Abstract

The increasing demand for lightweight, high-strength components in aerospace, automotive, and electronics has intensified interest in aluminium matrix composites (AMCs) with enhanced machinability. Drilling of particle-reinforced AMCs remains challenging due to burr formation and surface quality issues. In this study, Al6061 and Al6063 alloys reinforced with 3 wt.% SiC and 2 wt.% ZrO2 were fabricated via stir casting to achieve uniform particle dispersion. Drilling experiments evaluated the influence of spindle speed and feed rate on drilling time, burr formation, and surface roughness. Microstructural analysis (SEM/EDS) confirmed homogeneous reinforcement distribution with reduced clustering. Results revealed that increasing the spindle speed to 4540 rpm with a feed rate of 0.076 mm/rev reduced drilling time by 96% (Al6061) and 90% (Al6063), and improved surface finish by 32% and 55%, though burr heights increased significantly. TOPSIS identified 4540 rpm with 0.076 mm/rev as optimal, offering effective balance and applicable to precision AMC components.

Similar content being viewed by others

Introduction

The manufacturing sector has undergone a substantial transformation, with industries such as automotive, aerospace, electrical, electronics, and medical increasingly utilizing new engineering materials1,2. This transformation is driven by the growing need for materials that offer an optimal combination of superior mechanical capabilities and lightweight characteristics, resulting in enhanced performance, fuel efficiency, and sustainability3,4. Aluminium (Al) alloys have gained popularity due to their remarkable strength-to-weight ratio, corrosion resistance, and ease of manufacture5,6,7,8. These attributes render them ideal for structural applications requiring elevated stiffness and fatigue resistance7.

The aerospace industry mandates stringent standards for materials utilized in aircraft components, necessitating attributes such as high strength, thermal stability, and resistance to environmental degradation9. Al alloys, specifically Al6061 and Al6063, have gained popularity due to their superior mechanical and tribological characteristics10,11. Their excellent machinability and weldability significantly contribute to their prevalent use in aircraft structural components, fuselage frames, and wing panels10,11. The automobile sector has incorporated these alloys to manufacture lighter components, thereby enhancing fuel efficiency, reducing carbon emissions, and improving vehicle performance12,13. Recently, Electric Vehicles (EVs) have increased the need for lightweight materials to balance the weight of battery systems, making Al-based composites highly attractive14,15. Moreover, in the electrical and electronics industries, Al materials were considered for their exceptional electrical and thermal conductivity, facilitating the development of small, energy-efficient, and high-performance devices12.

Traditional Al alloys and composite materials enhanced with high-performance reinforcements, such as Silicon Carbide (SiC) and Zirconium Dioxide (ZrO2), have garnered considerable attention16,17. These composites exhibit superior mechanical and thermal properties compared to monolithic materials, making it well-suited for applications requiring high wear resistance, strength, and durability16,17. Combining SiC and ZrO2 reinforcements boosts thermal stability, hardness, and structural integrity, offering new possibilities for these composites in aerospace, automotive, and various high-performance engineering fields17,18. The addition of ceramic reinforcements notably enhances the wear resistance and load-bearing strength, making these composites especially useful for structural and tribological applications, including engine parts, brake rotors, and turbine blades17,18,19.

The utilization of Al-based composites presents numerous challenges due to their heterogeneous composition and the inclusion of abrasive reinforcement particles17,20. Traditional machining methods frequently result in problems such as increased cutting forces, subpar surface finish, quick tool wear, and burr formation21,22,23. The hardness and brittleness of ceramic reinforcements play a role in tool wear, which results in higher machining costs and lower efficiency21,22. Among various machining operations, drilling is a critical process in component fabrication, where precision, dimensional accuracy, and surface integrity play a vital role22,24,25,26. Achieving optimal drilling performance requires a precise selection of machining parameters to minimize tool wear, burr formation to enhance Material Removal Rates (MRR), and ensure superior surface quality24.

Due to the intricacy of optimizing machining parameters for Aluminium Matrix Composites (AMCs), Multi-Criteria Decision-Making (MCDM) methodologies have become essential to assess many performance measures and to determine the most appropriate process conditions27,28. These techniques help manufacturers and researchers navigate conflicting objectives, such as maximizing productivity while minimizing tool degradation and machining defects. Various machining parameters, including feed rate, spindle speed, cutting fluid application, and tool material, must be optimized to balance these competing factors27,28. One of the most effective tools used in machining optimization is the Technique for Order of Preference by Similarity to Ideal Solution (TOPSIS)27,29. This methodology helps to rank the various parameter sets by aligning them with an ideal solution, allowing for a thoughtful decision-making process that provides performance trade-offs27,29.

The primary objective of this study is to determine the optimal drilling settings that enhance machining efficiency while reducing production costs and ensuring superior component fabrication. In the current study, the TOPSIS is employed to integrate and rank multiple, often competing, machinability responses for Al6061/Al6063–SiC–ZrO2 composites. The selection of TOPSIS is driven by three main considerations. First, TOPSIS provides a straightforward, single ranking by comparing each alternative to both the ideal and least desirable solutions30,31. This is advantageous when practical implementation requires selecting one optimal parameter combination rather than interpreting an extensive Pareto front, as is the case with algorithms such as the Non-dominated Sorting Genetic Algorithm II (NSGA-II). Second, drilling trials on metal–matrix composites are costly and time-consuming, yielding limited data points. TOPSIS performs effectively under these conditions without the large data requirements or complex optimization processes often necessary for Artificial Neural Networks (ANN), Genetic Algorithm, and Machine Learning Algorithms26,32,33. Finally, TOPSIS enables the incorporation of priority weights for different criteria, allowing for the adjustment of the optimization process based on specific industrial needs and the easy evaluation of the impact of such changes. While more advanced methods, such as NSGA-II, can explore a broader optimization space, they still require an additional selection stage to pinpoint a final solution. Given the objectives and limitations of this work, TOPSIS offers a balanced, transparent, and resource-efficient approach that also provides a structured foundation for applying more complex methods in future research.

