Abstract

This study examines the thermal and hydrodynamic characteristics of Therminol VP-1 oil flow through perforated conical hollow-type turbulence promoters installed in a solar Scheffler dish collector receiver tube, utilizing computational fluid dynamics (CFD) analysis. The research examines these configurations using the RNG k-ε turbulence model with conventional wall functions. Simulations are conducted at Reynolds numbers ranging from 3000 to 15,000, with relative perforated conical hollow-type turbulence promoters ratios (PerID/PerOD) varying from 2.11 to 2.33, relative turbulence promoter pitch (PTP/Dtube) spanning from 2.25 to 3.08, and a relative turbulence promoter diameter (DBinlet/DBoutlet) is constant at 2.0 to evaluate heat transfer and friction factor characteristics. An experimental analysis has been conducted on a solar Scheffler dish collector receiver using a plain tube with Therminol VP-1 as the heat transfer fluid to validate the CFD results for the current study. Moreover, the CFD results have been verified through a comparison with a conventional surface solar Scheffler dish collector receiver tube utilizing Therminol VP-1 as the heat transfer fluid. This comparison encompassed theoretical relationships and empirical data pertaining to the Nusselt number and friction factor. The CFD results for the plain surface solar receiver tube demonstrated important alignment with experimental data and theoretical predictions based on the standard Dittus and Blasius equations, exhibiting reasonable deviation throughout the analyzed range. Overall, the CFD results demonstrate that Therminol VP-1, combined with perforated conical hollow-type turbulence promoters, improves thermal efficiency, providing an effective approach for enhancing Scheffler dish receiver tubes while reducing excess pressure losses. According to thermal and hydraulic performance data, hollow-type conical turbulence promoters enhanced heat transfer, with the best performance achieved at PerID/PerOD of 2.25 and a (PTP/Dtube) of 2.83.

Similar content being viewed by others

Introduction

Solar energy is harnessed and converted into vibrant power or high-temperature heat. Heat transfer is crucial in this dynamic conversion process, meaningfully enhancing the performance and efficacy of solar energy devices. Solar thermal devices utilize heat transfer technology to collect and transmit heat energy, thereby heating water and buildings. Heat transfer within photovoltaic systems is critical to improving cell performance, as solar panel efficiency is also affected by temperature1,2. Achieving extremely efficient heat transfer to optimize performance in energy conversion is a significant problem in solar energy systems. In solar power (CSP) arrangements, concentrated sunlight produces elevated temperatures, requiring more efficient heat transfer methods to convert thermal energy into electricity. The efficacy of heat transfer in solar energy devices is determined by the best heat fluids that transfer heat and their thermophysical properties. Specialized fluids, such as different types of thermal oil and nanofluids, have demonstrated potential in improving the energy conversion efficiency of hybrid photovoltaic/thermal (PVT) systems by optimizing the thermal and electrical aspects of the solar energy conversion3,4,5,6.

The literature describes many studies with complicated fluids, such as thermal oils and nanofluids, flowing over modified solar thermal collectors. Several researchers conducted these types of studies. Chakraborty et al.7 examine the thermal performance of a parabolic trough collector (PTC) equipped with a helical-type absorber tube. The objective is to use nanofluids as working fluids for thermal efficiency. The findings from these studies suggest that such enhancements could dramatically elevate the overall performance of the collectors, transforming their best performance and maximizing energy capture. Some previous investigations explore a range of factors such as Reynolds number, relative pitch ratio, relative roughness height, and angle of attack. The findings reveal that a specific configuration of the V-up baffle block achieves superior thermal efficiencies of 96.6% alongside an effective efficiency of 91.8%. The authors assert that the optimized parameters can significantly enhance the performance of solar air heaters, as evidenced by the findings explored by Pandey and Manoj8. Otanicar et al.9 investigate integrating concentrating-type photovoltaic (CPV) technology into pre-existing parabolic trough solar thermal power plants. A CPV retrofit optical stage’s design, construction, and testing are investigated. Experimental results show a max cell efficiency of 25.4% and an average of 33%. The results indicate that retrofitting CPV systems is viable for enhancing existing infrastructure and enabling cost-effective concentrating photovoltaics.

The application of computational fluid dynamics (CFD) technologies in designing parabolic trough-type collectors that incorporate internal finned category tubes. The findings indicate that utilizing finned-type tubes can improve the efficiency of the parabolic type of trough solar facilities examined by Muñoz and Abánades10. Manikandan et al.11discuss various aspects of parabolic-type trough collectors (PTC) for concentrated-type solar power (CSP) systems. The primary goal is to improve the optical and thermal efficiency of different arrangements of PTCs. The economic assessment of CSP kind technologies is also discussed, highlighting the necessity for a broader evaluation approach. Chang et al.12 study develops a 3D model and examines the effects of different parameters. The findings indicate that the two concentric and eccentric rod inserts can effectively enhance heat transfer. The findings provide insights for improving the accuracy and efficiency of parabolic trough solar collectors—the effect of slits within the arc-plug inserts of a solar parabolic trough receiver. The findings suggest that using slits within Inserts has the potential to improve the efficiency of parabolic trough collectors explored by Pandey et al.13. Tiwar et al.14 discussed the factors affecting thermal efficiency and various methods for mirror synthesis. To improve solar collector performance, hybrid nanomaterials are used. Foam formation, expense, and viscosity improvement are issues. The researchers also highlighted that the study underscores the significance of enhancing the heat transfer surface and increasing the turbulence in the fluid.

