Abstract

Photovoltaic (PV) modules typically convert only 15–22% of incident solar energy into electricity, with commercial modules averaging around 18–20% efficiency. Consequently, approximately 80–85% of solar energy is lost primarily as heat, increasing module temperatures to 50–75 °C and reducing electrical efficiency by about 0.4–0.5% per °C above standard conditions (25 °C). This substantial thermal loss presents an opportunity for energy recovery. Integrating thermoelectric generators (TEGs) with PV modules offers an effective method to recover this waste heat and convert it into additional electrical energy. This study presents a comparative assessment of a hybrid PV-TE system’s performance across three geographically diverse cities—Stockholm, Berlin, and Istanbul. The analysis is based on a hybrid experimental-numerical framework, anchored by field-based experimental data from Istanbul and extended via a validated performance model to simulate outcomes for Berlin and Stockholm. Seven commercial TEG modules were benchmarked under a standardized portable rig; among these, TEG3 and TEG4 exhibited the strongest performance enhancements across the tested conditions, with the most significant gains observed under active cooling. All performance metrics are derived from on-site measurements of solar irradiance and temperature at all three locations; external NREL/JRC datasets were consulted solely for consistency checks. The incorporation of TEGs into PV modules led to significant performance enhancements at all three test sites. Across the three locations, the hybrid configuration achieved ~ 2–5% gains with TEG3 and ~ 5–9% with TEG4, relative to a PV-only baseline under matched conditions, with the magnitude of improvement depending on local thermal conditions. Within the tested summer midday window (June–August, 11:00–15:00 local time), Berlin exhibited higher mean hybrid efficiency than Istanbul, underscoring the role of geographic and thermal context. These results highlight the strong commercialization potential of PV–TE hybrid systems and support the strategic deployment of PV–TE technology in diverse climates by leveraging site-specific thermal management.

Similar content being viewed by others

Introduction

Fossil fuel consumption significantly contributes to global greenhouse gas emissions, primarily through carbon dioxide (CO₂), methane (CH₄), and nitrous oxide (N₂O). Approximately 74% of total global greenhouse gas emissions are CO₂, of which about 92% result directly from fossil fuel combustion. Additionally, fossil fuel activities account for around 32% of global methane emissions and approximately 18% of anthropogenic nitrous oxide emissions. This underscores the urgent need to reduce reliance on fossil fuels to mitigate climate change1,2,3,4,5. Beyond their direct environmental impact, fossil fuels impose substantial hidden costs. These include significant health expenses due to pollution-related diseases such as respiratory and cardiovascular illnesses; environmental damage from extraction, transportation, and refining processes, causing habitat loss, soil degradation, and water contamination; geopolitical and security costs arising from re-source competition and the need to protect energy supply chains; and economic burdens from increased frequency of climate-driven natural disasters like floods, droughts, and storms, requiring extensive emergency responses and infrastructure repair6,7,8,9. Fossil fuels are currently responsible for approximately 80% of global greenhouse gas emissions and are estimated to be depleted within the next century. To mitigate these effects, there is an urgent need to transition to sustainable and renewable energy sources. The 1973 oil crisis significantly accelerated research into photovoltaic (PV) technologies by underscoring the vulnerabilities associated with dependence on imported fossil fuels. In response to sharply rising oil prices and energy security concerns, governments worldwide increased funding and support for renewable energy, stimulating technological advances, reducing PV system costs, and facilitating broader market adoption. This event marked a pivotal shift, transforming PV from a specialized technology into a viable solution for long-term energy sustainability and independence. Since then, advancements in PV technology have been a key focus for researchers worldwide10,11,12,13,14,15. However, with rapid industrialization, population growth, and increasing energy demands, global energy consumption is projected to rise by 30% by 204016,17,18,19,20,21,22,23. In this context, solar energy has emerged as a sustainable, reliable, and abundant power source, particularly in regions with high solar radiation typically defined as areas receiving global horizontal irradiance (GHI) values exceeding 1800–2000 kWh/m² per year where photovoltaic systems offer optimal efficiency, economic feasibility, and higher energy yields24,25. Typical thermal losses in PV modules are ~ 0.4% to 0.5% per °C above the standard operating temperature of 25 °C. Under real-world conditions, where module temperatures commonly reach 50–75 °C, these thermal effects can reduce PV module efficiency by approximately 10%–25% compared to their rated performance26. A significant portion about 80%–85% of the solar energy absorbed by PV cells is converted into heat rather than electricity, substantially reducing overall system efficiency. To address this limitation, thermoelectric generators (TEGs) have been explored as a suitable solution for recovering waste heat due to their ability to directly convert temperature gradients into electrical energy, operate reliably without moving parts, and seamlessly integrate with existing PV technologies27,28,29,30,31,32. Studies indicate that photovoltaic-thermoelectric hybrid (PV–TE) systems can achieve efficiency improvements ranging from approximately 3% to 7% compared to conventional PV modules by realistically recovering around 5%–15% of the otherwise lost thermal energy33,34,35,36,37,38. Building on this evidence, this paper presents a field-based comparative assessment across three locations. Rather than employing a formal optimization algorithm, the study systematically varies cooling strategies and TEG modules under a standardized portable rig to identify higher-performing configurations.

In light of this fundamental thermal inefficiency challenge, the academic research community has invested significant research effort toward hybrid technologies that can convert this waste heat to useful energy. Specifically, bundling thermoelectric (TE) devices with PV modules represents a potentially strong route forward. This following literature review situates current advances in this area, while detailing the unique gap this research aims to fill.

PV–TE hybrid systems17,39 have emerged as promising solutions, offering key advantages such as enhanced energy efficiency, reduced thermal losses, and increased power output per unit area. Particularly in urban areas with limited space for large-scale solar installations, these hybrid systems can improve energy generation, support decentralized energy production, and contribute significantly toward sustainable urban energy solutions40,41,42. Thus, PV–TE technology represents a practical and effective approach for maximizing solar energy utilization in densely populated environments.

The inherent challenge of substantial thermal losses in conventional PV systems, which can significantly degrade electrical efficiency and shorten module lifespan, has catalyzed extensive research into hybrid technologies. Among these, the integration of TE systems has emerged as a particularly compelling solution. Comprehensive reviews of the field have firmly established that coupling TE devices with PV modules is a viable and promising strategy, not only for active thermal management but also for harvesting waste heat to generate supplementary power, thereby enhancing overall system performance43. The foundational work in this area often involves a synthesis of theoretical modeling with rigorous performance evaluations. Such analyses provide an invaluable framework for system designers by elucidating the potential of higher-output configurations to yield greater energy outputs and promote long-term operational stability, thus charting a course for practical implementation44.

