Abstract

Enhanced heat transport in triangular fins have promising applications in heat exchangers, electronics cooling, automobile radiators and power plants etc. Use of nanolubricants is an innovative way to enhance the performance of triangular fin. Thus, this work aims to analyze the triangular fin’s performance coated with hybrid nanolubricant (SiC–Co3O4)/diathermic oil and investigate that how the active parameters radiation, convective-conduction, porosity and heating source affect the performance. The formulation is accomplished using the energy equations together with enhanced characteristics of SiC–Co3O4 and diathermic oil. As a result, the second order model obtained. The artificial intelligence (AI) based scheme levenberg marquardt back-propagation (LMBP) method implemented. Further, the results for the model furnished using feasible ranges of the parameters. Authenticity of the scheme is verified through histogram error, functions fitting, regression analysis and validation checks. It is examined that the device can be maintained at low temperature by augmenting the conduction parameter from \(1.0\) to \(4.0\). Optimum heat transfer is acquired when the heating source \(Q\) and Peclet number \(Pe\) increased. Presence of pores at the triangular fin’s surface would be advantageous to cool the device. In conclusion, the use of hybrid nanolubricant subject to radiations, heating source, and porosity effects together with AI scheme provided beneficial results regarding the transport of heat using triangular fin.

Similar content being viewed by others

Introduction

The triangular fins are extended surfaces over the primary objects which use to enhance the thermal transport rate. These are playing the role of heat exchanging devices which transmits heat from hot object to a cooler fluid. The effectiveness of fins usually depend on the material which use to form it and its shapes. Further, the efficiency of the fins is also associated to the orientation, angle, length, porosity, and the structure. The performance of such mechanical devices can be augmented by nanolubrication. Primarily, the nanolubricant is homogenous mixture of nanoparticles and oil which possesses the excellent thermal transport rate characteristics than conventional oil. Among the types of fins, the triangular shaped fins gain the researchers interest due to their unique geometric and convective/conduction transport.

Use of nanofluids over the surface of triangular fins is a process to augment an efficiency of the device. As, the nanofluids are effective than traditional fluids which optimize the performance. Hence, the coating of nanofluids over mechanical devices has multifarious applications. Ouada et al.1 have done analytical investigation of triangular fin inspired by pores on the surface. The nanoparticles (Cu–Al2O3–TiO2) used as catalytic nanomaterial to boost the effectiveness of the mechanical device. Raju et al.2 are concentrated on the functionality of three distinct shaped fins with use of hybrid nanoparticles. The Darcy model used to explore the porosity influences and also reported that triangular fins have rapid performance than other two types. Pai3 studied (Go/MoS2/Al2O3)/(C2H6O2/H2O) characteristics for rough longitudinal fin and examined that changing the nanoparticles shape has crucial role on the efficacy of the device and the thermal transport augments up to 23.26% when the nanoparticles shape changes from spherical to lamina. Ali and Arshad4 are tested the thermal outcomes of pin fins using graphene nanomaterial. From the experimental setup, they observed 20% increase in the efficiency when compared with distilled water. Further, considerable contribution of angle is noticed on the performance.

Babar et al.5 are discussed the performance of air foiled pin fin using oxide silica nanofluid. The authors noticed that the cooling efficacy enhanced due to increase in nanoparticles while 50:50% mixing provides excellent results. Sreehari et al.6 are studied the design of rhombus type fin subject to heat sink. The study performed through experiments in which 64 trials have reported to investigate the promising features of the fin. Gireesha et al.7 have explored the impacts of nanomaterials structure to facilitate the efficacy of accelerating fin under porosity features. The higher efficiency of the fin achieved for sphere-based nanomaterials. Recently, Adnan et al.8 are simulated the results for annular type fin and used joint effects of ternary nanoparticles to improve the performance. The excellent outcomes obtained by adding 2% of ternary nanoparticles and also analyzed the magneto radiative phenomena. Another significant contribution for plate type fin has been reported by Khudhur et al.9 in which they preferred the study of Nu.

Hosseinzadeh et al.10 are examined that enhancing the strength of Peclet number make the device efficient. The outcomes achieved through analytical scheme under certain ranges of the parameters. Goud et al.11 are exercised an AI approach and investigated the performance of longitudinal fin by focusing on the rough surface. The output provides remarkable contribution of convection and suggested that the AI scheme is reliable and an excellent solver to tackle such problems. Alharbi et al.12 are discussed the effectiveness of annular fin under magnetic field and radiation effects. The problem extended for ternary nanofluid and provided comparative outcomes for multiple classes. They observed that ternary nanofluid make the device more effective than other traditional fluids. Farajollahi et al.13, and Vaferi et al.14 are provided the NN investigations of optimum efficiency of heat exchangers comprising fin-tubes and the latent heat storage for enhancing charging/discharging capabilities. They found that the NN schemes provided more accurate results and hence should be effective for heat transfer problems.