Nanofluids are also explored for their potential in solar-thermal applications, as discussed by Norouzi et al.15. The results found in Abrofarakh and Moghadam16 showed that the presence of metal foam enhances thermal performance and reduces local EGR due to heat transfer, but at the same time increases local EGR due to viscous-type effects. Their study recommends using metal foam with lower pores per inch (PPI) for reduced global EGR due to viscous effects. It examines the thermal efficiency of novel configurations for parabolic trough receivers and conducts a comparative analysis of two heat transfer fluids: Syltherm800 and a hybrid nanofluid consisting of MWCTN-TiO2. The MWCTN-TiO2 category hybrid nanofluid demonstrated superior performance compared to the Syltherm800 category. These designs and nanofluids may increase thermal efficiency, and an investigation into the reduction of stresses in parabolic trough receivers has been conducted and explored by Byiringiro et al.17.

The impact of various types of rib configurations on the performance of a parabolic trough receiver (PTR) is examined. Both symmetrical anticlockwise and symmetrical clockwise configuration categories are considered. The shapes of double-inclined and single-inclined ribs achieve optimal performance by minimizing peak temperature and heat loss, as discussed by Liu et al.18. The researchers examined the effectiveness of a solar collector utilizing parabolic trough technology, creating an internal annular porous type structure within the solar trough collector and applying a blend of synthetic oil and Al2O3 as the heat transfer fluid. The research investigates the effects of the porous-type structure and the incorporation of nanoparticles on thermal efficiency, pressure loss, and heat transfer. Findings demonstrate that thermal efficiency and heat transfer are enhanced through the enhancement of the nanoparticle volume fraction and the Reynolds number explored by Bozorg et al.19.

Hassan et al.20 investigated turbulent flow inside tubes fitted with conical rings of different designs. Their results showed that divergent solid rings generated the most substantial heat transfer improvement, reaching a Nusselt number of about 360, because of intense boundary layer disturbance and flow acceleration. However, this advantage came at the cost of a large pressure drop. On the other hand, perforated rings yielded a more practical outcome, offering lower frictional resistance while improving heat transfer, with thermal enhancement factors of approximately 1.06. In another work, Sharaf et al.21 explored the effect of SiO₂/water nanofluids and spring wire inserts (SWI) in helical exchangers. They reported that SWI produced greater enhancement than nanofluids alone, but the combined use of both provided the most favorable results. A 0.3% nanofluid mixed with SWI gave the highest gain in Nusselt number (about 174%), whereas a 0.2% mixture delivered the best efficiency by balancing heat transfer and pumping power. These studies suggest that while more substantial modifications can push heat transfer to higher levels, the most effective designs are those that balance enhancement with hydraulic performance.

Ribbed-type surfaces enhance heat absorption in cylindrical solar collectors (CSCs). The findings indicate that embossing type ribs on various sides of the collector can improve its performance, as explored by Abu-Hamdeh et al.22. The absorber tube with an attached fin on the inner side impacts the efficiency of a two-fluid system parabolic trough solar collector (PTC) loaded with a nanofluid (NF) containing various nanoparticle (NP) shapes and sizes. The findings indicate that the energy efficiency of the two-fluid PTC surpasses that of the single-fluid PTC explored by Alnaqi et al.23. Other researchers, Allam et al.24 analyses research trends, insert configurations, and evaluate parameters. It also investigates nanofluids’ application and presents prospective research avenues for nanoparticle-based fluid mixtures. Researchers observed that the effectiveness of solar parabolic trough collectors is enhanced with the use of nanofluids. Numerical simulations evaluated the impact of various collector parameters on efficacy. Increasing Cu-based nanoparticle volume fraction increased receiver tube exit temperature gain, as explored by Samiezadeh et al.25.

PCM-type integrated solar receiver thermal analysis and performance evaluation for dish micro-gas turbine systems. The principal findings indicate favorable outcomes for rapid-term thermal storage. The subsequent phase entails laboratory-scale experimentation of the PCM-integrated solar receiver developed by Bashir et al.26. Incorporating rib roughness on the interior surface of the evacuated type of solar tube collectors improves overall thermal performance by disrupting the laminar layer. The consequences showed that using circular ribs enhanced heat transfer in the solar evacuated tube collectors explored by Singla et al.27. The study utilizes numerical analysis using COMSOL Multiphysics 6.1 software to simulate the receiver and receiver with fins within the PDC. The main objective is to assess the CO2 mitigation potential of PDCs. The results reveal that PDCs have significant potential for reducing carbon emissions Nallaperumal et al.28.

