Abstract

Addressing the insufficient pressure relief in the deep coal mass and the deterioration of the surrounding rock bearing structure due to increased borehole diameter in conventional borehole pressure relief techniques, a static expansive fracturing method for pressure relief in coal seam boreholes is proposed. A critical stress model for static expansive fracturing in coal seam boreholes is established through theoretical analysis, and numerical simulations are conducted to compare and analyze the differences between this method and conventional borehole pressure relief techniques in terms of roadway pressure relief effect and surrounding rock stability control. The results indicate that using a 150 mm borehole with a 75 MPa expansive stress achieves a comparable state of full pressure relief in the rib coal as a 250 mm borehole, while increasing the pressure relief range in the deep coal mass by a factor of approximately 3.6. Although conventional borehole pressure relief methods can enhance pressure relief by increasing the borehole diameter, they significantly expand the plastic zone in the shallow surrounding rock, aggravating surrounding rock deformation. In contrast, the static expansive fracturing method for pressure relief in coal seam boreholes actively directs fractures in the deep high-stress coal mass, promoting the expansion and interconnection of its plastic zone to form a deep structural weakening zone, while markedly reducing the disturbance and damage to the shallow surrounding rock. This method breaks through the limitations of passive borehole for pressure relief, offering dual advantages of efficient deep pressure relief and shallow surrounding rock stability protection, and providing a new approach for rockburst prevention.

Similar content being viewed by others

Introduction

As the depth and intensity of coal mining continue to increase, the issue of rockburst has become increasingly severe, posing a significant threat to safe production1,2,3,4. Common rockburst prevention technologies include coal seam borehole pressure relief, coal mass blasting pressure relief, and coal seam water injection. Among these, coal seam borehole pressure relief is widely used due to its simple process, low cost, and strong adaptability5,6,7,8,9. However, due to current technical limitations, the diameter of pressure relief boreholes typically does not exceed 150 mm, resulting in insufficient pressure relief capacity and failure to effectively curb rockbursts. Simply increasing the borehole diameter or reducing the borehole spacing to improve the pressure relief effect can easily lead to excessive damage to the shallow surrounding rock and a decrease in support strength, highlighting the contradiction between roadway pressure relief and surrounding rock stability control10,11,12,13,14,15.

To address the issues of roadway pressure relief and surrounding rock stability control, scholars have proposed various new pressure relief technologies. Yao et al.16, Hao et al.17, and Gu et al.18 developed a segmented borehole enlargement pressure relief technology that constructs small-diameter boreholes in the shallow surrounding rock to reduce disturbance while enlarging the borehole diameter in the deep high-stress coal mass to enhance the pressure relief effect. Chen et al.19 and Xie et al.20 proposed a synergistic support technology combining anchoring and pressure relief, which focuses on strengthening the anchoring support of the shallow surrounding rock to improve its bearing capacity and stability while implementing large-diameter borehole pressure relief in the deep high-stress coal mass to effectively release and transfer high stress. Wen et al.21 used high-pressure water jet slotting technology to treat high-stress coal mass in the roadway rib, utilizing high-pressure water to create slots in the deep coal mass to form pressure relief spaces, effectively reducing stress concentration in the coal mass while ensuring the stability of the shallow support structure of the roadway. Jiang et al.22 put forward a coordinated control method for borehole pressure relief and energy-absorbing support in high-stress roadways to comprehensively ensure the safety and stability of roadways. These studies provide innovative ideas for solving the problem of coordinated control of roadway pressure relief and surrounding rock stability and have important guiding significance for rockburst prevention practices.

However, these methods still belong to the category of passive pressure relief techniques, which rely on expanding the excavation space to passively release stress and enhance the pressure relief effect. Techniques such as borehole enlargement and hydraulic slotting, on the one hand, impose high demands on equipment capability, and on the other hand, the strong disturbances induced during construction increase safety risks in field operations.

Static expansive fracturing technology, as a non-explosive rock fragmentation method, demonstrates unique advantages in coal and rock mass fracturing. This technology utilizes the volumetric expansive pressure generated by the reaction between expansive agents and water to fracture and crush the surrounding rock mass in boreholes. Compared to explosive blasting, it has the advantages of no noise, no dust, minimal disturbance, and high safety23,24. Zhao et al.25 developed a dense linear multi-hole static expansive directional fracturing method that injects static expansive agents into densely linear boreholes to guide crack propagation along the borehole connection line, achieving directional fracture of rock masses. Tang et al.26 proposed using silent expansive agents (SCDAs) to pre-split and weaken hard roofs to address the problem of gas accumulation caused by the difficulty of roof caving, and they studied the influence of borehole angles on roof weakening effects. Shi et al.27 presented a controllable directional roof caving method through static stress intervention, utilizing borehole groups filled with expansive agents to form stress concentration zones and superimpose mining-induced stress, promoting tensile failure of the roof at predetermined locations to achieve directional roof caving. Zhai et al.28 studied the fracture behavior of specimens under different lateral stresses using non-explosive expansive methods, pointing out that crack formation originates from the coupling effect of expansive force and heat release, with the aim of applying this method to coal seam fracturing. Wang et al.29 focused on the challenge of gas extraction from low-permeability thick coal seams, employing static fracturing technology to enhance coal seam permeability. They analyzed the evolution laws of coal seam stress, plastic zones, permeability, and gas pressure during the fracturing process, confirming that it can significantly improve gas extraction. Gu et al.30 applied non-explosive expansive methods to rockburst prevention, verifying their pressure relief and rockburst prevention effects through rock expansive fracturing experiments and field borehole expansive fracturing tests. In addition, static expansive fracturing technology has been extensively researched and applied in fields such as the petroleum industry, rock fragmentation, and reinforced concrete structure demolition31,32,33,34,35.

In summary, static expansive agents exhibit significant fracturing capabilities and have been proven suitable for fracturing and weakening coal and rock masses in underground coal mines. However, research on applying static expansive fracturing technology to rockburst prevention in coal mines remains insufficient. Based on an analysis of the limitations of conventional borehole pressure relief technology, this paper proposes a method of static expansive fracturing for pressure relief in coal seam boreholes to address the issue of coordinated control of roadway pressure relief and surrounding rock stability. A multi-angle comparison and analysis of the differences between this method and conventional borehole pressure relief technology in terms of roadway pressure relief and surrounding rock control effects are conducted, aiming to provide a new and effective approach for rockburst prevention in coal mines.

