Abstract

To address the issue of excessive gas concentration in the return corner under “U”-shaped ventilation in high-gas mine working faces, the 317 working face of Wangjialing Mine was selected as the research object, and a combination of theoretical analysis, numerical simulation, and engineering experiments was employed to analyze the causes of gas accumulation, construct a 3D model to simulate gas distribution and flow in the goaf, and develop a novel active sealing-extraction-enhancement device, which was then tested in the field. The research results indicate that: (1) Air leakage in the goaf, sudden stress release due to delayed collapse of hard and relatively hard roof strata, and operations such as coal release and shield advancement during mining are the leading causes of rapid and large-scale gas emissions from the goaf, which can lead to a sharp increase in gas concentration in the return corner. (2) Simulation revealed the gas migration patterns, identifying a gas-rich zone near the return side where the concentration approached 1.5%, showing that the gas concentration in the return corner of the 317 working face in Wangjialing Mine is relatively high. (3) Field tests confirmed that under normal conditions, goaf gas extraction via buried pipelines effectively maintains the return corner gas concentration below 0.8%. However, during abnormal emissions, this conventional method responds too slowly. When the T0 sensor in the corner detects an abnormal increase in methane concentration, the active sealing, extraction, and enhancement device is activated. The device rapidly blocks the gas emission pathway using a compressible airbag while simultaneously increasing the negative extraction pressure, reducing the methane concentration in the return corner from 0.88% to 0.19% within 3.5 s. Even under abnormal gas emission conditions, the device can quickly reduce gas concentration, effectively eliminating gas concentration exceedance phenomena and ensuring safe and efficient production at the working face.

Similar content being viewed by others

Introduction

In recent years, the number of gas disaster accidents has significantly decreased, but their proportion in mining accidents remains relatively high1,2,3. Excessive gas concentration is one of the main causes of gas accidents in coal mines, which endanger the safety of underground workers, especially when the working face adopts “U”-shaped ventilation, which easily leads to excessive gas accumulation at the return corner, severely affecting the safe and efficient production of the mine4,5.

Current measures to solve the issue of excessive gas at the return corner include: wind barrier guidance and dilution, forced roof release for uniform discharge, coal seam water injection and pre-fracture release, ventilation system adjustment (changing from “U”-type to “Y”-type), return corner pipe burial (insertion) for gas extraction, and roof drilling for gas extraction6,7. Among them, wind barrier guidance and dilution involve installing wind barriers at the return corner to guide the airflow direction and increase the air volume to dilute the gas at the return corner, thus eliminating gas accumulation; Forced roof release for uniform discharge involves timely removal of anchors and disconnection of the mesh in the intake and return corner tunnels of the working face to ensure the full collapse of the roof after mining, reducing leakage pathways and gas accumulation space in the goaf8,9; Pre-split gas release through advanced coal seam water injection involves filling the voids in the coal body with high-pressure water, which moistens, softens, and loosens the coal before cutting; this causes the deep coal to undergo pressure-induced pre-splitting, resulting in more uniform gas release10,11; Ventilation system adjustment involves changing from “U”-shaped ventilation to “two-entry-one-return” Y-type ventilation, with both side tunnels serving as intake airways, thereby eliminating the gas accumulation areas at the return corner12,13; Return corner pipe burial (insertion) for gas extraction involves laying extraction pipes in the return tunnel, with branch pipes connected at regular intervals to extract gas from the goaf14; Roof drilling for gas extraction refers to drilling holes along the roof of the return side to extract gas from the pressure-relieved overlying strata. The strata collapse, deform, and form fracture zones under mining influence, where desorbed gas from the working face rises, diffuses, and accumulates in fracture zones. By arranging drilling holes, the pressure-relieved gas can be extracted, reducing the gas concentration at the return corner15,16. Although there are various technical measures for controlling excessive gas at the return corner, most of them have high construction requirements. Most mines mainly rely on gas extraction, such as the plan proposed by Guangming Liu17, which implements pipe insertion (burial) and high-position directional drilling for combined gas extraction in the goaf at the return corner; Gao Denyu18 and others adopt combined control techniques, including pipe insertion for gas extraction at the return corner, sealed pipe insertion extraction in the goaf, and drilling for gas extraction in the goaf; Lianqin Ni 19, based on gas migration theory in the goaf, proposed a misalignment-type double pipe burial gas extraction scheme at the return corner; Yongle Cui20 proposed a method for controlling return corner gas using high (low) position roof-directed drilling combined with pipe burial in the goaf; Zenghui Zhang21 and others used pipe burial in the goaf to solve the return corner gas problem and determined the extraction parameters for the buried pipes through simulations; Mengchang Chen22 and others solved the return corner gas problem by changing the ventilation method at the working face and using high-extraction tunnels; Quanyi Li 23 and others applied a combination of high-position drilling for gas extraction, pipe insertion (burial) extraction at the return corner, increased air volume at the working face, pipe insertion extraction in the intake tunnel, and water jet fan treatment for localized gas accumulation; Wenxian Zheng24 and others proposed using large-diameter drilling “to replace tunnels with holes” for gas extraction at the return corner and optimized the parameters of large-diameter drilling, determining the optimal hole diameter, hole spacing, and final hole location.

