Abstract

Additive manufacturing (AM) has transformed the production of complex parts, though high-performance composite filament development in this field is still limited. The primary objective of this study is the development of production setup of continuous fiber reinforced polymer (CFRP) composite filament for fused deposition modeling (FDM) applications. Despite their enhanced strength-to-weight ratio and mechanical properties, integrating CFRP composites into AM presents challenges like fiber alignment, breakage, interfacial adhesion, and process optimization. This study aims to address the above-mentioned challenges by developing a robust production setup for CFRP filament tailored for FDM. The design phase of the setup included gear driven CFRP winding system, extrusion system, heating system and pulling spool system. Upon the fabrication of the setup, CFRP was produced using PLA and glass fiber and the technique preserved the integrity and continuity of the reinforcement throughout the filament. Uniaxial tensile testing was performed to assess the mechanical performance of the produced filament. The experimental results demonstrated a significant improvement in tensile strength (146.75 MPa) and Young’s Modulus (4.95 GPa) at a fiber volume fraction of 2.8% for the composite filament and these values were in Line with the theoretical results. The tensile strength of the Continuous Glass Fiber-PLA showed an increase of 2.4 times while the young’s modulus yielded an increase of 1.35 times in comparison to the neat polymer. Scanning electron microscopy analysis of the fractured composite samples showed sufficient polymer impregnation and strong interfacial bonding. The energy dispersive X-ray spectroscopy was conducted confirming the polymer impregnation uniformity. The thermal characterization by differential scanning calorimetry and Thermogravimetric analysis validated the composite filament’s suitability for FDM printing. The outcomes of this study help to push forward the current advancements in AM using composite filament, paving the way for stronger, lightweight, and reliable printed structures. The insights gained are instrumental in expanding the application of composite AM in aerospace, automotive, and industrial sectors where high-performance materials are critical.

Similar content being viewed by others

Introduction

Additive Manufacturing particularly FDM has become prominent for producing complex, lightweight structures due to its design flexibility, affordability, and simplicity1. The limited mechanical properties of standard FDM thermoplastics hinder their use in high-performance sectors like aerospace and automotive; integrating CFRP composites offers improved strength-to-weight ratios, though challenges like alignment, bonding, and processing persist2,3,4,5,6.

Parandoush et al.7 introduced an innovative method for laser-assisted AM using continuous glass fiber and polypropylene polymer. Ismail et al.8 investigated methods for the FDM using CFRP, focusing on the effect of void formation and sintering of polymer. Kipping et al.9,10 emphasized the critical role of effective slicing and path-planning strategies. Wang et al.11 introduced a novel approach combining FDM-printed continuous carbon fiber composites with an aerosol jet-printed sensing network for real-time structural health monitoring. Bettini et al.12 employed an adapted FDM process to produce CFRP by making minor adjustments to a conventional 3D printer. Heidari-Rarani et al.13 fabricated CFRP composites using a custom-designed extruder specifically developed for FDM-based 3D printing systems. Zhang et al.14 developed an ultrasonic-assisted FDM printer and found that ultrasonic frequency significantly improved interfacial adhesion. Prusinowski and Kaczynski15 studied the tribological properties of FDM fiber composites using a novel print head with symmetrical filament feeding. Trad et al.16 analyzed and outlined the impact of 3D printing parameters on short CFRPs. Zhao et al.17 and Ming et al.18 suggested an FDM-based method that includes ultraviolet (UV) aid and a dual-curing procedure to produce CFRP. Aravind et al.19 investigated a unique method involving twisted carbon fiber filament and examined its impact on additively built materials. Key factors for high-quality CFRP production include reinforcement tension, surface preparation, feed rate, and precise temperature control4,20.

Dickson et al.21 evaluated the effectiveness of long glass, carbon, and Kevlar fiber reinforcements in FDM-fabricated composites. Liu, Xiong, and Zhou22 proposed a CFRP design approach via AM to enhance current product performance and enable future innovations. Huan Jiang et al.23 developed a cost-effective 4D printing method for continuous fiber-reinforced liquid crystal elastomer (LCE) composites, enabling programmable shape-morphing. Akhoundi et al.24 enhanced the mechanical properties of FDM printed components by optimizing the proportion of continuous fiber yarn. Naik et al.25 created samples by combining an onyx matrix with continuous fiberglass reinforcement using Markforged Mark Two printer. Using a Markforged Two 3D printer, Saeed et al.26 examined and contrasted the in-plane mechanical characteristics of long CF/PA composite. In order to create environmentally friendly composites via FDM, Billings et al.27 combined a bio-based PLA polymer with wood fibers. Hedayati et al.28 used FDM to create the CFRP using polyglycolic acid suture yarn as reinforcement inside PCL scaffolds. Kalova et al.29 used FDM to create a composite profile by mixing an onyx matrix with extended carbon reinforcements. Karimi et al.30 emphasized the significance of continuous fibers, as they play a crucial role in enhancing the strength of printed components. In a different study, Maqsood and Rimašauskas created solid and porous long carbon-reinforced composite models using FDM31. Dojan et al.32 introduced a mold-free, energy-efficient additive manufacturing process for fiber-reinforced thermoset composites using thermoresponsive resins. A PLA thermoplastic polymer was used in the AM of CFRP by Uşun and Gümrük33, who highlighted the material’s exceptional mechanical qualities. Using tensile and bending tests, Saeed et al.34 investigated the effectiveness of long CF/PA composite. Tuli et al.35 and Hu et al.36 examined existing techniques and important aspects pertaining to the structure and substrate type of carbon fiber used for FDM. Xiaohui Song et al.37 developed PLA/continuous cotton thread (CCT) filaments using a prepreg device, demonstrating that alkali treatment and optimal fiber parameters significantly enhanced interfacial bonding. Arjun Prihar et al.38 employed large-scale robotic additive manufacturing demonstrating that the biomimetic architecture significantly enhances fracture toughness.

PLA is widely favored for FDM because of its low melting temperature which ensures easy, low-warp printing, enables co-processing with heat-sensitive fibers, offers adequate structural stiffness, and is both biodegradable and compatible with most commercial printers39,40,41. While polymers like PA, PEEK, and ABS offers superior mechanical or thermal properties which consequently demand higher processing temperatures and pose challenges like warping and poor layer adhesion; PEEK needs specialized high-temp printers, and ABS often shrinks without a heated chamber42,43,44.

In this work, E-glass fiber yarn was chosen for its high tensile strength, stiffness, low cost, good polymer adhesion, and chemical resistance45,46. Compared to carbon fiber, it avoids issues like conductivity, cost, and nozzle wear, while offering thermal stability and enhanced load transfer in structural applications47. The following three methods are generally used for the 3D printing of CFRP4: (i) Coextrusion (separated filaments used - separate entrance channel/hole for PLA and Fiber), (ii) Dual extrusion (separate nozzles used - one for the deposition of PLA and other for the deposition of fiber), and (iii) Direct extrusion (kind of a coextrusion method with single filament consisting of both the PLA and the fiber was prepared and then directly fed to the printer for 3D printing).

