Abstract

Sensorless BLDC motor speed and torque control find a wide range of applications in electric vehicles, renewable power systems, industrial automation, and other places where efficient and reliable operation is required. Most of the conventional control techniques that have been traditionally used are the PID and ANFIS controllers, which generally bear limitations in performance for varying load conditions, complexity, and sensitivity to parameter variations. The goal of the paper presented in this context is to develop a smart controller for the Solar PV-fed sensorless BLDC motor. It combines a Q-Recurrent Adaptive Motor Controller (Q-RAMC) controlling mechanism with Levy-Enhanced Circular Search (LECS) for mapping function estimation. The novelty in this work rests on the combined effect of a Solar PV system with advanced control techniques for sensorless BLDC motor operation. Indeed, the developed method outperforms several existing control methods, hence yielding superior results in the form of smaller torque variations, smoother speed profile, and improved dynamic response. The simulation results show that the proposed approach significantly enhances motor control and outperforms conventional PID and ANFIS controllers. The system reduces torque ripple by 3.10%, which allows a smoother torque to be delivered, while overall efficiency reaches up to 99% that is an excellent energy utilization. Also, the speed transient time decreases by 1.5 s and the rise time shortens by 0.5 s that indicates the faster dynamic response and the better control precision.

Similar content being viewed by others

Introduction

The wide applications of Brushless DC (BLDC) motors in such areas as aerospace and automotive industries, robotics, medical devices, and most specifically, electric vehicles, have been widely applied1,2. There are reasons for their fame: first and foremost, their high efficiency, compact design, and easy speed control. Operationally and structurally, a BLDC motor resembles another form: permanent magnet synchronous motors. Thus, so much in this structure toward functionality of the motor, performance, and works depend on the site of motor. The Detection is done by a Hall Effect sensor, with which the desired data is obtained for the perfect control of the motor operations3,4,5. To get the optimal torque response about the speed and reduction of undesirable torque ripples, control of the BLDC motor should be appropriate. Among the general problems in the BLDC motors, there are torque ripples that usually take place because of the irregularities in stator current6,7,8. If these ripple levels are not controlled, they could cause noise, vibrations, and mechanical wear that could lower the motor performance in precision applications. These disturbances lower the consistency and accuracy of the motor, which is why it cannot be employed in applications requiring these factors, such as for medical instruments or robotics9,10,11. Further advances in motor control techniques and ripple reduction methodologies have increased their feasibility to a larger range of applications. With efficient and easy speed control, the BLDC motor-commonly known as the Brushless DC motor-finds increasingly wider applications across a broad spectrum from high-stakes ones: aerospace, automotive, robotics, medical instrumentation, and most importantly, electric vehicles.

This makes the BLDC motor an ideal candidate for systems needing reliable and controlled torque with high performance. Structurally, a BLDC motor is designed similar to a PMSM, with coils conjoined in the stator and permanent magnets on the rotor. The motor is so designed that efficient torque generation results through magnetic interaction12,13,14: the stator coils generate a rotating magnetic field which drives the permanent magnets on the rotor, comfortably and smoothly. A large part of how the BLDC motor functions involves accurately determining the rotor position relative to the stator. This is generally provided using Hall Effect sensors that catch the magnetic fields created by the rotor magnets while passing close to a particular sensor location15,16. The Hall sensors provide the motor controller with valuable information regarding the rotor position, and the controller controls the timing of the supply of current to each stator coil so that the magnetic field will rotate consistently with the rotor position. This is very vital in reaching proper commutation to enable the motor to give a fine torque control and minimize unwanted vibrations or misalignments that may damage its performance. Control of the BLDC motor requires a number of compromises to arrive at an optimal torque response that is characterized by minimum ripple-a small oscillation or “ripple” in the torque output when it should be steady17,18,19.

In addition, the presence of torque ripple and stator current losses in the BLDC motors may prevent their use in areas where high stability with minimum disturbance is required. For example, in precision-driven applications within the automotive and aeronautical industries, such fluctuation in motor performance could create either safety hazards or problems of reliability, which can limit their application in life-critical fields20,21,22. Nevertheless, control algorithms and design refinements are still being investigated to reduce such problems. Bearing in mind the minimization of stator current losses with the use of advanced control techniques, one can reduce ripple torque and develop higher overall performance from the motor, which enables the BLDC motor to be viable for a wider range of demanding applications23,24.

Minimizing torque ripple is one of the most important features in optimizing the performance of the BLDC motor, since these motors increasingly begin to find uses in applications relying on reliability, efficiency, and long life such as electric vehicles, robotics, and industrial machinery. The advantages of BLDC motors include cost, less mechanical interruption, more operational life, higher efficiency, and high power density25,26,27,28. Yet, even while enjoying these successes, one of the nagging concerns in BLDC motor design and control has been trying to reduce torque ripple-the small oscillations in torque which can reduce performance and make noise, thereby limiting the application of such motors in sensitive applications. The Hall Effect sensors mounted to detect the rotor position in conventional BLDC motors provide the information about the rotor position and, hence, inform the controller about the exact instants of commutation-or switching-of the stator currents to maintain proper magnetic alignment18,29. In this way, it allows the delivery of stable torque, possible by control of the exact timing of the rotor magnet interaction with the stator magnetic fields. However, Hall sensors have a string of shortcomings. They are easily prone to electromagnetic interference that may introduce errors by completely distorting the sensor’s ability to read the rotor position accurately. These EMI-related errors are very common in high-power applications where electric and magnetic fields can easily fluctuate30,31,32. Besides, installation and alignment during motor assembly may further lead to sensor accuracy errors. High temperatures usually generated inside the motor during longtime or high-load operation may degrade the performance and life of the sensor. Due to these drawbacks33, much work has been done in developing sensorless control strategies where an estimation of the rotor position is carried out by the motor control system without physical sensors.

The Adaptive Neuro-Fuzzy Inference System is a hybrid intelligent model that unifies the learning capabilities of artificial neural networks and the reasoning mechanism of fuzzy logic. This powerfully accounts for the treatment of complex nonlinear systems. In general, therefore, ANFIS operates under fuzzy if–then rules that embody qualitative features of human reasoning, while data-driven learning helps optimize dynamic membership function and rule parameters through the neural network component to adaptively model dynamic processes. Therefore, its dual nature makes ANFIS a very powerful candidate for control, prediction, and classification applications, considering that standard linear models break down under uncertainty, vagueness, or presence of nonlinear dependencies. However, this model is limited by so many constraints that it deters its widespread applicability. Among the limitations are: extremely arduous computations as the levels of fuzzification increase and the number of fuzzy rules and parameters increases with an increase in the number of inputs. This mostly gets to suffer from the dreaded "curse of dimensionality." Good quality training data is also a must for the ANFIS to adjust its parameters effectively, and it may not be capable of generalization when trained with small or low-quality datasets. Another bottleneck is that interpretability diminishes as the model scales up; too many fuzzy rules tend to sour their primary benefit. ANFIS is also very sensitive to the initial selection of membership functions and rule structures; a poor choice will either lead to suboptimal convergence or get trapped in a local optimum. The limitations substantiate that ANFIS is an excellent compromise between adaptability and interpretability, though not always suited for real-world problems embroiled in higher dimensions, data scarcity, or computational constraints.

