Abstract

New fixable composite materials were developed based on silicone rubber reinforced with brine sludge as the main filler, and enhanced with bismuth oxide (Bi2O3) prepared from olive leaves as a natural and sustainable resource. For clarity, the samples are coded from SBB0 to SBB5, since (SBB) refers to Silicone Rubber + Brine Sludge + Bi2O3, starting with the reference sample (SBB0) without bismuth and going up to (SBB5) with the highest content (35% wt). The shielding properties of these composites were evaluated by measuring the attenuation coefficients such as Linear attenuation coefficient (LAC) and radiation shielding efficiency (RSE%) using photons from a wide range of energies, including low-energy X-rays (15–50 keV) as well as gamma rays (241Am at 59.5 keV, 133Ba at 81 and 356 keV, and 137Cs at 661.7 keV). The results showed that increasing the Bi2O3 content significantly improved the performance of the samples, with SBB4 and SBB5 achieving shielding efficiencies of nearly 100% against X-rays up to 50 keV and over 95% against low-energy gamma rays at only 1 cm thick. This study also showed that increasing the thickness to 5 cm increased the efficiency at high energies, with the SBB5 efficiency reaching approximately 57% at 661.7 keV, compared to less than 10% for the reference sample (SBB0) with a thickness of 1 cm. These results demonstrate that these new composites, made from recycled and environmentally friendly materials, are good and safe compounds for radiation shielding applications in the medical and industrial fields.

Similar content being viewed by others

Introduction

Shielding materials are essential in the medical and industrial fields based on radioactive materials, contributing to reducing exposure to ionizing radiation, such as gamma rays and X-rays. Protective shields vary in design and fall into two main categories: rigid, inflexible shields, such as metal shields made of lead or stainless steel, which are effective but strong and difficult to shape; and flexible shields, which are made of polymeric or rubber materials that are easy to shape and provide environmentally friendly protection and high flexibility1,2,3. These shields allow for ease of movement in applications that require light weight, such as protective clothing and reading curtains, while providing an adequate level of protection4,5,6.

Silicone rubber is a flexible material used as a type of polymer shields, allowing for controlled bending and the possibility of coating it with suitable dense elements and oxides to enhance its radiation shielding7,8,9. Researchers have found that adding high-atomic-number oxides (such as Bi2O3, WO3, BaSO4, and SnO2) to a silicon matrix increases its density and improves shielding performance at various gamma and x-ray radiation energies10,11,12. However, the percentage of fillers added must be controlled, as increasing them leads to the formation of agglomerates and poorer mechanical properties13,14. Alresheedi et al., prepared silicon rubber with a mixture of nano and micro-particle heavy oxides and demonstrated clear evidence of improved attenuation and density of the sample15. El-Khatib et al. studied Bi2O3, CdO, and SnO2 nanostructured silicon rubber and found that composites up to 50% of adding these particles resulted in higher thermal stability and attenuation against gamma-rays16. Also, studies such as Moonkum et al. Studies have shown that combining BaSO4 with Bi2O3 in silicon rubber can achieve very high attenuation results in diagnostic X-ray energies (a valid example of a lead-based alternative)17.

Motakef-Kazemi et al. (Mentha pulegium extract) prepared nano-Bi2O3 and demonstrated UV-blocking properties and antimicrobial activity18; Negash et al. used bamboo leaf extract to synthesize CuO/Bi2O3 and demonstrated the success of the green method19; and in other literature (Palanisamy et al.) different structures of Bi2O3 produced from plant extracts have been documented20. Some researchers have been able to extract bismuth oxides from green plants and herbs rich in these elements, and then use them as additives in radiation shielding materials, reducing costs and making the process more sustainable.

