Abstract

Taking a mine in Guizhou Province as the research background, a combination of similar simulation experiments and numerical simulation was used to analyse the spatial distribution of overburden collapse and the development of fissures during the mining process. The results indicate that: (1) During the mining of the upper coal seam, the overlying rock is not affected by faults, the ‘three zones’ are significantly developed, the collapse morphology exhibits a typical ‘trapezoidal’ structure, and the fractures undergo stages of formation, expansion, and closure; (2) The lower coal seam is affected by reverse faults, resulting in asymmetrical overburden collapse patterns and discontinuous fissure development. When mining across faults, periodic pressure is intense, and the stride length is significantly reduced, with severe rock fragmentation near the faults. (3) Under repeated mining activities, the displacement and subsidence of the lower coal seam are greater than those of the upper coal seam. By quantifying the spatio-temporal distribution of mining-induced fractures using fractal dimension, it is clear that their development and evolution follow a process of formation, development, and closure. The research results can provide a theoretical basis for the safe development of coal mines under similar geological conditions.

Similar content being viewed by others

Introduction

With the development of the economy, the demand for coal is increasing year by year, but the traditional mining in the past has caused the gradual shortage of shallow coal resources, and people have begun to shift their attention to deep mining1,2,3,4. However, deep mining conditions are complex, geological structures such as faults are widespread, and mining coal seams under fault structures is challenging. Guizhou Province, known as the ‘Southwest Coal Sea’, is rich in coal resources. However, under the long-term geological tectonic action, the valleys in the whole province are vertical and horizontal, and ' multi-fault and high gas ' have become the typical characteristics of coal mining in Guizhou Province. The existence of faults not only disrupts the continuity of coal seams, increases the difficulty of coal seam mining, but also deepens the risk of disaster and increases the cost of mining5,6.

Given the risk of coal seam mining through faults, many scholars have studied the migration law of overlying strata, fracture development, and stress distribution under the influence of faults. Chen et al.7 studied the mechanism of fault activation and the fracture evolution of the floor rock mass and obtained the basis for the initiation of shear cracks, layered cracks, and vertical tensile cracks. The crack sequence in the mining rock mass includes vertical tensile cracks, shear cracks, and layered cracks. The initiation and expansion of shear cracks in the coal wall promote fault activation, and it is easy to cause fault activation at a specific dip angle of 45° ~ 75°. Wu et al.8 used numerical simulation to analyze the fault slip and fault energy evolution characteristics when the face slab advances to the normal fault. The cumulative energy of the fault increases gradually, and a large amount of energy is released rapidly during the fault instability activation process. When fault mining is studied, the high position of the rock mass near the fault turns to the goaf, resulting in the fracture of the fault. The high position of the fault is activated first, and the dislocation of the two walls is obvious. Due to the panel mining on the fault, the footwall overburden loses the support of coal, the whole overburden is cut off, and the fault activation degree is high.Li et al.9 studied the coal release parameters of deeply buried hard coal seams using PFC numerical simulation and other methods, taking the coal pillar working face outside the Zhao Gu mining area as the object of study. They concluded that a mining-to-release ratio of 1:1, a coal release step distance of 0.8 m, and single-wheel multi-hole interval coal release are optimal. The simulated recovery rate was 86.23%, and the results were verified to be effective in the field, providing support for related mining operations. Sun et al.10 studied the destruction of overlying rock and fracture evolution under repeated mining using multiple methods, taking the No. 6 and No. 7 coal seams in the Xinjiang mining area as a background. They found that there were four key layers, and repeated mining caused the destruction of the overlying rock to change from a ‘trapezoidal’ shape to a ‘double trapezoidal’ shape, with a significant increase in the height of the water-conducting fracture zone. Field monitoring verified the simulation results, providing a theoretical basis for water hazard prevention and other measures. Zuo et al.11 took the positive fault as the research object and simulated the mining stress evolution characteristics, fault activation mode and fault energy evolution characteristics in the process of the lower and upper working faces towards the positive fault, respectively, and found that when the working face faces towards the fault, the neighboring pressure and vertical stress of the surrounding rock increase and then decrease, and the mining stress of the upper plate is higher than the lower plate, and the high strata of the working face face face towards the positive fault, the fault activation precedes the lower strata. Zhao et al.12 studied the stress evolution and deformation failure law of coal seams with fault bottom, focused on monitoring the dynamic process of fault under mining conditions, and obtained the movement law of the surrounding rock mass near the fault zone. Li et al.13 used the Zhao Gu No. 2 Mine as a case study and analysed the optimal location of the working face entrance when fragment coal pillars and lower sub-layers are mined in tandem through theoretical calculations and FLAC3D numerical simulations. They found that the collapse of the upper sub-layer goaf affects the stress distribution of the coal pillar and determined that the side roadway of the lower sub-layer coal pillar should be offset by 10 m. Field verification showed that rock deformation was minimal at this location, ensuring safe production. Song et al.14 took the positive fault as the research object, simulated the activity process of the fault in the mining process, and carried out the analysis of the relationship between the advance distance and the fault dip angle, and found that: the activation of the fault caused by the mining action is positively correlated with the advance distance, and negatively correlated with the fault dip angle. Li et al.15 studied the stress evolution and fault slip behavior of normal faults with different dips using mechanical modeling, numerical simulation and engineering practice, and found that the probability of inducing fault slip is higher for mining the underplate of the fault, and the larger the dip of the fault, the smaller the risk of slip. Atsushi Sainoki et al.16 investigated the effect of mining activities on the reactivation of a down-dip fault, comparing the roles of two types of mining directions, bottom-up and top-down, in segmented airfield mining. Through static and dynamic analyses, combined with fault dip, intersection location and other parameters, it is found that when the fault dip is close to the ore body, the amount of mining in front of the intersection affects the fault seismic activity, and the difference is narrowed by decreasing the dip; the dynamic analysis shows that the maximum particle velocities of the two orientations are similar but the areas of high velocities are different. The dynamic analysis shows that the maximum particle velocity in both directions is similar but the high velocity area is different. Combined with the case of the Lucky Friday mine, it shows that the fault sliding will increase the bias stress near the mining site, aggravate the risk of rockburst, and it is recommended to choose the mining direction that can reduce the amount of mining before the intersection.