The first method coextrusion has limitations of fiber breakage, fiber misalignment, nozzle clogging, weak fiber polymer bonding and inconsistent fiber volume fraction. On the other hand, the dual extrusion method has limitations of path definition and synchronization of the nozzles. Therefore, after comparative analysis, the third method was selected for further exploration. Literature suggested that a method was used for the preparation of CFRP for direct extrusion and it is generally termed as Melt Impregnation which has limitations such as fiber tensioning, fiber unwinding/winding affecting performance, fiber breakage, fiber contact angle on the roller48,49. In a few studies, once the CFRP filament was prepared the 3D printer also had to be modified for the 3D printing of CFRP48. Hence, process optimization has yet to be achieved.

This work concentrates on catering for the above-mentioned challenges by developing a specialized production mechanism for CFRP composite filament. In this study, a novel setup was designed and fabricated to produce CFRP filament such that it eliminated the issue of fiber breakage and other limitations mentioned above. CGF-PLA composite filament was made utilizing the fabricated production setup. Uniaxial tensile testing was then undertaken, and Young’s modulus and strengths of the neat polymer and the composite filament were compared. Fiber-polymer bonding was thoroughly examined using SEM. Moreover, thermogravimetric analysis (TGA), and differential scanning calorimetry (DSC) were conducted to analyze the thermal performance. Energy-dispersive X-ray spectroscopy (EDS) Once the filament was produced using this setup it could be directly used for 3D printing without any modification in the 3D printer.

Materials and methods

Continuous E-glass fiber yarn and PLA were chosen for their processability, mechanical properties, FDM compatibility, cost-efficiency, and environmental sustainability. This study employed two primary materials: E grade glass fiber as the reinforcement and PLA as the thermoplastic matrix.

The fiber was sourced from Hefei Cross-Poly Electronic Commerce Co., Ltd. based in Mainland China. It was an E-grade continuous glass fiber with a diameter of 0.2 mm, supplied in spools weighing 200 g per reel while the single strand is 1 K. E-glass fiber is specified with its high mechanical strength, thermal stability, and electrical insulation properties. Moreover, the material is characterized by its high temperature resistance, flame retardancy, and excellent insulation performance, making it suitable for structural composite applications.

The thermoplastic polymer material was black colored PLA filament, procured in the form of three individual spools, each weighing 0.25 kg (net filament weight), with a gross weight of 0.55 kg including packaging. The filament had a diameter tolerance of ± 0.02 mm, which ensured consistent feed and dimensional accuracy. The PLA was vacuum-sealed with desiccant pouches to prevent moisture absorption and guaranteed to be 100% bubble-free, thereby maintaining print quality and mechanical consistency. The filament was obtained from a commercial 3D printing material supplier. Both the above-mentioned materials were used to produce the composite material as shown in Fig. 1 and their properties are given in Table 1.

To enable the production of CFRP filament suitable for FDM, a custom-built production setup was designed and fabricated. The primary objective of this setup was to ensure uniform winding of thermoplastic polymer onto continuous fiber, maintaining precise fiber alignment, and achieve synchronized feeding and extrusion speeds, being the key requirements for consistent filament quality. A novel CFRP filament production setup was designed as shown in Fig. 2, followed by its fabrication. The schematic diagram of the setup and the fabricated setup are shown in Fig. 3a and b. The key component of the setup includes the following: (A) Gear-driven CFRP winding system, (B) extrusion system, (C) heating system, and (D) pulling spool system.

Gear-driven CFRP winding

A gear mechanism was employed to facilitate the uniform winding of PLA onto the continuous E-glass fiber as shown in Fig. 4. The system consists of a 57BYGH stepper feed motor that is coupled to a driver gear by a shaft such that it powers the driver gear, which in turn drives a driven gear. The driven gear incorporates three evenly spaced holes, each positioned 14 mm from the center and separated by 120-degree intervals. These holes guide the 1.75 mm PLA filament, ensuring its uniform winding onto the 0.2 mm E-glass fiber that is centrally aligned within and passing through the center of the driven gear. It is pertinent to mention that the fiber initially passed throughout the setup (Fiber reel to the driven gear central hole to the extruder assembly passing through the rollers to the heater to the nozzle and finally to the Spool) till the last stage which is Pulling Spool system where the bare fiber tied to the spool in order to maintain the fiber tensioning. Three separate spools of PLA filament are mounted on a shaft coupled to the driven gear. To minimize the hygroscopic effect, the PLA filament used in the composite production was dried prior to processing to reduce its moisture content. As the driven gear rotates, the PLA filaments pass through the designated holes and wrap tightly around the tensioned glass fiber, effectively mitigating fiber misalignment issues observed in previous research50,51. This controlled winding process ensures consistent polymer winding along the fiber length.

Extrusion system

Once the fiber-polymer composite is properly wound, it advances into a specialized extruder designed to pull the material uniformly. The extruder system consists of a Wiper Motor such that a gear is mounted on its shaft and is in mesh with another gear. These gears remain in mesh are coupled with rollers manufactured via CNC TurnMill Machine, featuring a 3.75 mm central groove to securely grip and pull the 3.75 mm diameter winded composite forward toward the heating zone. The 3.75 mm central groove size was finalized based upon the cumulative size of 3 PLA filaments and the glass fiber yarn shown in Fig. 5a. Moreover, the extruder motor drives the gears and turns the rollers such that the extruder motor speed is synchronized with the feed motor speed to maintain optimal fiber polymer winding tension and prevent inconsistencies in the filament formation.

Figure 5b shows the velocity configuration with the twist angle. The following mathematical relations were derived to regulate the synchronization of speeds between the feed and extruder motors, ensuring seamless processing:

rtwist = 14 mm.

Number of teeth of driver gear = N1 = 20.

Number of teeth of driven gear = N2 = 44

Gear Ratio = G = 2.2

Angular Velocity of driver gear = ω1 = 10 rpm.

ω2 = ωtwist = 4.545 rpm.

rext = 4.5 mm.

