Abstract

To study the crack propagation characteristics of the V-shaped energy- accumulating charge at different angles, a new numerical laser caustics test system was used to observe the fracture process of the V-shaped energy-concentrating charge; the mechanical distribution mechanism around the blast hole of the energy-accumulating charge was analyzed, and fractal theory was used to evaluate the damage degree of the energy-accumulating charge. A series of caustics test results show that the main crack has a longer expansion length in the energy-concentrating direction, and the crack expansion length is shorter in the nonenergy-concentrating direction. The fractal damage results of the energy gathering perforating charge indicate that as the angle of the charge increases, the damage caused by energy gathering blasting gradually increases, the complexity of crack propagation increases, and the main crack follows the direction of energy accumulation. The directivity becomes increasingly less obvious. When the energy gathering angle is 120°, the main crack propagation process is similar to that of the circular charge (control group). The shaped charge can be used for directional fracture control blasting, which helps to control the direction and number of cracks and improve the blasting effect.

Similar content being viewed by others

Introduction

In the process of roadway excavation, it is difficult to effectively control the propagation direction of the surrounding blasthole cracks, and it is impossible to eliminate the damage of the surrounding blastholes to the surrounding rock of the roadway, causing overexcavation, resulting in waste of a large amount of shotcrete and supporting materials and affecting the efficiency of roadway excavation. Increasing construction costs and the use of directional fracture controlled blasting in the peripheral eye can solve the abovementioned problems. Currently, there are two methods commonly used for directional fracture control. One is to set small diameter holes on both sides of the blast hole or to artificially create defects in the medium and other technical measures to achieve the purpose of concentrating explosive energy in the fracture direction to realize directional fracture1; the other is to use the energy-concentrating charge or to use the energy-concentrated cutting or slotting shell on the charge roll sleeve.

The detonation products of ordinary blasting scattered randomly around the blasthole, and the resulting cracks expanded randomly. Energy blasting uses the cavitation effect to change the result of the charge to make the detonation products accumulate in a specific direction, which improves the destructive effect in a specific direction. Many engineering practices and studies have shown that the effect of shaped energy blasting is affected by factors such as the stress environment, surrounding rock properties, explosive type, packing quality and initiation method.

For coal seams with high gas content and low air permeability, Mu Chaomin2 used shaped energy blasting to achieve fracturing and anti-reflection. Yaoyin3 used the bilateral–groove-slot shaped charge (BGSSC) method to study the subtle-level timing effects of double-hole delay blasting. Hu et al.4 adopted bilateral cumulative tensile explosion (BCTE), which was applied in the subpillarless sublevel caving method. Wu et al.5 used acoustic emission technology to study the influence of different notch angles (45°, 60°, 90°, 120°, 135°) on crack propagation, and the notch angle and the degree of fracture were negatively correlated. Yang et al.6 used dynamic caustics to study the crack propagation characteristics of the slit charge under high ground stress conditions. Fan’s research results show that the shaped charge structure has a significant effect on the direction of explosive energy propagation7. Xie et al.8,9 studied the expansion of blasting cracks under confining pressure, and the confining pressure had a certain influence on the development of blasting cracks. Gong Min et al.10 studied blasting technology to improve gas drainage. Wu et al.11 studied the formation factors and crack propagation mechanism of elliptical bilinear jets. Ding et al.12 studied the superposition effect of stress waves between two holes and the mechanism of mechanical expansion. Different from chemical explosions, some scholars13,14 use electric explosions instead of chemical explosions. The advantages of electric explosions are safety, high efficiency and no need for chemical explosives.

Some scholars15,16,17 studied peripheral directional fracture-controlled blasting, which reduced the number of peripheral holes and over-under excavation. B. Mohanty18 studied the characteristics of the blasting strain wave distribution at the V-shaped energy accumulation and proposed to set up control holes on both sides of the blast hole to realize the crack propagation direction. Y. Nakamura et al.19 used a high-speed camera to study crack growth characteristics under the condition of a control hole with or without energy accumulation. The difference between the energy gathering blasting in this study and the abovementioned one is that the energy gathering blasting direction in this study is different from that in the abovementioned one. The energy gathering hole direction in the abovementioned study is an inner V shape, and the energy gathering hole direction in this article is an outside V-shaped. Yao Yin et al.20 investigated the blasting damage characteristics of rock shaped charges under bedrock stress conditions.Shixiang Xu et al.21 analysed that during tunnel construction, shaped charge loading facilitates the achievement of directional fracture.Guoqing Xu et al.22 elucidated the directional fracturing mechanism of arc-shaped charge hydraulic blasting and validated its validity.