Most of the existing research results focus on the overburden transport and fracture development of single coal seams in the case of faults, while the study of the overburden transport and fracture development of multiple coal seams in the case of faults through similar experiments, numerical simulations, and fractal dimensions is seldom involved. Therefore, this paper analyzes the collapse structure of multiple coal seams excavated over faults using similar simulation tests for the complex geological conditions of Guizhou coal mines, and uses numerical simulation to study the change of overburden rock in the process of excavation of multiple coal seams, and derives the rule of fissure development of multiple coal seams under the influence of faults, to provide theoretical support for the mining of coal seams with complex geological formations, such as over-fault mining.

Engineering background

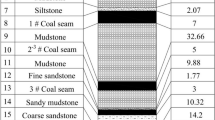

The mine is located in the western part of Guizhou Province, and the coal-bearing strata in the mine area are mainly developed in the Permian Longtan Formation, of which the coal-rich areas are centrally distributed in the peripheral area of the Yangzi land mass. Influenced by the long-term collision and extrusion of neighboring plates, the conditions of coal seams in Guizhou are relatively complex, mainly characterized by the extensive development of tectonic coal and the intensive distribution of fracture tectonics. The stratigraphy in this area is characterized by interbedded coal, mudstone, and sandstone, and the alternating lithological deposition constitutes a complex stratigraphic assemblage, with the overall thickness varying little, maintained within the range of 410 ~ 420 m. The stratigraphy in this area is characterized by the interbedded coal, mudstone, and sandstone.The coal mine is currently mining the 5# and 9# coal seams using a longwall retreat method. The working face has a strike length of 1,420–1,470 m, a dip length of 250–260 m, a coal seam burial depth of 450–500 m, and a vertical stress of 5.45–7.21 MPa. The average thickness of the coal seam is approximately 2 m, with an average dip angle of 8°. The fault dip angle ranges from 55 to 62°, with a maximum drop of 4.9 m. According to the geological exploration report of the coal mine, and combined with the coring data of the various coal and rock seams to draw the geological histograms, as shown in (Fig. 1).

Fault-bearing multi-seam mining similarity model

In order to better simulate the breakage and fissure development of the overlying rock layer caused by underground coal seam mining, similar materials were used to simulate the overlying rock layer and coal seam for physical simulation tests. The test selected river sand as aggregate, lime and gypsum as cementing materials, and used mica powder as a layering material. Based on the similarity theory17,18,19the geometric similarity ratio was determined to be 1:100, the volumetric similarity ratio to be 1:1.5, the stress similarity ratio to be 1:23, and the time similarity ratio to be 1:10 based on the mechanical parameters of coal and rock seams.The fault zone material is selected as a mixture of yellow clay, gypsum, and lime in a ratio of 6:3:1 to simulate the low strength and layered structure characteristics of an actual fault zone. According to the geological cross-section diagram, the fault dip angle is set at 58° and passes through the 9# coal seam. The materials of the fault zone were chosen to be prepared by mixing of yellow mud: gypsum: lime = 6: 3: 1, which simulated the characteristics of the actual fault fracture zone of low-strength and laminar structure. Combined with the geological histogram, similar simulation experiments were calculated by similar theory for each layered material dosage ratio, as shown in (Table 1). The test uses a hydraulic loading system to simulate the actual ground stress conditions and reproduces the stress state of the overlying rock layer by axial loading. Based on the measured results of the ground stress in the mining area, the vertical stress was set to 0.8 times the prototype value, and a graded loading strategy was implemented to ensure stable deformation of the model under loading and effectively prevent sudden damage.

To construct a more close to the real mining environment, the test adopts a movable multifunctional coal seam similarity simulation experimental bench developed by the School of Mining of Guizhou University, with the experimental model size (L×W×H) of 140 cm×40 cm×160 cm. After the similarity model is laid, it needs to go through the static stabilizing period of 7 days, to make the material particles complete the initial solidification; and then it enters into the natural drying period of 14 days, through the water evaporation enhances the contact stress between particles and promotes the complete curing of the binder, thus realizing the transformation of the model from microstructural densification to macroscopic mechanical property enhancement, as shown in (Fig. 2). Based on the coal mining conditions, boundary coal pillars are set 20 cm from the model boundary. The model excavates 10 cm at a time, with an interval of approximately 2.0 h between each excavation to ensure sufficient collapse of the overlying mining-induced rock layers and model stability.

Study on the caving characteristics of overlying strata in fault-containing coal seam mining