Krishnakumar, et al.34 have carried out an in-depth discussion of PMMs, focusing their attention on the challenges that, until now, hamper its diffusion, while the developments seen after COVID-19 have extended PMM’s application fields. In particular, they propose a quite detailed discussion of freedom in choosing sensor or sensorless configurations, underlining trade-off and opportunities opened by one or the other option. It gives an overview of pulse-width modulation techniques in detail, thereby underlining the role of PWM in further improvement of control and performance in PMMs. Further, the paper goes on to discuss in detail two critical areas-fault tolerance and future potential-of PMMs by mapping these aspects with the ongoing developments in power electronics, control methodologies, and energy storage systems. This review accentuates versatility and an increasing adoption in industries like EVs, aerospace, robotics, and the production of food, beverages, oil, and paper. All this wide application is a result of advancements that are going into improving the efficiency and reliability of PMMs through innovation in power converters, high-performance batteries, ultra-capacitors, and sophisticated energy management systems. The authors have pointed out that due to increasing demand for high-performance motors operating within a wide range of power ratings, from 25 kW to over 300 kW, especially in the transportation sectors, researchers are still optimizing PMM designs.

One of the important aspects of the paper is the elimination of torque ripples due to commutation processes, which is a critical challenge affecting smooth operation and efficiency of PMMs. This is followed by highlighting an impressive progress of control techniques, enabling tremendous enhancement in the performance of motors. The present review encompasses PMM knowledge, from problems with its present and bright future, most importantly from technological innovation, at each level of applications. This is considered to be an important reference by detailing the capabilities of researchers and practitioners in realizing full potentiality at various levels of PMM application. Akrami, et al.1 presents an in-depth critical review of the sensorless techniques applied in BLDC motors, with the focus on various advantages, limitations, and new developments of these sensors. The authors first cite some of the important benefits accruable from sensorless techniques as opposed to conventional sensor-based ones, including better system reliability, cost reduction, easy connections between motor and inverter, and prolonging motor life. These attributes have given sensorless drives increased attractiveness for use in most applications.

This review covers established sensorless methods, such as terminal voltage measurement, third harmonic back-EMF signals, and advanced estimation methodologies. The authors have discussed very recent developments in the form of flux linkage function methods and neural network-based techniques that have, of late, emerged as viable solutions for age-old challenges. Extra importance is given to the mitigation of the shortcomings of conventional methods, especially for high-speed BLDC drives, where LPF phase lag is critical, and very low-speed applications where back-EMF signal amplitudes are minimum. One of the key strengths of the paper is that it critically looks at non-ideal and asymmetric back-EMF conditions, which always arise in practical situations. The authors have highlighted improved accuracy in position estimation, speedier estimations to an extent enabling one-cycle estimation, and improved control precision of motors with irregular back-EMFs. These advances underpin the potential of sensorless techniques to surmount intricately related operational challenges; thus, they become more and more suitable for use in next-generation BLDC motor applications.

A frequency-adaptive prefilter has also been integrated into the approach to make it robust enough to handle input disturbances with assurance of dynamic and noisy operation. Among the major features of this study, the implementation of DSOGI-PLL with a proportional-resonant controller has been implemented. The authors35 comprehensively describe how the proposed rotor position estimator works by undertaking its dynamic and transient behavior analysis in order to make its performance understandable under different conditions. The comprehensiveness with which the paper attempts to explain the functionality of the estimator, further by solving one of the critical challenges on commutation accuracy, presents this paper as a worthy addition to this field. Its strong disturbance rejection property points toward the method’s ability for enhancement of reliability and precision in motor control systems toward applications needing efficiency and resilience. This work offers valuable information for researchers and engineers with optimization of motor performance and error minimization in commutation processes.

In this paper, the authors36 have proposed a new approach for driving a coupled BLDC motor with a DC motor using the ETEDPOF method. It applies the Hamiltonian operator to the system’s energy equations; hence, it gives a sound theoretical basis for the design of control. The proposed controller is linear, and it adapts dynamically by sensing the output current and motor position to achieve exact speed regulation for different reference conditions. One of the highlights of the study is the fact that it has been implemented in a sensorless manner; the position and speed sensors are eliminated, thus reducing the overall cost of the system considerably. The back electromotive force (back-EMF) method made this sensorless operation possible. The back-EMF signals from each winding are monitored, and zero-crossing detectors are employed for the determination of the initial rotor position to facilitate startup of the motor. Besides, back-EMF signals will be used to estimate the motor speed and generate appropriate gate signals for the inverter. This paper indeed blends theoretical stringency with practical applicability, hence proposing a cost-effective and efficient solution toward BLDC motor control. The integration of ETEDPOF and back-EMF methods proposed here gives the potential for accurate control and high performance in sensorless motor systems. In this respect, this work should be very useful for any researcher or practitioner who intends to develop more efficient and affordable BLDC motor systems, since the elaboration of the control mechanism and its implementation is done in great detail.

The important feature of this ASMO is that it has the robustness of self-correction against commutation errors, which again enables appropriate estimation of rotor angular position for continuous speed tracking in a closed-loop control system37. This enhances reliability and performance of the motor drive in varying operating conditions. The authors have incorporated, in the design, a canonical switching cell converter to optimize energy management and operation of the motor. CSC converters provide an interface to the energy source and provide maximum power point tracking, which is necessary for energy regeneration and offers soft start to the motor in sensorless start-ups. It provides ripple-free current to VSI with a minimum power loss and enhances the efficiency with simpler system design through a few components thus offering practicality and economical in LEVs. It will show that the proposed control methodology, obtained from the linear model of the BLDC motor, is robust. Sen and Singh38 propose a fully developed remedy for all position sensorless speed control aspects, presenting WPS designed for crop-specific irrigation. This contribution employs a technique of lower-order disturbance rejection control, whose purpose is to make the flow of water maintainable at steady values irrespective of changes in solar insolation. Integrating the LADR control algorithm with the state observer allows this system to counteract all types of disturbances due to periodic irregular solar energy availability with much stability and operational efficiency. A feature of this work is the implementation of the position sensorless control algorithm, making the system versatile and easily adaptable for applications in both surface-mounted and submerged water pumps. This system does not require any physical sensors that can easily increase maintenance or overall system costs. The integration of a battery-connected bidirectional power flow mechanism allows this system to operate at full capacity for 24 continuous hours, thus meeting the requirements of uninterrupted irrigation. The battery, along with the DC BUS voltage, acts as the local load source, thereby maximizing utility and energy management functionality. The authors perform the detailed stability analysis of the system regarding disturbance rejection under variable insolation conditions. This provides a very substantial idea about the parameter tuning of the control loop for optimal performance in this system. It offers a very strong and realistic approach toward irrigation problems in agriculture and thus helps considerably in finding sustainable and energy-efficient solutions for water pumping. This system, due to its novelty of LADR control, sensorless operation, and integration with energy storage, is a useful contribution to the researchers and practitioners working in the field of renewable energy and irrigation technology.

Intidam, et al.39 have presented a comparative study of various control techniques that are developed for high-performance BLDC motor systems. In this investigation, the performance of a classical PI controller is assessed against two advanced methodologies, namely, the PI-ANFIS and the PSO-PI-ANFIS. Attention is especially paid to the performance of controllers in terms of rotor speed regulation around a desired reference value, under disturbances in load torque and variations of parameter values40. The PI controller, which is simple and widely used, serves as a baseline, while the PI-ANFIS method proposes an adaptive neuro-fuzzy inference system so as to give a new degree of adaptability to time-varying working conditions. The paper has presented the relative strengths and weaknesses of each control strategy underlined, emphasizing the superiority of the advanced techniques when challenging situations arise in the presence of disturbances and parameter variations. Of these, the PSO-PI-ANFIS controller41 performs exceptionally well to provide the most precise and stable speed regulation even under difficult operating conditions. Some key insights into performance and reliability enhancement in BLDC motor systems for high-demand applications were developed in the paper by integrating intelligent control algorithms and optimization techniques42,43. The following comparative analysis will be an important reference for those researchers and engineers who would like to adopt advanced control solutions for BLDC motors.

