Abstract

To address the issues of low coupling accuracy and poor adaptability to time-varying boundaries in traditional transformer thermal analysis, an electric-magnetic-flow-thermal multi-field coupling simulation model was constructed for the S11-M-630/10 oil-immersed transformer. This model covers electromagnetic fields, eddy current losses, oil-solid heat conduction, and natural convection characteristics. The discrete-velocity lattice Boltzmann method (DDF-LBM) based on dual distribution functions was introduced to achieve efficient decoupling and solution of the non-steady thermal flow field. Combined with nonlinear temperature-dependent material properties and typical daily cycle boundary conditions, the dynamic evolution mechanism of the hotspot temperature rise of the winding was systematically characterized. The model was verified by measured temperature rise data, with an error control within 4.1%. It has good engineering adaptability. On this basis, hotspot response simulations under different load rates, operating times, and seasonal temperature fields were carried out. The results show that there is a significant synergistic amplification effect between load rate and ambient temperature on the hotspot temperature rise. Especially in the summer high-temperature and heavy-load conditions, the hotspot temperature can exceed 116 °C, and the local winding temperature gradient reaches 8.4 °C. The insulation life shows an exponential decay trend. The research results provide theoretical basis and technical support for the thermal management optimization and operational safety of oil-immersed transformers in the context of high penetration of new energy.

Similar content being viewed by others

Introduction

Transformers, as the core equipment of the power system, will cause significant impacts on social and economic life if they malfunction1. Overheating failure is one of the main types of transformer failures. If it is not detected in time at the early stage of the failure, the overheating failure will greatly accelerate the aging process of the insulation materials, thereby leading to the further development of the failure2. Therefore, timely and accurate identification of the transformer’s condition in the early stage of the failure is particularly important for promptly curbing the further development of the failure, avoiding the threat to the safe operation of the power grid, and reducing the harm to the social economy3,4.

In recent years, the phenomenon of significant fluctuations in transformer load has become increasingly prominent. As the load rate changes, the temperature of the transformer will fluctuate within a certain range. The dynamic information of the hot spot temperature of the transformer winding can promptly reflect the operating condition of the transformer and is an important basis for evaluating its load capacity and service life5,6. Therefore, conducting research on the dynamic temperature rise characteristics of transformer winding hot spots is of great significance for improving the operation control level of transformers.

Scholars such as ShuaiBing Li summarized the evaluation methods of transformer load capacity and the strategies for predicting and dynamically increasing the load capacity of transformers7; Ildar Daminov et al. evaluated the load capacity of transformers by considering the hot spot temperature and top layer temperature in addition to current and environmental temperature, and obtained the safe operating duration under different conditions8. Some scholars have also studied the dynamic load of transformers and proposed the impact of thermal aging on the lifespan of transformers and provided calculation methods9,10.

However, with the proposal of the concept of digital operation and maintenance of power transformers and Dynamic Thermal Rating (DTR) assessment, the rapid calculation of multiple physical fields of transformers has become a research hotspot11, especially the rapid calculation of the coupled model of heat and fluid fields is more important12. The Lattice Boltzmann Method (LBM), as an explicit numerical solution algorithm, has a natural advantage in solving the internal temperature field of transformers. In recent years, with the development of LBM, some scholars have applied LBM to heat transfer research and simulated the fluid characteristics and their influencing factors under different models13,14,15,16,17. Ali Tiftikci et al. used the D3Q27 lattice calculation model of Lattice Boltzmann to study the influence of different particle filling diameters on the temperature field and obtained the real-time temperature field under different radii18.

This paper takes the typical S11-M-630/10 oil-immersed transformer for power distribution as the research object. Centering on the problem of predicting the temperature rise of hot spots in the dynamic load environment, a three-dimensional coupling model integrating the multiphysical fields of electricity, magnetism, flow and heat is constructed, and the dynamic evolution characteristics of the transformer hot spots under steady-state, transitional state and seasonal temperature disturbance conditions are systematically analyzed. The coupling influence of operation duration and environmental field temperature on thermal stability was quantified for the first time, and the corresponding dynamic evaluation model of load capacity was constructed. The research results provide a theoretical basis and technical path for enhancing the operational safety and thermal management efficiency of oil-immersed transformers under the background of a high proportion of new energy integration.