Fracture development characteristics of overburden rock

The similarly modeled coal seams were mined in the order of 5# and 9# seams, and the 12# seam was not put into use due to production factors in the mine. To attenuate the influence of the boundary effect of the similar simulation test, according to the coal mining conditions, the boundary coal pillar was set at 20 cm from the model boundary at the open cut eye, as shown in (Fig. 3a). The open cut eye advances, the overburden rock is gradually revealed by the influence of coal seam mining, and tiny fissures begin to develop with the advancement of mining, The area of direct roof overhang increases, as shown in (Fig. 3b). When the working face advances 40 cm, the stress is rearranged under the influence of talent movement, and the direct roof initially collapses, and at this time it is the stage of initial pressure, the overburden forms the structure of “cantilever beam”, and the pattern of off-layer fissures is obvious, as shown in (Fig. 3c). The working face keeps advancing, the influence caused by the disturbance is intensified, the overlying rock gradually exhibits the macroscopic damage phenomenon, the overlying rock layer will fracture and collapse after the bearing capacity reaches the limit, and there is the phenomenon of cyclic pressure, as shown in (Fig. 3d). The continuous mining of the working face led to the destruction of the original stress balance of the mining area, the direct roof also appeared with the operation of the working face with the phenomenon of mining with the fall of the roof plate to the mining area slowly bending down, at this time by the impact of mining overburden rock damage to deepen the degree of disturbance, the overburden layer of the rock mass formed a new articulation relationship between the overburden, overburden fall to form the typical “trapezoidal” structure; fissures continue to develop twice to expand to the upper rock layer of the roof plate to a greater degree of fissure through the development of large. The overburden rock collapsed to form a typical “trapezoidal” structure; the fissures continued to develop twice, expanding to the upper rock layer of the roof plate, and the degree of fissure penetration development is larger. The overburden rock was severely damaged after mining, and the broken rock mass collapsed irregularly. At the end of 5# coal seam mining, the development of “three belts” is completed, and the overburden rocks form a new stable structure. The working face is close to the stop-mining line, the mining of the 5# coal seam is completed and in a stable state, the break angle of the left and right sides is close to 60°, and the cross-fall pattern is in the classic “trapezoidal” structure, as shown in (Fig. 3e). During the mining process of the No. 5 coal seam, there were a total of five cycles of pressure, with an average cycle pressure step distance of 8.5 cm.

Influenced by the mining of the 5# coal seam, during the process of opening the cutting eye of the 9# coal seam, the disturbing and destroying effect of the overlying rock layer is significant, and the developed fissure network penetrates through the upper and lower rock layers, as shown in (Fig. 4a). With the advancement of the working face, the distance between the working face and the fault gradually decreases, the disturbance has caused damage to the overlying rock, the area of the void zone is increasing, the support of the low overlying rock decreases, the high overlying rock is turned back to the void zone, the fault surface is subjected to the tensile action of the rock layer to form a tiny fissure, and at this time the fault surface is in the state of tensioning, as shown in (Fig. 4b). During the mining of the 9# coal seam, there were a total of 8 cycles of pressure, with an average cycle pressure step distance of 5.2 cm. After the end of 9# coal seam mining, the collapse of the overburden rock is serious, the bending and sinking is obvious, the top plate is very broken, and the vertical lateral line of the model is seriously disturbed, and the misalignment is obvious, which indicates that the overfault excavation cycle comes to the pressure violently, and the overburden rock periodically breaks and intensifies, as shown in (Fig. 4c).The existence of the fault blocked and cut the continuity of the upper and lower coal seams, the coal seams were all extracted, the high-level rock seams lost the lower support and turned back to the mining area, and the low-level fissures were extruded and appeared to be closed, and the morphology of overburden fissures was also “trapezoidal” with the fault as the boundary, but the high-level overburden fissures were continuously developed, and the off-platform fissures and transverse fissures developed towards the fault surface, which played a guiding role in the process of fissure development. The existence of faults plays a guiding role in the process of rift development. Due to the cutting effect of the fault, the left and right ends of the 9# coal seam mining collapse structure are asymmetrical and different from the state of the 5# coal seam after the excavation is completed. The mining of the lower coal seam also affects the upper coal seam, and the disturbance leads to the rearranging of stresses in the overlying rock layer, the redevelopment of fissures, and the change of the collapse pattern.

Roof subsidence law of similar experiment

According to the size of the model for the arrangement of measurement points, the surface layout of 15 cm×10 cm grid lines, vertical direction from the model of the lower boundary of the selected distance of 20 cm to 130 cm a total of 12 monitoring lines for data organization and analysis, as shown in (Fig. 5). After the end of mining and the model mining overburden rock is stabilized, Huaxing HTS-520R total station and Thousand Eyes Wolf M230M/C high-speed camera are used to monitor the subsidence data of each measuring point in real time and analyze them, as shown in (Fig. 6).

After the end of mining and stabilization of the 5# coal seam, the four monitoring lines above the coal seam produced different degrees of subsidence, and the degree of displacement change was different at different distances, as shown in (Fig. 7). At the same distance, the subsidence of the monitoring line gradually increases from top to bottom. For the same monitoring line, the subsidence of the measurement points near the left and right sides of the model is the smallest, and the subsidence curve in the figure is in the form of an ‘inverted triangle’.The amount of subsidence displacement is the largest in the middle of the extraction zone, and the amount of subsidence decreases gradually on both sides of the extraction zone. The fluctuation of the displacement and subsidence curve of measurement line 4 is the largest, i.e., the displacement and subsidence are the largest, and the maximum subsidence is 2.51 cm. At this time, the fault does not influence the mining of 9# coal seam; as the mining proceeds, the coal body is mined out, and the area of the mining hollow area keeps increasing, the stress of the overlying rock is redistributed, and the low rock body loses the support and turns back to the middle of the mining hollow area, and the high-level rock body is bending and subsiding. The rock layer near the front and rear ends of the model is gradually filled and compacted by the rock falling from the center, and the displacement curve is slower, At this time, the rock is in the state of being compacted and tends to be stabilized.

