Abstract

The surrounding rock between two ultra-closely spaced roadways, under biaxial compression (BC) condition, exhibits high failure propensity and consequently poses serious threats to the coal mining operations. The counter-pulled rockbolt (hereinafter referred as “bolt”) is widely employed to improve the stability of this kind of surrounding rock. However, the strength, deformation, macro- and micro-failure behaviors of bolted surrounding rock under BC condition are insufficiently understood. Therefore, these performances of the bolted samples (BSs) are investigated by using biaxial compressive experiments and acoustic emission (AE) technology. The research results indicate that the bolt diameter has an obvious capacity in improving the peak and residual strength of BSs, the bolt pretension force can significantly enhance the peak strength of BSs, yet has a minimal impact on the residual strength. Three types of axial stress-axial strain curves were categorized: post-peak instantaneous stress drop type, post-peak multi-step stress drop type and post-peak stress delay drop type. A new reinforcement effect, termed as the all-directional reinforcement effect of the bolt was observed. Insights into the influence of bolts on the elastic modulus and lateral displacement of the samples under BC condition were obtained, and two mechanisms for the reinforcement effect of bolt on the lateral displacement of samples were revealed. When the lateral pressure σ2 is 8.89 MPa, the effect of the bolt on the failure pattern of BSs is not obvious. Nevertheless, the fracture angle increases with the increase of bolt diameter and pretension force. The micro-failure crack types were classified based on AE parameters of AF–RA and it was found that the micro-failure of the BSs was dominated by shear cracks. The micro-failure process of the BSs underwent three stages, with most micro-failures occurring in Stage II. A new approach capable of computing the peak strength or the equivalent cohesion (c*) and equivalent internal friction angle (φ*) of sample reinforced by pretension bolt is proposed and used to calculate c* and φ* of the BSs under BC condition.

Similar content being viewed by others

Introduction

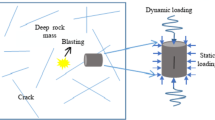

The surrounding rock between adjacent roadways with extremely close spacing is under typical biaxial compressive stress conditions (σ1 > σ2 ≠ σ3 = 0) and is liable to failure and lose stability1,2. Due to high efficiency and low cost, bolt is commonly used to improve the stability of the roadway surrounding rock. With the common use of bolt in military, civil and mining engineering, such as bomb shelters, slopes, tunnels and roadways, it is becoming more and more necessary and important to understand the properties closely related to the stability of the bolted surrounding rock of roadway, such as strength, deformation, macro- and micro-failure behaviors.

Early in 1974, Bjurström3 had reported the shear performance of the bolted hard rock joints under constant normal load (CNL) boundary condition. After that, the shear performances of BSs under CNL boundary condition are widely investigated, the influence of the parameters of bolt (such as diameter4,5installation angle6,7,8,9pretension force10,11types12,13,14, bolted medium (such as strength15,16joint parameters17,18,19, normal load20,21,22 and loading rates23 on the shear performance of BSs under CNL boundary condition are widely studied.

But, in general, it is considered that the CNL boundary condition only suits for rock slop engineering8,24the shear failure of the surrounding rock of underground openings occurs under the constant normal stiffness (CNS) boundary condition. Therefore, in order to reveal the shear performance of the bolted surrounding rock of underground caverns, Saadat and Taheri25 compared the shear properties of BSs under CNS with that of under CNL and pointed out that the CNS makes the shear resistance of bolted joints higher than that of CNL, but the CNS condition has little impact on the post-peak stage of the bolted joints. But Zhao et al.26 argued that at the later stage of loading, CNS boundary condition has a significant effect on the overall shear capacity of the system, which can resist greater transverse load and enhance the ‘‘ductility” of the bolt. Jiang et al.27 further found that the loss of the shear strength resulted from the joint wear can be counteracted by bolt reinforcement when the normal constraint stiffness is more than 3 GPa / m. But Zhang et al.28 argued that the bolt deformation mechanism is crucial to the bolt reinforcement effect. Han et al.29 further investigated the shear properties of the samples anchored by energy-absorbing bolt with CNS condition.

It should note that the surrounding rock of underground caverns not only suffers from shear failure, but also tensile and other failures30,31but the shear tests can only explore the shear performance of the bolted surrounding rock of underground spaces. Therefore, the quasi-triaxial compressive test is employed to investigate the mechanical performance of BSs according to the field situation that the surrounding rock of deep underground caverns subjecting to quasi-triaxial compression but having a free surface. Jing et al.32 used this method explored the effect of bolt number and joint angle on the peak strength of BSs with discontinuous joints. Zhu et al.33 conducted quasi-triaxial compression tests on bolted bedded rock samples and Ding et al.34 systematically analyzed the role of weak interlayer in the quasi-triaxial compression behaviors of the bolted rock mass. Wang et al.35 studied the quasi-triaxial compression properties of the BSs under static-dynamic cyclic loading and concluded that the lateral pressure and axial loading rate has an obvious effect on the failure modes of the free surface of BSs. By using conventional triaxial tests, Srivastava36 investigated the influence of confining pressure on the peak strength of the bolted jointed rock mass and discovered the conclusion that the peak strength of the bolted jointed rock masses increases with the increasing of confining pressure.

Furthermore, for widely understanding the mechanical performance of the bolted surrounding rock, some scholars investigated their uniaxial compressive performance. Under uniaxial compression, merely when the newly generated fractures intersect with the bolt in the samples, the bolt could have reinforcement effect on the samples. As a result, most of the uniaxial compressive tests were carried out on BSs containing defects, such as joints37,38,39fissures or fractures40,41 and layers42while few on bolted intact samples43. In further, with the technology development, the X-ray CT, AE, digital speckle correlation method and 3D printing technology were used to explore the uniaxial compressive performance of BSs44,45. Additionally, Li et al.46 explored the reinforcement behaviors of the bolted jointed samples under BC condition, Ding et al.47 experimentally explored the influence of lateral pressure on the reinforcement performance of bolted intact samples under BC condition.

The conclusions drawn from these studies indicate that the boundary conditions obviously affect the mechanical behavior of BSs. However, up to now, most of the attentions have been paid on the shear properties of BSs, seldom is focused on their bidirectional compression performances47and the micro-failure performances of the BS is rarely investigated. Therefore, this paper employs biaxial compressive tests and AE technology to explore the behaviors of BSs. The action of the bolt diameter and pretension force on the peak and residual strength, elastic modulus, lateral deformation of BSs under BC condition was obtained; reinforcement mechanism of the bolt was examined; the macro- and micro-failure modes were comprehensively analyzed in details; a new method was built and used to calculate c* and φ* of BSs suffering from BC condition.

Samples and testing scheme

Preparation of rock-like samples

Due to economical, easy preparation, similar mechanical properties to rock, cement-based materials are usually used to simulate rock samples48. For convenience and cost reduction, the samples are made of P. O. 32.5 cement, manufactured sands and water. The mass ratio of cement and sand is 1 : 4, and 15% of which is water. The size of the cubic samples is 150 mm3. The main mechanical parameters of the samples (unbolted) are obtained by using uniaxial compression test, Brazilian splitting test and direct shear test. The uniaxial compressive strength σc, the tensile strength σt and the elastic Eint are 25.40 MPa, 2.69 MPa and 6.04 GPa, respectively; the cohesion c and internal friction angle φ are 5.00 MPa and 33.4 °, respectively, as listed in Table 1. The mechanical properties of the rock-like material are compared with those of natural mudstone in Table 1. The comparison results shows that this rock-like material can be used to simulate mudstone.

Preparation of force measuring bolt used in experiments

The force measuring bolts, with length of 270 mm and diameters of 6, 12 and 18 mm are made of HPB335 rebar (Fig. 1 (a)). The face plate of the bolt, 40 mm in length and width and 2 mm in thickness is made of stainless steel sheet. The nuts are M6, M12 and M18 nuts, respectively (Fig. 1 (b)). For measuring the bolt stress during the deformation process of BS, two symmetrical notches of 6 mm in width are grooved in the opposite sides of the bolt with diameter of 12–18 mm and two strain gauges is symmetrically mounted in the center of notches (Fig. 1 (a) and (b)). The mechanical properties of the bolt are obtained by pull-out tests and its elastic modulus Eb and yield strength σyb are 200 GPa and 335 MPa, respectively, as shown in Table 2. Figure 2 shows the axial tensile stress -axial tensile strain curves of the bolts.