The study on thermal and hydrodynamic characteristics across turbulence promoters in a heat exchanger receiver tube can be contextualized with aerospace anti-icing research. Pazarlıoğlu et al.29 optimized piccolo tube jet parameters and showed that jet angle and spacing critically influence heat transfer and pressure drop. Their CFD-RSM method identified optimal settings with improved convective heating and controlled resistance. In Pazarlıoğlu et al.30 the same team assessed new slot jet methods, reporting an 85.52% increase in Nusselt number over circular jets. Although pressure drops were higher, the overall performance evaluation criteria remained favorable. These findings highlight how turbulence-promoting geometry can enhance thermo-hydraulic efficiency, supporting the application of solar thermal systems.

Previous research has widely explored heat transfer enhancement in solar collectors using nanofluids, fins, ribs, helical tubes, metal foams, and other modified inserts. Most of these studies have focused on parabolic trough collectors or air heaters, with water, air, or nanofluids as the working medium. However, the application of turbulence promoters within a solar Scheffler dish collector receiver tube, particularly with Therminol VP-1 oil as the heat transfer fluid, has not been reported in the literature. This presents a unique research gap, as Therminol VP-1 is a high-temperature synthetic oil commonly used in concentrated solar power systems, and its performance with perforated conical turbulence promoters (hollow type) remains unexplored. The present study addresses this gap by numerically and experimentally analyzing the combined effect of hollow-type perforated conical turbulence promoters and Therminol VP-1 on thermal and hydrodynamic characteristics, thereby offering a novel approach for enhancing receiver tube efficiency. The primary objectives are:

-

To analyze the effect of different geometrical parameters of perforated conical hollow-type turbulence promoters on the Nusselt number, friction factor, and overall heat transfer characteristics of Therminol VP-1 oil flow in a solar Scheffler dish collector receiver tube using CFD simulations.

-

To validate the CFD results through experimental analysis with a plain receiver tube and theoretical correlations, and to determine whether perforated conical hollow-type turbulence promoters can enhance solar collectors’ overall thermal and hydraulic efficiency.

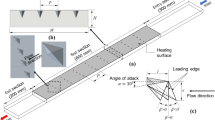

Geometrical parameters and design for analysis

The inlet and outlet sizes of the perforated conical hollow-type turbulence promoters used as turbulence promoters in the solar Scheffler dish collector receiver tube design exhibit a predictable fluctuation. In the case of perforated conical hollow-type turbulence promoters in a solar Scheffler dish collector receiver tube, the entrance turbulence promoters’ diameter \(({Per}_{ID})\) is more significant in comparison to the outlet turbulence promoters diameter \(({Per}_{OD})\) of turbulence promoters in the receiver tube. The relative turbulence promoters diameter ratio, denoted by the symbol (\({Per}_{ID}/{Per}_{OD}\)), displays a pattern of increasing from 2.11 to 2.33. While keeping the diameter of the tube constant, the geometric parameters exhibit a regular fluctuation in the pitch of the turbulence promoters, which is denoted by the initial symbol of pitch of turbulence promoters \({P}_{TP}\). The dimensionless ratio represents the relative spacing of turbulence promoters (\({P}_{TP}\)/\({D}_{tube}\)), which increased from 2.25 to 3.08 during the present investigation. The Reynolds number chosen for the present investigation ranges from 3000 to 15,000. Table 1 summarizes the ranges of geometrical and flow parameters considered in this study. Figure 1 illustrates the CFD domain and the geometric configurations analyzed for both smooth tubes and those fitted with perforated conical hollow-type turbulence promoters.

Mesh generation for plain and perforated conical hollow type solar receiver tubes and grid-independent test

Figure 2 displays two distinct mesh configurations for solar receiver tubes in a Scheffler dish collector system. The smooth surface tube (Fig. 2a) exhibits a uniform tetrahedral mesh pattern that follows the serpentine geometry of the tube. The mesh appears to be well-structured with consistent element sizes throughout the tube’s length, ensuring accurate flow and heat transfer calculations. Other (Fig. 2b), the turbulence promoter solar receiver tube shows a similar serpentine configuration but with a notably different mesh structure. The mesh appears to be more refined, with smaller elements distributed across the tube surface. Both meshes demonstrate careful consideration of computational fluid dynamics requirements, with visible refinement near the tube bends where flow characteristics are expected to be more complex.

