to gas extraction research. To improve the permeability of low-permeability coal seams, artificial measures to increase the cracking of coal seams are an effective means to improve the permeability of coal seams. By analyzing the principle of high-pressure water jet seam making, experimental research on the influencing factors of jet flat drag seam making was carried out with a true triaxial test device, and the influencing laws of jet angle, number of drilling holes, jet pressure, ground stress, and seam strength on the seam making effect were analyzed, and on-site applications were carried out. The test results show that the high-pressure water jet can form evenly distributed ‘tooth-like’ cracks on both sides of the slit hole, and with the increase of the jet angle and the increase of the strength of the coal seam, as well as the increase of the ground stress, the length of the cracks is gradually reduced; On the contrary, the crack length becomes progressively longer as the jet pressure increases.Field test results show that the optimal cutting pressure is 80 MPa, when the cutting time is 12 min, the corresponding depth of cutting is about 1.75 m, at this time, the reasonable optimal cutting hole spacing is 6 m, the optimal cutting slot spacing is 4 m. The experimental results can provide a reference for similar coal mine gas extraction and hydrometallisation measures for gas management.

Similar content being viewed by others

Introduction

Coal seam permeability is a decisive factor for gas extraction efficiency and directly affects the effectiveness of mine gas management1,2,3. During coal mining operations, methane extraction from high-methane, low-permeability coal seams has always been a major challenge in mine methane management, with the primary issue being low extraction efficiency4,5,6,7. As mining depths continue to increase, the problems of high methane pressure, low permeability, and poor methane control in deep coal seams are becoming increasingly prominent, posing a serious threat to mine safety and production continuity8,9,10,11. Therefore, improving the gas extraction efficiency of low-permeability coal seams has become an urgent issue that needs to be addressed12,13,14.

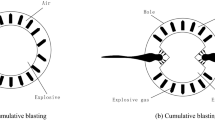

High-pressure water jet seam cutting technology as an advanced process means, through the special nozzle jet high-speed water column, the coal body cutting and crushing, and at the same time produce the stress wave effect and secondary crack expansion effect, the formation of large-area pressure relief penetration, and thus increase the permeability of the coal seam15. In recent years, scholars at home and abroad have conducted in-depth research around high-pressure water jet seam cutting technology. Sun et al.16 found that hydraulic seam-opening measures are particularly beneficial for gas control in high-ground-stress coal seams, and determined the optimum hydraulic seam spacing. Ma17on the other hand, combined high-pressure water jet cutting with fracturing to increase permeability and found that the technique was more uniform and effective in increasing coal seam permeability. In addition, the study by Jia et al.18 showed that high-pressure water jet impact can form a seam on the coal seam surface, which triggers stress release and thus improves the gas extraction efficiency. Another study pointed out that high-pressure hydraulic grooving technology is an effective means of unloading pressure and increasing penetration in high-gas, low-permeability coal seams, and the parameters such as cutting pressure, time, rotational speed, and spacing were discussed in depth19,20,21,22,23. Meanwhile, liquid CO2 fracturing technology has also been proved to be able to enhance the permeability and promote the management of gas extraction from low-permeability coal seams24,25,26,27,28. On the basis of high-pressure water jet technology, Ji and Lu29,30 studied the feasibility and implementation plan of the integrated high-pressure water drilling and slotting technology, and found that the ultra-high-pressure water-cutting coal seam cracking and penetration enhancement technology can effectively conduct the original cracks within the coal body and enhance the gas extraction effect of the drilling holes along the coal seam. Huang et al.31 proposed a multi-borehole pre-fracture blasting technique to improve permeability in response to the difficulty of gas extraction from soft coal seams. Li et al.32 on the other hand, proposed the deep-hole pre-cracking blasting penetration enhancement technology and studied its fracturing mechanism, and the results showed that this technology can effectively increase the permeability of low-permeability coal seams and improve the gas extraction rate; In terms of rock-breaking criterion, Ge et al.33 established an energy criterion for rock-breaking by water jets under true triaxial conditions based on the consideration of triaxial stress and studied the rock-breaking mode. Chen et al.34on the other hand, investigated the evolution of gas permeability induced by triaxial loading-unloading stresses using a triaxial loading-gas percolation test system. Zhao et al.35 analysed the effect of ground stress distribution on the permeability of coal reservoirs and found that the permeability of coal reservoirs decreases with increasing stress as the depth of burial increases. Hou et al.36 on the other hand, conducted coupled stress-strain-permeability tests on coal and investigated the evolutionary characteristics of coal permeability during stress loading and unloading. Li37 used ultra-high-pressure hydraulic trenching technology, combined with the characteristics of the mine, and proposed a new method of arranging trenching holes and ordinary holes.

The above study shows that many scholars have in-depth research on water jet seam cutting technology that can improve the permeability of the coal seam, but for the high-pressure water jet seam making influencing factors on the role of the mechanism of seam making needs to be further. Given this, to study the influence of the number of cloth control, ground stress, jet pressure, and other factors on the high-pressure water jet flat drag seam in the coal seam, this paper, with the help of self-developed true three-axis test device on the influence of the jet flat drag seam, the use of similar material simulation test method, by changing the ratio of similar materials, applying different stress conditions, simulating the changes in the coal reservoir under various geological conditions, to explore the rules of jet flat drag seam and the effect of cutting seam. Explore the law of jet flat drag seaming and the effect of cutting seams. The experimental results can provide a reference for similar coal mine gas extraction and hydrometallisation measures for gas management.

High-pressure jet flat drag seam making experiment

Experimental setup

Adopt self-developed multifunctional true three-axis high-pressure water jet flat drag seam-making experimental device for testing, the device consists of a test bench frame, manual hydraulic pump (6), pressure plate, jet flat drag pump, jet flat drag tube, panning trolley, pressure and flow collector, computer, pressure and data acquisition software and specimen making moulds and other components. The size of the test bench frame is 1000 mm×1000 mm×1000 mm, and a number of holes are reserved on one side of the test bench frame for jet flat towing, with a hole diameter of 40 mm and a horizontal distance of 100 mm, which can satisfy the requirements of different sizes of specimens in different positions of the jet flat towing tube during the flat towing jet experiment, as shown in Fig. 1-a.The pan trolley is specially designed to adjust the high-pressure water jet flat drag tube to different heights in order to realise the flat drag cutting slit in different positions of the borehole, and also to facilitate the safe operation of the high-pressure jet flat drag tube advancement in the borehole, as shown in Fig. 1-b; The inner diameter of the jet flat drag pipe is 20 mm, and there are two small holes with a diameter of 1 mm at 5 mm from the end, and the two holes are set at 180°, which can realise the two small holes to spray high-pressure water at the same time, forming a water jet cutter to cut the coal seam; The connecting hose between the jet flat drag tube and the high pressure pump is equipped with a pressure collector and a flow collector to facilitate the collection of jet pressure and flow rate. The homemade modified high-pressure pump is rated at 1.3 KW, with a speed of 2800 r/min, and is capable of delivering a maximum pressure of 8 MPa. ROS502 hydraulic jack is a device to provide three-way loading stress, the hydraulic jack consists of two pressure head, pressure display table, rubber hose and cylinder, each pressure head can provide 30 T pressure, a total of six pressure head can meet the three directions of pressure loading requirements, loading three-way stress as shown in Fig. 1-b.