For ɣ = 30°

By varying the values of ω1 and ɣ the above formulation can be standardized to find the values of \(\:{\varvec{\upomega\:}}_{\mathbf{e}\mathbf{x}\mathbf{t}}\). Additionally, Table 2 presents the extruder motor speeds relation corresponding to various feed motor speeds for a twist angle of 30° using the above formulations, enabling precise control over the material feeding process:

Heating system

After exiting the extruder, the fiber-reinforced filament enters a hotend assembly (Fig. 6), where it undergoes thermal processing to achieve uniform polymer-fiber adhesion. The hotend was heated via a heating element, controlled using a relay, power supply, and temperature controller, allowing precise thermal regulation within the range of 140 °C to 180 °C. Additionally, the in-line heating system of the production setup ensured that the polymer remained in a dry and molten state during impregnation, which reduced the possibility of moisture induced voids or weak bonding at the fiber matrix interface. The heating process softens the PLA, ensuring it fully encapsulates the E-glass fiber and achieves structural integrity. At the hotend outlet, a nozzle was positioned to shape the filament. The nozzle features an entry diameter of 4 mm and an exit diameter of 1.75 mm, allowing the composite material to be compressed and consolidated into a standard filament size compatible with FDM-based 3D printing.

Pulling spool system

Upon extrusion, the final composite filament was continuously pulled by a 12 V puller motor, which drives a spool mounted on its shaft as shown in Fig. 7. Between the heating system and the spool, a fan was installed that ensures uniform cooling of the extruded material before it reaches the spool. The cooling length was kept at 7 mm, the fan was placed at ~ 100 mm from the nozzle, while the Fan speed was kept 1.5–2 m/s and the temperature was maintained at ambient temperature between 23 and 25 °C. The cooling distance allows the filament to solidify gradually without inducing internal stresses. While higher air velocities of the fan may result in rapid cooling which could cause void occurrence and affect the dimensional quality. At the above-mentioned cooling length, the PLA consolidation around the fiber i.e., dimensional accuracy for the obtained filament was satisfactory. Moreover, no chamber was required as opposed to ABS, hence the process was conducted open air due to PLA’s low shrinkage property. The motor rotates at a speed between 5 and 10 rpm in synchronization with the speed of the extruder motor so that the filament could be pulled out of the extruder uniformly and smoothly and gets rolled onto the spool. This controlled collection process ensures that the filament is neatly rolled up onto the spool, making it readily available for subsequent 3D printing applications.

Using the above-described manufacturing setup, the composite material was produced rolled up on the spool. The extrusion parameters were systematically optimized to ensure uniform filament morphology and improved interfacial adhesion. Feed motor speed (30 rpm) was selected to provide a stable material supply without overloading, while extruder motor speed (74–75 rpm) balanced sufficient shear for homogeneous melting without inducing degradation. The heater temperature of 165 °C ensured complete melting of PLA while preventing thermal decomposition. A pulling spool speed of 10 rpm maintained dimensional accuracy by avoiding both sagging and overstretching, and controlled cooling at a fan speed of 1.5–2 m/s stabilized the filament structure without inducing surface cracks. Collectively, these optimized conditions (Table 3) produced filaments with consistent diameter, smooth surface finish, and enhanced matrix–fiber interaction, thereby addressing concerns regarding the influence of temperature, feed rate, and cooling rate on filament quality. Figure 8 shows the produced composite filament which was perfectly uniform and flexible having a cross-sectional diameter of 1.75 ± 0.05 mm.

Experimental setup

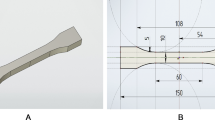

To evaluate the tensile properties of the materials involved in the development of the continuous fiber-reinforced PLA filament, uniaxial tensile testing was conducted on three different types of specimens: neat PLA, continuous E-glass fiber yarn, and continuous glass fiber yarn-reinforced PLA (GF/PLA) composite. All specimens were tested in their raw filament form (circular cross-section) prior to any additive manufacturing processes. Tensile specimens were prepared in accordance with ASTM D3379, which is standardized for the tensile testing of high-modulus single-filament materials. A total of 10 specimens were prepared, comprising three samples each of neat PLA (red color), E-glass fiber yarn (beige color), and four samples for GF/PLA composite (black color). Each specimen was cut to a total length of 120 mm with a defined gauge length of 30 mm. The diameters of the PLA and GF/PLA composite specimens were maintained at 1.75 mm, while the E-glass fiber yarn had a diameter of 0.2 mm.

All tests were carried out using a Universal Testing Machine (UTM), equipped with a 20 kN load cell as shown in Fig. 9. The temperature was maintained at 23–25 °C while the relative Humidity was maintained at 30% ± 5%. The specimens were mounted using self-tightening wedge grips. For E-glass fiber yarn specimens, capstan grips were employed to minimize stress concentrations and slippage, ensuring an even distribution of tensile load across the gauge section. Prior to testing, all specimens were conditioned at room temperature for 24 h. The UTM test configuration for each specimen is shown in Fig. 10. For neat PLA and GF/PLA composite specimens, testing was performed at a crosshead speed of 5 mm/min. Moreover, for E-glass fiber yarn specimens, a lower crosshead speed of 0.2 mm/min was adopted to accommodate the finer geometry and minimize dynamic effects. Load and displacement data were recorded continuously throughout each test and tests were terminated at the point of complete specimen fracture.

Optical Microscopy of the filament was performed, and the cross-sectional areas of the fiber and the composite were observed as displayed in Fig. 11. The fiber volume fraction (FVF) is as follows:

Area of fiber = 83270.92 μm2.

Area of composite = 3050190.73 μm2

TGA and DSC tests have been conducted to check the thermal stability of the composite filament. The thermal stability of the CGF-PLA specimen was evaluated using a TGA/DSC 1 STAR System by METTLER TOLEDO. The analysis was performed under dynamic conditions in a nitrogen atmosphere with a controlled flow rate of 10 mL/min to prevent oxidative degradation. Samples were placed in alumina crucibles and subjected to a heating program from 25 °C to 1000 °C at a constant heating rate of 10 °C/min. The mass loss as a function of temperature was recorded to determine the onset and peak degradation temperatures, assess thermal stability, and quantify the residual mass corresponding to the inorganic glass fiber fraction.

DSC tests were carried out on approximately 5 mg of accurately weighed filament samples, placed in aluminum pans that were hermetically sealed when necessary to avoid material loss. A nitrogen atmosphere was maintained throughout the experiment with a purge flow of about 20–50 mL/min to prevent oxidative degradation of the specimens. The samples were heated at a constant rate of 10 °C/min, which is a standard setting to ensure reproducibility and clear identification of thermal transitions. The temperature range extended from 20 °C up to 220 °C, sufficient to cover the glass transition, crystallization, and melting regions of the polymer. To eliminate any prior thermal history and to capture the true thermal behavior, the measurements were conducted in two successive runs, with the first run serving to erase previous processing effects and the second run used for detailed analysis.

The EDS test of the CGF-PLA filament was performed using a JEOL JSM-6490 A scanning electron microscope in order to evaluate the polymer impregnation. For the analysis, a 2 mm long piece of the filament was carefully cut and prepared in its longitudinal view to enable detailed inspection of the fiber–polymer distribution along the length of the sample. The specimen was examined without any conductive coating, ensuring that the natural surface characteristics of the material were preserved. The microstructural features were observed at a magnification scale of 500 μm, allowing sufficient resolution to identify the elemental composition and fiber–polymer interactions within the filament.