(Modified from Ding et al.47).

Bolts and their components.

After casted and 28 days cured, central through boreholes with diameters of 8, 14–20 mm are drilled in the unbolted samples, respectively. And then the bolts are fully grouted into boreholes by anchorage adhesive. Next, the BSs are kept for 48 h at room temperature for the grout solidification. Following complete grout curing, face plates and nuts are mounted on each end of the bolt in compliance with site-specific installation conditions of counter-pulled bolt. The BSs and their schematic diagram are shown in Fig. 3.

Experimental program and process

An electro-hydraulic servo machine of Henan Polytechnic University (as shown in Fig. 4) is employed for biaxial loading. DS2 AE instrument and DHDAS static strain indicator are used to monitor the AE information of the BSs and the strain of the bolt, respectively. The research program is shown in Table 3. According to the capacity of the experimental machine and to ensure the BSs can be crushed, the lateral stress is set as 8.89 MPa (200 kN). The pre-tension moments are 5, 10 and 15 N·m, respectively. And totally 22 samples are used to complete the research program. Before testing, vaseline is applied on the anti-friction paper to reduce friction between the BS and testing machine heads. The BS is put in the center of the loading space to prevent bias. After that, two AE probes are attached to the two free surfaces of BS to gather AE single. The data acquisition frequency, the threshold values of the AE instrument are 3 MHz, and 50 mV, respectively. The sensor adopts RS-35 C integrated preamplifier sensor, the preamplifier is 40 db according to the environmental noise, and its frequency is 150 kHz. Vaseline is applied between the sample and the AE probe as a coupling agent. And then, the pre-tension moment is applied on both ends of each bolt by using torque wrench. The threshold of the pre-tension moment on the torque wrench has been preset in advance. When the pre-tension moment reaches its threshold, the torque wrench emits a warning sound and then stops applying the pre-tension moment. The test rigs are shown in Fig. 4 (a) and the loaded sample can be seen in Fig. 4 (b).

The loads are applied in a displacement loading mode with loading rates of 0.3 and 0.2 mm/min in axial and lateral direction (σ2 direction), respectively. The axial and lateral forces are loaded simultaneously, the lateral pressure is loaded to 200 kN and then kept constant (σ2 = 8.89 MPa), while the axial load is continuously applied until specimen failure. The loading path is presented in Fig. 5. After test, the samples are photographed with a high-definition camera to analyze their crack distribution characteristics and failure mode.

Strength and deformation characteristics

Strength and deformation are two important characteristics of the bolted samples. In this section, the axial stress-axial strain, peak strength, residual strength, elastic modulus and lateral strain are used to analyze the strength and deformation characteristics of the BSs under BC condition.

Axial stress-axial strain curves and strength

Since the axial stress-axial strain curves (abbreviate as stress-strain curves) of the samples are similar, the representative samples are selected for analysis. The stress-strain curves and peak strength of samples influenced by bolt diameter (specimens UB-1, RBD6-1, RBD12-3, and RBD18-3) are presented in Fig. 6. The corresponding results for samples influenced by bolt pretension force (specimens UB-1, RBD12-3, RBP10-2, and RBP15-1) are shown in Fig. 7. According to Figs. 6 and 7, it is known that the pre-peak section of the stress-strain curves for BSs are similar, which consist of compaction section, elastic section and strain hardening section. However, the post-peak section of the stress-strain curves are different and presents three types.

(a) Type I: post-peak instantaneous stress drop type. Once reaching the maximum strength point, the stress drops immediately and significantly, and then reaches the residual strength. This type of stress-strain curve occurs to the unreinforced sample and the reinforced samples with bolt diameter of 6 mm and 12 mm. Due to lack of the constraint of the bolt or the poor reinforcement of the bolt, the samples will break down into small blocks when the stress comes up to the peak strength, and the interlocking effect among adjacent broken blocks is weak. Therefore, the broken samples lost bearing structure and bearing capacity, which causes an instantaneous large-scale stress drop at the post-peak stages for the unbolted samples and the reinforced samples by bolt in 6 mm diameter. (b) Type II: Post-peak multi-step stress drop type. This type of stress-strain curve is observed to occur in bolted specimens with pretension torque of 10 N·m and 15 N·m. Unlike Type I curve, the stress of Type II stress-strain curve drops in a step-like manner at the post-peak section of BSs, which indicates that the increase of bolt pretension force decelerates the strength deterioration of BSs at post-peak stage, weakens the post-peak brittleness and makes the failure mode of BSs transform from brittleness to ductility.

(c) Type III: Post-peak delayed stress drop type. This kind of stress-strain curve occurs to the specimens reinforced by bolt in diameter of 18 mm, namely this phenomenon appears when the bolt support strength is higher. At post-peak stage, the stress of Type III stress-strain curve drops slowly and then undergoes a plateau stage, indicating that the BS has reaches the residual strength stage. During the stress reduction stage, the ratio of stress reduction of type III is 19.91 MPa / (0.01ε1), while the stress reduction ratio of sample RBD12-3 belonging to the Type I is 42.55 MPa / (0.01ε1), the former is 46.79% of the later. The reason for this will be explained in the next paragraph.

The increase of bolt diameter could obviously enhance the peak and residual strength of BSs, as shown in Fig. 6 (b) and (c). With the increase of bolt diameter, the peak and residual strength of BSs magnifies significantly. The average peak strength of non-anchored specimens is 30.13 MPa, while the average peak strength of reinforced samples with bolt diameters of 6, 12 and 18 mm are 33.40, 36.44 and 40.28 MPa, respectively. The peak strengths of anchored samples by bolt in diameters of 6, 12 and 18 mm are 10.85, 20.94 and 33.69% bigger than that of non-anchored samples, respectively. With the bolt diameter increasing from 6 to12 and 18 mm, the residual strength of BSs increases from 7.24 to 17.16 and 21.21 MPa. After reinforced by bolt, the host materials and the bolt will form a composite bearing structure. Firstly, the pre-stressed bolt will apply a force on the free surface of the samples by face plate, which is equivalent of confining stress and makes the stress state of samples transform from BC condition to approximately true triaxial compression condition. Secondly, the bolt could increase the normal and anti-sliding force of fracture surface and the anti-sliding force and normal force increase as the bolt diameter increases. Consequently, the peak strength of BSs increases following the enlargement of bolt diameter, which coincides with the conclusions of paper Jing et al.32. When the BS breaks, the bolt could continue to bear load and improve the interlocking effect of broken blocks. And the interlocking effect increases as the bolt diameter magnifies. Therefore, following the enlargement of bolt diameter, the stress reduction ratio of the BSs at post-peak stage decreases and the residual strength of BSs increases.

The pretension force of bolt also significantly impacts the peak strength of BSs subjected to BC condition, as illustrated in Fig. 7 (b). The average peak strength of non-anchored specimens is 30.13 MPa and the average maximum strength of bolt-anchored samples with pretension torques of 5, 10 and 15 N·m are 36.44, 39.40 and 42.68 MPa, respectively. In comparison with the non-anchored specimens, the maximum strengths of the samples reinforced by bolt with pretension torques of 5, 10 and 15 N·m increase by 20.94, 30.76 and 41.65%, respectively. Bolt pretension force is able to apply an initial confining pressure on the sample free surface, and this initial confining pressure increases as the bolt pretension force increases. S econdly, at the peak strength point, the normal and anti-sliding forces of the fracture surface contributed by bolt increase following the enlargement of bolt pretension force. Hence the maximum strength of BS raises as the bolt pretension force increases. But the conclusion of paper Wang et al.51 showed that the peak strength of BS initially grows and then declines as the bolt pretension force increases. The reasons for this may be as follows: when the pretension force of the bolt is bigger than a certain threshold value, the host material will damage, or the debonding between bolt-grouting or grouting-borehole interface occurs before the BS reaches its peak-strength point, both of which will weaken the action of bolt pretension force on the peak strength of BS.