In the jet flat drag seam-making experiment, due to the experimental aperture being small and having a certain depth, coupled with the bottom of the hole environment being dim, the traditional observation method makes it difficult to effectively observe the effect of seam-making in the hole. Therefore, to facilitate the observation of the effect of flat drag stitching in the specimen hole, an intelligent omnidirectional imaging system is adopted, which, by its excellent imaging capability, can penetrate the darkness of the hole bottom and capture and present the subtle changes of cracks in an all-round and dead-angle manner, which greatly facilitates the intuitive observation of the effect of flat drag stitching in the specimen hole. An intelligent omnidirectional imaging system (drill hole peeper), consists of an imaging probe (with its light source), display plate, data acquisition software, power control box connecting cables, etc., as shown in Fig. 2. After the drill hole is peeped, the drill hole peeping picture is generated and then the picture is processed to get the crack extension map after the drill hole is cut.

Sample Preparation

Specimen mechanical parameters

It is very difficult to sample and process the large coal samples required for indoor large-scale jet flat drag seam making experiments, and in situ observation of the crack pattern is still difficult to achieve, so this test is simulated with the help of similar materials38,39. In order to more accurately simulate the hydraulic seam cutting experiments in the field coal seams, samples of the proposed construction of the flat dragged seam-making coal seams were taken and tested for physico-mechanical parameters prior to the similar simulation tests. The coal samples used in the experiment were taken from the 230,108 working face of the Xinjie No. 2 Mine, the test coal seam is a prominent coal seam, the coal seam thickness is 3.2 m. The basic parameters of the experimental coal samples are as follows: A-1: 50.1 × 100.2 mm, A-2: 50.2 × 100.2 mm, A-3: 50.1 × 100.4 mm, B-1: 50.1 × 25.2 mm, B-2: 50.1 × 25.1 mm, and B-3: 50.2 × 25.2 mm. The equipment is shown in Fig. 3.The equipment used for the experiments is the rock mechanics testing system of the State Key Laboratory of Gas Hazard Monitoring and Emergency Response Technology of Chongqing Research Institute of China Coal Industry Group Co. Ltd. The uniaxial compression test and Brazilian splitting test were used to determine the uniaxial compressive and tensile strengths, respectively.

Figure 4 shows the test results for physical and mechanical parameters, and the uniaxial compressive strength and Brazilian splitting experimental curves of different coal samples are similar. The presence of some primary fissures and weak faces in the coal samples resulted in some fluctuations in the curves obtained when performing the mechanical parameter tests. As shown in Table 1, the test results indicated that the average uniaxial compressive strength and tensile strength of the coal samples were 8.03 MPa and 0.44 MPa, respectively.

Similar material proportioning experiments

According to the mechanical parameters of the coal seam, the proportioning test of similar materials was carried out, and the specimens were mainly made of cement, sand gypsum, etc. The uniaxial compression and Brazilian split specimens were made with fine sand and coal powder (below 80 mesh) as aggregate and cement, and gypsum and lime as cementing materials. Specific similar material specimens were fabricated as shown in Fig. 5. The specimen with similar material mechanical parameters was carried out on a DN-W100KN universal testing machine (DANA) with a loading rate of 0.1 mm/min during the experiment, and the testing process is shown in Fig. 6.

Based on the results of similar materials and proportioning tests, the final determination of the experimental specimen ratio of fine sand: cement: lime: gypsum = 8:1:1:1, grey water ratio of 3:140, 41. specimen size of 300 mm × 300 mm × 300 mm. The test specimens were made by pouring method, and during the specimen pouring process, the plastic pipe with a hole diameter of 40 mm was pre-buried according to the experimental needs to simulate the coal seam drilling, as shown in Fig. 7.

Experimental programme

The test programme is shown in Table 2, this test by using the control variable method, respectively change the specimen of the jet angle, the number of drilling holes, the jet pressure, the ground stress, the strength of the coal seam in one of the influencing factors and ensure that the other influencing factors remain unchanged. As shown in Fig. 8, the jet angles are 0°, 30°, 45° and 60°. For the number of holes, the specimen size was 300 mm × 300 mm × 300 mm, and according to the experimental scheme, it was set up as a single hole (the slit hole was located in the centre of the specimen, and the core of the holes was 150 mm away from the edge of the specimen), two holes (the slit holes were horizontally arranged, with the core of the holes being 150 mm away from the upper and lower edges of the specimen, and the left hole being 100 mm away from the left edge of the specimen, and the distance between the two cores of the holes being 100 mm) at one time, Three holes (the seam holes are distributed in a triangular shape, the distance between the centres of the holes is 100 mm horizontally, and the distance between the centres of the holes is 100 mm vertically). Geopathic stress is based on the coal seams’ distribution at the coal mine site and the data provided by the coal mine.The simulated three-way stresses are \(\:{{\upsigma\:}}_{\text{H}}=3.4\:\text{M}\text{P}\text{a},{{\upsigma\:}}_{\text{h}}=3\text{M}\text{P}\text{a},{{{\upsigma\:}}_{\text{v}1}=2\:\text{M}\text{P}\text{a},{{\upsigma\:}}_{\text{v}2}=2.4\:\text{M}\text{P}\text{a},{{\upsigma\:}}_{\text{v}3}=2.8\:\text{M}\text{P}\text{a}}_{,}\)where \(\:{{\upsigma\:}}_{\text{H}}\:\)is the simulated maximum horizontal stress, \(\:{{\upsigma\:}}_{\text{h}}\) is the simulated minimum horizontal stress, and \(\:{{\upsigma\:}}_{\text{v}1}{,{\upsigma\:}}_{\text{v}2},{{\upsigma\:}}_{\text{v}3}\)are the simulated vertical stresses.The jet pressures were set to 6.8 MPa and 7.4 MPa according to the experimental equipment; Similar material strengths of 3.57 MPa and 4.02 MPa, respectively, were used to simulate coal seam strength. Jet angle, jet pressure, ground stress, and coal seam strength are the main influencing factors of seam making effect. The effect of jet flat drag seam making is investigated by changing the jet angle, number of drilling holes, jet pressure, ground stress, and coal seam strength of the seam making holes of the specimens, which provides a reference to the field jet seam making in coal mines.

Prior to the experiment, the materials were weighed and uniformly mixed according to a similar proportioning scheme, then poured into molds. Subsequently, a vibrating compactor was employed to compact the specimens, eliminating air bubbles and enhancing density. Pre-embedded tubes were positioned and inserted into the specimen surfaces, ensuring a level finish. After a 12-hour resting period, the pre-embedded tubes were removed, and the specimens underwent a 28-day standard curing process. Following this, injection flow angles and identification numbers were marked on the specimen surfaces. A borehole inspection device was utilized to verify the conformity of the fracture holes with experimental requirements. The specimens were then mounted onto a jetting and dragging fracture creation apparatus, where triaxial stress was applied. The height of the jetting tube was adjusted and inserted into the fracture holes, with all relevant equipment connected and the pressure pump activated. Upon stabilization of the pressure, the jetting tube was translated at a constant velocity to perform the fracture creation operation. Post-operation, the equipment was shut down, pressure was released, and the specimens were extracted. The experimental phenomena were documented and photographed, with the fracture creation efficacy observed using an intelligent imaging system. The borehole walls were inspected via drilling, revealing smooth and even surfaces devoid of cracks, meeting the jetting and dragging fracture creation criteria. Specimens exhibiting wall cracks upon inspection were discarded and remanufactured until compliance was achieved. Finally, the specimens were dissected to examine the fracture distribution patterns, with experimental data recorded and results analyzed.