In summary, the mainstream approach for controlling gas in the return corner, as evidenced by the literature, predominantly involves low-negative-pressure extraction via buried pipelines, often supplemented by other auxiliary measures. These methods are generally effective under regular and predictable conditions of gas emission. However, a common and critical limitation persists: their passive or slow-responsive nature. In the event of sudden, large-scale gas emissions caused by factors such as rapid face advance, hard roof collapse, or operational disturbances, these conventional measures respond too slowly to prevent a rapid buildup of gas concentration in the return corner. Once the gas concentration exceeds the statutory limit, production must be halted, and personnel evacuated immediately. This not only severely disrupts efficient mine production but also poses a continuous safety threat. Therefore, there is a pressing need for a technology capable of active, rapid intervention specifically targeting these transient abnormal emission events. To address the above technical bottleneck, this study focuses on the 317 working face of Wangjialing Mine and analyzes the causes of gas accumulation in the return corner. Based on the theory of “U”-shaped ventilation, the Fluent simulation software was used to model the spatial distribution of gas in the goaf of a high-gas mine with “U”-shaped working faces. The objective was to clarify the gas migration patterns within the goaf and identify the spatial distribution characteristics of gas in the return corner. Subsequently, an active sealing-extraction-enhancement device was developed for preventing gas overrun in the return corner of the working face. The device operates based on the synergistic principle of sealing and extraction, enabling proactive preventive control when signs of gas accumulation appear in the return corner of the goaf. It helps prevent disasters caused by gas overrun and has been experimentally validated for effectiveness through engineering trials. This provides an important reference solution for gas control in return corners of similar high-gas coal mines.

Engineering overview

Working face conditions

China Coal Hua Jin Group Wangjialing Branch is located about 9 km southwest of Xiangning County, with a mine area of 119.7109 km² and a production capacity of 7.5 Mt/a. The exploitable coal seams, from top to bottom, are the No. 2, 3, and 10 seams, with the main mining seams being No. 2 and No. 10. Currently, mining mainly takes place in the No. 2 coal seam, and the mine’s current working face is two active and two standby. The absolute gas outburst rate of the mine is 26.75 m³/min, and the relative gas outburst rate is 2.29 m³/t. The measured gas content in the 123 panel area ranges from 1.79 to 4.66 m³/t. Wangjialing Mine has been identified as a high-gas mine for many years. The 317 working face of the mine is located in the western part of the 123 panel area. The strike length of the working face is 785.1 m, and the inclined length is 260 m. The coal seam thickness ranges from 5.55 to 6.00 m, with an average of 5.80 m. The coal seam structure is relatively complex, generally containing 1 to 2 layers of carbonaceous mudstone and mudstone with gangue, ranging from fragmented to powdery, and from semi-dull to semi-bright coal. The recoverable reserve of the 317 working face is 6.409 million tons.

The surface elevation is + 1006.6 to + 847.1 m, and the underground elevation ranges from + 520 to + 430 m, with a maximum burial depth of approximately 480 m. The working face uses a fully mechanized top-coal caving mining technique. The layout of the fully mechanized caving face 317 at Wangjialing Mine is shown in Fig. 1.

Analysis of gas accumulation causes in the return corner

The third panel area of Wangjialing Mine employs the fully mechanized top-coal caving mining method, and the ventilation method for the working face is of the “U” type. The focus of gas control at the working face in Wangjialing Mine is on controlling the return airway corner gas. The main factors contributing to gas accumulation in the return corner include the working face ventilation method, the periodic roof caving characteristics, mining process parameters, and the effectiveness of gas control technologies.