Akyol and Bilen15 are discussed the performance of rectangular type fins. These fins are adjusted over a hollow surface and simulated the thermal results with increasing parametric ranges. The rectangular fins are configured for 10 cm height with 2 by 4 dimensions and thickness is kept as 0.2 cm. Jayaprakash et al.16 are analyzed the contribution of thermal dependent characteristics on the efficacy of accelerating device. The solutions computed through DTM and also explored the heat transfer rate. Nagaraju et al.17 and Kundu et al.18 are determined the dynamics of fins using numerical and analytical approaches. They emphasized on enthalpy, radiations and heat generating influences on the device efficiency. The outcomes revealed that the porous fin of annular type has better efficiency than without step. Sharma et al.19 are discussed the design of rough fin using ternary nanofluid and magnetic field. They found that implication of ternary nanofluids help to improve the fins efficacy under certain physical situations.

Pavithra and Gireesha20 have investigated the effectiveness of accelerating longitudinal fins subject to inclination factor. They used hybrid nanofluids to improve the heating characteristics of the fin. Further, the highest heat transfer is observed for joint strictures of platelets and spherical nanoparticles. Another effective study of the fin under changing pitch length has been reported by Kumar et al.21. They found that the pitch length from 1 to 5 is better for the efficiency. Further, the CFD simulations performed through ANSYS and compared with experimental data for validation. Din et al.22 are studied a problem of exponential fin using heating species. The optimized performance is observed for decay type fin in comparison with other two types. Buonomo23 has done the modelling for rectangular fin using pores at the face. The output obtained using analytical approach and exercised Darcy model for the formation. Ahmad et al.24 are provided computing intelligent analysis of thermal transport through rectangular fin.

The above studies provided comprehensive literature on the performance of different types of fins using numerical and CFD schemes. However, the machine learning methods are also attained the researcher’s attention to optimize the performance. Thus, in recent time the studies divert from numerical to machine learning for better outcomes. Krishnayatra et al.25 are examined the performance using K-Nearest Neighbor approach and estimated the efficiency. The study reveals that the efficiency optimizes by maximizing the thickness. Ostanek26 has discussed the Pin fin model with the help of neural networking based on experimental data. They suggested that the scheme is reliable even for increasing number of pin fins and found excellent efficiency using 73% testing data. Ermis et al.27 are introduced the application of ANN for phase change material’s uses in thermal energy storage systems. They noticed that the relative error 5.58% which gives excellent output and suggested ANN as better tool for energy storage problems.

The convective heat transport in wavy fin with additional physical constraints has been reported by Kumar et al.28. The nonlinear problem analyzed through Levenberg Marquardt (LM) AI scheme for multiple waves of the fin’s surface. The RK scheme provided the data set which helps to code the problem using AI scheme. The results shown that thermal dispersion rises as the radiation effects increases. Towsyfyan et al.29 are conducted a study by combining CFD and AI schemes for enhanced thermal distribution. The study reveals remarkable accuracy of heat transfer rate as 88.81%, and 88.98% by adjusting the pin fins. Saqib et al.30, and Hua et al.31, are designed new AI schemes termed as RNN (Recurrent neural networks) and convolutional type deep NN. The problems configured for triangular and fins tube using nanofluids. The studies opened new window towards the optimization of thermal transport using advanced AI schemes. Further, recent investigation regarding the design of AI schemes for improved thermal applications have been discussed in the studies32,33, and34.

The choice of triangular-shaped fins compared to other geometries is mainly due to their manufacturing and excellent thermal distribution advantages. The triangular shape provides a more effective distribution of the heat transfer since the cross-sectional area of the fin reduces along its length, correlating with the reduction in the temperature gradient between the base and the tip. This configuration also saves unneeded material towards the fin’s tip, where heat can be dissipated less efficiently, and thus results in a greater rate of heat transfer per unit mass relative to other geometries like longitudinal or rectangular shapes. The tapered form also saves weight and material expenses. From a production standpoint, triangular fins are simpler to manufacture by cost-saving techniques such as extrusion, stamping, or rolling that are effective for producing high volumes. Their uncomplicated geometry also simplifies assembly issues, further improving cost-effectiveness. Thus, the triangular fin’s best compromise of material’s economy, thermal effectiveness, and manufacturability makes it an attractive option for engineering and industrial applications.