Coupling modeling of electro-magnetic-fluid-thermal multi-physical fields for oil-immersed transformers

Transformer equivalent model and parameters

Taking the S11-M-630/10 oil-immersed transformer as the object, the physical architecture of its model is shown in Fig. 1. When constructing the three-dimensional simulation model of the transformer, the core, windings, insulating paper, end insulation, core sleeves, etc. are mainly considered, while the lifting rings, high-voltage connecting rods, struts, and clamps are ignored. The three-dimensional equivalent model is shown in Fig. 2, and the three-dimensional internal structure model is shown in Fig. 319. Among them, the low-voltage winding adopts foil winding, with a total of four turns and 16 turns from the inside out. The high-voltage winding is made of flat copper wire wound into a cylindrical coil, with a total of three turns and 638 turns from the inside out. Table 1 shows the main electrical parameters of the transformer, and Table 2 presents the material parameters of each component. As a fluid material, the nonlinear characteristic expression of the performance parameters of insulating oil is shown in Table 320. Although literature commonly adopts a value of 7650 kg/m³ for silicon steel, the present study uses 7500 kg/m³ based on manufacturer provided data for the specific transformer model.

Multi-physics field coupling mechanism and numerical model construction

In this study, the term eddy current losses specifically denotes the electromagnetic losses occurring within the transformer core, induced by time-varying magnetic flux penetrating the laminated steel sheets. These losses are distinct from eddy currents potentially induced in the winding conductors, which are addressed separately in the modeling of winding losses.

Consistent with established transformer loss decomposition methodologies, the core losses considered in this work are comprised of three primary components:

Hysteresis losses, arising from magnetic domain friction during cyclic magnetization;

Eddy current losses, resulting from induced circulating currents in the core laminations; and.

Excess losses (also known as anomalous losses), which account for additional dynamic effects such as domain wall motion.

For the purposes of both analytical modeling and thermal characterization, these three components are collectively referred to as core losses throughout the manuscript. This classification follows widely accepted conventions in electromagnetic and thermal modeling of power transformers20.

In the form, p0 is the iron core loss, the unit is W; Ph is the magnetic lag loss, the unit is W; Pe is the vortex loss of the core, the unit is W;C1 is the coefficient of hysteresis loss; V is the iron core volume, the unit is m3; f is the load current frequency, the unit is Hz; Bmax is the maximum magnetic induction intensity, the unit is T; ƞ is the Steinmetz coefficient, which characterizes the non-linear relationship between magnetic flux density and core loss. The value n = 1.6 is selected in accordance with literature values for non-oriented silicon steel, a material commonly used in transformer cores21. This value reflects typical loss behavior under industrial operating conditions. C2 is the eddy current loss coefficient; a is the thickness of silicon steel and the unit is m. Eddy current loss expressions are as follows:

In the formula, PW represents the total eddy current loss of the winding, with the unit of W. PFi is the radial eddy current loss of the winding, with the unit of W. Pzi represents the axial eddy current loss of the winding, with the unit of W. d represents the width of the wire turn, h represents the thickness of the wire turn, and Ri represents the distance from the i-th coil unit to the axis of the core column, with the unit being meters. γ represents electrical conductivity, with the unit of S/m. ω represents angular frequency, with the unit of rad/s; Bhi and Bri are represent the axial leakage flux and longitudinal leakage flux of the i-th coil unit, with the unit being T.

In addition, during actual operation, the transformer will also generate winding losses, which satisfy the full current formula of Maxwell’s equations. By introducing the vector magnetic potential A, the distribution of the magnetic field magnitude of the transformer winding under the working current is studied. The magnetic field control equation is shown in (7).

In the formula, um represents the magnetic permeability of the medium, with the unit of H/m; Js represents the ampere-turn current density of each wire turn, with the unit of A/m ². D is the electric displacement vector, with the unit of C/m ².

When an oil-immersed transformer is in operation, heat is mainly transferred in the forms of heat conduction, heat convection and heat radiation, as shown in Fig. 3. Heat is generated by the windings, transferred via conduction and natural convection through the core and oil, and dissipated to the ambient air through the tank and radiators by conduction, convection, and radiation.