However, the theoretical potential outlined in these models requires robust empirical validation to confirm its applicability in real-world operating conditions. To this end, experimental investigations on field-operating PV panels within industrial plants have been crucial. These studies have successfully provided concrete evidence of the technology’s effectiveness, demonstrating considerable temperature drops in panels and, as a direct consequence, quantifiable increases in electrical efficiency. This practical verification offers critical insights into the scalability and viability of large-scale applications45. Moving beyond simple cooling, the core of PV-Thermoelectric Generator (PV–TEG) hybridization lies in the efficiency of the energy conversion process itself, which is intrinsically limited by the efficacy of heat transfer at the component interface. Recognizing this bottleneck, cutting-edge research has focused on advanced mathematical modeling to explore optimization pathways. These models demonstrate that enhancing thermal transport—for instance, through the application of innovative, high-conductivity thermal interface materials like pyrolytic graphite sheets—provides a direct and innovative route to achieving superior PV–TEG system performance46. Ultimately, for widespread commercial adoption, this demonstrated technical superiority must be accompanied by clear economic competitiveness. This final, critical dimension is addressed by holistic experimental studies that analyze hybrid PV–TEG systems through a comprehensive lens. By evaluating not only the electrical output, energy, and exergy but also the all-important levelized cost of energy (LCOE), these analyses provide a complete picture of both the technical and economic advantages, thereby solidifying the case for this technology as a cost-effective and robust solution ready for integration into the broader renewable energy landscape47.

While these foundational researches help to demonstrate the potential for PV-TE systems, an obvious gap in the literature is that there are no thorough, multi-variable comparisons made under steady-state, field-based conditions. The majority of the work presented in this area is fragmented, focusing on either a singular cooling method, an isolated geographic location, or a purely theoretical model. To address this gap, I provide an original hybrid experimental - numerical method to thoroughly investigate aspects of three unique climates, four thermal management methods, and seven commercial TEG modules. This comprehensive approach allows for direct, “apples-to-apples” comparison, that is fundamentally more than just re-documenting known patterns and trends, to establish non obvious conclusions - such as a superior hybrid efficiency in a moderate climate compared to a high-irradiance climate – and provide practical design guidance for optimizing systems.

In our previous study, we analyzed the efficiency of TEG modules in PV–TE systems by testing seven different TEGs under four different scenarios48. Two of these TEGs demonstrated significantly higher performance than the others did. To further investigate their potential, this study evaluated the performance of PV–TE hybrid systems in different geographical locations using real experimental data from the most efficient TEGs. This study provides a practical assessment of the efficiency of PV–TE hybrid systems by comparing its performance across three distinct European regions: Stockholm (Northern Europe), Berlin (Central Europe), and Istanbul (Southern Europe). In this study, the performance of the hybrid PV–TE system was determined through on-site experimental measurements in Istanbul. The data obtained were used to validate a numerical model that predicts the system’s behavior. Subsequently, using this validated model, the system’s performance was simulated for the cities of Berlin and Stockholm using standard meteorological data obtained from the National Renewable Energy Laboratory (NREL) and Joint Research Centre (JRC) databases. The findings indicate that PV–TE hybrid systems hold strong potential for commercialization, with system efficiency varying according to climatic conditions. Within the tested summer midday window, the mean hybrid efficiency in Berlin was higher than in Istanbul, supporting the viability of PV–TE integration across diverse environments. These insights contribute to ongoing efforts to optimize renewable energy technologies for real-world applications.

Methodology

On-site measurements and cross-checks. Solar irradiance and temperatures were measured on site at all three locations (Stockholm, Berlin, Istanbul) using calibrated instruments under a standardized portable rig. Measurements were conducted under outdoor conditions during June–August (11:00–15:00 local time) with repeated trials to ensure comparability across sites. External datasets from NREL and the EU JRC were consulted solely for consistency checks (seasonal/diurnal patterns) and were not used as primary inputs to compute performance metrics.

A basic PV – TE hybrid system consists of a PV module and a TEG, without any additional cooling mechanisms. In this configuration, the TEG converts the waste heat from the PV module into electrical power. When passive cooling is used typically through a heat sink the system generates relatively low power due to limited heat dissipation.

This study was designed to experimentally evaluate the performance of a PV–TE hybrid system under diverse geographical (solar irradiance, ambient temperature, wind speed) and thermal (cooling strategy, temperature gradient) conditions. This study employs a systematic comparative experimental design, varying operating conditions and module configurations under a standardized portable rig to identify higher-performing setups.

The hybrid system consisted of a monocrystalline silicon PV module thermally coupled to a TEG. Seven different TEG modules were tested in turn under four operating conditions:

-

Case 1: Standard Test Conditions (STC) at 25 °C without cooling (EN/IEC 61215).

-

Case 2: Passive cooling using aluminum heat sinks attached to the TEG cold side.

-

Case 3: Active cooling with circulating water as coolant.

-

Case 4: Active cooling with a nanofluid as coolant.

Environmental parameters

To measure the coupled electrical–thermal performance of the PV–TE hybrid, we captured the environmental drivers that dictate both photovoltaic conversion and TEG temperature gradient (ΔT). Field measurements were collected solely in Istanbul on a common portable rig during June–August (11:00–15:00 local time) to have more comparable, near-peak irradiance windows as well as mitigate diurnal hysteresis. The same sensor mounting, wiring, and sampling methods were utilized regardless of operating condition (no cooling, passive, active-water, active-nanofluid). In this study, the performance of the hybrid PV–TE system was determined through on-site experimental measurements in Istanbul. The collected data were used to validate a numerical model predicting the system’s behavior. Subsequently, using this validated model, the system’s performance was simulated for the cities of Berlin and Stockholm using standard meteorological data obtained from the NREL and JRC databases. To maintain a relatively same convective regime, time intervals longer than the low-wind criterion were omitted; all calculated statistics were calculated from steady-state portions of three replicate trials.

Parameters (refined wording; keep your existing sensors/specs):

-

Plane-of-array solar irradiance (W/m2): Measured with a calibrated pyrometer aligned with the PV module plane.

-

Ambient temperature (°C): Recorded using a naturally ventilated, shaded thermistor probe.

-

PV back-surface temperature (°C): Monitored on the rear of the active cell area with K-type thermocouples and thermal paste to ensure good contact.