The nanolubrication inspired by the hybrid nanomaterials is groundbreaking scheme to augment the performance of triangular fin. Thus, the present attempt aims to modify the traditional triangular fin model using enhanced innovative characteristics of hybrid nanolubricant (SiC–Co3O4)/diathermic oil. Further, an innovative influence of significant physical parameters like porosity, radiations, Peclet, and conduction are integrated in the model to acquire more state-of-the-art results. For remarkable results of the model, the AI scheme (LMBPS) together with bvp4c algorithm will be exercised. The use of LMBPS for triangular fin is warranted based on its promising benefits in network training, most notably convergence speed, precision, and resilience. The LMBPS algorithm utilizes the SDS (steepest descent scheme) together with the Gauss–Newton method to achieve faster convergence than common backpropagation methods, particularly for medium-scaled networks. This is especially useful for the current problem, as it deals with optimizing intricate, nonlinear models where efficiency and accuracy are paramount. Moreover, the LMBPS has been found to be effective in dealing with ill-conditioned problems and overcoming local minima more than regular gradient descent techniques, increasing the reliability of solutions. Nonetheless, a recognized weakness of the LMBPS is that it requires more computation and memory compared to regular gradient descent techniques, which can be an issue with very large-scale networks. In spite of this, the scheme is warranted due to the magnitude of the triangular fin problem and the algorithm’s better performance when it comes to better accuracy with less iterations. Relying on the LMBPS, this work guarantees a stable and effective optimization process, which enhances the methodological support of this work while recognizing its limitations in certain situations.

Formulation of triangular fin device

Applications of nanofluids is an innovative area of research because of their enhanced thermophysical characteristics. Previous attempts are limited to the triangular fin’s performance using simple nanofluids or without them using traditional solution methodologies. However, it lacks the efficient performance using hybrid nanolubricant which possesses an excellent heat transport due to enrich thermal conductivity. Thus, this work focuses on efficient heat transport in triangular fin using hybrid (SiC-Co3O4)/diathermic oil nanolubricant. Further, the machine learning approach will be implemented for accurate results instead of traditional schemes. Use of hybrid nanolubricant together with AI approach would help to acquire excellent output for enhanced thermal applications specifically in mechanical and thermal engineering.

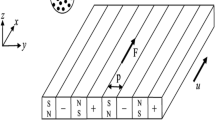

Consider the mechanism of heat in a fin designed for triangular fin device. The surface has pores and the length \(L\) and cross-section area is taken as \(A\) which is extendable to finite length. Further, the surface, base and ambient temperature is designated by \({T}_{s}, {T}_{b}\) and \({T}_{a}\), respectively. The other constrains are convective coefficient (\(h\)), emissivity (\(\epsilon\)). The triangular fin is supposed to accelerate in horizontal direction taking the speed \(U\). Hence, the final configuration of the device is demonstrated in Fig. 1.

This study is limited to triangular fin incorporating the influences of radiations, porosity, Peclet and heating source. The hybrid nanolubricant (SiC-Co3O4)/diathermic oil is homogenous mixture. The nanoparticles mixed in the diathermic oil uniformly.

The associated energy equation for designed triangular fin is expressed in Eq. (1) by taking the other constraints into the account35.

In Eq. (1), the term \(m\) designates for the flow of mass rate and described as \(m=\Delta x(Wv\rho )\). The velocity is expressed by Darcy formula as \(v_{w} = \frac{{\left( {\check{T} - \check{T}_{a} } \right)\beta gK}}{v}\). The improved TC mentioned in Eq. (1) is estimated by the formula36.

The properties for the components36 described in Eq. (2) are summarized in Fig. 2a–d, respectively. These characteristics are density (kg/m3), heat capacity (J/K), thermal conductivity (W/m.K), and electrical condutivity (S/m). Further, the tabular form of the thermophysical characteristics are enlisted in Table 136.

Assume that the difference of temperature during the heat flow in the fin’s material is small. Thus, according to this assumption, the uniform temperature is applied and fin’s thermal characteristics with35:

Using these assumptions in Eq. (1), the following version is obtained35.

Here, \(\lambda =\frac{{k}_{nf}}{\rho {c}_{pnf}}\) indicates the thermal diffusivity. Taking the below dimensionless variables for further simplification35. These parameters are Peclet number (\(Pe\)), radiation (\({N}_{r}\)), porosity (\({S}_{p}\)), Darcy number (\({D}_{a}\)), temperature ratio (\({\theta }_{a}, and {\theta }_{s}\)), and dimensionless variable \(X\).

Using these information, the energy equation change into the following form.

The conditions on the fin are \(\check{T}_{x = L} = \check{T}_{b} \,{\text{and}}\,\frac{{d\check{T}}}{dx} \downarrow x = 0 = 1\). These conditions reduce in the following version.

The fin efficiency expression is given in Eq. (8) which represents the difference in thermal potential form fin to the surrounding.

The solution of Eq. (6) gives the thermal distribution while the efficiency is expressed in Eq. (8). These depend on the factors included in the model.

