Abstract

Efficient extraction of subsurface resources relies heavily on the performance of drilling fluids, which necessitates constant innovation in their formulation. This study introduces a novel Polylactic Acid/Henna composite for significant enhancement of drilling fluid properties. The composites was characterized via Scanning Electron Microscopy (SEM), Energy-Dispersive X-ray Spectroscopy (EDS), and Fourier-Transform Infrared Spectroscopy (FTIR), confirming the uniform Henna particles dispersion in PLA matrix. The composite was added to water-based drilling fluids at concentrations of 0.5 wt%, 1 wt%, 2 wt%, 4 wt%, and 10 wt%, followed by rigorous evaluation of rheological and filtration performance. Experimental results demonstrated that fluids containing 2 wt% PLA/Henna composite exhibited the best performance, with a 32% increase in yield point and a 21% improvement in plastic viscosity compared to the base fluid. Furthermore, filtration volume decreased by 42%, while spurt loss was reduced by 35% due to improved filter cake formation. These quantitative improvements optimize fluid efficiency and minimize permeability, enhancing the ability to control fluid loss under simulated drilling conditions. Such enhancements promote better wellbore stability and operational reliability.

Similar content being viewed by others

Introduction

Drilling fluids are essential for contemporary drilling activities, performing numerous vital roles that directly affect the effectiveness, safety, and overall success of well development1,2,3,4,5. These functions consist of lubrication and cooling of the drill bit, moving cuttings from the bit to the surface, preserving wellbore stability by applying hydrostatic pressure to avoid the influx of formation fluids, and reducing formation damage by managing fluid loss effectively6,7,8,9,10. The ideal composition of drilling fluids is thus crucial, as it directly affects drilling speed, operational expenses, and the avoidance of wellbore stability issues such as lost circulation, stuck pipe, and formation failure11,12,13,14,15.

The quest for improved drilling fluid performance has resulted in substantial research on innovative additives, with considerable attention recently directed toward the utilization of nanotechnology16,17,18,19,20. Nanoparticles, due to their distinctive physicochemical characteristics stemming from their elevated surface area to volume ratio, have the possibility to greatly improve the effectiveness of drilling fluid in difficult subsurface conditions21,22,23,24,25. These characteristics comprise increased thermal conductivity, better lubricating properties, altered flow behavior, and enhanced filtration management26,27,28,29,30.

Conventional drilling fluid additives frequently encounter restrictions in extreme environments, like high-pressure, high-temperature (HPHT) reservoirs, where standard polymers may break down, resulting in a decline in viscosity and filtration management18,31. Nanoparticles, due to their enhanced stability and distinctive interaction methods, offer a hopeful path for addressing these constraints32,33,34. Their capacity to create stable network structures within the drilling fluid matrix can increase viscosity, enhance suspension characteristics, and minimize fluid loss to the formation35,36.

Several research efforts have explored the use of diverse nanoparticles to improve the characteristics of drilling fluids. For example, research has investigated the application of silica (SiO2) nanoparticles to enhance fluid performance by boosting viscosity and stability, especially under elevated temperature and pressure conditions17,35,37. Nanoparticles of iron oxide (Fe2O3) have been studied for their magnetic characteristics, which can help improve dispersion and decrease settling time38,39,40. Chromium oxide (Cr2O3) nanoparticles have demonstrated potential as anti-corrosion agents, enhancing the mechanical properties and prolonging the durability of drilling equipment41,42. Alumina (Al2O3) nanoparticles have been employed as reinforcing agents, enhancing viscosity and lowering filtration rates17,43.

Expanding on this groundwork, researchers have additionally investigated the application of composite materials and surface modification methods to further improve the efficacy of nanoparticles in drilling fluids. The integration of various nanoparticles or the alteration of nanoparticle surfaces with polymers or surfactants can result in synergistic effects, enhancing dispersion, stability, and overall effectiveness44,45.

The filtration properties of drilling fluids are extremely significant, since excessive fluid loss may result in formation damage, wellbore instability, and higher operational expenses46,47,48. Nanoparticles can be essential in decreasing fluid loss by sealing the pores in filter cake, constructing a more secure barrier and reducing fluid infiltration into the formation49. Numerous studies have shown that nanoparticles can decrease filtration volume and enhance the properties of filter cakes50,51,52.

Recent advances in composite materials for drilling and structural applications further underscore the need for multi-criteria performance optimization and cross-disciplinary insights. Studies such as the multi-attribute optimization of drilling Carbon–Innegra fiber–reinforced composites using Entropy–TOPSIS have demonstrated how quantitative decision-making tools can guide material selection under complex operational constraints. Investigations into the structural relationships between composition and performance in polymer composites have revealed critical parameters influencing mechanical integrity and durability. Additionally, works on incorporating metal inserts into glass fiber–reinforced polymer nanocomposite joints highlight strategies for enhancing long-term performance under accelerated aging, while research on additive manufacturing of sandwiched ABS/glass fiber composites combined with machine learning underscores the potential of predictive modeling to optimize material behavior53,54,55,56.

This research introduces a novel biodegradable additive for drilling fluids by synergistically combining polylactic acid (PLA), a renewable thermoplastic with mechanical stability, and Henna, a plant-derived particulate rich in bioactive compounds and functional hydroxyl groups. While conventional biopolymers such as xanthan gum, starch, and carboxymethyl cellulose, or synthetic nanoparticles, have shown performance benefits, they often face limitations including thermal or microbial instability, environmental concerns, or the need for costly modifications. PLA contributes a stable polymeric backbone for viscosity enhancement and filter cake formation, while Henna offers high thermal tolerance, pore-bridging capacity, and reactive sites to improve rheology and fluid loss control. The composites is fabricated and structurally validated using SEM, EDS, and FTIR. Comprehensive rheological and filtration testing under simulated conditions demonstrates the potential of this bifunctional, eco-friendly additive to outperform single-component materials, offering a scalable and sustainable solution for diverse drilling environments.

Materials and methods

Materials

Polylactic acid

PLA pellets utilized in this study were sourced from ItLavga’s company. PLA is a renewable, thermoplastic polymer resulting from herbal source including sugarcane or corns’ starch, making it highly appropriate. Its natural biodegradability, strong mechanical properties, and straightforward processing capabilities have contributed to its broad adoption across multiple industries. In the context of drilling fluid rheology, PLA offers potential advantages due to its compatibility with natural fillers and ability to enhance fluid performance under diverse conditions57,58.

Henna powder

Henna powder, used as the natural filler in this study, was procured from EbnManooye with a certified purity of over 98%. The powder was produced via a spray-drying method to ensure high quality and consistency. This processing technique yielded fine Henna particles with enhanced uniformity and stability, making it suitable for incorporation into polymer composites. The superior purity and controlled particle properties of the Henna powder were essential for achieving the desired compatibility and performance when combined with the PLA matrix.

HPAM

Hydrolyzed Polyacrylamide (HPAM) utilized in this research was taken in Merck (98%), and a molar mass in range of 4 to 6 million daltons. HPAM is a widely used polymer in drilling fluids due to its exceptional viscous properties, which play a crucial role in optimizing the efficacy of drilling operations. Acting as a thickening agent, HPAM reduces fluid movement within wells, thereby improving filtration control and enhancing operational stability.

Figure 1 illustrates the chemical structure and molecular arrangement of Polyacrylamide (PAM) and its hydrolyzed derivative, HPAM. Both polymers consist of long, flexible chains with carboxylic functional groups attached to their backbones. The negatively charged carboxylic groups cause electrostatic repulsion among the polymer molecules, keeping the chains in an elongated state. This structural configuration contributes to the enhanced viscosity of HPAM when dissolved, making it highly effective for applications demanding superior rheological performance in drilling fluids59,60,61.

KCl (potassium chloride)

Potassium chloride is an essential compound employed in this study, primarily for its role as an electrolyte in drilling fluid systems. This salt is crucial for regulating the pressure, stability, and physical characteristics of the fluid under varying pressure and temperature conditions. KCl effectively enhances the stability of drilling fluids, preventing sedimentation and maintaining the fluid’s homogeneity during operations. Furthermore, the inclusion of KCl in drilling fluids helps mitigate adverse impacts on geological formations and contributes to preserving the quality of subterranean water resources. By minimizing interactions between drilling fluids and sensitive geological layers, KCl plays a dynamic part in enhancing the environmental compatibility of drilling operations, positioning it as a critical component in fluid formulations62,63,64,65.