Results and discussions

The results were processed using stress strain data obtained by the experimentation of the specimen. The outcomes of ultimate tensile strength (UTS) and Young’s modulus of all the three materials for each test specimen are summarized and compared in Figs. 12 and 13. Moreover, the comparison of the stress strain behavior of the polymer and composite is exhibited, also the average Young’s modulus and UTS are also represented in the graphs in subsequent sections.

The full stress strain curves presented in Fig. 12 offer further insight into the strength characteristics of the different material systems. Neat PLA samples failed at UTS values ranging from 58 MPa to 63 MPa, exhibiting ductile behavior with moderate strain at failure of about 3–5%. Glass fibers, as expected, exhibited the highest UTS values, ranging from 3451 MPa to 3617 MPa, with sharp and brittle failure profiles. These results highlight the immense tensile strength potential of continuous glass fibers when uncoated and unimpeded by polymer matrix effects. Composite filaments showed a substantial increase in UTS, ranging from 121 MPa to 174 MPa. These values represent a 2–3 times improvement over pure PLA. The composite samples also displayed varying degrees of post-UTS deformation, indicating a mixture of brittle and semi-ductile failure modes depending on coating uniformity and interface integrity. This trend in strength similarly followed the stiffness hierarchy as Fiber > Composite > Polymer. The high UTS of the composite samples validates the preservation of fiber integrity during the coating process and the effectiveness of PLA as a matrix in distributing applied loads.

The elastic region of the stress–strain curves, depicted in Fig. 13 clearly illustrates the differences in stiffness between the three material systems. Neat PLA polymer specimens (T1–T3) exhibited a Young’s modulus in the range of 3.459 to 3.827 GPa, consistent with literature-reported values for thermoplastic PLA. Bare E-glass fiber yarns (T1–T3) showed the highest stiffness, with modulus values between 70.763 and 76.351 GPa. PLA coated composite filaments (T1–T4) demonstrated significantly enhanced stiffness, with modulus values ranging from 4.833 to 5.067 GPa, representing approximately 1.3 times increase over neat PLA. The results reveal a clear hierarchical trend in stiffness depicting Fiber > Composite > Polymer. This increase in elastic modulus with each stage of material integration affirms the effective transfer of load from the PLA matrix to the embedded glass fibers. The measured modulus of the composite filament falls between those of neat PLA and pure glass fiber, as expected for a continuous fiber-reinforced system. The data validates the efficacy of the filament production mechanism in maintaining fiber alignment and ensuring effective interfacial bonding, which is essential for stiffness enhancement.

The significant increase in both UTS and Young’s modulus from polymer to composite strongly supports the reinforcing role of continuous glass fibers. The improvement confirms successful load transfer across the fiber–matrix interface, which is crucial for mechanical performance in FDM printed structural components. Interestingly, the strain-to-failure of the composite was generally lower than that of neat PLA but higher than that of bare fibers, indicating a transitional failure mode i.e. partial ductility and fiber-matrix interaction during deformation. Post-yield analysis also suggested partial ductility, implying a balanced mechanical performance suitable for applications like structural brackets and automotive interior components. It is also noteworthy that some composite specimens (e.g., T3 and T4) showed post-peak load retention, suggesting fiber pull-out or partial delamination as secondary failure modes, rather than catastrophic breakage. The UTM failure configuration of each specimen is expressed in Fig. 14.

To visualize the improvement imparted by glass fiber reinforcement in PLA matrix, a direct overlay of the stress–strain curves of polymer and composite specimen is presented in Fig. 15. The comparison clearly highlights the significant enhancement in both stiffness and strength due to reinforcement. The initial slope of the composite curve is markedly steeper, consistent with a Young’s modulus of 4.833 GPa for the composite vs. 3.459 GPa for the polymer. Additionally, the ultimate tensile strength of the composite 121 MPa far exceeds that of the pure PLA filament 63 MPa. The composite demonstrates a more abrupt fracture profile, indicative of a more brittle but structurally superior failure mode, whereas the polymer shows a plateau-like behavior suggestive of plastic deformation before fracture. This curve overlay reaffirms the fundamental mechanical transformation achieved by incorporating continuous glass fibers into the PLA filament, elevating the material from a moderately ductile thermoplastic to a load-bearing structural filament.

Figure 16 presents a comparative bar graph of average ultimate tensile strength for the three tested material groups: polymer, composite, and fiber, including standard deviation. Polymer: UTS = 60.3 MPa (Average of the UTS values of 3 PLA samples tested and mentioned in Fig. 12 (a)), with minimal variation, representative of neat PLA. Fiber: UTS = 3508.3 MPa (Average of the UTS values of 3 GF samples tested and mentioned in Fig. 12b), showing the inherent high strength of continuous E-glass fibers. Composite: UTS = 146.75 MPa (Average of the UTS values of 4 GF/PLA Samples tested and mentioned in Fig. 12 (c)), showing 2.4 times increase over the neat polymer. This quantitative comparison strongly supports the assertion that a significant portion of the load-bearing capacity of the composite filament is derived from the embedded glass fibers. The increase in UTS from polymer to composite represents effective load transfer and stress distribution across the fiber–matrix interface. The lower standard deviation observed in polymer samples reflects the homogeneous nature of thermoplastic PLA, while the slightly higher deviation in composites may stem from factors such as PLA coating uniformity, fiber wetting, or microscopic interfacial voids. The fiber group, despite its high strength, shows moderate variation, likely due to natural inconsistencies in fiber packing density and tension during testing. Using the formula for the theoretical UTS of the composite Sc and inserting the obtained experimental values of E for polymer and the fiber:

\(\:\mathbf{v}\)p = Volume Fraction of Polymer = 0.972.

\(\:\mathbf{v}\)p = Volume Fraction of Polymer = 0.972.

\(\:\mathbf{v}\)f = Volume Fraction of Fiber = 0.028.

Sf = UTS of Fiber = 3508.3 MPa

While,

The sole reason for low value of UTS is low FVF i.e. 2.8% for this study. However, the results of the strength & quality of the filament produced from this production setup promise higher UTS values upon increasing the FVF. Some of the studies have been cited in Table 4 below in which 3D printing of CGF-PLA was done using various methods (coextrusion, dual extrusion). The third study cited in Table 4 is the closest to this research work as it yields a tensile strength of 171.66 MPa at an FVF of 5.21%, that further supports the results of this study to be satisfactory.