To make the jet stitching more visible, different colored tracers were investigated to be added to the stitching fluid (clear water). Try to use water, black ink spray, water + green ink, and three kinds of seam-making liquid for flat drag jet seam-making experiments, The making operation is completed after 30 min, along the direction of seam-making to dissect the specimen, to get three kinds of seam making liquid seam making effect as shown in Fig. 9. After the completion of the test of clear water seam sealing liquid, the outline of the seam can be generally seen; after the completion of the test of black ink spray seam sealing, the outline of the seam is visible; after the completion of the test of clear water + green ink seam sealing, the outline of the seam can be seen, and the traces of the seam are obvious; by comparing the three kinds of seam sealing liquids to show the effect, it is concluded that the clear water + green ink seam sealing liquid can highlight the effect of seam sealing better. Therefore, this time, water + green ink was used as the seam-making fluid for the jet flat drag seam-making test. In addition, as can be seen in Fig. 9, a comparison of the effect of the three types of cuts, the longest crack extension in the dentate crack on the clear water cut surface was 13.8 cm, and the shortest length was 1.7 cm; the longest crack extension in the dentate crack on the black ink spray cut surface was 4.8 cm, and the shortest was at the edge of the hole wall; and the longest crack extension in the dentate crack on the clear water + green ink cut surface was 14.7 cm, and the shortest was 0.3 cm. The crack extension is seen to be jagged and of varying lengths, with the cracks expanding and extending to the sides with the borehole as the center, forming a toothed crack pattern.

Analysis of test results

Influence of different jet angles on the effect of coal seam jet flat drag seam creation

The jet angle affects the extension length of the cutting seam in the coal seam, in order to study the influence of the jet angle on the effect of jet flat drag seam making, and investigate the relationship between the jet angle and the distribution pattern of cracks, the depth of the seam making and the influence area of the seam making, this paper carries out the research on the influence of different jet angles on the effect of jet flat drag seam making according to the geological conditions of the coal seam, and the pressure of the water out of the jet pipe in the flat drag is controlled to be 6.8 MPa; The jet angles are shown in Fig. 10(a), a single-hole specimen was selected for the experiment, and the jet angles were 0°, 30°, 45° and 60°; Before carrying out the jet flat drag seam-making operation, the inner wall of the specimen seam-making hole was peeped at using a drill hole peeper, and the hole wall was peeped at as shown in Fig. 10(b), from which the inner wall of the seam-making hole was seen to be flat and smooth, and no cracks or fissures were found.

At different jet cutting angles (0°, 30°, 45°, 60°), high-pressure water jets were able to cut slots on both sides of the borehole. Specifically, when the jet slit angle is 0°, Fig. 11(a) shows that the inner wall of the hole changes from seamless to two symmetrical slits and grooves at least 2 mm wide, horizontally distributed; After dissecting the specimen, it was found that there were traces of ‘tooth-like’ cuts of different lengths on both sides of the borehole, and the longitudinal length of the cut surface was up to 23.7 cm, with the longest crack expanding to 14.7 cm, and the shortest cracks on both sides were 5.6 cm and 1.7 cm respectively, and uniformly distributed, which indicated that it was feasible to make axial planar cuts of the jet in the borehole in the coal seam, and the difference in the length of the crack could be due to the non-homogeneity of the specimen. The difference in length may originate from the non-homogeneity of the specimen. When the jet slit angles are 30°, 45° and 60°, Figs. 11(b), 11(c), and 11(d) show that the inner wall of the hole changes from seamless to two slits and grooves with at least 1 mm width distributed at 30°, 45°, and 60°, respectively; After dissecting the specimen, there were traces of different lengths of cuts on both sides, which were unevenly ‘toothed’, and the longitudinal lengths of the cracked surfaces were 23.4 cm, 22.5 cm, and 22.4 cm, respectively, and the lengths of crack extensions were different on both sides. In short, the jet cutting angle of 0 °, 30 °, 45 ° and 60 °, high-pressure water jets can be cut on both sides of the slit hole in the basic uniform distribution of slit grooves, cracks on both sides of the borehole expansion length varies, showing uneven ‘tooth-like’ slit groove morphology.

As can be seen from Fig. 12, with the gradual increase of the jet cutting angle from 0° to 60°, the length of the slit groove on both sides of the cutting hole decreases gradually, and the length of the crack decreases from 14.7 cm to 9.5 cm, and the crack extension surface on both sides of the drilling hole is gradually reduced. The reason for the analysis is that perpendicular to the 0° angle is smaller ground stress, crack cracking is easier; and with the increase of the jet angle, the role of the ground stress is gradually revealed, the ground stress will inhibit the growth of the seam groove in different directions, so that the increase in the length of the jet incision slit is gradually difficult so that the growth of the jet incision slit length is more affected by the jet angle.

Influence of different arrangements of the number of seaming holes on the effectiveness of coal seam jet flat drag seaming

The number of seaming holes is one of the important factors to control the effect of coal seam jet flat drag seaming, in the coal mine site in the coal seam will be arranged more than one seaming drill holes, more than one drill holes jet seaming whether they affect each other, need to carry out further research, For this experiment, single-hole specimens (the influence of single-hole specimens on the effect of coal seam jet drag stitching has been illustrated in the influence of different jet angles on the effect of coal seam jet drag stitching), double-hole specimens and three-hole specimens were selected as the object of the study of jet drag stitching, and the layout of stitching holes is shown in Fig. 13.

The water jets were able to cut slots on both sides of each borehole at different two-hole jet cutting angles (0°, 30°, 45°, 60°). The results of the experiment show that: When the slit angle of 0 °, double-hole slit hole wall originally no cracks, after the jet slit are appearing left and right two basically the same horizontal distribution, the width of at least 2 mm above the slit groove; After the specimen is dissected, both sides of the double drilled holes are now cut traces of cracks, the longitudinal direction of the crack surface is 26.7 cm, and the rightmost and leftmost cracks have different lengths of extension, and there is an overlap in the middle of the joints, which indicates that the double drilled holes cut the joints through each other, and at this time, there should be a suitable spacing; When the slit angle of 30°, 45° and 60°, the double slit hole wall peeping from no crack to the jet slit after the appearance of the left and right two crack distribution angle and the jet slit angle is basically the same, the width of at least 1 mm above the slit groove; specimens dissected, both sides of the drilling hole is now slit traces, and cracks in the expansion of the length of the two sides of the different. Since none of the twin holes at these slit angles were in the same horizontally extending region, the twin drilled slit peepshots did not reveal any cross-over overlap of the two slits, and thus the twin drilled slits extended independently of each other. This discovery provides an important reference for the use of high-pressure water jet technology for porous seaming in coal seam mining.

As can be seen from Fig. 14 (a-h), the two-hole jet made a seam angle from 0° to 60°, the seam hole is a single crack, the crack extension direction is basically the same as the seam angle, the seam hole is not penetrated by other cracks, and the seam cracks are independently expanding on their own with a crack extension length of at least 6.7 cm. When creating a seam at an angle of 0°, the two drilled holes should be spaced apart to avoid cross overlap of the cracks. Therefore, the seam lengths of different angle jets are expanded independently to form an independent single crack, and the crack angle is basically the same as that of the jet, which indicates that it is feasible to make a single crack in each of the two holes in the coal seam with a two-hole water jet.

As shown in the experimental results in Fig. 15: At 0° slit angle, the inner wall of the three holes was originally free of cracks, but after the jet slit, the inner wall of each hole formed two slits on the left and right which were basically distributed at the same level, and the width of the cracks was at least 1 mm, After the specimen was dissected, the traces of these slits and grooves were clearly visible, especially in the upper first borehole and the lower double borehole, where the slits and grooves were of uneven morphology and the length of crack extension varied, with the longest being up to 11.2 cm and the shortest being 3.5 cm; As the cut angle was increased to 30° and 45°, at both angles, the cuts in the twin boreholes no longer overlapped in the same direction of extension area, but extended independently of each other, although cut traces still appeared on both sides of each borehole and the crack widths were still at least 1 mm.At 30°, the crack extension lengths differed between the upper first borehole and the lower double borehole, a trend that became more pronounced at 45°, and no cross overlap of other slots was observed in the peep charts, further confirming the independent extension of the cuttings.However, when the slit angle reached 60°, jagged toothed slits were still formed on both sides of each borehole and the crack width was still at least 1 mm, but the upper borehole and the lower left borehole showed traces of overlapping slits at the intermediate joints due to the slit angle being in the same direction, suggesting that the two boreholes may be intersecting each other at the same slit.