Methodology of solutions

The solution of the problem was estimated using AI based LMBPS which processes after obtaining the data. Initially, the data was tabulated using bvp4c and then operating the LMBPS, the solutions will obtain. The dataset was obtained by fixing the 15 neurons in the first layer (hidden layer) and 5 in the output layer. The computation was accomplished in MATLAB and then proceed with further results. The design of ANNS37 for the current problem is given in Fig. 3a,b where \(w\) and \(b\) represent the weights and biases. The weight functions help to execute the influence of input parameters on the output while the biases help to adjust the neurons to acquire the best fitting data. Both weights (\(w\)), and biases (\(b\)) was trained during the computing process to make the network prediction more accurate.

Bvp4c procedure

The bvp4c algorithm was implemented after performing the following steps.

-

Rearranged the given problem by moving the highest order derivative term on the first while all other terms on the second side.

-

Assigned an appropriate transformation in the view of the problem’s order which was second in the current problem.

-

Using the suitable expressions from second step into the first step, the desired IVP was obtained.

-

Finally, operate the bvp4c algorithm and the solutions were obtained. The accuracy was fixed at \({10}^{-6}\) for better outcomes.

-

Using the dataset in the previous step, the ANN based LMBPS was implemented and achieved the error, functions fitting, testing, validation and performance of the data.

ANN procedure

The AI scheme LMBP algorithm is an effective optimization method that combines Gauss Newton and gradient descent (GD) schemes for improved convergence. The scheme initiates using weights (\(w\)) and biases (\(b\)), followed by calculating the MSE (mean squared error) through forward propagation. Rather than employing traditional gradient descent, LMBP estimates the Hessian matrix through the error’s Jacobian with regard to the weights, forming the update rule:

Here, \(\mu\) is an adaptively adjusted damping factor (raised if error increases, lowered else). The scheme solves the system iteratively to update weights. Training goes on until the convergence are satisfied (e.g., error drops below a certain value). The LMBP is well suited to medium class networks because it is computationally intensive but provides better convergence than ordinary backpropagation for problems for which it is appropriate.

Figure 3c,d depicts the implementation procedure of the scheme. The model was coded in MATLAB for data generation and the LMBP was successfully operated. The data divided into three ranges from which 80% was used to train the network while 10% for validation and 10% for problem testing was used. For the present data of triangular fin, the number of neurons as \(10\) and \(2\) was selected. The accuracy of the problem up to suitable stage was achieved for these neurons. By exceeding the neurons strength, over functions fitting was observed. However, excellent results were obtained for the selected number of neurons. The two types of activation functions were used termed as tan-sig and purelin. The tan-sig function was used in the hidden layer while purelin function was used in the output. Operating these functions ensured the continuous output in response of nonlinear mapping in the hidden layer of the network.

Data generation procedure

To create data for ANN through the bvp4c method, the bvp solver is used first to solve triangular fin model numerically over a given parameter ranges. The procedure starts with BCs and a list of input problem parameters. The numerical solutions are then computed over a discretized domain using the bvp4c algorithm in MATLAB. The solutions was obtained, together with respective input parameters, are gathered into the dataset with each data point being input–output pairs-inputs as problem parameters, and outputs as solution values computed. To guarantee a strong dataset, several runs of simulation over the model parameter variations was run systematically sampling the anticipated operational cases. The number of data points is a function of the discretization resolution and number of parameter combinations touched. The dataset was then preprocessed for separating training and validation sets prior to passing it on ANN for machine learning operation. This data generation process for the triangular fin problem makes the ANN reproducible and easy to understand.

Results interpretation

The triangular fin’s thermal distribution changes with the physical parameters. This section is dedicated to stimulates and analyze the changes in the temperature due to varying model parameters. Further, the errors, functions fitting, regression and validation are also obtain through LMBPS.

Figure 4 demonstrating the influence of \(N, {N}_{r}, Pe, Q\) and \({S}_{p}\) on the thermal distribution of triangular fin. The convection and radiative conduction reduce the thermal mechanism of the fin. As, conduction is a slow heat transport process due to which the heat transfers mechanism is relaxed. The maximum decrease is noticed at the fin’s surface. The Peclet and heating source numbers enhance the thermal distribution excellently in Fig. 4c,d. Physically, both of these parameters add energy in the fin setup. Due to conduction process inside the triangular fin and convection near the surface, the thermal distribution boosts quickly. Hence, Peclet and \(Q\) are good physical tools to improve the performance of triangular faced fin. The porosity \({S}_{p}\) effects on the behavior of triangular fin’s heat transfer are demonstrated in Fig. 4e. The output reveals minimal changes in the thermal mechanism. The heat mechanism in the triangular fin’s body becomes very slow due to the Darcy influences. Along with conduction, the Darcy effects support the slow thermal mechanism. That’s why the fin’s performance becomes minimal.