-

(1)

According to relevant ventilation theories, as illustrated in Fig. 2, in working faces with a “U”-type ventilation system, gas tends to migrate toward the return roadway the vortex entrains gas from the goaf, leading to accumulation; due to the geometry of the goaf and the dynamics of airflow, a vortex zone is likely to form in the return corner of the working face. The vortex induces rotational gas motion, which impedes gas diffusion and results in gas accumulation in this area. Meanwhile, the vortex entrains gas from the goaf, leading to its accumulation in the return corner. The gas concentration in this area may increase due to the sustained effect of the vortex, potentially leading to gas overrun.

-

(2)

Delayed caving of hard and relatively hard roof strata. During the initial weighting of the working face, the distance between the basic roof and the goaf floor is considerable (approximately 40 m), resulting in delayed roof caving and rendering the boreholes on the return side ineffective at this stage. Gas emitted from the working face relies primarily on ventilation for dilution; the return airflow carries away part of the gas, while the remainder enters the goaf and migrates toward the return corner under the influence of leakage flow. This situation efficiently induces gas overrun and leads to excessive gas concentrations in the return corner.

-

(3)

Mining method. The 317 working face employs the fully mechanized top-coal caving mining method. By monitoring the changes in gas concentration at the return airway corner, near the mining machine, and in the return airway during mining operations such as coal cutting, moving supports, and releasing coal, the gas concentration distribution pattern at the working face during recovery was analyzed.

Under the action of the return airflow, gas outbursts from the fully mechanized caving working face mainly originate from coal cutting and releasing coal, especially during coal release and support movement when the fully mechanized support and the roof suddenly press down. The gas desorbs and is released from the collapsed coal body in the rear. Under the influence of the return airflow, the accumulated gas in the goaf is discharged from the return airway corner, which easily causes gas accumulation at the return airway corner.

Therefore, gas control at the return airway corner in the recovery working face is a key focus of gas control in the mine.

Characteristics of gas emission in Goaf under U-Type ventilation

Geometric model establishment

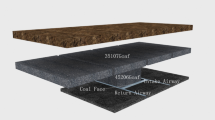

Based on the actual layout of Panel 317 at Wangjialing Mine and the theoretical framework of overburden fracture evolution under mining-induced stress, a three-dimensional trapezoidal spatial model of the overburden was constructed under underground mining conditions to facilitate analysis. The three-dimensional spatial model of the goaf is shown in Fig. 3.

The goaf model dimensions are specified as follows:

-

Length: 400 m.

-

Width: 300 m.

-

Height: 6 m.

The working face parameters include:

-

Length: 300 m.

-

Width: 8 m.

-

Height: 4 m.

The intake and return airways are modeled with:

-

Length: 50 m.

-

Width: 5 m.

-

Height: 3.5 m.

The computational domain was discretized using a refined mesh scheme with localized grid densification to ensure numerical accuracy in critical zones.

Boundary conditions

The boundary type of the interface between the working face, the roadway, and the goaf is selected as Interior. The boundary type of the intake airflow is chosen as a velocity inlet. According to the mine’s actual ventilation schedule, the total airflow is set to 1800 m³/min.

The boundary type for the return airflow is selected as Natural Outflow. The boundary type of the surrounding solid walls of the working face, roadway, and goaf is set to Wall. The mathematical expressions for the distribution of porosity and permeability in the goaf are given by Eqs. (1) and (2) 25.

Where n(x, y, z) represents porosity of the coal; L is the length of the working face, in meters; k(x, y, z) is the permeability, in m²; Dp is the average particle size of the collapsed rock blocks in the goaf, taken as 250 mm26.

The calculation formula for the viscous resistance coefficient is:

Where η is the viscous resistance coefficient, which is the reciprocal of permeability.

The calculation formula for the inertia resistance coefficient is:

Where \(\zeta\) is the inertia resistance coefficient. Affected by the roof rock properties, working face pressure, and thickness, Dp exhibits an exponential decay pattern. A program was developed using the distance from the working face as the independent variable, and it was written as a User Defined Function (UDF) and imported into the Fluent solver for coupled computation. Key model parameters are listed in Table 1. The User-Defined Function (UDF) for the spatial decay of the average particle size, Dp, was programmed in the C language and compiled into the Fluent solver. The rationale for the exponential decay model is based on the observed compaction behavior of the goaf, where rock fragments are progressively crushed and compacted with increasing distance from the working face due to overburden pressure25. All simulations were conducted using the pressure-based solver in ANSYS Fluent (2022 R1). The SIMPLE algorithm was employed for pressure-velocity coupling, and second-order upwind schemes were adopted for the discretization of momentum and species transport equations to ensure numerical accuracy.