Principle and limitation analysis of coal seam borehole pressure relief

Principle of coal seam borehole pressure relief

According to the dynamic and static load superposition principle of rockburst36, rockburst disasters are induced when the superposition of dynamic and static loads exceeds the critical load for impact failure of coal and rock masses. The critical condition for rockburst occurrence can be expressed as:

where \(\sigma_{j}\) is the static load in the coal and rock mass,\(\sigma_{d}\) is the dynamic load induced by mine earthquakes, and \(\sigma_{bmin}\) is the critical load for rockburst occurrence.

Equation (1) indicates that the core of rockburst prevention lies in reducing the degree of static stress concentration in the coal and rock mass, weakening the dynamic strength and its induced dynamic effects, and increasing the critical stress level of the coal and rock mass to resist impact failure, making it less prone to impact failure.

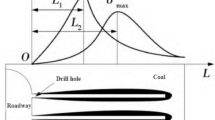

Coal seam borehole pressure relief technology is a commonly used engineering measure for rockburst prevention. Its principle of pressure relief and rockburst prevention is show in Fig. 1. Roadway excavation disrupts the original in-situ stress equilibrium state of the coal and rock mass, leading to an increase in tangential stress on both sides of the roadway and the formation of an abutment pressure zone, as shown by the red stress curve in Fig. 1. Within this zone, the surrounding rock of the roadway experiences a high degree of stress concentration, and the peak stress position is close to the roadway surface, making it prone to inducing rockburst. By drilling boreholes in the rib coal mass of the roadway, the stress concentration effect around the boreholes is utilized to induce failure in the surrounding coal mass. When the failure zones of multiple boreholes interconnect, a large-scale low-stress pressure relief zone is formed within the coal mass. The stress distribution after pressure relief is shown by the blue curve in Fig. 1, the stress concentration degree of the roadway surrounding rock is reduced, and the peak stress is transferred deeper into the coal mass, thereby lowering the risk of rockburst occurrence. The boreholes can also disrupt the original structure of the coal mass, dissipate the accumulated strain energy within the coal mass, and reduce its energy storage capacity, thereby increasing the critical stress level for rockburst occurrence in the coal mass. Additionally, the weakened coal mass structure formed by the boreholes can provide a certain impedance effect and absorb part of the impact energy, which is beneficial for weakening the dynamic effects induced by impact loads. In summary, coal seam borehole pressure relief technology achieves effective rockburst prevention and control through the synergistic effects of “stress regulation, energy dissipation, resistance enhancement, and shock absorption”.

Limitation analysis of coal seam borehole pressure relief

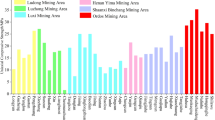

Although coal seam borehole pressure relief technology is widely used in rockburst prevention in mines, the borehole diameters commonly used do not exceed 150 mm, with borehole spacings of 1–3 m. In practical applications, there is an issue of insufficient pressure relief capacity10. As evidenced by rockburst accidents such as the “6.9” incident at Longjiabao Coal Mine, the “5.24” incident at Mengcun Coal Mine, and the “1.1” incident at Liuhuanggou Coal Mine, even after adopting coal seam borehole pressure relief measures, they failed to effectively play a role in pressure relief and rockburst prevention37.

Research shows11,12 that increasing the borehole diameter or reducing the borehole spacing can help improve the pressure relief and rockburst prevention effects of boreholes. After the excavation of a coal seam roadway, the surrounding rock sequentially forms, from the surface inward, a crushed zone, a plastic zone, an elastic zone, and the original rock stress zone. The stress state and energy accumulation characteristics of the coal and rock mass in each zone are shown in Fig. 2. Crushed Zone: The stress and energy in the coal and rock mass have been fully released, and the surrounding rock structure is relatively loose. Support should be strengthened to control surrounding rock deformation. Plastic Zone and Elastic Zone: The coal and rock mass experience a high degree of stress concentration and accumulate a large amount of strain energy, making them potential risk zones for rockburst. Original Rock Stress Zone: The coal and rock mass remain unaffected by the excavation disturbance and are still under the original rock stress state. Due to the differing stress and energy accumulation states in the various zones, their requirements for pressure relief also differ significantly. Increasing the borehole diameter or reducing the borehole spacing in the plastic and elastic zones can aggravate the damage and failure of the high-stress coal mass, promote the dissipation of strain energy, and thereby enhance the pressure relief and rockburst prevention effect. However, adopting the same measures in the crushed zone may damage the synergistic bearing structure formed by the roadway surrounding rock and the anchor support, weaken the support strength, and increase the difficulty of controlling surrounding rock stability. Therefore, conventional borehole pressure relief methods struggle to effectively reconcile the contradiction between the demand for pressure relief and the control of surrounding rock stability. Furthermore, increasing the borehole diameter not only requires higher drilling rig capabilities but also increases on-site construction risks, such as inducing borehole bursts38. Reducing the borehole spacing also increases drilling workload and economic costs.

In summary, due to the comprehensive constraints of roadway surrounding rock stability control, drilling rig equipment capabilities, construction safety risks, and economic costs, the selection space for key parameters such as the borehole diameter and spacing of conventional borehole pressure relief measures is limited, resulting in pressure relief effects that are difficult to meet actual needs. There are obvious limitations in rockburst prevention, making it difficult to effectively reduce rockburst risks.

Method of static expansive fracturing for pressure relief and rockburst prevention in coal seam boreholes

Principle of static expansive fracturing by expansive agents

The main component of commonly used static expansive agents is CaO. Its core mechanism is the hydration reaction of CaO with water, generating Ca(OH)2 and releasing heat, as shown in Eq. (2). The principle of static expansive fracturing by expansive agents is illustrated in Fig. 324. The black spheres in the figure represent CaO particles, which react with water to form Ca(OH)₂ with a larger volume. As the hydration products continuously increase, volumetric expansive occurs, and the expanded volume can reach 2–4 times the original volume of the expansive agent39,40. The expansive behavior of static expansive agents varies depending on the spatial confinement conditions. In a free space, the hydration product Ca(OH)₂ can expand freely without volume constraints. However, within the confined space of a borehole, the volumetric expansive of Ca(OH)₂ is restricted by the borehole wall. The mutual squeezing and deformation between molecules generate a continuously increasing expansive pressure on the borehole wall. When this pressure reaches the failure threshold of the coal and rock mass, it induces fracturing and crushing of the coal and rock mass. Research shows30,41,42 that the expansive pressure generated by current commercial expansive agents can reach 100–120 MPa, which is much higher than the tensile strength of coal and rock materials. Additionally, the hydration reaction product Ca(OH)2 of expansive agents is powdery and has good fluidity, effectively avoiding the induction of secondary stress concentration in the roadway coal mass.