In a grid-independent test, an appropriate size is chosen for better accuracy. The number of elements selected for the grid independence test ranges from 690432 to 1165342 for the solar receiver tube. The results were recorded in terms of the percentage variation of the Nusselt number for Reynolds numbers ranging from 3000 to 15000. The variation in the results is illustrated in (Table 2). According to the smallest variation of Nusselt number, the optimum number of elements chosen for all the analysis is in the range of 1060557. The grid-independent tests of the Nusselt number and friction factor for different numbers of elements are shown in (Fig. 3a,b).

Validation of CFD results with experimental outcomes for a plain solar receiver tube

The system has a variety of essential elements that work together in a closed loop to capture solar energy effectively. The principal collector is a large parabolic Scheffler dish that captures and focuses solar radiation. The receiver tube, a crucial system component, features a distinctive design with several parallel channels for the flow of the heat transfer fluid (Therminol VP-1). The channels are arranged in a serpentine pattern within a rectangular enclosure, thus optimizing the surface area for heat transfer. The system functions within a framework that is a closed-loop circulation. Therminol VP-1 oil is contained in a cylindrical type of storage tank and is moved through the system by a pump unit that features an integrated means by control valve. The oil flows through a receiving tube, absorbing concentrated solar energy from the Scheffler-type dish. Oil is drawn from the storage tank, heated by concentrated solar radiation inside the receiving tube, and then returned to the tank to complete the cycle. The setup features a control valve positioned between the pump and the receiver tube, allowing for precise flow regulation. This overall flow closed-loop system allows operators to control flow rates and pressure levels within the system, ensuring effective heat transfer and the finest system performance. Direct Normal Irradiance (DNI) is a crucial parameter for evaluating the optical performance of a Scheffler dish collector. In this study, a pyranometer was employed to measure the solar flux at different time intervals. These measured flux values were then used as inputs in the numerical analysis to determine the performance parameters for various collector geometries. Figure 4 depicts a comprehensive experimental setup of a Solar Scheffler dish collector system implemented at the University of Petroleum and Energy Studies (UPES), Dehradun.

Numerous researchers have recommended the RNG k-epsilon model for exploring complex structures and designs, which is why it is widely used in computational fluid dynamics (CFD) simulations to investigate heat transport in solar collectors. Also, the RNG k-epsilon turbulence model is excellent for analysing intricate flow patterns in enhanced absorber solar-type tubes, and other complex designs of heat exchangers, because it accurately simulates swirling flows and rapidly flowing complex fluids31,32. The results of recent studies have demonstrated that it is effective in predicting pressure reductions and rising heat transfer coefficients in parabolic trough-type collectors featuring various category insert configurations. Due to its accuracy in modeling swirling flows and turbulence near rough and heated walls, the RNG k-epsilon model is useful for studying solar system heat transfer and friction factors. This model also accurately predicts temperature distributions and turbulent kinetic energy profiles in parabolic trough solar collectors and other various solar energy applications27,31,32,33.

The RNG k-epsilon model is good for understanding the solar system, capable of accurately predicting pressure drops and friction factors in complex shapes, such as tubes with internal fins used in parabolic trough-type collectors or other heat exchangers10. The k-epsilon model effectively analyzes flat plate solar collectors, accurately forecasting heat transfer improvements and frictional flow characteristics for different rib configurations and shapes. In research comparing flat-plate solar air heater setups, the RNG k-epsilon model exactly predicted results in airflow, temperature, relative humidity, and velocities, with deviations between simulated and experimental results as low as 7%34. Table 3 summarizes selected studies from the literature that have applied the RNG k–ε model to ribbed surfaces, conical inserts, and nanofluid systems, confirming its suitability for the present work.

The steady-state RNG k-epsilon model consists of two transport equations. 35,36,37:

Turbulent kinetic energy (k) equation:

Dissipation Rate (\(\epsilon )\) equation:

The distinctive \({R}_{\epsilon }\) term that separates RNG from k-\(\epsilon\) is:

The turbulent viscosity is calculated as:

where: \(\eta =Sk/\epsilon\), \({\eta }_{o}=4.38\), \(\beta =0.012\), S represents the modulus of the mean rate of the strain tensor 35,36,37:.

Experimental analysis equations and uncertainty analysis

Figure 5a,b illustrates the heat transfer and fluid flow validation in a smooth surface solar receiver tube employing Therminol VP-1 oil (thermophysical properties presented in Table.4), based on theoretical correlations, experimental results, and CFD simulations. The Nusselt number exhibits a linear increase with the Reynolds number within the range of 3,000 to 15,000. CFD estimates increase at elevated Reynolds numbers, while predictions from the Dittus-Boelter equation38 \(({Nu}_{ss}=0.023{{Re}_{num}}^{0.8}{Pr}^{0.4})\) align closely with experimental data. All three methods for predicting heat transfer demonstrate a concordance within 5–7%, reflecting a significant level of agreement. The Blasius equation39 \(\left({f}_{ss}=0.316{{Re}_{num}}^{-0.25}\right)\) indicates that the friction factor diminishes as the Reynolds number increases. Experimental and CFD results closely align with the theoretical predictions of the Blasius equation, although experimental values are slightly lower at mid-range Reynolds numbers. The methods for forecasting heat transfer and flow behavior in smooth surface solar receiver tubes are reliable, as they demonstrate consistency among theoretical correlations, empirical data, and CFD simulations across both parameters.