-

TEG hot/cold temperatures (°C): Measured simultaneously with matched K-type thermocouples on each side; ΔT = Thot − Tcold computed in real time.

-

Wind speed (m/s): Logged to enforce low-wind screening (target < 2 m/s) for consistency; out-of-criterion windows were excluded from steady-state averages.

PV–TEG modelling

This section creates a coupled electro-thermal framework that connects the irradiance and temperature dependent PV behavior to the ΔT driven conversion of the TEG via a common thermal interface and the four operating states prescribed for the standardized, portable rig. Model parameters are obtained through calibration and then validated only against the Istanbul field campaign: both PV temperature response and TEG response are derived from measured operating states. The calibrated configuration is then extended to Berlin and Stockholm, using site-specific plane-of-array irradiance, ambient temperature, and wind inputs obtained from the National Renewable Energy Laboratory’s National Solar Radiation Database (NREL/NSRDB) and the European Commission Joint Research Centre Photovoltaic Geographical Information System (EU JRC PVGIS), producing accurate simulation counterparts to the Istanbul states without introducing unconstrained degrees of freedom. The benchtop STC point is maintained only for contextual position. Stage definitions and equations are kept as presented in “Photovoltaic model” and “Thermoelectric generator model” sections, though treatment of uncertainty and updating performance metrics methods are consistent as described in the Methods.

Photovoltaic model

The PV model, represented as plane-of-array irradiance and back-surface cell temperature under the standard manufacturer, portable module specifications (reference efficiency, reference temperature coefficients) serves as priors that later get updated with Istanbul field data taken from steady, near-peak windows with duplicated runs, and was grounded in the empiricism. The PV output power takes as input parameters solar irradiance G, cell temperature TPV, and module area APV. The conventional single-diode equation can be used to derive the current–voltage (I–V) characteristics, although for algorithmic configuration of power/efficiency we can describe it—as represented below—without introducing additional degree freedom. Temperature inputs as measured with rear surface temperature thermocouples provides variable dependence as measurement not assumption; the symbols and units below are consistent with equations to follow, and laboratory STC point is noted only in context. Equation (1) ensues.

Thermoelectric generator model

In the usage of the coupled PV–TE model the thermoelectric stage is seen as the converter, whereby the operating point is defined by the PV back-surface (hot-side) temperature and the sink/coolant (cold-side) temperature as realized for the standardized portable rig - in the four scenarios (no cooling, passive heat-sink, active water, active nanofluid). The calibrations from the actual Istanbul on-site tests were utilized for the device, and interface parameters, and the calibrated set is then held constant for Berlin and Stockholm that take site meteorological inputs for the respective thermal boundary conditions, yielding energy consistency at the PV–TE interface and attributing variances in electrical output to primarily the achievable ΔT and cooling strategy, with the rest of the formalism being essentially the same; laboratory STC point is held for relative context.

The TEG converts a portion of the waste heat from the PV into electrical power. It depends on the temperature difference ΔT between the hot and cold sides and the Seebeck coefficient S, internal electrical resistance Rint, load resistance Rload and thermal conductance Eqs. (2) and (3) :

The current–voltage (I–V) characteristics of the PV module were recorded at each test point. The instantaneous PV electrical power PPV was obtained as Eq. (4):

The open-circuit voltage and load current of each TEG were measured to determine its electrical power output PTEG Eq. (5)

All instruments were calibrated before testing. Each data point represents the average of multiple readings collected under stable conditions.

PV efficiency can be calculated as Eq. (6)

where G is the solar irradiance (W/m²) and APV is the illuminated area of the PV module (m²).

TEG efficiency can be calculated as Eq. (7)

Qin is the thermal power transferred from the PV module to the TEG. It was estimated as Eq. (8)

for the active cooling cases, or using the measured heat flux and ΔT for passive cooling.

Hybrid system efficiency can be calculated as Eq. (9)

The relative efficiency gain (or performance increase) of the hybrid system compared to PV only was computed as Eq. (10):

This figure represents the percentage increase in electrical power output due to the TEG component under each test condition.

All values were corrected for instrument accuracy, and uncertainties were propagated using root-sum-square (RSS) methods. ΔT, PV power, TEG power, and derived efficiencies were reported with their associated uncertainties as described in the Uncertainty Analysis section (“Uncertainty analysis”).

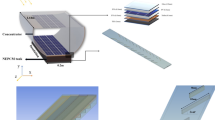

To address this limitation and improve overall system efficiency, an active cooling (AC) mechanism was implemented. In active cooling, a cold liquid circulates through the system, enhancing heat transfer and enabling TEG to produce significantly more power compared to passive cooling. Figure 1 illustrates a schematic of the basic PV–TE system, where the upper part represents the PV module, and the thermoelectric generator lies directly beneath it. The TE component transforms the absorbed heat energy into additional electrical energy.

For the TEG, the cold plate side temperature (Tc) was initially set to the temperature of the Ta during both non-cooled and cooling system-equipped tests. However, for active cooling system evaluations, a liquid coolant maintained at 10 °C was introduced into the testing setup. This controlled cooling medium facilitated the dissipation of heat more effectively, enabling a thorough examination of the effects of active cooling mechanisms on the PV–TE’s electrical and thermal performance.

The experimental investigations involving the TE component of the photovoltaic–thermoelectric (PV–TE) hybrid system were conducted at the Calibration Laboratory of the Turkish Standards Institution (TSE), an accredited facility ensuring adherence to international standards. To assess the PV–TE system’s performance, a heated plate from the ACSII-2000 Temperature Calibration System, manufactured by Anritsu Meter Co., LTD, Tokyo, Japan, was employed. This equipment was instrumental in simulating and maintaining precise temperature conditions for the PV component of the hybrid system.

The TE component testing system, as depicted in Fig. 2, was specifically designed to ensure accurate thermal regulation and measurement consistency throughout the experimental process. This setup facilitated a comprehensive evaluation considering the PV–TE system’s electrical and thermal properties under controlled conditions, supporting the validity and dependability of the study’s conclusions.

Figure 2 displays the TE component test bench constructed at the TSE calibration laboratory where the PV–TE interface was replicated under controlled boundary conditions using the ACSII-2000 temperature calibration system to apply and maintain the hot-side set points(Th), with synchronized instrumentation providing traceable measurements. The bench allows for passive trials (natural convection/fin heat sink) and includes the actively cooled configuration seen in Fig. 3. In this configuration, a recirculating chiller drives distilled water maintained at 10 °C through an insulated cold plate via flexible piping and liquid pump, elevating and maintaining the temperature difference across the TEG. This arrangement was chosen to increase measurement consistency (repeatable ΔT) and to evaluate the cooling strategy of heat removal from the TE assembly independent of the sensor arrangement or electrical metrology.