Although the literature on BLDC motor systems is extensive and diverse, several critical research gaps appear that need discussion for further advancements in performance, reliability, and adaptability of these systems across a wide range of applications. Most of the literature is devoted to classical control strategies, such as PI and PID controllers, which, though simple and easy to implement, usually fail when applied to complex dynamic environments with disturbances, parameter variations, and nonlinearities. These conventional methods are not flexible enough to be performed at an optimum under variable load and speed conditions44; thus, their use in most modern high-performance applications such as electric vehicles, robotics, and renewable energy systems is limited. Another gap exists in the limitation of sensor-based systems. While position sensors, such as encoders and Hall-effect sensors, have been used to ensure proper commutation and speed control, they add extra cost, require periodic maintenance, and are sensitive to environmental conditions, especially in submersible or harsh industrial applications. Sensorless techniques, while very promising due to the absence of physical sensors that decreases the complexity of the system, still have many challenges to be confronted in order to get a high-accuracy algorithm45 in low-speed conditions, treat asymmetric back-EMF signals, and guarantee robust operations under fluctuating operating conditions. However, most sensorless techniques depend on advanced signal processing or computational algorithms and hence are not applicable in low-cost or resource-limited systems.

Energy efficiency and integration with renewable energy sources introduce other gaps. Although many studies are available on BLDC motor drives for solar-powered or battery-supported systems, issues like the management of irregular solar insolation, delivery of ripple-free current, and integration of bidirectional power flow control with a battery system for 24-h operation need more attention. Similarly, only a few works are done on how energy regeneration can be optimized along with efficient motor control in order to enhance the sustainability for applications like irrigation and electric vehicles. Finally, growing complexities of contemporary applications inspire new approaches toward fault tolerance and resilience in BLDC motor drives46. Though there has been discussion on fault detection and mitigation, the practical implementation of sensorless, high-speed, low-speed operations remains underexplored. Furthermore, lack of systematic ways to analyze and improve system stability and disturbance rejection capability justifies the requirement to employ more advanced methodologies in the process of making BLDC motor systems robust and versatile for future applications. From this point, the multi-dimensional research needs to bring together advanced control strategies, intelligent algorithms, energy-efficient designs, and fault tolerance mechanisms toward next-generation BLDC motor systems. Classic methods47,48 cannot provide the required adaptability and precision to handle dynamic environments with very usual disturbances, parameter variations, and nonlinearities. This seriously reduces the potential of BLDC motors in modern applications for high-demand scenarios regarding precision, efficiency, and robustness.

The structure of this work is done in such a way that, by going through it, one would understand the proposed approach fully and its effectiveness to further improve it. Section “Proposed methodology” proposes the methodology of controlling, including the in-depth discussion of new methodologies developed for effective control of BLDC motors. It also elaborates on the used techniques, mathematical model, system architecture, novelty behind those, and benefits provided compared to traditional methods. Section “Results and discussion” presents discussions on performances and results comparisons. In this regard, experimental results are carried out discussing the performance analysis of the proposed system with existing techniques. Evidence for quantitative improvements at the level of efficiency, accuracy, and robustness is given through graphs, tables, and in-depth discussion. Finally, Sect. “Discussions” presents the conclusion and the future work. It summarizes the main contributions, lessons learned from this work, and points to possible areas where, if further investigated and developed, the scope and flexibility of the proposed system can be improved.

Proposed methodology

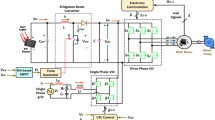

In the field of BLDC motors, speed control and minimization of torque ripple are major concerns for stability, efficiency, and life. Many applications involve the use of BLDC motors due to their high torque density and reliability. However, the control of these motors, when performed without any sensors, poses a problem in maintaining accurate speed with minimum torque ripple, resulting in vibration, acoustic noise, and deteriorated performance. Traditional methods that have been widely adopted to cope with these problems include open-loop control, sensor-based feedback systems, and PID controllers; each of these methods possesses its own limitations regarding accuracy, dynamic response, and system complexity. The performance of sensorless BLDC motors is improved with the proposed method, incorporating advanced techniques in control for optimization of both speed regulation and torque ripple suppression. In contrast to traditional approaches, the developed methodology will integrate intelligent control algorithms like PID, ANFIS, and a new hybrid strategy, which will adaptively react to changes in load conditions and dynamic changes in motor characteristics. It can be noticed from the above that, besides obtaining appropriate speed regulation, the torque ripple unwanted effects would also be effectively reduced by the usage of such controllers in order to improve the general performances of the motor and enhance its service life. This section covers the design and implementation of a control system that forms part of the proposed system design, including details on mathematical modeling with mechanisms for sensorless feedback, and comparative performance analysis relative to traditional and advanced techniques. The proposed method should robustly serve the challenges in the area of sensorless BLDC drives with a promise of high efficiency and reduction of vibration, besides ensuring an increase in operational stability across wide applications. The overall block diagram of the proposed PV fed sensorless BLDC motor control system is shown in Fig. 1.

Presently, there is a high demand for renewable energy systems, and one of the possible applications is the integration of a photovoltaic array with a Brushless DC motor. The work proposed here concerns a high-efficiency control system for PV-fed sensorless BLDC motors, which has been designed in order to optimize its performance in the most feasible solar conditions. The novelty of the present work is to integrate three main components: a Solar PV system, a high-gain DC-DC converter, and a sensorless BLDC motor, with a novel control strategy called Q-Recurrent Adaptive Motor Controller (Q-RAMC) that will keep the motor running smoothly and efficiently without any traditional rotor position sensors. It was proposed to demonstrate a holistic approach in the area of motor control in renewable energy systems, solving some key challenges: solar power variability, sensorless control complexity, and precision in motor speed and torque regulation. At the core of the proposed system, a Solar PV array will be integrated with a high gain DC-DC converter to effectively convert the fluctuating DC output from the solar panel into a stable, regulated voltage that can power the BLDC motor. VSI is the essential device for converting the DC output from the converter to three-phase AC voltage for driving the BLDC motor. Here, the motor is to be controlled by the Q-Recurrent Adaptive Motor Controller, Q-RAMC, which is a novel control scheme using advanced RNNs in adaptive and real-time motor control. Q-RAMC optimizes the BLDC motor for speed and torque through a Q-learning-based framework, which adapts with any variation in system dynamics and further gives optimal performance against broad changes in operating conditions and random variability of solar power. In this work, Levy-Enhanced Circular Search has been integrated into a torque command mapping function estimation algorithm. The LECS algorithm was developed using Levy strategy-based chaotic systems to map the torque command precisely into the appropriate motor control inputs so that the desired amount of torque is fed efficiently and precisely to the BLDC motor. The idea here is that this algorithm embeds the strengths of CSA with the chaotic behavior of Levy flights, which helps in the efficient exploration of the search space and escaping from the local optima to arrive at a robust solution for torque control in the PV-fed BLDC motor system. The uniqueness here is provided by the LECS algorithm through improving precision in torque command mapping relevant for ensuring smooth motor operation, mainly subjected to dynamic and intermittent characteristics in solar power generation.