Another recent trend is the recycling of industrial waste, such as brine sludge from desalination processes or some chemical industries. This waste often contains heavy elements or metal compounds that can be reused in critical applications such as building materials or radiation shielding. Izidoro et al. described a careful chemical analysis of brine sludge samples and proposed non-structural uses21; Garg and Pundir presented applications in building slabs/blocks at controlled concentrations22; Kuriakose et al. demonstrated methods of soil stabilization/improvement of geotechnical properties using specific ratios of brine sludge with additives such as lime23. Some studies have indicated that recycling this waste into reinforced polymer composites contributes to reducing the environmental impact of waste while simultaneously producing high-value-added materials. The uniqueness of this work lies in the use of an environmentally friendly method to prepare Bi2O3 from natural extracts and integrate it within a flexible silicon matrix to improve radiation performance while maintaining flexibility and sustainability.

This work seeks to develop a flexible radiation shield based on silicone rubber as the base material, reinforced with bismuth oxide, extracted from olive leaves using an environmentally friendly method, and brine sludge, a product of some industries. The goal of this formulation is to produce a flexible, lightweight material with a high absorption capacity for X-rays and low-energy gamma rays, while achieving environmental benefits through waste recycling and the exploitation of natural resources.

Materials and method

Matrix and fillers materials

In this manuscript, the flexible composites were formulated from three compounds: liquid silicone rubber (LSR) as matrix and brine sludge (BS) with bismuth oxides (Bi2O3) as fillers. LSR is a polymeric material characterized by its flexibility, chemical and thermal stability, and high resistance to corrosion. These properties make it a good choice for radiation shielding applications, also the LSR matrix is a chemically and radiologically stable material, characterized by its ability to trap the added particles and prevent their leakage or decomposition over time. It was purchased from a local store (1 kg of liquid silicone rubber and 25 g of hardener) with a density of 1.15 g.cm3 and a viscosity of 170 Pa.s.

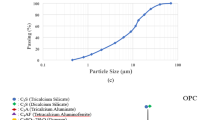

Brine sludge was obtained as a by-product of the chlor-soda industry during the brine purification process. Initially, a quantity of raw sludge was collected from the treatment plant and allowed to settle to remove excess water. The sludge was then oven-dried at 100–110 °C. The dried sludge was ground using a mechanical grinder and sieved through a 75-μm screen to obtain fine particles suitable for filler use. The sample was analyzed using a scanning electron microscope (SEM), (JEOL JEM-1400 plus) to determine its composition, as shown in Fig. 1. The BS was used here as an environmentally friendly, low-cost filler. It contains natural salts and minerals that contribute to enhancing the physical dispersion of Bi2O3 particles within the polymer matrix, improving the consistency and distribution accuracy. The 15% ratio was chosen based on preliminary experiments that demonstrated that this ratio represents the best balance between density, elasticity, and consistency of the composition, without agglomeration or loss of mechanical properties.

For bismuth oxide, it was prepared by the green method from olive leaves. The leaves were first collected and thoroughly washed with distilled water to remove impurities. They were then dried in an oven at 80–100 °C. The dried leaves were then ground into a fine powder and calcified at 700 °C to yield ash containing a mixture of metal oxides. The ash was placed in an acidic solution (HNO₃) to dissolve the bismuth ions and convert them into a soluble form. An alkaline solution (NaOH or NH₄OH) was then added to precipitate bismuth hydroxide (Bi(OH)3). The resulting precipitate was collected, filtered, dried, and then calcined again at 500 °C to yield pure bismuth oxide (Bi2O3) in the form of a fine powder. Transmission electron microscope (TEM), (JEOL JEM-1400 plus) and EDX analysis were performed on the resulting powder as shown in Fig. 2 and Fig. 3, respectively, to measure the purity percentage as well as the shape (circular) and average size (30 ± 10 nm) of the resulting particles. The small particle size resulting from the preparation process improves dispersion within the DGBA matrix and enhances radiation attenuation efficiency due to increased effective surface area for photon interaction.