Key components of the system include flexible pipes, an aluminum water-cooling block, a heat sink, and a liquid pump. These elements work together to circulate the coolant, regulate the system temperature, and maximize the thermal gradient (ΔT) across the TEGs. By maintaining a consistent cold-side temperature of 10 °C, the system enhances the temperature difference between the hot and cold sides of the TE component, leading to improved energy conversion efficiency. The experimental results confirmed that the active cooling mechanism significantly increased the efficiency of the PV–TE hybrid system by minimizing thermal losses and maintaining optimal operating conditions.

Results analysis

To analyze the differences in energy production of the PV–TE system, we evaluated its performance in three distinct European cities with varying solar irradiation levels:

-

Stockholm Selected owing to its low solar irradiation values, providing insight into system performance under suboptimal sunlight conditions.

-

Istanbul Chosen for its high solar irradiation values, as it has one of the highest levels of solar radiation in Europe.

-

Berlin Positioned between Stockholm and Istanbul in terms of solar irradiation, which allows us to assess the system’s efficiency under moderate conditions.

Simulation tools and programming

Pseudocode 1 implements the proposed model. It starts from irradiance, PV/TEG parameters, and temperature difference, then outputs PV power, TEG power, total hybrid efficiency, and percentage gain. I have used the MATLAB Programming on MATLAB R2024a software for simulation of our research work.

The PV–TE G tests that were recorded as Tables 2, 3, 4 and 5 were conducted as controlled outdoor measurements under the peak-sun conditions in each city to obtain representative high-irradiance data. In particular, measurements were taken throughout the summer season (June-August 2024) when the solar irradiance is usually at the highest point. Experiments in each city were conducted over a three-day span at the noon (11:00–15:00 local time) with individual data item being an average of several measurements made under constant irradiance and temperature conditions. The method promoted comparability between the sites and reduced short-term fluctuations.

For an accurate analysis, we first selected the most efficient TEGs from our previous study48. We used EU JRC summaries only to pre-screen likely peak-temperature days for scheduling; all reported performance metrics were computed from on-site measurements. All reported measurements in Tables 2, 3, 4 and 5 were made in clear-sky and peak-irradiance conditions to allow inter-site comparison. The following parameters of environment were recorded during every test day:

-

Solar Irradiance The midday values at 850–1000 W/m2 in all three locations are equal to the average peak-sun values in summer.

-

Ambient Temperature This was recorded to span between about 21 °C in Stockholm and 39 °C in Istanbul during the measurements (Tmax in Table 2).

-

Temperature of PV Modules The data is observed and recorded in Table 2 as TPVmax (e.g. 32.8 °C in Stockholm, 58.1 °C in Istanbul).

Temperature gradient across TEG: Tables 2 and 3 also contain these values, 22.8 °C in Stockholm and 48.1 °C in Istanbul.

Wind speed: To reduce convective cooling conditions and consistency, all tests were run under low-wind conditions (less than 2 m/s).

These values indicate the true conditions of the environment at any given time we were measuring and the variation in the output power witnessed at various locations. To ensure clarity of the information, we have included the same in the revised manuscript.

The corresponding solar irradiance (G) values were then obtained for these days to evaluate the system performance under peak temperature conditions. The monocrystalline PV module used in this study had approximate dimensions of 156 mm×156 mm per cell (industry standard 6-inch cells), assembled into a small laboratory-scale panel of approximately 0.5 m² active area for hybrid integration with the TEG modules.

In our research the solar radiation values to be used in determining the performance and efficiency were directly measured at the actual sites in the three cities using calibrated pyrometers in respect to the EN/IEC 61215 standard test conditions. Ambient temperature, PV surface temperature and the speed of the wind were also noted at the same time with every test. Where we could not measure the effect of parameters that did not necessarily vary on-site (long-term average solar spectra or hourly historical irradiance), we compared our data with publicly available data on NREL and the JRC Photovoltaic Geographical Information System (PVGIS) so that we could verify the consistency of our data and verify the accuracy of our results. The mixed methodology enabled us to rely on real measurements in the field and at the same time keep in line with accepted reference databases.

The system utilizes solar radiation as the primary input and generates electrical power under STC. STC is a widely adopted industry standard for evaluating the performance of PV modules. It defines specific testing parameters, including a cell temperature of 25 °C, an irradiance of 1000 W/m², and an air mass of 1.5 (AM1.5) spectral distribution. These conditions provide a consistent and comparable basis for assessing the electrical output of PV systems. Under high solar irradiance, the PV module temperature (Tmax) can rise to 50–60 °C, deviating from the ambient temperature (Tamb) by approximately 30–40 °C. The temperature of the PV panel, which is influenced by incident light, operating conditions, and installation parameters, can be calculated as follows Eq. (11)49:

where c (K m²/W) is a coefficient dependent on the PV panel installation conditions, and G (W/m²) is the irradiance. In this study, we assumed c = 0.020 K m²/W, considering that we were analyzing free-standing PV power plants. In our previous research, seven different TEGs were tested under varying conditions, and the two most efficient modules were selected for this study. Table 1 provides details of the selected TEGs, including their structural parameters.

In Table 2, the maximum panel temperature is denoted by Tmax, while ΔT and ΔTTEG represent the temperature differences between Tmax and a reference temperature of 10 °C under varying concentration ratios (c) for each selected city. The calculated values for Stockholm, Berlin, and Istanbul are summarized in this table.

In this instance, the PV and TE module performance will be determined by the front-side temperature (T) and the operating temperature of TE (Tm), respectively. Specifically, Tamb and the solar radiation flux (G) affect the temperature of the PV module (T), and the rear panel temperature (Th) and Tamb affect the operational TE temperature (Tm). It must be remembered that heat (Q) travels from the PV to the TE module before dissipating.

The rear temperature of the panel is almost equivalent to the hot-side temperature of the TEGs50,51,52,53,54. TE modules convert heat into electric power, whereas PV cells transform sunlight into electricity. Additionally, the conversion efficiency increases as the thermo-element length and temperature differential increase55. In this study, a PV module comprising only one monocrystalline solar cell from the company Hunan Red Solar was used.

