Abstract

This in vitro study presents new comparative results for titanium alloy (Ti6Al4V) and cobalt–chromium alloy (Co–Cr) used in removable dental prostheses, including the 3-point bending test and microhardness. For the 3-point bending test, two groups of specimens were designated as group Ti6Al4V and group Co-Cr. For each group, 10 specimens with dimensions of 0.5 × 3 × 25 mm according to ISO 9693-1 were prepared. The Micro-Vickers hardness was measured for 6 specimens of each alloy, with a cylindrical shape (approximately 10 mm in diameter and 3 mm in height). Specimens were prepared with a selective laser melting system for selective laser melting alloys. Different grading of silicon carbide (SiC) papers was used to polish the prepared samples. The surface contaminants were cleaned ultrasonically with acetone and deionized water for at least 10 min. Data were analyzed using Welsh and Mann-Whitney U tests (α = 0.05). No difference in stress values was detected between groups (P = 0.087). However, Ti6Al4V showed higher strain lower modulus of elasticity, and lower microhardness (P < 0.05).

Similar content being viewed by others

Introduction

Removable prostheses are still widely used, which calls for attention to be developed and made more accurate, lighter, better in retention, stability and support, provide a good level of comfort for the patient, have a socially acceptable appearance, and have a reasonable cost1. Metal frames form the basis of which removable dentures are made, so the dentist must take into account the way the metal frame is prepared and the type of metal used as they affect the quality and effectiveness of the denture1.

There are several methods for making metal structures, including the traditional casting method or what is known as the Lost Wax Technique, which was one of the first methods developed2. However, it is fraught with problems and difficulties, as it is not able to produce complex prostheses in an ideal shape, and there is difficulty in the casting of metal alloys due to oxidation and high melting point2.

In addition to this, changes occur in the dimensions of the metal structures as a result of thermal contraction during cooling, and the finishing and polishing procedures are more complex and take more time2. The casting process includes successive stages that prevent obtaining the necessary accuracy, and lead to the appearance of defects such as porosity, warping, and defective edges2.

In contrast, other modern methods that work according to the computer-aided design and manufacturing system (CAD-CAM) have seen great advancement. For example, the selective laser melting method (SLM) has proven successful and highly efficient2. Moreover, it enjoys high speed and has the ability to produce complex-shaped structures with unique mechanical properties superior to its traditional counterpart3. Additive manufacturing (AM) has changed the way medical implants are made in recent years by making it possible to create parts that are very specific to each patient. With the layer-by-layer building method, it’s easier to get complex internal shapes, better mechanical performance, and better surface properties than with traditional methods. AM technologies, like SLM, are being used more and more not just in dentistry but also in the production of orthopaedic, cardiovascular, and maxillofacial implants. This shows that they have a lot of potential to improve clinical outcomes and treatments that are tailored to each patient4.

SLM is an additive manufacturing technology that uses a high-power laser beam to melt certain areas of a powder bed and build metal parts layer by layer. This process makes it possible to make parts that are very complex in shape, work very well mechanically, and waste very little material. The method has been used more and more in dentistry and biomedicine because it is accurate and can be used on complicated anatomical shapes5,6.

As for alloys, cobalt chromium is one of the most common for fixed and removable dental prostheses7. On the other hand, titanium and its alloys are commonly used in maxillofacial prostheses and implants8. Titanium is the most common alloy used in the medical fields within the body’s hard and soft tissues8. However, it is still less common in dental applications such as crown structures, bridges, and removable dental appliances9.

It is also known that titanium has a very light atomic weight equivalent to half the weight of other non-precious metals, including cobalt chromium10, which is vital for structures that cover the entire palate or for those prostheses where we need to overcome the effect of gravity1. In addition, it has high flexibility that allows clasps to be placed in deeper retention areas than those recommended for cobalt-chromium clasps, thus, achieving a better cosmetic aspect and periodontal health11, and it may be an alternative for patients who are sensitive to cobalt chromium12.