Therefore, the same attention to proper spacing is required when there are two drilled holes with cuts at the same angle and in the same direction at a 60° cut-off angle.

The three-hole seam specimens are susceptible to fragmentation when dissected, which may lead to the illusion of seam penetration between the drill holes, and are therefore more accurately illustrated by using a peephole view of the three-hole seam after it has been created. As can be seen in Fig. 16, the width of the crack is at least 1 mm or more, regardless of the jet-making angle from 0° to 60°, the drilling jet-making crack is a single crack, and the crack extension direction is basically the same as the jet making angle, and these single cracks are independently expanding on their own. In particular, at 0° and 60° seam angles, the cracks of the two boreholes may cross overlap due to the tendency of their seam angles to coincide in the same direction. Therefore, the cracks formed by different angles of jet fracturing are independently extended, and the minimum length of the crack extension is 3.2 cm, forming an independent single crack, which indicates that it is feasible to use three holes of water jet fracturing to form a single crack in the coal seam, but a certain spacing needs to be maintained between the two holes to avoid the cracks from crossing and overlapping. At the same time, three drill holes can effectively increase the fracture area of the coal seam, which is conducive to the unloading and penetration of the coal seam, and provides an important reference for multiple drill holes.

Influence of ground stress on the effectiveness of coal seam jet levelling drag seaming

In order to study the influence of ground stress on the effect of coal seam jet flat drag stitching, similar materials were used to cast specimens (length, width and height of 300 mm × 300 mm × 300 mm) for simulation experiments. According to the geological conditions of the coal seam endowment at the mine site, the simulated three-directional stresses were \(\:{{\upsigma\:}}_{\text{H}}=3.4\:\text{M}\text{P}\text{a}, {{\upsigma\:}}_{\text{h}}=3\text{M}\text{P}\text{a},{{\upsigma\:}}_{\text{v}1}=2\:\text{M}\text{P}\text{a}\), \(\:{{\upsigma\:}}_{\text{v}2}=2.4\:\text{M}\text{P}\text{a}, {{\upsigma\:}}_{\text{v}3}=2.8\:\text{M}\text{P}\text{a}\), where \(\:{{\upsigma\:}}_{\text{H}}\:\:\)is the modelled maximum horizontal ground stress and \(\:{{\upsigma\:}}_{\text{h}}\)is the modelled minimum horizontal ground stress,\(\:{{\upsigma\:}}_{\text{v}1}{, {\upsigma\:}}_{\text{v}2}, {{\upsigma\:}}_{\text{v}3}\) To simulate vertical ground stress, The angle of the jet flat tow to create a seam is 0°, and the test process is shown in Fig. 17.At the end of the test of different stress variations of jet seam making the specimen was moved to the ground, and the specimen was gradually dissected along the direction of seam making, and the effect of seam making inside the specimen could be seen as shown in Fig. 18.

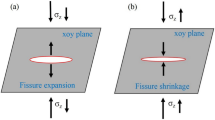

As shown in Fig. 18, the specimen was moved to the ground after the jet incision test with different stress variations. The specimen was gradually dissected along the direction of the incision, and the effect of the incision inside the specimen could be seen, and the width of the crack was at least more than 1 mm. Under different ground stress conditions, slots of different lengths appeared on both sides of the jet incised borehole, the incision was a single vertical slit, the surface of the slots was relatively rough, the extension direction of the slots was the same as the direction of the maximum principal stress, and the slots as a whole showed a jagged, toothed morphology. At a vertical ground stress of 2 MPa, the crack extension on one side of the borehole was 14.5 cm at the longest and 11.2 cm at the shortest, and on the other side the crack extension was 14.5 cm at the longest and 11.5 cm at the shortest; At a vertical ground stress of 2.4 MPa, the crack extension on one side of the borehole was 13.2 cm at the longest and 7.5 cm at the shortest, and on the other side the crack extension was 14.2 cm at the longest and 10.1 cm at the shortest; At a vertical ground stress of 2.8 MPa, the crack extension on one side of the borehole was 4.2 cm at the longest and 2.1 cm at the shortest, and on the other side the crack extension was 4.6 cm at the longest and 2.5 cm at the shortest. From the figure, it can be seen that with the horizontal principal stress from small to large, the length of the slit groove of the jet cut gradually becomes shorter, and the longest length of the crack extension decreases from 14.5 cm to 14.2 cm and finally to 4.6 cm. The crack extension surface is gradually reduced. The main reason is that the specimen is compressed by the gradual increase of the ground stress, which makes the seam groove in the process of expansion subject to greater resistance, and it is difficult to extend forward, resulting in the seam groove gradually becoming shorter.

Influence of jet pressure on the effect of coal seam jet levelling drag crevice creation

Jet pressure is also an important factor affecting the effectiveness of coal seam slitting. To study the effect of jet pressure on the effectiveness of jet flat-drag slitting of coal seams, a standard test piece (300mm3was used for simulation experiments.

The diameter of the jet hole of the seam-making pipe selected for this test is 1 mm, and after the completion of the jet flat drag seam-making test with different jet pressures, the specimen is moved to the ground, and the specimen is dissected along the direction of the seam-making direction, and the result of the seam-making of the specimen can be seen as shown in Fig. 19.

As shown in Fig. 19, the specimen was moved to the ground after the completion of the jet axial plane slit test with different pressures. The specimen was dissected along the direction of the slit, and the result of the slit of the specimen could be seen, and the width of the slit was at least 1 mm. Under different jet pressures, jagged slits and grooves appeared on both sides of the borehole, the surface of the slits and grooves was relatively rough as a single vertical slit, and the overall shape of the slits and grooves of the jet at different pressures showed jagged and toothed slits and grooves. At a jet pressure of 6.8 MPa, the longest borehole crack extension was 14.4 cm and the shortest was 5.4 cm; At a jet pressure of 7.4 MPa, the longest borehole crack extension was 14.5 cm and the shortest was 5.4 cm. From the figure, it can be seen that with the increase of jet pressure, the length of the slit groove of the jet incision gradually becomes longer, the longest length of the crack extension rises from 14.4 cm to 14.5 cm, and the length of more than 14 cm in the crack extension surface increases. The main reason is that the increase in jet pressure makes the water jet force greater, and the erosion effect on the specimen is intensified, which makes it easier for the slit groove to expand and extend forward, resulting in the gradual lengthening of the slit groove.

Influence of coal seam strength on the effectiveness of coal seam jet levelling drag seaming

Coal seam strength, as an important index to measure the ability of coal seam to resist external damage, directly determines the initiation, expansion and morphology of cracks in the process of hydraulic seam making, and is also an important influencing factor on the effect of coal seam making. To study the effect of coal seam strength on the effectiveness of coal seam jet flat dragging seam formation, a standard test piece (300mm3 was used in the simulation experiment.Taking the single-hole specimen as the research object, the angle of the flat drag jet is 0°, and the strength of the coal seam is simulated by the strength of the similar material is 3.57 MPa and 4.02 MPa, respectively, and the effect of the flat drag jet to make a seam under the condition of this strength is shown in Fig. 20.