In Table 3, the performance values of TEG3 and TEG4 in different cities are listed. For TEG3, the power outputs in Stockholm, Berlin, and Istanbul were 0.0688611, 0.1377222, and 0.196746 W, respectively. The highest output in Istanbul was driven by an elevation of 46.1 °C, demonstrating a direct correlation between thermal gradients and energy generation. The performance values of TEG4 in different cities are listed. About TEG4, similarly, TEG4 exhibited the highest power output in Istanbul (0.507822 W), compared to 0.1777377 W in Stockholm and 0.3554754 W in Berlin. This performance superiority underscores the material and design optimization of TEG4, which allowed for better utilization of the temperature gradients.

To obtain information about the performance of the thermoelectric generator, the power outputs of the thermoelectric modules were analyzed. The results, given in Tables 4 and 5, reveal significant variations across the selected locations.

The results confirmed that TEG4 consistently outperformed TEG3, largely owing to its advanced material composition and structural enhancements. This result highlights the importance of high-efficiency thermoelectric materials in maximizing the energy contribution of hybrid systems.

We obtained total hybrid power by adding the measured PV power and measured TEG power under matched conditions. External JRC/NREL datasets were consulted only to cross-check seasonal/diurnal patterns and were not used as primary inputs.

The integration of TEGs with the PV module significantly enhanced the total energy output of the hybrid system. The combined outputs and percentage increases for each configuration are listed in Tables 4 and 5, showcasing the effectiveness of incorporating TEGs to boost system performance.

In Table 4, the Power of PV, combined power of PV–TE system, and increase in performance for TEG3 are presented. Regarding the integration of TEG3 in Stockholm, the combined output reached 3.3568611 W, reflecting a 2.09% increase over the standalone PV system. Berlin’s output increased to 3.6997222 W, representing a 3.87% increase. Istanbul demonstrated the highest combined output of 5.676746 W, which corresponds to a 3.59% increase.

In Table 5, the power output of the PV module, combined power of the PV–TE system, and percentage increase in the performance of TEG4 are presented. The integration of TEG4 resulted in a combined power output of 3.4657 W in Stockholm, representing a 5.41% increase. In Berlin, the combined output reached 3.9175 W, representing an 9.98% enhancement, whereas Istanbul exhibited the highest combined power of 5.9878 W, with a 9.28% increase compared with the PV-only system.

The PV–TE values in Tables 4 and 5 were calculated from our research results published in our previous research paper mentioned above. PPV values are based on on-site measurements under matched irradiance and temperature; external databases were consulted only for consistency checks. All the values belong to summer months; for example, the best absolute results were recorded in Istanbul in July.

These results clearly demonstrate that incorporating TEGs into PV modules can significantly enhance the energy output, particularly in regions with higher solar irradiance. The performance of the PV–TE hybrid system was evaluated by analyzing the power generation, efficiency, and measured hybrid efficiency and percentage gain within the tested summer midday window, using on-site irradiance and temperature. The selected cities allowed for a comprehensive comparison of performance variations under different temperature and irradiance conditions across the three European locations. Solar irradiance (G), sunlight duration (dh), and ambient temperature (Tamb) were measured on site; external JRC/NREL datasets were consulted solely for consistency checks.

The contribution of the TE component to the total energy output of the PV–TE system varied by location. In Berlin, the TE component accounted for 9.98% of the total energy, whereas in Istanbul, this value was approximately 9.27%. Within the tested summer midday window (June–August, 11:00–15:00 local time), Berlin exhibited higher mean hybrid efficiency than Istanbul. This suggests that PV–TE system performance is highly dependent on both temperature variations and irradiance.

A direct comparison of PV–TE system configurations across locations was performed using the measured hybrid efficiency and percentage gain within the tested summer midday window normalized to the rated power of the system. The relative deviation percentage between the PV-only and PV–TE systems for the day with the highest temperature of the year is presented in Tables 4 and 5, respectively.

Although all locations exhibited higher TE power outputs during summer, the best absolute results were recorded in Istanbul in July. However, the highest percentage increase in power generation was observed in Berlin, whereas Stockholm had the lowest TE power output during the summer months.

These findings highlight the importance of customizing PV–TE system designs based on site-specific conditions, energy requirements, and climatic factors to achieve optimal efficiency and cost effectiveness. In addition, the ideal number of TE modules should be carefully determined based on environmental parameters, component selection, and PV panel resistance to maximize the energy yield of the system.

In our work the primary source of solar radiation and ambient data was our own on-site measurements at all three experimental locations. The values were measured in the test periods at the locations of the PV–TE modules with the help of the calibrated pyrometers and digital temperature probes.

The external datasets (NREL and JRC) were not utilized as the raw input in the efficiency calculations; they were only utilized as the basis of reference to confirm and cross-check the viability of the on-site measurements. Specifically:

Specifically, for Stockholm and Berlin, our on-site irradiance data were compared against JRC PVGIS products for the same days and times. For the Istanbul analysis, our on-location measurements were cross-validated with the Solar Resource Data (NSRDB) from NREL for the respective coordinates.

This also made sure that the performance results that we report in our paper are grounded on measured data first and on publicly available data second to confirm, thus the differences between NREL and JRC assumptions did not directly impact our efficiency calculations.

Table 6 presents the comparative performance of the PV–TEG hybrid system equipped with TEG3 and TEG4 under four cooling strategies. It is evident that both modules produced the lowest PV and TEG outputs under the “No Cooling” baseline and progressively higher outputs as heat removal improved. Passive aluminium heat sinks provided a modest rise in hybrid efficiency (about 4% gain), while active water cooling yielded more substantial improvements (12–13% gain). The highest values were recorded under active nanofluid cooling, where the combined effect of enhanced heat transfer and greater temperature differential across the TEG resulted in hybrid efficiencies exceeding 19% and efficiency gains of roughly 17% relative to the no-cooling baseline at matched irradiance and temperature. This clear trend confirms that active cooling not only reduces PV cell temperature but also increases the TEG temperature gradient, leading to a measurable and consistent enhancement in total system performance.

Uncertainty analysis

To rigorously establish the fidelity of the reported performance metrics, and thereby substantiate the scientific claims of this work, a formal uncertainty analysis was conducted. The fundamental purpose of this section is to transparently quantify the confidence intervals associated with the principal derived quantities—specifically, the electrical power outputs and the critical figure-of-merit, the percentage gain attributable to the thermoelectric generator. This process is indispensable in experimental science, as it contextualizes the results by acknowledging and systematically propagating the inherent limitations of the measurement chain, thus elevating numerical outcomes to scientifically defensible findings.