The abovementioned studies mostly considered the engineering application angle of energy-accumulating blasting, and there are few studies on the angle of the V-shaped energy-accumulating groove. In this study, a dynamic caustics test system is used to study the angle of the V-shaped energy-concentrating groove, and fractal theory is used to calculate the binary image of burst cracks. A circular blasthole is set as a control group to study the influence of the angle of the V-shaped energy-concentrating groove on the dynamic propagation characteristics of blasting cracks.

Mechanical analysis of shaped charge

Under the action of the explosion shock wave, the effective stress Von Mise of any point in the rock mass is23:

where \({\upsigma _i}\) is the stress intensity at any point; \({\upsigma _r}\) and \({\upsigma _\theta }\) are the radial stress and the tangential stress, respectively; \({\upsigma _z}\) is the vertical stress.

With the blast hole as the center, the explosive propagates outward from around the blast hole. At this time, the stress at any point of the rock mass is expressed as:

where \({r^\prime }\) is the specific distance, \({r^\prime }=r/{r_b}\), r is the distance from the point to the center of the charge, \(\alpha\) is the shock wave attenuation coefficient, \({\mu _d}\) is the dynamic Poisson’s ratio of the coal and rock mass, and b is the lateral pressure coefficient.

The shock wave pressure around the blasthole is p:

where \({p_0}\) is the explosive detonation pressure, \({\rho _0}\) is the explosive density, D is the explosive velocity, \(\gamma\) is the expansion adiabatic index of the detonation product, k is the radial charge noncoupling coefficient, \({l_e}\) is the charge axial coefficient, and n is the pressure increase coefficient around the blast hole, generally n= 10.

Test system and test method

Test system

The test adopts a new digital laser dynamic caustic line method test system. The test system is mainly composed of a laser, a beam expander, a field lens and a high-speed camera. In the experiment, the shooting frequency of the high-speed camera is 100,000 fps between two adjacent photographs. The time interval is 10 µs. First, the laser emits a monochromatic light, which passes through a beam expander to form divergent light, and forms parallel light through the field lens I. The parallel light passes through the test piece, and the field lens II condenses the parallel light onto the high-speed camera. The information collected by the high-speed camera is transmitted to the computer, and the start signal is sent to the high-speed camera and the explosive in the test piece through the synchronization controller ; the new digital laser caustics test system is shown in Fig. 1.

When a beam of parallel light passes vertically through a test specimen, the light path remains unchanged. However, when the light beam passes through a tensile test specimen, the thickness and refractive index of the specimen change, causing the parallel light rays to deflect. This deflection forms a three-dimensional envelope surface in the space behind the specimen. The curved surface formed by this envelope is known as the shadow area. The principle of the pipeline is illustrated in Fig. 2.

Test principle

The test is based on the transmission dynamic caustics method. By observing the shape of the crack tip caustic speckle, the instantaneous stress state of the crack tip can be obtained, and the dynamic stress intensity factor value of the propagating crack tip can be accurately obtained. The calculation formula of the dynamic stress intensity factor at the crack tip is24:

In the formula, \(D_{{\hbox{max} }}^{{}}\) is the maximum diameter of the focal speckle at the crack tip, \({z_0}\) is the distance from the reference plane to the test piece, and the value is \({z_0}\) = 1 m, and d is the thickness of the test piece, where d is 3 mm, \(F\left( v \right)\) is the adjustment factor under dynamic load, \(F\left( v \right)\)= 1, c is the optical constant, c =1.08 × 10− 10 m2/N, g is the numerical factor, g= 3.17, and \(\mu\) is the ratio of the stress intensity factor. For a particular test, \(K_{I}\) is determined by the maximum radius \(D_{{\hbox{max} }}^{{}}\) of the focal speckle, and \(K_{{{\rm I}{\rm I}}}^{{}}\) is determined by both \(\mu\) and \(K_{{\rm I}}^{{}}\).

According to the literature25, Matlab software was used to plot the different shadow area patterns of crack tips. The light distribution of the shadow area of Type I cracks is shown in Fig. 3a, and that of Type II cracks is shown in Fig. 3b .