Composite preparation

The components of the formulations were mixed in proportions according to Table 1. The liquid silicone was placed in a container, and the fillers (BS and Bi2O3) were gradually added in the proportions shown in the table, with continuous stirring to achieve a homogeneous distribution. The hardener was then added at a rate of 2% of the liquid silicone added and mixed well. The mixture was poured into circular plastic molds of varying thicknesses and left to cure for 24 h at room temperature for measurements and testing. Density was measured experimentally using mass per volume.

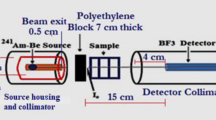

Theoretical and experimental attenuation measurements were performed, where the attenuation coefficients were calculated theoretically using Phy-X24 at specific energies of X-rays (15.0, 36.4, 44.5, 50.4 keV) emitted by the Rb-37, Ba-56, and Tb-65, respectively, and gamma rays (59.5, 81.0, 356.0, and 661.7 keV) emitted by Am-241, Ba-133, and Cs-137, respectively. Experimentally, gamma rays were measured using the nuclides Am-241 and Cs-137, and the results were compared with the theoretical values. An HPGe detector was used, and the resulting data was analyzed using Genie-2000, since the intensity of the incident photons was determined before (I0) and after (I) placing the SBB-composite between the HPGe detector and the gamma source as shown in Fig. 4. The linear attenuation coefficient was measured experimentally from the Equation25,26,27,28,29,30,31,32,33:

Additional attenuation factors considered necessary, namely: half-value/tenth-value layers (HVL/TVL), and radiation shielding efficiency (RSE), were obtained using the following equations34,35,36,37,38,39:

Results and discussion

The theoretical LAC values calculated from Phy-X software in Table 2 showed that the SBB composites showed a significant improvement in their ability to attenuate both X-ray and gamma-ray photons compared to the free silicone rubber (SBB0). For example, at the 15 keV Rb line, the LAC increased from 5.32 cm−1 for SBB1 to 76.10 cm−1 for SBB5, reflecting the significant effect of increasing bismuth concentration at lower energies. Similarly, at 36.4 keV for the Ba line, the values gradually increased from 0.56 cm−1 in SBB0 to 11.88 cm−1 in SBB5, demonstrating the role of bismuth in enhancing the dominant photoelectric interaction in this energy range. At the higher energies of Tb lines (44.5 and 50.4 keV), gradual increases were also observed, with values in SBB5 reaching approximately 7.12 cm−1 and 5.20 cm−1, respectively, compared to the very low values in SBB0. In contrast, at higher gamma-ray energies such as 59.5 keV (Am-241) and 81 keV (Ba-133), the increase was less, with the attenuation increased from 0.22 cm−1 in SBB0 to 3.44 cm−1 and 1.67 cm−1 in SBB5, respectively. This reflects that the greatest effect of the Bi2O3 addition is evident in the low- and medium-energy X-ray range, while it is relatively weaker at higher gamma energies due to different dominant reaction mechanisms. Overall, the results confirm that samples with a high Bi2O3 composition, particularly SBB4 and SBB5, exhibit the best radiation shielding performance, with a clear correlation between the increase in density and the improved shielding values, making them most suitable for applications requiring high shielding levels. Furthermore, comparison of the calculated values using the Phy-X software with the measured experimental results as shown in Table 3 showed good agreement with limited error percentages (diff% in the range of 2–5%), reflecting the reliability of the results and the accuracy of the measurements.

Figure 5 (a, b) show that the LAC values decrease with increasing photon energy for both X-ray and gamma rays, an expected behavior due to the decreased probability of interactions at higher energies. Composites rich in Bi2O3 (such as SBB4 and SBB5) exhibited the highest LAC values, especially at low energies, reflecting their high attenuation efficiency in this range. The remarkable improvement in the attenuation coefficient at low and intermediate energies is mainly attributed to the dominance of the photoelectric effect resulting from the high atomic number of bismuth (Z = 83), which increases the probability of photon absorption in this energy range. In addition, the fluorescence yield resulting from the excitation of the K-shell electrons of bismuth may partially contribute to the overall absorption enhancement, especially near the K-absorption edge (at about 90.5 keV). At high energies (such as 356 and 661.7 keV), the differences between composites diminish due to the dominance of the Compton effect, although the bismuth composites remain relatively superior. These results confirm that the addition of Bi2O3 significantly enhances shielding performance at low energies, with a relatively smaller effect at high energies. The direct relationship between Bi2O3 content, density, and measured LAC values is tabulated in Table. 4