The main control equation for heat transfer in the winding area is shown in Eq. (8). The non-isothermal flow process of fluids follows the mass conservation equation, momentum conservation equation and energy conservation equation, and satisfies the constraints of the Navier-Stokes equation (N-S), as shown in Eq. (8) to (13):

In the formula, km represents the thermal conductivity coefficient, with the unit of W/(m·K). Q represents the heat flow rate, with the unit being W. u is the velocity vector, with the unit of m/s; p represents fluid pressure, with the unit of N. ρ represents the density of the fluid, with the unit of kg/m³. τ represents viscous force, with the unit of kg/(m·s). c represents specific heat capacity, with the unit of J/(kg·K). T is the temperature scalar value of the transformer, with the unit of K. F is the external force acting on the fluid micro-element, with the unit being N.

Multi-field coupling solution process based on lattice Boltzmann

Lattice Boltzmann equation (LBE) solution process

The LBM solution process mainly includes three steps: Lattice domain discretization, Lattice Boltzmann Equations (LBEs) solution, and macroscopic physical field transformation, as shown in Fig. 417.

D2Q9 lattice Boltzmann model

The discretization of the lattice domain is an important step in achieving LBM solution. In the lattice domain, the basic solution unit can be represented by DxQy, where x represents the dimension and y represents the migration direction of the lattice. In two-dimensional model calculations, the D2Q9 model (two-dimensional with 9 velocity direction components) can better ensure macroscopic isotropy22.

The lattice velocity vectors ci are as follows:

In the formula, c represents the unit length of the grid velocity, θi is the direction Angle, and i is the direction of velocity.

Lattice Boltzmann formulation for fluid flow and heat transfer

Based on the simplified double distribution function model (DDF) in reference 23, this paper adopts the single relaxation time format and introduces the external force term to construct the lattice Boltzmann equations (LBEs) for flow and heat transfer respectively, and solves the momentum and energy distribution functions fi(x, t) and gi(x, t) at the mesoscale.

In the formula, Δt represents the lattice time step, and ωf and ωg are the fluid relaxation factor and the thermal relaxation factor, respectively. \({f_i}^{{eq}}(x,t)\) and \({g_i}^{{eq}}(x,t)\) are the equilibrium distribution functions of the flow velocity field and the temperature field respectively; F is the external force term acting on the particle, which is calculated using the Boussinesq approximation, as shown in the following formula:

In the formula, ρ represents the density of insulating oil; gy is the gravitational acceleration along the -y direction; β is the coefficient of thermal expansion; Th and Tc are respectively the temperatures of the solid boundary (hot wall) and the shell (cold wall), and cy is the velocity component along the -y direction,ωi represents angular frequency.

The calculation formulas for the relaxation time of the velocity field and the temperature field are:

In the formula, v represents the kinematic viscosity; a represents the rate of thermal diffusion; cs represents the lattice sound velocity. For the D2Q9 model in this paper, its cs2=c2/324.

The equilibrium momentum and heat distribution function is:

In the formula,u is the flow rate of the macroscopic insulating oil fluid; wi represents the weights in each direction under the D2Q9 lattice.

The density, fluid velocity and temperature of the macroscopic insulation oil are calculated by the momentum and thermal balance function of different lattice.

In LBM simulation calculations, the more grids there are, the more accurate the results will be, but the calculation cost and resource occupation will also increase significantly. By conducting grid independence tests, the final number of grids was selected as 1250 × 420 for LBM modeling simulation.

Source term modeling and thermal field solution

To achieve multi-physical field coupling, the simulation incorporates core magnetic loss, eddy current losses of each coil, and the iterative coupling of fluid flow, energy, and conduction equations. The iterative process continues until the temperature variation between two consecutive steps falls below 0.01 K, ensuring convergence. The final result provides the detailed temperature distribution of the transformer.

The multi-field coupling process—including electromagnetic, flow, and thermal domains—is illustrated in the flow chart shown in Fig. 5.

Model validity verification

To verify the validity of the simulation model, the room temperature during the experiment was maintained between 25 ℃ and 28 ℃. Thermocouples are buried at the hot spots of the B-phase high-voltage winding (T1), B-phase low-voltage winding (T2), A-phase high-voltage winding (T3), and A-phase low-voltage winding (T4) of the transformer, and the real-time temperature rise data is recorded. The criteria for thermal steady-state determination in the experiment follow the guidelines of IEC 60076-2:2011 for oil-immersed power transformers. Specifically, steady-state is considered achieved when the temperature rise of the transformer windings does not exceed 1 K over a 1-hour interval.