Schematic diagram of the principle of static expansive fracturing by expansive agents24.

Method of static expansive fracturing for pressure relief and rockburst prevention in coal seam boreholes

Addressing the contradiction between the pressure relief requirements of deep roadway surrounding rock and the stability control of shallow surrounding rock, this paper proposes a method of static expansive fracturing for pressure relief and rockburst prevention in coal seam boreholes. This method is based on conventional pressure relief boreholes and uses expansive agents to induce fracturing and enhanced pressure relief in deep high-stress coal masses, as shown in Fig. 4.

After constructing boreholes in the roadway rib, expansive agents are filled into the boreholes, ensuring that the charging section covers the high-stress zone of the roadway rib and is located outside the roadway anchorage zone to avoid damaging the anchorage bearing structure of the shallow surrounding rock. The rest of the borehole is sealed. The expansive agents expand within the confined space of the borehole, compressing the borehole wall to generate expansive stress. When the expansive stress exceeds the critical stress for coal mass fracturing, fractures are induced in the surrounding coal mass. As the expansive stress continues to increase, cracks in the coal mass between multiple boreholes propagate and connect, ultimately forming a large-scale low-stress pressure relief zone within the roadway rib coal mass, effectively reducing stress concentration in the surrounding rock. Meanwhile, static expansive fracturing in boreholes not only disrupts the coal mass structure, dissipates the accumulated elastic energy within the coal mass, and weakens its energy storage capacity but also forms a weakened coal mass structure with a certain shock absorption and energy dissipation effect, thereby comprehensively playing a role in rockburst prevention.

Compared to conventional borehole pressure relief methods, this method utilizes expansive agents to induce fracturing in deep high-stress coal masses for pressure relief, minimizing the disturbance to the anchorage bearing structure of the shallow surrounding rock and maintaining its good bearing capacity. This is conducive to achieving the dual goals of efficient deep pressure relief and shallow surrounding rock stability control in roadways.

Critical stress for static expansive fracturing in coal seam boreholes

During static expansive fracturing in coal seam boreholes, the expansive stress and in-situ stress jointly promote crack propagation and connection in the coal mass. To determine the critical expansive stress required for this process, a model of static expansive fracturing in coal seam boreholes is established, as shown in Fig. 5.

Based on the theory of elastic mechanics43,44, the problem of static expansive fracturing in coal seam boreholes can be simplified into an analytically tractable elastic mechanics model. In this model, the coal mass is assumed to be a linear elastic, isotropic, and homogeneous material, and the borehole axis is aligned with the direction of the minimum horizontal principal stress \({\sigma }_{h}\). Considering that the depth of large-diameter pressure relief boreholes in coal seams is typically much greater than their diameter, the stress variation along the borehole axis can be neglected compared to the radial and tangential stresses around the borehole. Therefore, the stress distribution around the borehole can be approximated as a plane strain problem. The coal seam is treated as an infinite plate, the borehole as a circular hole within the plate, the inner wall of the hole is a free surface with zero radial stress, and the stress at infinity equals the original in-situ stresses.

The borehole radius is a, subjected to vertical principal stress \(\sigma_{v}\) and maximum horizontal principal stress \(\sigma_{H}\). The stress state at any point M outside the borehole is:

where \(\sigma_{r}\) is the radial stress, \(\sigma_{\theta }\) is the tangential stress, \(\tau_{r\theta }\) is the shear stress, and \(r\) is the distance from point M to the borehole center.

When \(r = a\), point M is located on the borehole wall. At this time, the radial stress \(\sigma_{r}\) and shear stress \(\tau_{r\theta }\) are both 0, and the tangential stress \(\sigma_{\theta }\) is:

When the direction angles \(\theta\) are 0 and 90°, the tangential stresses at points A, B, C, and D on the borehole wall are:

When \(\sigma_{H} > \sigma_{v}\), then \(\sigma_{A} < \sigma_{B}\), indicating that the tangential stress at points A and C on the borehole wall is the minimum. Conversely, when \(\sigma_{H} < \sigma_{v}\), then \(\sigma_{A} > \sigma_{B}\), indicating that the tangential stress at points B and D on the borehole wall is the minimum. If the expansive stress P applied within the borehole is greater than the stress that the borehole wall can withstand, tensile fracture will occur at the location with the minimum tangential stress. The minimum additional expansive stress P required to cause initial tensile failure of the borehole wall is the critical stress for static expansive fracturing in coal seam boreholes, and its value is equal to the tangential stress value at the tensile failure point plus the tensile strength T of the coal mass.

The critical stress P for static expansive fracturing in coal seam boreholes is determined by the following equation:

Equation (9) shows that the critical stress P depends on the stress environment of the coal mass around the borehole and the tensile strength of the coal mass itself. It should be emphasized that the P value is the theoretical critical value under plane strain conditions. However, in actual engineering, the redistribution of coal and rock mass stress after roadway excavation forms a complex disturbed stress field around it, and the stress states of coal masses at different locations are significantly different. Additionally, during the expansive fracturing process of the coal mass, crack initiation, propagation, and connection are dynamic evolution processes. Therefore, to ensure effective fracturing and the formation of a connected pressure relief zone, the actual applied expansive stress must be greater than the theoretical critical stress.

Effectiveness of static expansive fracturing for pressure relief and rockburst prevention in coal seam boreholes

Numerical model

To verify the effectiveness of the method of static expansive fracturing for pressure relief and rockburst prevention in coal seam boreholes, a numerical model was established using FLAC3D software, as shown in Fig. 6. A comparative analysis was conducted between conventional borehole pressure relief and borehole static expansive fracturing pressure relief methods. The model dimensions are 45 m in length, 20 m in width, and 20 m in height. The thickness of the roof and floor strata is 7.5 m each, and the coal seam thickness is 5 m. The roadway is located in the middle of the model, arranged along the bottom of the coal seam, with a cross-sectional size of 5.0 m in width and 4.0 m in height. The upper surface of the model is a free boundary, and the remaining surfaces adopt fixed boundary conditions. The simulated burial depth is 600 m, with a vertical stress of 15 MPa applied to the top of the model and a lateral pressure coefficient of 1.2. To accurately characterize the post-peak softening characteristics of the coal mass, the coal seam adopts a strain-softening constitutive model, while the roof and floor strata adopt a Mohr–Coulomb constitutive model45. The physical and mechanical parameters of the coal seam and roof and floor strata are detailed in Table 146.

Numerical simulation scheme

To investigate the differences between conventional coal seam borehole pressure relief and static expansive fracturing pressure relief in coal seam boreholes regarding the pressure relief effect of the rib coal mass and the control of surrounding rock stability, a numerical simulation scheme was designed as shown in Table 2.