The novelty of this work is primarily based on the innovative synchronism of a Solar PV-fed sensorless BLDC motor system with a hybrid intelligent controller that includes Q-RAMC and LECS for estimating the dynamic mapping functions. The proposed framework also marks a paradigmatic shift away from PID and ANFIS for their limitations in addressing situations involving nonlinearities, load fluctuations, and parameter sensitivity by introducing advanced recurrent adaptive learning strength combined with an evolutionary-inspired optimization search method. Q-RAMC, with its superior adaptability, learns motor dynamics in real time, captures system variation without any dependency on a priori parameter tuning, while the LECS algorithm enhances this process with optimal mapping and convergence in the control loop using its circular search trajectory combined with Levy flight behavior. With this dual synergism, the torque and speed regulation are highly robust and downsized overshoot, ripple, and instability problems commonly associated with existing methods. Further novelty arises from the renewable energy context as the controller has been specifically designed to fit into the constraint of solar PV systems, addressing the intermittency and efficiency issues that arise in real-world renewable power applications. By synergizing intelligent adaptive learning with bio-inspired optimization in a solar-integrated sensorless BLDC drive, this work proposes a smart control solution for faster convergence, smoother operation, greater energy efficiency, and reliable performance in varying load and operating conditions. Such a many-way performance enhancement clearly distinguishes the proposed Q-RAMC with LECS as a landmark in sensorless BLDC motor control compared with states-of-the-art schemes, thereby presenting a propitious avenue for renewable-energy-powered motor applications.

The proposed Q-RAMC along with LECS is essentially a control and optimization framework that functions on the dynamic behavior of the motor, not hard-coded for a fixed system setup. It is, thus, inherently flexible to adapt to other motor configurations, power ratings, and renewable energy integration schemes. Indeed, while this study has demonstrated the performance on a Solar PV-fed sensorless BLDC motor with defined parameters, the mathematical formulation, adaptive learning structure of Q-RAMC, and the search optimization mechanism of LECS are independent of the actual hardware configuration. The recurrent adaptive structure of Q-RAMC, actually learns the system behavior in real-time and tunes itself automatically according to various conditions like load fluctuations, parameter uncertainties, source variability, while LECS algorithm ensures optimal convergence regardless of the initial configuration. That is why proposed technique can be scaled up to include different types of BLDC motors with varied power ratings or even other categories of electrical machines like PMSMs or induction motors without any basic change in the controller design.

The choice of a Solar PV-fed sensorless BLDC motor serves as a proof-of-concept platform for a variety of reasons: such systems are widely used in renewable-powered systems, electric mobility, and industrial automation, and the control strategy itself is scalable and portable. For instance, the mapping and optimization carried out by LECS is not tied to the motor parameters but to the error dynamics of the system, meaning that any motor system providing error feedback can be effectively controlled using the same mechanism. The adaptive and recurrent nature of Q-RAMC ensures that any changes to either the motor or source configuration cause the controller to automatically re-calibrate itself without requiring any explicit re-design. This feature provides strong evidence of validity beyond the presented system.

The Q-RAMC + LECS framework incorporates two fundamental control principles, pertaining to adaptive reference modeling and dynamic error-corrective stabilization. Continuous updating of the reference model by the Q-RAMC keeps the control signal dynamically matched to the motor’s nonlinear characteristics and reduces mismatches between desired response and actual response. The LECS unit stabilizes the mechanism through error-compensated learning adjustments that dampen oscillations and enhance convergence towards optimal torque regulation. Convergence analysis of the proposed model indicates that the error is rapidly reduced with stable performance through successive iterations as the compensation and learning mechanisms work together to avoid divergence under varying load conditions. This not only ensures that the control task is completed with acceptable accuracy but also guarantees convergence to a global optimum solution, thus proving to be advantageous over conventionally or intelligently controlled solutions that show either slow adaptation or partial convergence under highly nonlinear motor dynamics.

The Q-RAMC offers a radical feature, among others, such as a design that innovates sensorless BLDC motor control to handle an application in a smart and flexible way by giving users the opportunity to incorporate a recurrent learning framework with the functionality of adaptive weight adjustment. Generally, PID and ANFIS standard controllers operate with parameters which values are predefined or only partially refined. However, Q-RAMC utilizes a recurrent structure that not only considers the entire motor dynamic states history but also references past data while altering the control solution by merging them. This is the memory phenomenon in the recurrent that is the main factor which makes the controller capable of coping with changing loads over time as well as nonlinear system behaviors in an efficient way. Moreover, the feedback process that updates the control weights is always carried out in real-time, hence a change in the control policy, that is, a different set of parameters is now possible, thus the case when parameters have changed, a load disturbance has occurred, or an external uncertainty is available can be handled. Levy-Enhanced Circular Search (LECS) is the smart optimization layer that fine-tunes the mapping functions as well as the controller parameters, hence the role of the LECS is to handle the adjustment of the functions and parameters that make up the controller. One of the main factors that contribute to LECS is the combination of Levy flight and the circular search space that allows one to balance local exploitation and global exploration thus achieving faster convergence as well as better parameter estimation than those of conventional algorithms. The adaptive recurring Q-RAMC, therefore, enables the continuous learning and adaptation capacity even when solar input and load conditions are different, and the LECS-based optimization facilitates the attainment of the control tuning goal at the point of minimum torque ripple, mechanical stress, and overall dynamic stability improved.

PV-fed sensorless BLDC motor modelling

Large interest, under a general pressure for sustainable and energy-efficient technologies, has been shown in integrating renewable energy sources into electrical drives, such as a photovoltaic system. The BLDC motor49,50 is a high-efficiency, low-maintenance, and precisely controllable actuator that makes it a very suitable choice for applications including systems based on renewable energy. From conventional pumps to autonomous and off-grid applications, BLDC motors may play a vital role in achieving perfect matching with PV-based power supplies. However, efficient systems would need appropriate motor control strategies adaptable to variable solar energy availability, load conditions, and scenarios of operation. Among all, the estimation of rotor position without using any extra physical sensor will be one of the most important issues that concern BLDC operation in the frame of PV-fed systems. For that, sensorless control techniques are used which are cost-effective, dependable in comparison to traditional methods of control requiring rotor position sensors. The sensorless control methods are generally based on back EMF or other motor parameters and utilize a sophisticated algorithm to estimate the rotor speed and position for the control of the motor at a given operating point without the use of a direct position sensor. Herein, in this modeling approach, the feeding of the BLDC motor is done through the PV array, which delivers the essential power; the system, however, is designed with an aim for optimization regarding power conversion efficiency and smooth operation in varied environmental conditions.