After the end of mining and stabilization of 9# coal seam, the subsidence of 6 monitoring lines in the overlying rock layer is shown in (Fig. 8). 6 monitoring lines above 9# coal seam have undergone different degrees of subsidence, among them, the monitoring line 1, which is the farthest away from the 9# coal seam, has the least amount of subsidence, and the displacement curve is relatively flat, and the subsidence of monitoring line 5 is the largest, with the maximum amount of subsidence of 2.85 cm, and the fluctuation of the displacement curve is the largest. Under the condition of repeated mining, the amount of roof subsidence of the 9# coal seam over fault excavation is relatively complicated compared with that of the ordinary mining of the 5# coal seam, but the overall settlement displacement is consistent with the morphology of the roof subsidence curve of the excavation of the 5# coal seam. The existence of the fault blocks the distribution of stress, the development of fissures, and the continuity of the collapse pattern, resulting in the discontinuity of their distribution on the left and right sides of the fault, and its blocking effect makes the settlement amount asymmetrical on the left and right sides. When the lower face of 9# coal seam is fully mined, the range of the mining void area gradually increases, the overburden rock loses the support force of the coal seam, the high rock body is extruded to the mining void area due to the self-weight and the force between the rock layers, the high rock body is turned back to the fault, and the bending and sinking phenomenon occurs as a whole, the low rock body close to the fault is unable to complete the stress transfer, and it firstly unloads the pressure, and turns back to the fault, and the top slab is broken and collapses seriously, at this time, the maximum amount of sinking is 70 cm away from the model boundary (near the fault), the maximum amount of sinking is 70 cm away from the model boundary. At this time, the sinking amount is the largest at 70 cm from the model boundary (near the fault). The overlying rock shows a “trapezoidal” collapse pattern under the influence of mining, and the geological structure of the fault forms a ‘triangular’ structure with the rock body of the upper working face, and the “triangle” is the most stable structure. As the most stable structure, the “triangle” provides support for the rock layer, which is conducive to the equilibrium state of the overlying rock and the stabilization of the fault, therefore, the sinking amount of the measurement point is reduced after the excavation over the fault. When the working face is gradually away from the fault, due to the abnormal distribution of stress in the rock body near the fault area, the stress balance between each other is fragile, when the mining reaches a certain degree, the high rock body is not affected by the fault but still bends and sinks to the mining area, and the lower rock layer collapses and is continuously compacted, resulting in an increase in the amount of subsidence, so the amount of subsidence at the distance of 100 cm from the model increases significantly compared with the previous one. In the excavation process of the coal seam over the fault, the fault caused the cutting of the upper and lower plates and the staggering of the two plates occurred, and the influence of the self-weight of the rock layer in the excavation process of the lower plate as well as the phenomenon of the rock layer to the fault rotary phenomenon is obvious, so the lower plate’s subsidence displacement is relatively larger than the upper plate’s subsidence displacement.

Study on numerical simulation of multi-coal seam mining with faults

Using the UDEC (Version:6.0; URL:https://www.itascacg.com) discrete element numerical calculation software, a numerical calculation model was established, with each coal and rock layer in the numerical model constructed according to the geological columnar diagram of the coal mine (Fig. 1).The model size (length×height) was set to 140 m×150 m. To eliminate the boundary effect, 20 m was left on the left and right sides of the model as a protective coal pillar. In order to verify the similar experimental results, the coal seams were mined in the order of 5# coal seam and 9# coal seam, and excavated from left to right, with each step of 10 m. In order to facilitate the calculation, the 5# and 9# coal seams were regarded as near-horizontal seams, and the inclination angle of the seams was set to 0°, and The numerical model is shown in (Fig. 9).

In the model, the Mohr-Coulomb criterion is used for the ontological relationship of coal and rock layers, and the contact-Coulomb slip criterion is used for the joint surfaces, the bottom boundary of the model is set as the displacement boundary that restricts the displacement in the vertical direction, the left and right sides of the model are set as the displacement boundary that restricts the displacement in the horizontal direction, and the upper boundary is set as the free boundary, and the homogeneous load of 6.34 MPa is applied to the uppermost part of the model, and the physical and mechanical parameters of the coal and rock layers are shown in (Table 2). The physical and mechanical parameters of each coal and rock layer are shown in (Table 2).

Development characteristics of mining-induced fractures in multi-coal seams with faults

Development characteristics of mining-induced fractures in 5# coal seam

At the early stage of coal seam advancement, the fissures are in the stage of slow development, dominated by the newly developed mining overburden fissures, with fewer through and away fissures, with a small increase in the range of variation, and the overburden fissures are distributed in a classic “trapezoidal” structure, as shown in (Fig. 10a–c). When the coal seam was mined back to 40 m, the development of the fissure zone expanded widely, and the direct roof collapsed for the first time under the action of cyclic pressure, and the collapse of the low rock layer caused the upper rock layer to lose its support force, and the displacement change was inconsistent, and the development of fissures was more intensive; the fissures between the neighboring rock layers developed through and through, and communicated with each other, and the development of fissures was obvious in the off-loading layer. And the working face just passes through the overlying rock right above the fault, at this time, tiny fissures also appeared in the underlying rock layer of the coal seam, and the fissures of the bottom plate extended to the vicinity of the fault zone, indicating that the existence of faults and other geological structures has a guiding role in the development of fissures, as shown in (Fig. 10d). With the increase of mining distance, the fissure still develops to the higher rock layer, the range of the fissure zone continues to increase, and the fissure development is more intensive, as shown in (Fig. 10e, f). With the advancement of the working face, the working face is gradually away from the fault zone, and the tiny fissures appearing near the fault zone tend to be closed, and the direct top falls with mining after being influenced by mining, which forms a certain pressure on the bottom plate and the underlying rock layer, and the fissures in the rock layer are continuously compacted, and the overburden rock presents a “trapezoidal” structure that is constantly growing, as shown in (Fig. 10g, h). As shown in (Fig. 10i–k). After the 5# coal seam advances 90 m, the development of mining fissures tends to be stable and smooth, the fissures in the low-level overburden have gone through the stage of development and closure, the fissures are no longer shifted to a higher level, the range of change of the fissure zone basically maintains stability, and the height of the fissure zone is no longer changing. In the stress cloud map of the 5# coal seam mining, the stress in the fault zone always remains at a relatively low level, with an initial original rock stress state of 1.7 MPa. When the working face advances to directly above the fault, the shear stress rises to 2.1 MPa. From the spatial distribution of the stress contour map, the high-stress zones formed by the mining of the 5# coal seam are primarily concentrated on both sides of the coal pillars in the goaf. No distinct strip-like high-stress concentration zones have appeared near the fault zone, indicating that the fault remains in a stable state. During the mining of the 5# coal seam, since it is not affected by the fault, it is recommended to leave a coal pillar of 5–8 m along the void to meet the requirements for roof stability. When the cycle pressure step distance reaches 8.5 m, the advance support range of the working face should be strengthened to 15 m.