In the conventional borehole pressure relief simulation scheme, boreholes were arranged on both sides of the roadway. The boreholes were 20 m in length, spaced 1 m apart, and their centers were located 1.5 m above the roadway floor. By varying the borehole diameter, the influence of different diameters on the pressure relief effect of the rib coal mass and the stability of the surrounding rock was analyzed.

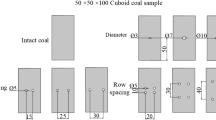

In the simulation scheme for static expansive fracturing pressure relief in coal seam boreholes, assuming a tensile strength of 1 MPa for coal, combined with Eq. (9), the critical stress for static expansive fracturing in coal seam boreholes is calculated to be approximately 28 MPa. To ensure effective fracturing, the applied expansive stress needed to be higher than this critical value. Based on the numerical model with a 150 mm borehole diameter, normal stress was applied to the borehole wall to equivalently simulate the expansive stress generated by the expansive agent29. Considering the actual bolt length of 2.4 m in the field and preliminary simulation results indicating that the peak stress after roadway excavation was about 4.04 m from the rib surface, the application range of the normal stress was limited to the borehole depth interval of 3–20 m to minimize disturbance to the bolted zone of the roadway rib. By varying the magnitude of the expansive stress, the influence of different expansive stresses on the pressure relief effect of the rib coal mass and the stability of the surrounding rock was studied.

Simulation results and analysis

Distribution characteristics of vertical stress in the roadway rib coal mass

The vertical stress nephograms of the roadway rib coal mass under different pressure relief methods are shown in Fig. 7. Fig.7a shows the vertical stress distribution in the rib coal mass with coal seam borehole pressure relief. As seen in Fig. 7a, with conventional coal seam borehole pressure relief, the stress evolution of the roadway rib coal mass exhibits two-stage characteristics. When the borehole diameters are 150 mm and 200 mm, stress concentration occurs in the coal mass between adjacent boreholes, indicating that smaller borehole diameters fail to achieve a pressure relief effect. When the borehole diameter increases to 250 mm and 300 mm, a large-scale continuous low-stress pressure relief zone appears in the roadway rib coal mass, with high stress transferring to the outside of the pressure relief zone, indicating that increasing the borehole diameter disrupts the integrity of the roadway rib coal mass, realizing stress release and transfer, and the pressure relief effect is significant.

Fig.7b shows the vertical stress distribution in the roadway rib coal mass under static expansive fracturing pressure relief in coal seam boreholes. As seen in Fig. 7b, with static expansive fracturing for pressure relief in coal seam boreholes, the stress evolution of the roadway rib coal mass exhibits a gradual change characteristic. When the expansive stress is 35 MPa, stress concentration is evident in the coal mass between adjacent boreholes, and the coal mass structure remains largely undamaged. When the expansive stress increases to 55 MPa, although stress concentration still exists in the coal mass between adjacent boreholes, the range of stress concentration is significantly reduced, indicating that the expansive stress effectively weakens the stress concentration. When the expansive stress increases to 75 MPa and 85 MPa, fractures occur in the coal mass structure between adjacent boreholes, forming a large-scale continuous low-stress pressure relief zone with a significant pressure relief effect.

Measurement lines are arranged axially between adjacent boreholes on the right side of the roadway. The vertical stress variation curves of the roadway rib coal mass under different pressure relief methods are shown in Fig. 8. Based on the characteristics of the vertical stress curves of the roadway rib coal mass, feature parameters are extracted to analyze the pressure relief and rockburst prevention effects, as detailed in Tables 3 and 4. The proportion of the deep coal mass pressure relief zone is defined as the ratio of the zone length with stress below the original rock stress to the borehole length after the peak stress.

The original rock stress in the coal mass is 15.24 MPa. After roadway excavation, the peak stress in the roadway rib coal mass reaches 21.79 MPa, with the peak position 4.04 m from the roadway rib. Combining Fig. 8a and Table 2, it can be seen that when the borehole diameters are 150–200 mm, the vertical stress curves exhibit a “single-peak” distribution. Compared to the no-pressure-relief state, the vertical stress in the roadway rib coal mass significantly increases, indicating that smaller borehole diameters fail to achieve a pressure relief effect. As the borehole diameter increases, the vertical stress curves transition to a “double-peak” distribution, with the peak stress in the shallow coal mass gradually decreasing and high stress transferring to the deep coal mass, resulting in a gradual increase in the proportion of the deep pressure relief zone. When the borehole diameter is 225 mm, the peak stress in the shallow coal mass decreases by 8.81%, and the peak stress transfers 12.47 m to the deep coal mass. Although it exhibits a certain pressure relief effect, the stress in the deep coal mass is still higher than the original rock stress, indicating that the roadway rib coal mass is in a non-fully pressure-relieved state. When the borehole diameter is 250 mm, the peak stress in the shallow coal mass decreases by 32.91% and approaches the original rock stress level, with the peak stress transferring 16.18 m to the deep coal mass and the proportion of the deep pressure relief zone increasing to 18.55%, significantly enhancing the borehole pressure relief effect. When the borehole diameter further increases to 275 mm and 300 mm, the stress in the shallow coal mass continues to decrease and is significantly lower than the original rock stress, indicating that excessive borehole diameters lead to over-pressure relief in the shallow coal mass.

Combining Fig. 8b and Table 3, it can be seen that with static expansive fracturing for pressure relief in coal seam boreholes, when the expansive stress is 35 and 45 MPa, compared to the no-pressure-relief state, the vertical stress in the roadway rib coal mass actually increases, indicating that smaller expansive stresses are insufficient for fracturing the coal mass between boreholes and the pressure relief effect is poor. When the expansive stress is 55 and 65 MPa, the peak stress in the shallow coal mass decreases by 5.00 and 14.55%, respectively, compared to the no-pressure-relief state, and the proportion of the deep coal mass pressure relief zone reaches 44.40% and 59.55%, respectively, indicating that as the expansive stress increases, the fracturing and pressure relief effects gradually emerge. When the expansive stress reaches 75 MPa, the peak stress in the shallow coal mass decreases by 30.34% and approaches the original rock stress level, with the proportion of the deep coal mass pressure relief zone increasing to 84.85%, indicating a significant fracturing and pressure relief effect. When the expansive stress further increases to 85 MPa, the proportion of the deep coal mass pressure relief zone increases to 86.50%, but the stress in the shallow coal mass continues to decrease and is significantly lower than the original rock stress, indicating that excessive expansive stress leads to over-pressure relief in the shallow coal mass.