Results and analysis

The 3D spatial gas distribution simulation results for the 317 working face of Wangjialing Mine are shown in Fig. 4. The primary sources of gas in the goaf of Wangjialing Mine are: ① Under the influence of mining-induced stress, the dynamic equilibrium of gas in the coal seam is broken, causing large amounts of desorbed gas to surge out from the coal wall. The top coal disturbance caused by top-coal caving also forms a large number of fractures, resulting in more gas outbursts; ② During top-coal caving, the release of gas from the coal body due to the collapse of the roof causes the coal to desorb adsorbed gas into free gas, which then seeps through fractures into the working face; ③ Due to limitations imposed by the shearer and supports, a specific thickness of the coal seam remains in the goaf, from which gas desorbs and migrates into the goaf; ④ After mining, the exposed coal walls in the tunnels and working face allow the stored gas in the coal to seep into the roadway and working face. The gas migration characteristics in the goaf of Wangjialing Mine are that the return air dilutes a small amount of gas in the working face, while most of the gas surges out into the mining area. Due to the uneven distribution of gas content in the coal seams, the amount of gas released when the mining machine cuts coal also varies. The concentration of desorbed gas is unbalanced in the mining-affected zone, and some areas experience high concentrations of gas accumulation. This causes a density difference between the accumulated gas and the surrounding gases, resulting in gas flotation. At the same time, gas molecules in high-concentration gas regions diffuse due to their own concentration (density) gradient. Under the influence of various dynamic effects, including seepage, flotation, and diffusion, the gas migrates along the mining-induced overburden fractures and accumulates throughout the entire goaf. Also, as shown in Fig. 4a, the gas concentration on the intake airway side of the 317 working face of Wangjialing Mine is lower than that on the return airway side. The gas concentration from the intake airway to the deep part of the goaf is significantly affected by air leakage. At the same horizontal level, the gas concentration in the return airway is higher than that in the intake airway. Therefore, the return air side is the area where gas accumulates in the goaf.

The gas concentration gradually increases from the 317 working face to the deep part of the goaf, with a noticeable gradient of gas concentration variation in the middle of the goaf. The highest gas concentration area is near the deep return airway of the goaf. Due to the negative pressure in this area, the air leakage flow in the goaf is slower, making it difficult for high-concentration gas to enter the return airflow, causing the gas concentration to exceed 30%. Under the influence of air leakage in the goaf, the return corner of Panel 317 at Wangjialing Mine has become the primary outlet for gas migration within the goaf, resulting in significantly elevated gas concentrations in this area; simulation results indicate a concentration approaching 1.5%.

As shown in Fig. 4b, some of the gas in the goaf is discharged through air leakage flow from the return airway side, while some gas flows towards the deep part of the goaf and the mining-induced fracture zones near the return airway side. This is because the density of the gas is relatively low, and the air leakage flow pressure is insufficient. Therefore, as the gas moves towards the return airway side, it floats into the fractures in the overlying rock layers. Meanwhile, fewer gas streamlines are observed in the central part of the goaf due to the limited development of fractures in the compacted zone. In contrast, a greater density of streamlines near the return air side indicates gas accumulation driven by leakage airflow pressure, which can easily cause gas overrun during actual mine production.

Based on the simulated characteristics of gas distribution and migration patterns in the goaf, a new approach to managing return corner gas is proposed: controlling abnormal gas outflow in the goaf by altering the boundary conditions of the mining panel, combined with an integrated strategy to enhance extraction efficiency.

Active sealing-promoted drainage technology for gas concentration control at return corner

Technical principle

To address the challenge of controlling transient abnormal gas outbursts, this study developed an active sealing and enhanced extraction device for preventing gas overlimit in the return corner of the working face, based on theoretical knowledge and extensive field experience. The device is designed to enhance the efficiency and safety of mine gas control by implementing proactive prevention and control measures to reduce the risk of gas overlimit and ensure the safety of miners .

As shown in Fig. 5, the device primarily consists of four components: the extraction pipeline section, the gas monitoring section, the compressible sealing airbag section, and the active control section. In response to the issue of gas overlimit at the return corner caused by gas being carried into the goaf due to airflow in high-gas mines with “U”-shaped ventilation, an extraction pipeline is installed along the left coal wall of the return airway at the working face. This buried pipeline extracts gas from the return corner by extending into the goaf, with T-joints and pipes installed at regular intervals. Perforated screen pipes connected via T-joints serve as extraction units, ensuring the effective connection of the extraction system. As the working face advances, the installation of the extraction pipeline is continuously repeated to ensure that the buried pipes at the return corner of the fully mechanized face can extract gas from the goaf normally. When rapid face advance and high gas content in the coal seam lead to a large amount of gas outburst in the goaf, the T0 sensor in the gas monitoring section detects increased gas concentration at the return corner. It sends a signal to the active control system. The active control section then opens the pneumatic valve of the compressed air pipeline via control components to rapidly inflate the variable sealing airbag. The variable sealing airbag is expandable, and under high-pressure inflation, it inflates to form a wall, blocking the gas surging from the goaf. Simultaneously, the active control system adjusts the opening of the pneumatic butterfly valve on the extraction pipeline to increase the negative pressure and enhance gas extraction.