Development characteristics of mining-induced fractures in 9# coal seam

In the early stage of mining, the effect of excavation on the overlying rock layer of the 9# coal seam is small, mainly dominated by the newborn mining fissures, and the density coefficient, the development pattern is not obvious enough, and the connectivity of the fissures between different rock layers is not enough; however, under the repetitive mining, it makes the transport of the overlying rock layer of the 5# coal seam complicated, and derives the new fissures, and the range of fissure zones changes in the transverse direction, and the fissures in the low overburden rock go through the development again, expansion, and closure in a new stage, as shown in (Fig. 11a, b). When the coal seam is excavated to 40 m, as shown in (Fig. 11c, d), the effect of mining on the development of overburden rock fissures is obvious, and the development of fissures shows a typical “trapezoidal” structure, and with the advance of mining, the range of fissure development continues to expand upward, the number of fissure development is constantly increasing, and the height of fissure zones continues to develop upward. When the coal seam is excavated for 50 m, as shown in (Fig. 11e), the working face reaches the vicinity of the fault, and due to the existence of the fault, the development of the mining fissure zone shows asymmetry, and there is almost no fissure generation in the overlying rock layer on the upper disk of the fault, but the fissures in the rock layer in the upper part of the mining airspace area are well-developed, including off-deck fissures and broken fissures, and there are more kinds of fissure development, the density of the fissure development is denser, and the fissures between the neighboring rock layers start to Communication and connectivity are high, indicating that the faults have a certain degree of obstruction to the development of fissures; with the collapse of the low overburden rock, the fissures of the high overburden rock continue to develop upward, and the repetitive mining causes the fissures of the underlying rock seams of the 5# coal seam to continue to develop downward, and the fissures of both fissures are connected. When the working face was excavated over the fault, some microscopic fissures appeared in the vicinity of the fault as the excavation distance kept getting larger and larger, and the high level of the fault gradually produced new mining fissures, as shown in (Fig. 11f, g). Until the excavation to 80 m, the fissure development pattern of the overlying rock layer on the upper plate showed a certain regularity, which was consistent with the collapsed state of the overlying rock showing a “trapezoidal” state; at the same time, the fissure soon connected with the fissure at the right end of the 5# coal seam and penetrated into each other, and the height of the fissure zone increased greatly, as shown in (Fig. 11h). As shown in (Fig. 11i–k), the coal seam is fully mined, the low-level fissures have gone through the development process of development, expansion and compaction, and the upper and lower coal seam fissure zones have been formed, but under the action of the faults, the upper and lower discs are unevenly developed, and in the space in asymmetric, with the faults as the boundaries, the left and right fissure zones can’t be through fusion, which explains that the blocking effect of the faults is becoming more and more obvious with the mining; the low-level faults are more densely developed due to serious collapse, and the low-level fissures can be connected across the faults for cross-fault communication, and are developed to the underlying rock layers with a faster development rate. In the stress cloud diagram of the 9# coal seam mining across the fault, when the working face advances to 50 m from the fault, the stress in the fault zone increases from the initial bedrock stress state (1.8 MPa) to 3.2 MPa, which corresponds to the initial stage of the ‘activation trend.’ Furthermore, the stress cloud diagram shows a strip-shaped high-stress zone along the fault plane, indicating that the fault zone has begun to enter an unstable state. When the working face passes the fault by 20 m (Fig. 11g), the stress contour map shows a local stress increase beneath the fault, with a maximum value of 4.1 MPa. The shear stress increment rate in this area is 0.3 MPa/h, with the corresponding shear displacement rate of the fault plane increasing from 0.1 cm/h to 0.4 cm/h, and the energy release rate reaching 6.2 × 10⁴ J/m², quantitatively corresponding to the characteristics of ‘small-area sliding instability.’ When mining the 9# coal seam across a fault, considering the risk of fault activation and the asymmetric collapse characteristics of the overlying rock, a protective coal pillar of 10–15 m should be retained on the upper side of the fault. On the lower side, due to large settlement and severe rock fragmentation, it is recommended to expand the protective pillar to 15–20 m. Additionally, when the working face advances to within 30 m of the fault, the support strength should be increased and the monitoring cycle shortened.