The center of the caustic spot is the position of the crack tip; thus, the caustic spot position at each instant can be obtained from the caustic photos taken by the high-speed camera. Because the time interval between two adjacent caustic photos is very short (10 µs), the average crack speed of two adjacent photos can be regarded as the instantaneous speed of crack propagation at that moment. The calculation formula of the instantaneous crack velocity is26:

In the formula, \(\nu\) is the instantaneous velocity of the crack, \(\varDelta s\) is the displacement value of the crack tip of adjacent caustics photos, \(\varDelta t\) is the time difference between adjacent caustics photos, the camera shoots at 100,000 fps, and \(\varDelta t\)= 10µs.

Regarding the calculation of crack propagation velocity: First, use image processing software such as Photoshop to measure the position of the crack tip at different time points. Based on the scale factor between the image and the reference object, convert this to the actual crack propagation length. Using the time difference between adjacent photographs, calculate the crack propagation velocity based on the spatial relationship between adjacent points and the time difference. The calculation method is illustrated in Fig. 4.

Specimen description

The test uses plexiglass as the material, and its dynamic fracture characteristics are similar to those of brittle rock. Plexiglass has dynamic fracture characteristics similar to those of rock materials27,28. The mechanical parameters of plexiglass and sandstone are shown in Table 1.

The test piece is a plexiglass plate with a size of 400 mm × 400 mm × 3 mm; the energy gathering hole is located in the center of the plexiglass plate; the angle of the V-shaped energy gathering groove is set to 30°, 60°, 90° and 120°. A partially enlarged view is shown in Fig. 5. The diameter of the shaped charge is 6 mm, the shaped charge contains a 60-milligram propellant charge, and the type of explosive is lead azide.

Dynamic caustics test results and analysis

Series of caustics images

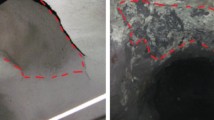

Under the action of the explosion of the polymerization package series of focalized shadow area photographs shown in Fig. 6. After the explosion of the polymerized energy packet, in Fig. 6a, for example, under the action of the explosion shock wave, the crushed area is formed around the gun hole. Subsequently, the explosive shock wave decays into a compressive stress wave, the intensity of which is less than the dynamic compressive strength of Plexiglas, and at about 20µs, the explosion cracks begin to develop under the action of tensile and compressive coupling. With the gathering of explosive energy, shadow area began to gather at the tip of the crack. At about 130µs, the explosive gas begins to expand, promoting the further expansion of the crack. At about 350µs, the crack stops expanding under the combined effect of the explosive stress wave and the explosive gas.

Analysis of crack propagation characteristics

Figure 7 shows the time history curve of the stress intensity factor at the tip of the main crack at different energy gathering angles. The main crack along the energy gathering direction begins to crack under the action of the explosive shock wave. After the main crack cracks, the stress intensity factor at the crack tip keeps changing. At about 130µs, due to the effect of explosive gas, the stress intensity factor at the tip of the main crack sharply increases and then gradually decays. The difference is that with the increase in the energy accumulation angle, the stress intensity factor of the main crack tip of the 30°, 60°, 90°, 120° energy accumulation charge also gradually decreases.

Figure 8 shows the time history curve of the main crack growth rate at different energy gathering angles. The time-dependent curve of the main crack propagation rate generally follows the same trend as the stress intensity factor curve; this will not be elaborated upon further here. Notably, as the focusing angle increases, the overall propagation velocity of the main crack decreases. This occurs because, with increasing focusing angle, the stress concentration at the focusing tip becomes less pronounced, making it increasingly difficult for the main crack to initiate propagation along the focusing direction. Figures 7 and 8 both indicate that the optimal energy concentration angle of the energy-accumulating charge is 30°.

Fractal results of crack propagation in shaped charge

Fractal principle

According to the idea of the box dimension algorithm, combined with the image analysis technology and the MATLAB calculation function, the calculation method is developed based on the MATLAB digital image box dimension. The picture pixels are processed to an integer power of 2. In this experiment, the picture pixels are 1024 × 1024. The picture is binarized, and the processed binarized picture is imported into the MATLAB program for operation.