Precise identification of rotor position is important for the operation of BLDC motors, where optimal commutation of the signals to the stator windings is required. These commutation signals are necessary in producing the needed torque and maintenance of performance. In conventional BLDC motors, rotor position sensors, such as Hall Effect sensors or encoders, are usually used to detect the rotor position. These sensors provide real-time feedback to the controller for the appropriate switching of the power devices in the inverter. On the other hand, many drawbacks related to rotor position sensors exist, including cost increase, complications in the system design procedure, and increased physical components in the overall setup, which affect failure rates and maintenance cost. Furthermore, the necessity to align the sensors precisely with the rotor of the motor makes the setting up of the system a lot of effort and further decreases the reliability of the whole motor. While this may be effective, limitations in flexibility and scalability will be expected with regard to the motor system, which is sensitive to space, weight, and cost. The sensorless BLDC motor has emerged for solving these drawbacks. Eliminating position sensors, the sensorless approach simplifies a motor design and reduces its cost while improving the reliability and life of the system. In sensorless BLDC motors, the rotor position is estimated indirectly from the back electromotive force that occurs due to the motion of the permanent magnet rotor. This trapezoidal back EMF is the key to estimating the rotor position without physical sensors. With this voltage information, the system is able to find out the right timing of commutation for proper motor operation. It estimates the most important parameters of motor operation, such as speed, torque, and flux linkage, based on the detection of phase voltages and corresponding currents in the motor only, without any direct feedback from rotor position sensors.

It is observed that a sensorless BLDC motor provides a cost-effective and efficient solution due to a decrease in the amount of hardware used for rotor position estimation. In turn, such lesser complexity of hardware further eases its implementation and integratability into power systems. A typical application of sensorless BLDC motors involves drives for pumps, fans, and any other auxiliary equipment with their motors in photovoltaic systems. In the case of a PV-fed system, the motor draws its energy directly from the photovoltaic panels, which convert incident solar energy into electrical power. The control and operation of the BLDC motor, in this case, involve critical coordination between the characteristics of the motor and the power delivered by the PV system for the smooth operation of the motor even under variable lighting conditions. The output of the photo-voltaic system is not constant but variable with the intensity of sunlight, to which the sensorless BLDC motor is designed. The advantages that accrue from the major characteristics of the sensorless BLDC motor are reduced problems related to variations witnessed in the sensor feedback systems. These are subject to possible deterioration with time or sensitivity due to environmental conditions of temperature and electromagnetic interference. Contrariwise, the sensorless BLDC motor avoids those concerns because the important parameters like speed, torque, and flux linkage depend upon the intrinsic properties of the motor, such as back EMF and input current.

The computation of the motor parameters-speed, torque, and flux-can be computed from sensorless BLDC motors by a combination of terminal voltages and input current. In relation to voltage and current, the motor electrical power may be directly derived, and then the mechanical output power can be obtained, along with torque and speed. It is also possible for a control system to dynamically run the motor with optimum guaranteed performance and reduced energy losses by observing its performance and making appropriate adjustments to the voltage and current inputs. In brief, the sensorless BLDC motor is one of the best options with high efficiency and reliability, which will have minimal maintenance costs and are low in operation. Without the use of rotor position sensors and using back EMF, the electrical parameters give similar performance to the traditional control with increased simplicity and robustness. This is especially useful in photovoltaic-fed systems, where not only is the overall complexity of the system reduced, but also where reliable motor performance is provided despite variable-power input. That makes the sensorless BLDC motor an ideal choice for renewable energy applications where cost, reliability, and efficiency are the prime issues.

The back EMF for the sensorless BLDC motor is estimated according to the following equation:

where, \(EM{F}_{PA}\) represents the EMF of phase A, \({\mathcal{k}}_{e}\) indicates the constant, \(\varpi\) is the angular speed of rotor, and \(\text{sin}(\theta )\) is the position of rotor. As a consequence of this, the back EMF is calculated for other phases B and C using the following equations:

where \(\frac{2\pi }{3}\) is the phase shift for 3-phase motor. Similarly, the motor rotor speed is also calculated using the following equation:

Moreover, the motor torque is also estimated according to the armature current and back EMF values based on the following equation:

where \({\mathcal{T}}_{M}\) is the motor torque, \({I}_{A}\) defines the armature phase A current, and \(\mathcal{p}\) represents the number of pole pairs. Furthermore, the voltage across the motor is computed according to the resistive voltage drop and back EMF values based on the following equation:

where \({V}_{A}\) is the phase A voltage, \(R\) represents the resistance, \(L\) denotes the inductance of the motor, and \(\frac{d{I}_{A}}{dt}\) indicates the rate of change of current.

Q-recurrent adaptive motor controller (Q-RAMC)

Q-RAMC represents a new control framework that combines reinforcement learning principles and recurrent neural networks to allow for precise and adaptive control of sensorless BLDC motors. This technique has given answers to some of the most challenging issues in motor speed and torque regulation and has been quite different from other traditional control methods such as PID controllers, fuzzy logic controllers, and even modern neuro-fuzzy systems. The most important contribution from Q-RAMC is dynamic learning and adaptation of changes in motor dynamics and variations of external load by the reinforcement learning framework together with the operation of recurrent networks. Such synergy allows the controller to predict and react with minimal delay in variations in motor behavior, making for smooth and efficient operations when conditions change. The novelty of Q-RAMC is to incorporate Q-learning into the reinforcement learning framework, which is impressively effective in decision-making under uncertainty. It is associated with the RNNs known for handling sequential data and temporally capturing dependencies. Rather than being a traditional model of control, Q-RAMC continuously improves upon its decision-making process as it interacts with the motor system and environment. This works by optimizing a reward function, which is engineered with a purpose to minimize the spread in speed and ripple torque. The Q-RAMC model allows passing all the limits resulting from either a static or rule-based approach because of their inability to accommodate most of the nonlinearities and disturbances naturally characteristic in BLDC motors. Meanwhile, the recurrent structure of the model remembers a number of its past states in order to enrich the predictive capability for the stabilization of the control responses.

The proposed controller integrates Q-recursion as a learning mechanism driven by reinforcement, which further refines the control policy based on previous interaction and error feedback. Contrary to rigid controllers based on fixed rules or optimization criteria, Q-recurrence uses torque ripple minimization and efficiency maximization as long-term outcomes to assign dynamic values to each control action. Through recursive updating, the controller learns not only to react to present states but also to anticipate the future effects of its actions, resulting in decisions for a more stable and intelligent control action. By thus integrating Q-recurrence in the control scheme, the system achieves self-correction, adaptation to the nonlinearities of motor dynamics, adaptively improving with each iteration and thus providing faster convergence and greater robustness compared to conventional pursuit or heuristic controllers.

State representation initiates the working process of Q-RAMC, where the operational parameters of the motor map into a state space including speed, torque, and terminal voltages. This output of the RNN feeds into the Q-learning algorithm, which makes an estimate of the available actions-manifesting as modifications in the duty cycle of the PWM signals or commutation timings-based on expected rewards. The choice of an action will be guided by maximization of cumulative reward associated with reaching the desired speed and torque while keeping losses, oscillations, and overshoot at a minimum. Q-RAMC utilizes the predictive capability for speed control by real-time adjustments in motor input parameters with the purpose of maintaining the rotor speed as close as possible to the desired setpoint, despite load disturbances. Q-RAMC dynamically adjusts the control signals based on the feedback and predicted states in such a way that it minimizes overshoot and undershoot to provide stable and efficient speed regulation. The torque control optimizes the system for commutation and current flow to reduce ripples and transient fluctuations, hence smoothing the torque delivery. The duality of optimization ensures high efficiency and reliability of the motor in a wide range of load and speed conditions. Generally speaking, Q-RAMC is a giant leap forward in BLDC motor control. Self-learning, adaptability, and predictability of motor behavior underpin its superiority against traditional approaches. The proposed Q-RAMC leverages the power of reinforcement learning with strengths from recurrent neural networks; hence, besides enriching motor performance, Q-RAMC prolongs the lifespan of the motor components by smoothing the mechanical stresses that would be caused by inconsistent torques and speeds. The new framework gives a robust and scalable solution for high-precision applications requiring high adaptability such as robotics, electric vehicle, and industrial automation systems.