Failure characteristics of mining-induced overburden strata in multi-coal seams with faults

Failure characteristics of overlying strata in 5# coal seam mining

Figure 12 represents the characterization of overburden damage for every 10 m of advancement to the right from the eye of the open cut. After the first excavation of 10 m, the direct roof did not collapse directly, and the rock state remained stable on the whole, as shown in (Fig. 12a). With the deepening of the excavation, the effect of the mining movement on the overlying rock layer is gradually strengthened, and different rock layers show different degrees of displacement changes, due to the distance from the fault, the impact on the stability of the overlying rock in the vicinity of the fault zone is small, as shown in (Fig. 12b, c). When the working face advances to 40 m, the exposed area of the direct top expands and starts to collapse after reaching the limit span, the direct top collapses for the first time, and the broken rock blocks rotate and deform to the hollow area, with obvious collapsing characteristics, and the initial cyclic pressurization starts to appear the off-seam fissures; after the coal seam is mined, the basic top loses the gravity-bearing force and bends and sinks under the effect of its gravity, and at this time, the damage of the basic top is in the form of bending damage, as shown in (Fig. 12d). As the working face continues to advance, the basic top is affected by the cyclic pressure, and cyclic breakage occurs, and the “trapezoidal” collapsing structure of the overlying rock layer is obvious, and the influence of mining on the stability of overlying rock gradually increases, as shown in (Fig. 12e). When the working face is excavated to 60 m, the overburden subsidence reaches the maximum value, and the maximum subsidence is 1.6 m, as shown in (Fig. 12f). When the working face reaches 90 m, the overburden rock collapses drastically, the degree of change of the overburden rock by mining is deepened, the area of collapsed rock changes to deeper and higher positions, and the structural characteristics of overburden rock collapsing in three zones are obvious; the overburden rock in high level is turned back to the mining area, and the overburden rock in low level is severely crushed after experiencing the cycle of pressurization, and the dilute rock pieces fall directly into the mining area, as shown in (Fig. 12g–i). Direct top with the advance of the working face appeared with the phenomenon of mining with the fall, until the 5# coal seam excavation is completed, the effect of mining on the fault is not big, the fault from the figure shows the closed state, 5# coal seam mining mining mining overburden rock transport law and the overburden rock transport law under the ordinary mining conditions are generally consistent with, as shown in (Fig. 12j, k).

Failure characteristics of overlying strata in 9# coal seam mining

Figure 13 shows the overburden rock collapse diagram for different excavation distances of coal seams. 9# coal seam mining destroyed the overburden rock structure after the completion of mining of the upper coal seam, exacerbated the destabilization state of the overburden rock layer, resulting in the original overburden rock subsidence becoming larger, the impact of the mining is still in the initial stage, and the impact on the overburden rock layer and the faults is less, and the amount of subsidence is smaller as shown in (Fig. 13a–c). As the mining continues to advance, when the working face reaches the fault, the bending deformation of the overlying rock is intensified under repeated disturbances, and the overlying rock collapses seriously, the overlying rock collapses in a “trapezoidal” structure obviously, and the rock layers continue to extend horizontally to each other, and the characteristics of the collapsed zone are obvious; at this time, the overlying rock layer as a whole turns back to the fault zone within the scope of influence with a small range, and is subjected to the fault cutting effect, and the effect of mining on the right side of the fault zone is not prominent. The effect of mining on the right side of the fault zone is not prominent, and the overlying rock on the right side of the fault zone is still in the closed state, and the maximum subsidence of the overlying rock at this time is 1.6 m. After the workface crosses the fault, cyclic breakage occurs at the direct top, and the collapse of the overlying rock layer in the air-mining zone to the right of the fault is not obvious, but at this time, the rock near the fault zone at the rear of the workface is broken, and the overlying rock is not sufficiently supported, as shown in (Fig. 13d, e). Continue to excavate forward, when the working face excavation 80 m, from (Fig. 13f–h) can be seen, the fault disk of the airspace area of the overlying rock collapse intensified, the fault disk as a whole to the airspace area in the middle of the rotary sinking, the overall collapse is obvious; high fault near the emergence of a small degree of bending subsidence, the fault has a high level of “revitalization” of the tendency. Over the fault excavation overlying rock collapse morphology has changed greatly, the overlying rock collapse on the upper and lower plates of the fault presents a “trapezoidal” collapse morphology, the upper plate of the fault appears to fall with the mining, the lower plate in the mining motion for a long time under the influence of the amount of sinking increases; the lower plate of the mining airspace and the fault contact with the phenomenon of unstable collapse occurs insignificantly, at this time, the fault is “activated” trend is more obvious. The trend of “activation” is more obvious, and we should focus on strengthening the support of the fault and the roof plate at this stage, as shown in (Fig. 13i). As mining continues, repeated mining causes the overlying rock layer of 5# coal seam to collapse in a serious form, and the subsidence of the low overlying rock increases, with the maximum subsidence reaching 3 m; at the same time, the mining of 9# coal seam reaches full mining, and the collapse of the overlying rock layer shows the typical “trapezoidal” shape, with the overall change of the amplitude being relatively small, and the fault is relatively stable, and there is no large-scale collapse and fragmentation. At the same time, the mining of 9# coal seam reaches full mining, the collapse of overlying rock shows typical “trapezoidal” state, the overall change is small, the fault state at this time is relatively stable, there is no large-scale collapse and fragmentation, and the maximum subsidence of overlying rock in 9# coal seam mining is close to 1.6 m, and the subsidence of overlying rock in overthrow excavation is larger than that in overlying collapsed overlying rock in overthrow excavation, as shown in (Fig. 13j, k).

Fractal dimension analysis of mining-induced fracture

The development characteristics of the mining fracture field are more complicated and affect the gas direction to a certain extent. The fracture network formed by overburden mining has good statistical self-similar fractal properties, and the fractal dimension is applied to the study of mining fracture field, which can better analyze the overburden fracture subdevelopment law, and the expression of its computational relationship is20,21,22,23,24:

In the formula, D: fractal dimension, reflecting the complexity of the distribution of mining-induced fractures. The higher the value, the denser the fractures and the more irregular their distribution.

r: Box side length, representing the scale unit used in the calculation;

N: The minimum number of boxes required to cover all cracks.