The uncertainty analysis is carried out on Nusselt number and friction factor, considering mass flow rate and diameter uncertainty, using Kline–McClintock’s method41. The uncertainty in the Nusselt number is given by Eq. (5)41.

where \(\Delta N\) is the change in performance parameter and \({\Delta u}_{1}\), \({\Delta u}_{2}\), \({\Delta u}_{3}\) … is the uncertainty in independent variables. Based on the above equation, the uncertainty in the Nusselt number is calculated by (Eq. 6)41.

where, \({u}_{{m}_{f}}\) is the uncertainty in mass flow rate and \({u}_{d}\) is the uncertainty in diameter. Based on the flowmeter accuracy, the uncertainty in the mass flow rate is \(\underset{\_}{+}2.5\%\). Similarly, the uncertainty in diameter due to instrument resolution is taken \(\underset{\_}{+}0.1 mm\). Based on this, the uncertainty in the Nusselt number calculated is 2.42%.

Results and discussion

Calculated CFD data comprehensively compare heat transfer and fluid flow characteristics between smooth and perforated conical hollow-type turbulence promoter tubes under varying Reynolds numbers. The graph Fig. 6a presents the CFD analysis results of heat transfer performance through different tube configurations, a ratio of inlet turbulence promoters diameter to outlet turbulence promoters diameter (\({Per}_{ID}/{Per}_{OD}\)) 2.11 to 2.33 comparing modified tubes with varying perimeter ratios to a smooth tube via Therminol VP-1 oil flow. Under fixed conditions of \({DB}_{inlet}/{DB}_{outlet}=2.0\) and \({P}_{TP}/{D}_{tube}=2.83\), the results reveal significant insights into heat transfer enhancement.

The modified tubes demonstrate substantially higher Nusselt numbers compared to the smooth tube across all Reynolds numbers from 3000 to 15,000. This performance gap widens as Reynolds numbers increase, with modified tubes reaching \({Nu}_{TP}\) values 2.4 times higher at \({Re}_{num}=15000\), when compared with the smooth tube. The ratio of the inlet turbulence promoters’ diameter to the outlet turbulence promoters’ diameter (\({Per}_{ID}{/Per}_{OD}\)) shows a notable influence on heat transfer performance. The highest ratio of 2.33 generally yields the best performance at higher Reynolds numbers, though the differences between the modified tubes are relatively small. The performance hierarchy among different perimeter ratios becomes more pronounced as the Reynolds number increases, with the ratio of inlet turbulence promoters diameter to outlet turbulence promoters diameter (\({Per}_{ID}{/Per}_{OD}\)) = 2.25 and 2.33 consistently show superior performance above \({Re}_{num}=9000\). In conclusion, Fig. 6a shows that modified tubes show nearly 2.4 times higher Nusselt numbers compared to smooth tubes. The performance advantage of higher perimeter ratios becomes more evident at higher Reynolds numbers. The differences between modified tubes become less pronounced at higher Reynolds numbers, converging to similar values around \({Re}_{num}=15000\).

The graph Fig. 6b presents a comprehensive analysis of friction factor performance through different tube configurations, a Ratio of inlet turbulence promoters diameter to outlet turbulence promoters diameter (\({Per}_{ID}{/Per}_{OD}\)) 2.11 to 2.33 comparing modified tubes with varying perimeter ratios to a smooth tube via Therminol VP-1 oil flow. Under fixed conditions of \({DB}_{inlet}/{DB}_{outlet}=2.0\) and \({P}_{TP}/{D}_{tube}=2.83\), the results reveal significant insights into pressure drop characteristics. All modified tubes show significantly higher friction factors (0.15–0.20) compared to the smooth tube (approximately 0.03). The friction factors decrease with increasing Reynolds number, with the rate of decrease being more pronounced in the lower Reynolds number range (3000–9000). Interestingly, the differences in friction factors among modified tubes with different perimeter ratios are relatively small, suggesting that the geometric modifications primarily affect heat transfer rather than flow resistance.