Figure 17 illustrates the average Young’s modulus of the three material categories, again supplemented by standard deviation indicators. Polymer Young’s Modulus: 3.68 GPa, Fiber Young’s Modulus: 74.3 GPa, Composite Young’s Modulus: 4.96 GPa. The plot clearly visualizes the stiffness hierarchy established earlier i.e. Fiber > Composite > Polymer. The near 1.35 times increase in modulus from polymer to composite confirms the stiffness imparted by the continuous glass fibers and the efficient elastic response of the hybrid filament. The low spread in composite modulus values further indicates consistent bonding and reinforcement during the filament fabrication process. It is important to note that while the modulus of the composite is lower than that of the pure fiber, this is expected due to the polymeric encapsulation around the fibers and the resulting load-sharing mechanism. Nonetheless, the achieved modulus demonstrates the suitability of the composite filament for structural FDM printing applications requiring moderate stiffness and high tensile strength. Using the formula for the theoretical Young’s Modulus of the composite Ec and inserting the obtained experimental values of E for polymer and the fiber:

Where,

\(\:\varvec{v}\)p = Volume Fraction of Polymer = 0.972.

Ep = Young’s Modulus of Polymer = 3.68 GPa.

\(\:\varvec{v}\)f = Volume Fraction of Fiber = 0.028.

Ef = Young’s Modulus of Fiber = 74.3 GPa

While,

At a low fiber volume fraction (FVF = 2.8%), the load transfer efficiency from the PLA matrix to the continuous E-glass fibers becomes highly dependent on the quality of interfacial bonding. While PLA offers good adhesion properties, the absence of surface treatment on the glass fiber could have led to suboptimal bonding, resulting in a reduced modulus in experimental observations. The theoretical modulus is calculated using the rule of mixtures, which assumes perfect fiber alignment along the loading direction. However, during the filament production process, slight deviations from ideal alignment may introduce local misorientation of fibers which reduce the composite’s stiffness under tensile loading, thereby lowering the effective modulus. Inherent challenges in coextrusion at such a small scale (especially with a 0.2 mm diameter yarn) may result in voids or resin-rich areas. These micro-defects can act as local stress concentrators and compromise the stiffness of the composite. Despite the relatively low FVF, the experimental Young’s modulus (4.96 GPa) is still in agreement with the theoretical value (5.66 GPa), indicating that the filament production method holds promise.

To gain insight into the failure mechanism and fiber–matrix interactions of the fabricated CFRP filament, SEM was conducted on the composite cross-section and the fractured surface. Figure 18 presents representative SEM micrographs of the PLA-coated E-glass fiber illustrating the low-magnification SEM images of the filament pre- and post-fracture. Figure 18a reveals the cross-sectional view of the composite filament displaying the fiber and polymer regions i.e. pre-test fiber distribution. It can be clearly seen in the SEM image that the fiber is completely encapsulated by the polymer which has resulted due to the coordinated effect of the driven gear rotation and extrusion rollers. Moreover, the SEM image shows that the fiber is not fully at the center however it is completely encapsulated by the polymer resolving the problem of misalignment/fiber sidelining which arises in the case when the fiber and the polymer are entered into the nozzle via separate entry points for 3D printing as in coextrusion method. With this filament as the fiber is encapsulated within the polymer the fiber misalignment issue gets resolved. Figure 18b further shows the fiber bundle having fractured in a relatively clean manner, with minimal fiber fraying, indicating a hybrid fracture behavior (brittle at some zones & fiber pull out at some zones) of the glass fiber phase, while the polymer matrix around the interface exhibits the ductile failure. This figure expresses the after-failure side view of the composite indicating partial fiber pull-out from the PLA matrix, indicating debonding along the fiber-matrix interface which is an expected failure mode in low-FVF systems. The central fiber shows distinct pull-out behavior as some strands are seen partially detached from the matrix. This is a strong indication of interfacial bonding behavior. These observations confirm that while the fiber reinforcement bore most of the load, the matrix played a crucial role in stress distribution up to the failure point. Figure 19 presents a high-magnification SEM micrograph focusing on the cross section of the glass fiber yarn. It is basically displaying after failure high magnification top view of the fiber strand which expresses microvoids and irregular morphology, both indicative of interfacial stress during mechanical loading. Size range of voids (~ 8–10 μm) and rough matrix topography suggest possibly microcracking during fracture. These features may correspond to debonding, microvoid coalescence which are the indicators of interfacial performance. These microstructural observations directly support the mechanical test results and provide insight into the nature of fiber-matrix bonding and failure mechanisms in the produced continuous glass fiber-reinforced PLA composite.

The low FVF is primarily influenced by the small diameter (0.2 mm) of the continuous glass fiber yarn which was used based upon its ease of availability and compatibility with the custom-developed filament production system. Higher FVF values would have required larger fiber yarns or more complex multi-fiber alignment strategies, which were beyond the scope and perhaps a limitation to single-yarn filament production setup used in this study. Despite the low FVF, the composite specimens exhibited significant improvements in tensile strength and modulus compared to neat PLA, aligning well with predictions from theoretical calculations. This suggests efficient stress transfer between the fiber and matrix, thereby validating the efficacy of the process even at low reinforcement content. Here it is worth mentioning that exploring higher FVF levels with this setup would surely further enhance mechanical properties. However, this will involve important trade-offs such as increased processing difficulty i.e., nozzle clogging/jamming risk with high fiber content and reduced filament flexibility and issues in extrusion i.e., poor flow.

The TGA curve (black) and its first derivative (DTG, red) provide insight into the thermal stability and degradation behavior of CGF-PLA as shown in Fig. 20. The composite shows negligible mass loss up to approximately 291 °C, indicating high thermal stability in this range, with no significant volatilization or degradation of the PLA matrix or the glass fibers. The mass loss region in one of the studies on TGA of neat PLA cited in Literature indicates the values from 211.9 °C to 324 °C54. A sharp and pronounced mass loss is observed between 291 °C and 437 °C, corresponding to the primary thermal degradation phase of the PLA matrix. In this interval, a mass loss of ~ 90% is recorded, which is attributed mainly to the thermal decomposition of the PLA polymer chains through random chain scission and depolymerization, while the continuous glass fibers remain thermally stable. The DTG curve peaks within this region, representing the maximum degradation rate of the PLA phase. Beyond 437 °C, the weight stabilizes, leaving a char yield of ~ 7% which further reduces to ~ 3% at 1000 °C. This residual mass is primarily due to the non-combustible continuous glass fibers and minor inorganic residues. The high char yield relative to neat PLA reflects the presence of thermally stable reinforcement, which not only improves the composite’s mechanical integrity at elevated temperatures but also enhances its fire resistance. The TGA results also indicate absence of any moisture. Overall, the TGA results confirm that the incorporation of continuous glass fibers into PLA significantly improves the thermal stability and high-temperature residue content compared to neat PLA, making CGF-PLA more suitable for sustained performance under elevated thermal conditions.