NaCl (sodium chloride)

Sodium chloride, typically characterized as table salt, was employed in this study as a key additive in drilling fluids to optimize their chemical and physical properties. Due to its high solubility in water, NaCl plays a critical role in maintaining pressure equilibrium within the fluid system and preventing precipitation, ensuring stability and performance of drilling fluid. Moreover, NaCl serves as a viscosity-modifying agent, contributing to the control and adjustment of rheological properties as required for efficient drilling operations. The NaCl utilized in the current work was taken in Merck guaranteeing consistency and reliability in experimental applications.

Lime (calcium hydroxide)

Calcium hydroxide, commonly referred to as lime, is employed in this study as an alkaline agent in drilling fluid formulations. Lime plays a critical role in adjusting the pH of the fluid, contributing to the improvement of its rheological properties. Additionally, lime acts as an anti-sedimentation additive, effectively preventing the formation of sediments within the drilling environment. The calcium hydroxide used in this study was procured from Pars Ore Company, with a certified purity exceeding 90%, ensuring reliable performance.

The incorporation of lime improves the overall stability and efficiency of drilling fluids, which enhances fluid management and operational effectiveness. By maintaining optimal fluid characteristics, calcium hydroxide serves as a key component in improving drilling performance and ensuring consistent fluid functionality under varied operational conditions66,67,68,69.

Barite

Barite, a naturally occurring dense material composed primarily of barium sulfate (BaSO₄), is extensively utilized in drilling fluid formulations to increase fluid density. Its high density is vital for preventing fractures and controlling fluid loss in wells, thereby ensuring wellbore stability during drilling operations. In addition to pressure management, barite contributes to the effective control of formation pressures, reducing the risks of blowouts and improving overall drilling efficiency. Due to its unique chemical and physical characteristics, barite is a critical component in the design and optimization of drilling fluids. The barite used in this study was procured from China Petroleum National Company (CNPC) in Iraq, ensuring consistent quality and reliability for experimental applications.

Experimental procedure

Synthesizing PLA/Henna composite

The fabrication of the PLA/Henna composite was performed following a carefully structured protocol aimed at achieving uniform filler dispersion and optimal integration within the polymer matrix. Initially, the raw materials were conditioned. PLA pellets underwent drying in a vacuum oven at 60 °C for 12 h to remove residual moisture, as the presence of water during melt processing can promote hydrolytic degradation, leading to a reduction in molecular weight and weakening of the polymer’s mechanical performance. Henna powder, sieved to obtain a consistent particle size of 80–100 μm, served as the reinforcing filler and was introduced into the PLA at a weight fraction of 15%. Prior to extrusion, manual premixing was carried out to enhance the initial distribution of the Henna within the PLA, thereby reducing compositional inhomogeneity.

The premixed blend was subsequently processed using a single-screw extruder, where the temperature profile was maintained between 180 °C and 200 °C to match the melting characteristics and thermal stability of PLA, while preventing thermal degradation. A screw rotation speed of around 30 rpm allowed adequate residence time to ensure thorough melting, blending, and filler dispersion. The molten composite was then extruded through a die to produce continuous filaments, which were air-cooled to ambient temperature to preserve their structure before being wound onto spools.

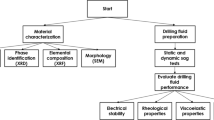

Finally, the obtained filaments were converted into fine particulate form by manually grinding with a mortar and pestle, preparing the material for subsequent utilization steps. This step was performed carefully to achieve particle sizes small enough to pass through a 400-mesh sieve (with a particle size of approximately 37 microns). This ensured uniformity in particle size, which is critical for optimizing the composite’s performance in its intended application, particularly for enhancing drilling fluid rheology and filtration properties. The synthesized composite material thus featured well-dispersed Henna particles within the PLA matrix, indicating the success of the processing technique. Figure 2 illustrates the schematic graphical flowchart of the PLA/Henna composite synthesis process:

Drilling fluid preparation

The preparation of the drilling fluid was conducted in a stepwise manner to ensure proper dispersion and uniform mixing of all components. In the first stage, a solution was prepared by gradually dissolving salts into deionized water while stirring at a speed of 6000 rpm for 20 min. This high-speed mixing was essential to ensure the complete dissolution of the salts and the formation of a homogenous solution.

In the second stage, the newly synthesized PLA/Henna composite material was introduced into the solution at various concentrations. The mixture was stirred at 6000 rpm for an additional 20 min to ensure proper dispersion of the composite within the fluid.

Afterwards, HPAM was added to the fluid at a concentration of 2 wt%. The fluid was then mixed at 6000 rpm for 10 min to evenly incorporate the polymer, which is crucial for achieving the desired rheological properties.

Finally, additional materials, such as barite (to adjust fluid density) and lime (to regulate pH), were added to the fluid. This mixture was stirred at 6000 rpm for 30 min to ensure uniform distribution of these additives, resulting in a stable drilling fluid with the appropriate weight and pH characteristics. Each step of the process was carefully controlled to produce a homogeneous drilling fluid suitable for experimental and practical applications27,37,70. Fig. 3 shows a schematic diagram that illustrates the key steps involved in drilling fluid preparation.

Measurement of rheological properties

The rheological behavior of the synthesized drilling fluids was analyzed using a Brookfield Viscometer (VG-meter) presented in Fig. 4A, an instrument designed to measure the shear stress of fluids at varying shear rates. The VG-meter operates based on rotational viscometer, where a spindle immersed in the fluid rotates at predetermined speeds to generate shear forces. The torque required to rotate the spindle is measured by the instrument, providing an accurate determination of the fluid’s resistance to shear, which corresponds to the shear stress.

For this study, the synthesized drilling fluids were subjected to shear rate variations by adjusting the rotational speed of the VG-meter spindle. The instrument was calibrated prior to experimentation to ensure measurement accuracy. During the procedure, an appropriate amount of drilling fluid was placed in the sample container, ensuring complete immersion of the spindle according to standard operating protocols. Measurements were taken at multiple rotational speeds to capture the fluid’s response across a wide range of shear rates.

The shear stress data collected at each shear rate was recorded and used to construct shear stress versus shear rate curves, which provide a detailed characterization of the fluid’s rheological behavior. These curves illustrate how the fluid reacts to applied stress under various flow conditions, offering key insights into its performance for drilling applications. The procedure was repeated for all synthesized fluid samples to ensure reproducibility and to compare the rheological behavior under different compositional and experimental conditions71,72,73.

The shear stress versus shear rate curves obtained in the study were analyzed using established theoretical rheological models to characterize under varying shear conditions. These models are essential for understanding the flow dynamics of complex fluids and are categorized as follows:

Newtonian

They exhibit an unchanging viscosity that is independent of the applied shear rate, illustrating a linear relationship between shear stress and shear rate. Their behavior is mathematically described by the equation.

where τ represents the shear stress, µ is the viscosity, and γ denotes the shear rate. Newtonian fluids, such as water and air, exhibit predictable flow patterns under external forces, making them fundamental for applications such as fluid transport in pipelines and pumping systems. Due to their simplicity, Newtonian behavior serves as a baseline comparison when analyzing complex non-Newtonian fluids.

Power law fluids (Pseudoplastic and Dilatant)

Unlike Newtonian fluids, power-law fluids exhibit a viscosity that varies with changes in shear rate. Their behavior can be described using the equation.

where K is the consistency index, n is the flow behavior index, and γ represents the shear rate. When n < 1, the fluids are pseudoplastic, meaning their viscosity decreases with increasing shear rate—a property beneficial for applications requiring ease of flow, such as mixing or coating processes (e.g., paints, sauces). Conversely, when n > 1, the fluids are dilatant, exhibiting shear-thickening behavior where viscosity increases with the applied shear rate. Dilatant behavior is particularly advantageous in applications like impact-absorbing materials.

Bingham plastics

They performs as solid inr low shear stress but flows as liquids once the applied stress exceeds a specific yield point. The flow behavior is characterized by.

where τ₀ is the yielding stresses, and µₚ denotes the viscosity during flow.