Therefore, these advantages warrant expanding the scope of the use of titanium in the field of dentistry and giving it more research and attention. This research aims to conduct a comparative laboratory study between the titanium alloy (Ti6Al4V) and the cobalt chrome alloy (Co-Cr) used in the structures of removable dental appliances and prepared by the selective laser melting method (SLM), focusing on two mechanical properties:

-

1.

3-point Bending Test.

-

2.

Microhardness.

Results

This section presents the results of the three-point bending and microhardness tests conducted on the Ti6Al4V and Co-Cr specimens. The mechanical behavior of the two alloys was evaluated and compared based on stress, strain, modulus of elasticity, and surface microhardness.

3-Point bending test

Stress

The stress averages (in MPa) were calculated for each of the research groups Fig. 1, then other statistical variables were calculated and organized in Table 1.

Mann-Whitney U test did not show significant differences in the mean ranks of the two groups P = 0.087.(95% CI = [0, 1500], rrb = 0.45).

Strain

The strain averages were calculated for each of the research groups Fig. 2, then other statistical variables were calculated and organized in Table 2.

Welch’s t-test (Levene’s Test p = 0.009) showed a significant difference in the mean values of the two groups P = 0.026. (95% CI = [0.031, 0.4], cohen’s d = 1.164).

Modulus of elasticity (Young’s modulus)

The elastic modulus means (in GPa) were calculated for each of the research groups Fig. 3, then other statistical variables were calculated and organized in Table 3.

Welch’s t-test (Levene’s Test p = 0.007) showed a significant difference in the mean values of the two groups P < 0.001.(95% CI = [46.169, 101.595], cohen’s d = 2.66).

Microhardness

The microhardness means were calculated for each of the research groups Fig. 4, then other statistical variables were calculated and organized in Table 4.

Welch’s t-test (levene’s P = 0.04) showed a significant difference in the mean values of the two groups P = 0.001.(95% CI = [91.6, 212.28], cohen’s d = 3.614).