From the above analysis, it can be seen that regardless of conventional borehole pressure relief or borehole static expansive fracturing pressure relief, the stress state of the roadway rib coal mass exhibits a regular evolution from “non-fully pressure-relieved → fully pressure-relieved → over-pressure-relieved” as the borehole diameter increases or the expansive stress rises. When the borehole diameter increases to 250 mm, the peak stress in the shallow part of the rib coal mass approaches the original rock stress level, and the proportion of the deep pressure relief zone reaches 18.55%, essentially achieving effective pressure relief. However, this method is inherently passive. Its enhanced pressure relief effect relies on increasing the borehole diameter, which forces the high stress to transfer deeper into the coal mass by damaging the integrity of the shallow surrounding rock. Consequently, it struggles to simultaneously meet the dual requirements of shallow surrounding rock stability and deep coal mass pressure relief. In contrast, applying a 75 MPa expansive stress within 150 mm diameter boreholes for expansive fracturing can achieve a low-stress state in the shallow surrounding rock equivalent to that achieved by 250 mm boreholes. Furthermore, the proportion of the deep pressure relief zone in the rib increases significantly to 84.85%. This method is inherently active. It employs high expansive stress to actively promote the propagation and connection of fractures within the deep coal mass, forming a large-scale low-stress pressure relief zone. This approach significantly increases the pressure relief range in the deep coal mass while maintaining the stability of the shallow surrounding rock, thereby resolving the contradiction between deep coal mass pressure relief and shallow surrounding rock stability. Therefore, the static expansive fracturing pressure relief method in coal seam boreholes overcomes the limitations of conventional borehole pressure relief, which depends solely on increasing the borehole diameter, and demonstrates unique advantages in regulating the stress within roadway surrounding rock.

Distribution characteristics of the plastic zone in the roadway rib coal mass

The distribution characteristics of the plastic zone in the roadway rib coal mass under different pressure relief methods are shown in Fig. 9. It can be observed that regardless of whether large-diameter borehole pressure relief or static expansive fracturing pressure relief is used, the failure mode of the roadway and the surrounding rock around the boreholes is predominantly shear failure. When using borehole pressure relief, the radial stress around the borehole reduces to zero, and the concentration of tangential stress leads to an increase in shear stress. When this exceeds the shear strength of the coal mass, shear cracks initiate at the borehole wall and gradually propagate and connect, ultimately forming a macroscopic shear failure zone. In contrast, during static expansive fracturing pressure relief, the expansive agent applies radial compressive stress to the borehole wall, which interacts with the tangential stress to create high shear stress, similarly inducing shear failure in the coal mass. Therefore, although large-diameter borehole pressure relief is a passive method and static expansive fracturing is an active method, both essentially promote shear failure in the coal mass through shear stress, thereby achieving stress release and energy dissipation.

Fig. 9a shows the distribution of the plastic zone in the roadway rib coal mass under different pressure relief borehole diameters. As seen in Fig. 9a, when the borehole diameters are 150 and 200 mm, most areas around the boreholes remain undamaged, indicating that poor pressure relief effects with smaller borehole diameters. When the borehole diameter increases to 250 and 300 mm, the plastic zones around the boreholes are largely connected, forming a continuous strength-weakened coal mass structure zone, significantly enhancing the pressure relief effect. However, as the borehole diameter increases, the original plastic zone range of the roadway surrounding rock exhibits a sharp expansion. Fig. 9b shows the distribution of the plastic zone in the roadway rib coal mass under different expansive stresses. As seen in Fig. 9b, when the expansive stresses are 35 and 55 MPa, the plastic damage range around the boreholes is also small, and the pressure relief effect is not obvious. When the expansive stress increases to 75 and 85 MPa, the plastic zones around the boreholes are largely connected, forming a continuous strength-weakened coal mass structure zone and significantly enhancing the pressure relief effect. However, the original plastic zone range of the roadway surrounding rock does not exhibit a synchronous expansion trend as the expansive stress increases.

The volumes of plastic zones under different pressure relief methods are calculated using the FISH language, as shown in Fig. 10. After roadway excavation, the initial plastic zone volume of the model is 968.44 m3.

As seen in Fig. 10a, the plastic zone volume of the model exhibits non-linear growth as the borehole diameter increases. When the borehole diameter exceeds 200 mm, the plastic zone volume exhibits a sharp upward trend. Combined with Fig. 9a, it can be analyzed that increasing the borehole diameter not only expands the plastic zone range around the boreholes but also significantly expands the plastic zone of the shallow surrounding rock, both effects contributing to a sharp increase in the plastic zone volume of the model.

As seen in Fig. 10b, the plastic zone volume of the model also exhibits non-linear growth as the expansive stress increases. However, compared to borehole pressure relief, the increase in plastic zone volume is relatively small. Combined with Fig. 9b, it can be analyzed that static expansive fracturing for pressure relief in coal seam boreholes primarily acts on the coal mass within the 3–20 m depth range of the roadway, preferentially inducing plastic damage to the surrounding rock around the boreholes, while having limited disturbance and damage effects on the structure of the shallow surrounding rock. Therefore, the plastic zone volume of the model does not exhibit a sharp increase.

From the above analysis, it can be seen that although conventional borehole pressure relief methods can improve the pressure relief effect of the roadway rib coal mass by increasing the borehole diameter, they easily induce excessive expansion of the plastic zone in the shallow surrounding rock, leading to deterioration of the bearing structure and reduced stability of the roadway surrounding rock. In contrast, the method of static expansive fracturing for pressure relief in coal seam boreholes induces fracturing in the deep high-stress coal mass within the 3–20 m range of the roadway through expansive agents, forming a continuous strength-weakened coal mass structure zone in the deep coal mass. While ensuring the pressure relief effect, this method minimizes the disturbance and damage to the structure of the shallow surrounding rock, combining the advantages of efficient pressure relief and shallow surrounding rock protection, which is more conducive to achieving the coordinated control of effective pressure relief in the deep coal mass and stability of the shallow surrounding rock.

Evolution law of roadway surrounding rock deformation

After roadway excavation, the maximum roof subsidence is 84.4 mm, and the maximum horizontal deformation of the roadway rib is 81.4 mm. The deformation law of roadway surrounding rock under different pressure relief methods is shown in Fig. 11.