However, it should be pointed that the action of bolt pretension force on the residual strength is not obvious, as presented in Fig. 7 (c). The residual strength of BS is influenced by several factors, such as bearing structure, the angle, shape and number of dominant factures. The fracture angle increases with increasing of bolt pretension force (Figs. 20 and 21 (b)). However, not all these parameters are influenced by the bolt pretension force. For example, as shown in Fig. 20, the curvature of fracture F2 when bolt pretension torque is 10 N·m is smaller than that of bolt pretension torque is 5 N·m and 15 N·m. Consequently, the influence of bolt pretension force on residual strength of BS is less pronounced.

Deformation characteristics

Elastic modulus and axial deformation are usually preferred to interpret the deformation behavior of rock. But under BC condition, the lateral deformation (σ2 direction) could not be neglected, and the axial deformation behavior of BS has been paid more attention. Therefore, in this sub-section, the elastic modulus and lateral deformation are selected to explore the action of the bolt diameter and pretension force on the deformation characteristics of BS.

Elastic modulus

The elastic modulus of the sample reinforced by bolt with varying diameters and pretension force under BC condition are shown in Figs. 8 and 9, respectively.

The elastic modulus of BSs is significantly improved in comparison with that of unbolted specimens, and it increases sharply with the increase of bolt diameter, as indicated in Fig. 8. The modulus of elasticity for unbolted specimens is 1.63 GPa, while the modulus of elasticity for the samples anchored by bolt with diameters of 6, 12 and 18 mm are 1.89, 1.97 and 2.28 GPa, respectively. In comparison with the unbolted ones, the elastic modulus of BSs with bolt diameters of 6, 12 and 18 mm raised by 15.95, 20.86 and 39.87%, respectively. During BC process, the bolt applies a constraint stress (σ3 direction) by face plate on the free surface of the samples, which increase the deformation resistance of BSs in the axial direction, indicating bolting could increase the elastic modulus and decrease the deformation of roadway surrounding rock. In addition, the constraint stress increases with the increase of bolt diameter. Consequently, the elastic modulus of BSs grows with the enlargement of bolt diameter.

The elastic modulus of BSs also rises significantly as the bolt pretension force magnifies, as is predicted in Fig. 9. The elastic modulus of non-anchored samples is 1.63 GPa, and the elastic modulus of BSs with bolt pretension moments of 5, 10, and 15 N m are 1.97, 2.01, and 2.15 GPa, respectively. In comparison with the non-anchored samples, the modulus of elasticity for the anchored specimens by bolt with pretension moments of 5, 10, and 15 N m increases 20.86, 23.31 and 31.90%, respectively, which indicates that the pretension force of bolt could effectively enhance the elastic modulus of BSs. The bolt pretension force equals to the initial confining of BSs and this equivalent initial confining stress increases as the bolt pretension force magnifies. And as the confining stress grows, the axial deformation resistance of BSs improves. Therefore, the elastic modulus of BSs increases as the bolt pretension force increases. Consequently, it is important to apply suitable pretension force on the bolt to reduce the displacement of roadway surrounding rock. And, this is an effective and economic measure to improve the stability of the surrounding rock of roadway.

Lateral deformation

Lateral deformation is vital to the stability of roadway surrounding rock suffering from BC condition. Up to now, the axial deformation behavior of BS under quasi-triaxial or uniaxial compression has been better studied32,52. Jing et al.32 found that with the bolt number increases from 0, 3, 6, to 9, the axial post-peak deformation behavior of the jointed rock mass changes from brittleness to ductility. Yin et al.52 summarized that the axial deformation process of the fractured bolted samples into four stages, namely, initial compression stage, elastic and pre-peak load-bearing stage, post-peak load-bearing stage and residual strength stage. However, it should point out that in papers Jing et al.32 and Yin et al.52, the lateral deformation behavior of the BS is not investigated. Therefore, in this paper, these behaviors of BS are studied. For the sake of analysis, the lateral deformation is positive for compression and negative for expansion.

The developing process of the lateral strain of the samples without and with bolt in varying diameters is characterized by two stages, i.e. the linear rising section (Stage I) and the nonlinear changing section (Stage II), as presented in Fig. 10. For stage I, the lateral stress does not reach the setting value. While for stage II, the lateral stress has reached the setting value. Since the lateral pressure is applied in displacement-controlled mode, the lateral strain of the samples increases linearly in stage I. At stage II, the lateral strains of the BSs decreases as the bolt diameter increases. As the lateral stress reaches the presetting magnitude, the lateral strains of unreinforced and reinforced specimens with bolt diameters of 6, 12 and 18 mm are 1.53, 1.47, 1.42 and 1.33% respectively. In comparison with the non-anchored samples, the maximum reduction of lateral deformation of BSs is 13.07%. This demonstrates that bolting can improve the lateral deformation resistance and reduce the lateral deformation of BSs, and the resistance of BSs to lateral deformation grows as the bolt diameter increases.

Additionally, the pretension force of the bolt also has a great positive action on the lateral deformation of BSs, and the developing process of which also is characterized by two stages (Fig. 11). At stage II, the lateral strain decreases significantly with the increment of the pretension force of bolt. At this stage, the lateral strains of the unreinforced and reinforced specimens with bolt pretension force of 5, 10 and 15 N·m are 1.53, 1.42, 1.27 and 1.21%, respectively. In comparison with the non-anchored samples, the maximum reduction of lateral deformation is 20.92%. And the bigger the bolt pretension force is, the smaller of the lateral strain of BSs at stage II is. The reason for this is similar to that of the impact of bolt pretension force on the elastic modulus of BSs. Therefore, it is noteworthy that in the bolt supporting engineering, properly increase in the pretension force of bolt helps to reduce the lateral deformation of surrounding rock.

Therefore, it is clear that bolting not only improves the axial elastic modulus, but also enhances the lateral elastic modulus of the samples suffering from BC condition. This further indicates that bolt reinforcement effect is in all directions for the sample under BC condition. This function of the bolt is defined as the all directional reinforcement effect of bolt, and it is different from the bolt reinforcement effects discovered by Bjurström3 through shear test. This, again illustrates the necessity of this research. This is one of the mechanisms of the phenomenon that the lateral strain of the sample under BC condition decrease as the bolt diameter and pretension force grows.

In order to deeply reveal the mechanism of the impact of bolt on the lateral deformation of BSs, the lateral strain ε2 is given as:

where ε2 is lateral strain; σ1, σ2 and σ3 are the major, secondary and third principal stresses, respectively (σ3 is applied by bolt); E and µ are elastic modulus and Poisson ‘s ratio of BSs, respectively.

According to Eq. (1), it is known that when σ2 reaches presetting value and maintains constant, the lateral strain is only affected by σ1 and σ3. The axial strain of bolt is assumed to be equal to the normal strain (in σ3 direction, along the bolt axial direction) of the BS. The confining pressure σ3 of the BS applied by bolt can be obtained according to bolt axial force. When lateral stress σ2 reaches setting value, σ1 and σ3 of BS can be obtained according to strain-time curve of BS. It is showed from the test results that when σ2 reaches the setting value, σ1 of the samples with the bolt diameter of 12 and 18 mm are 4.59 and 5.47 MPa, respectively; and σ3 of the samples with the bolt diameter of 12 and 18 mm are 0.119 and 0.135 MPa, respectively. This shows that the axial stress σ1 and confining pressure σ3 of BSs increases as bolt diameter magnifies. As σ2 reaches the setting value, the axial stress σ1 corresponding to pretension torques of 5, 10 and 15 N·m are 4.59, 7.07 and 7.38 MPa respectively, and the value of σ3 applied by the bolt are 0.119, 0.516 and 0.820 MPa, respectively. This shows that when σ2 reaches preset value, σ1 and σ3 of BSs increase following the enlargement of the bolt pretension force. In addition, according to the Eq. (1), when σ2 is a fixed value, the lateral strain of the sample decreases with the growth of σ1 and σ3. This is another mechanism for the phenomenon that the lateral strain of BSs under BC condition reduces with the enlargement of bolt diameter and pretension force.