As shown in the figure, the specimen was dissected along the direction of the cut after the completion of the jet axial plane cut test for different coal seam strengths, and the width of the crack was at least 1 mm. It can be seen that the intensity of different coal seams jet cutting on both sides of the borehole formed a different length of the slit groove, the slit groove surface uneven for a single slit groove, the slit as a whole presents uneven teeth-like slit groove morphology.The longest crack extension was 11.7 cm and the shortest was 6.1 cm at a seam strength of 3.57 MPa; The longest crack extension was 11.2 cm and the shortest was 5.2 cm at 4.02 MPa coal seam strength.As the strength of the coal seam increases, the seam length of the jet cut becomes shorter, and the longest length of the crack extension decreases from 11.7 cm to 11.2 cm, and the crack extension surface is reduced.The main reason is that the strong internal bonding and dense structure of high-strength coal seams require more energy from the jet system, and it is more difficult to form and expand the slots and grooves in high-strength coal seams under the same water jet cutting parameters.

Field trials and applications

In the process of high-pressure jet flat drag stitching, different cutting parameters selection will directly affect the cutting effect, in order to achieve the best cutting effect, selected for the 1 coal seam cutting process, the test started before the beginning of the hydrodynamic cutting technology process research in the Xinji No.2 mine 230,108 lower bottom plate road, the test area working surface shown in Fig. 21. During the research process, key parameters such as slit pressure and slit spacing were compared and tested to determine the optimal slit process parameters.

Cutting pressure

The test design examined five different slit pressures, respectively 60 MPa, 70 MPa, 80 MPa, 90 MPa, 100 MPa, for the five different slit pressures of the flat drag hydraulic slit test, continuous recording of the slit process in the borehole out of the amount of coal. The statistical results of the average coal output per metre under different slit pressures are shown in Fig. 22.

It can already be seen from Fig. 22 that the average amount of coal discharged per meter of the cutting process increases as the slit pressure increases. It can be found that the cut seam pressure reaches 80 MPa when there is a more obvious increase, and after 80 MPa the increase in coal output is not obvious, at this time the submergence effect makes the jet distal striking force decrease. Therefore, the optimum cutting pressure was selected as 80 MPa to achieve the best results of hydraulic cutting.

According to the seam formation pattern of the hydraulic slit, the depth of the hydraulic slit groove can be judged based on the amount of coal discharged from the hydraulic slit. According to the research of others and previous experiments, it is believed that the average height of the slit groove of a hydraulic slit is 12 cm, and assuming that the capacity of coal is 1.4 t/m3, the depth of the slit can be known by calculating the average amount of coal discharged per meter of the slit process. Specifically, as shown in Fig. 23, the depth of the slit is about 1.75 m when the slit pressure is 80 MPa.

Cutting time

At the slit pressure of 80 MPa, the test design examines six different slit times, that is, the time on both sides of the borehole within the range of 1 m, and the studied times are 10 min, 12 min, 14 min, 16 min, 18 min and 20 min, respectively, and the UHP hydraulic slit test is carried out for the six different slit times, and the amount of coal discharged from the borehole in the process of slit is continuously recorded. The statistical results of average coal output under different cutting time are shown in Fig. 24.

Coal output under different slotting time Fig. 25. Slit depth under different slit time.

Coal output under different slotting time Fig. 25. Slit depth under different slit time.

As can be seen from Fig. 24, with the increase of slit time, the average coal output also increases. When the increase in coal output is not obvious after 12 min of slit time, the comprehensive analysis shows that the optimal slit time for each meter of slit channel is 12 min. At the same time also on the different cutting times caused by the slit depth calculation analysis, as shown in Fig. 25, can be found with the increase of cutting time slit depth increase tendency to gradually slow down, which means that relying solely on the increase in cutting time to enhance the slit depth of the cost-effective slit, when the slit pressure of 80 MPa, the slit depth of the slit when the slit time is 12 min is about 1.75 m.

Drill hole spacing and slot spacing

Drill hole spacing

It is difficult to measure the effect of cutting seams with different drill spacing and slot spacing in terms of the amount of coal produced, so the effect of different cutting seams is judged by carrying out drilling with different drill spacing and slot spacing and extracting. In the test of different drill hole spacing and seam slot spacing, the cutting pressure used was 80 MPa, the cutting time of each metre of seam slot was 12 min, and the spacing of the designed downhole was 4 m, 5 m, 6 m and 7 m, respectively, and the specific arrangement is shown in Fig. 26.

From Fig. 27 shows the variation curve of the average single-hole gas extraction pure volume under different drilling spacings, from which it can be seen that the single-hole gas extraction pure volume of different drilling spacings show a decreasing trend with time, and the decreasing trend is sharp first and then slow. Overall, there is little difference in the pure amount of gas extracted from a single hole for different drill spacings. A careful comparison shows that the smaller the borehole spacing, the greater the pure amount of gas extracted from a single borehole at the initial stage, but at the later stage of extraction the pure amount of gas extracted from a borehole with a small borehole spacing is relatively smaller. The reason is that the smaller the spacing between drill holes, the smaller the control range, the more obvious effect of unloading pressure and penetration increase makes the initial extraction volume larger, and in the process of extraction the gas desorption of the coal seam gradually becomes less, resulting in the extraction volume is lower than that of the drill holes with a larger control range. By comparing the average single-hole extraction pure volume data, the average pure volume of gas extraction in 60 days when the spacing of downhole drill holes is 4 m, 5 m, 6 m, and 7 m respectively is 0.079 m³/min, 0.074 m³/min, 0.080 m³/min, 0.069 m³/min, so it can be known that the reasonable spacing of cut-off drill holes in the coal seam in the test area is 6 m.

Spacing of seams and slots

It is difficult to measure the effectiveness of the slit for slit spacing in terms of the amount of coal produced, but also by drilling holes with different slit spacing in real time and pumping to judge the effectiveness of the different slits. The cutting pressure used in the seam cutting process is 80 MPa, and the cutting time of each metre of seam groove is 12 min, and the designed seam groove spacing is 3 m, 4 m, 5 m and 6 m, respectively, and the specific arrangement is shown in Fig. 28.

Figure 29 shows the variation curve of the average pure volume of single-hole gas extraction under different slit slot spacing, from which it can be seen that the pure volume of single-hole gas extraction under different slit slot spacing shows a decreasing trend with time, and the decreasing trend is sharp first and then slow. Overall, the difference in the pure amount of gas extracted from a single hole with different seam slot spacing is minimal. The main reason is that the number and size of slots in each seam drill hole are the same, the only difference is the spacing of the slots, and the change in the spacing of the slots does not affect the control range of the slots on the coal seam and the effect of pressure relief. By comparing the data analysis of the average single-hole extraction pure volume of the drill holes, the average pure volume of gas extraction in 60 days when the spacing of the downhole drill holes was 3 m, 4 m, 5 m, and 6 m were 0.075 m³/min, 0.080 m³/min, 0.073 m³/min, 0.070 m³/min, respectively. It can be known that the reasonable spacing of the slit slot of the coal seams in the test area is 4 m.

Discussion

Effect of spray angle on seam formation and physical mechanism

According to fracture mechanics theory, the driving force behind crack propagation is determined by the stress intensity factor (K). When K exceeds the fracture toughness of coal (KIC), cracks initiate and propagate42,43. The spray angle directly affects the stress decomposition of the jet impact force within the coal body. At 0°, the jet direction is aligned with the borehole axis, and the impact force primarily generates tensile stress perpendicular to the direction of minimum stress. This direction exhibits the lowest resistance to crack propagation (consistent with the observation that “the longest crack forms at 0°” in the experiment). As the angle increases, the component force of the impact force in the effective fracture direction decreases, the K value at the crack tip decreases, and the propagation ability weakens. When the jet is at 0°, the water flow penetrates more thoroughly along the axis of the borehole, and the water pressure distribution within the fracture is uniform. Through the “water wedge effect”, the crack continues to expand44. However, high-angle jets (such as 60°) may cause uneven water distribution within the cracks, resulting in insufficient local water pressure and weakening the driving force on the cracks, which is consistent with the phenomenon of “shorter and irregular tooth-like crack distribution” observed in the experiment. The increase in the spray angle makes the combined effect of the jet impact force and the ground stress field more complex. The impact force of the 60° jet may partially overlap with the horizontal stress (σH = 3.4 MPa) in the same direction, causing a local increase in compressive stress in the coal body and inhibiting crack propagation. This explains why the crack propagation surface is significantly reduced at large angles.