Figure 11a shows that as the borehole diameter increases, the deformation of the roadway surrounding rock exhibits two stages of change. When the borehole diameter is between 150 and 200 mm, the variation in the maximum roof subsidence and the maximum horizontal deformation of the roadway rib is small, indicating that the borehole has a slight impact on the deformation of the roadway surrounding rock within this diameter range. When the borehole diameter is greater than 200 mm, the deformation of the roadway surrounding rock begins to increase sharply, showing an obvious abrupt change. This indicates that increasing the borehole diameter can enhance the pressure relief effect but will also aggravate the deformation of the shallow surrounding rock of the roadway, which is not conducive to the stability control of the roadway surrounding rock.

Figure 11b shows that as the expansive stress increases, the deformation of the roadway surrounding rock exhibits a smooth and gradual change. When the expansive stress is between 0 and 75 MPa, the roof subsidence and the roadway rib deformation remain stable, indicating that within this stress range, the expansive stress has a slight impact on the deformation of the shallow surrounding rock of the roadway, and the deformation is controllable. When the expansive stress exceeds 75 MPa, the roof subsidence and the roadway rib deformation increase significantly, indicating that the further increase in expansive stress gradually has a more pronounced impact on the deformation of the roadway rib.

When the borehole diameter is 250 mm, the increments in the maximum roof subsidence and the maximum horizontal deformation of the roadway rib are 109.12 and 94.47%, respectively. When the expansive stress is 75 MPa, the increments in the maximum roof subsidence and the maximum horizontal deformation of the roadway rib are 7.46 and 9.09%, respectively. Although a 250 mm borehole for pressure relief and a 150 mm borehole with 75 MPa expansive stress for fracture-induced pressure relief achieve an equivalent low stress state in the shallow part of the roadway rib, the static expansive fracturing method has less disturbance to the deformation of the roadway surrounding rock.

The above analysis indicates that for conventional borehole pressure relief methods, increasing the borehole diameter significantly increases the deformation of the shallow surrounding rock, which is detrimental to the stability of the roadway surrounding rock. In contrast, under appropriate expansive stress, the method of static expansive fracturing for pressure relief in coal seam boreholes not only effectively achieves pressure relief in the deep coal mass but also has a smaller impact on the deformation of the shallow surrounding rock. This method can effectively balance the conflict between the demand for pressure relief in the deep coal mass of the rib and the need for stability control in the shallow surrounding rock of the rib.

Discussion

This study demonstrates that compared with conventional borehole pressure relief methods, the static expansive fracturing pressure relief method in coal seam boreholes shows significant advantages in roadway pressure relief and surrounding rock stability control. Using 150 mm boreholes with 75 MPa expansive stress in roadway ribs can achieve pressure relief effects similar to 250 mm boreholes, while increasing the pressure relief range in deep coal mass by about 3.6 times. This method utilizes expansive stress to directionally fracture deep high-stress coal mass for pressure relief, while the plastic zone of shallow surrounding rock does not expand significantly, maintaining stable surrounding rock deformation. The fundamental reason lies in the essential difference in pressure relief mechanisms between the two methods. Conventional borehole pressure relief is a passive method that relies on borehole deformation to provide yielding space for stress release and transfer, but the boreholes also damage the bearing structure of shallow surrounding rock, weakening its bearing capacity and leading to significant expansion of plastic zone in shallow surrounding rock and substantial increase in roadway deformation. In contrast, the static expansive fracturing pressure relief method in coal seam boreholes is an active method that directionally fractures and weakens deep high-stress coal mass through expansive stress, achieving larger pressure relief range while minimizing the deterioration of bearing structure in shallow surrounding rock, thereby realizing the coordinated goals of efficient deep pressure relief and shallow surrounding rock stability control.

It should be noted that this study is based on FLAC3D numerical simulation, simplifying coal and rock mass as homogeneous continuous media and simplifying the expansive process of expansive agent as constant pressure loading on borehole wall without considering time effects. These simplifications may affect the accuracy of quantitative results, but they have certain reference value for qualitative patterns and comparative conclusions. In future research, more refined models considering discontinuous medium characteristics and time-varying properties of expansive agent can be established, and sensitivity analysis of parameters such as expansive pressure, borehole diameter and spacing on expansive fracturing pressure relief effects can be conducted, along with field industrial tests to verify the pressure relief and rockburst prevention effects of this method.

In summary, the static expansive fracturing pressure relief and rockburst prevention method in coal seam boreholes proposed in this study significantly improves the pressure relief effect of deep coal mass while ensuring the stability of shallow surrounding rock. This method breaks through the limitations of conventional borehole pressure relief relying on increasing borehole diameter, providing new ideas for solving the coordinated control problem of roadway pressure relief and surrounding rock stability. Subsequent research needs to further verify its applicability by optimizing numerical models and conducting field tests.

Conclusions

Aiming at the limitations of conventional borehole pressure relief technology in practical applications, this paper proposes a static expansive fracturing pressure relief and rockburst prevention method in coal seam boreholes, and comparatively analyzes the differences between the two methods in terms of roadway pressure relief effect and surrounding rock stability control. The main conclusions are as follows:

-

(1)

Conventional large-diameter borehole pressure relief methods are constrained by factors such as surrounding rock stability control, drilling rig equipment capacity, construction safety risks, and economic costs. These constraints result in a limited selection range for key parameters, making it difficult for the pressure relief effect to meet the requirements of rockburst prevention, thereby demonstrating significant technical limitations.

-

(2)

Pressure relief effect and stress state evolution: As the borehole diameter increases or the expansive stress rises, the stress state of roadway rib coal mass shows a regular evolution from “non-fully pressure-relieved → fully pressure-relieved → over-pressure-relieved”. The study shows that using 150 mm boreholes with 75 MPa expansive stress in static expansive fracturing scheme can achieve a fully pressure-relieved state of roadway rib coal mass similar to 250 mm boreholes, with the proportion of the deep pressure relief zone increased by about 3.6 times.

-

(3)

Surrounding rock stability control: Conventional borehole pressure relief causes significant disturbance and damage to shallow roadway surrounding rock, manifested as dramatic expansion of plastic zone in shallow surrounding rock and substantial increase in roadway deformation with increasing borehole diameter. In contrast, the disturbance and damage effects of static expansive fracturing pressure relief in coal seam boreholes on shallow roadway surrounding rock are markedly reduced, manifested as limited expansion amplitude of plastic zone in shallow surrounding rock and minimal increment of roadway deformation with increasing expansive stress, maximizing the protection of integrity of bearing structure in shallow surrounding rock.