Micro-failure process and macro-failure modes

Micro-failure process

As a non-destructive detection technique, the AE is often used to explore the micro-failure process of rock or concrete53,54. The parameters of RA (rise time / peak amplitude, ms / V) and AF (ringing counts / duration time, kHz) of AE are often used to classify the types of tensile and shear cracks of the rock during micro-failure process due to the tensile crack has a high AF and low RA, while the shear crack has a low AF and high RA53,54. Namely, if the ratio of AF to RA is equal to or greater than a certain value, the crack will be identified as a tensile crack; otherwise, it is identified as a shear crack. Therefore, for identifying the crack types more accurately, the key is to determine a reasonable value of AF / RA, which is expressed as k = AF / RA.

Determination of k

Ohno and Ohtsu55 found that k = 200 is reasonable for concrete. But Ma et al.54 argued that the reasonable value of k varies with the curing way of concrete. Therefore, this paper adopts trial and error method to determine the reasonable value of k. First, give the initial value of k; second, check the rationality of k value. According to the research results of Ohno and Ohtsu55the initial value of k is set as 200. Then, it is used to identify the crack types of the bolted samples falling into tensile failure mode, as presented in Fig. 12. It should point out that the physical and mechanical parameters and curing measurement of the sample in Fig. 12 is the same to those of the samples used in this paper. But due to the lateral pressure of the sample showed in Fig. 12 is 0.44 MPa, it fell into tensile failure mode and its failure process is dominant by tensile crack.

(Modified from Ding et al.47).

Macro-failure mode of bolted sample with 0.44 lateral pressure.

The identification results of crack types of the sample falling into tensile failure mode are shown in Fig. 13. Moreover, to understand the failure process of this sample, the cumulative process of tensile crack and shear crack is drawn in Fig. 13 (c). According to Fig. 13 (a) and (b), it is known that k = 200 is reasonable, due to 91.06% tensile cracks are identified, which agrees well with the failure mode of BS falling into tensile failure mode. In addition, as presented in Fig. 13 (c), the micro-failure process can be divided into two stages. Stage I corresponds to pre-yielding phase of the BS. In this stage, the proportions of tensile and shear cracks to the total number of cracks are small and the number of these two kinds of cracks increase slowly, which coincides with the crack growth characteristics at the stable crack propagation stage of the BS. Before yielding, the sample mainly undergoes elastic deformation. Consequently, a small number of cracks generates in this phase. Stage II corresponds to the post-yielding phase of BS, at which the tensile and shear cracks increase rapidly. This is because stage II is the crack unstable propagation phase of the sample and lots of cracks yields in this period of time. Furthermore, the proportion of tensile crack increase more rapidly in stage II than that of shear crack, which coincides with the macro-failure mode of this sample. These again indicate that the micro-failure process of the bolted sample can be explored to a certain extent by analyzing the cumulative process of tensile crack and shear crack, and this method is termed as crack accumulation process method (CAP method).

However, it should point out that although the distribution diagram of FA-AR and CAP method can be used to classify the crack types and to investigate the growth process of tensile and shear cracks, the micro-failure mode of the brittle materials is not only influenced by the type and number of cracks, but also by their scales. But the distribution diagram of FA-AR and CAP method cannot be used to explore crack scale during the failure process, nor can it be used to explore the micro-failure process of rock or concrete samples. But up to now, most of the papers have only used the distribution diagram of FA-AR to explore the micro-failure characteristics of rock or concrete. Therefore, in order to better understand the micro-failure process and the dominant micro-crack, the crack classification energy accumulation curve (CCEAC) method proposed by Ding et al.56 is adopted to investigate the type of the dominant micro-crack and the micro-failure process of the BSs during the BC process. Still taking the sample in Fig. 12 as an example, the results of CCEAC show that when the sample failed, the tensile crack energy occupies 95.85% of the total AE energy, while proportion of shear crack energy to total AE energy is only 4.15%, as presented in Fig. 14. And during the whole micro-failure process, the proportion of tensile crack energy is always higher than that of shear crack energy, especially in the stage III. This indicates that during the BC process, the micro-failure of the BS is dominated by tensile cracks, which coincides with the macro-failure of the bolted sample as shown in Fig. 12. Therefore, the value of k determined in this paper is reasonable and the CCEAC method adopted in this sub-section can be used to explore the micro-failure process of the BSs under BC condition.

Micro-failure process

For better understanding the micro-failure process of the BSs under BC condition, this sub-section explores the types, number and energy of micro-cracks of BS under BC condition. Considering the length of this manuscript, only the representative samples of RBD6-1, RBD12-4, RBP10-2 and RBP15-2 are selected to investigate the micro-failure process of the BS under BC condition.

The AF–RA scatter diagrams of these selected samples are presented in Figs. 15 (a) and (b), 16, 17 and 18 (a) and (b). According to the AF–RA distribution diagram, the crack types are identified. On the base of the identification of crack types, the proportion curves of the cumulative tensile and shear cracks to the total number of cracks are plotted, as presented in Figs. 15 (c), 16, 17 and 18 (c). According to Figs. 15 (c), 16, 17 and 18 (c), it is known that during the BC process, the micro-failure process can be divided into three phases, namely, Stages I, Stage II and Stage III.

Stage I corresponds to the pre-yielding or peak stage of BSs (the OA sections of the stress-time curves). During Stage I, the generation of both tensile and shear cracks is slowly. The maximum proportions of tensile crack and shear cracks to the total number of cracks are 9.77% and 13.57%, respectively, as shown in Fig. 15 (c), but the minimum proportions are only 5.41% and 2.24%, respectively, as presented in Fig. 17 (c). Stage II begins from the yielding point or peak strength point to a point on the strain-softening section (the AB sections of the strain-time curves). In Stage II, both tensile and shear cracks increase sharply. The proportion of tensile cracks generated in this stage to the total number of cracks are approximately 33.04–43.84%, and the proportion of shear cracks yielded in this stage to the total number of cracks are approximately 27.80–33.15%. Stage III corresponds to the strain-softening and residual strength stages of these samples (the BC sections of the strain-time curves). In Stage III, the generation of tensile and shear cracks is also slow. The tensile crack generated during this stage account for approximately 3.04–10.62% of total cracks, and the shear cracks occupy only between 0.09 and 9.88%. This indicates that most of the micro cracks generate in stage II and the reason for this has been explained in sub-Sect. of "Determination of k" .

Additionally, except for sample RBD6-1, the proportion of tensile crack is always higher than that of shear crack. However, after point D (Fig. 15 (c)) the proportion of tensile crack of sample RBD6-1 exceeds the proportion of shear crack. Moreover, during the rapid stress-drop phase, the proportions of both tensile and shear cracks increase sharply, as shown in the yellow region of Fig. 18 (c). This indicates that the post-peak stress drop is a direct result of microcrack generation.