The effect of ground stress on joint formation and its physical mechanism

In the experiment, when the vertical stress increased from 2 MPa to 2.8 MPa, the maximum crack length suddenly decreased from 14.5 cm to 4.6 cm (Fig. 18). The physical essence of this phenomenon is the inhibitory effect of stress on crack propagation in coal45,46. According to the stress redistribution theory, the propagation of cracks within coal bodies requires overcoming the compressive stress generated by in-situ stress47. As the vertical stress (σv) increases, the coal body is subjected to higher triaxial stress (\(\:{{\upsigma\:}}_{\text{H}}\) = 3.4 MPa, \(\:{{\upsigma\:}}_{\text{h}}\)= 3 MPa, \(\:{{\upsigma\:}}_{\text{v}}\) increases), and the jet impact requires more energy to offset the compressive stress, resulting in a decrease in the effective tensile stress at the crack tip.In high-stress environments, the dynamic resistance to crack propagation increases.According to fracture propagation theory, crack propagation velocity is positively correlated with energy release rate. However, increased in-situ stress reduces the energy release rate, making it difficult for cracks to propagate rapidly, ultimately resulting in shorter crack lengths (e.g., the longest crack is only 4.6 cm at 2.8 MPa).

Influence of coal seam strength on joint formation and physical mechanisms

Experiments show that when the coal seam strength increases from 3.57 MPa to 4.02 MPa, the maximum crack length decreases from 11.7 cm to 11.2 cm (Fig. 20). The physical basis for this is related to the coal body’s own ability to resist damage. Coal seam strength (uniaxial compressive strength) is positively correlated with fracture toughness KIC48. High-strength coal bodies (4.02 MPa) have a denser internal structure, stronger intergranular bonding, and require a higher KIC to initiate cracking.Under the same jet pressure, the stress intensity factor K generated by the jet is more difficult to exceed the KIC of high-strength coal bodies, resulting in a smaller crack propagation range.From the perspective of fluid-solid coupling, part of the energy of high-pressure water jets is used to overcome the strength of coal.During the cutting process of high-strength coal, more energy is used for particle fragmentation than for crack propagation, resulting in a reduction in the effective energy acting on the crack tip.The short segments of “tooth-like cracks” in the experiment (such as the shortest crack of 5.2 cm at 4.02 MPa) are precisely a manifestation of increased energy dissipation.In addition, low-strength coal bodies (3.57 MPa) contain more primary pores and microcracks, and jet impact easily causes stress concentration in these weak areas, accelerating crack propagation. High-strength coal bodies have better homogeneity and weaker stress concentration effects, and crack propagation is more dependent on the direct impact force of the jet, resulting in shorter crack lengths.

Comparison of engineering test results

Zhang49 conducted a carbon dioxide fracturing experiment at the 1312 working face of the No. 3 coal seam at the Sanyuan Coal Mine. Eleven observation holes were set up, with an initial pressure of 300 MPa and a fracturing blast hole depth of 80 m.The average gas extraction flow rates for holes 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, and 11 are 0.002 m3/min, 0.013 m3/min, 0.003 m3/min, 0.002 m3/min, 0.038 m3/min, 0.002 m³/min, 0.016 m³/min, 0.002 m³/min, 0.001 m³/min, 0.003 m³/min, and 0.004 m³/min.It can thus be seen that the gas extraction volume of the observation hole is lower than that of the high-pressure water jet process at the site, and it takes effect quickly with fewer extraction cycles.High-pressure water jet fracturing technology uses the powerful impact force of high-pressure water jets to form long fractures in coal seams, effectively increasing the range of fractures in the coal seam. To a certain extent, its fracturing effect may be more stable.From the perspective of carbon dioxide fracturing costs, in order to achieve good fracturing results, strict requirements must be met for drilling holes, such as precise control of parameters such as hole spacing and angle, which may increase the difficulty and cost of drilling operations.Taking the example of increasing permeability in low-permeability coal seams, during carbon dioxide fracturing permeability enhancement tests in the No. 3 coal seam at Sanyuan Coal Industry, a large number of blasting boreholes and observation holes were arranged.In contrast, high-pressure water jet drilling may offer greater flexibility in terms of hole placement and relatively lower drilling costs.In addition, the carbon dioxide fracturing and permeability enhancement construction process involves multiple steps, including fracturing device filling, transportation, installation, and detonation. The operation is relatively complicated, and each step must be carried out in strict accordance with regulations, which is time-consuming.In contrast, high-pressure water jet grouting technology is relatively simple to operate. Once the equipment is started, it can operate continuously, enabling the completion of permeability enhancement work in a given area within a relatively short period of time, thereby improving construction efficiency.

Conclusion

Based on indoor similar material tests and on-site engineering applications, This study systematically reveals the mechanism of action and key influencing factors of high-pressure water jet flat dragging seam formation.The regulatory patterns of different parameters on the seam formation effect have been clarified.and determined the optimal process parameters for on-site application.The main conclusions are as follows:

(1)Independently developed flat drag jet seam forming true triaxial testing device, It consists of a three-way loading system, an experimental table frame, a pressure and flow collection system, a pump pressure system, a flat drag jet seam forming mobile trolley, and seam forming pipes. Jet-cutting experiments on test pieces of specified dimensions can be performed within a space measuring 1000 mm × 1000 mm × 1000 mm.

(2) In the flat drag jet slotting test, the arrangement of the number of slotting holes has a significant impact on the results. If the jet at the same angle generates cracks, the cracks will expand independently along the direction consistent with the jet angle; and if two holes slot at the same direction and angle, they tend to penetrate each other, so a proper spacing must be maintained.

(3) In the flat drag jet slotting test, high-pressure water jets can form evenly distributed ‘tooth-like’ cracks on both sides of the slotting hole. However, the crack length is affected by several factors: with the increase of jet angle, coal seam strength and ground stress, the crack length gradually decreases; on the contrary, with the increase of jet pressure, the crack length gradually increases.

(4) Through on-site tests at Xinji No.2 Mine, the optimized cutting pressure is determined to be 80 MPa, the cutting time is 12 min, corresponding to a cutting depth of about 1.75 m. At this time, the reasonable spacing of cutting holes is 6 m and the spacing of cutting grooves is 4 m.

Research limitations analysis and future prospects

Analysis of research limitations

-

1.

Limitations of experimental methods: Although the physical similarity simulation test using similar materials can reflect the crack evolution law of high-pressure water jet slotting, the simulation accuracy of the actual coal seam’s complex geological conditions (such as original fractures, inhomogeneity, and groundwater environment) is limited by the performance of similar materials and the size of the test device. For example, the similar material ratio (fine sand: cement: lime: gypsum = 8:1:1:1) adopted in the test cannot fully reproduce the actual coal seam’s physical and mechanical properties and structural characteristics, which may lead to certain deviations between the crack extension law and the actual situation.

-

2.