-

(4)

Pressure relief mechanism and advantages: Through expansive agents, the static expansive fracturing pressure relief method in coal seam boreholes directionally fractures deep high-stress coal mass, promoting the expansion and connection of plastic zone in deep coal mass to form strength-weakening zone, achieving efficient deep pressure relief while effectively avoiding excessive damage to shallow surrounding rock. This method breaks through the inherent limitations of conventional borehole pressure relief relying on increasing borehole diameter, transforming passive pressure relief into an active pressure relief method, which is conducive to achieving the coordinated goals of roadway pressure relief and surrounding rock stability control, providing a new effective approach for rockburst prevention.

Data availability

The datasets used and analysed during the current study available from the corresponding author on reasonable request.

References

Tan, Y. L. et al. Calculation model for kinetic energy and rock burst risk evaluation method during roadway excavation. Int. J. Min. Sci. Technol. 35, 677–690. https://doi.org/10.1016/j.ijmst.2025.03.006 (2025).

Yin, Y. C. et al. Experimental study and evaluation on the weakening of bursting liability of coal with boreholes. Eng. Fail. Anal. 155, 107754. https://doi.org/10.1016/j.engfailanal.2023.107754 (2024).

Peng, C. & Liu, W. R. Study on pressure relief effect of rock mass with different borehole parameters. Adv. Civ. Eng. 2021, 5558673. https://doi.org/10.1155/2021/5558673 (2021).

Shi, Q. W., Mishra, B., Wang, S. W. & Xu, G. In situ assessment of the effectiveness of an undisturbed single driving entry’s relief borehole in coal burst-prone seam. Min. Metal. Explor. 38, 2443–2452. https://doi.org/10.1007/s42461-021-00511-x (2021).

Cui, F., Zhang, S. L., Chen, J. Q. & Jia, C. Numerical study on the pressure relief characteristics of a large-diameter borehole. Appl. Sci. 12, 7967. https://doi.org/10.3390/app12167967 (2022).

Luo, Y. et al. Impact analysis of pressure-relief blasting on roadway stability in a deep mining area under high stress. Tunn. Undergr. Space Technol. 110, 103781. https://doi.org/10.1016/j.tust.2020.103781 (2021).

Hao, Z. et al. Pressure-relief mechanism and application of large-diameter boreholes in coal seams with rockburst hazard. Geofluids 2021, 5469999. https://doi.org/10.1155/2021/5469999 (2021).

Wang, P., Jiang, Y. Z., Li, P., Zhou, J. L. & Zhou, Z. Experimental analysis of pressure relief effect of surrounding rock in high-stress roadways under different drilling parameters. Appl. Sci. 13, 2511. https://doi.org/10.3390/app13042511 (2023).

Li, Y. Y. et al. Experimental study on pressure relief mechanism of variable-diameter borehole and energy evolution characteristics of the surrounding rock. Energies 15, 6596. https://doi.org/10.3390/en15186596 (2022).

Pan, J. F., Yan, Y. D., Ma, H. Y., Wu, D. & Liu, S. H. Using 300 mm diameter boreholes for coal burst prevention: A case study. J. Min. Strata Control Eng. 4, 5–15. https://doi.org/10.13532/j.jmsce.cn10-1638/td.2022.05.001 (2022).

Zhang, S. C., Li, Y. Y., Shen, B. T., Sun, X. Z. & Gao, L. Q. Effective evaluation of pressure relief drilling for reducing rock bursts and its application in underground coal mines. Int. J. Rock Mech. Min. Sci. 114, 7–16. https://doi.org/10.1016/j.ijrmms.2018.12.010 (2019).

Liang, S. W., Zhang, L., Ge, D. & Wang, Q. Study on pressure relief effect and rock failure characteristics with different borehole diameters. Shock. Vib. 2021, 3565344. https://doi.org/10.1155/2021/3565344 (2021).

Lyu, J. G. et al. Study on the pressure relief energy dissipation law of variable-diameter boreholes in roadway surrounding rock. Sci. Rep. 15, 5460. https://doi.org/10.1038/s41598-025-89378-2 (2025).

Yin, Y. C. et al. Anchorage weakening effect of coal roadway sidewall with different destressing borehole diameters. Energy Sci. Eng. 11, 1325–1335. https://doi.org/10.1002/ese3.1394 (2023).

Wang, M. et al. Impact of depressurizing boreholes on energy dissipation in deep roadway. Geofluids 2022, 6821810. https://doi.org/10.1155/2022/6821810 (2022).

Yao, J. P. et al. Segmented enlarged-diameter borehole destressing mechanism and its influence on anchorage support system. Energy Sci. Eng. 8, 2831–2840. https://doi.org/10.1002/ese3.700 (2020).

Hao, J. et al. Research on pressure relief hole parameters based on abutment pressure distribution pattern. Shock. Vib. 2021, 7143590. https://doi.org/10.1155/2021/7143590 (2021).

Gu, S. T., Chen, C. P., Jiang, B. Y., Ding, K. & Xiao, H. J. Study on the pressure relief mechanism and engineering application of segmented enlarged-diameter boreholes. Sustainability 14, 5234. https://doi.org/10.3390/su14095234 (2022).

Chen, D. D., Jiang, Z. S. & Xie, S. R. Mechanism and key parameters of stress load-off by innovative asymmetric hole-constructing on the two sides of deep roadway. Int. J. Coal Sci. Technol. 10, 82. https://doi.org/10.1007/s40789-023-00635-z (2023).

Xie, S. R., Jiang, Z. S., Chen, D. D. & Wang, E. Failure mechanism of continuous large deformation and a novel pressure relief control technology on the two sides of deep coal roadway. Eng. Fail. Anal. 144, 106941. https://doi.org/10.1016/j.engfailanal.2022.106941 (2023).

Wen, Y. Y. et al. Optimization of destressing parameters of water jet slits in rock burst coal seams for deep mining. Processes 11, 1056. https://doi.org/10.3390/pr11041056 (2023).

Jiang, Z. H., Zhang, J. C., Yue, L. J. & Li, D. H. Coordinated control of pressure relief and energy absorption support of deep mining roadway. Phys. Fluids 37, 047138. https://doi.org/10.1063/5.0267108 (2025).

De Silva, R. V., Gamage, R. P. & Perera, M. S. A. An alternative to conventional rock fragmentation methods using SCDA: A review. Energies 9, 958. https://doi.org/10.3390/en9110958 (2016).

Xu, Z. J., Cao, Y., Li, C., Tai, L. H. & He, S. F. Study on mechanism of static blasting-induced hard rock fracture expansion. Appl. Sci. 13, 11310. https://doi.org/10.3390/app132011310 (2023).

Zhao, X. L., Huang, B. X., Cheng, Q. Y., Wang, C. W. & Chen, S. L. Experimental investigation on basic law of rock directional fracturing with static expansive agent controlled by dense linear multi boreholes. J. Central South Univ. 28, 2499–2513. https://doi.org/10.1007/s11771-021-4782-y (2021).