However, to precisely understand the micro-failure mode of the sample, it is not enough to merely analyze the types and quantities of micro-cracks; it is also necessary to analyze the scale of the microcracks. The existing research results indicated that the AE energy is closely related to the crack scale, the larger the crack scale is, the greater the released AE energy will be57,58. Consequently, this sub-section adopts the AE energy to analyze the type of dominant micro-cracks of BS. On the base of crack types identification, the AE energy of tensile crack and shear crack are identified, and the accumulative energy of tensile crack and shear crack curves are plotted, as shown in Figs. 15 (d), (e), 16, 17 and 18 (d), (e). Similar to the curves of proportion of tensile crack and shear crack, the curves of cumulative energy of AE also can be divided into three stages: Stage I, Stage II, and Stage III. It should be noted that due to the significant difference between the cumulative energy proportion curves of tensile crack and shear crack, the three stages of these two kinds curves are divided separately. In stage I, the proportions of tensile crack energy and shear crack energy to the total AE energy are very low, and both of which increases slowly. In this stage, the highest proportion of tensile crack energy to the total AE energy is only 1.10%, and the maximum proportion of shear crack energy to the total AE energy is 9.71%. In stage II, the proportions of tensile crack energy and shear crack energy to the total energy increase sharply, the minimum and maximum proportions of tensile crack energy to the total AE energy are 5.72% and 14.63% respectively; while the proportions of shear crack energy to the total AE energy are between 40.06 and 84.59%, respectively. In stage III, the proportions of tensile crack energy and shear crack energy to the total AE energy are also very low and increase slowly, the proportions of tensile crack energy to the total AE energy are between 0.06 and 6.28%; while the proportions of shear crack energy to the total AE energy are between 3.07 and 7.73%. In addition, in the whole BC process of BSs with a macroscopic failure mode of shear failure (as shown in Figs. 19 and 20), the proportions of shear crack energy are always higher than that of tensile crack energy. However, for the BSs with a macroscopic tensile failure mode (Fig. 12), the proportion of shear crack energy is always lower than that of tensile crack energy during the whole biaxial compression process, as shown in Fig. 14. This indicates that during the BC (σ2 = 8.89 MPa) process, the microscopic failure of BSs is dominated by shear cracks and the micro–failure mainly generates in stage II.

Macro-failure modes

The macro-failure patterns of the samples reinforced by bolt with varying diameters and pretension force are presented in Figs. 19 and 20, respectively.

The macro-failure modes of BSs are dominant by shear failure, as shown in Figs. 19 and 20. When bolt diameter is 6, 18 mm and bolt pretension torque is 10 N·m, two approximately symmetrical shear cracks occur to the samples, as shown in Figs. 19 (a), (c) and 20 (b). When bolt diameter is 12 mm and bolt pretension moments are 5 and 15 N·m, two approximately symmetrical shear cracks and an arch-shaped crack are observed occurring to the BSs, as presented in Figs. 19 (b), 20 (a) and (c). The arch-shaped crack also belongs to the shear fracture extends from the main crack F1 to the surface of the sample and splits a fractured rock block. The fractured rock block is close to the free surface and does not fall off due to the constraint of the bolt. Additionally, the cracks yield on the lateral side (σ2 loading surface) of BSs, because the cracks always propagate along the optimal direction, that is, the free surface direction. The research results of paper Cai59 show that under the condition of BC, when σ2 is medium or high, the crack initiation perpendicular to σ2 direction is delayed till stress level of σ1 is higher. Therefore, there are few cracks in the σ3 direction, and the cracks mainly generate along the directions parallel to σ1 and σ2, that is, the fracture surface of the specimen develops along the stress surface of σ1 and σ3.

The existing research conclusions indicate that the dominant macro-failure mode of rock sample is tensile and shear failure under low and relatively high lateral stress60,61respectively. While suffering from triaxial compression, the rock sample falls into shear failure mode62,63. In this paper, all of the non-anchored and anchored samples with lateral pressure of 8.89 MPa fall into shear failure mode, indicating that bolting does not change the failure pattern of the samples under this condition. However, due to the influence of the bolt diameter and pretension force, the fracture angles (the angle between the fracture surface and the horizontal plane) are slightly different. When the diameters of bolt are 6, 12, 18 mm, the average fracture angles are 62°, 64.5° and 69°, respectively. When the pretension torques are 5, 10, 15 N·m, the average fracture angles are about 64.5°, 65° and 65.5°, respectively. This indicates that following the enlargement of bolt diameter and pretension force, the fracture angle of BSs magnifies gradually, as shown in Fig. 21.

Based on M-C criterion, the fracture angle β can be expressed as follow:

where φ0 and β are the internal friction angle and fracture angle of the non-anchored sample, respectively.

According to Eq. (2), if the fracture angle of BS grows, it can be considered the internal friction angle of BSs magnifies compared with unbolted samples. This may be due to the friction strengthening effect of the bolt on the shear surface3. With the bolt diameter enlargement, the contact areas between the bolt and the host materials increase. As a consequence, the reinforcement effect of the bolt improves as the bolt diameter increases. Therefore, β and φ0 grow with the growth of bolt diameters. In addition, according to Wei et al.64, the pretensioned bolt can enhance the cohesion and internal friction angle of rock mass, and following the enlargement of bolt pretension force, the normal stress in the shear surface exerted by bolt magnifies, which results in the augment of internal frictional angel and fracture angel of the BSs. Therefore, the fracture angle of BSs grows gradually, following the increase of bolt pretension force.

Analysis of reinforcement effect of bolt

M-C criterion is commonly employed to calculate the strength of BS in compression-shear failure conditions65,66,67which is adopted in this paper, due to the BSs of this paper fell into compression-shear failure mode. The cohesion and internal friction angle are two basic parameters for M-C criterion. To make a distinction, the cohesion and friction of BS are named as equivalent cohesion c* and equivalent internal friction angle φ*, respectively. Therefore, if c* and φ* can be obtained, the strength of BS with BC condition can be calculated by M-C criterion. However, at present, c* and φ* are calculated mostly according to the results of pure shear test and need monitoring the bolt stress65,66,67which leads the calculation work is cumbersome and relatively difficult. What’ more, most of the existing methods adopt the ultimate strength of the bolt to calculate the peak strength of BSs65,66,67. But the experimental results indicate that at the peak strength point of the BSs under bi- or triaxial compression, the bolt does not break47,68. Consequently, it is clearly that these methods overestimate the contribution of the bolt to the peak strength of BSs under BC condition, which leads to the less safe of the roadway supported by bolt. Therefore, it is important and necessary to find a new method to calculate the peak strength of BS under BC condition.

Influence of bolting on the equivalent cohesion c * of BS

Under BC condition, the slip of the rock block is negligible before and at the peak strength point of BS. Therefore, only the axial deformation of the bolt induced by Poisson’s effect is taken into consideration. The bolt bending moment is small at the peak strength point of BS47,68 and is almost disregarded, namely, the transverse effect of the bolt is neglected. Hence, the mechanical model of the bolt can be simplified and is illustrated in Fig. 2247.

(Modified from Ding et al.47).

Mechanical model of bolt grouted in sample under BC condition.

On the base of these assumptions, the axial force of the passive bolt at the peak strength point of BS is obtained as follow47:

where Eb is the bolt elastic modulus, MPa; Ab is the bolt cross-sectional area, m2; εb is the bolt axial strain; Db is the bolt diameter, m; µ is the Poisson’s ratio of BS; ε1p is the peak axial strain of BS.

However, it should be pointed out that the effect of bolt pretension on the peak strength of BS under BC condition is not considered in paper Ding et al.47. In China, most of the bolt used in roadway is pretensioned bolt. Therefore, in order to quantitatively evaluate the influence of bolt pretension, it is assumed that the pretension force Fpre and axial force N0 of the bolt have the equivalent reinforcement effect on c*. At the maximum strength point of BS, the total axial force of a pre-stressed bolt is N1 = N0 + Fpre, as is shown in Eq. (4).

According to Fig. 22, the component Rot of pre-stressed bolt acting on the shear surface is:

The cohesion contributed by a pre-stressed bolt is shown in Eq. (6):

The calculation method of c* is obtained by adding c0 and \(\Delta {c_b}\), which is shown in Eq. (7):

where c0 is the cohesion of the unbolted sample, MPa.

Substituting Fpre, β (the mean value of fracture angle of the specimen is used), µ (0.2 in the test), E (200 GPa), Db and ε1p into the Eq. (7), c* is obtained, as is listed in Table 4.

As shown in Table 4; Fig. 23, c* increases with the enlargement of the bolt diameters and pretension force. In Comparison with unbolted specimens, the magnitudes of c* for reinforced specimens by bolt with diameter of 6, 12 and 18 mm increase by 8.40, 30.20 and 68.40%, respectively. The c* values of reinforced specimens by bolt with pretension moment of 5, 10 and 15 N m increase by 30.20, 32.00% and 33.80%, respectively. Further analysis shows that when the fracture angle is constant, the bigger the peak axial strain is, the larger the c* value is. When the peak axial strain keeps constant, c* decreases with the magnification of fracture angle.