Figure 7a presents a comprehensive analysis of heat transfer performance through different tube configurations, a Ratio of the turbulence promoters’ pitch to tube diameter (\({P}_{TP}/{D}_{tube}\)) 2.25 to 3.08 comparing modified tubes with varying perimeter ratios to a smooth tube via Therminol VP-1 oil flow. Maintaining constant other parameters such as \({DB}_{inlet}/{DB}_{outlet}=2.0\) and \({Per}_{ID}{/Per}_{OD}=2.25\), the results reveal significant insights into heat transfer enhancement. The results are indicated at the lowest Reynolds number of 3000, the modified tubes show \(({Nu}_{TP})\) around 80, nearly triple that of the smooth tube at approximately 30. This enhancement becomes more pronounced as the Reynolds number increases, with the \({P}_{TP}/{D}_{tube}\)=2.83 configuration consistently outperforms other ratios. At \({Re}_{num}\) = 15,000, this optimal configuration achieves a \({Nu}_{TP}\) value exceeding 300, while the smooth tube only reaches about 130. The performance hierarchy among the modified configurations remains relatively consistent across all Reynolds numbers, with the 2.83 ratio consistently outperforming other geometries.

Figure 7b presents a comprehensive analysis of friction factor performance through different tube configurations, a ratio of the turbulence promoter pitch to tube diameter (\({P}_{TP}/{D}_{tube}\)) 2.25 to 3.08 comparing modified tubes with varying perimeter ratios to a smooth tube via Therminol VP-1 oil flow. Constant other parameters such as \({DB}_{inlet}\)/\({DB}_{outlet}\)=2.0 and \({Per}_{ID}/{Per}_{OD}=2.25\), the results reveal significant insights into friction factor enhancement. The friction factor analysis presents a more complex picture of the modifications’ impact on flow behaviour. At \({Re}_{num}\)=3000, all modified configurations exhibit \({f}_{TP}\) around 0.20, substantially higher than the smooth tube’s approximately 0.04. The friction penalty gradually decreases with increasing Reynolds number but remains significant throughout the tested range. The \({P}_{TP}/{D}_{tube}\) of 2.25 configuration consistently shows the highest friction factors, while the 3.08 ratio demonstrates the lowest among modified tubes, suggesting that larger pitch ratios help mitigate flow resistance.

The combined analysis of both graphs (Fig. 7 a,b) indicates a clear engineering trade-off. While all modified configurations significantly enhance heat transfer, they do so at the cost of increased flow resistance. The \({P}_{TP}/{D}_{tube}\) of 2.83 configuration emerges as particularly interesting, achieving the highest heat transfer enhancement while maintaining moderate friction penalties compared to other modified geometries. This suggests it might represent an optimal balance point between thermal performance improvement and pumping power requirements. Despite exhibiting the lowest friction factors, the smooth tube demonstrates limited heat transfer capability, underscoring the need for surface modifications to achieve enhanced thermal performance.

The superior heat transfer observed at \({P}_{TP}/{D}_{tube}\)=2.83 can be explained by vortex dynamics. At this spacing, vortices shed from each promoter reattach to the wall just upstream of the next promoter, ensuring continuous disruption of the thermal boundary layer and enhanced radial mixing (Figs. 8, 9). Smaller pitch ratios (e.g., 2.25) suppress vortex development due to premature interaction, while larger ratios (e.g., 3.08) allow vortices to dissipate before reattachment, reducing enhancement. Similarly, the optimal \({Per}_{ID}/{Per}_{OD}\)=2.25 reflects a balance between flow acceleration and blockage. This ratio generates strong shear and turbulence without excessive pressure penalties, whereas higher ratios (e.g., 2.33) disproportionately increase blockage and friction losses.

The perforated receiver tube fitted with conical turbulence promoters exhibits pronounced heat transfer enhancements compared to a smooth tube by continuously disrupting and thinning the thermal boundary layer. Each promoter tip creates a high‐shear region that rolls into coherent vortices, entraining cooler core fluid toward the wall and sweeping heated boundary‐layer fluid outward. As shown in Figs. 8, 9, these vortices shed downstream of each promoter, merge, and then reattach to the tube wall, sustaining elevated turbulent kinetic energy in the near‐wall region. The alternating contraction through the promoter throat and subsequent expansion downstream further destabilize the boundary layer, preventing it from reestablishing and maintaining a steep temperature gradient at the wall. This cyclic process of shear‐layer formation, vortex shedding, and reattachment generates intense fluid mixing zones that drive the significantly higher local and overall Nusselt numbers observed in the perforated conical hollow type turbulence promoter tube.

Thermohydraulic performance parameter

The graph Fig. 10a presents the CFD analysis results of thermohydraulic performance through different tube configurations, a ratio of inlet turbulence promoters diameter to outlet turbulence promoters diameter (\({Per}_{ID}\)/\({Per}_{OD}\)) 2.11 to 2.33 comparing modified tubes with varying perimeter ratios to a smooth tube via Therminol VP-1 oil flow. Under fixed conditions of \({DB}_{inlet}/{DB}_{outlet}\)=2.0 and \({P}_{TP}\)/\({D}_{tube}\)=2.83, the results reveal significant insights into enhancing thermohydraulic performance. The plot identifies a peak THP value at a specific combination of \({Re}_{num}\) and \({Per}_{ID}\)/\({Per}_{OD}\). As \({Re}_{num}\) increases, THP initially rises, reaches a peak, and then begins to decline. This trend suggests that there is an optimal range of Reynolds numbers where the system operates most efficiently in terms of thermohydraulic performance42,43.