The DSC test for the neat PLA and the CGF-PLA composite was conducted to investigate the characteristic temperatures and the following thermal information in terms of temperature was recorded as shown in Fig. 21. Glass transition (Tg): PLA: onset ≈ 53.2 °C, peak heat-capacity step at 58.8 °C. CGF-PLA: onset ≈ 54.7 °C, peak ≈ 59.2 °C. The ~ 1–2 °C up-shift in the composite indicates slightly restricted chain mobility due to the glass-fiber framework and/or better packing after processing.

Cold crystallization (Tcc): PLA: onset ≈ 111.6 °C, peak 126.3 °C, ΔHcc ≈ 19.84 J g⁻¹. CGF-PLA: onset ≈ 113.1 °C, peak 127.7 °C, ΔHcc ≈ 14.57 J g⁻¹. The composite crystallizes at a marginally higher temperature with a smaller enthalpy, consistent with nucleation on fiber surfaces but reduced overall mobile matrix fraction and constrained lamellae growth.

Melting (Tm): PLA: onset ≈ 145.4 °C, peak 151.2 °C, ΔHm ≈ 22.33 J g⁻¹. CGF-PLA: onset ≈ 146.3 °C, peak 152.1 °C, ΔHm ≈ 17.53 J g⁻¹. The ~ 1 °C higher Tm in CGF-PLA suggests slightly thicker/more perfect crystallites promoted by fiber-induced nucleation; the lower ΔHm reflects dilution by the inorganic fiber and the constrained crystallization noted above.

The composite shows a slightly higher Tg and Tm, a reduced crystallization enthalpy and a shifted Tcc. Together these features indicate that continuous glass fibers promote nucleation while constraining chain mobility and crystal growth behavior typical of well-impregnated, fiber-reinforced PLA. Moreover the results of DSC are in close agreement with the previous studies55.

The SEM micrograph (Fig. 22) with the highlighted red encircled region shows the longitudinal view of the CGF-PLA filament, where the EDS analysis was conducted. The EDS spectrum (Fig. 23) and quantitative results (Table 5) show that the analyzed region primarily consists of: Carbon (63.6 wt%), Oxygen (36.2 wt%) and Sodium (0.2 wt% - trace impurity). This composition is in excellent agreement with the expected stoichiometry of PLA, which is a carbon-oxygen rich polymer. The strong carbon and oxygen peaks validate that the polymer matrix is present across the selected region. The presence of carbon and oxygen throughout confirms that the PLA has effectively impregnated the continuous glass fibers. The absence of significant peaks from glass fiber elements, like Si, Al, Ca, Mg, which dominate E-glass composition, in the analyzed matrix area indicates that the polymer uniformly surrounds the fibers rather than leaving voids or unimpregnated regions. This has also been exhibited in the Optical Microscopy image (Fig. 11) where the cross-sectional view of the composite filament showed that the glass fiber is fully encapsulated in the PLA. The uniform weight percentages of carbon and oxygen across the drawn area strongly suggest that the PLA is homogeneously distributed. The trace sodium content can be attributed to minor contamination, but it is negligible and does not affect the impregnation quality. Thus, the EDS results confirm that the devised CFRP production setup produced a continuous, void-free PLA coating, ensuring proper fiber–matrix bonding. Hence, the EDS results validate the uniformity of polymer impregnation.

Limitations and future recommendations

As future work, investigation on higher FVFs by using fiber yarns with large size and multi-fiber integration strategies while maintaining processability, can be conducted using the devised production setup56. Also, this setup can be utilized for the production of filaments with combination of different fibers and polymers57. Integration of multi-scale reinforcements study, such as combining continuous fibers with nano-fillers can be undertaken58. Moreover, the comparative analysis of mechanical performance between continuous fiber (produced using this production setup), short-fiber, and particle-reinforced filaments can be carried out59. While this study is Limited to the filament production, the performance of the filament in an actual 3D printer with respect to printability, nozzle clogging, and interlayer adhesion can be analyzed in the future60. 3D Printing of multilayer pre-impregnated specimen and their mechanical testing using the CFRP filament produced by the production setup devised in this research study can be done. Surface coating techniques can be explored to improve filament smoothness, and enhance bonding61. Dynamic mechanical testing with temperature sweep, fatigue and creep tests can be conducted after the 3D printing of the samples and results can be analyzed62,63.

Conclusions

This study effectively demonstrated the development of the novel production setup for CFRP, and mechanical evaluation of CFRP composite filament produced for additive manufacturing applications. The key conclusions are as follows: Incorporating continuous E-glass fibers into PLA significantly improved mechanical performance. The composite filament showed 2.4 times increase in UTS and 1.35 times increase in Young’s modulus compared to neat PLA. These values align well with theoretical predictions, confirming the filament’s potential. The stress–strain behavior confirmed efficient stress transfer and adequate interfacial bonding. SEM analysis revealed uniform fiber coating and maintained fiber alignment. The thermal transitions remain within the processing window for FDM, supporting the composite filament’s suitability for printing without additional thermal penalties. The production system ensured dimensional consistency and improved bonding through optimized processing. It enabled continuous, well-oriented fiber embedding with uniform polymer coating, producing a filament suitable for additive manufacturing applications. In summary, the findings from this study confirm that continuous fiber-reinforced PLA filaments fabricated using the devised setup exhibit considerable potential for FDM-based 3D printing. The developed approach offers a scalable and efficient pathway for producing composite filaments tailored for FDM based AM.

Data availability

The datasets used and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

Gibson, I., Rosen, D. & Stucker, B. (BOOK)Directed Energy Deposition Processes. In: Additive Manufacturing Technologies. (2015).

Bermingham, M. J., Nicastro, L., Kent, D., Chen, Y. & Dargusch, M. S. Optimising the mechanical properties of Ti-6Al-4V components produced by wire + arc additive manufacturing with post-process heat treatments. J. Alloys Compd. 753, 247–255 (2018).

Tian, X. et al. Recycling and remanufacturing of 3D printed continuous carbon fiber reinforced PLA composites. J. Clean. Prod. 142, 1609–1618 (2017).

Jamal, M. A., Shah, O. R., Ghafoor, U., Qureshi, Y. & Bhutta, M. R. Additive manufacturing of continuous fiber-reinforced polymer composites via fused deposition modelling : a comprehensive review. Polymers, 16(12), 1622 (2024).

Matsuzaki, R. et al. Three-dimensional printing of continuous-fiber composites by in-nozzle impregnation, Sci. Rep., vol. 6, no. February, pp. 1–7, (2016).

Islam, M. R., Uddin, M. N., Taylor, W., Warren, R. & Hsiao, K. T. Enhancing the longitudinal compressive strength of freeform 3d-printed continuous carbon fiber-reinforced polymer composite laminate using magnetic compaction force and nanofiber z-threads. Mater. (Basel), 17(7), 1589 (2024).