Limited work has examined the comparative machinability of both Al6061 and Al6063 alloys reinforced simultaneously with dual ceramic particles (SiC and ZrO2), fabricated via stir casting, and evaluated under identical drilling conditions. Moreover, previous investigations often relied on single-response optimization, overlooking the practical trade-offs between productivity, burr control, and surface finish. The proposed research work bridges these gaps by conducting a comprehensive experimental study that integrates microstructural characterization, detailed burr and roughness analysis, and MCDM using TOPSIS to identify optimal drilling parameter ranges. This combined comparative and optimization-focused approach provides a novel framework for machining reinforced Al alloys, offering insights directly relevant to aerospace, automotive, and precision manufacturing sectors.

Materials and methods

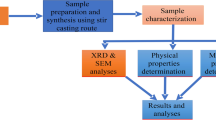

The methodology is structured to ensure the accuracy, consistency, and robust scientific basis for data collection and analysis. The experimental workflow comprises five principal stages: (i) Material Selection, (ii) Composite Fabrication, (iii) Drilling Process, (iv) Evaluation of Machining Performance, and (v) Optimization of Drilling Parameters. The process flow is illustrated in Fig. 1.

Material selection

Selecting appropriate materials is crucial for ensuring the applicability and reliability of drilling tests. This study examines Al6061 and Al6063 due to their widespread application across multiple industries, owing to their excellent corrosion resistance, machinability, and dependable mechanical properties. These alloys are commonly used in automotive, aerospace, and structural applications, making them suitable for analyzing and optimizing drilling parameters. Tables 1 and 2 present the chemical compositions of Al6061 and Al6063. Standard metallurgical characterization procedures were followed to identify the composition and characteristics prior to subsequent processing.

Casting and fabrication

The manufacturing process is a crucial phase in preparing Al composite specimens to exhibit their mechanical properties. The selected parent alloys, Al6061 and Al6063, were initially fabricated as cylindrical rods and transformed into a composite rectangular block for drilling the specimens. The casting technique ensured the uniformity of material qualities with efficient machining conditions. The casting method employed a controlled metal casting technique, where Al alloys were melted inside a crucible furnace at a temperature ranging from 680 to 720 °C, facilitating complete liquefaction while minimizing oxidation. Reinforced particles were mixed during the casting process to enhance the material characteristics of the Al matrix. Utilizing insights from previous studies34 3% SiC and 2% ZrO2 were used as reinforcements. SiC is esteemed for its exceptional durability, hardness, and ability to enhance the tensile strength of metal matrices for machining applications. ZrO2 improves toughness, chemical stability, and thermal degradation resistance, ensuring the material maintains structural integrity under varying machining conditions. The reinforcement particles were heated up to 300 °C prior to incorporation into the molten Al to improve their wettability and ensure optimal dispersion within the matrix. This phase is crucial, since improper dispersion of the reinforcing particles may lead to inconsistencies that adversely affect the mechanical performance of the finished composite material.

The molten metal was poured into the prepared rectangular moulds to get the required shape. The procedure was meticulously monitored to prevent defects such as porosity, cracks, or other metallurgical defects that could compromise the final mechanical qualities of the specimens. After pouring the molten Al composite into the moulds, it was allowed to harden under ambient conditions to avert any internal defects. After reaching room temperature, it is removed from the moulds by a shaking process. The rectangular specimens were subsequently ground and roughly processed by a milling operation to achieve the required dimensional precision and surface smoothness. The final dimensions of the specimens were verified using accurate measuring instruments to ensure compliance with the experimental specifications.

Experiment planning and drilling process

Drilling is a crucial step in the manufacturing process, where burr formation influences the service life and/or surface quality23. Optimizing the drilling parameters is crucial for producing high-quality holes with low defects. This study investigated the drilling process to assess the impact of spindle speed and feed rate on burr development, surface roughness, and the overall quality of holes in Al6061 and Al6063 composites. The spindle speed and feed rate were selected because they are major parameters that determine the quality of drilled holes35. The Taguchi technique was employed to evaluate these factors and to determine the optimal drilling settings. The Taguchi design was chosen for its efficacy in reducing variability and improving process efficiency. The L27 orthogonal array was initially chosen for the detailed assessment of the required parameters. This methodology yielded 27 distinct experimental trials with different spindle speed and feed rates. The parameter combinations were generated utilizing Minitab 21 statistical software, which facilitates a systematic and uniform testing methodology. The selected parameter levels were provided in Table 3 to illustrate variations in spindle speed and feed rate, facilitating the performance study. Following each experimental run, the response variables such as burr height, burr thickness, and surface roughness were assessed to determine the impact of the machining settings.

The drilling process was conducted on an LMW LMill55 CNC machining center, providing precise control over feed rate, spindle speed, and cutting depth. The machine offers a minimum spindle speed of 200 rpm and a maximum of 6000 rpm with a wide range of speed options to evaluate different machining conditions. A 6 mm diameter, straight-shank twist drill bit of 2022 series with a 118° tip angle, 93 mm overall length, 57 mm flute length, and a shank diameter of 6 mm, manufactured by Jobber, was used for the drilling experiments. The drill bit was selected for its efficacy with Al alloys, producing clean and precise holes while reducing deflection35. The parameters’ range, as shown in Table 3, was determined based on the manufacturer’s recommendations and compatibility with the selected tool. The range was also ensured by several trial runs prior to actual experiments. Before each drilling operation, the specimens were securely affixed to the machine table to prevent vibrations that could affect the precision of the holes. To maintain optimal cutting efficiency and minimize tool wear, lubrication and cooling were applied intermittently during the drilling process. Upon completion of the drilling, burr height at both the entry and exit positions of each hole was measured using a Coordinate Measuring Machine (CMM) to ensure precision. The burr thickness was determined using a digital Vernier Caliper. The surface roughness has been calculated by using a surface roughness tester, yielding an accurate assessment of the inner surface quality of the hole. Three measurements were obtained for each specimen. Statistical analysis, including Analysis of Variance (ANOVA), was conducted to identify the primary factors that affect surface roughness and burr formation. These findings provide significant results for enhancing drilling conditions and reducing machining defects in Al composites. The specimens were configured with dimensions of 130 mm in length, 115 mm in width, and 14 mm in thickness.