Herschel-Bulkley

The model presents a more roboust frameworks to describe the behavior of non-Newtonians. The model is represented by.

where τ₀ indicates the yield stress required to initiate flow, K is the consistency coefficient, and n represents the flow behavior index. This model is versatile and encompasses other rheological models, such as Bingham plastics (when n = 1) and power-law fluids (when τ₀ = 0). The Herschel-Bulkley model is particularly useful for analyzing the complex behavior of fluids encountered in industries such as construction, food processing, and energy production. By accounting for both yield stress and variable flow characteristics, this model provides a comprehensive understanding of non-Newtonian fluid dynamics under different shear conditions74,75,76.

These rheological models serve as critical tools for characterizing the performance of drilling fluids and other industrial materials, enabling precise control over flow properties for optimized application16,77,78.

Measurement of drilling fluid filtration

The filtration performance of the drilling fluids was assessed using both LPLT and HPHT conditions. For this purpose, an API filter press apparatus (See Fig. 4B) was implemented to experimentally detect filtration volumes under controlled experimental settings. Initially, 400 cc of drilling fluid was poured into a cup and subjected to hot rolling at 90 °C for 16 h. This step was performed to simulate bottomhole agitation conditions, ensuring that the fluid experienced equivalent thermal and mechanical stress similar to those encountered during drilling operations. After hot rolling, the sample was allowed to cool to room temperature before being transferred into the cup of the API filter press for filtration testing.

For LPLT experiments, the temperature was maintained at 25 °C and the applied pressure was set to 100 psi. In HPHT experiments, the testing conditions involved a higher temperature of 100 °C and increased pressure of 400 psi. Under both conditions, the filtration process was conducted for a duration of 30 min. The volume of filtration was carefully measured and recorded, providing insight into the fluid’s ability to control fluid loss under varying operational conditions. These experimental procedures ensure a comprehensive evaluation of the filtration properties of the drilling fluids, which is essential for optimizing their performance in reducing fluid loss and maintaining well stability during drilling operations37,79.

Results and discussion

PLA/Henna composites synthesize and characterization

It was performed twice following the described methodology to evaluate the repeatability of the process. To ensure consistency, the synthesized materials were subjected to advanced characterization techniques, including Fourier Transform Infrared Spectroscopy FTIR, EDS, and SEM. The characterization results from both synthesis batches were highly similar, confirming the reproducibility of the procedure and the stability of the composite’s properties.

Figure 4C displays the physical appearance of the newly synthesized PLA/henna composites after being processed into powder form. These images allow for visual assessment of the composites’ texture and coloration.

The SEM images, presented in Fig. 5, provide compelling evidence regarding the microstructural quality and consistency of the PLA/Henna composites produced across two independent synthesis batches. Both sets display a notably smooth and homogeneous surface topology, characterized by minimal void formation and the absence of detectable agglomerates. Such morphological uniformity, consistent between batches, underscores the robustness and reproducibility of the extrusion process employed, a critical consideration for scalable material production and industrial reliability.

The SEM images reveal a smooth and homogeneous surface morphology across both synthesis batches, with minimal voids and no visible agglomeration. This uniformity confirms effective dispersion of Henna particles within the PLA matrix and suggests strong interfacial compatibility, which is critical for mechanical integrity and consistent performance in drilling fluids.

Further, the clear and even dispersion of Henna particles within the PLA matrix, as discerned from the micrographs, highlights the effectiveness of the processing conditions in overcoming the inherent polarity differences between the hydrophobic PLA and hydrophilic Henna. Uniform particle distribution is not merely a visual feature; it is deeply consequential for composite performance. Strong interfacial compatibility, as evidenced by the absence of interfacial voids or separated filler domains, points to efficient stress transfer at the fiber–matrix interface. This contributes directly to enhanced mechanical integrity and resilience under operational stresses.

Additionally, uniform dispersion mitigates the risk of localized defects or performance variability, which is especially critical for the intended application in water-based drilling fluids. In this context, any heterogeneity, such as filler-rich regions or poorly bonded interfaces, could lead to non-uniform rheological modification and unpredictable filter cake formation. Instead, the observed structure ensures that the composite material will impart predictable, reproducible improvements in both the rheological behavior of drilling fluids and the quality of the formed filter cake, leading to stable borehole conditions and improved drilling performance.

Comparative analysis of the two batches also justifies the reliability of the reported modeling results, as reproducibility at the microstructural level establishes a solid foundation for the observed macroscopic trends. The experimental outcomes related to rheological properties, filtration performance, and cake morphology can thus be confidently attributed to designed compositional and structural factors, rather than uncontrolled batch-to-batch variability80.

The EDX spectra (Fig. 6) obtained from both batches provide elemental confirmation of the successful incorporation and uniform distribution of Henna as a filler material within the PLA matrix. The distinct peaks corresponding to key elements associated with Henna, such as potassium (K), calcium (Ca), and magnesium (Mg), are consistently detected across the composite samples. This elemental fingerprint not only verifies the presence of Henna but, when coupled with the uniform dispersion observed in SEM, strongly suggests that the Henna particles are not merely surface contaminants but are indeed integrated throughout the composite structure. The consistent elemental composition and distribution between the two synthesis batches further validate the robustness and repeatability of our fabrication methodology, ensuring that the functional properties derived from Henna are consistently present across the composite material.

The EDS spectra further validate the presence and distribution of Henna through distinct elemental peaks for potassium, calcium, and magnesium—key constituents of Henna—uniformly detected across the composite surface. These findings confirm that Henna is not merely surface-bound but well-integrated into the PLA matrix.

The FTIR spectra (Fig. 7) of the synthesized PLA/Henna composites provide crucial insights into the chemical interactions and functional groups present, substantiating the successful composite formation and hinting at potential mechanisms for drilling fluid modification. The FTIR spectra show characteristic PLA peaks, including C = O stretching in 1760 cm⁻¹ and C-H stretching around 2977 cm⁻¹, indicating preserved polymer structure. Additionally, the broad absorption band between 3500 and 3700 cm⁻¹ corresponds to hydroxyl (-OH) groups from Henna, suggesting potential hydrogen bonding interactions between PLA and Henna. These interactions likely contribute to enhanced rheological behavior and improved filter cake formation in drilling fluid applications. Collectively, the SEM, EDS, and FTIR analyses confirm the structural integrity, chemical compatibility, and functional potential of the PLA/Henna composite.

The persistence and clear definition of these peaks confirm that the chemical integrity of PLA is largely preserved during the extrusion process despite the incorporation of Henna. More significantly, the FTIR spectra reveal a broad absorption band in the 3500–3700 cm⁻¹ region. This band is directly pertinent to the hydroxyl (-OH) functional groups primarily contributed by the Henna filler. The intensity of this peak is expected to correlate with Henna content (though only a single concentration is shown in the figure, the interpretation should reflect the potential for varying content if tested). The presence of these hydroxyl groups on Henna, alongside the ester groups of PLA, suggests the strong likelihood of hydrogen bonding interactions between the Henna particles and the PLA matrix, as well as with the aqueous fluid components. These intermolecular interactions are fundamental to enhancing interfacial adhesion within the composite and are anticipated to play a critical role in promoting favorable interactions with the drilling fluid’s polymeric additives (like HPAM) and water molecules, thereby influencing rheological behavior and filter cake formation mechanisms. The consistency of FTIR results across both synthesis batches further reinforces the reliability and reproducibility of our composite fabrication method81,82,83.

Synthesizing drilling fluid and measuring specification

In accordance with the presented experimental methodology, drilling fluids were formulated incorporating the synthesized PLA/Henna composite as a novel additive. The fabrication of these fluids followed the systematic procedure outlined earlier, ensuring precise preparation and consistency. The PLA/Henna composite was introduced into the drilling fluid formulations at varying concentrations to thoroughly evaluate its influence across a broad range of material loading levels. The investigated concentrations included 0.5 wt%, 1 wt%, 2 wt%, 4 wt%, and 10 wt% of the composite relative to the total fluid volume. This range was selected to examine both low and high dosages of the composite, enabling a comprehensive investigation of its impact on drilling fluid properties.