Parandoush, P., Tucker, L., Zhou, C. & Lin, D. Laser assisted additive manufacturing of continuous fiber reinforced thermoplastic composites, Mater. Des., vol. 131, no. April, pp. 186–195 (2017).

Ismail, K. I., Yap, T. C. & Ahmed, R. 3D-printed fiber-reinforced polymer composites by fused deposition modelling (FDM): fiber length and fiber implementation techniques. Polym. (Basel). 14 (21), 4659 (2022).

Kipping, J., Kállai, Z. & Schüppstuhl, T. A set of novel procedures for carbon fiber reinforcement on complex curved surfaces using multi axis additive manufacturing. Appl. Sci., 12(12) 5819 (2022).

Kipping, J. & Schüppstuhl, T. Load-oriented nonplanar additive manufacturing method for optimized continuous carbon fiber parts. Mater. (Basel), 16(3), 998 (2023).

Wang, Q. et al. November,., ‘Totally-additive-manufacturing’-functionalized carbon fiber-reinforced polymer composites with an ultrasensitive self-sensing network. Compos Part. Appl. Sci. Manuf, 189, 108596 (2025).

Bettini, P., Alitta, G., Sala, G. & Landro, L. D. Fused deposition technique for continuous fiber reinforced thermoplastic. J. Mater. Eng. Perform. 26 (2), 843–848 (2017).

Heidari-Rarani, M., Rafiee-Afarani, M. & Zahedi, A. M. Mechanical characterization of FDM 3D printing of continuous carbon fiber reinforced PLA composites, Compos. Part B Eng., vol. 175, no. July, p. 107147, (2019).

Zhang, R. et al. Amelioration of interfacial properties for CGF/PA6 composites fabricated by ultrasound-assisted FDM 3D printing. Compos. Commun. 39, 101551 (2023).

Prusinowski, A. & Kaczynski, R. Tribological behaviour of additively manufactured fiber-reinforced thermoplastic composites in various environments. Polym. (Basel). 12 (7), 1–17 (2020).

Abdallah, T., Ghazi, M. & Mourad, A. I. Impact of 3D printing parameters of short carbon fiber reinforced polymer CFRP on the mechanical and failure performance: Review and future perspective, Next Mater., vol. 8, no. December p. 100645, 2025. (2024).

Zhao, Z. et al. Variable pitch approach for performance improving of straight-bladed VAWT at rated tip speed ratio. Appl Sci, 8(6), 957 (2018).

Ming, Y., Xin, Z., Zhang, J., Duan, Y. & Wang, B. Fabrication of continuous glass fiber-reinforced dual-cure epoxy composites via UV-assisted fused deposition modeling. Compos. Commun. 21, 100401 (2020).

Aravind, A. U., Bhagat, A. R. & Radhakrishnan, R. A novel use of twisted continuous carbon fibers in additive manufacturing of composites, Mater. Today Proc., vol. 46, no. xxxx, pp. 7049–7055, (2021).

Maier, R. et al. Investigation into thermomechanical response of polymer composite materials produced through additive manufacturing technologies. Mater. (Basel). 15, 14 (2022).

Dickson, A. N., Barry, J. N., McDonnell, K. A. & Dowling, D. P. Fabrication of continuous carbon, glass and kevlar fibre reinforced polymer composites using additive manufacturing. Addit. Manuf. 16, 146–152 (2017).

Liu, G., Xiong, Y. & Zhou, L. Additive manufacturing of continuous fiber reinforced polymer composites: Design opportunities and novel applications, Compos. Commun., vol. 27, no. August, p. 100907, (2021).

Jiang, H., Chung, C., Dunn, M. L. & Yu, K. 4D printing of liquid crystal elastomer composites with continuous fiber reinforcement. Nat. Commun. 15 (1), 8491 (2024).

Akhoundi, B., Behravesh, A. H. & Bagheri Saed, A. Improving mechanical properties of continuous fiber-reinforced thermoplastic composites produced by FDM 3D printer. J. Reinf Plast. Compos. 38 (3), 99–116 (2019).

Naik, M., Thakur, D. & Salunkhe, S. Evaluation of thermal and mechanical properties of continuous fiberglass reinforced thermoplastic composite fabricated by fused deposition modeling. J. Appl. Polym. Sci. 140 (26), 10–11 (2023).

Saeed, K., McIlhagger, A., Harkin-Jones, E., Kelly, J. & Archer, E. Predication of the in-plane mechanical properties of continuous carbon fibre reinforced 3D printed polymer composites using classical laminated-plate theory, Compos. Struct., vol. 259, no. November, p. 113226, (2021).

Billings, C., Siddique, R., Sherwood, B., Hall, J. & Liu, Y. Additive manufacturing and characterization of sustainable wood fiber-reinforced green composites. J. Compos. Sci., 7(12), 489 (2023).

Hedayati, S. K., Behravesh, A. H., Hasannia, S., Bagheri Saed, A. & Akhoundi, B. 3D printed PCL scaffold reinforced with continuous biodegradable fiber yarn: A study on mechanical and cell viability properties, Polym. Test., vol. 83, no. January, p. 106347, (2020).

Kalova, M. et al. 3d printed Hollow off-axis profiles based on carbon fiber-reinforced polymers: mechanical testing and finite element method analysis. Polymers (Basel), 13(17), 2949 (2021).

Karimi, A. & Rahmatabadi, D. Various FDM Mechanisms used in the Fabrication of continuous-fiber Reinforced Composites: a review. Polymers, 16(6), 831 (2024).

Maqsood, N. & Rimašauskas, M. Tensile and flexural response of 3D printed solid and porous CCFRPC structures and fracture interface study using image processing technique. J. Mater. Res. Technol. 14, 731–742 (2021).

Dojan, C. F., Ziaee, M., Masoumipour, A., Radosevich, S. J. & Yourdkhani, M. Additive manufacturing of carbon fiber-reinforced thermoset composites via in-situ thermal curing. Nat. Commun. 16 (1), 1–10 (2025).

Uşun, A. & Gümrük, R. March, The mechanical performance of the 3D printed composites produced with continuous carbon fiber reinforced filaments obtained via melt impregnation. Addit. Manuf., 46, 102112 (2021).

Saeed, K. et al. November., Characterization of continuous carbon fibre reinforced 3D printed polymer composites with varying fibre volume fractions, Compos. Struct., vol. 282, no. p. 115033, 2022. (2021).

Tuli, N. T., Khatun, S. & Bin Rashid, A. Heliyon unlocking the future of precision manufacturing: A comprehensive exploration of 3D printing with fiber-reinforced composites in aerospace, automotive, medical, and consumer industries. Heliyon 10 (5), e27328 (2024).

Hu, Y. Additive manufacturing of carbon fiber-reinforced composites: a review. Appl. Compos. Mater. 31, 353–398 (2024).