Measurement and analysis

After the drilling operation, precise measurement techniques were employed to evaluate critical output parameters, including burr thickness, burr height, and surface roughness. These measurements were crucial for understanding the impact of machining parameters on hole quality, thereby optimizing drilling conditions for AMCs. The burr height was assessed at the entry and exit of each drilled hole using CMM. Due to the significant influence of burr formation on post-processing and assembly, precise measurement is crucial for improving the machining efficiency. The burr thickness was determined using a digital vernier calliper. To minimize inaccuracies, multiple readings were taken into account for the analysis. The surface roughness of the drilled holes’ surfaces was assessed using a Mitutoyo Surftest SJ-410 surface roughness tester. Following ISO 4288:1996, a cut-off length (λc) of 0.8 mm was selected, as this value is recommended for surfaces with an expected Ra range of 0.1–2.0 μm, which corresponds to the finish typically obtained in precision drilling of AMCs. Measurements were taken at three axial depths of the drilled hole as near the entry, mid-depth, and close to the exit, and repeated at angular positions separated by 120° around the circumference to account for circumferential variations. The average of these readings was reported as the representative surface roughness (Ra). This protocol ensured consistency, minimized localized bias, and aligned with standard surface evaluation practices. The collected data were analyzed statistically using ANOVA to identify the optimal machining parameters that affect burr development and surface roughness. ANOVA provides significant insights into the effect of spindle speed and feed rate on the measured responses, facilitating the identification of ideal settings to minimize burr formation and improve surface quality. Signal-to-noise (S/N) ratio analysis was performed utilizing the Taguchi framework, employing a “smaller-the-better” technique for burr thickness, burr height, and surface roughness to minimize undesirable machining effects. This comprehensive research facilitated the development of an enhanced drilling method, resulting in superior machining capability for Al composites.

Optimization of drilling parameters

The TOPSIS approach is used to optimize the drilling process parameters. This methodology is an MCDM tool that assists in evaluating and selecting the optimal machining conditions. The experimental results, derived from the Taguchi S/N ratio, were employed as input data for the TOPSIS analysis. This method facilitates the determination of optimal parameter combinations that minimize burr formation and surface roughness, thereby improving hole quality. This process involves normalizing the experimental data, computing the weighted Euclidean distance from both the ideal and negative-ideal solutions, and determining the relative closeness coefficient for each experimental set. The drilling parameters with the maximum closeness coefficient were considered as optimal, resulting in reduced machining defects and enhanced performance. This study provides significant insights for industrial applications in achieving cost-efficient and high-quality machining of Al composites by optimizing drilling process parameters.

TOPSIS was originally proposed by Hwang et al.36, and it is a robust approach for MCDM that aids in identifying the optimal alternatives by emphasizing the notion of compromise solutions. The optimal solution is the one that is closer to the positive ideal and furthest from the negative ideal. The subsequent steps delineate the TOPSIS methodology employed in this research:

Step 1: Identification of Decision Parameters.

The parameters that need to be minimized, including burr height, burr thickness, surface roughness, and drilling time, are viewed as cost criteria, whereas any parameters that need to be maximized would be seen as benefit criteria.

Step 2: Formation of the Decision Matrix.

A decision matrix [Xij] was created, with each row i representing an alternative (experimental run) and each column j representing a criterion (response parameter).

Step 3: Normalization of the Decision Matrix.

Each element of the matrix is normalized using the Eq. (1)

where Nij is the normalized value, Xij is the original decision matrix value, and m represents the number of alternatives.

Step 4: Construction of the Weighted Normalized Decision Matrix.

To get the weighted normalized matrix, multiply each normalized value by the weight assigned to its corresponding criterion using Eq. (2)

where Wij is the weight assigned to criterion j, determined based on expert judgment and literature references. Each criterion’s weight (Wj), which is determined by expertise, is assigned a value of 0.1 for the remaining criteria and 0.3 for drilling duration and surface roughness.

Step 5: Determination of Positive and Negative Ideal Solutions.

The ideal solutions are determined using Eqs. (3) and (4)

where J is connected to the benefit criteria and can take the values 1, 2, 3,…, n, J’ is associated with the cost criteria, J’ = 1, 2, 3, …, n. While the unfavourable ideal solution (A−) is calculated based on maximizing, the positive ideal solution (A+) is determined via minimizing. According to the current study, minimizing all the reactions is necessary to improve the component’s production and quality.

Step 6: Calculation of Separation Measures.

The Euclidean distance of each alternative from the ideal solutions is calculated using Eqs. (5) and (6).

Similarly, Eq. (6) is used to determine the unfavourable ultimate one.

Step 7: Computation of Relative Closeness Coefficient.

The relative closeness coefficient (Ci) of each alternative to the ideal solution is computed using Eq. (7) where a higher Ci value indicates a better alternative.

Step 8: Ranking of Alternatives.

The alternatives are ranked based on Ci, with the highest value representing the optimal set of drilling parameters. This systematic application of the TOPSIS method ensures an objective and quantitative selection of the best machining conditions, balancing multiple conflicting response parameters efficiently.

Results and discussions

In addition to the casting of Al6061 and Al6063 reinforced with 3 wt.% SiC and 2 wt.% ZrO2, the specimens were subjected to microstructural examination and Energy Dispersive Spectroscopy (EDS) to evaluate the uniform distribution of the reinforcement particles and elemental compositions. This research offers critical insights into the reinforcement distribution, bonding at interfaces, and potential defects within the composite structure, which directly impact its mechanical and machining properties. The results from Scanning Electron Microscopy (SEM) and EDS are crucial for evaluating the uniformity of reinforcement distribution, which in turn determines the wear resistance, strength, and thermal stability of composite materials. After the testing process, the drilling performance was evaluated using TOPSIS-based MCDM techniques to rank the tests based on their optimal machining conditions. The subsequent sections offer a comprehensive examination of these findings, elucidating the relationships among composite microstructure, machining reactions, and process optimization.

Microstructural analysis

Microstructural analysis of Al6061

The microstructural analysis of the prepared Al composites was conducted using SEM. This enabled us to assess the distribution of the reinforcement particles, the integrity of the interfaces, and the overall morphology of the matrix.