The damage evolution process of the rock conforms to the fractal characteristics. Therefore, the initial microcracks and cracks in the rock are continuously activated and evolve into a process of macroscopic cracks. The box covering method can be used to calculate the fractal dimension of each area after blasting. Taking the box with side length \(\delta\) to cover the image, some of the boxes are empty, and the rest of the boxes cover part of the fractal. Count the number of all nonempty boxes and continuously reduce the side length \(\delta\) of the box. When \(\delta\) → 0, we can obtain29:

In the actual calculation process, a box with side length \(\delta\) is selected; after a series of changes (\(\lg \delta\), \(\lg N(\delta )\)), perform a linear fit for the two and find the slope between the two by the least squares method; the slope is the fractal dimension D.

In order to quantify the damage extent of Plexiglass after blasting, fractal theory and damage are combined. The correspondence between fractal damage \(\omega\) under blasting load and crack fractal dimension D can be expressed as:

In the formula: \(\omega\) is the fractal damage after blasting; \({D_t}\) is the fractal dimension of the crack after blasting; \({D_{\text{0}}}\) is the fractal dimension of the crack before blasting. Before blasting, the material is undamaged, \({D_{\text{0}}}\) = 0; \(D_{{\text{t}}}^{{\hbox{max} }}\) is the fractal dimension under complete damage conditions. For two-dimensional problems, \(D_{{\text{t}}}^{{\hbox{max} }}\) = 2.

Analysis of fractal results

Figure 9 show the main crack propagation direction of 30°, 60°, and 90° shaped energy blasting is basically the same as that of energy accumulation, and the main crack propagation direction of 120° shaped energy blasting starts to deviate from the energy accumulation direction.

Figures 10 and 11 show that the fractal damage of burst lines at 30°, 60°, 90°, and 120° are 0.6249, 0.6326, 0.6603, and 0.6670, respectively. The fractal damage of the burst lines in the circular charge control group is 0.6689. This result shows that with the increase in the energy gathering angle, the fractal damage of the energy gathering hole burst crack pattern gradually increases, and the crack propagation degree becomes increasingly complicated and disordered. Among these results, the ordinary circular blasthole has the largest fractal damage, and the crack propagation degree is the most complex and disordered.

This occurs because in the case of a certain energy gathering width, as the energy gathering angle increases, the energy gathering area gradually decreases (as shown in Fig. 2), and less blasting gas enters the energy gathering, which is not conducive to cracks. With further expansion, when the energy gathering angle is 120°, the expansion direction of the main crack begins to deviate from the energy gathering direction. The circular blasthole acts as a control group, there is no focused energy setting, and the main crack direction of the blasthole shows disorder and randomness.

Numerical simulation study of “V”-shaped energy-accumulating charge

The finite element software LS-DYNA is used to simulate the explosion crack propagation process of the shaped charge, which is divided into three parts: explosive, air, and rock. Explosives are described by the JWL equation of state, which can accurately describe the pressure, volume, and energy characteristics of the explosive during the explosion process. The model uses MAT_HIGH_EXPLOSIVE_BURN, combined with the JWL state equation, to simulate the relationship between pressure and volume during explosion30. The basic parameters of explosives are shown in Table 225.

In the abovementioned formula, P is the detonation pressure; V is the relative volume; \({E_0}\)is the internal energy per unit volume; \(\omega\), A, B, \({R_1}\), and \({R_2}\) are parameters related to explosive materials.

This simulation uses Ls-dyna in the finite element Ansys software to simulate the explosion process of a shaped charge. The element type used is Solid164, and the number of meshes is 344,914. The model is divided into three parts: explosives, rock, and air. The model is constrained by non-reflective boundary conditions on all sides. The grid division is shown in Fig. 12.

Figure 13 shows that after the explosive exploded, the blast hole was the center of the circle to form a crushing zone. Under the combined action of the explosive shock wave and the explosive gas, the crack further expanded forward. The crack propagation in the direction perpendicular to the energy accumulation direction is shorter; the crushing area of the 60° energy-accumulating cartridge is enlarged, the main crack propagation length along the energy accumulation direction is reduced, and the crack expansion length in the vertical energy accumulation direction is increased. The energy accumulation effect of 90° and 120° shaped charge packs in the energy accumulation direction gradually becomes unclear, but the main crack in the energy accumulation direction still exists; the crack growth pattern of the round charge pack is used as a control group, and the main crack growth direction shows randomness, evenly distributed along the circumference of the blast hole. The main crack growth pattern of the energy-accumulating powder charge in the numerical simulation is basically the same as that of the main crack in the explosion experiment.