Through the coordinated action of each component in the technical system, gas outburst from the goaf can be effectively sealed and extracted. Compared with traditional return corner gas control technologies (such as single buried pipe extraction, wind barriers, and high-level boreholes), the core innovations and advantages of this device lie in the following aspects:

-

(1)

Active response and rapid control: Existing technologies are mostly passive or slow to respond. This device triggers action at the early stage of abnormal gas concentration rise via real-time monitoring from the T0 sensor, achieving second-level response (see Sect. 4.2.2 of this paper). Traditional methods (such as airflow adjustment or starting additional extraction pumps) typically require more time to take effect.

-

(2)

Sealing-extraction synergy: Existing techniques often rely solely on sealing (e.g., wind barriers, which are limited in effect and prone to damage) or extraction (e.g., buried pipes, which underperform when negative pressure is insufficient). This device innovatively integrates rapid physical sealing via a compressible airbag with simultaneous enhancement of negative pressure for gas extraction. The inflating airbag quickly seals the main gas outburst pathway toward the corner. At the same time, the increased negative pressure actively extracts the gas accumulated near the sealed area, creating a “combined blocking and extraction” synergy that significantly improves control efficiency for sudden gas surges. Quantitatively, our device achieves control within 3.5 s (as shown in Fig. 8), whereas traditional methods, such as adjusting ventilation or starting additional extraction pumps, typically require several minutes to take effect, during which production haltshalts and personnel evacuation may be necessary. Although the initial installation cost of the proposed system is higher than that of a single buried pipe, the potential benefits from preventing production downtime and enhancing safety could lead to favorable long-term economics. Maintenance primarily involves periodic checks of the airbag, valves, and sensors, which can be integrated into the mine’s routine maintenance schedule.

-

(3)

Intelligence and integration: The device integrates sensing, control, and execution units (airbag, valves), enabling automated control based on gas concentration thresholds and reducing delays and uncertainties associated with manual intervention.

-

(4)

Applicability and safety: The device is suitable for managing sudden, large-volume gas outbursts caused by fast face advance, sudden roof collapse, and coal loading or support operations—challenges difficult to address by existing technologies. It allows rapid control of corner gas without halting production or evacuating personnel, thereby ensuring continuous safe operation.

Engineering tests

Active blocking - Installation of the promoting extraction device

At the return air corner of the 317 working face in Wangjialing Mine, a compressible airbag is arranged at the alignment between the end of the working face and the backflow to perform blocking operations. The arrangement location is about 1 to 1.5 m away from the hydraulic support of the individual column (depending on the specific situation of the return air corner). Attention must be paid to the condition of the roof, and the airbag should be installed under safe and stable conditions. The air source for the compressible airbag is provided by the compressed air pipeline installed in the return air tunnel, which delivers air to the airbag through high-pressure air pipes from the supply air pipeline.

Installation process of active blocking-promoting device, (a)Ground-based airbag performance testing; (b) Physical experiment on airbag compressive resistance characteristics; (c) Pre-installation of pipeline system prior to airbag deployment; (d) Integrated connection between underground ventilation ductwork and airbag intake assembly; (e) Engineering installation of airbag system; (f) Configuration of active control system ; (g) Completion of airbag system installation.

The specific process for installing underground blocking airbags is as follows:

-

①

Check whether the surface of the airbag is clean, free of dirt, and undamaged. Inflate a small amount of air to check for leaks in the fittings and the airbag.

-

②

Before blocking, check the top, bottom, and both sides of the head and tail for broken coal and sharp protrusions. If found, remove them immediately to avoid puncturing the airbag.

-

③

After cleaning, place the airbag horizontally at the location where blocking is required (avoid placing it at an angle to prevent trapping air and bursting the airbag). After placement, use binding wire to twist and secure the bottom of the airbag to the iron mesh on the coal wall.