Figure 2a and b depict the SEM image at different magnifications of the Al6061 composite, and it is evident that a well-distributed reinforcement phase is within the Al6061 matrix, suggesting that the processing was effective and the material is homogeneous. The SiC and ZrO2 particles show up as areas of clear contrast, indicating that they have been successfully integrated into the matrix. Few areas exhibit slight clustering, possibly due to particles grouping together because of insufficient dispersion during the manufacturing process. The interface of the reinforcement matrix looks solidly bonded, showing very few visible voids or signs of detachment. This is crucial for enhancing the mechanical properties of the composite, particularly its hardness, wear resistance, and thermal stability. Moreover, the inclusion of ZrO2 particles is expected to refine the grains, thereby helping to prevent excessive growth and enhancing the overall mechanical strength. Certain dark contrast areas in the microstructure might suggest the presence of micro-porosities that developed during solidification. These could serve as stress concentration points, which may affect the composite’s ability to resist fractures.

Figure 3 depicts the EDS analysis at the indicated EDS Spot 1 in Fig. 2a to verify the elemental makeup of the reinforcement particles and confirm their dispersion properties. This evaluation of microstructure offers key insights into how adding reinforcement affects the structural integrity of the composite. It emphasizes the importance of optimizing fabrication parameters like stirring speed, compaction pressure, and sintering temperature to ensure a more even distribution of the reinforcement phase and enhance mechanical performance. From the analysis it is evident that the reinforced particles were spread over the areas of the prepared samples.

Microstructural analysis of Al60663

The SEM and EDS analysis on Al6063 reinforced with 3 wt.% SiC and 2 wt.% ZrO2 was performed. Figure 4a and b depicts the SEM image at different magnification and it shows an even distribution of SiC and ZrO2 reinforcements within the Al6063 matrix, suggesting that the fabrication process was well-controlled. The lighter areas in the image indicate the reinforcing phases, whereas the darker sections show the matrix. The presence of fine and evenly distributed reinforcement particles indicates that the stir casting process successfully facilitated dispersion, improving the composite’s mechanical strength and wear resistance. Localized particle agglomeration can be seen in specific areas, potentially creating stress concentration sites that affect the composite’s fracture toughness and ductility.

The connection between the matrix and the reinforcements seems to be well-integrated, reducing the chances of debonding, which is essential for achieving better load transfer efficiency. ZrO2 inclusions also play a role in refining grains, helping to stop excessive grain growth, and enhancing the overall hardness of the composite. The surface shows some micro voids and porosities, likely resulting from solidification shrinkage or insufficient degassing during processing. The presence of porosity can affect thermal conductivity, mechanical stability, and tribological performance.

Figure 5 shows the EDS analysis of the highlighted EDS Spot 1 in the Fig. 4a which is crucial for confirming the elemental composition and ensuring the uniformity of reinforcement dispersion. This analysis offers important insights into the microstructural behavior of Al6063-SiC-ZrO2 composites. It emphasizes the importance of optimizing fabrication parameters like stirring speed, compaction pressure, and sintering temperature to ensure a more even distribution of the reinforcement phase and enhance mechanical performance. From the analysis it is evident that the reinforced particles were spread over the areas of the prepared samples.

Drilling trials on Al6061 and Al6063 composites

The results from the 27 planned drilling experiments on Al6061 and Al6063 based composites are carefully examined to evaluate how machining parameters affect drilling performance. The key response parameters, such as drilling time (s), entry burr height (mm), exit burr height (mm), entry burr thickness (mm), exit burr thickness (mm), and surface roughness (µm), have been recorded and are shown in Tables 4 and 5. The parameters offer a way to quantitatively assess how well the Al composites can be machined when different spindle speeds and feed rates are applied37. The differences in response values indicate a clear link between the cutting parameters and how material is removed. These machining parameters greatly affects the drilling results, making it essential to conduct a thorough multi-response optimization to find the best operating conditions.

ANOVA results

The ANOVA results provided in Tables 6 and 7 reveal distinct trends in how spindle speed, feed rate, and their interaction influence drilling performance for both Al6061 and Al6063 composites. For both composites, drilling time exhibits extremely high coefficients of determination (R2 ≈ 0.99), indicating that nearly all variability is explained by the selected parameters. Spindle speed and feed rate are both highly significant (p < 0.001), with feed rate contributing slightly more (41.88% in Al6061 and 40.32% in Al6063) than spindle speed. The interaction term also shows strong significance, contributing around 19–20%, underscoring that optimal drilling speed combinations depend on coordinated parameter settings rather than independent adjustments.

Effect size metrics can provide valuable understanding into the practical importance of the variables, even in the absence of strong statistical significance. The common measures of effect size is η2 which can be calculated using the Eq. (8). For entry burr height, the models for Al6061 (R2 = 0.43) and Al6063 (R2 = 0.62) show weaker fits, suggesting other uncontrolled factors may influence burr formation. None of the main effects are statistically significant for Al6061, while in Al6063, the interaction term (p = 0.005) dominates, contributing an effect size of 0.457. This implies that in Al6063, burr height control is more dependent on the interplay between spindle speed and feed rate than on individual parameter settings. However, for exit burr height both alloys exhibit strong models, especially Al6063 (R2 = 0.95), where feed rate is the most influential factor (effect size of 0.448, p < 0.001). In Al6061, both spindle speed (p = 0.002) and feed rate (p = 0.008) are significant, with effect sizes of ~ 0.30 and 0.22, respectively. These findings indicate that exit burrs are more sensitive to machining parameters than entry burrs.

Entry burr thickness shows weak models for both alloys (R2 = 0.44 for Al6061, 0.31 for Al6063) suggest minimal dependence on the studied parameters. High error effect size (> 0.55) indicate that other factors such as tool wear, material microstructure variations, or cutting edge geometry may play a greater role. Similarly, for exit burr thickness in Al6061, both spindle speed (p = 0.001) and feed rate (p < 0.001) significantly affect exit burr thickness, with feed rate having the highest effect size (0.387). For Al6063, feed rate is the dominant factor (0.672, p < 0.001), while spindle speed remains non-significant.

Surface Roughness for Al6061 (R2 = 0.68), spindle speed (p = 0.002) and the interaction term (p = 0.010) are significant, both contributing around 0.31–0.32, while feed rate has negligible influence. In Al6063 (R2 = 0.70), spindle speed (p = 0.001) and feed rate (p = 0.006) are significant, indicating that both cutting velocity and feed rate affect surface finish, although spindle speed remains the more influential factor. Overall, feed rate emerges as the dominant parameter for controlling drilling time and exit burr characteristics in both alloys. Spindle speed shows greater influence on surface roughness and, in combination with feed rate, affects burr formation patterns, particularly in Al6063. Interaction effects are especially notable for entry burr height in Al6063, suggesting that parameter optimization should consider combined settings rather than isolated changes. More findings can be drawn by analysing main effects plots of the results.