Simplification of test conditions: In the true triaxial test, the simulated ground stress, coal seam strength, and other parameters are set as fixed values, ignoring the dynamic changes of ground stress in the actual mining process and the inhomogeneity of coal seam strength distribution. In addition, the test mainly focuses on the influence of several key factors such as jet angle and pressure, while the influence of other factors (such as jet speed, nozzle shape, and coal seam moisture content) on the slotting effect is not considered, which may make the research results lack comprehensiveness.

-

3.

Field trials were conducted only at Xinjie No. 2 Mine.The optimised parameters include cutting pressure (80 MPa), time (12 min), drilling hole spacing (6 m) and slot spacing (4 m).Based on the specific geological conditions of the mine (such as coal seam distribution and stress distribution)Its applicability may be limited to similar coal seam backgrounds.For coal seams with different burial depths, gas content, or thickness, further verification is required.

Future prospects

-

1.

Optimization and innovation of experimental systems: A more advanced true triaxial test device will be developed to realize the simulation of dynamic ground stress changes and complex geological conditions (such as containing original fractures and groundwater). At the same time, combined with advanced testing technologies such as CT scanning and acoustic emission monitoring, the internal crack evolution process of the specimen during high-pressure water jet slotting will be tracked in real-time to reveal the slotting mechanism more accurately. In addition, new similar materials that can better simulate the physical and mechanical properties.

-

2.

Expansion and deepening of research content: The research scope will be expanded to consider the influence of more factors (such as jet speed, nozzle structure, coal seam moisture content, and temperature) on the slotting effect, and a comprehensive evaluation system of slotting effect will be established. On the basis of laboratory tests, more field application tests in different geological conditions will be carried out to verify and optimize the slotting parameters. Moreover, numerical simulation methods will be introduced to establish a high-pressure water jet slotting numerical model considering multiple factors, so as to realize the prediction and optimization of slotting effect and provide more accurate theoretical guidance for engineering practice.

Data availability

Data is provided within the manuscript or supplementary information files.

References

Cheng, X., Zhang, Q., Zhang, Z., Zou, Y. & Junjie, G. Stress Relief and Stimulation of Coal Reservoir by Hydraulic Slotting. Yao C, ed. Advances in Civil Engineering. ;2021(1):6664696. (2021). https://doi.org/10.1155/2021/6664696

Zhou, X. et al. Research method of pressure relief and permeability enhancement in low permeability coal seam: A review. AIP Adv. 12 (1), 010702. https://doi.org/10.1063/5.0078373 (2022).

Zhang, X., Wang, Z. & Chen, W. Optimisation of synergistic ventilation between dust and gas in a gas tunnel. Sci. Rep. 14 (1), 27582. https://doi.org/10.1038/s41598-024-78840-2 (2024).

Wen, H. et al. Gas Displacement Engineering Test by Combination of Low and Medium Pressure Injection with Liquid CO2 in High Gas and Low Permeability Coal Seam. Xia BW, ed. Geofluids. ;2020:1–13. (2020). https://doi.org/10.1155/2020/8840602

Huang, D. et al. Influence of strength inhomogeneity on transboundary expansion characteristics of hydraulically fractured fractures in coal seams. Sci. Rep. 14 (1), 29094. https://doi.org/10.1038/s41598-024-80588-8 (2024).

Liu, C., Zhang, R., Wang, Z. & Zhang, X. Research on the fire extinguishing performance of new gel foam for preventing and controlling the spontaneous combustion of coal gangue. Environ. Sci. Pollut Res. 30 (38), 88548–88562. https://doi.org/10.1007/s11356-023-28585-8 (2023).

Zhang, X., Sun, J., Liu, C. & Sun, Q. Synthesis comparative evaluation of hydrophobic polymer/surfactant fracturing fluids on methane adsorption–desorption and pore structure modifications in coal. Int. J. Coal Sci. Technol. https://doi.org/10.1007/s40789-025-00825-x (2025).

Wu, X. et al. Mechanism of Coal Seam Permeability Enhancement and Gas Outburst Prevention under Hydraulic Fracturing Technology. Sun Z, ed. Geofluids. ;2022:1–9. (2022). https://doi.org/10.1155/2022/7151851

Wang, T. et al. Principle and practice of hydraulic softening top-cutting and pressure relief technology in weakly cemented strata. Front. Earth Sci. 12, 1367933. https://doi.org/10.3389/feart.2024.1367933 (2024).

Xinlei, L., Ziyuan, R., Zhengzheng, C. & Hao, R. Study on coal drawing parameters of deeply buried hard coal seams based on PFC. Sci. Rep. 15 (1), 21934. https://doi.org/10.1038/s41598-025-08154-4 (2025).

Chaoshang, S. et al. Overburden failure characteristics and fracture evolution rule under repeated mining with multiple key strata control. Sci. Rep. 15 (1), 28029. https://doi.org/10.1038/s41598-025-14068-y (2025).

Li, X., Zhou, W., Hao, S., Wu, T. & Zhang, J. Prevention and control of coal and gas outburst by directional hydraulic fracturing through seams and its application. ACS Omega. 8 (41), 38359–38372. https://doi.org/10.1021/acsomega.3c04737 (2023).

Wang, L., Zhu, L., Xue, Y., Cao, X. & Liu, G. Multiphysics modeling of thermal–fluid–solid interactions in coalbed methane reservoirs: simulations and optimization strategies. Phys. Fluids. 37, 076649. https://doi.org/10.1063/5.0278665 (2025).

Wang, L., Zhang, W., Cao, Z., Xue, Y. & Xiong, F. Coupled effects of the anisotropic permeability and adsorption-induced deformation on the hydrogen and carbon reservoir extraction dynamics. Phys. Fluids 2025;37;066608;.doi: https://doi.org/10.1063/5.0270765

Zhang, Y. Study on the theory of high pressure water jet coal breaking and its main controlling factors. IOP Conf. Ser: Mater. Sci. Eng. 735 (1), 012083. https://doi.org/10.1088/1757-899X/735/1/012083 (2020).

Sun, Z., Liu, Y., Qi, Q., Chai, J. & Gu, B. The influence of High-Pressure water jet cutting parameters on the relief of pressure around the coal slot. Processes 11 (7), 2071. https://doi.org/10.3390/pr11072071 (2023).

Ma, S. Analysis of Influence of Ultra-High Pressure Water Jet Cutting Pressure Sequence on Pressure Relief and Reflection Improvement of Coal Seam. Chen Z, ed. Advances in Civil Engineering. ;2023:1–15. (2023). https://doi.org/10.1155/2023/7738042

Jia, L., Sun, Z., Lu, J. & Gu, B. Coal breaking characteristics of high pressure water jet and the law of coordinated pressure relief of slits. Front. Earth Sci. 11, 1211117. https://doi.org/10.3389/feart.2023.1211117 (2023).

Li, C. Experimental study on rock cross-cut coal Uncovering with ultra-high pressure hydraulic slotting. IOP Conf. Ser: Earth Environ. Sci. 546 (5), 052036. https://doi.org/10.1088/1755-1315/546/5/052036 (2020).

Wang, H. et al. Stress release mechanism of deep bottom hole rock by ultra-high-pressure water jet slotting. Pet. Sci. 20 (3), 1828–1842. https://doi.org/10.1016/j.petsci.2022.12.002 (2023).

Wei, G. et al. Enhanced coalbed permeability and methane recovery via hydraulic slotting combined with liquid CO2 injection. Process Saf. Environ. Prot. 147, 234–244. https://doi.org/10.1016/j.psep.2020.08.033 (2021).

Zhang, J. et al. Calculation model of High-Pressure water jet slotting depth for coalbed methane development in underground coal mine. Appl. Sci. 9 (23), 5250. https://doi.org/10.3390/app9235250 (2019).