Figure 6a, b show the relationship between the half-value layer (HVL) and the energy of both X-rays and gamma rays for different samples. It is clear that the HVL values gradually increase with increasing energy, increasing from 0.130 cm at 15 keV to 7.223 cm at 661.7 keV for SBB0, for example, indicating a decrease in absorption efficiency at higher energies. In contrast, Bi2O3-rich composites (such as SBB5) exhibit the lowest HVL values across the studied energy range, decreasing from 0.009 cm at 15 keV to 4.127 cm at 661.7 keV, reflecting a significant improvement in shielding efficiency compared to composites with lower Bi2O3 content. Likewise, at 59.5 keV, the energy for gamma rays from 241Am, the HVL decreased from 2.433 cm in SBB0 to just 0.201 cm in SBB5, a nearly 12-fold improvement in performance. These results confirm that the addition of bismuth significantly reduces the thickness required for attenuation, especially at low and medium energies. Table 5 shows normalized comparison using calculated HVL values relative to density (g.cm−3) to demonstrate whether the improved attenuation performance of Bi2O3-rich composites is due solely to increased density or to intrinsic properties of the photon interaction coefficients with Bi. The results showed that even after normalization with respect to density, composites with higher Bi2O3 content still exhibit lower HVL values, confirming that the improvement is due not only to density but also to the large interaction cross-section with Bi, especially its characteristic effect near the K-edge (at about 90.5 keV).

Figure 7 shows that the TVL value clearly increases with increasing photon energy. For example, at low energy such as 15 keV (Rb), very small thicknesses of about 0.43 cm are sufficient and decrease to 0.03 cm with material optimization. At medium energy such as 36 keV (Ba), the values reach about 4.05 cm and decrease to 0.19 cm. They increase further at 50 keV (Tb) to reach 6.7 cm at the beginning and decrease to 0.44 cm. In the case of gamma rays with higher energy such as 59.5 keV (Am-241), we find that the thicknesses start from 8.08 cm and decrease to 0.67 cm. At 81 keV (Ba-133), they reach 10.2 cm and decrease to 1.37 cm. At 356 keV, they increase sharply to about 18.5 cm, and even with material optimization, they remain 7.5 cm. The maximum values are reached at 661 keV (Cs-137) where 24 cm are required in SBB0. 13.7 cm is needed to reduce the intensity of this energy to one tenth in SBB5, which highlights that high-energy radiation requires thick barriers and that material optimization reduces thickness but does not eliminate the significant need for shielding. Bi2O3 addition leads to a significant reduction in the thickness required for photon absorption, especially at low and intermediate energies. This is due to bismuth’s high atomic number (Z = 83) and its large photoelectric cross-section, which enhances its interaction with photons via photoelectric absorption mechanisms.

Figure 8 shows the behavior of the Mean Free Path (MFP), which represents the distance a photon travels in the silicon rubber composite before it undergoes an interaction (absorption or scattering). it was noted that, like the HVL and TVL, it increases with energy. For example, at low energy 15 keV (Rb) the values are very small, about 0.19 cm, and decrease to 0.013 cm with material improvement. At 36 keV (Ba) the values rise to range between 1.76 cm and 0.084 cm, then increase further at 50 keV (Tb) to reach 2.93 cm and decrease to 0.19 cm. In the gamma range at 59.5 keV (Am-241) we find the values starting from 3.51 cm and decrease to 0.29 cm. At 81 keV (Ba-133) we find that the values start from 3.51 cm and decrease to 0.29 cm. At 81 keV (Ba-133) they become about 4.43 cm and decrease to 0.60 cm. At 356 keV they jump to 8.0 cm and remain at 3.28 cm even with the best materials. They reach a maximum at 661 keV (Cs-137) where they reach 10.4 cm in SBB0 and do not fall below About 5.95 cm in SBB5, which shows that high-energy photons need denser materials and greater thickness to reduce their free path. The addition of Bi2O3 increases the sample density, which increases the probability of photon interaction within the material per unit path. Furthermore, the homogeneous distribution of bismuth particles within the SR-matrix enhances multiple scattering and gradual photon energy loss, ultimately improving gamma-ray shielding ability.