Main effects plots

Factorial experiments are frequently used in research to investigate the influence of different process factors on significant response variables in the machining process. The main effects plots were generated using Minitab to provide a clear and effective visualization of the influences of spindle speed and feed rate on burr height, drilling time, surface roughness, and burr thickness while drilling Al6061 and Al6063 composites. Comprehending these impacts is essential to optimizing the drilling conditions and minimizing the defects with enhanced surface quality.

Effect on drilling time

The main effects plot, shown in Figs. 6a, and 7a, illustrates the effect of spindle speed and feed rate on drilling time. When the spindle varies from 1100 rpm to 4540 rpm, the drilling time decreases significantly. This indicates that faster spindle speeds can enhance the efficiency of the material by increasing the cutting velocity and facilitating chip evacuation. At 1100 rpm with lower feed rate, the drilling time is high, taking nearly 18 s due to the slower material penetration. In contrast, at 4540 rpm, the drilling time reduces to around 4 s, showcasing enhanced machining efficiency. Similarly, increasing the feed rate from 0.038 mm/rev to 0.203 mm/rev significantly reduces drilling time, as faster feed rates enable more material to be removed with each revolution, thereby accelerating the entire process. At 0.038 mm/rev, the drilling time is the longest, taking nearly 18 s due to the slower penetration rate. In contrast, at 0.203 mm/rev, the time is reduced to around 3 s, highlighting that finding the right feed rate can enhance productivity. However, high feed rates can lead to effects such as more burr formation and increased tool wear. It is recommended to select a spindle speed ranging between 2920 and 4540 rpm and a feed rate ranging from 0.076 to 0.203 mm/rev to ensure the effective drilling of Al6061/Al6063-SiC-ZrO2 composites.

Effect on burr height

It is evident from Figs. 6b,c and 7b,c that both spindle speed and feed rate have a significant impact on the entry and exit of burrs formations. At lower spindle speeds i.e. 1100 rpm, exit burr heights are measured to be lowest. In contrast, entry burr height is lowest (~ 0.170 mm) at lower spindle speed (1100 rpm) for Al6061 composite, while moderate spindle speed (2920 rpm) resulted lowest entry burr height (~ 0.22 mm). This is because the cutting force becomes more effective, which helps in removing the chip and minimizing plastic deformation at both points on the drill. On the other hand, increasing the feed rate above 0.076 mm/rev leads to an increase in burr height, due to higher material deformation and strain hardening at the cutting edges except entry burr height of Al6061 composite. Hence, the right balance between spindle speed and feed rate is essential to reduce burr formation. At elevated spindle speeds and feed rates, the increase in burr height (65–68%) is explained by localized plastic flow and stress accumulation near the cutting edge. The material underwent extrusion before final fracture, leading to excessive burr development. This physics-based explanation aligns with reported machining studies on Al-based composites.

Effect on burr thickness

The burr thickness, an important factor affecting post-machining processes, is examined in Figs. 6d,e and 7d,e. An average spindle speed of 2920 rpm helps minimize burr thickness to a moderate level (between 0.35 and 0.45 mm) on both entry and exit of Al 6063 composite by encouraging chip fragmentation and improving material removal, resulting in reduced tool dwell time at the cutting edges. On the other hand, lower spindle speed of 1100 rpm resulted lowest entry and exit burr thicknesses (~ 0.2 mm) of Al6061 composite. At higher spindle speeds, specifically between 2920 and 4540 rpm, the extended interaction between the tool and material results in the formation of thicker burrs, as the material is not fully sheared. Conversely, raising the feed rate to 0.203 mm/rev leads to thicker burrs, likely due to greater cutting forces, increased plastic deformation, and strain build-up except the entry burr thickness of Al6063 composite. The results indicate that a good mix of spindle speed (between 2920 and 4540 rpm) and a higher feed rate (0.203 mm/rev) can effectively minimize burr thickness, which in turn reduces the requirement for extensive de-burring work.

Effect on surface roughness

The quality of the surface is an essential factor in precision machining, influencing how well component’s function, their fatigue life, and their adhesion characteristics. The main effects plots in Figs. 6f and 7f show that spindle speed and feed rate are crucial factors in influencing surface roughness. Using higher spindle speeds, such as 4540 rpm, typically yields a smoother surface because it reduces tool vibrations and minimizes the marks left by the tool. In contrast, lower speeds, ranging from 1100 to 2920 rpm, led to the formation of rougher surfaces due to increased friction and uneven shearing of the material. On the other hand, increasing the feed rate to 0.203 mm/rev leads to decreased surface roughness at the lowest (~ 0.85 μm for Al6061 composite and ~ 0.6 μm for Al6063 composite) due to, significant tool engagement, and noticeable feed rates. The results revealed that maintaining a high spindle speed (~ 4540 rpm) along with a controlled feed rate (approximately 0.200 mm/rev) can yield excellent surface finish.

Surface plots

Surface plots provide a detailed visual insight into how spindle speed and feed rate interact and affect drilling performance metrics, including drilling time, burr formation, and surface roughness. These plots help pinpoint the optimal machining conditions to enhance both efficiency and quality.

Effect on drilling time

Figures 8a and 9a show that as spindle speed and feed rate increase, the drilling time noticeably decreases in both the Al6061 and Al6063 composite samples. A spindle speed of 4000 rpm and a feed rate of 0.20 mm/rev result in reduced drilling time due to improved material removal rates and effective chip formation. On the other hand, when using lower spindle speeds (1000–2000 rpm) and feed rates (0.05 mm/rev), the drilling process takes significantly longer due to slow penetration and inadequate chip formation.

Effect on entry and exit burr heights

Figures 8b,c and 9b,c show the changes in burr height for both the Al6061 and Al6063 composites. When the spindle speed is set between 2000 and 3000 rpm and the feed rate is at 0.10 mm/rev, the highest entry burr height is noted, and this height tends to decrease as both parameters are increased for Al6061 composite. On the other hand, the lowest spindle speed of 1000 rpm with a feed rate of 0.10 mm/rev yielded lowest burr height. The maximum exit burr height is observed at 4000 rpm with a feed rate of 0.20 mm/rev for both the composites, whereas a feed rate between 0.05 and 0.10 mm/rev with a spindle speed of 1000 rpm leads to the lowest exit burr height. This indicates a favourable balance between the amount of material removed and the interaction with the tool. After this point, the exit burr height increases again with higher feed rates due to significant material deformation.