The color gradient from blue to orange represents increasing performance values, with the warmest colors indicating regions of highest efficiency. The surface topology shows a clear peak region surrounded by gradual slopes, suggesting a stable optimal operating zone. The relative turbulence promoters ratio shows a complex relationship with thermohydraulic performance. The performance varies notably across the turbulence promoters ratio range of 2.11 to 2.33. Higher performance values are observed in the mid-range of turbulence promoters ratios, with a slight decline at both extremes. This behaviour indicates an optimal turbulence promoters ratio for maximizing thermohydraulic efficiency. The existence of a clear maximum suggests that designers should aim for operating conditions with a Reynolds number value of 6000 and a turbulence promoter ratio of approximately 2.25 to achieve optimal system performance.

The graph Fig. 10b presents the CFD analysis results of thermohydraulic performance through different tube configurations, a ratio of the turbulence promoters pitch to tube diameter (\({P}_{TP}/{D}_{tube}\)) 2.25 to 3.08 comparing modified tubes with varying perimeter ratios to a smooth tube via Therminol VP-1 oil flow, maintaining constant other parameters such as \({DB}_{inlet}\)/\({DB}_{outlet}\)=2.0 and \({Per}_{ID}/{Per}_{OD}=2.25\). The \({P}_{TP}/{D}_{tube}\) exhibits a notable impact on the system’s thermohydraulic performance. As the pitch ratio increases, the THP shows a consistent improvement, reaching its peak just before a ratio of 2.83. The performance landscape displays a distinctive dome-shaped surface, with the highest performance region (indicated in orange) concentrated near the optimal Reynolds number and pitch ratio combination. The gradual color transition from blue to green to yellow across the surface indicates a smooth, continuous variation in performance across the parameter space, suggesting stable and predictable system behaviour under varying conditions.

Conclusions

This study presents a CFD analysis of the heat transfer and fluid flow in perforated solar receiver tubes featuring conical hollow perforations. The investigation focuses on two key parameters: the ratio of inlet to outlet perforation (hollow type) diameter (\({Per}_{ID}\)/\({Per}_{OD}\)) ranging from 2.11 to 2.33, and a ratio of turbulence promoter pitch to tube diameter (\({P}_{TP}\)/\({D}_{tube}\)) ranging from 2.25 to 3.08 compared to a smooth tube, under Reynolds numbers from 3,000 to 15,000. An experimental investigation was carried out on a solar Scheffler dish collector receiver using a plain tube with Therminol VP-1 as the heat transfer fluid to validate the CFD results for this study. The primary conclusions derived from the current study are:

-

\({Nu}_{TP}\) increases steadily with \({Re}_{num}\) across all perforated conical hollow type tubes, with values consistently exceeding those of the smooth tube. The maximum enhancement occurs at \({Re}_{num}\)=15,000. Among the tested geometries, \({Per}_{ID}\)/\({Per}_{OD}\)=2.25 achieves the highest \({Nu}_{TP}\), while 2.11 provides moderate improvement. In terms of \({f}_{TP}\), the maximum value occurs at \({Per}_{ID}\)/\({Per}_{OD}\) = 2.11, whereas 2.33 records the lowest among the perforated conical hollow type configurations. This improvement occurs because the perforations promote boundary layer disruption and enhance fluid mixing within the tube, thereby intensifying convective heat transfer. The 2.25 ratio strikes the best balance between turbulence generation and flow resistance, making it the most effective configuration for heat transfer performance.

-

For pitch ratio effects, the tube with \({P}_{TP}\)/\({D}_{tube}\)=2.83 consistently achieves the best thermal performance, with a \({Nu}_{TP}\) nearly 2.4 times higher than that of the smooth tube at \({Re}_{num}\)=15,000. In terms of frictional behaviour, all perforated conical hollow type turbulence promoter tubes exhibit higher \({f}_{TP}\) than the smooth tube, though values decrease with increasing \({Re}_{num}\). Among the configurations, \({P}_{TP}\)/\({D}_{tube}\)=2.25 produces the higher \({f}_{TP}\) across most \({Re}_{num}\) while 3.08 yields the lowest. This highlights the trade-off between maximizing \({Nu}_{TP}\) enhancement at 2.83 and minimizing pressure losses at 3.08.