Discussion

The contribution of this study lies in its comparison between Ti6Al4V alloy and Co-Cr alloy, both of which were prepared using a modern method, selective laser melting (SLM). It also highlights the potential for expanding the application of Ti6Al4V alloy in prosthetic dentistry, given its aforementioned advantages. The comparison of these two alloys in terms of 3-point bending test and microhardness was also chosen due to their clinical importance. The objectives of this study differ from previous studies in that the latter compared the mechanical properties of each alloy separately. For example, some studies compared cobalt-chromium alloys prepared by different methods, such as the traditional casting method, the milled method, the selective laser melting method, and others7,13,14,15,16,17,18,19,20,21,22. Other studies compared different titanium alloys in their chemical composition such as, commercially pure titanium alloy (grade 2), titanium alloy Ti6Al4V (grade 5)11,23, and other alloys; or they studied a single alloy, such as Ti6Al4V, by preparing it using different methods and comparing them20,24,25,26. The statistical analysis showed no significant difference in the mean stress values between the two tested groups. The Ti6Al4V alloy specimens recorded a mean stress of approximately 4050 MPa, which was relatively close to the 3200 MPa measured for the Co–Cr alloy specimens. This indicates that both materials exhibited similar resistance to deformation under the 3-point bending test conditions. Due to the novelty of this study and the limited availability of prior research using the same bending test, comparisons were made with previous studies that investigated stress values under tensile testing. Although the testing methods differ, the average stress values reported in those studies were relatively close to each other, suggesting a comparable mechanical behavior trend among the same alloys. This general agreement in trend can be seen in the results of Wu et al. (2014), Klimek, Bułhak, & Śmielak (2024), Okazaki & Ishino (2020), and Dobrzański et al. (2020)14,27,28,29. Hence, despite the difference in testing approaches, the similarity in stress ranges reinforces the mechanical reliability of Ti6Al4V as a promising alternative to Co–Cr in dental frameworks. In the 3-point bending test, the specimens exhibited noticeable deflection prior to fracture. The statistical analysis demonstrated a significant difference in the mean strain values between the two groups. Ti6Al4V specimens showed a higher mean strain (approximately 1.565%) compared to Co–Cr specimens (approximately 1.347%), indicating a greater degree of deformation before failure. Although the testing method in the current study differs from those used in previous research—where strain was typically assessed under tensile testing—our findings are in agreement with the general trend reported by Wu et al. (2014) and Cherneva et al. (2023)14,26, in which Ti6Al4V exhibited higher strain values than Co–Cr. This higher strain capacity may offer clinical advantages in cases where greater flexibility and deformation tolerance are desired, such as in extensive removable prosthetic designs or in anatomically complex cases. The statistical analysis revealed a significant difference in the mean values of the modulus of elasticity between the two groups. Ti6Al4V alloy specimens exhibited a lower mean modulus of elasticity (approximately 154.1 GPa) compared to Co–Cr alloy specimens (approximately 227.98 GPa). This indicates that the Ti6Al4V alloy is more flexible (less rigid) than the Co–Cr alloy. These findings align with previous studies, such as those by Dolgov et al. (2016) and Wang et al. (2018), where the modulus of elasticity for Co–Cr alloys prepared via the SLM method ranged between 200 and 213 Gpa19,30. Additionally, the results are consistent with those of Tao et al. (2019) and Wojtaszek et al. (2013), who reported that Ti6Al4V alloys prepared by SLM had a modulus of elasticity in the range 103 and 117 GPa31,32. This difference in the modulus of elasticity further emphasizes the contrasting mechanical properties of the two alloys. Ti6Al4V offers more flexibility, which could be advantageous in prosthetic designs requiring more deformation tolerance, particularly in cases where the material needs to adapt to complex anatomical structures or when higher levels of patient comfort are necessary. On the other hand, Co–Cr alloys provide greater rigidity, which may be beneficial in applications requiring higher stiffness, such as in fixed prosthetic structures or areas subject to greater mechanical stresses. According to the results obtained at the 95% confidence level, there is a statistically significant difference in the mean values of microhardness (Vickers) between Ti6Al4V and Co-Cr alloys. The mean microhardness of Co-Cr alloy (about 797 Vickers) is higher than the microhardness of Ti6Al4V alloy (about 645 Vickers). In this result, we agree with previous studies (Cosma, Moldovan, Simion, & Balc, 2022), (Zeng et al., 2014), (Ghadhban & Hasan, 2022), (Gao et al., 2021), (Foudzia et al., 2024), and (Ghio, Cerri, Riccio, & Sisti, 2022)7,15,33,34,35,36, in which we observed that the values of Co-Cr microhardness are higher than the values of Ti6Al4V microhardness. A limitation of the current study is that it was conducted on laboratory samples, without clinical results being known under the influence of various occlusal forces and factors that cause localized deformation on the surfaces of metal frameworks. Furthermore, it is necessary to evaluate the resistance of direct retainers to bending forces when modified by a dentist. Therefore, similar clinical studies are recommended.

Materials and methods

For the 3-point bending test, two groups of specimens were prepared: the titanium group (Ti6Al4V) and the cobalt-chromium group (Co-Cr). Each group included 10 specimens with dimensions of 0.5 × 3 × 25 mm, in accordance with ISO 9693-114,17. Micro-Vickers hardness was measured for 6 specimens of each alloy, using samples with a cylindrical shape approximately 10 mm in diameter and 3 mm in height15.

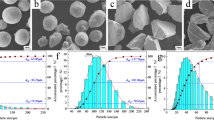

A selective laser melting (SLM) machine designed for dental applications (SISMA MYSINT 100, Vicenza, Italy) was used to fabricate the two groups. The system operates with a 200 W fiber laser and a beam control unit enabling X–Y axis movement. The processing parameters included a scanning speed of 0.8 m/s, a layer thickness of 30 μm, and a beam spot size of 55 μm. The only difference between the two alloys was the protective gas: argon for Ti6Al4V and nitrogen for Co–Cr. All specimens were fabricated at the same build orientation of 45°. The Co–Cr alloy utilized was Realloy C Powder (Krefeld, Germany), while the Ti6Al4V alloy powder was Titanium Alloy – Grade 5 (Guangzhou, China). Their compositions are shown in Tables 5 and 6.