Conclusion

-

(1)

We conducted model experiments and numerical calculations on the shaped charge structure, with results indicating that the optimum shaped charge angle is 30°.

-

(2)

During the detonation process of the energy-accumulating charge, the fractal damage of the 30° V-shaped energy-accumulating charge is 0.6249, which is the smallest fractal damage; the fractal damage of the 120° V-shaped energy-accumulating charge is 0.6670, which is the largest fractal damage. This is primarily because as the angle of the V-shaped energy-accumulating charge increases, the energy-accumulating effect becomes less pronounced. This is because, with a fixed V-shaped groove width, a larger V-shaped groove angle results in a smaller V-shaped groove area, thereby causing the ‘gas wedge’ effect of the explosive gases to become less pronounced. The primary crack propagation morphology of the 120° V-shaped energy-accumulating charge gradually approaches that of the circular charge.

-

(3)

The fractal damege of the burst crack of the circular charge ladle is 0.6689, and all of its fractal damage are greater than those of the energy-focused charge ladle. This indicates that the main crack propagation of the circular charge ladle has the characteristics of randomness and disorder. The orientation of the main crack of the V-shaped Energy-accumulating Charge is obvious, along the direction of energy concentration.

-

(4)

Numerical simulation results of explosive charges with different angles show that the 30° explosive charge has the longest main crack length along the energy concentration direction and the best energy concentration effect, while the 120° explosive charge has the worst energy concentration effect. The calculation results show that as the angle increases, the energy concentration effect is not obvious, and the crack propagation direction of the circular explosive charge is randomly distributed. The numerical simulation results are basically consistent with the model test results.

Data availability

The datasets used and/or analysed during the current study available from the corresponding author on reasonable request.

References

Liang, W. M., Yang, X. L., Yu, Y. Q. & Wang, J. X. Research on theory on directional fracture controlled blasting. J. Liaoning Tech. Univ. 03, 15–16 (2006).

Mu, C. M., Wang, H. L., Huang, W. Y. & Kuang, C. J. Increasing permeability mechanism using directional cumulative blasting in coal seams with high concentration of gas and low permeability. Rock. Soil. Mech. 34 (09), 2496–2500 (2013).

Yao, Y., Sun, Q., Zou, B. P. & Mu, Q. Y. Numerical study on an innovative shaped charge approach of rock blasting and the timing sequence effect in microsecond magnitude. Rock Mech. Rock Eng. 54 (9), 4523–4542 (2021).

Hu, J. Z. et al. Directional presplit blasting in an innovative no-pillar mining approach. J. Geophys. Eng. 16 (5), 875–893 (2019).

Wu, S. J. et al. The performance of soundless cracking agents for weakening rock roof under different notch angles. Arab. J. Geosci. 12 (11), 1–13 (2019).

Yang, R. S., Ding, C. X., Li, Y. L., Yang, L. Y. & Zhao, Y. Crack propagation behavior in Slit charge blasting under high static stress conditions. Int. J. Rock Mech. Min. Sci. 119, 117–123 (2019).

Fan, H. F. & Li, S. F. A Peridynamics-SPH modeling and simulation of blast fragmentation of soil under buried explosive loads. 318, 349–381 (2017).

Xie, L. X. et al. Damage evolution mechanisms of rock in deep tunnels induced by cut blasting. Tunn. Undergr. Space Technol. Incorporating Trenchless Technol. Res. 58, 257–270 (2016).

Xie, L. X., Lu, W. B., Zhang, Q. B., Jiang, Q. H. & Chen, Zhao, J. Analysis of damage mechanisms and optimization of cut blasting design under high in-situ stresses. Tunn. Undergr. Space Technol. 66, 19–33 (2017).

Gong, M. et al. Controlled blasting technique to improve gas pre-drainage effect in a coal mine. J. Univ. Sci. Technol. Beijing 28 (03), 223–226 (2006).

Wu, B., Wei, H., Xu, S. X., Meng, G. W. & Li, H. L. Analysis of the cracking mechanism of an elliptical bipolar Linear-Shaped charge blasting. Adv. Civil Eng. 12, 1–12 (2021).