-

④

Take the prepared air pipe, connect one end to the main air supply pipeline, and the other end to a pressure gauge. The pressure gauge is connected to the intake valve, forming a connection from the air supply pipeline to the pressure gauge to the airbag. The detailed installation process of the entire device is shown in Fig. 6.

The pneumatic system was calibrated prior to installation to ensure the airbag could achieve the required inflation pressure (0.5 MPa) within 2 s. The T0 methane sensor was calibrated using a standard gas mixture (1.0% CH₄) before deployment. The entire system was tested over a period of three months across multiple advanced cycles of the working face to ensure reliability and repeatability.

Under normal conditions of gas outflow at the recovery working face, the valve opening of the extraction pipeline is small. To prevent too much air from entering the extraction system, low negative pressure extraction is primarily used to extract gas from the goaf. A compressible blocking airbag is used to seal the return air corner between the goaf and the recovery working face. The extraction pipeline buried in the goaf is equipped with a flower-tube slotted pipe, and the axis of the flower-tube is vertical to the ground. A wooden stack protects the outer shell of the slotted pipe, and a T-joint connects the extraction pipeline. When the buried pipeline in the goaf reaches a certain distance, subsequent connections with the extraction pipeline, equipped with a pneumatic butterfly valve, are made. The pipeline connection process follows the working face’s cycle. The gas monitoring section primarily consists of the T0 methane sensor, suspended at the return air corner, which is used to detect methane concentration.

When the gas outflow from the goaf is large, the T0 methane sensor sends a signal to the active control section by pre-setting the methane concentration threshold. The active control section simultaneously opens the pneumatic butterfly valve, causing the compressible blocking airbag to quickly expand and block the goaf. The extraction pipeline increases the negative pressure to promote the extraction of gas from the goaf, effectively mitigating transient methane exceedance events during critical periods.

Results analysis

During normal recovery operations at the working face, return air corner, and extraction conditions:

Based on the monitoring data of buried pipe gas extraction at the return corner of Panel 317 in Wangjialing Mine from January 1 to 31 March 2024, statistical analysis was conducted. As shown in Fig. 7, although the gas concentration of buried pipe extraction fluctuated, it generally maintained a stable trend, with concentrations ranging from 1.06% to 3.65%. The extracted mixed flow rate showed a stable trend. Affected by concentration variations, the pure volume of gas extracted by the buried pipe exhibited a slight downward trend, ranging from 1.08 to 4.19 m³/min.

During the production period from 1 January to 31 March 2024, the gas concentration at the return corner of Panel 317 remained between 0.05% and 0.65%. The gas concentrations in both the return corner and the return airflow were below 0.8%, in compliance with Article 172 of the Coal Mine Safety Regulations. It can be concluded that under normal conditions, buried pipe extraction is an effective method for controlling gas in the return corner of the working face.

Performance verification of the device under abnormal working face conditions

During the working face retreat, rapid face advance, coal seam thickening, cutting, support movement, coal releasing, or sudden roof collapse can lead to large amounts of gas outbursts from the coal seam. Methane sensor monitoring data at the return corner under such conditions is shown in Fig. 8, with one segment of gas outburst caused by sudden roof pressure selected for analysis. It can be observed that under conditions of large gas outbursts in the goaf, the installation of the active sealing–extraction device at the return corner enables rapid control of gas in this area, promoting the extraction of gas from regions near the return corner. The extraction flow rate through the buried pipe increases from approximately 0.70 m³/min to around 3.20 m³/min.

As shown in Fig. 8, the gas concentration at the return corner dropped rapidly from 0.88% to 0.19% within 3.5 s (from 94s to 97.5s), effectively preventing gas overlimit. Engineering tests have demonstrated that after the application of the active sealing–extraction device, both gas concentration and flow rate in the buried pipeline increased rapidly. At the same time, the T0 sensor readings at the return corner returned to normal, with gas concentration dropping below 0.6%.

Discussion

Limitations of the technology

While the active sealing-extraction-enhancement device demonstrates excellent performance in controlling transient gas exceedances, several limitations should be noted. First, the device relies on a stable compressed air supply for the rapid inflation of the airbag; any interruption in the air supply could impair its functionality. Second, mechanical components such as the airbag and pneumatic valves are subject to wear and potential failure under harsh underground conditions, necessitating regular inspection and maintenance. Third, the applicability of this technology may vary under different geological conditions. For instance, in mines with extremely soft roofs or highly fractured strata, the stability of the installation site for the airbag might be compromised, requiring additional supporting measures. Future work will focus on optimizing the device’s robustness and adapting it for a broader range of mining and geological conditions.