The results shown in Table 6 clearly demonstrate the shielding efficiency of the glass materials (SBB0–SBB5) against both X-rays and γ-rays at different thicknesses (1, 2, and 5 cm) and at various energies. It can be seen that the shielding performance improves significantly with increasing thickness and with the increasing percentage of heavy elements in the composition. At a thickness of 1 cm, the superiority of the SBB3 samples and above is clearly evident, as their efficiency in stopping low-energy X-rays (15 keV) reaches 100%, while it gradually improves at higher energies such as 36.4, 44.5, and 50.4 keV, until SBB4 and SBB5 achieve almost complete shielding. For γ-rays at the same thickness, the efficiency is relatively lower, with SBB5, for example, achieving 96.8% efficiency at 59.5 keV, while the values of the thinner samples (SBB0–SBB2) remain very limited, especially at higher energies such as 356 and 661.7 keV. As the thickness increases to 2 cm, the efficiency doubles significantly, with all samples from SBB3 and above achieving near-complete X-ray shielding even at energies of 50.4 keV. They also achieve good performance against γ-rays, with SBB5 approaching 100% at 59.5 keV and achieving around 28.5% at 661.7 keV, compared to the very modest values of SBB0 and SBB1. At 5 cm, the results clearly confirm the superiority of the heavier assemblies (SBB3–SBB5), with their efficiency reaching nearly 100% at all X-ray energies, even γ-rays at 59.5 and 81 keV. Shielding challenges remain at higher energies (356 and 661.7 keV), but with a significant improvement of 56.8% for SBB5 versus less than 40% for SBB0. Overall, the results demonstrate that shielding performance is dependent on three key factors: sample composition (and the percentage heavy elements), radiation energy (lower energies are easier to stop than higher ones), and finally, thickness (efficiency increases almost exponentially with increasing thickness). These trends confirm the potential of the improved samples (SBB4 and SBB5) as effective materials for practical shielding applications, especially in the medium- and low-energy medical and industrial radiation range.

Finally, Table 7 reports the attenuation factors of the SR-composites containing Bi2O3 and BS in this study with those of similar systems reported previously. It is evident that the present samples exhibit a gradual improvement in attenuation efficiency with increasing Bi2O3 content, with SBB5 (density 1.84 g.cm−3) achieving HVL, MFP, and TVL values of 4.127, 5.953, and 13.708 cm, respectively, at 661.7 keV, which are better than those of the lower Bi2O3-containing samples (SBB3 and SBB4) and close to the performance of some systems containing B2O3 and TeO237. Although the density of the current materials is slightly lower than that of their heavy oxides-based SR-materials (such as SR-3 and SR-439), their attenuation efficiency is comparable, confirming that green-prepared bismuth oxide can represent an effective and safe alternative to traditionally toxic materials.

Conclusion

The results of this study confirmed that silicone rubber composites reinforced with brine deposits and bismuth subsalicylate, extracted from olive leaves, offer good elastic protection against ionizing radiation, especially photons. The measured linear attenuation coefficient (LAC) and radiation shielding efficiency (RSE) values showed clear superiority for composites with higher bismuth subsalicylate content, such as SBB4 and SBB5. At a thickness of 1 cm, the absorption or shielding efficiency reached nearly 100% for X-rays at 15 keV, while it achieved absorption or efficiency exceeding 93% at lower gamma energies (59.5 keV). As the thickness increased to 5 cm, the absorption ratio increased to more than 99% for most energies up to 356 keV, and increased to 56.8% at 661.7 keV. This study confirms that the studied compounds have high absorption capacity over a wide range of energies, making them suitable for use in some applications requiring effective and sustainable flexible radiation shielding materials.