Effect on the thickness of entry and exit burrs

In both the Al6061 and Al6063 composite samples, the burr thickness shows a trend that closely resembles that of burr height, as indicated in Figs. 8d,e and 9d,e. The thickest entry burr is observed at 3000 rpm with a feed rate of 0.10 mm/rev for the Al6061 composite, whereas the exit burr thickness is greatest at 4000 rpm and 0.20 mm/rev, representing the most extreme machining condition tested. The minimum burr thickness values for both entry and exit occur at a spindle speed of 1000 rpm and a feed rate of 0.10 mm/rev, suggesting that reduced speeds combined with moderate feed rates can help reduce burr formation in Al6061/Al6063-SiC-ZrO2 composites.

Effect on surface roughness

The trend in surface roughness, illustrated for both the Al6061 and Al6063 composite samples shown in Figs. 8f and 9f, indicates that a spindle speed of 3000 rpm, combined with a feed rate of 0.10 mm/rev, leads to the roughest surface for Al6063 composite. This is attributed to increased tool vibrations and uneven chip formation. The best surface finish is achieved at 4000 rpm with a feed rate of 0.10 mm/rev, indicating that a balance of high spindle speed and moderate feed rate results in improved surface quality. However, when the feed rate of 0.10 mm/rev at 4000 rpm, reduced surface roughness in Al6061 composite due to proper tool engagement, resulting in even material removal.

Examination of the surface plots reveals that higher spindle speeds, combined with moderate feed rates (0.10–0.15 mm/rev), yield the optimal combination for minimizing drilling time, reducing burr formation, and improving surface finish. Nevertheless, using excessive feed can result in thicker burrs and rougher surfaces, so it is essential to find the optimal balance of machining parameters to enhance the drilling performance of Al6061/Al6063–SiC–ZrO2 composites.

The analysis revealed that porosity and particle clustering in the composites correlate positively with burr height and surface roughness. ANOVA further confirmed that these microstructural defects significantly influence machinability responses, highlighting the need for controlled fabrication to minimize defects.

Ranking through TOPSIS

A MCDM approach employing the TOPSIS method was used to determine the optimal drilling conditions, as shown in Table 8. It examines the separation measures of the positive ideal solution (S+) and the negative ideal solution (S−), along with the relative closeness coefficient (Ci), which serves as the ranking criterion for all the experimental trials. The computed values provide a definitive insight into the efficacy of each parameter combination in minimizing burr formation and surface roughness. The TOPSIS ranking results indicate that increased spindle speeds with regulated feed rates enhance machining performance. This combination stabilizes heat generation and chip formation, thereby minimizing tool wear and ensuring a superior drilled surface quality.

The optimization results showed that for the Al6061-based composite, the 22nd experiment reached the top ranking, with a spindle speed of 4540 rpm and a feed rate of 0.076 mm/rev. This indicates the optimal machining conditions, resulting in reduced burr formation and a superior surface finish. The 24th trial of the Al6063-based composite was notable, achieving optimal performance at a spindle speed of 4540 rpm and a feed rate of 0.076 mm/rev. The findings indicate that both Al6063 and Al6061 composites exhibits superior performance at moderate feed rates, at higher spindle speeds. The observed tendencies correlate with the existing literature on drilling Al composites25. It shows that increasing the spindle speeds results in a refined cutting process, eliminating tool wear and enhancing the quality of the produced holes. This research validates the efficacy of the TOPSIS method in optimizing multiple responses and provides significant insights for engineers aiming to enhance the drilling quality of metal matrix composites in a confined production environment.

Confirmation test and sensitivity analysis

To verify the optimized results, a confirmatory experiment was conducted using the identified optimal parameters, and the observed values were compared to the predicted outcomes. Experimental trials for Al6061 and Al6063 composites with an optimum combination of parameters, such as a spindle speed of 4540 rpm and a feed rate of 0.076 mm/rev, resulted in improvements in all the responses except a slight decline of 3% drilling time in Al6061 and burr height (− 5%), exit burr thickness (− 2.94%), and roughness (− 1.54%) in Al6063 composites. From an industrial perspective, the optimized parameters are projected to reduce machining costs by approximately 12–15% due to reduced drilling time and lower tool replacement frequency. The results of confirmation tests are shown in Table 9. The confirmation test demonstrated a strong correlation between the experimental and predicted values, indicating that the optimization method is reliable. Sensitivity analysis has been conducted for both the composites with revised experimental values and different weights assigned to the responses for two different cases. For the first case, drilling time and surface roughness were assigned with a weight of 0.25 and other parameters with 0.125. For the second case, drilling time and surface roughness were assigned with a weight of 0.2 and the other parameters with 0.15. Both the cases resulted in same ranking as same as the initial ranking that confirms stability of the TOPSIS approach in ranking the alternatives.

Conclusion

This study investigated the drilling performance of Al6061 and Al6063 alloys reinforced with 3 wt.% SiC and 2 wt.% ZrO2 composites produced via stir casting. This study provides novelty by simultaneously evaluating Al6061 and Al6063 reinforced with dual ceramic reinforcements (SiC + ZrO2) under identical drilling conditions. Unlike prior works, the present study integrates multi-criteria optimization using TOPSIS with detailed microstructural correlations, thereby bridging gaps in machinability analysis. This research emphasized the microstructural features, elemental makeup, and drilling behaviour. The study provided valuable insights into how spindle speed and feed rate affect drilling time, burr formation, and surface roughness, ultimately leading to improved drilling conditions and enhanced performance. This study leads to the following key conclusions:

-

Detailed microstructural examination using SEM and EDS confirmed a consistent particle distribution with minimal clustering, validating the fabrication process and reinforcing the theoretical framework that uniform particle dispersion enhances structural integrity and machinability.