The analytical approach is grounded in established metrological conventions, employing a first-order, uncorrelated root-sum-of-squares (RSS) treatment consistent with the Guide to the Expression of Uncertainty in Measurement (GUM) framework56. A clear distinction is maintained between the propagation of uncertainties for sums versus products/ratios. The analysis consolidates a comprehensive uncertainty budget, encompassing Type B uncertainties derived from instrument specifications (e.g., sensor accuracy, resolution) and calibration, alongside Type A uncertainties evaluated from the statistical variance observed across replicated experimental trials under steady-state conditions57. The subsequent sections delineate the formal propagation methodology and its underlying assumptions (“Propagation methodology and consolidated uncertainty budget” section) before executing a numerical propagation anchored to the empirical dataset from the Istanbul test site to provide a concrete and traceable case study (“Numerical propagation anchored to the Istanbul experimental case” section).

Propagation methodology and consolidated uncertainty budget

The propagation of uncertainty followed a systematic protocol dictated by the mathematical relationships between measured and derived quantities. For parameters computed as linear sums or differences, such as the temperature gradient (ΔΤ = Th - Ta) and the total hybrid power (Ptot = PPV + WTEG), their absolute uncertainties were combined via the RSS method. Conversely, for parameters computed as products or ratios, including the electrical power (W = V I) and the fractional gain (R = WTEG / PPV), their fractional (relative) uncertainties were propagated in quadrature56,57.

The consolidated uncertainty budget, which provides the inputs for this propagation, was established based on conservative estimates from instrument specifications and experimental experience, consistent with best practices documented in photovoltaic performance analysis58. The key contributors are as follows:

-

Temperature Sensors (u(T)) A standard uncertainty of ± 0.5% was assigned to both the hot- and cold-side temperature measurements, encompassing calibration error, resolution, and thermal contact effects.

-

Electrical Measurements The standard uncertainties for voltage (\(\:u\left(V\right)\left(V\right)\) and current (\(\:u\left(I\right)\left(I\right)\) were specified as 0.5% and 1.0%, respectively, covering instrument accuracy and wiring resistance.

-

Irradiance A standard uncertainty of 5.0% was attributed to the pyranometer measurements, reflecting its calibration, cosine response, and soiling effects. This component was identified as the dominant contributor to the overall PV power uncertainty.

-

Repeatability (urep) A Type A standard uncertainty of 0.5% was assigned to all power readings to account for the statistical standard error derived from averaging multiple samples within stable measurement windows.

Numerical propagation anchored to the Istanbul experimental case

To illustrate the practical application of this framework, the formal propagation was executed using the empirical dataset from the Istanbul field tests, specifically for the TEG4 module under peak conditions: ΔΤTEG = 46.1 °C, WTEG4 = 0.507822 W, and PPV = 5.48 W.

The propagation commenced with the primary measured quantities. The absolute uncertainty in the temperature gradient, \(\:u\left({\Delta\:}T\right)\), was calculated as 0.7071 °C by applying the RSS method to the hot- and cold-side sensor uncertainties, which corresponds to a relative uncertainty of 1.53%. Subsequently, the combined relative uncertainty in the TEG4 power was determined to be approximately 1.225% by propagating the fractional uncertainties of voltage, current, and repeatability in quadrature. This yielded an absolute uncertainty, u(WTEG4), of ≈ 0.00621 W. For the PV power channel, where the uncertainty budget is dominated by the irradiance measurement, the combined relative uncertainty was calculated to be 5.125%, resulting in a significantly larger absolute uncertainty, u(PPV), of ≈ 0.281 W.

Finally, the uncertainty in the principal derived metric—the fractional gain (R = 9.266%)—was quantified by combining the relative uncertainties of the TEG and PV power channels in quadrature. This propagation resulted in a final uncertainty of 0.488% points for the gain value. Therefore, the principal finding of this performance enhancement is reported with its standard uncertainty (coverage factor k = 1) as follows:

Percent Increase = 9.27% ± 0.49%.

Conclusions

This research confronted the pivotal challenge of enhancing the energy conversion efficiency of PV technology by developing and validating an efficacious strategy for waste heat recovery. By systematically investigating a hybrid PV–TE system, this study moves beyond theoretical potential to provide a rigorously quantified assessment of its real-world performance across diverse climatic conditions. The novelty of this work resides not in a single discovery, but in its holistic and comparative methodology: a unique hybrid experimental-numerical framework was established, anchored by empirical field data from Istanbul and extended via validated simulations for Berlin and Stockholm. This approach enabled a geographically decoupled yet methodologically consistent assessment that contrasts with the limitations of single-variable, location-specific, or purely theoretical studies that dominate the extant literature.

The investigation yielded several key scientific conclusions that both confirm and challenge conventional expectations for hybrid solar systems. The principal findings are enumerated as follows:

-

The Primacy of Engineered Thermal Gradient over Ambient Temperature Counter-intuitively, the analysis demonstrated that the mean hybrid efficiency in the moderate climate of Berlin surpassed that of the hotter, high-irradiance environment of Istanbul during the tested summer midday window. This pivotal finding underscores a critical paradigm: the thermoelectric conversion efficiency is less dependent on high ambient temperatures and more critically governed by the magnitude of the engineered temperature gradient (ΔT) across the TEG, which is maximized through effective thermal management.

-

Quantification of Active Cooling as an Enabling Technology The study quantified the dramatic performance uplift achievable with advanced thermal management. The implementation of an active nanofluid cooling strategy yielded a transformative enhancement, boosting the total hybrid efficiency by up to 17% relative to the non-cooled baseline. This substantiates the conclusion that advanced cooling strategies should not be viewed as an incremental benefit but as an essential enabling technology required to unlock the full performance potential of PV–TE systems.

-

Empirical Validation of Material Superiority Through the direct, side-by-side benchmarking of commercial TEG modules under matched conditions, the consistent outperformance of the TEG4 module was empirically validated. This result directly correlates superior system-level performance with advanced material properties, specifically a high Seebeck coefficient and low thermal conductivity, providing clear guidance for component selection in future system designs.

In synthesizing these findings, this study makes a unique contribution by demonstrating that a holistic, multi-variable approach is essential for the meaningful evaluation and strategic deployment of PV–TE technology. By simultaneously assessing the interplay between geographic location, TEG material properties, and multiple cooling strategies—all underpinned by a rigorous uncertainty analysis—this work provides a comprehensive and reliable blueprint for system optimization.