Song, X. et al. 3D printing of continuous cotton thread reinforced Poly (lactic acid). Sci. Rep. 14 (1), 1–16 (2024).

Prihar, A., Gupta, S., Esmaeeli, H. S. & Moini, R. Tough double-bouligand architected concrete enabled by robotic additive manufacturing. Nat. Commun. 15 (1), 1–11 (2024).

Espalin, D., Muse, D. W., MacDonald, E. & Wicker, R. B. 3D printing multifunctionality: structures with electronics. Int. J. Adv. Manuf. Technol. 72, 5–8 (2014).

Freeland, B. et al. A review of polylactic acid as a replacement material for single-use laboratory components. Materials (Basel), 15(9), 2989 (2022).

Wu, H. et al. Recent developments in polymers/polymer nanocomposites for additive manufacturing. Prog Mater. Sci, 111, 100638 (2020).

Morgan, A. B. Flame Retardant fiber-reinforced Composites (Woodhead Publishing Limited, 2013).

Tanoto, Y. Y. & Anggono, J. Processing and materials efficiency in fused deposition modeling: A comparative study on parts making using abs and pla polymers, no. December pp. 66–76, 2017. (2017).

Farah, S., Anderson, D. G. & Langer, R. Physical and mechanical properties of PLA, and their functions in widespread applications — A comprehensive review. Adv. Drug Deliv Rev. 107, 367–392 (2016).

Mohanty, A. K., Misra, M. & Drzal, L. T. Sustainable bio-composites from renewable resources in green materials world, J. Polym. Environ., vol. 10, no. April, pp. 19–26, (2002).

Taniguchi, N. et al. Experimental study on impact tensile property of glass fiber. Adv. Compos. Mater. 21 (2), 165–175 (2012).

Balla, V. K., Kate, K. H., Satyavolu, J., Singh, P. & Tadimeti, J. G. D. Additive manufacturing of natural fiber reinforced polymer composites: processing and prospects. Compos. Part. B Eng. 174, 106956 (2019).

Yu, L., Chen, K., Xue, P., Cui, Y. & Jia, M. Impregnation modeling and Preparation optimization of continuous glass fiber reinforced polylactic acid filament for 3D printing. Polym. Compos. 42 (11), 5731–5742 (2021).

Wang, Y., Lyu, C., Zhang, Q., Li, W. & Liu, J. Preparation and performance index test of continuous glass fiber reinforced filament- polylactic acid for 3d printer, J. Phys. Conf. Ser., vol. no. 1, 2021. (1906).

Zhang, H., Chen, J. & Yang, D. Fibre misalignment and breakage in 3D printing of continuous carbon fibre reinforced thermoplastic composites, Addit. Manuf., vol. 38, no. December p. 101775, 2021. (2020).

Ashebir, D. A. et al. Detecting multi-scale defects in material extrusion additive manufacturing of fiber-reinforced thermoplastic composites: a review of challenges and advanced non-destructive testing techniques. Polym. (Basel). 16, 21 (2024).

Chen, K., Yu, L., Cui, Y., Jia, M. & Pan, K. Optimization of printing parameters of 3D-printed continuous glass fiber reinforced polylactic acid composites. Thin-Walled Struct. 164, 107717 (2021).

Wang, Y., Kong, D., Zhang, Q., Li, W. & Liu, J. Process parameters and mechanical properties of continuous glass fiber reinforced composites-polylactic acid by fused deposition modeling. J. Reinf Plast. Compos. 40, 17–18 (2021).

Giita Silverajah, V. S. et al. A comparative study on the mechanical, thermal and morphological characterization of poly(lactic acid)/epoxidized palm oil blend. Int. J. Mol. Sci. 13 (5), 5878–5898 (2012).

Cao, M. et al. Preparation and characterization for the thermal stability and mechanical property of PLA and PLA/CF samples built by FFF approach. Materials (Basel), 16 (14), 5023 (2023).

Pichard, P. L. et al. 3D printing strategies and mechanical performance assessment of continuous basalt-fibre/PA12 composites with high fibre volume fraction, Polym. Test., vol. 150, no. June, p. 108936, (2025).

Mei, H., Ali, Z., Ali, I. & Cheng, L. Tailoring strength and modulus by 3D printing different continuous fibers and filled structures into composites. Adv. Compos. Hybrid. Mater. 2(2), 312–319 (2019).

Li, J. et al. Mechanical characterization of 3D printed multiscale carbon nanofiller/continuous fiber reinforced polymer hybrid composites. Polym. Compos. 46(11), 10331–10349 (2025).

Isobe, T., Tanaka, T., Nomura, T. & Yuasa, R. Comparison of strength of 3D printing objects using short fiber and continuous long fiber. IOP Conf. Ser. Mater. Sci. Eng., 406 (1), 012042 (2018).

Tlegenov, Y., Hong, G. S. & Lu, W. F. Nozzle condition monitoring in 3D printing, Robot. Comput. Integr. Manuf., vol. 54, no. December pp. 45–55, 2018. (2017).

Haidiezul, A. H. M., Aiman, A. F. & Bakar, B. Surface finish effects using coating method on 3D printing (FDM) parts. IOP Conf. Ser. Mater. Sci. Eng., 318(1), 012065 (2018).

Shanmugam, V. et al. August., Fatigue behaviour of FDM-3D printed polymers, polymeric composites and architected cellular materials, Int. J. Fatigue, vol. 143, no. p. 106007, 2021. (2020).

Reis, P. N. B., Valvez, S. & Ferreira, J. A. M. Creep and stress relaxation behaviour of 3D printed nanocomposites, Procedia Struct. Integr., vol. 37, no. C, pp. 934–940, (2022).

Acknowledgements

The authors would like to acknowledge the support from Mr. Hassan Nazir, Thermal Energy Research Lab, U.S.Pakistan Center for Advanced Studies in Energy (USPCAS-E) and Mr. M. Zafar Khan, School of Chemical & Materials Engineering (SCME), National University of Sciences & Technology, Islamabad, Pakistan.

Funding

This work was supported by the Deanship of Graduate Studies and Research (DGSR) Program, Ajman University, United Arab Emirates.

Author information

Authors and Affiliations

Contributions

Conceptualization, M.A.J. and Y.Q.; methodology, O.R.S.; software, U.G.; validation, U.H.S.; formal analysis, M.A.J. and Y.Q.; investigation, O.R.S.; resources, U.G.; data curation, M.A.J., Y.Q., and O.R.S.; writing—original draft preparation, M.A.J.; writing—review and editing and funding acquisition, U.G. and U.H.S. All authors have read and agreed to the current version of the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Jamal, M.A., Ghafoor, U., Shah, O.R. et al. Development of novel filament production setup of continuous fiber reinforced composite filament for additive manufacturing applications. Sci Rep 15, 33227 (2025). https://doi.org/10.1038/s41598-025-18423-x

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-18423-x