Generalizability and adaptability

Despite being tested in a specific high-gas mine, the fundamental principle of active sealing, coupled with enhanced extraction, is broadly applicable to other underground coal mines that employ U-type ventilation. For successful implementation in various settings, adaptations may include customizing the airbag size and pressure rating according to roadway dimensions, adjusting the negative extraction pressure to match local gas emission rates, and integrating the device with the mine’s existing environmental monitoring and control system. The numerical model developed in this study can also be adapted to predict gas distribution and optimize device parameters for new mining layouts by adjusting geometric parameters and boundary conditions.

Conclusions

-

(1)

For working faces with “U”-shaped ventilation, air leakage in the goaf, sudden roof pressure due to delayed collapse of hard or relatively hard roof strata, and operations such as coal releasing and support advancing are the leading causes of abnormal gas outbursts in the goaf, leading to a rapid increase in gas concentration at the return corner. Simulations reveal that gas streamlines in the central goaf are sparse, while those on the return side are dense, indicating that the return side is a gas-enriched zone. The simulated gas concentration at the return corner of Panel 317 in Wangjialing Mine approaches 1.5%.

-

(2)

An active sealing–extraction enhancement device was developed to prevent gas overlimit at the return corner of the working face. The device consists of an extraction pipeline and a compressible sealing airbag installed at the return corner, with the airbag connected to a compressed air pipeline. When an abnormal gas outburst occurs in the goaf and the T0 methane sensor detects an overlimit concentration, the active control system is triggered. The system simultaneously activates rapid inflation of the airbag to seal the gas outburst pathway and increases the negative pressure to enhance extraction. This coordinated mechanism can resolve transient gas overlimit issues within tens of seconds. Compared to conventional technologies, the core advantage of this device lies in its second-level control capability through active response and coordinated sealing and extraction.

-

(3)

After applying the active sealing–extraction device, the daily gas concentration at the return corner of Panel 317 remained stable below 0.6%. Even during abnormal gas outbursts, the gas concentration at the corner can quickly drop from 0.88% to 0.19% within 3.5 s after triggering, effectively eliminating overlimit gas accumulation and ensuring safe and efficient production at the working face.

Data availability

The original contributions presented in the study are included in the article, further inquiries can be directed to the corresponding author.

References

Yang, J., Cai, F. & Feng, J. Research on analysis and prediction of coal mine safety accidents. Min. Saf. Environ. Prot. 50, 144–148. https://doi.org/10.19835/j.issn.1008-4495.2023.05.023 (2023).

Xu, C. et al. Gas extraction of coal seam roof fractured zone in china: A review. Fuel 357, 129930. https://doi.org/10.1016/j.fuel.2023.129930 (2024).

Fang, S. et al. Study on the adsorption characteristics and pore-fissure response mechanism of meagre coal and anthracite under different methane pressures. Energy 332, 137283. https://doi.org/10.1016/j.energy.2025.137283 (2025).

Wang, H. Study and practices on zero overlimit gas prevention system of high gassy mine. Coal Sci. Technol. 44, 145–150. https://doi.org/10.13199/j.cnki.cst.2016.05.028 (2016).

Yu, Z. et al. Experimental study on the Goaf flow field of the U + I type ventilation system for a comprehensive mechanized mining face. Int. J. Min. Sci. Technol. 25, 1003–1010. https://doi.org/10.1016/j.ijmst.2015.09.019 (2015).

Xing, H. & Zhang, Q. Practice of gas control technology in Return-air corner of fully mechanized mining face. Shandong Coal Sci. Technol. 39, 99–100 (2021).

Gong, Z. Gas control technology in upper corner of 2-101 fully mechanized mining face in Zisheng coal industry. China Mine Eng. 49, 38–40. https://doi.org/10.19607/j.cnki.cn11-5068/tf.2020.05.010 (2020).

Wang, L. et al. Safe strategy for coal and gas outburst prevention in deep-and-thick coal seams using a soft rock protective layer mining. Saf. Sci. 129, 104800. https://doi.org/10.1016/j.ssci.2020.104800 (2020).

Chen, J. & Zhuo, J. Roof control technology and gas control measures in fully mechanized working face during initial mining. Coal Technol. 40, 113–116. https://doi.org/10.13301/j.cnki.ct.2021.09.034 (2021).

Li, S. Practice on precision prevention and control technology for deep Stress-dominated outburst. Saf. Coal Mines. 51, 81–87. https://doi.org/10.13347/j.cnki.mkaq.2020.04.018 (2020).