Q-RAMC has a number of key highlights that have not been present in the available literature of motor control. In the Q-RAMC approach, its central idea is to try and solve some inherent sensorless BLDC motor control issues, such as nonlinearities, time delays, and uncertainties in the system, with the integration of state-of-the-art deep reinforcement learning with temporal modeling capabilities of recurrent neural networks. A key novelty of Q-RAMC is its dual-layered learning mechanism. The Q-learning-based reinforcement learning layer is intrinsically designed to optimize decision making in an iterative manner through the process of trial and error, without requiring extensive offline tuning or pre-defined datasets. Q-RAMC is robust against changes in system dynamics or when the external conditions deviate from the expected norm. It is this recurrent structure of Q-RAMC that brings in the historical data to let Q-RAMC make much better predictions, hence making pre-acting upon the control actions to keep instabilities or inefficiencies from building up. Another critical contribution of Q-RAMC is its power to minimize torque ripples at high speed, a somewhat challenging task in sensorless BLDC motor control. Traditional techniques, such as PID controllers, fail to balance the objectives due to their quite limited capacity for handling nonlinearities and phase delays in motor dynamics. On the other side, Q-RAMC applies reward-based technique while optimizing multi-optimization objectives like minimization of speed error, torque ripples, and maximization of system efficiency. This holistic optimization will ensure superior metrics of performance by the controller in all major operational parameters and hence highly suitable for applications that demand precision and reliability.

Ultimately consists of the Input Layer receiving all motor control parameters, like terminal voltage and currents, which are intended to be related more or less to target speed and torque. Their importance constitutes a very vital aspect when defining the initial condition of motor systems, including electrical and mechanical information for the decision-making process. The input values are then sent into State Representation where they will be represented in a finite format useful for the learning model. Thus, they combine electrical parameters with performance values targeted by the system to give a clear picture of the operational status of the motor. The RNN would be the one used to do the state mapping, as it is the most suitable for time based data. Motor behavior and dynamics are never static; they utilize the memory capacity of the RNN to extract sequential pattern recognition, correlations, and dependencies to make accurate predictions from past and present states. After the temporal features have been processed, they will be forwarded to the Q-Network to estimate Q-values for all valid actions. Then, each Q-value symbolizes the anticipated long-term reward for taking that action in the particular state and lays the groundwork for intelligence decisions.

Selection of Action chooses the best action from different control actions based on epsilon greedy policy. This helps to use exploitation (that is choosing an action based upon the best-known Q-values) for exploration (that is sometimes trying some actions randomly) for making it better in terms of learning efficiency. The selected action was passed to the Motor Dynamics block, which updated real-world motor parameters speed and torque concerning the control commands. The updated state was evaluated under the Reward Function, which compared actual outcomes with target objectives, such as efficiency, stability, and error reduction, to analyze the optimization performance of the chosen action. This reward has its feedback mechanism for Q-Network Update, where upon principles of reinforcement learning, the policy is learned incrementally to improve the model in choosing effective actions in future states. Finally, the Output Layer generates output signals for optimized control-the practical embodiment of the learned strategy by which the performance of the device would be improved optimally. This whole pathway from inputs to outputs with optimized control under persistent feedback forms a closed-loop intelligent control system that will learn from experience to achieve enhanced motor control efficiency.

In this controlling model, the state of the motor is represented initially according to the parameters of voltage, current, rotor speed and torque as shown in the following mathematical equation:

where, \({\mathbbm{v}}_{a,t}, {\mathbbm{v}}_{b,t}, {\mathbbm{v}}_{c,t}\) are the phase voltages, \({i}_{a,t}, {i}_{b,t}, {i}_{c,t}\) indicates the phase currents, \({\mathcal{w}}_{r,t}\) denotes the rotor speed, and \({\eta }_{r,t}\) denotes the rotor torque. As a consequence of this, the action of agent is estimated according to the voltage based on the stator windings, which supports to control the speed and torque of motor as illustrated in below:

Similarly, the Q-function is also computed according to the expected future reward value in state using the following equation:

where, \({r}_{t+k}\) is the reward at time, and \({\mathfrak{X}}^{k}\) indicates the discount factor. Furthermore, the Q-learning state update is carried out that supports the agents to obtain the optimal actions, and the Q-values are computed as follows:

Where, \(\tau\) denotes the learning rate, and \(\alpha {\prime}\) indicates the possible actions carried in the next state. Then, the RNN layer module is implemented to prevent the model from overfitting as shown in the following model:

where, \(\varphi\) indicates the activation function, \({\omega }_{\mathcal{h}}\) and \({\omega }_{y}\) are the weight matrices, \({\mathfrak{V}}_{t}\) denotes the bias value, and \({z}_{t}\) is the output of RNN.

Besides, Q-RAMC has a self-tuning mechanism whereby the controller is able to auto-tune its hyperparameters, like learning rates and discount factors, depending on the motor operating conditions. This feature reduces manual effort significantly and makes the controller perform optimally even in changing system dynamics. Such a feature is of special importance for industrial and automotive applications, where motors very often face dynamic and unpredictable conditions. From a practical point of view, the new architecture of Q-RAMC provides the basis for hardware efficiency and cost reduction. By availing a sensorless approach with advanced computational algorithms that obviate the need for physical rotor position sensors, Q-RAMC reduces hardware complexity and hence the associated costs of BLDC motor systems. Its reliance on the readily available terminal voltages and currents for state estimation further simplifies the implementation while providing accurate and reliable control.

Levy-enhanced circular search (LECS) for torque command mapping function estimation

LECS is a new optimization technique proposed for the estimation of the torque command mapping function in a sensorless BLDC motor control system. It integrates the principles of Levy flight and circular search strategies in a synergistic manner for handling key challenges in the optimization of control parameters, namely torque commands, in dynamic motor systems. The main rationale, in this context, for using LECS is that it has been found to balance the exploration–exploitation dilemma rather effectively within the parameter space of the motor control system. The circular search allows for an effective exploration of the solution space as a consequence of exploiting spatial properties of circular trajectories, while the Levy flight mechanism introduces random large-step explorations that avoid getting stuck on local minima during the process of optimization. The combination significantly enhances optimization, especially in such specific applications like BLDC motors with complex nonlinear dynamics and advanced, flexible control strategies. LECS also offers controlling performance improvements compared to the traditional methods of optimization. First, the better approximation of the torque command mapping function is translated into enhancing the capability of the motor to perform the optimal speed and torque control. While the circular search component allows the exploration in solution space to be systematic with respect to spatial constraints and motor characteristics, the Levy flight mechanism introduces randomness to the search process during an optimization algorithm. It has thus allowed the possibility for the method to probe wider solution space regions, possibly containing the optimum or near-optimum parameters of control. This is all the more so in sensorless BLDC motor control, whereby one tries to estimate torque command with the best accuracy devoid of any rotor position sensors. Adaptation in search through solution space, allowed by LECS, makes available more robust and more exact control strategies, even for variable operating conditions.