Polishing of the prepared samples was performed sequentially using silicon carbide (SiC) abrasive papers with grit sizes of (150, 200, 400, 600, 800, 1000, 1200, and 2000), spending approximately 2 min at each grit size. After polishing, the samples underwent ultrasonic cleaning for a total of 10 min: 5 min in acetone followed by 5 min in deionized water.

The testing machine recorded the 3-point bending is a DY34 general mechanical testing device from ADAMEL LHOMARGY, France). Each end of the specimen was placed on a supporting column, and the span length was 25 mm. A crosshead was loaded at the center of the specimen at a speed of 1.0 mm/min until fracture occurred. Stress (σ), strain (ε) and modulus of elasticity (E) were calculated according to the following equations, respectively: σ = 3FL/(2bh^2 ), ε = 6hδ/L^2 and E = (FL^3)/48Iδ37,38,39. Micro-Vickers hardness was measured, with a hardness tester (Galileo Durometria, Antegante, Italy). All the tests were conducted with a load of 300 g and a contact time of 15 s with the application of a 136-degree diamond pyramid penetrator. Each specimen was measured at 3 points around the center, and then the average of these three measurements was calculated. Statistical analysis was performed using SPSS V25 (USA, IBM). Welch’s test was used to compare mean group values due to the lack of variance homogeneity after confirming the normal distribution (Shapiro-Wilk’s P > 0.05). Otherwise, the Mann-Whitney U test was used. The significance level was set at 0.05.

Conclusions

From the results of this research, we can conclude the following:

-

1.

Both Co-Cr and Ti6Al4V have similar stress values.

-

2.

Ti6Al4V has higher strain values than Co-Cr.

-

3.

Ti6Al4V has a smaller modulus of elasticity than Co-Cr, thus higher elasticity and lower stiffness.

-

4.

Co-Cr has higher microhardness than Ti6Al4V.

Data availability

The data provided for the results presented in this study is available through the corresponding author upon request.

Change history

04 November 2025

A Correction to this paper has been published: https://doi.org/10.1038/s41598-025-26792-6

References

Carr, A. B. & Brown, D. T. Partially edentulous: epidemiology, physiology, and terminology and denture base considerations. In McCracken’s Removable Partial Prosthodontics 12th edn (eds Carr, A. B. & Brown, D. T.) 103–114 (Elsevier Health Sciences, 2010).

Çelik, G. E. & Balkaya, M. C. Metal manufacturing techniques used in prosthetic dentistry. Essent. Dent. 2(3), 135–140 (2023).

Gunasekaran, J., Sevvel, P. & John Solomon, I. Metallic materials fabrication by selective laser melting: A review. Mater. Today Proc. 37(3), 252–256 (2021).

Li, J. et al. Bond strengths of porcelain to cobalt-chromium alloys made by casting, milling, and selective laser melting. J. Prosthet. Dent. 118(1), 69–75 (2017).

Chen, L.-Y., Qin, P., Zhang, L. & Zhang, L.-C. An overview of additively manufactured metal matrix composites: preparation, performance, and challenge. Int. J. Extreme Manuf. 6(5), 052006 (2024).

Su, J. et al. Recent innovations in laser additive manufacturing of titanium alloys. Int. J. Extreme Manuf. 6(3), 032001 (2024).

Ghadhban, A. H. & Hasan, I. H. Hardness and surface roughness of cobalt-chromium alloy produced by selective laser melting and casting techniques (an in vitro study). J. Res. Med. Dent. Sci. 10(6), 203–207 (2022).

Riviș, M. et al. The implications of titanium alloys applied in maxillofacial osteosynthesis. Appl. Sci. 10(9), 3203 (2020).