Subsequently, the synthesized fluids were subjected to rigorous testing to assess their performance characteristics. Rheological experiments were conducted to evaluate the fluids’ flow behavior, which involved measuring shear stress at various shear rates using a Brookfield viscometer to construct shear stress versus shear rate curves. These curves enabled in-depth analysis of the fluids’ rheological profiles under different compositional and operational conditions. The measurements included key parameters such as apparent viscosity, yield point, and flow behavior indices, allowing comparison against theoretical rheological models to characterize fluid behaviors (Newtonian, pseudoplastic, Bingham plastic, etc.).

In addition to rheological evaluation, filtration performance tests were conducted to analyze the fluid’s ability to minimize fluid loss under simulated operational conditions. Both LPLT and HPHT filtration tests were performed using an API filter press. Each drilling fluid sample was hot-rolled at 90 °C for 16 h prior to testing to simulate downhole agitation and thermal exposure conditions, ensuring realistic evaluations of fluid behavior. For LPLT filtration tests, the pressure was set to 100 psi and the temperature to 25 °C, while for HPHT tests, a higher pressure of 400 psi and a temperature of 100 °C were applied. The filtration volumes were measured over a standardized testing duration of 30 min, providing quantitative data on fluid loss behavior under each set of conditions.

The combination of rheological and filtration tests enabled a thorough assessment of the PLA/Henna composite’s impact on drilling fluid specifications. By comparing results across the different composite concentrations, key insights were gained regarding the additive’s effects on rheological properties, filtration performance, and its suitability for optimizing drilling fluid formulations in practical applications. These analyses provide a foundation for understanding the composite’s role in enhancing drilling fluid function and performance under challenging operational environments.

Effect of nanoparticles on drilling fluid rheology

Figures 8, 9, 10, 11, 12 and 13 collectively demonstrate the excellent agreement between experimental shear stress–shear rate measurements and the predictions of standard rheological models across a broad range of PLA/Henna composite concentrations. The consistently high R² values (≥ 0.991) for both models confirm their capacity to robustly describe the flow behavior of both the base and modified drilling fluids. This high degree of fit is essential, as it not only validates the experimental methodology and data quality, but also assures that the most critical aspects of the fluids’ non-Newtonian behavior, specifically yield stress and plastic viscosity, are accurately represented for practical application.

Crucially, while the Herschel-Bulkley model offers marginally better statistical fits in select cases, the close numerical proximity of R² values for both models, even at high composite concentrations, indicates that the additional model complexity of Herschel-Bulkley yields only minimal improvement in predictive power. Therefore, the Bingham Plastic model, due to its simplicity, transparency in parameter interpretation, and computational efficiency, stands out as the more practical choice for routine engineering design and field calculations, especially where rapid decision-making is required.

Moreover, the results reveal a consistent trend: increasing the PLA/Henna composite content enhances yield stress, confirming that the composite’s structured network is effectively tuning the fluid’s resistance to flow, a property essential for controlling particle suspension and filtration during drilling operations. The linearity of these effects and the ability of simple models to capture them provide strong justification for the experimental design and modeling approach adopted in this study. Altogether, these findings reinforce both the reproducibility and the predictive reliability of the rheological models chosen for these advanced composite drilling fluids.

Figure 11 demonstrates the rheological measurements for the drilling fluid containing 2 wt% PLA/Henna composite. Here, the R² values indicate an exceptional fit for both Bingham Plastic (R² = 0.999) and Herschel-Bulkley (R² = 0.999). The higher composite concentration slightly alters the flow characteristics but remains well-described by the Bingham Plastic model due to its simplicity and robust predictive capability.

Figure 12 represents the rheological behavior for the drilling fluid with 4 wt% PLA/Henna composite. Both Bingham Plastic and Herschel-Bulkley models achieve the highest accuracy (R² = 0.998 for both), demonstrating their ability to represent rheological behavior at higher composite concentrations. The consistency between these two models highlights that Bingham Plastic continues to be a practical choice, particularly for applications demanding simplicity in calculations.

Figure 13 highlights the rheological data for the drilling fluid containing 10 wt% PLA/Henna composite, the highest concentration tested. Both Bingham Plastic and Herschel-Bulkley models provide identical fits with R² = 0.999, indicating exceptional statistical accuracy. Despite the complexity introduced by the elevated composite content, the Bingham Plastic model remains straightforward and effective for describing the fluid’s flow behavior.

Table 1 offers a comprehensive comparison of how well major rheological models fit the experimental data across a series of PLA/Henna composite concentrations. The Bingham Plastic and Herschel-Bulkley models both consistently achieve very high coefficients of determination (R² values between 0.991 and 0.999), strongly validating their ability to describe the non-Newtonian and yield stress behaviors inherent in drilling fluids containing polymeric and particulate additives. Such performance confirms that both models effectively capture the essential flow characteristics and the complex particle–matrix interactions as the composite content increases.

Notably, the slightly better fit of the Herschel-Bulkley model is attributable to its extra degree of freedom, which allows more nuanced capture of shear-thinning effects present at higher filler loadings. However, the magnitude of improvement in R² relative to the Bingham Plastic model is marginal, especially given that all R² values for the Bingham Plastic model remain above 0.99, even at the highest concentrations. This demonstrates not only the robustness but also the versatility of the Bingham Plastic model for fluids exhibiting moderate yield stress and pseudo-plasticity. The choice to prefer Bingham Plastic is further justified by its simple mathematical expression, which reduces computational complexity and minimizes the risk of overfitting when applied to field data, thus facilitating practical implementation in routine drilling engineering calculations.

By contrast, the poor performance of the Newtonian and Power Law models (R² as low as 0.21 and generally below 0.71) highlights that these models are fundamentally unsuitable for the current system. Their inability to account for fluid yield stress or non-linear shear dependence results in notable under- or over-prediction of flow properties, which could potentially lead to operational risks or incorrect fluid performance assessments in real-world applications.

The consistent statistical accuracy of the Bingham Plastic model across all composite concentrations, especially at higher loadings (4 wt% and 10 wt%), is particularly noteworthy. This trend suggests that the physical mechanisms governing flow are well represented by the model’s parameters (yield stress and plastic viscosity), regardless of particle content, underscoring its reliability for design, optimization, and quality control in composite drilling fluids.

While the statistical agreement of the Bingham Plastic model is evident, its superiority in this system can be attributed to the moderately yield-stress-dominated flow behavior of PLA/Henna-modified drilling fluids, where plastic viscosity and yield point remain the dominant parameters governing performance. The particulate–polymeric network formed within the fluid produces a shear-independent yield plateau, which is well captured by the model’s two-parameter framework. However, the model’s simplicity also implies intrinsic limitations: under transient surge–swab operations, highly unsteady gel structure recovery, or extreme shear-thinning regimes (induced by downhole pressure pulsations or the presence of high concentrations of ultra-fine solids) the Bingham Plastic model may underpredict viscosity at low shear rates or fail to describe thixotropic recovery kinetics. In such cases, more flexible models, including Herschel–Bulkley or time-dependent rheological formulations, would be required to ensure accurate engineering predictions. Consequently, while Bingham Plastic is optimal for most steady-state wellbore circulation conditions encountered in standard field drilling, its applicability should be re-evaluated when operations deviate from these stable flow regimes.

Table 2 presents the effect of varying concentrations of the PLA/Henna composite on the plastic viscosity (in centipoise, cp.) and field point of drilling fluids, providing valuable insights into its impact on rheological behavior. The data show that both plastic viscosity and yield point increase significantly with the addition of PLA/Henna composite, particularly up to a concentration of 2 wt%, after which the improvement plateaus. The base fluid exhibits a plastic viscosity of 27 cp. and a yield point of 9.07 Pa, reflecting its baseline rheological properties before the addition of the composite. With the incorporation of 0.5 wt% PLA/Henna, the viscosity increases moderately to 30 cp., while the yield point rises to 10 Pa, indicating initial improvements in the fluid’s resistance to deformation.

At 1 wt% composite, the drilling fluid’s viscosity increases further to 33 cp., and yield point reaches 10.2 Pa, reflecting continued enhancement of its rheological performance. The most notable improvements are observed at 2 wt% composite, where the plastic viscosity increases sharply to 41 cp., and the yield point reaches 12.1 Pa, demonstrating the composite’s peak effectiveness at this concentration. Beyond 2 wt%, increasing the concentration to 4 wt% and 10 wt% results in negligible changes, with viscosity stabilizing around 41–42 cp. and the yield point fluctuating slightly around 12 Pa. This indicates a saturation effect, where additional composite does not further enhance the fluid’s rheological properties.