The training state of the problem for parameters of interest is depicted in Fig. 5a–d. These states are obtained for \(N, {N}_{r}, Pe, Q\) and \({S}_{p}\), respectively. In all the cases, the validation checks meets zero which are excellent checks. The gradients are estimated \(9.8232{e}^{-08}, 9.666{e}^{-08}, 9.4577{e}^{-08}, 9.8562{e}^{-08}\) and \(9.9886{e}^{-08}\) at epochs 117, 70, 22, a46 and 207, respectively. The gradient approaches to \({10}^{-10}\) for different training states. Further, the Mu achieved up to \(1{e}^{-10}\) in the cases 1, 2 and 3 while it reaches to \(1{e}^{-11}\) and \(1{e}^{-09}\) for the cases 3 and 5. Figure 5a–e displays the effects of physical quantities on TD (training data) of triangular fin and shows how the model’s learning process is affected by different variables. Trends in the plots indicate that the parameters have a substantial impact on the convergence and accuracy during the training state. The parameters associated with material or geometric properties can dominate the response of the model, as reflected in their significant influence on the training trends. It is important to understand these influences in order to optimize the design of the triangular fin, since it helps discover principal variables that improve performance at reduced computational expense. The findings emphasize the value in parameter selection towards a reliable and effective training phase. These values are summarized in Table 2.

Figure 6a–d demonstrated the train, best, test, and validation performance comparison for the physical parameters. The validated performance is acquired as \(1.0027{e}^{-11}, 2.1913{e}^{-11}, 3.5986{e}^{-11}, 4.1809{e}^{-12}\) and \(5.5733{e}^{-11}\) at epochs 117, 70, 22, 146 and 207. The MSE is estimated as \(10^{{ - 12}} ,\,{\text{and}}10^{{ - 10}} ,\) in the plotted results. The training states are observed much better in all the cases. However, it is quite slow in case 3. Figure 6a–e shows the parametric impacts on validation performance, which is best for generalizing to new data. The results plot measures like error rates or accuracy versus various parameter of triangular fin model and indicates what combinations provide the most accurate predictions. The validation is important for ensuring the triangular fin’s design is reliable under changing conditions since validation measures act as a surrogate for real-world use. The results highlight the necessity of strict validation to verify the triangular fin’s parametric design robustness. Further, the MSE, VP and corresponding epochs are enlisted in Table 3.

Figures 7 and 8 elucidating the histogram errors and fitting of functions for five cases for \(N, {N}_{r}, {P}_{e}, Q\) and \({S}_{p}\), respectively. The remarkable error in Fig. 7 is obtained which provides authenticity of implemented ANN. The EH (error histogram) in Fig. 7 is a detailed spread of the prediction errors and gives us clues about the accuracy of the model and possible biases. A thin, symmetric plot with a point of concentration around zero indicates high accuracy and low systematic error, while a non-symmetric or broad distribution could be an indicator of problems like parameter sensitivity or overtraining. Through the examination of the manner in which various triangular fin’s model parameters affect this distribution, the EH supports the determination of variables that reduce errors or cause instability. This data is crucial in the fine-tuning of the model of the triangular fin since it indicates areas with which changes will result in more stabilized and predictable mode.

Figure 8 assesses the quality of the predicted function from the model in relation to the observed data. The extent of closeness between predicted and observed values indicates that the parameters capture the triangular fin’s behavior well, and discrepancies can be indicative of constraints in the model form or assumptions. Analysis of this kind is fundamental to ensuring that the design of the triangular fin will be both theoretically valid and realistic, since it affirms the model’s capacity to simulate the real-world effects.

Regression analysis is an important component when implementing the ANN scheme. The subsequent Fig. 9a–d depicting the training, validation, test and combined regression for the cases in this study. For all the cases it is obvious that the \(R=1.0\) which indicates the excellent regression. Figure 9 investigates input variables’ correlation with the performance of the triangular fin using regression analysis, measuring by evaluating the impact of variable changes on output parameters. Strong correlations relationships uncovered in the results can be used to inform optimizations in design, including choosing parameter ranges for maximizing efficiency or error minimization. The regression results also lay a statistical basis for estimating the behavior of the triangular fin when testing conditions are not available, making it more useful across various scenarios. By methodically evaluating these parametric factors, the results advance the understanding of performance for triangular fin and enables data-driven design enhancements.

The heatlines affect by the varying constrains in the feasible ranges. Thus, to investigate the trends of these lines, Fig. 10a–i is furnished for multi values of \(N, {N}_{r}\) and \(Q\), respectively. When the strength of \(N\) enhances from \(3.0\) to \(7.0\), the heatlines bend towards the extending direction of \(x\). However, the intensity reduces as move back to \(x=0.0\). Further, the less intensive heatlines observed for \({N}_{r}\) in Fig. 10d–f for \({N}_{r}=\text{3.0,5.0,7.0}\), respectively. The heatlines accelerated for heat generation number \(Q\). These curves extend in the direction of \(x\) when the values of \(Q\) changes from \(3.0\) to \(7.0\).