-

From the drilling trials, spindle speed and feed rate were found to be the most influential parameters affecting machining responses. Higher spindle speeds (3000–4000 rpm) combined with moderate feed rates (0.076 mm/rev) achieved an optimal balance in reducing drilling time by enhancing chip evacuation, minimizing burr formation, and improving surface finish.

-

Higher feed rates (0.203 mm/rev) increased burr thickness and surface roughness, highlighting a trade-off between productivity and precision. These trends are consistent with established machining theories on the effect of cutting velocity and feed on chip formation, cutting forces, and surface integrity.

-

TOPSIS analysis yielded an optimal combination of parameters namely, a spindle speed of 4540 rpm, and a feed rate of 0.076 mm/rev for both the Al6061/Al6063-SiC-ZrO2 composites, which was consistent with ANOVA results.

-

The practical implication for engineering and manufacturing is that process parameters must be carefully tuned for particle-reinforced Al composites to achieve high productivity without compromising surface integrity. The identified optimal parameter range can serve as a reference for industries such as aerospace, automotive, and precision manufacturing, where burr control and surface finish are critical to component performance.

-

Although this work focuses on 3 wt.% SiC and 2 wt.% ZrO2 reinforcements, the methodology can be extended to other reinforcement ratios (e.g., 5 wt.% SiC) and emerging composites such as Al-CNT. In such cases, machining parameters may require adjustments to account for variations in hardness, ductility, and thermal conductivity.

Future research scope and recommendations

-

Future studies could investigate how minimum quantity lubrication impacts the drilling performance of Al6061/Al6063-SiC-ZrO2 composites, aiming to further minimize burr formation and improve surface integrity.

-

Comparing carbide tools with polycrystalline diamond or diamond-coated drills to assess performance gains and tool wear trends under industrial cutting speeds.

-

Extending multi-criteria optimization with machine learning algorithms and evolutionary optimization (e.g., ANN–NSGA-II frameworks) to develop adaptable machining strategies.

Data availability

All data generated or analyzed during this study are included within this article.

References

Alami, A. H. et al. Additive manufacturing in the aerospace and automotive industries: Recent trends and role in achieving sustainable development goals. Ain Shams Eng. J. 14(11), 102516. https://doi.org/10.1016/j.asej.2023.102516 (2023).

Gao, W. et al. The status, challenges, and future of additive manufacturing in engineering. Comput. Aided Des. 69, 65–89. https://doi.org/10.1016/j.cad.2015.04.001 (2015).

Sun, G., Chen, D., Zhu, G. & Li, Q. Lightweight hybrid materials and structures for energy absorption: A state-of-the-art review and outlook. Thin-Walled Struct. 172, 108760. https://doi.org/10.1016/j.tws.2021.108760 (2022).

Zhang, W. & Xu, J. Advanced lightweight materials for automobiles: A review. Mater. Design. 221, 110994. https://doi.org/10.1016/j.matdes.2022.110994 (2022).

Kar, A., Sharma, A. & Kumar, S. A critical review on recent advancements in aluminium-based metal matrix composites. Crystals 14(5), 412. https://doi.org/10.3390/cryst14050412 (2024).

Khalid, M. Y., Umer, R. & Khan, K. A. Review of recent trends and developments in aluminium 7075 alloy and its metal matrix composites (MMCs) for aircraft applications. Results Eng. 20, 101372. https://doi.org/10.1016/j.rineng.2023.101372 (2023).

Sun, Y. The use of aluminum alloys in structures: Review and outlook. Structures, 57, 105290. https://doi.org/10.1016/j.istruc.2023.105290 (2023).

Koklu, U. The drilling machinability of 5083 aluminum under shallow and deep cryogenic treatment. Emerg. Mater. Res. 9(2), 323–330. https://doi.org/10.1680/jemmr.19.00127 (2020)

Tiwary, A., Kumar, R. & Chohan, J. S. A review on characteristics of composite and advanced materials used for aerospace applications. Mater. Today: Proc. 51, 865–870. https://doi.org/10.1016/j.matpr.2021.06.276 (2022).

Doddamani, A. M. et al. Studies on physical, mechanical and tribological properties of Al6063 incorporated with CNT and nano clay as filler materials. Tribol. Ind. 46(4), 722–735. https://doi.org/10.24874/ti.1748.09.24.11 (2024).

Sharma, S. K. et al. Progress in aluminum-based composites prepared by stir casting: Mechanical and tribological properties for automotive, aerospace, and military applications. Lubricants 12(12), 12. https://doi.org/10.3390/lubricants12120421 (2024).

Wazeer, A., Das, A., Abeykoon, C., Sinha, A. & Karmakar, A. Composites for electric vehicles and automotive sector: A review. Green. Energy Intell. Transp. 2(1), 100043. https://doi.org/10.1016/j.geits.2022.100043 (2023).

Wu, X. & Zhang, W. A review on aluminum matrix composites’ characteristics and applications for automotive sector. Heliyon 10, 20. https://doi.org/10.1016/j.heliyon.2024.e38576 (2024).

Adhikari, S., Tathavadkar, V. & Basu, B. Aluminium as a structural material, in Future Landscape of Structural Materials in India, (eds Bhattacharjee, D. & Chakrabarti, S.) 25–43 (Springer Nature, Singapore, 2022). https://doi.org/10.1007/978-981-16-8523-1_2.

Trzepieciński, T. & Najm, S. M. Current trends in metallic materials for body panels and structural members used in the automotive industry. Materials 17(3), 590. https://doi.org/10.3390/ma17030590 (2024).

Karadimas, G. & Salonitis, K. Ceramic matrix composites for aero engine applications—A review. Appl. Sci. 13(5), 5. https://doi.org/10.3390/app13053017 (2023).

Ujah, C. O. & Kallon, D. V. V. Trends in aluminium matrix composite development. Crystals 12(10), 10. https://doi.org/10.3390/cryst12101357 (2022).

Aguirre, T. G., Lamm, B. W., Cramer, C. L. & Mitchell, D. J. Zirconium-diboride silicon-carbide composites: A review. Ceram. Int. 48(6), 7344–7361. https://doi.org/10.1016/j.ceramint.2021.11.314 (2022).

Deepakaravind, V. & Gopal, P. Evaluating the hardness and microstructural analysis of reinforcing the nano silicon carbide and nano zirconium oxide in hybrid Al6061 metal matrix composite, in Advances in Automotive Technologies, (eds Nalim, M. R., Vasudevan, R. & Rahatekar, S.) 231–239 (Springer, Singapore, 2021). https://doi.org/10.1007/978-981-15-5947-1_19.