Looking forward, the promising results presented herein lay the groundwork for several critical avenues of future research. To transition this technology toward commercial bankability, the following areas warrant investigation:

-

Long-Term Durability and Reliability Long-term field trials are essential to assess the system’s performance under cyclic thermo-mechanical stress, evaluating potential material degradation at the PV–TEG interface and the long-term stability of the cooling apparatus.

-

Dynamic System Integration and Control Future work should focus on integrating the hybrid system with smart, dynamic control algorithms that optimize real-time thermal management based on fluctuating irradiance and load demands, thereby maximizing annual energy yield.

-

Comprehensive Techno-Economic and Lifecycle Assessment While this study provides the foundational performance data, a comprehensive techno-economic analysis, including a full lifecycle assessment (LCA), is required to quantify the levelized cost of energy (LCOE) and the environmental payback time, which are critical metrics for commercial adoption.

Ultimately, this research substantiates that PV–TE hybridization, when intelligently coupled with site-specific thermal management, represents a technically robust and highly promising pathway for significantly enhancing the energy yield of solar installations, thereby advancing their contribution to a global sustainable energy future.

Data availability

The processed datasets and summary tables are available from the author upon reasonable request. External NREL/JRC datasets were consulted solely for consistency checks and were not used as primary inputs to compute performance metrics.

References

Filonchyk, M., Peterson, M. P., Zhang, L., Hurynovich, V. & He, Y. Greenhouse gases emissions and global climate change: Examining the influence of CO2, CH4 and N2O. Sci. Total Environ. 935, 173359 (2024).

ClientEarth. Fossil fuels and climate change: The facts & ClientEarth (2025). https://www.clientearth.org/latest/news/fossil-fuels-and-climate-change-the-facts/.

IPCC. IPCC Special Report on Carbon Dioxide Capture and Storage (eds Metz, B., Davidson, O., de Coninck, H., Loos, M. & Meyer, L.) (Cambridge Univ. Press, 2005).

Perera, F. Pollution from fossil-fuel combustion is the leading environmental threat to global pediatric health and equity: Solutions exist. Int. J. Environ. Res. Public. Health 15, 16 (2017).

Pang, Y. L., Lim, S., Lai, S. O. & Chong, W. C. Green chemistry for the development of biomass conversion process into cellulose and bioethanol. in Green Sustainable Process for Chemical and Environmental Engineering and Science (eds Inamuddin, Altalhi, T. & Alrooqi, A.) 121–137 (Elsevier, 2023).

Chen, F. et al. Breathing in danger: Understanding the multifaceted impact of air pollution on health impacts. Ecotoxicol. Environ. Saf. 280, 116532 (2024).

Erhart, S. et al. Environmental ranking of European industrial facilities by integrated toxicity and climate risk. Sci. Rep. 13, 1213. https://doi.org/10.1038/s41598-022-25750-w (2023).

Paisi, N. et al. Health effects of carbonaceous PM2.5 compounds from residential and transport emissions in Europe. Sci. Rep. 14, 51916. https://doi.org/10.1038/s41598-024-51916-9 (2024).

Jin, X. et al. Ammonia emissions from agricultural products at high resolution across Europe. Sci. Data. 12, 05110. https://doi.org/10.1038/s41597-025-05110-9 (2025).

Castro, M., Antón, I. & Sala, G. Pilot production of concentrator silicon solar cells: Approaching industrialization. Sol Energy Mater. Sol Cells 92, 1697–1705 (2008).

Baig, H., Heasman, K. C. & Mallick, T. K. Non-uniform illumination in concentrating solar cells. Renew. Sustain. Energy Rev. 16, 5890–5909 (2012).

Miles, R., Hynes, K. & Forbes, I. Photovoltaic solar cells: an overview of state-of-the-art cell development and environmental issues. Prog Cryst. Growth Charact. Mater. 51, 1–42 (2005).

Jelse, K. & Johnson, H. Increasing the rate of solar cell diffusion in Japan: dynamics of the PV innovation system, 1973–2007. Chalmers University of Technology, ESA Report No. 2008:14. (2008). https://publications.lib.chalmers.se/records/fulltext/74727.pdf

Davenport, K. et al. Relaxation processes in silicon heterojunction solar cells probed via noise spectroscopy. Sci. Rep. 11, 13238. https://doi.org/10.1038/s41598-021-92866-w (2021).

International Renewable Energy Agency (IRENA). Future of solar photovoltaic: deployment, investment, technology, grid integration and socio-economic aspects. IRENA (2019). https://www.irena.org/publications/2019/Nov/Future-of-Solar-PV

Galy Adam, A. & Yeşilata, B. Use of hybrid photovoltaic–thermoelectric (PV–TE) solar module for enhancing overall system efficiency. in Proc. Int. Symp. Multidiscip. Stud. Innov. Technol. (ISMSIT) 1–8 (2019). https://doi.org/10.1109/ISMSIT.2019.8932949.

Deng, Y., Zhu, W., Wang, Y. & Shi, Y. Enhanced performance of solar-driven photovoltaic–thermoelectric hybrid system in an integrated design. Sol Energy. 88, 182–191 (2013).

Kannan, N. & Vakeesan, D. Solar energy for future world: A review. Renew. Sustain. Energy Rev. 62, 1092–1105 (2016).

Wellington, T. A. A. & Mason, T. E. The effects of population growth and advancements in technology on global mineral supply. Resour. Policy. 42, 73–82 (2014).

World Economic Forum. The Fourth Industrial Revolution: What it means, how to respond. (World Economic Forum, 2016). https://www.weforum.org/stories/2016/01/the-fourth-industrial-revolution-what-it-means-and-how-to-respond/

Romitti, Y. & Sue Wing, I. Heterogeneous climate change impacts on electricity demand in world cities circa mid-century. Sci. Rep. 12, 4280. https://doi.org/10.1038/s41598-022-07922-w (2022).

Nøland, J. K. et al. Spatial energy density of large-scale electricity generation from power sources worldwide. Sci. Rep. 12, 21280. https://doi.org/10.1038/s41598-022-25341-9 (2022).

Qureshi, M., Arbab, M. A. & Rehman, S. Deep learning-based forecasting of electricity consumption. Sci. Rep. 14, 6489. https://doi.org/10.1038/s41598-024-56602-4 (2024).

Raj, A. K., Kunal, G., Srinivas, M. & Jayaraj, S. Performance analysis of a double-pass solar air heater system with asymmetric channel flow passages. J. Therm. Anal. Calorim. 136, 21–38 (2019).

Liu, Y. W., Feng, H., Li, H. Y. & Li, L. L. An improved Whale algorithm for support vector machine prediction of photovoltaic power generation. Symmetry 13, 212 (2021).