Conclusions

Intelligent computing investigation of triangular fin along with parameters of practical interest is conducted in this research. The ANN scheme using LMBPS is implemented and simulated the results.

-

The research validates that convective-conduction in the range of \(N=1.0\) to \(N=4.0\), is an efficient range for controlling heat transport in triangularly designed fin using innovative hybrid (SiC–Co3O4)/nanolubricant. The findings emphasize the noticeable influence of \(N\) on the fin performance and show improved efficiency which is good for heat exchanging devices and cooling purposes. It is possible to increase heat management with nanolubricant-enhanced triangular fins by optimizing these parameters.

-

The investigation showcases that the application of hybrid nanolubricant at different \(Pe\) together with heat source (\(Q=\text{1.0,2.0,3.0,4.0}\)) greatly improves heat transfer and has distinct behavior near the surface. The observation is important for maximizing thermal systems like electronics and microchannel cooling through triangular fin, where restricted heat dissipation is important. The findings indicate that the optimization of \(Pe\) and \(Q\) in applications of nanolubricant can result in improved thermal performance in next-generation engineering devices.

-

Practically, porosity (\({S}_{p}\)) in triangular fins diminishes thermal performance by hindering heat transfer processes. This impact indicates that porous fins can be advantageous for material savings or light weight but can be less efficient in high-efficiency coolers where optimum heat transport is needed.

-

The Levenberg–Marquardt backpropagation method is found to be efficient in optimizing the thermal performance of triangular fins with hybrid nanolubricants, exhibiting rapid convergence and excellent predictive accuracy. The scheme greatly facilitates the analysis by accurately modeling intricate nonlinear correlations by connecting the model parameters and heat port behavior in a computationally efficient manner. The data-driven method offers a strong and computationally effective alternative to conventional approaches, facilitating optimal design for enhanced thermal management in real-world applications.

Data availability

The datasets used and/or analysed during the current study available from the corresponding author on reasonable request.

Abbreviations

- \(L\) :

-

Length (m)

- \(A\) :

-

Cross sectional area (m2)

- \({T}_{s}\) :

-

Surface temperature (\(K\))

- \({T}_{b}\) :

-

Base temperature (\(K\))

- \({T}_{a}\) :

-

Ambient temperature (\(K\))

- \(\rho\) :

-

Density (kg/m3)

- \({k}_{hnf}\) :

-

Hybrid nanofluid thermal conductivity (W/m·K)

- \({k}_{nf}\) :

-

Nanofluid thermal conductivity (W/m·K)

- \({k}_{f}\) :

-

Diathermic oil thermal conductivity (W/m·K)

- \({N}_{r}\) :

-

Radiation number

- \(Pe\) :

-

Peclet number

- \(Q\) :

-

Heat generation number

- \({S}_{p}\) :

-

Porosity number

References

Ouada, M. et al. Heat transfer characteristics of moving longitudinal porous fin wetted with ternary (Cu–Al2O3–TiO2) hybrid nanofluid: ADM solution. Eur. Phys. J. Plus. 138, 1–12. https://doi.org/10.1140/epjp/s13360-023-04459-3 (2023).

Raju, C. S. K., Sajjan, K. & Yook, S. J. Heat transfer characteristics of rectangular/triangular/convex-shaped fins filled with hybrid nanoparticles under dry and wet conditions. Phys. Fluids. https://doi.org/10.1063/5.0176926 (2023).

Pai, A. G. & Pai, R. G. Thermal characterization of porous longitudinal rectangular moving fin wetted with GO-MoS2-Al2O3/C2H6O2-H2O ternary hybrid nanofluid. Cogent Eng. 11(1), 2364052. https://doi.org/10.1080/23311916.2024.2364052 (2024).

Ali, H. M. & Arshad, W. Effect of channel angle of pin-fin heat sink on heat transfer performance using water based graphene nanoplatelets nanofluids. Int. J. Heat Mass Transf. 106, 465–472 (2017).

Babar, H., Wu, H., Ali, H. A., Shah, T. R. & Zhang, W. Staggered oriented airfoil shaped pin-fin heat sink: Investigating the efficacy of novel water based ferric oxide-silica hybrid nanofluid. Int. J. Heat Mass Transf. 194, 123085. https://doi.org/10.1016/j.ijheatmasstransfer.2022.123085 (2022).

Sreehari, D. & Prajapati, Y. K. Comparative analysis of heat transfer and fluid flow in circular and rhombus pin fin heat sink using nanofluid. J. Therm. Sci. Eng. Appl. 13(5), 051028. https://doi.org/10.1115/1.4050416 (2021).