Ding, C. X., Yang, R. S. & F C Stress wave superposition effect and crack initiation mechanism between two adjacent boreholes. Int. J. Rock Mech. Min. Sci. 138 (11), 104622 (2021).

Andres, U. Parameters of disintegration of rock by electrical pulses. Powder Technol. 58 (4), 265–269 (1989).

Lisitsyn, I. V., Inoue, H., Nishizawa, I., Katsuki, S. & Akiyama, H. Breakdown and destruction of heterogeneous solid dielectrics by high voltage pulses. J. Appl. Phys. 84 (11), 6262–6267 (1998).

Yong, L. & Shen, Z. Study on orientation fracture blasting with shaped charge in rock. J. Univ. Sci. Technol. Beijing(English Edition). 13 (3), 193–198 (2006).

Yang, L., Huang, C., Bao, S. & Zhang, L. Model experimental study on controlled blasting of Slit charge in deep rock mass. Soil Dyn. Earthq. Eng. 138, 106318 (2020).

Li, Q., Gao, Z. H., Xu, W. L., Wang, K. & Hu, Y. Experimental research on the dynamic propagation process of mode Ⅰ cracks in the rock under directional fracture blasting using the strain gauge method. Eng. Fract. Mech. 235, 107113 (2020).

Mohanty, B. Explosion generated fractures in rock and rock-like materials. Eng. Fract. Mech. 35 (4), 889–898 (1990).

Nakamura, Y., Cho, S. H., Yoneoka, M., Yamamoto, M. & Kaneko, K. Model experiments on crack propagation between two charge holes in blasting. Sci. Technol. Energ. Mater. 65 (2), 34–39 (2004).

Yin, Y., Esmaeili, K., Sun, Q. & Cao, J. Numerical investigation of rock damage induced by bilateral–groove-slot shaped charge blasting under the influence of in-situ stresses. Comput. Geotech. 180, 107070 (2025).

Xu, S. et al. Directional crack propagation and optimization strategies for multi-hole shaped charge blasting in tunnel construction. In Structures 72 108268. (Elsevier, 2025).

Xu, G. et al. Model testing and numerical study on directional fracture induced by arc-shaped charge hydraulic blasting. Eng. Fract. Mech. 111500. (2025).

Dai, J. Calculation of radius of the broken and cracked areas in rock by a long charge explosion. J. Liaoning Tech. Univ. (Natural Science). 2001 (02), 144–147 (2001).

Beinert, J. & Kalthoff, J. F. Experimental Determination of Dynamic Stress Intensity Factors by Shadow Patterns. 281–330. (Springer, 1981).

Luo, H. et al. Research on the dynamic propagation characteristics of cracks in Special-Shaped charges. J. Test. Eval. 50 (4), 2227–2239 (2022).

Qiu, P., Yue, Z. W. & Yang, R. S. Experimental study on mode-I and mixed-mode crack propagation under tangentially incident p waves, s waves and reflected waves in blasts. Eng. Fract. Mech. 247 (12), 107664 (2021).

Rossmanith, H. P. et al. Fracture mechanics applications to drilling and blasting. Fatigue Fract. Eng. Mater. Struct. 20 (11), 1617–1636 (1997).

Daehnke, A., Rossmanith, H. P. & Napier, J. A. L. Gas pressurisation of blast-induced conical cracks. Int. J. Rock Mech. Min. Sci. 34 (3–4), 263–e1 (1997).

Ding, C. X. et al. Fractal damage and crack propagation in decoupled charge blasting. Soil Dyn. Earthq. Eng. 141, 106503 (2020).

Qu, S. J. & Liu, J. F. Numerical analysis of joint angle effect on cracking with presplit blasting. Rock. Soil. Mech. 015 (36(01), 189–194 (2015).

Author information

Authors and Affiliations

Contributions

[Haohao Luo]: Conceptualization, Methodology, Writing—Original Draft; [Zhiliu Wang]: Data Curation, Formal Analysis, Visualization; [Zhenxia Yuan]: Validation, Resources, Supervision; [Yadong Bian]: Writing—Review & Editing, Funding Acquisition. All authors contributed to manuscript revision and approved the final version.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Luo, H., Bian, Y., Wang, Z. et al. Experimental and numerical study on dynamic crack propagation of shaped charge at different angles. Sci Rep 15, 41560 (2025). https://doi.org/10.1038/s41598-025-25485-4

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-25485-4