Skoplaki, E. & Palyvos, J. A. On the temperature dependence of photovoltaic module electrical performance: A review. Sol. Energy. 83, 614–624 (2009).

Xuan, X. & Li, D. Optimization of a combined thermionic–thermoelectric generator. J. Power Sources. 115, 167–170 (2003).

Zhang, Z., Li, W. & Kan, J. Behavior of a thermoelectric power generation device based on solar irradiation and the earth’s surface–air temperature difference. Energy Convers. Manag. 97, 178–187 (2015).

Dallan, B., Schumann, J. & Lesage, F. J. Performance evaluation of a photoelectric–thermoelectric cogeneration hybrid system. Sol Energy. 118, 276–285 (2015).

Lin, J., Liao, T. & Lin, B. Performance analysis and load matching of a photovoltaic–thermoelectric hybrid system. Energy Convers. Manag. 105, 891–899 (2015).

Cui, T. & Xuan, Y. Design of a novel concentrating photovoltaic–thermoelectric system incorporated with phase change materials. Energy Convers. Manag. 112, 49–60 (2016).

Chow, T. T. & Li, Q. A review on photovoltaic/thermal hybrid solar technology. Appl. Energy. 87, 365–379 (2010).

Li, Y. et al. Wide spectrum solar energy harvesting through an integrated photovoltaic and thermoelectric system. Particuology 15, 39–44 (2014).

Narducci, D. & Lorenzi, B. Challenges and perspectives in tandem thermoelectric–photovoltaic solar energy conversion. IEEE Trans. Nanotechnol. 15, 348–355 (2016).

Tohidi, F., Holagh, S. G. & Chitsaz, A. Thermoelectric generators: A comprehensive review of characteristics and applications. Appl. Therm. Eng. 201, 117793 (2022).

Champier, D. Thermoelectric generators: A review of applications. Energy Convers. Manag. 140, 167–181 (2017).

He, W. et al. Recent development and application of thermoelectric generator and cooler. Appl. Energy. 143, 1–25 (2015).

Kraemer, D., McEnaney, K., Chiesa, M. & Chen, G. Modeling and optimization of solar thermoelectric generators for terrestrial applications. Sol Energy 86, 1338–1350 (2012).

Zhang, J., Xuan, Y. & Yang, L. Performance estimation of photovoltaic–thermoelectric hybrid systems. Energy 78, 895–903 (2014).

Dewangan, D., Ekka, J. P. & Arjunan, T. V. Solar photovoltaic thermal system: A comprehensive review on recent design and development, applications and future prospects in research. Int. J. Ambient Energy 43, 7247–7271 (2022).

Lee, J. et al. Performance enhancement of hybrid energy devices using cooling patches. Int. J. Photoenergy 2022, 364240 (2022)

Tang, J., Ni, H., Peng, R. L., Wang, N. & Zuo, L. A review on energy conversion using hybrid photovoltaic and thermoelectric systems. J. Power Sourc. 562, 232785 (2023).

Chandel, R. et al. Review on thermoelectric systems for enhancing photovoltaic power generation. Sustain. Energy Technol. Assess. 53, 102585 (2022).

Chandel, R., Chandel, S. S. & Khosla, A. Modelling and experimental investigation of cooling of field-operating PV panels using thermoelectric devices for enhanced power generation by industrial solar plants. Next Energy. 5, 100162 (2024).

Chandel, R. et al. A comprehensive analysis of photovoltaic panel integrated thermoelectric cooling system for enhanced power generation. Appl. Res. 3, e202400100 (2024).

Shurafa, S. M. A. et al. Enhancing photovoltaic–thermoelectric generator (PV–TEG) system performance via mathematical modeling and advanced thermal interface material: An emphasis on pyrolytic graphite sheet (PGS). Sol Energy. 273, 112514 (2024).

Qasim, M. A., Velkin, V. I. & Shcheklein, S. E. Experimental study on hybridization of a PV–TEG system for electrical performance enhancement using heat exchangers, energy, exergy and economic levelized cost of energy (LCOE) analysis. Clean. Energy. 7, 808–823 (2023).

Bulat, S., Büyükbıçakcı, E. & Erkovan, M. Efficiency enhancement in photovoltaic–thermoelectric hybrid systems through cooling strategies. Energies 17, 430 (2024).

Zhao, Q., Zhang, H., Hu, Z. & Hou, S. Achieving a broad-spectrum photovoltaic system by hybridizing a two-stage thermoelectric generator. Energy Convers. Manag. 211, 112778 (2020).

European Commission Joint Research Centre. Photovoltaic Geographical Information System (PVGIS) (European Commission Joint Research Centre, 2025). http://re.jrc.ec.europa.eu/pvgis/.

Van Sark, W. G., J. H. M. Feasibility of photovoltaic–thermoelectric hybrid modules. Appl. Energy 88, 2785–2790 (2011).

Yang, D. & Yin, H. Energy conversion efficiency of a novel hybrid solar system for photovoltaic, thermoelectric, and heat utilization. IEEE Trans. Energy Convers. 26, 662–670 (2011).

Wang, N., Han, L., He, H., Park, N. H. & Koumoto, K. A novel high-performance photovoltaic–thermoelectric hybrid device. Energy Environ. Sci. 4, 3676–3679 (2011).

Chávez-Urbiola, E. A., Vorobiev, Y. V. & Bulat L. P. Solar hybrid systems with thermoelectric generators. Sol Energy. 86, 369–378 (2012).

Rowe, D. M. & Min, G. Evaluation of thermoelectric modules for power generation. J. Power Sourc. 73, 193–198 (1998).

JCGM 100:2008 Evaluation of measurement data – Guide to the expression of uncertainty in measurement (GUM 1995 with minor corrections) Joint Committee for Guides in Metrology. (2008).

Taylor, J. R. An Introduction To Error Analysis: The Study of Uncertainties in Physical Measurements 2nd edn (University Science Books, 1997).

Kuai, D. P. K. et al. A review of uncertainty analysis in photovoltaic systems performance. Renew. Sustain. Energy Rev. 75, 225–235 (2017).

Funding

This research received no external funding.

Author information

Authors and Affiliations

Contributions

E.B. was responsible for the conception and design of the study, data acquisition, data analysis and interpretation, as well as writing and revising the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Buyukbicakci, E. Geographic and thermal impact on the performance of hybrid PV–TE energy systems. Sci Rep 15, 40169 (2025). https://doi.org/10.1038/s41598-025-23850-x

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-23850-x