Jorge, J. R. P. et al. Titanium in dentistry: historical development, state of the art and future perspectives. J. Indian Prosthod. Soc. 13(2), 71–77 (2013).

Jang, K.-S., Youn, S.-J. & Kim, Y.-S. Comparison of castability and surface roughness of commercially pure titanium and cobalt-chromium denture frameworks. J. Prosthet. Dent. 86(1), 93–98 (2001).

Bridgeman, J. T., Marker, V. A., Hummel, S. K., Benson, B. W. & Pace, L. L. Comparison of titanium and cobalt-chromium removable partial denture clasps. J. Prosthet. Dent. 78(2), 187–193 (1997).

Canay, Ş, Hersek, N., Culha, A. & Bilgiç, S. Evaluation of titanium in oral conditions and its electrochemical corrosion behaviour. J. Oral Rehabil. 25(10), 759–764 (1998).

Xin, X. Z., Chen, J., Xiang, N., Gong, Y. & Wei, B. Surface characteristics and corrosion properties of selective laser melted Co–Cr dental alloy after porcelain firing. Dent. Mater. 30(3), 263–270 (2014).

Wu, L., Zhu, H., Gai, X. & Wang, Y. Evaluation of the mechanical properties and porcelain bond strength of cobalt-chromium dental alloy fabricated by selective laser melting. J. Prosthet. Dent. 111(1), 51–55 (2014).

Zeng, L., Xiang, N. & Wei, B. A comparison of corrosion resistance of cobalt-chromium-molybdenum metal ceramic alloy fabricated with selective laser melting and traditional processing. J. Prosthet. Dent. 112(5), 1217–1224 (2014).

Hedberg, Y. S., Qian, B., Shen, Z., Virtanen, S. & Wallinder, I. O. In vitro biocompatibility of CoCrMo dental alloys fabricated by selective laser melting. Dent. Mater. 30(5), 525–534 (2014).

Lucchetti, M. C. et al. Cobalt-chromium alloys in dentistry: An evaluation of metal ion release. J. Prosthet. Dent. 114(4), 602–608 (2015).

Li, J. et al. Bond strengths of porcelain to cobalt-chromium alloys made by casting, milling, and selective laser melting. J. Prosthet. Dent. 118(1), 69–75 (2017).

Dolgov, N. A., Dikova, Ts., Dzhendov, D., Pavlova, D. & Simov, M. Mechanical properties of dental Co–Cr alloys fabricated via casting and selective laser melting. Mater. Sci. 2(3), 3–7 (2016).

Tan, F.-B., Song, J.-L., Wang, C., Fan, Y.-B. & Dai, H.-W. Titanium clasp fabricated by selective laser melting, CNC milling, and conventional casting: a comparative in vitro study. J. Prosthodont. Res. 63(1), 58–65 (2019).

Tasaka, A. et al. Accuracy of removable partial denture framework fabricated by casting with a 3D printed pattern and selective laser sintering. J. Prosthodont. Res. 64(2), 224–230 (2020).

Schweiger, J., Güth, J.-F., Erdelt, K.-J., Edelhoff, D. & Schubert, O. Internal porosities, retentive force, and survival of cobalt–chromium alloy clasps fabricated by selective laser-sintering. J. Prosthodont. Res. 64(2), 210–216 (2020).

Poondla, N., Srivatsan, T. S., Patnaik, A. & Petraroli, M. A study of the microstructure and hardness of two titanium alloys: Commercially pure and Ti–6Al–4V. J. Alloy. Compd. 486(1–2), 162–167 (2009).

Xie, W., Zheng, M., Wang, J. & Li, X. The effect of build orientation on the microstructure and properties of selective laser melting Ti-6Al-4V for removable partial denture clasps. J. Prosthet. Dent. 123(1), 163–172 (2020).

Takahashi, K. et al. Fitness accuracy and retentive forces of additive manufactured titanium clasp. J. Prosthodont. Res. 64(4), 468–477 (2020).