The temperature measurements were conducted using PT100 platinum resistance sensors (accuracy class A, IEC 60751), with a measurement range of −50 °C to 250 °C and an uncertainty of ± 0.3 °C.A multi-channel temperature acquisition system (Model: Yokogawa MW100) was used for continuous monitoring, with a sampling interval of 10 s and a resolution of 0.1 °C.

Temperature sensors were installed at key positions on the transformer, including the high-voltage winding, low-voltage winding, core surface, and oil top layer. The installation was performed manually by the research team prior to the test. A schematic diagram of the sensor placement is provided in Fig. 6.

Tables 4 and 5 respectively present the comparison of errors between the measured temperature values and the simulated calculated values at each temperature measurement point when the load rates are 40% and 100%. The calculation of the error percentage is as follows.

In the formula, \({\delta _1}\)the percentage of the error of the simulation calculation is calculated. Tsimu is the simulation temperature, the unit is ℃; Ttest temperature is the test temperature.

The simulation and measured temperature rise data show a high degree of consistency under the two load rate conditions, verifying the accuracy and robustness of the constructed electro-magnetic-fluid-thermal coupling model. At a 40% load rate, the maximum error at point T₁ is 4.08%, and the errors at the other points are 1.41%, 1.28%, and 0.58% respectively. All relative errors presented in Tables 4 and 5 are within 5%, which is considered acceptable according to IEC 60076-7 (thermal performance evaluation of liquid-immersed transformers). In contrast, the errors of each measurement point at 100% load rate were 2.73%, 1.60%, 1.34% and 0.51% respectively, demonstrating better accuracy and consistency. This indicates that under high-power conditions, the LBM thermal flow field coupling mechanism constructed by the model can more effectively capture the characteristics of non-steady-state thermal convection. The minimum error always occurs at the T₂ point, indicating that the flow field and thermal field changes in this area are stable and the model response is sufficient. The maximum error mostly occurs at points T₁ and T₃, which may be caused by the setting of boundary conditions or insufficient local grid density.

Additionally, In Table 4, a temperature asymmetry is observed between the high-voltage (T1) and low-voltage (T2) windings, where T1 is generally higher than T2. Notably, an exception is found in coil A, where T2 exceeds T1. This localized inversion may result from non-uniform coolant distribution, geometric placement of the windings relative to the oil flow, or localized variations in current density.

Conversely, Table 5 demonstrates a more uniform thermal profile, with no evident inversion between T1 and T2. This consistency suggests that the second experimental configuration may have benefited from more stable thermal boundary conditions, improved convective heat transfer, or reduced ambient interference. The discrepancy between Tables 4 and 5 underscores the influence of ambient conditions, sensor positioning, and cooling dynamics, and highlights the necessity of maintaining controlled environmental parameters when interpreting transformer thermal behavior.

Analysis of dynamic response characteristics of multi-parameter hot spot temperature rise in transformers

To enhance the load adaptability and thermal safety of transformers under actual operating conditions, this paper further conducts operation evaluation and analysis based on different load rates and ambient temperature conditions. Under the premise that the temperature rise does not exceed its allowable threshold, the evaluation index of insulation life loss is introduced simultaneously to more comprehensively describe the operating limit of the transformer under the thermally life coupling constraint condition. This analytical framework is based on the thermally lifetime degradation model proposed in reference [25] as a key criterion for operational safety.

In the equation, K is the load factor; t is the operating time of the transformer; θtop,1 is the top-oil temperature of the transformer; θhs,1 is the hotspot temperature of the transformer; K₁ is the per-unit loss of auxiliary equipment such as bushings and sleeves; T is the operating cycle of the transformer; L₁ is the loss of life value.

According to the Transformer guidelines25, the relative life loss of a transformer using heat-modified insulating paper within one cycle is as follows.

Steady-state load capacity assessment

Under the condition of a constant ambient temperature of 25 ℃, numerical simulation of the transformer operating state under different load factor conditions was conducted in this paper, with a focus on evaluating key indicators such as the top layer oil temperature, winding hot spot temperature and relative insulation life loss. The summary results of the maximum hot spot temperature, top layer oil temperature and relative life loss corresponding to each load factor are shown in Table 6.