Influence of bolting on equivalent internal friction angle φ* of BS

Using a modified poly-axial M-C criterion69the maximum strength σ1 of the passive bolt anchored specimen suffering from BC condition is built, as is shown in Eq. (8).

where φ* is the equivalent internal friction angle of BS.

By substituting c* obtained from Eq. (6) into Eq. (8), Eq. (9) is obtained to calculate the peak strength σ1 of BS.

In addition, it is also known that φ* also can be calculated by Eq. (9) on the base of the other parameters obtained. Therefore, Eq. (9) is used to compute φ*.

Substituting Fpre, β, µ (0.2 in the test), E (200 GPa), db, ε1p and c* into Eq. (9), φ* is obtained, as presented in Table 5.

Db, Mpre, Fpre are diameter, pretension moment and pretension force of bolt, respectively; β, ε1p and φ* are mean value of fracture angle, peak axial strain and internal friction angle of BSs, respectively.

Table 5; Fig. 24 show that with the increase in bolt diameter, the value of φ* declines gradually, but they are still bigger than that of non-anchored samples. With the increase in bolt pretension force, φ* increases gradually. Compared with the unbolted samples, the φ* value of the reinforced samples by bolt with diameter of 6, 12 and 18 mm increases by 13.47, 8.98 and 1.86%, respectively. The φ* value of reinforced specimens by bolt with pretension force of 5, 10 and 15 N·m increases by 8.98, 14.67 and 20.66% respectively. In addition, when the fracture angle of BS is constant, the larger the peak axial strain is, the smaller of φ* is. When the peak axial strain of BS keeps constant, φ* increases with the enlargement of fracture angle of BRSs.

Conclusions

In this paper, BC (biaxial compression) experiments are conducted on BSs, the strength, deformation and macro-failure behaviors are analyzed in detail, the micro-failure performances of BSs are explored in virtue of in-depth analysis of AE parameters, a novel empirical method is put forward and used to compute c*and φ* of BSs under BC condition. The main conclusions are as follows:

-

1.

The bolt diameter has great impact on the peak and residual strength of BSs subjected to BC condition. The bolt pretension has an obvious action on the maximum strength, yet a slight function on the residual strength of BSs under BC condition. As the bolt diameter increases, the peak strength, residual strength and elastic modulus of BSs grows obviously; following the growth of bolt pretension force, the peak strength and elastic modulus of BSs magnifies greatly, but the residual strength changes slightly. A new reinforcement effect of bolt, termed as all directional reinforcement effect of bolt is discovered.

-

2.

The developing process of lateral strain of the non-anchored and anchored samples are characterized by two stages, namely linear rising section (Stage I) and nonlinear changing section (Stage II). When the lateral stress is constant, following the increase of the bolt diameter and pretension force, the lateral strain of the BSs ε2 decrease. Two mechanisms for the effect of bolt on the lateral deformation of BSs suffering from BC condition are revealed.

-

3.

The influence of the bolt diameter and pretension force on the macro-failure pattern of BSs is not obvious. All BSs influenced by bolt diameters or pretension force exhibit compression-shear failure pattern when lateral pressure σ2 is 8.89 MPa. The fracture angle of BSs grows with the growth of bolt diameter and pretension force. The micro-failure of the BSs experiences three obvious stages, and most of the micro-failure yields in stage II. Under BC condition, in most cases, the proportion of tensile crack is higher than that of shear crack, but the proportion of shear crack energy consistently exceeds that of tensile crack energy, indicating that the micro-failure is dominate by shear cracks when σ2 = 8.89 MPa.

-

4.

A new empirical approach capable of calculating the peak strength or c*and φ* of BSs under BC condition is put forward. In virtue of this new approach, the effects of the bolt diameter and pretension force on c* and φ* of BSs under BC condition are calculated. The computation results illustrate that bolting can enhance c*and φ* of BSs with BC condition. The mechanism of bolt reinforcement to enhance the strength of BSs suffering from BC condition is revealed.

Data availability

All the relevant data is available in the manuscript.

Abbreviations

- BC:

-

Biaxial compression

- BS:

-

Bolted sample

- AE:

-

Acoustic emission

- CAP:

-

Crack accumulation process

- CCEAC:

-

Crack classification energy accumulation curve

- CNL:

-

Constant normal load

- CNS:

-

Constant normal stiffness

- M-C:

-

Mohr-Coulomb criterion

- E int :

-

Elastic modulus of unbolted sample, GPa

- E :

-

Elastic modulus of bolted sample, GPa

- σ c :

-

Uniaxial compressive strength of unbolted sample, MPa

- σ t :

-

Tensile strength of unbolted sample, MPa

- E b :

-

Bolt elastic modulus, GPa

- σ tb :

-

Bolt tensile strength, MPa

- σ yb :

-

Bolt yield strength, MPa

- ε b :

-

Bolt axial strain, %

- ε 2 :

-

Lateral strain of BS, %

- AF :

-

Ratio of ringing counts to duration time, kHz

- RA :

-

Ratio of rise time to peak amplitude, ms / V

- k :

-

Ratio of AF to RA

- σ 1 :

-

The maximum principal stress, MPa

- σ 2 :

-

The intermediate principal stress, MPa

- σ 3 :

-

The minimum principal stress, MPa

- ε 1p :

-

The peak axial strain of BS

- c 0 :

-

Cohesion of unbolted sample, MPa

- c * :

-

Equivalent cohesion of BS, MPa

- Δ c b :

-

The cohesion contributed by prestressed bolt, MPa

- φ 0 :

-

Internal friction angle of unbolted sample, °

- φ * :

-

Equivalent internal friction angle of BS, °

- µ :

-

Poisson’s ratio

- β :

-

Fracture angle of the non-anchored sample, °

- M pre :

-

Bolt pretension moment, N·m

- F pre :

-

Bolt pretension force, N

- N 0 :

-

Axial force of bolt, N

- N 1 :

-

The total axial force of the prestressed bolt, N

- R ot :

-

The component of the pre-stressed bolt acting on the shear surface, N

- D b :

-

Bolt diameter, mm

- A b :

-

Bolt cross-sectional area, m2

References

Ding, X. L. et al. Stability of large parallel tunnels excavated in weak rocks: A case study. Rock. Mech. Rock. Eng. 50, 2443–2464. https://doi.org/10.1007/s00603-017-1247-6 (2017).

Wang, X. Q. Analysis for bearing characteristics and reinforcement effect of counter-pulled bolts and cables. J. China Coal Soc. 44, 430–438. https://doi.org/10.13225/j.cnki.jccs.2019.0919 (2019).

Bjurström, S. Shear strength of hard rock joints reinforced by grouted untensioned bolts. Conference. Int. J. Rock Mech. Min. Sci. & Geomech. Abstr. 12, 181. (1975). https://doi.org/10.1016/0148-9062(75)90705-6

Meng, B. et al. Experimental Study on the Shear Behavior of Bolted Concrete Blocks with Oblique Shear Test. Adv. Civ. Eng. 7281218. (2018). https://doi.org/10.1155/2018/7281218 (2018).

Li, L. et al. Parametric study of Rockbolt shear behaviour by double shear test. Rock. Mech. Rock. Eng. 49, 4787–4797. https://doi.org/10.1007/s00603-016-1063-4 (2016).

Yuan, W. et al. Experimental and numerical study on the anchoring mechanism of an anchor bolt considering its lateral restraint effect. Rock. Mech. Rock. Eng. 57, 9617–9633. https://doi.org/10.1007/s00603-024-03981-9 (2024).

Liu, H. L. et al. Experimental study on the shear deformation characteristics and mechanical properties of bolted joints. Int. J. Geomech. 23, 04022265. https://doi.org/10.1061/(ASCE)GM.1943-5622.0002641 (2023).

Cui, G. J. et al. Effect of bolt inclination angle on shear behavior of bolted joints under CNL and CNS conditions. J. Cent. South. Univ. 27, 937–950. https://doi.org/10.1007/s11771-020-4342-x (2020).