Using MATLAB self-programmed language, the mining fracture development maps calculated by UDEC 6.0 software were first binarized, and then their fitting relationship was derived on top of it, where the box dimension is the slope of the curve. Several representative fracture development maps were selected from 5# and 9# coal seams for binarization processing, and the fitting relationship was summarized, as shown in (Figs. 14 and 15). From this, the fractal dimension of the overlying rock fracture can be seen; it can be seen that the interior of the mining fracture field is disorderly and the regularity is low. It can be concluded from Tables 3 and 4 that all the fitting coefficients are greater than 0.99, indicating a high degree of fit, and it is more appropriate to apply the fractal box number to the study of fissures, and the fractal box dimension is one of the favorable means of quantitatively characterizing the mining fissure field, and the more densely the fissures are developed, the higher the fractal dimension is.

To deeply analyze the development law of mining fracture field, the changes of fractal fraction under different excavation distances are shown in Fig. 16, under the comparative analysis, the value of fractal dimension in the excavation process of 9# coal seam is larger than that of 5# coal seam in general, which indicates that the fracture development under the influence of repetitive mining is more intensive and less regular in the excavation process. Compared with the excavation process of 5# coal seam, the change of fractal dimension of over-fault excavation fluctuates less, showing a tendency of rising and then falling, the reason is that under the double influence of repetitive mining and faulting, the fissures will be developed rapidly, and the fractal dimension will be elevated, and after the face is excavated over the fault, the morphology of overburden rock suffers serious damage, and collapses violently, and a large range of fissures undergoes cyclic closing and compacting, leading to the fractal dimension Decrease. It is concluded that the mining overburden fissures experienced the dynamic evolution process of generation, closure, and compaction during the mining process of the coal seam group.

Conclusion

-

(1)

Based on the similar simulation test, it is analyzed that the mining of 5# coal seam is not affected by the fault, the continuity of fissure development is outstanding, and the development of “three belts” is obvious; due to the existence of the fault, the mining of 9# coal seam over the fault exacerbates the destruction of overburden rock, resulting in the cycle of coming pressure is violent, the step of coming pressure is significantly reduced, and the amount of overburden rock subsidence increases significantly, and the development of fissures is discontinuous. The development of fissures is not continuous, and the development range of fissures on both sides of the fault is not consistent.

-

(2)

Based on UDEC 6.0 numerical simulation software, the unpressurization pattern after excavation of 5# coal seam shows common “trapezoidal” structure, and obvious stress concentration phenomenon occurs at the eye of cutting and at the front end of the working face; during the excavation process of 9# coal seam over the fault, the collapse pattern of overburden rock in upper and lower pans and the development pattern of fissure are more different, and the settlement amount of lower pan is larger than that of upper pan. The amount of settlement in the lower plate is larger than that in the upper plate, and the development of overlying rock fissures at the left and right ends of the fault is discontinuous and asymmetric; after the working face crosses the fault, the fault undergoes a small-area slip destabilization, and the phenomenon of stress concentration in the fault zone is particularly prominent.

-

(3)

By using MATLAB to binarize the distribution of fractured mining fissure development and launch a quantitative analysis of it, the fractal dimension of different coal seams mining is different, and the trend of change shows a trend of rising and then decreasing, and the mining fissures have experienced the process of generation, closure and compaction. The linear fitting coefficient is close to 0.99, and the fitting degree is high, indicating that the fractal box dimension can fit the mining fracture development law.

Analysis of research limitations and future prospects

Analysis of research limitations

-

(1)

Deviation between model simplification and actual conditions: In numerical simulation, the coal seam dip angle is assumed to be 0° for the sake of simplifying calculations, which differs from the actual dip angle of 8° in the engineering context. Although gently dipping coal seams have a limited impact on the macro-destruction patterns of overburden, this assumption may result in details such as the differentiation of mining stress along the dip direction and asymmetry in overburden collapse not being fully reflected, thereby affecting the model’s ability to accurately reproduce actual conditions to a certain extent.

-

(2)

Limitations of research scale and dynamic processes: Similarity modelling and numerical modelling both focus on the macroscopic failure of overlying rock and the distribution characteristics of fractures, without delving into the micro-scale mechanisms of fracture initiation and fault activation. At the same time, there is insufficient analysis of the dynamic coupling effects of ‘upper coal seam mining-lower coal seam mining’ during repeated mining operations, and the impact of different mining intervals on overburden stability has not been quantified. Only vertical stress in the strata was considered, while little attention was paid to the structural stress objectively present in the strata, which was not included in the scope of the study. This has, to a certain extent, affected the comprehensiveness and accuracy of the analysis of the destruction of overlying rock and the development of fractures during the mining of faulted coal seams.

-

(3)

Shortcomings of field verification: The research results are mainly based on indoor experiments and numerical simulations. Although they are consistent with the trends observed in similar geological conditions in the region, they lack direct field measurement data for verification. The engineering applicability of the conclusions needs to be further verified through field practice.

Future outlook

-

(1)

Refined modelling and multi-field coupling analysis: Construct a three-dimensional numerical model that considers the actual coal seam dip angle and the microstructure of the fault zone. Introduce the ‘stress-fracture-seepage’ multi-field coupling theory to analyse the correlation mechanism between gas migration and water hazard prevention during fault activation, providing theoretical support for safety control in high-gas mines during fault crossing operations.

-

(2)

Micro-mechanism and dynamic response research: Using technologies such as CT scanning and acoustic emission monitoring, capture the formation and propagation patterns of micro-cracks within rock blocks during mining operations. Combine fractal dimension and damage mechanics theories to establish a correlation model between micro-crack development and macro-scale failure. Additionally, through dynamic loading tests, simulate the stress relaxation and crack closure characteristics of overlying rock under different mining rhythms, and quantify the time effects of repeated mining operations.

-

(3)

Field testing and engineering application: Field tests were conducted in mines with similar geological conditions. By deploying fibre optic sensors, borehole observation systems, and other equipment, real-time monitoring was carried out of overburden displacement, fracture distribution, and fault stress changes during fault-crossing mining. The results of indoor research were compared and validated with field data, forming a closed-loop research system of ‘theory-experiment-engineering.’ This provides more direct technical guidance for support design in fault-crossing multi-coal seam mining.