Within the load rate range of 50% to 120%, the oil temperature at the top layer of the transformer, the hot spot temperature of the winding, and the insulation life loss all show a typical nonlinear upward trend, demonstrating excellent thermo-life response coupling characteristics. As the load rate increases from 50% to 120%, the top layer oil temperature rises from approximately 53 ℃ to 87.8 ℃, an increase of approximately 65%. The hot spot temperature at point T1 rose from 85.0 ℃ to 116.2 ℃, an increase of approximately 31.2 ℃. The relative life loss rapidly increased from 0.015 to 0.854, an increase of more than 55 times, demonstrating the high sensitivity of the insulation system to temperature changes.

A horizontal comparison of the hot spot temperatures at each temperature measurement point shows that T1 (high-voltage B phase) is always the highest temperature point, while other points such as T2 (low-voltage B phase), T3 (high-voltage A phase), and T4 (low-voltage A phase) maintain a certain temperature difference throughout the full load range, indicating that the winding structure has a significant impact on local heat accumulation. Especially at 100% load rate, the maximum temperature difference between T1 and T4 reaches approximately 8.4 ℃, further indicating the thermal asymmetry between different winding phases and electrical structures.

The relative life loss curve shows a typical exponential growth feature, especially after the load rate exceeds 100%, the growth rate significantly accelerates, reflecting the significant promotion of the insulation aging acceleration effect caused by the increase in hot spot temperature. This is consistent with the prediction results of the Arrhenius lifetime model, indicating that the constructed thermally lifetime coupled simulation model has good trend consistency and physical rationality.

In conclusion, the simulation results not only quantitatively reveal the influence law of load rate on key thermal parameters and insulation life, but also provide a reliable data basis and response boundary judgment for subsequent load optimization and thermal control strategies.

The influence of continuous operation time on hot spot evolution and thermal stability

During the operation of the power grid, the windings of power transformers are constantly under different load conditions, and the changes in the temperature of the internal hot spots directly affect the service life of the equipment and operational safety. The temperature rise of hotspots is not only affected by the load rate, but also continuously accumulates heat over time. This simulation adopts a multivariable thermodynamic modeling approach to analyze the hot spot temperature rise variation trends of the low-voltage winding and the high-voltage winding under different times and load rates, revealing their thermal response characteristics.

The simulation results show that the hot spot temperature rise of the low-voltage winding and the high-voltage winding exhibits significant differences under different load rates and operating times. The high-voltage winding is more sensitive to changes in load rate. The transformer temperature increases steeply under load conditions, indicating intensified thermal stress during high-power operation. Especially under long-term operation conditions, the temperature rise rapidly approaches the limit value, indicating that the high-voltage winding has stronger thermal responsiveness and lower thermal capacity margin. For the low-voltage winding, the temperature rise shows a relatively stable growth trend as the load rate increases, and the surface change is relatively slow, indicating that its thermal response to load changes has a certain lag and thermal stability. However, under continuous high-load conditions, the temperature at the hot spot still has a cumulative rise, posing a potential risk of overheating.

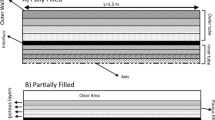

Analysis of the impact of ambient temperature field on the load capacity of Transformers

Considering that the heat exchange performance of transformers is significantly affected by fluctuations in ambient temperature during actual operation, this paper selects the daytime temperature variation curves of typical summer and winter as the input conditions for ambient temperature (as shown in Fig. 9). Based on this, a model was constructed to simulate the temperature rise response of the transformer from 6 a.m. to 6 p.m. Combined with different load coefficients, dynamic simulation analysis of hot spot temperature rise was carried out to reveal the coupled influence of load and environmental factors on its thermal behavior.

Figures 10 and 11 illustrate that the temperature response of the low-voltage winding, particularly at the monitored locations, exhibits significant variation with time and load ratio due to seasonal effects. It should be noted that although the temperature measurements were obtained from the low-voltage winding for practical installation reasons, the true thermal hotspot typically occurs in the high-voltage winding. As such, the analysis herein reflects a relative thermal trend rather than an absolute hotspot temperature.