Zhao, C. X. et al. Research on the Stress Distribution Law of Fully Anchored Bolt and Analysis of Influencing Factors under the Condition of Surrounding Rock Deformation. Adv. Civ. Eng. 1–14. (2020). https://doi.org/10.1155/2020/8818375 (2020).

Sun, X. M. et al. Strength characteristics of rock anchored by NPR bolt with different preloads. J. Mt. Sci. 20, 834–844. https://doi.org/10.1007/s11629-022-7798-3 (2023).

Gregor, P. et al. Shear behaviour of fibreglass rock bolts for various pretension loads. Rock. Mech. Rock. Eng. 56, 8083–8113. https://doi.org/10.1007/s00603-023-03474-1 (2023).

He, M. C. et al. Experimental study on the shear performance of quasi-NPR steel bolted rock joints. Chin. J. Rock. Mech. Eng. 15, 350–362. https://doi.org/10.1016/j.jrmge.2022.03.011 (2023).

Zhang, S. B. et al. Experimental and numerical study on shear behaviors of rock joints reinforced by SFCBs and BFRP bars. Rock. Mech. Rock. Eng. 56, 1717–1737. https://doi.org/10.1007/s00603-022-03144-8 (2022).

Li, X. W. et al. Behavior of fiber glass bolts, rock bolts and cable bolts in shear. Rock. Mech. Rock. Eng. 49, 2723–2735. https://doi.org/10.1007/s00603-015-0907-7 (2016).

Jiang, Y. J. et al. Study on shear behavior and failure characteristics of bolted anisotropic rock joints. Materials 16, 2210. https://doi.org/10.3390/ma16062210 (2023).

He, M. C. et al. Experimental study on influence of host rock strength on shear performance of Micro-NPR steel bolted rock joints. Int. J. Rock. Mech. Min. Sci. 159, 105236. https://doi.org/10.1016/j.ijrmms.2022.105236 (2022).

Wang, G. et al. Shear behaviour and acoustic emission characteristics of bolted rock joints with different roughnesses. Rock. Mech. Rock. Eng. 51, 1885–1906. https://doi.org/10.1007/s00603-018-1438-9 (2018).

Wu, X. Z. et al. Effect of Cyclic shear loading on shear performance of rock bolt under different joint roughness. Rock. Mech. Rock. Eng. 56, 1969–1980. https://doi.org/10.1007/s00603-022-03174-2 (2023).

Wang, Y. K. et al. Experimental study on the effect of anchored bolts on failure and strength behavior of nonpersistent jointed rock model. Bull. Eng. Geol. Environ. 82, 95. https://doi.org/10.1007/s10064-023-03129-z (2023).

Zhu, L. F. et al. Shear creep characteristics and creep constitutive model of bolted rock joints. Eng. Geol. 327, 107368. https://doi.org/10.1016/j.enggeo.2023.107368 (2023).

Liu, Q. S. et al. Shearing mechanical model and experimental verification of bolts in jointed rock mass. Chin. J. Geotech. Eng. 40, 794–801. https://doi.org/10.11779/CJGE201805003 (2018).

Li, Y. Z. et al. Laboratory study of the effects of grouted rebar bolts on shear failure of structural planes in deep hard rocks. Int. J. Rock. Mech. Min. Sci. 162, 105308. https://doi.org/10.1016/j.ijrmms.2022.105308 (2023).

Luo, G. M. et al. Shear performance of quasi-NPR steel bolted rock joints at different shear rates. Int. J. Rock. Mech. Min. Sci. https://doi.org/10.1016/j.ijrmms.2023.105542 (2023). 170,105542.

Thirukumaran, S. & Indraratna, B. A review of shear strength models for rock joints subjected to constant normal stiffness. J. Rock. Mech. Geotech. Eng. 8, 405–414. https://doi.org/10.1016/j.jrmge.2015.10.006 (2016).

Saadat, M. & Taheri, A. A numerical study to investigate the influence of surface roughness and boundary condition on the shear behaviour of rock joints. Bull. Eng. Geol. Environ. 79, 2483–2498. https://doi.org/10.1007/s10064-019-01710-z (2020).

Zhao, Z. H. et al. Shear behaviour of anchored jointed rock mass under different engineering conditions considering damage and joint surface morphology. Undergr. Space. 13, 316–334. https://doi.org/10.1016/j.undsp.2023.04.004 (2023).

Jiang, Y. J. et al. Experimental study on shear characteristics of bolted rock joints under constant normal stiffness boundary conditions. Chin. J. Rock. Mech. Eng. 40, 663–675. https://doi.org/10.13722/j.cnki.jrme.2020.0871 (2020).

Zhang, Y. C. et al. Anchorage effect of bolt on en-echelon fractures: A comparison between energy-absorbing bolt and conventional rigid bolt. Eng. Fail. Anal. 137, 106256. https://doi.org/10.1016/j.engfailanal.2022.106256 (2022).

Han, G. S. et al. Experimental study on shear characteristics of energy-absorbing bolt anchored jointed rock mass under constant normal stiffness condition. Chin. J. Rock. Mech. Eng. 43, 999–1012. https://doi.org/10.13722/j.cnki.jrme.2023.0599 (2024).

Jiang, J. Q. et al. Failure characteristics of surrounding rocks along the radial direction of underground excavations: an experimental study. Eng. Geol. 281, 105984. https://doi.org/10.1016/j.enggeo.2020.105984 (2021).

Deng, P. H. et al. FDEM numerical modeling of failure mechanisms of anisotropic rock masses around deep tunnels. Comput. Geotech. 142, 104535. https://doi.org/10.1016/j.compgeo.2021.104535 (2022).

Jing, H. W. et al. An experimental study on anchorage strength and deformation behavior of large-scale jointed rock mass. Tunn. Undergr. Space Technol. 43, 184–197. https://doi.org/10.1016/j.tust.2014.05.006 (2014).

Zhu, W. X. et al. Strength and deformation behaviors of bedded rock mass under bolt reinforcement. Int. J. Min. Sci. Technol. 28, 593–599. https://doi.org/10.1016/j.ijmst.2018.03.006 (2018).

Ding, S. X. et al. Influence of weak interlayer on the mechanical performance of the bolted rock mass with a single free surface in deep mining. Minerals 11, 496. https://doi.org/10.3390/min11050496 (2021).

Wang, P. et al. Mechanical responses of anchoring structure under triaxial Cyclic loading. J. Rock. Mech. Geotech. Eng. 16, 545–560. https://doi.org/10.1016/j.jrmge.2023.04.020 (2024).

Srivastava, L. P. Strength prediction of a passive bolt-reinforced natural jointed rock under confined condition. Innov. Infrastruct. Solut. 8, 143. https://doi.org/10.1007/s41062-023-01117-6 (2023).

Li, S. et al. Mechanical behavior of anchored rock with an infilled joint under uniaxial loading revealed by AE and DIC monitoring. Theor. Appl. Fract. Mech. 123, 103709. https://doi.org/10.1016/j.tafmec.2022.103709 (2023).

Srivastava, L. P. & Singh, M. Effect of fully grouted passive bolts on joint shear strength parameters in a blocky mass. Rock. Mech. Rock. Eng. 48, 1197–1206. https://doi.org/10.1007/s00603-014-0615-8 (2015).

Zhu, C. et al. Failure behavior and strength model of blocky rock mass with and without rockbolts. Int. J. Min. Sci. Technol. 34, 747–762. https://doi.org/10.1016/j.ijmst.2024.06.008 (2024).

Lei, G. F. et al. Experimental study on mechanical properties of fractured rock mass under different anchoring modes. Eur. J. Environ. Civ. Eng. 24, 931–948. https://doi.org/10.1080/19648189.2018.1429321 (2020).

Wen, G. P. et al. Characteristics of stress, crack evolution, and energy conversion of anchored granite containing two preexisting fissures under uniaxial compression. Bull. Eng. Geol. Environ. 82, 5. https://doi.org/10.1007/s10064-022-03002-5 (2023).