Anuar, N. F. B. W. et al. Wear properties of graphene-reinforced aluminium metal matrix composite: A review. Rev. Adv. Mater. Sci. 62(1), 20220326. https://doi.org/10.1515/rams-2022-0326 (2023).

Bhardwaj, A. R., Vaidya, A. M., Meshram, P. D. & Bandhu, D. Machining behavior investigation of aluminium metal matrix composite reinforced with TiC particulates. Int. J. Interact Des. Manuf. 18(5), 2911–2925. https://doi.org/10.1007/s12008-023-01378-6 (2024).

Okay, F., Islak, S. & Turgut, Y. Investigation of machinability properties of aluminium matrix hybrid composites, J. Manuf. Process. 68, 85–94. https://doi.org/10.1016/j.jmapro.2021.05.041 (2021).

Baysal, E., Koçar, O., Kahrıman, F. & Köklü, U. Investigation of microstructure, hardness, corrosion and machinability properties of commercially pure aluminum alloyed with rare-earth elements. Int. J. Metalcast. https://doi.org/10.1007/s40962-025-01627-2 (2025).

Chakraborty, S., Raut, R. D., Rofin, T. M. & Chakraborty, S. Optimization of drilling processes of aluminium metal matrix composites using the robust ordinal priority approach. Decis. Anal. J. 7, 100258. https://doi.org/10.1016/j.dajour.2023.100258 (2023).

Vinay, K. B. et al. The effect of process parameters on quality characteristics in the drilling of aluminium–metal matrix composites. Eng. Proc. 59, 53. doi: https://doi.org/10.3390/engproc2023059053 (2023).

Arslane, M. et al. Advanced optimization of drilling parameters in composite materials: A Topsis-Based approach for enhanced manufacturing precision. J. Nat. Fibers. 22(1), 2527276. https://doi.org/10.1080/15440478.2025.2527276 (2025).

Chakraborty, S. & Chakraborty, S. A scoping review on the applications of MCDM techniques for parametric optimization of machining processes. Arch. Comput. Methods Eng. 29(6), 4165–4186. https://doi.org/10.1007/s11831-022-09731-w (2022).

Chowdhury, S. R., Das, P. P. & Chakraborty, S. Optimization of CNC turning of aluminium 6082-T6 alloy using fuzzy multi-criteria decision making methods: A comparative study. Int. J. Interact Des. Manuf. 17(3), 1047–1066. https://doi.org/10.1007/s12008-022-01049-y (2023).

Chatterjee, S. & Chakraborty, S. A study on the effects of objective weighting methods on TOPSIS-based parametric optimization of non-traditional machining processes. Decis. Anal. J. 11, 100451. https://doi.org/10.1016/j.dajour.2024.100451 (2024).

Bhuvanesh Kumar, M. et al. Decision-making through fuzzy TOPSIS and COPRAS approaches for lean tools selection: A case study of automotive accessories manufacturing industry. Int. J. Manage. Sci. Eng. Manage. 18(1), 26–35. https://doi.org/10.1080/17509653.2022.2064356 (2023).

Deepika, S., Anandakumar, S., Bhuvanesh Kumar, M. & Baskar, C. Performance appraisement of supplier selection in construction company with Fuzzy AHP, Fuzzy TOPSIS, and DEA: A case study based approach. J. Intell. Fuzzy Syst. 45(6), 10515–10528. https://doi.org/10.3233/JIFS-231790 (2023).

Tamang, S. & Chandrasekaran, M. Multi-objective optimization of turning performance characteristics using GA coupled with AHP based approach. Int. J. Integrat. Eng. 13(6), 126–136 (2021).

Tandon, S., Singh, S. K., Kacker, R., Gautam, S. S. & Tamang, S. K. Multi-response optimization of 3D printed parts with triangular patterns using nonlinear machine learning regressor technique. J. Mater. Eng. Perform. 34(11), 10642–10658. https://doi.org/10.1007/s11665-024-09869-7 (2025).

Yadav, S., Gangwar, S., Yadav, P. C., Pathak, V. K. & Sahu, S. Mechanical and corrosion behavior of SiC/Graphite/ZrO2 hybrid reinforced aluminum-based composites for marine environment. Surf. Topogr. Metrol. Prop. 9(4), 045022. https://doi.org/10.1088/2051-672X/ac2f87 (2021).

Varatharajulu, M., Duraiselvam, M., Kumar, M. B., Jayaprakash, G. & Baskar, N. Multi criteria decision making through TOPSIS and COPRAS on drilling parameters of magnesium AZ91. J. Magnes. Alloys 10(10), 2857–2874. https://doi.org/10.1016/j.jma.2021.05.006 (2022).

Hwang, C. L. & Yoon, K. Methods for multiple attribute decision making, in Multiple Attribute Decision Making 58–191 (Springer, Berlin 1981). https://doi.org/10.1007/978-3-642-48318-9_3.

Geçgel, B. et al. Effect of silicon on machinability in AlSi6, AlSi12 and AlSi18 alloys. Silicon 16(4), 1467–1479. https://doi.org/10.1007/s12633-023-02760-5 (2024).

Acknowledgements

The authors wish to thank Kongu Engineering College, especially the Materials Research Laboratory, for providing the facilities that aided in the completion of this research work.

Funding

This research received no external funding.

Author information

Authors and Affiliations

Contributions

Bhuvanesh Kumar Manickam—Conceptualization, methodology, investigation, resources, writing-review and editing, visualization. Milon Selvam Dennison—original draft preparation, writing-review and editing, visualization. K. V. Satheesh Kumar—writing-review and Editing. Selvaprasanth S—project administration, investigation, data collection, analysis.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Ethical appoval and informed consent

All authors have read and approved the final manuscript and consent to its publication.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Manickam, B.K., Dennison, M.S., Kuppusamy Vellingiri, S.K. et al. Optimization of drilling parameters for Al6061/Al6063–SiC–ZrO2 composites using TOPSIS considering microstructure and machinability. Sci Rep 15, 39265 (2025). https://doi.org/10.1038/s41598-025-23094-9

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-23094-9