Data availability

The data presented in this study are available on request from the corresponding author.

References

Wang, L. et al. Biomass materials and their derivatives for electromagnetic interference shielding: A review. J. Mater. Sci. Technol. 243, 28–44 (2026).

Ganguly, S., Kanovsky, N., Das, P., Gedanken, A. & Margel, S. Photopolymerized thin coating of polypyrrole/graphene nanofiber/iron oxide onto nonpolar plastic for flexible electromagnetic radiation shielding, strain sensing, and non-contact heating applications. Adv. Mater. Interfaces 8(23), 2101255 (2021).

Ganguly, S. et al. Mussel-inspired polynorepinephrine/MXene-based magnetic nanohybrid for electromagnetic interference shielding in X-band and strain-sensing performance. Langmuir 38(12), 3936–3950 (2022).

Oliver, N., Ramli, R. M. & Azman, N. Z. An empirical study on the X-ray attenuation capability of n-WO3/n-Bi2O3/PVA with added starch. Nucl. Eng. Technol. 54(9), 3459–3469 (2022).

Hou, X. et al. Recent progress in smart electromagnetic interference shielding materials. J. Mater. Sci. Technol. 186, 256–327 (2024).

Dubey, K. A. et al. Synthesis of flexible polymeric shielding materials for soft gamma rays: Physicomechanical and attenuation characteristics of radiation crosslinked polydimethylsiloxane/Bi2O3 composites. Polym. Compos. 37(3), 756–762 (2016).

Al-Yousef, H. A. et al. Effect of the Fe2O3 addition on the elastic and gamma-ray shielding features of bismuth sodium-borate glass system. J. Mater. Sci. Mater. Electron. 32, 6942–6954 (2021).

Al-Sarray, E. & Jabbar, A. Gamma ray attenuation properties of lead-barium sulfate-epoxy composite materials. Nucl. Technol. Radiat. Protect. https://doi.org/10.2298/NTRP2502112A (2025).

Tarek, M. M., Fouad, R. A., Badawy, M. S. & Ali, A. G. Effects of different nano-size and bulk WO₃ enriched HDPE composites on attenuation of the X-ray narrow spectrum. Nucl. Technol. Radiat. Protect. 40(1), 15–24. https://doi.org/10.2298/NTRP2501015T (2025).

Verdipoor, K., Alemi, A. & Mesbahi, A. Photon mass attenuation coefficients of a silicon resin loaded with WO3, PbO, and Bi2O3 Micro and Nano-particles for radiation shielding. Radiat. Phys. Chem. 1(147), 85–90 (2018).

Elsafi, M. et al. Shielding properties of some marble types: A comprehensive study of experimental and XCOM results. Materials. 14(15), 4194 (2021).

Elsafi, M. et al. The potentials of egyptian and indian granites for protection of ionizing radiation. Materials. 14(14), 3928 (2021).

Elsafi, M., Almuqrin, A. H., Almutairi, H. M., Al-Saleh, W. M. & Sayyed, M. I. Grafting red clay with Bi2O3 nanoparticles into epoxy resin for gamma-ray shielding applications. Sci. Rep. 13(1), 5472 (2023).

Elsafi, M., Almuqrin, A. H., Yasmin, S. & Sayyed, M. I. The affinity of bentonite and WO3 nanoparticles toward epoxy resin polymer for radiation shielding. E-Polymers 23(1), 20230011 (2023).