These findings reveal that the addition of PLA/Henna composite has a significant impact on plastic viscosity and yield point, with optimal performance achieved at 2 wt% concentration. Beyond this threshold, further increases in composite concentration offer diminishing returns, suggesting that higher concentrations not only fail to enhance the drilling fluid’s properties significantly but may also be less cost-effective for practical applications. Therefore, 2 wt% composite is the ideal concentration for maximizing the plastic viscosity and yield point, ensuring improved performance without material wastage. This plateauing behavior at higher concentrations underscores the efficiency of using the composite at its optimal dosage for drilling fluid formulations.

The rheological characterization of the water-based drilling fluids, particularly the yield point, revealed a significant dependency on the concentration of the synthesized PLA/Henna composite. The yield point of the drilling fluid increased progressively with composite loading, reaching an optimal 32% increase at a concentration of 2 wt% compared to the base fluid. This substantial enhancement in yield point signifies the fluid’s improved ability to suspend drill cuttings and maintain wellbore stability under static conditions, a critical requirement for efficient drilling operations and prevention of issues like barite sag or differential sticking84.

The observed increase in yield point can be primarily attributed to the formation of a more robust, three-dimensional network structure within the drilling fluid system, facilitated by the well-dispersed PLA/Henna composite particles. At the molecular level, Henna, as a natural additive, contains abundant hydroxyl (-OH) functional groups, as confirmed by our FTIR analysis (Fig. 7). These highly polar groups can engage in strong hydrogen bonding interactions with the aqueous phase and other polar components of the drilling fluid, including the carboxylic and amide groups of the hydrolyzed polyacrylamide (HPAM) and water molecules. Furthermore, the ester linkages within the PLA matrix also possess polar characteristics that can contribute to these intermolecular associations. When uniformly dispersed, as indicated by SEM imaging (Fig. 5), these composite particles act as active nodes or bridges, creating an extended network that resists initial deformation, thus increasing the shear stress required to initiate flow (i.e., the yield point)85,86,87.

At the optimal 2 wt% concentration, the composite particles are present in sufficient quantity and are ideally spaced to maximize these attractive forces and create an interconnected scaffold that effectively traps water molecules and other fluid components. This leads to a higher structural integrity at rest. Below this concentration, the number of particles might be insufficient to form a continuous, load-bearing network. Conversely, at higher concentrations, the system may become overly crowded, leading to potential particle-particle aggregation or steric hindrance. This could disrupt the optimal network formation, leading to a reduction in the efficiency of force transfer and potentially lower yield point values or an increase in plastic viscosity due to excessive mechanical friction between particles88,89. Similar phenomena have been reported in studies involving other biopolymer and natural particle additives in drilling fluids, where an optimal concentration balances beneficial interactions with potential steric effects or agglomeration90.

Effect of nanoparticles on drilling fluid filtration

Figure 14 depicts the relationship between the concentration of PLA/Henna composite nanoparticles and the volume of fluid lost during filtration over a 30-minute period. The data clearly illustrate that as the concentration of PLA/Henna increases, the volume of filtration decreases significantly, with the most profound effect observed at 2 wt% concentration, where the filtration volume is reduced to 4 mL. This reduction in filtration volume indicates that the addition of the PLA/Henna composite enhances the fluid’s ability to form a more effective filter cake, thereby limiting fluid loss during drilling operations. The sharp decline in filtration volume from 10 mL for the base fluid to 4 mL at optimal concentration suggests improved sealing properties due to the nanoparticles, which likely contribute to a denser, more coherent filter cake structure.

Table 3 summarizes comprehensive data from the filtration test results, providing insight into several key parameters: filtration volume, filter cake thickness, spurt loss, and filter cake permeability at varying concentrations of PLA/Henna composite. At 0 wt%, the base fluid exhibits a filtration volume of 10 mL and a filter cake thickness of 623 μm, with a spurt loss of 2 mL and filter cake permeability of 8.1 nm². These values indicate significant initial fluid loss and a relatively thick filter cake. As the concentration of PLA/Henna is increased to 0.5 wt%, the filtration volume decreases slightly to 9.2 mL, and similar trends are observed with reductions in both filter cake thickness to 621 μm and spurt loss to 2.1 mL.

The most notable improvements occur at 2 wt% concentration, where filtration volume reaches its minimum at 4 mL, and the filter cake thickness drops to 289 μm. At this concentration, the spurt loss is also minimized to 1 mL, indicating a more efficient filtration process and better fluid retention. Higher concentrations, such as 4 wt% and 10 wt%, maintain low filtration volumes (3.9 mL and 3.8 mL, respectively) and similar filter cake thicknesses (299 μm and 270 μm), but show only marginal gains over the 2 wt% concentration. In terms of permeability, there is a noticeable decrease from 8.1 nm² in the base fluid to 3.1 nm² at 2 wt%, indicating that the PLA/Henna composite effectively enhances the compactness and impermeability of the filter cake, contributing to reduced fluid loss.

Overall, the combined analysis of Fig. 14; Table 3 reveals that the optimal concentration of 2 wt% PLA/Henna composite significantly improves the filtration performance of the drilling fluid by enhancing filter cake formation, minimizing fluid loss, and effectively controlling fluid properties under operational conditions. This suggests that utilizing nanoparticle additives such as PLA/Henna can play a critical role in optimizing drilling fluid formulations, particularly in environments where fluid loss and filter cake performance are paramount for effective drilling operations.

Beyond its impact on rheological properties, the PLA/Henna composite significantly optimized the filtration performance of the drilling fluid. The addition of the composite led to a notable reduction in both filtration volume and spurt loss. Specifically, at an optimal concentration of 2 wt% PLA/Henna composite, the filtration volume decreased by an impressive 42%, while spurt loss was reduced by 35% compared to the base fluid. These improvements are crucial for maintaining wellbore stability, minimizing formation damage, and reducing overall fluid loss into permeable formations during drilling operations91.

The enhanced filtration control can be primarily attributed to the formation of a more effective and less permeable filter cake on the wellbore wall. The uniformly dispersed PLA/Henna composite particles, with their size and surface chemistry, act as effective pore-blocking agents. The Henna particles, embedded within the PLA matrix, possess polar hydroxyl groups that can interact with the water molecules and solid surfaces (e.g., formation pores) through hydrogen bonding and other adsorption mechanisms. This interaction promotes the rapid and efficient bridging of pores at the rock-fluid interface, immediately reducing spurt loss, which is the initial rapid influx of fluid into the formation92,93.

As the drilling fluid continues to filter, these composite particles, along with other solid components (like barite) and adsorbed HPAM polymer chains, are deposited to form a denser, more cohesive, and less porous filter cake. The polymeric nature of PLA provides a binding effect, contributing to the mechanical strength and integrity of the filter cake. This creates a more impermeable barrier that effectively minimizes subsequent fluid leakage (filtration volume) into the formation. The tortuosity of the flow paths within the filter cake is increased, forcing the filtrate to travel a longer and more resistive path, thereby reducing the overall filtration rate94. Furthermore, the hydrophilic nature of Henna’s surface, enhanced by the hydroxyl groups, might also contribute to a lubricating effect within the cake, allowing for more compact packing of particles while maintaining its integrity95.

The observed optimal performance at 2 wt% highlights a critical balance. At lower concentrations, there might be an insufficient number of PLA/Henna particles to effectively plug pores or form a continuous, low-permeability filter cake. Conversely, at higher concentrations, while more particles are available, excessive loading can lead to a very thick and potentially fragile filter cake, or even cause bridging issues at the surface, which might paradoxically increase the effective permeability or become more prone to erosion under dynamic drilling conditions96. Furthermore, high concentrations can also increase the overall viscosity of the fluid excessively, potentially hindering the efficient transport and deposition of particles at the filter cake interface97. The 2 wt% concentration likely offers the optimal particle size distribution and quantity for efficient pore bridging and the development of a robust, thin, and low-permeability filter cake.