Sun, X., Ma, Z. & Zhang, F. Analysis on causes of abnormal gas emission from working faces with rock burst and research on its treatment technology. Coal Technol. 40, 122–125. https://doi.org/10.13301/j.cnki.ct.2021.04.036 (2021).

Cheng, H., Zhou, L. & Li, M. Study on flow field characteristics and gas concentration distribution law of working face under U and Y ventilation modes. J. North. China Inst. Sci. Technol. 20, 84–93. https://doi.org/10.19956/j.cnki.ncist.2023.05.011 (2023).

Ding, H., Qin, H. & Deng, Q. Study on gas seepage and distribution in Goaf of fully mechanized mining face under Y-type ventilation collaborative drainage. Saf. Environ. Eng. 30, 146–153. https://doi.org/10.13578/j.cnki.issn.1671-1556.20221167 (2023).

Kang, J. et al. Study on gas distribution law under high-level drainage roadway and buried pipe drainage in Goaf. J. Min. Saf. Eng. 38, 191–198. https://doi.org/10.13545/j.cnki.jmse.2020.0090 (2021).

Zhou, A. et al. Coal mine gas migration model establishment and gas extraction technology field application research. Fuel 349, 128650. https://doi.org/10.1016/j.fuel.2023.128650 (2023).

Wu, T., Yang, C. & Xiong, J. Study on roof gas migration law and surge reduction mechanism under condition of long borehole drainage. Coal Technol. 43, 131–135. https://doi.org/10.13301/j.cnki.ct.2024.02.028 (2024).

Liu, G. Study on integrated gas control technology of the return air corner in 3413 completely mechanized mining face at Hexi coal mine. Coal 33, 1–4 (2024).

Gao, D. & Li, R. Upper corner gas control technology in fully mechanized working face in Shendong mining area. Coal Eng. 55, 87–91 (2023).

Ni, L. & Gao, J. Parameters of staggered double buried-pipe for gas extraction in upper corner. Coal Eng. 54, 63–67 (2022).

Cui, Y. Gas control of air return corner of fully mechanized caving face in extremely close distance coal seam. China Min. Magazine. 32, 100–106 (2023).

Zhang, Z. & Xue, Y. Numerical simulation study on gas control in fully mechanized top coal caving face based on U downward ventilation. Saf. Coal Mines. 52, 183–187. https://doi.org/10.13347/j.cnki.mkaq.2021.12.038 (2021).

Chen, M., Wu, X. & Xing, Y. Study on gas control of corner angle in Gaohe energy high gas fully mechanized caving face. China Min. Magazine. 29, 128–134. https://doi.org/10.12075/j.issn.1004-4051.2020.07.030 (2020).

Li, Q., Qin, L. & Yin, D. Comprehensive gas control technique in upper corner at high gas fully mechanized mining face. China Coal. 40, 120–121. https://doi.org/10.19880/j.cnki.ccm.2014.10.028 (2014).

Zheng, W., Wang, K. & Li, Q. Optimization and application of gas control parameters in the upper corner of large diameter borehole. China Min. Magazine. 30, 145–149. https://doi.org/10.12075/j.issn.1004-4051.2021.09.022 (2021).

Qian, M. & Xu, J. Study on the O-shape circle distribution characteristics of mining-induced fractures in the overlying strata. J. China Coal Soc. 23, 20–23 (1998).

Li, S. Study on mining-induced fractures field evolution and gas migration rule. Ph.D. Thesis, Chongqing University (2012).

Funding

The authors thank the editor and anonymous reviewers for their valuable comments. This research is funded by the China Coal Major Science and Technology Project(20221BY001) and National Key Research and Development Program of China (202323YFF0615404)

Author information

Authors and Affiliations

Contributions

Baoqiang Sun: Conceptualization, Investigation, Visualization, Soffware, Data curation, Writing—original draff, Writing—review & editing. Xuanping Gong: Conceptualization, Methodology, Formal analysis, Supervision, Funding acquisition. Xiaogang Fan: Investigation, Conceptualization, Formal analysis, Supervision. Xiaoyu Cheng: Formal analysis, Writing—review & editing. Peng Yang: Investigation, Conceptualization, Formal analysis, Supervision. Lu Xiao: Formal analysis, Methodology. Cheng Cheng: Data curation, Investigation. Xingying Ma: Formal analysis, Investigation. All authors have read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Sun, B., Gong, X., Fan, X. et al. Research on the active sealing and promoting extraction technology of high-gas mine working face return air corner gas. Sci Rep 15, 40534 (2025). https://doi.org/10.1038/s41598-025-24265-4

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-24265-4