Tang, W. et al. The influence of borehole arrangement of soundless cracking demolition agents (SCDAs) on weakening the hard rock. Int. J. Min. Sci. Technol. 31, 197–207. https://doi.org/10.1016/j.ijmst.2021.01.005 (2021).

Shi, H., Hao, B. Y., Ren, X. Y. & Zhang, J. Mechanism and application of static stress intervention for controlled directional roof caving in fully mechanized mining faces. Processes 13, 1552. https://doi.org/10.3390/pr13051552 (2025).

Zhai, C., Xu, J. Z., Liu, S. M. & Qin, L. Fracturing mechanism of coal-like rock specimens under the effect of non-explosive expansion. Int. J. Rock Mech. Min. Sci. 103, 145–154. https://doi.org/10.1016/j.ijrmms.2018.01.037 (2018).

Wang, X. F. et al. Static expansion fracturing mechanism for enhancing gas permeability in low permeability coal seams. Sci. Rep. 14, 25046. https://doi.org/10.1038/s41598-024-76071-z (2024).

Gu, S. T., Liu, Z. Y., Li, W. S., Jiang, B. Y. & Chen, C. P. Research on mechanism and practice of expansion-induced fracturing and pressure relief in deep coal mines. Energy Sci. Eng. 12, 5230–5244. https://doi.org/10.1002/ese3.1941 (2024).

De Silva, V. R. S., Ranjith, P. G., Perera, M. S. A. & Wu, B. The effect of saturation conditions on fracture performance of different soundless cracking demolition agents (SCDAs) in geological reservoir rock formations. J. Nat. Gas Sci. Eng. 62, 157–170. https://doi.org/10.1016/j.jngse.2018.11.013 (2019).

Chen, T., Vennes, I. & Mitri, H. S. Investigation into rock breakage with expansive cement under biaxial confinement. Rock Mech. Rock Eng. 55, 6263–6277. https://doi.org/10.1007/s00603-022-02988-4 (2022).

Zhong, Z. et al. Experimental and numerical explorations on the optimized applications of SCDA in cracking concrete blocks. Measurement 206, 112335. https://doi.org/10.1016/j.measurement.2022.112335 (2023).

Sun, J. S. et al. Experimental study on residual compressive bearing capacity of cracked reinforced concrete columns by SCDA. Mater. Res. Expr. 11, 105502. https://doi.org/10.1088/2053-1591/ad7d71 (2024).

Li, R. S., Zheng, W. Z., Xia, Z. H. & Tian, W. C. Destruction extent of reinforced concrete shear walls demolished by soundless chemical demolition technology: Improvement by structural and parameter design. Constr. Build. Mater. 440, 137295. https://doi.org/10.1016/j.conbuildmat.2024.137295 (2024).

Dou, L. M., He, J., Cao, A. Y., Gong, S. Y. & Cai, W. Rock burst prevention methods based on theory of dynamic and static combined load induced in coal mine. J. China Coal Soc. 40, 1469–1476. https://doi.org/10.13225/j.cnki.jccs.2014.1815 (2015).

Du, X. L. Research progress and prospects of drillhole destressing in the prevention of rock burst. Saf. Coal Mines 55, 28–40. https://doi.org/10.13347/j.cnki.mkaq.20240465 (2024).

Li, Y. P., Zhang, H. W., Zhu, Z. J. & Guo, C. Study on safety parameters of pressure relief borehole in rockburst coal seam. China Saf. Sci. J. 28, 122–128. https://doi.org/10.16265/j.cnki.issn1003-3033.2018.11.020 (2018).

Zhang, Y. et al. Research status and prospect of coal expansion fracturing and permeability improvement. Saf. Coal Mines 55, 19–27. https://doi.org/10.13347/j.cnki.mkaq.20230472 (2024).

Zhang, Q. et al. Study on the mechanism and preliminary application of efficient directional rockbreaking using a coal-based solid waste non-explosive expansive agent. Chin. J. Rock Mech. Eng. 44, 898–911. https://doi.org/10.3724/1000-6915.jrme.2024.0553 (2024).

Qi, J. L. et al. Study on the influence laws of hole distribution parameters on guided groove-static expansion synergistic fracturing effect. Saf. Coal Mines 56, 127–136. https://doi.org/10.13347/j.cnki.mkaq.20240112 (2024).

Li, Y. F., Li, W. H. & Feng, G. Research on pressure relief technology of roof cracking caused by static expansion agent in No. 1305 working face of Runhong Coal Industry. China Energy Environ. Protect. 46, 280–286. https://doi.org/10.19389/j.cnki.1003-0506.2024.06.046 (2024).

Xu, Y. D. et al. Quantitative evaluation of borehole pressure relief effect and stress distribution in coal seam. Min. Res. Dev. 43, 98–105. https://doi.org/10.13827/j.cnki.kyyk.2023.05.027 (2023).

Lyu, Y. C. Application of the hydraulic fracturing technology in the high pressure and low permeability mine. J. Chongqing Univ. 33, 102–107 (2010).

Yin, Y. C. et al. Evolution law of stress field and pressure relief effect of coal seam after drilling. Energy Sci. Eng. 12, 5493–5503. https://doi.org/10.1002/ese3.1961 (2024).

Peng, Y. J. et al. Mechanisms and influential factors of rock bursts in tunneling roadways of extra-thick coal seams. Coal Geol. Explor. 52, 25–39. https://doi.org/10.12363/issn.1001-1986.24.07.0500 (2024).

Funding

This work was funded by the National Natural Science Foundation of China (NO.52174127, 52374137, 52274120), the Youth Innovation Team Project of Shaanxi University (2022–23), the Key Program of Hebei Natural Science Foundation(E2024508004) and the Hebei Natural Science Foundation (E2025508033).

Author information

Authors and Affiliations

Contributions

W.L. and X.Z. were mainly responsible for writing the entire manuscript. X.Z. and Z.O. proposed the static expansive fracturing method for pressure relief and rockburst prevention in coal seam boreholes, and designed the research methodology. X.Z., R.Y. and H.Y. performed the numerical simulations, conducted data collection, and processed the data. Y.W., P.X., J.L. and N.Z. were mainly responsible for reviewing the manuscript and providing revision suggestions. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Lyu, W., Zhou, X., Ouyang, Z. et al. Study on static expansive fracturing for pressure relief and rockburst prevention in coal seam boreholes. Sci Rep 15, 39602 (2025). https://doi.org/10.1038/s41598-025-23374-4

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-23374-4