Table 4 highlights that PLA/Henna composite performs competitively with established additives, particularly in reducing filtration volume and spurt loss, while maintaining strong rheological properties. Table 4 summarizes key performance metrics—plastic viscosity, yield point, filtration volume, and spurt loss—for PLA/Henna and commonly used additives such as xanthan gum, carboxymethyl cellulose (CMC), and silica nanoparticles. The comparative data were compiled from peer-reviewed literature and normalized to similar testing conditions to ensure consistency98,99,100,101.

Potential industrial applications and limitations of PLA/Henna composite

The mechanism of PLA/Henna composite enhancement in drilling fluids lies in its structural and chemical properties. The PLA matrix provides mechanical stability and ensures uniform distribution of Henna particles, facilitating strong interactions within the fluid matrix. Henna’s hydroxyl (-OH) groups form hydrogen bonds with the PLA’s ester functional groups, improving compatibility and adhesion. These interactions enhance rheological properties, allowing the drilling fluid to sustain shear stress and resist filtration loss effectively. In filtration tests, the composite significantly reduces permeability by forming a compact, impermeable filter cake, minimizing voids and reducing spurt loss and overall filtration volume. These attributes position PLA/Henna composite as a scientifically validated additive for improving fluid performance.

The PLA/Henna composite also offers substantial industrial potential due to its scalability, cost-effectiveness, and eco-friendly nature. Its compatibility with existing drilling fluid systems supports easy integration without major procedural modifications, while the biodegradable characteristics of PLA and Henna align with industry sustainability goals. However, there are limitations, including the reliance on laboratory-scale testing that may not fully replicate large-scale industrial processes. Challenges such as maintaining uniform filler dispersion during high-volume production and assessing performance under extreme pressure and temperature conditions remain unresolved. Additionally, the biodegradable nature of PLA and organic composition of Henna may introduce long-term stability issues and compatibility challenges in extended drilling operations. These factors highlight the need for further optimization and validation to ensure reliable performance in diverse field applications while addressing environmental and operational demands.

Several practical challenges may arise when transitioning the PLA/Henna composite to field-scale implementation, including:

-

Mixing dynamics: At industrial scale, achieving uniform dispersion of PLA/Henna particles may be more complex due to variations in shear forces and residence times in large-volume mixers. We have noted that optimizing mixing protocols and equipment design will be essential to maintain homogeneity and prevent agglomeration.

-

Biodegradation under HPHT conditions: While PLA and Henna are biodegradable under ambient conditions, their stability under high-pressure, high-temperature (HPHT) environments may differ. We have acknowledged the need for long-term thermal aging studies to assess the composite’s degradation kinetics and mechanical integrity under downhole conditions.

-

Interaction with other fluid additives: The composite’s compatibility with conventional drilling fluid additives (e.g., HPAM, barite, lime) may influence its performance. We have added commentary on the potential for synergistic or antagonistic interactions, particularly with polymers and salts, and emphasized the importance of compatibility testing during formulation.

Conclusion

This study presented a novel PLA/Henna composite as a viable additive to enhance water-based drilling fluid performance, backed by quantitative analysis. Fluids containing PLA/Henna composite demonstrated significant improvements in rheology and filtration. At an optimal concentration of 2 wt%, the composite increased plastic viscosity by 21% and yield point by 32%, indicating enhanced suspension and flow properties. Filtration volume decreased by 42%, while spurt loss reduction by 35% mitigated fluid loss and ensured superior sealing through compact filter cake formation. Such advances are critical for preventing formation damage, reducing drilling fluid permeability, and improving wellbore stability. The testing conditions highlight the composite’s ability to perform optimally at moderate temperatures and pressures, providing substantial fluid efficiency improvements for routine drilling operations. Its biodegradable nature offers additional environmental benefits, reducing the ecological impact of traditional synthetic additives. However, broader testing under HPHT conditions is recommended to validate its suitability for extreme drilling environments. Additionally, optimization of composite concentration beyond laboratory conditions may yield further refinements in fluid performance. The quantitative findings of this study establish the PLA/Henna composite as a cost-effective and sustainable solution for drilling fluid formulation, reducing environmental impact while enhancing operational efficiency. The study provides a compelling case for the integration of environmentally conscious materials into industry practices, advancing the oil and gas sector toward a greener future.

The enhanced yield point and reduced fluid loss achieved with the PLA/Henna composite demonstrate a significant advance towards more sustainable and high-performance drilling fluids. Many biopolymer-based additives, while environmentally friendly, can face challenges with thermal stability or shear degradation in downhole conditions. Our composite, leveraging the inherent stability of PLA and the integrated nature of the Henna particles, appears to mitigate some of these issues, offering a robust and versatile solution. This unique combination presents a compelling alternative to synthetic polymers and single-component natural additives, providing a pathway for developing drilling fluids that are not only effective but also align with increasing environmental regulations and industry demands for sustainable operations. The PLA/Henna composite shows strong potential for diverse drilling operations, including conventional wells, environmentally sensitive areas, and high fluid-loss formations. Its biodegradability meets rising environmental standards while maintaining performance. Future work should address scale-up, stability under HPHT and deepwater conditions, and compatibility with other additives to expand its use in extreme drilling environments.

Data availability

Data will be available at the academic request from the corresponding author.

References

Hajiabadi, S. H. et al. Effects of surface modified Nanosilica on drilling fluid and formation damage. J. Petrol. Sci. Eng. 194, 107559 (2020).

Ahmed, A. et al. Developing a thermally stable Ester-Based drilling fluid for offshore drilling operations by using aluminum oxide nanorods. Sustainability 13 (6), 3399 (2021).

Shanmugasundar, G. et al. Innovative machine learning for drilling fluid density prediction: a novel central force search-adaptive XGBoost in HPHT environments. Front. Energy Res. 12, 1411751 (2024).

Agwu, O. E. et al. A critical review of drilling mud rheological models. J. Petrol. Sci. Eng. 203, 108659 (2021).

Dai, T. et al. Waste glass powder as a high temperature stabilizer in blended oil well cement pastes: Hydration, microstructure and mechanical properties. Constr. Build. Mater. 439, 137359 (2024).

Lee, J. K. et al. Use of magnetic nanoparticles for smart drilling fluids. (2009)

Amanullah, M., Al-Arfaj, M. K. & Al-Abdullatif, Z. Preliminary Test Results of nano-based Drilling Fluids for Oil and Gas Field Application. (SPE, 2011)

Zakaria, M. F., Husein, M. & Hareland, G. Novel nanoparticle-based Drilling Fluid with Improved Characteristics. (SPE, 2012)

Sun, H. et al. Theoretical and numerical methods for predicting the structural stiffness of unbonded flexible riser for deep-sea mining under axial tension and internal pressure. Ocean Eng. 310, 118672 (2024).

Cao, D. et al. Correction of linear fracture density and error analysis using underground borehole data. J. Struct. Geol. 184, 105152 (2024).

Sharifi, O. et al. Laboratory study of the application of a novel Bio-Based polymer to synthesize aphron drilling fluids. J. Pet. Sci. Technol. 12 (2), 42–50 (2022).

Khezerlooe-ye Aghdam, S. et al. Mechanistic assessment of Seidlitzia Rosmarinus-derived surfactant for restraining shale hydration: A comprehensive experimental investigation. Chem. Eng. Res. Des. 147, 570–578 (2019).

Yin, Y. et al. Integrated geophysical prospecting for deep ore detection in the Yongxin gold mining area, Heilongjiang, China. Sci. Rep. 15 (1), 7258 (2025).

Zhao, M. et al. Biodegradable microplastics coupled with Biochar enhance cd chelation and reduce cd accumulation in Chinese cabbage. Biochar 7 (1), 1–17 (2025).

Yu, H. et al. Modeling thermal-induced Wellhead growth through the lifecycle of a well. Geoenergy Sci. Eng. 241, 213098 (2024).

Parizad, A. & Shahbazi, K. Experimental investigation of the effects of SnO2 nanoparticles and KCl salt on a water base drilling fluid properties. Can. J. Chem. Eng. 94 (10), 1924–1938 (2016).

Misbah, B. et al. Friction reduction of Al2O3, SiO2, and TiO2 nanoparticles added to non-Newtonian water based mud in a rotating medium. J. Petrol. Sci. Eng. 217, 110927 (2022).