Alresheedi, M. T. et al. Assessment of silicone rubber/lead oxide composites enriched with Bi₂O₃, WO₃, BaO, and SnO₂ nanoparticles for radiation shielding applications. Polymers 15(9), 2160. https://doi.org/10.3390/polym15092160 (2023).

El-Khatib, A. M., Zard, K., Abbas, M. I. & Gouda, M. M. Novel composite based on silicone rubber and a nano mixture of SnO₂, Bi₂O₃, and CdO for gamma radiation protection. Sci. Rep. 14, 1578. https://doi.org/10.1038/s41598-024-51965-0 (2024).

Moonkum, N., Pilapong, C., Daowtak, K. & Tochaikul, G. Evaluation of silicone rubber shielding material composites enriched with BaSO₄ and Bi₂O₃ particles for radiation shielding properties. Mater. Res. Innovations 27(17), 1–8. https://doi.org/10.1080/14328917.2022.2141953 (2022).

Motakef-Kazemi, N. & Yaqoubi, M. Green synthesis and characterization of bismuth oxide nanoparticle using Mentha pulegium extract. Iran. J. Pharm. Res. 19(2), 70–79 (2020).

Negash, A., Derseh, L. M., Tedla, A., & Yassin, J. M. (2024). Eco-friendly synthesis of CuO/Bi₂O₃ nanocomposite for efficient photocatalytic degradation of rhodamine B dye. Scientific Reports/PMC (open access). (plant-extract mediated synthesis example).

Palanisamy, K., Gurunathan, V. & Sivapriya, J. Biogenic synthesis of bismuth oxide nanoparticles and its antifungal activity. Orient. J. Chem. 39(3), 1–3 (2023).

de Carvalho, I. J., Fungaro, D. A., Viviani, L. C. & da Costa, S. R. Brine sludge waste from a chlor-alkali industry: Characterization and its application for non-structural and structural construction materials. J. Appl. Mater. Technol. 3(1), 1–7 (2021).

Kuriakose, M., Athira, K. N., Benny, M. A., & Sobha, C. (2022). Brine sludge: stabilization and use in soil/construction (Proceedings IGS). (IGS conference paper/proceedings).

Garg, M. & Pundir, A. Utilization of brine sludge in nonstructural building components: a sustainable approach. J. Waste Manag. 2014, 389316. https://doi.org/10.1155/2014/389316 (2014).

Sakar, E., Ozpolat, O. F., Alım, B., Sayyed, M. I. & Kurudirek, M. Phy-X/PSD: Development of a user friendly online software for calculation of parameters relevant to radiation shielding and dosimetry. Radiat. Phys. Chem. 166, 108496 (2019).

Sayyed, M. I., Abdel-Gawad, E. H., Hanafy, T. A. & Elsafi, M. Experimental evaluation of radiation shielding characteristics of borate-based-glass system reinforced with titanium oxide. Opt. Mater. 1(154), 115738 (2024).

Elsafi, M., Almousa, N., Almasoud, F. I., Alyahyawi, A. R. & Sayyed, M. I. A novel epoxy resin-based composite with zirconium and boron oxides: An investigation of photon attenuation. Crystals 12(10), 1370 (2022).

Sayyed, M. I., Yasmin, S., Almousa, N. & Elsafi, M. Shielding properties of epoxy matrix composites reinforced with MgO micro- and nanoparticles. Materials 15(18), 6201 (2022).

Elsafi, M., Almuqrin, A. H. & Sayyed, M. I. Experimental study on borotellurite glasses: Unveiling the radiation attenuation effects of BaO and Er₂O₃. Nucl. Technol. Radiat. Protect. 40(2), 121–126. https://doi.org/10.2298/NTRP2502121E (2025).

Sayyed, M. I., Alrashedi, M. F., Almuqrin, A. H. & Elsafi, M. Recycling and optimizing waste lab glass with Bi2O3 nanoparticles to use as a transparent shield for photons. J. Market. Res. 1(17), 2073–2083 (2022).