The novelty in LECS is the hybridization by combining two powerful optimization strategies, namely, Levy flights and circular search. Levy flights are efficient in performing global searches due to their random step sizes, whereas circular search algorithms tend to perform well in those problems that possess some inherent cyclic or spatial patterns. By incorporating the two methods, LECS presents a better-balanced optimization technique with global search capabilities and the capability to exploit the spatial coherence in the motor dynamics. The obtained results show faster convergence to optimum solutions and are more robust against dynamic changes in operating conditions of the motor. Besides, LECS overcame some of the limitations traditional gradient-based methods have, which might be computationally expensive and prone to converging to local optima. In contrast, the combination of random exploration with structured search trajectories in LECS results in better adaptability, especially towards real-time control applications. The advantages of LECS over existing controlling techniques have several facets. First, this further gives more accuracy and stability to torque command mapping, contributing directly to smoother operation of the motor, low-level torque ripple, and the obvious exactitude in speed regulation. All these factors boost the general efficiency of a BLDC motor by the elimination of power losses and providing enhanced reliability to the entire system. In addition, it is more flexible to tune the control parameters, which might be applied for many kinds of motors or working conditions. Contrasting to other previously proposed traditional PID and/or ANFIS-based controllers, the models and parameters are fixed. Motor behavior keeps on continuously developing in some direction in LECs while self-regulating the strategy for performing a search. It can work very robustly in the case of unexpected variations of the load or disturbances in the environment. A big plus here is little dependence on hardware: The LECS is good at sensorless configuration without highly sensitive and costly rotor position sensors but at the same time ensuring very high accuracy regarding the control. Estimation of the torque command mapping function should be performed in such a way that it considers nonlinearities and uncertainties inherently present in the dynamics of the motor due to variation in operating conditions such as load, voltage, and temperature. Unlike conventional methods for controlling motors, which rely on pre-measured torque-speed curves, this estimation must be done in an adaptive and active manner with respect to the real behavior of the motor in operation.

The control system can dynamically adjust the voltage that is applied to the windings of the motor using the proper estimation of the torque command function in an attempt to optimize both the speed and torque outputs instantaneously. This eliminates any expensive and complicated rotor position sensors, making the system more economic and easier to maintain than the high-performance drives would. Most importantly, LECS estimates this mapping function by incorporating the dual optimization approach: the global search capability of Levy flight and the structured search provided by circular search strategies. Because of this mechanism of Levy flight, the process of optimization can scan the solution space in a much better way, which would have gotten stuck with a local minimum generated through traditional techniques of optimization. This feature becomes most important while estimating the torque command function, in view of the fact that the system has to navigate in a highly complex and nonlinear search space where no indication about the location of the global minimum is given. The circularity of search guarantees that exploration is nonrandom and can be supported by the spatial characteristics of the motor’s operation-often a cyclic or rotational feature. This makes the estimation process more efficient and accurate, as the search is done with regard to the physical structure and dynamics of the motor system.

Results and discussion

The section is devoted to the results obtained through simulation for the Q-Recurrent Adaptive Motor Controller-Q-RAMC being proposed to control speed and torque in a sensorless BLDC motor, which is fed by a Solar PV system. Simulation models of the above-mentioned model were developed in the MATLAB/Simulink environment in order to analyze the efficacy and performance of the proposed controller scheme under various operating conditions. In this context, the performance of Q-RAMC is compared with several existing control strategies51,52 like traditional PI control, fuzzy logic-based controllers, and some other adaptive motor control techniques. While analyzing the results regarding motor speed, torque, efficiency, and system stability, the aim is to bring out the advantages and improvements provided by Q-RAMC upon the conventional methods. The simulation results give the details required for analyzing the motor response under variable load conditions, voltage fluctuations from the Solar PV array, and variable solar irradiance. The proposed Q-RAMC is tested both under steady-state and dynamic conditions to assess the capability of precise motor speed and torque control even when the system is subjected to disturbances or power fluctuations. It should also be pointed out that great attention has been paid and given to the controller capability to real-time adapt to changes of system parameters, such as load torque, solar input, and motor speed, in regard to the critical requirements by a sensorless BLDC motor operation. In addition, it presents results in terms of major performance indices comparison of speed regulation, torque accuracy, system efficiency, and response time. The performance of the proposed system is benchmarked with existing control systems for superior torque command tracking, stability during transient conditions, and robustness to variations in generation from solar power. These simulation results clearly evidence that Q-RAMC significantly improves the overall control of the BLDC motor for better dynamic performance, reduced torque ripple, and more stable speed regulation (Fig. 2).

The selected sensorless BLDC motor for this research has the following characteristics: a rated power of 2.2 kW, DC link voltage of 310 V, rated current of 7.5 A, rated torque of 7 Nm, rated speed of 3000 rpm, stator resistance of 1.2 Ω, stator inductance of 3.5 mH, and a moment of inertia of 0.0035 kgm2. These is the parameter value of a medium-capacity BLDC motor quite used in renewable energy and electric drive fields, especially in distributed solar PV-based power systems, light electric vehicles, and automation units. It can be said that conventional BLDC motor systems may not always be as complex as high-power induction or synchronous motors. The reason for choosing sensorless BLDC motor systems in this work has been that its beneficial attributes like higher efficiency, compact design, and reduced maintenance, strong suitability for renewable energy-based distributed setups, reliability, fast dynamic response, and quite efficient torque regulation have made it clear. Also sensorless configuration eliminates the Hall sensors and encoders so less hardware complexity and cost that are crucial in solar PV-powered systems where energy conversion efficiency and economy of the system are top priorities (Fig. 3).

Rotor speed difference is presented in Fig. 4 when no control technique is used. This figure represents the base condition under which the motor operates without having a feedback mechanism or with no control strategy. The fluctuations of the rotor speed will be quite erratic and large-deviated in time. Without having a control system, the motor is highly unstable, and largely differs in rotor speed at the set point. These are highly undesirable variations, considering that the implication on motor performance can result in inefficiency, high torque ripple, and reduced system stability. Without any type of control method for the maintenance of the motor speed, the system will become highly vulnerable to external disturbances, fluctuations in the load, and other changes in input power-mostly when supplied by a Solar PV system with voltage that may further vary owing to changes in solar irradiance.

This gives an indication of the necessity of a strong control strategy in order to reduce speed deviation and improve motor performance.

Figure 4b represents the rotor speed difference using the conventional Proportional-Integral-Derivative (PID) controller. Although one of the most popular control strategies in view of simplicity and extensive applicability, the PID controller’s performance still has bounds within certain scenarios, especially for processes with nonlinearities, time-varying dynamics, and external disturbances53. Hence, in this paper, the PID controller will be tasked to make the difference in rotor speed a minimum by actuating the control inputs because of errors between desired and actual speeds. However, the rotor speed shows some oscillations and overshoots during the transient period. This means that the controller is not able to be effective in the tradeoff between responsiveness and stability, and the system still had a tendency for slight oscillations and did not result in the desired steady-state performance in an optimal manner. As shown in Fig. 4c, the ANFIS controller has an edge over the PID controller in that it incorporates fuzzy rules which adaptively change with dynamic changes in system parameters6. In Fig. 4c, the rotor speed difference is less for the ANFIS-controlled system compared to the PID-controlled system, and the oscillations are not so pronounced54. On the one hand, while ANFIS offers a much smoother response, it is not yet able to correctly follow the desired rotor speed at each instant of fast-occurring variations when a system undergoes serious alterations in load or solar power input. This performance gap underlines the need for a more adaptive and efficient control strategy, where the proposed Q-RAMC controller proves to be very effective. The proposed Q-RAMC controller performs much better in regulating the rotor speed compared to the PID and ANFIS controllers, as shown in Fig. 4d. The transient response is much faster and smoother, maintaining the desired speed under fluctuating load conditions and changing input power from the Solar PV system. Q-RAMC dynamically adapts to the real-time system parameters and disturbances. The controller is very efficient in sensorless BLDC applications because it learns from prior experiences and optimizes actions in a continuous process.