Gireesha, B. J., Sowmya, G. & Gorla, R. S. R. Nanoparticle shape effect on the thermal behaviour of moving longitudinal porous fin. Part N J. Nanomater. Nanoeng. Nanosyst. 234(3), 115–121. https://doi.org/10.1177/2397791420915139 (2020).

Adnan, A. et al. Numerical analysis of magneto-radiated annular fin natural-convective heat transfer performance using advanced ternary nanofluid considering shape factors with heating source. Case Studies in Thermal Engineering 44, 102825. https://doi.org/10.1016/j.csite.2023.102825 (2023).

Khudhur, D. S., Al-Zuhairy, R. C. & Kassim, M. S. Thermal analysis of heat transfer with different fin geometry through straight plate-fin heat sinks. Int. J. Therm. Sci. 174, 107443. https://doi.org/10.1016/j.ijthermalsci.2021.107443 (2022).

Hosseinzadeh, S., Hosseinzadeh, K., Hasibi, A. & Ganji, D. D. Thermal analysis of moving porous fin wetted by hybrid nanofluid with trapezoidal, concave parabolic and convex cross sections. Case Stud. Therm. Eng. 30, 101757. https://doi.org/10.1016/j.csite.2022.101757 (2022).

Goud, J. S. et al. Heat transfer analysis in a longitudinal porous trapezoidal fin by non-Fourier heat conduction model: An application of artificial neural network with Levenberg–Marquardt approach. Case Stud. Therm. Eng. 49, 103265. https://doi.org/10.1016/j.csite.2023.103265 (2023).

Alharbi, K. A. M., Bani-Fwaz, M. Z., Sayed, M. E. & Akgul, A. Thermal management in annular fin using ternary nanomaterials influenced by magneto-radiative phenomenon and natural convection. Sci. Rep. 13, 9528. https://doi.org/10.1038/s41598-023-36418-4 (2023).

Farajollahi, A., Vaferi, K. & Baharvand, M. Analyzing tube arrangements of a finned-tube heat exchanger to optimize overall efficiency using artificial neural network and response surface methodology. Case Stud. Therm. Eng. 63, 105302. https://doi.org/10.1016/j.csite.2024.105302 (2024).

Vaferi, K., Farajollahi, A., Gholizadeh, T. & Rostami, M. Enhancing charging and discharging performance in a novel latent heat storage via design optimization and artificial neural network modeling. J. Energy Storage 114, 115757. https://doi.org/10.1016/j.est.2025.115757 (2025).

Akyol, U. & Bilen, K. Heat transfer and thermal performance analysis of a surface with hollow rectangular fins. Appl. Therm. Eng. 26(2), 209–216 (2006).

Jayaprakash, M. C. et al. Thermal distribution through a moving longitudinal trapezoidal fin with variable temperature-dependent thermal properties using DTM-Pade approximant. Case Stud. Therm. Eng. 28, 101697. https://doi.org/10.1016/j.csite.2021.101697 (2021).

Nagaraju, T. T. et al. Thermal analysis of natural convection in rectangular porous fin wetted with CNTs nanoparticles and thermal radiation. J. Appl. Math. Mech. 104(8), e202300969. https://doi.org/10.1002/zamm.202300969 (2024).

Kundu, B. & Lee, K. S. A proper analytical analysis of annular step porous fins for determining maximum heat transfer. Energy Convers. Manage. 110, 469–480 (2016).

Sharma, A. et al. A thermal analysis of a convective-radiative porous annular fin wetted in a ternary nanofluid exposed to heat generation under the influence of a magnetic field. Energies https://doi.org/10.3390/en16176155 (2023).

Pavithra, C. G. & Gireesha, B. J. Heat transfer in a wet porous moving inclined longitudinal fin exposed to convection and radiation in the presence of shape-dependent hybrid nanofluid: Adomian decomposition Sumudu transformation approach. J. Mol. Liq. 393, 123582. https://doi.org/10.1016/j.molliq.2023.123582 (2024).

Kumar, B. et al. Numerical and experimental investigation of heat transfer of longitudinal fin with varying pitch length in flat plate solar air heater. Part E J. Process Mech. Eng. https://doi.org/10.1177/09544089241288070 (2024).

Din, Z. U., Ali, A., Khan, Z. A. & Zaman, G. Heat transfer analysis: Convective-radiative moving exponential porous fins with internal heat generation. Math. Biosci. Eng. 19(11), 11491–11511 (2022).

Buonomo, B., Cascetta, F., Manca, O. & Sheremet, M. A. Heat transfer analysis of rectangular porous fins in local thermal non-equilibrium model. Appl. Therm. Eng. 195, 117237. https://doi.org/10.1016/j.applthermaleng.2021.117237 (2021).