Al-Hadeethi, Y., Sayyed, M. I., Barasheed, A. Z., Ahmed, M. & Elsafi, M. Preparation and radiation attenuation properties of ceramic ball clay enhanced with micro and nano ZnO particles. J. Market. Res. 1(17), 223–233 (2022).

Hannachi, E., Sayyed, M. I., Slimani, Y. & Elsafi, M. Experimental investigation on the physical properties and radiation shielding efficiency of YBa2Cu3Oy/M@ M3O4 (M= Co, Mn) ceramic composites. J. Alloy. Compd. 25(904), 164056 (2022).

Hannachi, E. et al. Synthesis, characterization, and performance assessment of new composite ceramics towards radiation shielding applications. J. Alloy. Compd. 5(899), 163173 (2022).

Sayyed, M. I., Alrashedi, M. F., Almuqrin, A. H. & Elsafi, M. Recycling and optimizing waste lab glass with Bi2O3 nanoparticles to use as a transparent shield for photons. J. Market. Res. 17, 2073–2083 (2022).

Şakar, E., Özpolat, Ö. F., Alım, B., Sayyed, M. I. & Kurudirek, M. Phy-X/PSD: Development of a user friendly online software for calculation of parameters relevant to radiation shielding and dosimetry. Radiat. Phys. Chem. 1(166), 108496 (2020).

Kaewjang, S. et al. New gadolinium based glasses for gamma-rays shielding materials. Nucl. Eng. Des. 1(280), 21–26 (2014).

Hartmann, P., Jedamzik, R., Reichel, S. & Schreder, B. Optical glass and glass ceramic historical aspects and recent developments: A Schott view. Appl. Opt. 49(16), D157–D176 (2010).

Alhamdi, W. & Khalil, M. Investigation of the gamma shielding efficiency reduction by depositing PbO and MnO₂ composition on various types of substrates. Nucl. Technol. Radiat. Protect. 38(3), 179–186. https://doi.org/10.2298/NTRP2303179A (2023).

Kartalović, N. M., Kovačević, U. D., Nikezić, D. P. & Osmokrović, P. V. The influence of neutron and gamma radiation on the reliability of magnetic and semiconductor memories. Nucl. Technol. Radiat. Protect. 39(1), 1–87 (2024).

Knezević, S. et al. Radiological characterization of alkali-activated material doped with Sm₂O₃ and its polymerization products. Nucl. Technol. Radiat. Protect. 39(4), 280. https://doi.org/10.2298/NTRP2404280K (2024).

Elsafi, M., Alasali, H. J., Almuqrin, A. H., Mahmoud, K. G. & Sayyed, M. I. Experimental assessment for the photon shielding features of silicone rubber reinforced by tellurium borate oxides. Nucl. Eng. Technol. 55(6), 2166–2171. https://doi.org/10.1016/j.net.2023.02.022 (2023).

Alorain, D. A., Almuqrin, A. H., Sayyed, M. I. & Elsafi, M. Impact of WO₃ and BaO nanoparticles on the radiation shielding characteristics of polydimethylsiloxane composites. E-Polymers 23(1), 20230037. https://doi.org/10.1515/epoly-2023-0037 (2023).

Alresheedi, M. T. et al. Assessment of silicone rubber/lead oxide composites enriched with Bi₂O₃, WO₃, BaO, and SnO₂ nanoparticles for radiation shielding applications. Polymers 15(9), 2160 (2023).

Author information

Authors and Affiliations

Contributions

M Elsafi: Conceptualization; Investigation; Writing—Original Draft ; Writing—Review & Editing, Haifa M. Almutairi: Investigation; Writing—Review & Editing; Resources; Writing—Original Draft.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Almutairi, H.M., Elsafi, M. Development of green silicone rubber/waste sludge composites with Bi2O3 extracted from olive leaves for radiation shielding application. Sci Rep 15, 44674 (2025). https://doi.org/10.1038/s41598-025-26822-3

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-26822-3