Under elevated ambient temperatures during summer, the overall winding temperature rise is markedly greater than in winter. Specifically, during periods of high load (80%–100%) and peak ambient conditions (12:00–16:00), the temperature exhibits a nonlinear and accelerated increase, with peak values exceeding 65 °C. This trend approaches critical thermal thresholds and suggests a heightened risk of thermal accumulation. In contrast, during winter, the cooler ambient air facilitates improved heat dissipation. At identical load conditions, the measured temperature in the low-voltage winding is approximately 15–20 °C lower than in summer.

Furthermore, the temperature gradient becomes steeper with increasing load ratio. This observation confirms the amplifying effect of load disturbance on winding thermal response, with summer conditions exhibiting significantly higher sensitivity due to reduced thermal margins. These findings underscore the regulatory role of ambient temperature in thermal field evolution, as well as the importance of environmental adaptation in dynamic load management of transformers.

Conclusion

This study develops an electro-magnetic-fluid-thermal coupling model to address the limitations of traditional thermal analysis in oil-immersed transformers operating under dynamic conditions. By integrating multi-physics interactions and real-time ambient temperature profiles, the model enables accurate prediction of hotspot evolution across different load levels and seasonal variations.

Key findings reveal that the hotspot temperature increases nonlinearly with load rate, and under high-load summer conditions, it rapidly approaches thermal limits, posing risks of accelerated insulation degradation. The high-voltage winding exhibits steeper gradients and lower thermal margins, confirming it as the primary risk region for thermal runaway. Due to experimental constraints, measurements were taken from the low-voltage winding, and the reported 15–20 °C seasonal difference corresponds to that region only. Nevertheless, the thermal trends and coupling effects remain valid.

Notably, the model captures the compound interaction between operational time, ambient temperature, and load stress, revealing that thermal accumulation leads to exponential insulation aging beyond 100% load. These insights provide a physics-informed foundation for real-time thermal risk evaluation, offering technical support for life prediction and intelligent cooling control in power transformers exposed to increasingly variable grid environments.

This study is limited by partial sensor coverage and simplified material assumptions. Future work will focus on incorporating insulation aging effects and real-time monitoring to enhance model accuracy and support intelligent thermal management.

Data availability

All data generated or analysed during this study are included in this published article.

Change history

29 January 2026

A Correction to this paper has been published: https://doi.org/10.1038/s41598-026-37482-2

References

Farfan, C. A. et al. Assessing consequences of the final failure of a power transformer using fuzzy logic and expert criteria. In 2018 IEEE Canadian Conference on Electrical & Computer Engineering (CCECE), 1–6 (2018).

Przybylek, P. & Gielniak, J. Analysis of gas generated in mineral oil, synthetic ester, and natural ester as a consequence of thermal faults[J]. IEEE Access. 7, 65040–65051 (2019).

Gao, Y. & Wang, J. Analysis and prospect of power transformer fault diagnosis technology. In Ninth International Conference on Energy Materials and Electrical Engineering (ICEMEE 2023). 12979, 1283–1291. (SPIE, 2024).

Cao, H. et al. Advancement in transformer fault diagnosis technology[J]. Front. Energy Res. 12, 1437614 (2024).

LI, H. et al. Test and analysis on extended temperature rise of 110 kV transformer based on distributed temperature Sensing[J]. IEEE Trans. Power Delivery. 38 (2), 1030–1041 (2023).

Rodrigues, T. F. et al. Evaluation of power transformer thermal performance and optical sensor positioning using CFD simulations and temperature rise test. IEEE Trans. Instrum. Meas. 72, 1–11 (2023).

Li Shuaibing, L. et al. Load capability assessment and enhancement for Transformers with integration of large-scale renewable energy: a brief review[J]. Front. Energy Res. 10, 1002973 (2022).

Daminov, I. et al. Assessment of dynamic transformer rating, considering current and temperature limitations[J]. Int. J. Electr. Power Energy Syst. 129, 106886 (2021).

Alvarez, D. L., Rivera, S. R. & Mombello, E. E. Transformer thermal capacity Estimation and prediction using dynamic rating monitoring[J]. IEEE Trans. Power Delivery. 34 (4), 1695–1705 (2019).