Data availability

All data, models, and code generated or used during the study appear in the published article.

References

Shi-hua, R. et al. Demand and fluctuation range of china’s coal production under the dual carbon target. Energy Rep. 11, 3267–3282 (2024).

Huang, W., Zhang, K., Tang, X., Zhao, Z. & Wan, H. Coking coals potential resources prediction in deep coal beds in Northern China. Energy Explor. Exploit. 28 (4), 313–325 (2010).

Li, Q., He, X., Wu, J. & Ma, S. Investigation on coal seam distribution and gas occurrence law in guizhou, China. Energy Explor. Exploit. 36 (5), 1310–1334 (2018).

Cao, B., Fu, X., Kang, J., Tang, P. & Xu, H. Enrichment factors and metallogenic models of critical metals in late permian coal measures from yunnan, guizhou, and Guangxi provinces. Minerals 14 (2), 206 (2024).

Kong, B., Cao, Z., Sun, T., Qi, C. & Zhang, Y. Safety hazards in coal mines of Guizhou China during 2011–2020. Saf. Sci. 145, 105493 (2022).

Tang, X. Occurrence regularities of coal resources in Guizhou Province. Coal Geol. Explor. 5, 1–5 (2012).

Chen, J. et al. Analysis of mining crack evolution in deep floor rock mass with fault. Geofluids 1–15 (2021).

Wu, Q. et al. Study on overburden rock movement and stress distribution characteristics under the influence of a normal fault. Adv. Civ. Eng. 2020 (1), 7859148 (2020).

Xinlei, L., Ziyuan, R., Zhengzheng, C. & Hao, R. Study on coal drawing parameters of deeply buried hard coal seams based on Pfc. Sci. Rep. 15 (1), 21934 (2025).

Chaoshang, S. et al. Overburden failure characteristics and fracture evolution rule under repeated mining with multiple key strata control. Sci. Rep. 15 (1), 28029 (2025).

Zuo, Y. et al. Study on catastrophe theory of activation-induced prominence of faults under dynamic disturbance. Adv. Civ. Eng. 2018 (1), 2801957 (2018).

Zhao, J., Juntao, C., Huilin, X., Zhao, Z. & Xinguo, Z. Dynamic mechanical response and movement evolution characteristics of fault systems in the coal mining process. Pure Appl. Geophys. 179 (1), 233–246 (2022).

Li, X. et al. Determination method of rational position for working face entries in coordinated mining of section coal pillars and lower sub-layer. Sci. Rep. 15 (1), 29440 (2025).

Song, W. & Liang, Z. Theoretical and numerical investigations on mining-induced fault activation and groundwater outburst of coal seam floor. Bull. Eng. Geol. Environ. 80 (7), 5757–5768 (2021).

Li, Z. et al. Study on the influence of the fault dip angle on the stress evolution and slip risk of normal faults in mining. Bull. Eng. Geol. Environ. 80 (5), 3537–3551 (2021).

Sainoki, A. & Mitri, H. S. Influence of mining activities on the reactivation of a footwall fault. Arab. J. Geosci. 10 (5), 99 (2017).

Zhang, M., Zhang, Y., Ji, M., Guo, H. & Li, H. Research on physical similarity simulation of mining uphill and downhill at the large-angle working face. Adv. Civ. Eng. 2019 (1), 7696752 (2019).

Wu, Z., Sun, Q. & Wang, Y. Evolution laws of water-flowing fracture zone and mine pressure in mining shallow-buried, hard, and extra-thick coal seams. Appl. Sci. 14 (7), 2915 (2024).

Wang, X. et al. Model test study on overburden failure and fracture evolution characteristics of deep Stope with variable length. Adv. Civ. Eng. 2022 (1), 9818481 (2022).

Zhang, Z. et al. Size and Spatial fractal distributions of coal fracture networks under different mining-induced stress conditions. Int. J. Rock. Mech. Min. Sci. 132, 104364 (2020).

Deng, G., Xie, H., Gao, M., Li, C. & He, Z. Numerical simulation on the evolution of mining-induced fracture network in a coal seam and its overburden under the top coal caving method. Adv. Civ. Eng. 2020 (1), 8833193 (2020).

Xie, H., Yu, G., Yang, L. & Zhang, Y. Research on the fractal effects of crack network in overburden rock stratum. Chin. J. Rock. Mech. Eng.. 02, 29–33 (1999).

Peng, R., Xie, H. & Ju, Y. Computation method of fractal dimension for 2-d digtial image. J. China Univ. Min. Technol. 01, 22–27 (2004).

Huang, L. et al. A new calculation approach of heterogeneous fractal dimensions in complex hydraulic fractures and its application. J. Petrol. Sci. Eng. 219, 111106 (2022).

Author information

Authors and Affiliations

Contributions

Baoyan Zhi: Conceptualization, Investigation, Visualization, Software, Data curation, Writing—original draft, Writing—review & editing. Rui Guo: Conceptualization, Methodology, Formal analysis, Writing—review & editing, Supervision, Funding acquisition. Gang Guo: Investigation, Conceptualization, Formal analysis. Shusen Zhang: Formal analysis, Writing—review & editing. Jiankun Yuan: Investigation, Conceptualization. Canyu Lei: Formal analysis, Methodology. Zuhao Xu: Investigation.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Zhi, B., Guo, R., Guo, G. et al. Study on fracture development and failure characteristics of repeated mining overlying strata in multi-coal seams with faults. Sci Rep 15, 32215 (2025). https://doi.org/10.1038/s41598-025-18221-5

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-18221-5