Teng, J. Y. et al. CT experimental study on the damage characteristics of anchored layered rocks. KSCE J. Civ. Eng. 22, 3653–3662. https://doi.org/10.1007/s12205-018-0425-8 (2018).

Wu, B. W. et al. A study of the anchorage body fracture evolution and the energy dissipation rule: comparison between tensioned rock bolts and torqued rock bolts. Adv. Civ. Eng. 2021 (5542569). https://doi.org/10.1155/2021/5542569 (2021).

Yang, S. Q. et al. An experimental study on fracture evolution mechanism of a non-persistent jointed rock mass with various anchorage effects by DSCM, AE and X-ray CT observations. Int. J. Rock. Mech. Min. Sci. 134, 104469. https://doi.org/10.1016/j.ijrmms.2020.104469 (2020).

Feng, X. W. et al. Reinforcing effects of 3D printed bolts on joint-separated standard soft rock specimens. Compos. Part. B Eng. 193, 108024. https://doi.org/10.1016/j.compositesb.2020.108024 (2020).

Li, Y. et al. An experimental investigation on mechanical property and anchorage effect of bolted jointed rock mass. Geosci. J. 21, 253–265. https://doi.org/10.1007/s12303-016-0043-8 (2017).

Ding, S. X. et al. Influence of lateral pressure on the mechanical performance of bolted specimens under biaxial compression. KSCE J. Civ. Eng. 28, 456–470. https://doi.org/10.1007/s12205-023-1202-x (2024).

Li, Y. et al. Experimental and numerical investigations on mechanical property and reinforcement effect of bolted jointed rock mass. Constr. Build. Mater. 126, 843–856. https://doi.org/10.1016/j.conbuildmat.2016.09.100 (2016).

Sun, C. C. Association Study on Micro Fabric and Mechanical Properties of Terrestrial Coal Series Mudstone. Chinese Master’s Thesis, CUMT. (2015).

Li, W. T. et al. Mechanism and control of failure of rock roadway support in highly stressed soft rock. Chin. J. Rock. Mech. Eng. 34, 1836–1848. https://doi.org/10.13722/j.cnki.jrme.2014.1594 (2015).

Wang, W. J. et al. Simulation on anchorage mechanism of rock mass. J. Chin. Coal Soc. 48, 177–184. https://doi.org/10.13225/j.cnki.jccs.2021.1987 (2023).

Yin, Q. et al. Experimental study on mechanical properties and anchorage performances of rock mass in the fault fracture zone. Int. J. Geomech. 18, 04018067. https://doi.org/10.1061/(ASCE)GM.1943-5622.0001187 (2018).

Zhou, Z. L. et al. Investigating crack evolution, and failure precursor warning in sandstones with different water contents from the perspective of tensile-shear crack separation. Eng. Fail. Anal. 167, 108997. https://doi.org/10.1016/j.engfailanal.2024.108997 (2025).

Ma, G. et al. Experimental study on acoustic emission and surface morphology characteristics of concrete under different fracture modes. Theor. Appl. Fract. Mech. 123, 103702. https://doi.org/10.1016/j.tafmec.2022.103702 (2023).

Ohno, K. & Ohtsu, M. Crack classification in concrete based on acoustic emission. Constr. Build. Mater. 24, 2339–2346. https://doi.org/10.1016/j.conbuildmat.2010.05.004 (2010).

Ding, S. X. et al. A new method for identifying the initiation and propagation of tensile and shear cracks of rock samples based on acoustic emission energy. Environ. Earth Sci. 84, 328. https://doi.org/10.1007/s12665-025-12234-z (2025).

Radon, J. C. & Pollock, A. A. Acoustic emissions and energy transfer during crack propagation. Eng. Fract. Mech. 4, 295–310. https://doi.org/10.1016/0013-7944(72)90043-4 (1972).

Zeng, Z. W. et al. Characteristics and implications of acoustic emission energy in the process of deformation and failure of single-joint Rockmass. Seismol. Geol. 16, 71–77. https://doi.org/CNKI:SUN:DZDZ.0.1994-01-011 (1994).

Cai, M. Influence of intermediate principal stress on rock fracturing and strength near excavation boundaries—Insight from numerical modeling. Int. J. Rock. Mech. Min. Sci. 45, 763–772. https://doi.org/10.1016/j.ijrmms.2007.07.026 (2008).

Zhang, W., Guo, W. Y. & Wang, Z. Q. Influence of lateral pressure on mechanical behavior of different rock types under biaxial compression. J. Cent. South. Univ. 29, 3695–3705. https://doi.org/10.1007/s11771-022-5196-1 (2022).

Wang, X. M. et al. Research on meso-scale deformation and failure mechanism of fractured rock mass subject to biaxial compression. Arab. J. Geosci. 14, 1390. https://doi.org/10.1007/s12517-021-07769-x (2021).

Arora, S. & Mishra, B. Investigation of the failure mode of shale rocks in biaxial and triaxial compression tests. Int. J. Rock. Mech. Min. Sci. 79, 109–123. https://doi.org/10.1016/j.ijrmms.2015.08.014 (2015).

Luo, P. K. et al. Experimental investigation on biaxial mechanical properties of laminated rock and floor heave mechanism of tunnel based on DIC. Eng. Fail. Anal. 156, 107848. https://doi.org/10.1016/j.engfailanal.2023.107848 (2024).

Wei, S. J. & Li, B. F. Anchor bolt body formation and instability mode under the influence of anchoring pretension. J. Chin. Coal Soc. 38, 2126–2132. https://doi.org/10.13225/j.cnki.jccs.2013.12.018 (2013).

Pellet, F. & Egger, P. Analytical model for the mechanical behaviour of bolted rock joints subjected to shearing. Rock. Mech. Rock. Eng. 29, 73–97. https://doi.org/10.1007/BF01079755 (1996).

Singh, P. & Spearing, A. J. S. An improved analytical model for the elastic and plastic Strain-hardening shear behaviour of fully grouted rockbolts. Rock. Mech. Rock. Eng. 54, 3909–3925. https://doi.org/10.1007/s00603-021-02439-6 (2021).

Zheng, L. B. et al. Analytical model of the shear behaviors of bolted rough joints based on the dilation effect and surface abrasion. Eng. Geol. 294, 106399. https://doi.org/10.1016/j.enggeo.2021.106399 (2021).

Ding, S. X. et al. Stress evolution and support mechanism of a bolt anchored in a rock mass with a weak interlayer. Int. J. Min. Sci. Technol. 27, 573–580. https://doi.org/10.1016/j.ijmst.2017.03.024 (2017).

Singh, M., Raj, A. & Singh, B. Modified Mohr–Coulomb criterion for non-linear triaxial and polyaxial strength of intact rocks. Int. J. Rock. Mech. Min. Sci. 48, 546–555. https://doi.org/10.1016/j.ijrmms.2011.02.004 (2011).

Funding

This work was supported by the financial support of the National Natural Science Foundation of China (No. 51974106), the Doctor Foundation of Henan Polytechnic University (B2019-35), the Fundamental Research Funds for the Universities of Henan Province (NSFRF230410), the Science and Technology Project of Henan Province (242102321165) and the Science and Technology Project of Jiaozuo City (2023210039, 2024210100).

Author information

Authors and Affiliations

Contributions

Hua Nan: Writing – review & editing, Methodology, Funding acquisition, Supervision, Con-ceptualization, Investigation. Jing Qiao: Writing – original draft, review & editing, Supervision, In-vestigation, Conceptualization. Shuxue Ding: Writing - review & editing, Methodology, Funding ac-quisition, Supervision. Yibo Chen: Writing - original draft, Visualization, literature organization. Peilin Jiang: Writing - original draft, Data curation, Visualization, Validation. Sijiang Wei: Writing - review & ed-iting, Methodology, Supervision.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Nan, H., Qiao, J., Ding, S. et al. Strength, deformation and macro and micro-failure performances of the bolted samples under biaxial compression. Sci Rep 15, 36553 (2025). https://doi.org/10.1038/s41598-025-19667-3

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-19667-3