Ahmad, I., Zahid, H., Ahmad, F., Raja, M. A. Z. & Baleanu, D. Design of computational intelligent procedure for thermal analysis of porous fin model. China J. Phys. 59, 641–655 (2019).

Krishnayatra, G., Tokas, S. & Kumar, R. Numerical heat transfer analysis and predicting thermal performance of fins for a novel heat exchanger using machine learning. Case Stud. Therm. Eng. 21, 100706. https://doi.org/10.1016/j.csite.2020.100706 (2020).

Ostanek, J. K. Improving pin-fin heat transfer predictions using artificial neural networks. J. Turbomach. 136(5), 051010. https://doi.org/10.1115/1.4025217 (2014).

Ermis, K., Erek, A. & Dincer, I. Heat transfer analysis of phase change process in a finned-tube thermal energy storage system using artificial neural network. Int. J. Heat Mass Transf. 50(15–16), 3163–3175 (2007).

Kumar, R. S. V., Alsulami, M. D., Sarris, I. E., Sowmya, G. & Gamaoun, F. Stochastic Levenberg–Marquardt neural network implementation for analyzing the convective heat transfer in a wavy fin. Mathematics 11(10), 051010. https://doi.org/10.3390/math11102401 (2023).

Towsyfyan, H., Freegah, B., Hussain, A. A. & Faik, A. M. E. Novel design to enhance the thermal performance of plate-fin heat sinks based on CFD and artificial neural networks. Appl. Therm. Eng. 219, 119408. https://doi.org/10.1016/j.applthermaleng.2022.119408 (2023).

Saqib, S. U. et al. Novel Recurrent neural networks for efficient heat transfer analysis in radiative moving porous triangular fin with heat generation. Case Stud. Therm. Eng. 64, 105516. https://doi.org/10.1016/j.csite.2024.105516 (2024).

Hua, Y. et al. Surrogate modeling of heat transfers of nanofluids in absorbent tubes with fins based on deep convolutional neural network. Int. J. Heat Mass Transf. 202, 123736. https://doi.org/10.1016/j.ijheatmasstransfer.2022.123736 (2023).

Chandan, K. et al. Predicting the thermal distribution in a convective wavy fin using a novel training physics-informed neural network method. Sci. Rep. 14, 7045. https://doi.org/10.1038/s41598-024-57772-x (2024).

Zhu, C. et al. Numerical simulation and optimization with artificial neural network of two-phase nanofluid flow in a circular heatsink with cylindrical pin-fins. Eng. Anal. Boundary Elem. 148, 305–316 (2023).

Beigzadeh, R., Rahimi, M., Jafari, O. & Alsairafi, A. Computational fluid dynamics assists the artificial neural network and genetic algorithm approaches for thermal and flow modeling of air-forced convection on interrupted plate fins. Numer. Heat Transf. Part A Appl. 70(5), 546–565 (2016).

Ullah, I. et al. Heat transfer analysis from moving convection-radiative triangular porous fin exposed to heat generation. Case Stud. Therm. Eng. 38, 102177. https://doi.org/10.1016/j.csite.2022.102177 (2022).

Galal, A. M. et al. Comparison study of modified and classical Hamilton-Crosser models for electrophoretic and thermophoretic particle deposition in stagnation point flow of diamond–SiC–Co3O4/diathermic oil-based trihybrid nanofluid. J. Therm. Ana. Calorim. https://doi.org/10.1007/s10973-024-13918-7 (2024).

Muhammad, B., Farooq, M., Ahmad, H., Ullah, I. & Alam, M. M. Mathematical simulation of tangent hyperbolic nanofluid flow coupled with homogenous/heterogeneous chemical reaction by using Levenberg–Marquardt back propagation over a Riga plate. J. Therm. Anal. Calorimet. https://doi.org/10.1007/s10973-024-13554-1 (2024).

Funding

This work was supported and funded by the Deanship of Scientific Research at Imam Mohammad Ibn Saud Islamic University (IMSIU) (grant number IMSIU-DDRSP2503).

Author information

Authors and Affiliations

Contributions

Adnan and H.M.: Formulation, methodology, writing original draft, writing review and editing. B.A., M.B.B.H., H.A., S.U.K., N.A., and Y.K.: Formal analysis, software, validation, visualization, methodology, language editing, mathematical analysis and results and discussion, and writing review and editing.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Ayadi, B., Ben Hamida, M.B., Adnan et al. Performance of triangular fin device coated with (SiC–Co3O4)/diathermic nanolubricant inspired by convective and radiation conduction using AI driven approach. Sci Rep 15, 34761 (2025). https://doi.org/10.1038/s41598-025-18610-w

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-18610-w