Cherneva, S., Petrunov, V., Petkov, V., Bogdanov, V. & Simeonova, S. Structure and mechanical properties of milled and 3D-printed Ti-6Al-4V alloys for subtractive and additive CAD/CAM manufacturing in dentistry. Appl. Sci. 13(21), 11958 (2023).

Klimek, L., Bułhak, B. & Śmielak, B. A comparison of the structure and selected mechanical properties of Cr/Co alloys obtained by casting and selective laser melting. J. Funct. Biomater. 15(3), 61 (2024).

Okazaki, Y. & Ishino, A. Microstructures and mechanical properties of laser-sintered commercially pure Ti and Ti-6Al-4V alloy for dental applications. Materials 13(3), 609 (2020).

Dobrzański, L. A., Dobrzański, L. B., Achtelik-Franczak, A. & Dobrzańska, J. Application of solid laser-sintered or machined Ti6Al4V alloy in manufacturing of dental implants and dental prosthetic restorations according to Dentistry 4.0 concept. Processes 8(6), 664 (2020).

Wang, H. et al. Preparation and properties of Co–Cr alloy denture by selective laser melting. Mater. Res. Express 6(2), 026552 (2018).

Tao, P. et al. Microstructure, mechanical properties, and constitutive models for Ti–6Al–4V alloy fabricated by selective laser melting (SLM). Metals 9(4), 447 (2019).

Wojtaszek, M., Śleboda, T., Czulak, A., Weber, G. & Hufenbach, W. A. Quasi-static and dynamic tensile properties of Ti-6Al-4V alloy. Arch. Metall. Mater. 58(4), 1261–1265 (2013).

Cosma, C., Moldovan, M., Simion, M. & Balc, N. Impact of laser parameters on additively manufactured cobalt-chromium restorations. J. Prosthet. Dent. 128(3), 421–429 (2022).

Gao, J. B. et al. Effects of electropulsing on the microstructure and microhardness of a selective laser melted Ti-6Al-4V alloy. J. Alloy. Compd. 875, 160044 (2021).

Foudzia, F. M. et al. Physical and hardness performance at different surfaces for titanium alloy (Ti6Al4V) printed using selective laser melting process (SLM). Jurnal Kejuruteraan 36(3), 1217–1226 (2024).

Ghio, E., Cerri, E., Riccio, M. & Sisti, J. Mechanical properties and microstructure of Ti6Al4V Extra Low Interstitial alloy produced via laser and electron beam additive manufacturing processes. La Metall. Ital. 69, 70–78 (2022).

Mechanical properties of dental materials. In Phillips’ Science of Dental Materials 12th edn (eds Anusavice, K. J. et al.) 48–68 (Elsevier/Saunders, 2012).

Hong, J.-K., Kim, S.-K., Heo, S.-J. & Koak, J.-Y. Mechanical properties and metal-ceramic bond strength of Co-Cr alloy manufactured by selective laser melting. Materials 13(24), 5745 (2020).

Dowling, N. E. Elastic behavior and Young’s modulus. In Mechanical Behavior of Materials, International Edition (ed. Dowling, N. E.) 118–177 (Pearson Higher Education, 2013).

Author information

Authors and Affiliations

Contributions

Leen Audi: Conceptualization, Methodology, Project administration, Data curation, Investigation, Roles/writing - original draft, Formal analysis, Methodology, Writing - review and editing. Ammar Almustafa Conceptualization, Methodology, Project administration, Resources, Supervision, Roles/writing - original draft, Writing - review and editing.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

The original online version of this Article was revised: The original version of this Article contained an error in the name of authors Leen Audi and Ammar Almustafa, which were incorrectly given as respectively L. Aud and A. Al-mustafa.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Audi, L., Almustafa, A. Bending strength and hardness comparison of titanium and cobalt–chromium alloys for dentures made by selective laser melting. Sci Rep 15, 36463 (2025). https://doi.org/10.1038/s41598-025-21191-3

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-21191-3