Zhang Chen, D. et al. Dynamic thermal rating assessment of oil-immersed power Transformers for multiple operating conditions[J]. High. Voltage. 9 (1), 195–205 (2024).

Liu Gang, H. et al. Research on rapid calculation method of transient temperature rise of winding of dynamic mode decomposition-adaptive time stepping oil-immersed power transformer[J]. Trans. China Electrotechnical Soc. 39 (12), 3895–3906 (2024).

Yunpeng, L. et al. Digital twin conception of intelligent operation and maintenance of power transformer. Proc. CSEE 43 (22), 8636–8652 (2023).

Nazarafkan, H. et al. Numerical study of natural convection of nanofluid in a semi-circular cavity with lattice Boltzmann method[J]. Int. J. Numer. Methods Heat. Fluid Flow. 30 (5), 2625–2637 (2020).

Hasani Malekshah, E. & Kolsi, L. Local/volumetric entropy production analysis of natural convective flow using lattice Boltzmann method for heat exchanger application[J]. Int. J. Numer. Methods Heat. Fluid Flow. 34 (2), 520–538 (2024).

Shruti, B. et al. LBM study of natural convection heat transfer from a porous cylinder in an enclosure[J]. Theoret. Comput. Fluid Dyn. 36 (6), 943–967 (2022).

Sobhani, M. & Ajam, H. Taguchi optimization for natural convection heat transfer of Al2O3 nanofluid in a partially heated cavity using LBM[J]. J. Therm. Anal. Calorim. 138 (2), 889–904 (2019).

Chelia, W. et al. Investigation of nanofluid natural convection inside a square cavity for two orientations using lattice Boltzmann method[J]. J. Nanofluids. 12 (4), 889–903 (2023).

Tiftikci, A. et al. Investigation of natural convection heat transfer of self-heating packed beds[J]. Int. Commun. Heat Mass Transfer. 142, 106642 (2023).

Fa, Y. Zhang is the month of Quanbo, etc., based on the oil immersion transformer magnetic field - flow field - temperature field simulation calculation and hot temperature inversion prediction of the porous medium. High Volt. Technol. 202551 (011), 62–74.

Jixiang, W. et al. Research on dynamic temperature rise evolution law and deduction calculation model of winding hotspots in Oil-immersed Transformers [J/OL] high voltage technology, 1–13. https://doi.org/10.13336/j.1003-6520.hve.20241108

Bertotti, G. Hysteresis in Magnetism: for Physicists, Materials Scientists, and Engineers (Academic, 1998).

Mohamad, A. A. Lattice Boltzmann Method (Springer, 2011).

Yu Wenxu, Guan Xiangyu, Zhao Junyi, et al. Transient Temperature Rise Simulation and Load Capacity Evaluation of Oil-immersed Transformer Based on Lattice Boltzmann Method [J]. Transactions of the Chinese Society for Electrical Engineering, 40 (10), 3315–3325. https://doi.org/10.19595/j.cnki.1000-6753.tces.240772 (2025).

Dong Xuzhu, Z. et al. Research and practices of dynamic thermal rating for oil-immersed power transformer[J]. High. Voltage Eng. 47 (6), 1959–1968 (2021).

General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China, Standardization Administration of China Power transformers - Part 7: Load guidelines for Oil-immersed power transformers: GB/T 1094.7–2008 (China Standards, 2009).

Acknowledgements

Special thanks the Science and Technology Project of China Southern Power Grid Company (YNKJXM20240361). are hereby expressed.

Funding

No funding.

Author information

Authors and Affiliations

Contributions

He Zhu conceived and supervised the project, led the methodology development, and was responsible for data analysis and manuscript writing. Ren Xiaohang, Yu Guobo, Yi Chunlei, and Bai Xiaoqian contributed to data collection, experimental support, and manuscript review. All authors have read and approved the final manuscript.Corresponding Email:18387510392@163.com.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Additional Information

The original online version of this Article was revised: The original version of this Article contained errors in the Main text and Reference list of the paper. Full information regarding the corrections made can be found in the correction for this Article.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Zhu, H., Xiaohang, R., Guobo, Y. et al. Research on multi-physical field coupling modeling and multi-condition dynamic load capacity evaluation of oil-immersed transformers. Sci Rep 15, 36714 (2025). https://doi.org/10.1038/s41598-025-20747-7

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-20747-7