Figure 5a shows how the torque varies when no controller is applied to the motor system. In that case, the torque of the motor is seen to vary significantly. This implies there is no regulation and hence no stability in the torque. High torque ripple arises due to the absence of any control strategy, which then results in undesirable mechanical stresses on the motor and hence inefficient performance. Without control, the system can’t adapt to changes either in load or power input and hence inconsistency in delivering torque. Thus, making it unsuitable for high performance-based applications. The said behavior really makes a robust control strategy essential to eliminate such issues and to obtain smoother and more predictable regulation of torque. Figure 5b is the performance of the motor with an existing PID controller. In a word, although PID control improves it somehow, the torque stability of PID controllers during transient periods is very poor, thus slowing down the response and increasing the torque ripple when compared to other advanced controllers. However, it performs badly when subjected to dynamic operating conditions with a lot of non-linearities and variable load demands. This proves the limitation of PID control in complex, more unpredictable systems- say, those including sensorless BLDC motors. Figure 5c represents torque variation when an ANFIS controller is implemented. Besides, the computational complexity due to the training and adaptation in ANFIS model has prevented its practical use for the real-time motor control in systems that demand strict performance.

Figure 5d demonstrate an impressive reduction in torque fluctuation, and the proposed controller maintains torque stability even under varied load conditions. Moreover, the torque regulation is not only smoother than that of PID and ANFIS controllers but also exhibits faster transient responses with minimum overshoot and settling time.

The superior performance underlines the potential of Q-RAMC for high-precision torque control in sensorless BLDC motor systems and hence will be an ideal choice for applications where torque stability is crucial, for instance, renewable energy systems, robotics, and electric vehicles.

Figure 6 shows the detailed stator current behavior analysis in a sensorless BLDC motor system under various control techniques. The stator current profile comparison is important to understand the efficiency and stability of the motor control system. Subplots (a), (b), (c), and (d) represent the stator current waveforms without any controller, with a PI controller, with an ANFIS controller, and with the proposed controller, respectively. Figure 6a shows the stator current of sensorless BLDC when no controller is applied. In that case, stator current experiences severe fluctuation and exhibits instability in a nature as the motor operates freely without any control for stability and smooth operation. A high ripple of current in the case of no control makes the operation inefficient and the system components may experience overloading. These existing oscillations can cause excessive heating of the motor, deterioration in performance, and even complete system breakdown after some time.

The dynamic response of the uncontrolled motor is not good; the stator current reaches its peak during the transition of the load-a fact that calls for the proper control strategy in mitigating such issues for the optimization of the system performance.

Figure 6b represents the stator current when a PI controller is applied to the motor. While the PI controller reduces some of the current fluctuations compared to an uncontrolled case, it also cannot eliminate oscillations fully. The stator current waveforms are now smoother due to reduced ripple, but again, the system still experiences the noticeable current spikes and dips, especially at transient states. While the PI controller is an improvement on no controller at all, the inability to adapt to changes in load conditions or nonlinearities of the system renders it unsatisfactory for current regulation in a steady state. The motor is still quite inefficient during transient load changes, and it is far from ideal in applications where high precision and responsiveness are required.

The current waveforms in Fig. 6b,c appear only in the positive region since the modeled system is based on the magnitude of phase currents rather than the bipolar alternating waveform usually found in raw three-phase motor signals. Thus, the simulation focuses upon the envelope or effective instantaneous value of the current during the controller operation rather than directly showing sinusoidal AC waveforms oscillating above and below zero. This representation is mostly used in the comparative studies of control techniques (PID, ANFIS, and Proposed) as it makes the attenuation, overshoot, and ripple content more obvious without the distraction of the negative half-cycles involved in nominal sinusoidal signals. The analysis essentially focuses on the smoothness, stability, and ripple suppression of the current as shaped by each controller by only plotting the positive magnitude. In practice, the actual three-phase currents would of course alternate between positive and negative values, but for controller evaluation, representing only the positive current magnitudes provides a clearer and more interpretable comparison.

Figure 6c reflects the stator current behavior of an ANFIS controller, which possesses characteristics from both neural networks and fuzzy logic for adaptive control. The stator current response in the ANFIS controlled system is far smoother, with much less current ripple and reduced overshoots compared to the PI controlled system. This allows an ANFIS controller to adapt to dynamic motor characteristic changes, which could better regulate the current and result in finer stability. However, the improved performance brought by ANFIS, residual oscillations still appear at load variations, especially when operating conditions experience abrupt changes in a motor operation. The computation burden, along with a necessity to adapt in real time, limits the opportunities for obtaining optimal current regulation by the ANFIS-based controller within all possible regimes of its operation. Figure 6d illustrates stator current when a controller with the proposed approach has been employed. In comparison, the proposed controller exhibits the best performance, much smoother current profile, and minimum ripple in case of dynamic changes both for load or input variations. Therefore, under a wider range of operating conditions, the stator current can remain stable, and thus transients would be quickly damped out for efficiency in its operation. Since the proposed controller learns from the dynamic behavior of the motor, it is more responsive in case of motor load change for the optimal regulation of currents. This superior performance indicates that the proposed controller is capable of handling the current in sensorless BLDC motors for higher efficiency, lower losses, and increased life.

Figure 7 presents the EMF induced in the stator of a sensorless BLDC motor for different control methods. The graph illustrates how the different control strategies affect the waveforms of the EMF. In the case of an uncontrolled motor, the waveform of EMF tends to show some irregularities, reflecting that the operation of the motor is not under control. The stator EMF becomes unstable without appropriate regulation, hence leading to inefficient energy conversion and probable instability of the motor. On the other hand, when controllers like PI, ANFIS, and the proposed controller are used, the stator EMF becomes stable, showing better energy efficiency. The proposed controller gives a smoother and more consistent EMF waveform, which indicates better control of the motor operation.

Figure 8 illustrates in detail the analysis of rotor speed for the sensorless BLDC motor using the different control strategies applied. Among all the parameters that estimate the dynamic response and stability of a motor system, the rotor speed is one key parameter since it is directly linked with the real-time performance of the motor. With the PI and ANFIS controllers, the rotor speed shows improvements, though the systems still exhibit some degree of oscillation and slower responses during load transients. However, the proposed controller exhibits a very good speed regulation characteristic in terms of small fluctuation and faster settling times in comparison with the existing controllers. This means that, in practice, the proposed Q-RAMC controller achieves better stability, responsiveness, and accuracy of maintaining the desired rotor speed. It is highly suitable for the applications where tight speed control and high response against load or operating changes are required. Figure 9 illustrates the torque responses of the uncontrolled system, conventional PI controller, ANFIS controller, and the proposed Q-RAMC controller under four sets of control strategies. When unsteeled, the torque jumps around irregularly due to spikes and drops of values that can cause a lack of stability in the motor operations, and possible long-run damages of the system. At this point, the PI controller manages to reduce only some of the fluctuations but not eliminate the oscillation totally, especially when experiencing dynamic changes either in loading or speed. The ANFIS controller outperforms the PI controller, with smoother torque profiles.