Zhang, Y. & Zou, Q. A prediction model for the slot depth of high pressure water jet. Results Phys. 11, 1105–1109. https://doi.org/10.1016/j.rinp.2018.11.020 (2018).

Cao, Y. et al. CO2 gas fracturing: A novel reservoir stimulation technology in low permeability gassy coal seams. Fuel 203, 197–207. https://doi.org/10.1016/j.fuel.2017.04.053 (2017).

Jia, J., Wang, D., Li, B. & Tian, X. Study of the influencing factors of the liquid CO2 phase change fracturing effect in coal seams. Mosa AM, ed. PLoS ONE. ;16(7):e0254996. (2021). https://doi.org/10.1371/journal.pone.0254996

Pan, Z. & Connell, L. D. Modelling permeability for coal reservoirs: A review of analytical models and testing data. Int. J. Coal Geol. 92, 1–44. https://doi.org/10.1016/j.coal.2011.12.009 (2012).

Wang, H. et al. Elimination of coal and gas outburst risk of an outburst-prone coal seam using controllable liquid CO2 phase transition fracturing. Fuel 284, 119091. https://doi.org/10.1016/j.fuel.2020.119091 (2021).

Yu, R. et al. Study on the Mechanism of Liquid Carbon Dioxide Fracturing and Permeability Enhancement Technology in Low Permeability Thick Coal Seam. Wu Z, ed. Geofluids. ;2022:1–20. (2022). https://doi.org/10.1155/2022/4688347

Ji, F. & Lu, Z. Research and field application of ultra high pressure hydraulic cutting technology in Gaohe coal Minethe title of your paper here. IOP Conf. Ser: Earth Environ. Sci. 804 (2), 022041. https://doi.org/10.1088/1755-1315/804/2/022041 (2021).

Lu, Z. & Ji, F. Experimental study on ultra high pressure hydraulic cutting seam pressure relief and permeability enhancement of strip drilling along seam in C19 coal seam of shiping 1 coal mine. IOP Conf. Ser: Earth Environ. Sci. 804 (2), 022040. https://doi.org/10.1088/1755-1315/804/2/022040 (2021).

Huang, C., Zhang, Y., He, J., Luo, Y. & Sun, Z. Permeability improvements of an outburst-prone coal seam by means of presplitting and blasting with multiple deep boreholes. Energy Sci. Eng. 7 (5), 2223–2236. https://doi.org/10.1002/ese3.426 (2019).

Li, H., Zhang, K., Zu, H. & Qian, J. Study on the technology of permeability enhancement of deep hole pre-splitting blasting in a low-permeability coal seam. Environ. Earth Sci. 83 (1), 40. https://doi.org/10.1007/s12665-023-11332-0 (2024).

Ge, Z., Gao, F., Zhou, Z., Cao, S. & Zhang, D. Fracture characteristics and failure modes of coal, sandstone, and shale impacted by water jet under true triaxial conditions. Energy Fuels. 36 (9), 4770–4781. https://doi.org/10.1021/acs.energyfuels.2c00278 (2022).

Chen, Z. et al. An experimental investigation of the gas permeability of tectonic coal mineral under triaxial loading conditions. Minerals 12 (1), 70. https://doi.org/10.3390/min12010070 (2022).

Zhao, J., Tang, D., Lin, W., Qin, Y. & Xu, H. In-situ stress distribution and its influence on the coal reservoir permeability in the Hancheng area, Eastern margin of the Ordos basin, China. J. Nat. Gas Sci. Eng. 61, 119–132. https://doi.org/10.1016/j.jngse.2018.09.002 (2019).

Hou, P. et al. Numerical evaluation on stress and permeability evolution of overlying coal seams for gas drainage and gas disaster elimination in protective layer mining. Min. Metall. Explor. 39 (3), 1027–1043. https://doi.org/10.1007/s42461-022-00584-2 (2022).

Li, C. Study on the application of ultra-high pressure hydraulic slotting in low permeability coal seam. IOP Conf. Ser: Earth Environ. Sci. 546 (5), 052022. https://doi.org/10.1088/1755-1315/546/5/052022 (2020).

Sun, L., Wang, W. X. & Xu, J. S. Study on proportioning scheme of coal system Rocky similar material based on orthogonal test. Materials 16 (22), 7113. https://doi.org/10.3390/ma16227113 (2023).

Sun, P. et al. Experimental study on the ratio model of similar materials in the simulation test of coal and gas outburst. Sci. Rep. 11 (1), 13513. https://doi.org/10.1038/s41598-021-92880-y (2021).

Li, Q. et al. Review and prospect of coal rock hydraulic fracturing physical experi mental research. Coal Sci. Technol. 50 (12), 62–72. https://doi.org/10.13199/j.cnki.cst.mcq22-08 (2022).

Sun, H. et al. Orthogonal experimental study on proportioning model construction of similar materials of outburst coal seam. Coal Sci. Technol. 47 (8), 116–122. https://doi.org/10.13199/j.cnki.cst.2019.08.014 (2019).

Gong, S. et al. Dynamic fracture toughness and fractal characteristics of crack in pressurized acidified Qinshui coal under impact loading. Phys. Fluids. 37 (1), 016140. https://doi.org/10.1063/5.0251415 (2025).

Wu, J., Du, Y., Wang, C. & bai, Zong, Q. Experimental study on dynamic tensile mechanical behavior and fracture mechanical characteristics of sandstone with a single prefabricated fissure. Adv. Civil Eng. 2024 (1), 5501703. https://doi.org/10.1155/2024/5501703 (2024).

Chen, A. et al. Impact of the water-wedge deterioration effect of pulsating water injection on AE waveforms and crack propagation during fracturing processes. Eng. Fract. Mech. 303, 110127. https://doi.org/10.1016/j.engfracmech.2024.110127 (2024).

Yang, X. et al. Study on the stress field and crack propagation of coal mass induced by High-Pressure air blasting. Minerals 12 (3), 300. https://doi.org/10.3390/min12030300 (2022).

Xu, S. et al. The influence of biaxial loads on the dynamic crack interaction of two opposite propagating. Eng. Fract. Mech. 314, 110732. https://doi.org/10.1016/j.engfracmech.2024.110732 (2025).

Zhu, F., Ding, W., Liu, Z. & Huang, A. C. Coal damage and failure from shaped charge blasting with an empty hole under high ground stress. Phys. Fluids. 37 (6), 067157. https://doi.org/10.1063/5.0273444 (2025).

Li, Y., Jia, D., Li, W. & Zhang, K. Model of T-Type fracture in coal fracturing and analysis of influence factors of fracture morphology. Energies 11 (5), 1196. https://doi.org/10.3390/en11051196 (2018).

Zhang Jiahang Research of CO2 Fracturing Technique. and Application on Coalmine Safety Production[D].BeiJing:China Coal Research Institute, (2017).

Funding

The authors thank the editor and anonymous reviewers for their valuable comments.This study was supported by the Regional Funds of the National Natural Science Foundation of China (52264015) and Guizhou Science and Technology Support Programme Project (Qiankehe Support [2023] General 306), are gratefully acknowledged.

Author information

Authors and Affiliations

Contributions

Ping Cao: Conceptualization, Investigation, Visualization, Software, Data curation, Writing - original draft, Writing - review & editing. Xiangtao Kang: Conceptualization, Methodology, Formal analysis, Writing -review & editing, Supervision, Funding acquisition. Xingang Niu: Formal analysis, Writing - review & editing.Chao Ren : Investigation.Zuhao Xu: Investigation.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Cao, P., Kang, X., Niu, X. et al. Research on the main controlling factors of low permeability coal seam under the action of high-pressure water jetting. Sci Rep 15, 32560 (2025). https://doi.org/10.1038/s41598-025-18176-7

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-18176-7