Abdo, J. & Haneef, M. D. Clay nanoparticles modified drilling fluids for drilling of deep hydrocarbon wells. Appl. Clay Sci. 86, 76–82 (2013).

Hussain, A., Emadi, H. & Botchway, K. How nanoparticles have ameliorated the challenges in drilling operations. J. Petrol. Sci. Eng. 197, 107931 (2021).

Yanchun, L. I. et al. Surrogate model for reservoir performance prediction with time-varying well control based on depth generative network. Pet. Explor. Dev. 51 (5), 1287–1300 (2024).

Ejileugha, C. et al. Metal oxide nanoparticles in oil drilling: aquatic toxicological concerns. J. Hazard. Mater. Adv. 7, 100116 (2022).

Mahmoud, O. et al. Using Ferric Oxide and Silica Nanoparticles To Develop Modified Calcium Bentonite Drilling Fluids. 33 12–26 (SPE Drilling & Completion, 2017).

Sagala, F. & Nassar, N. N. Nanoparticles for Drilling, Cementing, Hydraulic Fracturing, and Well Stimulation Fluids, in Nanoparticles: An Emerging Technology for Oil Production and Processing Applications, N.N. Nassar, F.B. Cortés, and C.A. Franco, Editors. Springer International Publishing: Cham. pp. 359–380. (2021).

Fang, T. et al. Multi-scale mechanics of submerged particle impact drilling. Int. J. Mech. Sci. 285, 109838 (2025).

Zhang, L. et al. Seepage characteristics of broken carbonaceous shale under Cyclic loading and unloading conditions. Energy Fuels. 38 (2), 1192–1203 (2023).

Mikhienkova, E. I. et al. Experimental study on the influence of nanoparticles on oil-based drilling fluid properties. J. Petrol. Sci. Eng. 208, 109452 (2022).

Parizad, A., Shahbazi, K., Ayatizadeh, A. & Tanha Enhancement of polymeric water-based drilling fluid properties using nanoparticles. J. Petrol. Sci. Eng. 170, 813–828 (2018).

Minakov, A. V. et al. A study of the influence of nanoparticles on the properties of drilling fluids. Colloid J. 80 (4), 418–426 (2018).

Zhang, L. et al. Seepage characteristics of coal under complex mining stress environment conditions. Energy Fuels. 38 (17), 16371–16384 (2024).

Yin, B. et al. An experimental and numerical study of gas-liquid two-phase flow moving upward vertically in larger annulus. Eng. Appl. Comput. Fluid Mech. 19 (1), 2476605 (2025).

Magzoub, M. I. et al. Loss circulation in drilling and well construction: the significance of applications of crosslinked polymers in wellbore strengthening: A review. J. Petrol. Sci. Eng. 185, 106653 (2020).

Balavi, H. & Boluk, Y. Dynamic filtration of drilling fluids and fluid loss under axially rotating crossflow filtration. J. Petrol. Sci. Eng. 163, 611–615 (2018).

Davoodi, S. et al. Thermally stable and salt-resistant synthetic polymers as drilling fluid additives for deployment in harsh sub-surface conditions: A review. J. Mol. Liq. 371, 121117 (2023).

Bangtang, Y. I. N. et al. Deformation and migration characteristics of bubbles moving in gas-liquid countercurrent flow in annulus. Pet. Explor. Dev. 52 (2), 471–484 (2025).

Li, Y. et al. Preparation of Nano-SiO2/Carbon Fiber-Reinforced concrete and its influence on the performance of oil well cement. Int. J. Polym. Sci. 2019 (1), 2783018 (2019).

Khalil, M. et al. Advanced nanomaterials in oil and gas industry: Design, application and challenges. Appl. Energy. 191, 287–310 (2017).

Parizad, A., Shahbazi, K. & Tanha, A. A. SiO2 nanoparticle and KCl salt effects on filtration and Thixotropical behavior of polymeric water based drilling fluid: with zeta potential and size analysis. Results Phys. 9, 1656–1665 (2018).

Mahamadou, A. S. & Jun, G. Enhancement of rheological properties of nano-Fe2O3-modified drilling fluids. SPE J. 29, 1–14 (2024).

Vryzas, Z. et al. Development and testing of novel drilling fluids using Fe2O3 and SiO2 nanoparticles for enhanced drilling operations. In International Petroleum Technology Conference. (2015).

Alvi, M. A. et al. The effect of micro-sized boron nitride bn and iron trioxide Fe2O3 Nanoparticles on the properties of laboratory bentonite drilling fluid. In SPE Norway One Day Seminar. (2018).

Mukhametgazy, N. et al. Synthesis and characterization of salt tolerant ternary polyampholyte as rheology enhancer and fluid loss additive for water-based drilling fluids. Eng. Sci. 26, 965 (2023).

Omotioma, M. et al. Effects of process factors on the characteristics of water based mud viscosified by kaolin and bentonite. Read. Time 192, 04–09 (2024).

Ali, J. A. et al. A state-of-the-art review of the application of nanotechnology in the oil and gas industry with a focus on drilling engineering. J. Petrol. Sci. Eng. 191, 107118 (2020).

Chernova, M. et al. Substantiation of the use of polymer-composite materials, which reduce the influence of dynamic friction forces of macrostructural surfaces, when drilling wells. Int. Multidisciplinary Sci. GeoConference: SGEM. 22 (1.1), 417–428 (2022).

Shaymanova, R. S. et al. IMPROVEMENT OF DRILLING FLUID FOR CONSTRUCTION OF WELLS. Multidisciplinary J. Sci. Technol. 2 (2), 12–14 (2022).

Al-Shargabi, M. et al. Nanoparticle applications as beneficial oil and gas drilling fluid additives: A review. J. Mol. Liq. 352, 118725 (2022).

Yunita, P., Irawan, S. & Kania, D. Optimization of Water-based drilling fluid using Non-ionic and anionic surfactant additives. Procedia Eng. 148, 1184–1190 (2016).

Jain, R. & Mahto, V. Evaluation of polyacrylamide/clay composite as a potential drilling fluid additive in inhibitive water based drilling fluid system. J. Petrol. Sci. Eng. 133, 612–621 (2015).

Cheraghian, G. Nanoparticles in drilling fluid: A review of the state-of-the-art. J. Mater. Res. Technol. 13, 737–753 (2021).

Arthur, K. G. & Peden, J. M. The evaluation of drilling fluid filter cake properties and their influence on fluid loss. In International Meeting on Petroleum Engineering. (1988).

Krueger, R. F. Evaluation of Drilling-Fluid Filter-Loss additives under dynamic conditions. J. Petrol. Technol. 15 (01), 90–98 (1963).

Griffith, J. & Osisanya, S. O. Effect of drilling fluid filter cake thickness and permeability on cement slurry fluid loss. J. Can. Pet. Technol. 38(13) (1999).

Kumar, M., Kumar, R. & Kumar, R. Material extrusion-based additive manufacturing of sandwiched acrylonitrile butadiene styrene/glass fibers composites: machine learning approach to model tensile stress. Polym. Compos. 45 (16), 15100–15112 (2024).

Singh, K., Kumar, M. & Saini, J. S. Metal inserts for performance improvement in glass fiber-reinforced polymer nanocomposite joints under accelerated aging conditions. Polym. Compos. 43 (3), 1448–1461 (2022).

Sharma, H. et al. From composition to performance: structural insights into polymer composites. Next Mater. 8, 100852 (2025).

Ramachandran, A. R. et al. Multi-attribute optimization of drilling Carbon-Innegra fiber–reinforced composites using Entropy-TOPSIS. Int. J. Adv. Manuf. Technol. 139 (7), 3361–3379 (2025).

Henton, D. E. et al. Polylactic Acid technology, in Natural fibers, biopolymers, and Biocomposites. 559–607 (CRC Press, 2005).

Davachi, S. M. & Kaffashi, B. Polylactic acid in medicine. Polym.-Plast. Technol. Eng. 54 (9), 944–967 (2015).

Chen, L. et al. Mechanism of sodium tripolyphosphate inhibiting the syneresis of HPAM hydrogel. RSC Adv. 5 (103), 84872–84878 (2015).

Sun, F. et al. Effect of composition of HPAM/Chromium(III) acetate gels on delayed gelation time. J. Dispers. Sci. Technol. 37 (6), 753–759 (2016).

Jia, H. et al. Research on the Gelation Performance of Low Toxic PEI Cross-Linking PHPAM Gel Systems as Water Shutoff Agents in Low Temperature Reservoirs. 49 9618–9624 (Industrial & Engineering Chemistry Research, 2010).

Aghdam, S. K. et al. Thermodynamic modeling of saponin adsorption behavior on sandstone rocks: an experimental study. Arab. J. Sci. Eng. 48 (7), 9461–9476 (2023).

Aghdam, S. K., Kazemi & Ahmadi, M. A laboratory study of a novel bio-based nonionic surfactant to mitigate clay swelling. Petroleum 7 (2), 178–187 (2021).

Aghdam, S. K., Kazemi & Ahmadi, M. Studying the effect of various surfactants on the possibility and intensity of fine migration during low-salinity water flooding in clay-rich sandstones. Results Eng. 18, 101149 (2023).

Hazbeh, O. et al. Hybrid computing models to predict oil formation volume factor using multilayer perceptron algorithm. J. Petroleum Min. Eng. 23 (1), 17–30 (2021).

Elsen, J. M. et al. Application of a Lime-Based drilling fluid in a High-Temperature/High-Pressure environment. SPE Drill. Eng. 6 (01), 51–230 (1991).

Holt, C. A. et al. Use of Potassium/Lime drilling-Fluid system in Navarin basin drilling. SPE Drill. Eng. 2 (04), 323–330 (1987).

Harrison, J. R. et al. Novel Lime-Free Drilling Fluid System Applied Successfully in Gulf of Thailand. in SPE/IADC Drilling Conference. (1999).

Kelly, J. Jr. Drilling fluids Selection, Performance, and quality control. J. Petrol. Technol. 35 (05), 889–898 (1983).

Parizad, A., Shahbazi, K. & Tanha, A. A. Enhancement of polymeric water-based drilling fluid properties using nanoparticles. J. Petrol. Sci. Eng. 170, 813–828 (2018).

Arora, G. et al. Micro-scale analysis of HA-PLLA bio-composites: effect of the interpenetration of voids on mechanical properties. Mater. Today Commun. 28, 102568 (2021).

Rana, M., Kumar, M. & Kumar, R. Fused deposition modelling approach in recycled polypropylene/aluminum powder composites for sustainable development. Appl. Sci. Eng. Progress. 17 (4), 7501–7501 (2024).

Singh, H. et al. Influence of natural crosslinker and fibre weightage on waste kibisu fibre reinforced wheatgluten biocomposite. (2021).

Bhowmik, P. et al. Influence of natural crosslinker and fibre weightage on waste Kibisu fibre reinforced wheatgluten biocomposite. J. Polym. Res. 28 (4), 106 (2021).

Singh, H. et al. The synergistic influence of lemon extract on the physio-chemical properties of Kibisu silk reinforced wheat gluten biocomposite. (2022).

Bhowmik, P. et al. The synergistic influence of lemon extract on the physio-chemical properties of Kibisu silk reinforced wheat gluten biocomposite. Polym. Bull. 80 (4), 4371–4386 (2023).

Heidarpour, M. et al. New magnetic nanocomposite Fe3O4@Saponin/Cu(II) as an effective recyclable catalyst for the synthesis of aminoalkylnaphthols via Betti reaction. Steroids 191, 109170 (2023).

Parizad, A. et al. Experimental Investigation of the Effect of TiO2 Nanofluid and KCl Salt on Polymeric water-based Drilling Fluid Properties. Oil & Gas Science and Technology–Revue d’IFP Energies nouvelles. 74 9 (2019).

Davoodi, S. et al. Hybridized machine-learning for prompt prediction of rheology and filtration properties of water-based drilling fluids. Eng. Appl. Artif. Intell. 123, 106459 (2023).

Dong, Z. et al. A novel method for automatic quantification of different pore types in shale based on SEM-EDS calibration. Mar. Pet. Geol. 173, 107278 (2025).

Asemani, M. & Rabbani, A. R. Detailed FTIR spectroscopy characterization of crude oil extracted asphaltenes: curve resolve of overlapping bands. J. Petrol. Sci. Eng. 185, 106618 (2020).

Ovchinnikov, O. V. et al. Manifestation of intermolecular interactions in FTIR spectra of methylene blue molecules. Vib. Spectrosc. 86, 181–189 (2016).

Bhowmik, P. Development and Characterisation of Waste Kibisu Silk Reinforced Biodegradable Polymer Composite. (2023).

Shah, S. N., Shanker, N. H. & Ogugbue, C. C. Future challenges of drilling fluids and their rheological measurements.

Ancey, C. & Jorrot, H. Yield stress for particle suspensions within a clay dispersion. J. Rheol. 45 (2), 297–319 (2001).

Gradzielski, M. Polymer–surfactant interaction for controlling the rheological properties of aqueous surfactant solutions. Curr. Opin. Colloid Interface Sci. 63, 101662 (2023).

Li, X. L. et al. A new environmentally friendly water-based drilling fluids with laponite nanoparticles and polysaccharide/polypeptide derivatives. Pet. Sci. 19 (6), 2959–2968 (2022).

Fan, W. et al. Review of nanoparticles in water-based drilling fluids: innovations, challenges, and future directions. (Energy & Fuels, 2025).

Lin, Y. et al. Effect of nanoparticles on rheological properties of water-based drilling fluid. Nanomaterials 13(14), 2092 (2023).

Oseh, J. O. et al. Experimental investigation of the effect of Henna leaf extracts on cuttings transportation in highly deviated and horizontal wells. J. Petroleum Explor. Prod. Technol. 9, 2387–2404 (2019).

Hamza, A. et al. Polymeric formulations used for loss circulation materials and wellbore strengthening applications in oil and gas wells: A review. J. Petrol. Sci. Eng. 180, 197–214 (2019).

Cheraghian, G. et al. Adsorption polymer on reservoir rock and role of the nanoparticles, clay and SiO 2. Int. Nano Lett. 4, 1–8 (2014).

Ibrahim, M. A. et al. A review on the effect of nanoparticle in drilling fluid on filtration and formation damage. J. Petrol. Sci. Eng. 217, 110922 (2022).

Ma, T., Peng, N. & Chen, P. Filter cake formation process by involving the influence of solid particle size distribution in drilling fluids. J. Nat. Gas Sci. Eng. 79, 103350 (2020).

Ikram, R. et al. Utilization of eco-friendly waste generated nanomaterials in water-based drilling fluids; state of the Art review. Materials 14 (15), 4171 (2021).

Bayat, A. E. et al. Experimental investigation of rheological and filtration properties of water-based drilling fluids in presence of various nanoparticles. Colloids Surf., A. 555, 256–263 (2018).

Rafieefar, A. et al. Rheological behavior and filtration of water-based drilling fluids containing graphene oxide: experimental measurement, mechanistic understanding, and modeling. ACS Omega. 6 (44), 29905–29920 (2021).

Akpan, E. U., Enyi, G. C. & Nasr, G. G. Enhancing the performance of Xanthan gum in water-based mud systems using an environmentally friendly biopolymer. J. Petroleum Explor. Prod. Technol. 10 (5), 1933–1948 (2020).

Bardhan, A. et al. Performance evaluation of novel silane coated nanoparticles as an additive for high-performance drilling fluid applications. IPTC. (2023).

Bharat, N. et al. Development and characterization of novel PLA/Henna biocomposites for sustainable additive manufacturing. J. Inorg. Organomet. Polym Mater. 1–18 (2025).

Mohammed, A. A. & Elrayah, A. A. I. Production of high-performance drilling fluid additive converting and valorization palm frond waste into a value-added derived carboxymethyl cellulose (CMC). J. Eng. Appl. Sci. 72 (1), 111 (2025).

Author information

Authors and Affiliations

Contributions

All authors contributed equally to this research paper.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Hsu, CY., Kumar, A., Hussain, M. et al. Synthesis of polylactic acid/Henna polymer composite and its application in optimizing drilling fluid rheology and filtration performance. Sci Rep 15, 38942 (2025). https://doi.org/10.1038/s41598-025-22807-4

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-22807-4