-

The relative perforation ratio \({Per}_{ID}\)/\({Per}_{OD}\) achieves maximum thermohydraulic performance (THP) at 2.25, while the relative pitch ratio \({P}_{TP}\)/\({D}_{tube}\) peaks at 2.83. Both geometrical parameters exhibit comparable performance patterns, with THP values rising steadily with \({Re}_{num}\) and attaining peak levels of approximately 1.8–1.9 at higher \({Re}_{num}\). These results suggest that \({Per}_{ID}\)/\({Per}_{OD}\)=2.25 and \({P}_{TP}\)/\({D}_{tube}\)=2.83 represents the optimal configurations, balancing enhanced heat transfer with manageable pressure drop.

Future possibilities

The integration of a small height V-shaped and various dimpled rib pattern configuration may prove beneficial in future investigations of solar Scheffler dish collector receiver tubes aligned with the flow direction to boost overall thermal performance. Further research is required on the synthesis of various type of nanoparticles with thermal oil as the base fluid to enhance the thermal and hydraulic performance of the solar Scheffler dish collector receiver tube system.

Data availability

Data will be made available on request.

Abbreviations

- \({D}_{tube}\) :

-

Diameter of solar receiver tube, mm

- \({DB}_{inlet}\) :

-

Diameter of inlet turbulence promoter, mm

- \({DB}_{outlet}\) :

-

Diameter of outlet turbulence promoter, mm

- \({DB}_{inlet}/{DB}_{outlet}\) :

-

Ratio of inlet to outlet turbulence promoter diameters

- \({f}_{ss}\) :

-

Friction factor for smooth tube

- \({f}_{TP}\) :

-

Friction factor for turbulent promoter

- \({G}_{b}\) :

-

Generation due to buoyancy, \({{m^{2} } \mathord{\left/ {\vphantom {{m^{2} } {s^{3} }}} \right. \kern-0pt} {s^{3} }}\)

- \({G}_{k}\) :

-

Generation of turbulent kinetic energy resulting from mean velocity gradients, \({{m^{2} } \mathord{\left/ {\vphantom {{m^{2} } {s^{3} }}} \right. \kern-0pt} {s^{3} }}\)

- \(k\) :

-

Turbulent kinetic energy, \({{m^{2} } \mathord{\left/ {\vphantom {{m^{2} } {s^{2} }}} \right. \kern-0pt} {s^{2} }}\)

- \({Nu}_{ss}\) :

-

Nusset number for smooth tube

- \({Nu}_{TP}\) :

-

Nusselt number for turbulent promoter

- \({P}_{\text{TP}}\) :

-

Pitch between turbulence promoters, mm

- \({P}_{\text{TP}}/{D}_{tube}\) :

-

Ratio of pitch to tube diameter

- \({Per}_{ID}\) :

-

Inlet turbulence promoter diameter, mm

- \({Per}_{OD}\) :

-

Outlet turbulence promoter diameter, mm

- \({Per}_{ID}/{Per}_{OD}\) :

-

Ratio of inlet to outlet promoter diameters

- \({Re}_{num}\) :

-

Reynolds number

- \({V}_{W}\) :

-

Velocity of working fluid, m/s

- \({Y}_{M}\) :

-

Contribution of fluctuating dilatation to dissipation rate, \({{m^{2} } \mathord{\left/ {\vphantom {{m^{2} } {s^{3} }}} \right. \kern-0pt} {s^{3} }}\)

- ε:

-

Dissipation rate of turbulent kinetic energy, m2/s3

- η:

-

Thermohydraulic performance parameter

- ρ:

-

Density of fluid, kg/m3

- μ:

-

Dynamic viscosity, Ns/m2

- μeff:

-

Effective (turbulent) viscosity, kg/m·s

References

Kalogirou, S. A., Karellas, S., Braimakis, K., Stanciu, C. & Badescu, V. Exergy analysis of solar thermal collectors and processes. Prog. Energy Combust. Sci. 56, 106–137. https://doi.org/10.1016/j.pecs.2016.05.002 (2016).

Ibrahim, A., Othman, M. Y., Ruslan, M. H., Mat, S. & Sopian, K. Recent advances in flat plate photovoltaic/thermal (PV/T) solar collectors. Renew. Sustain. Energy Rev. 15, 352–365 (2011).

Faizal, M., Saidur, R., Mekhilef, S. & Alim, M. A. Energy, economic and environmental analysis of metal oxides nanofluid for flat-plate solar collector. Energy Convers. Manag. 76, 162–168 (2013).

Ishak Bin, M. A. A. et al. Exergy performance of a reversed circular flow jet impingement bifacial photovoltaic thermal (PVT) solar collector. Case Stud. Ther. Eng. 49, 103322 (2023).

Al-Rashed, A. A. A. A., Alnaqi, A. A. & Alsarraf, J. Thermo-hydraulic and economic performance of a parabolic trough solar collector equipped with finned rod turbulator and filled with oil-based hybrid nanofluid. J. Taiwan Inst. Chem. Eng. 124, 192–204 (2021).

Kumar, A. et al. A review on exergy analysis of solar parabolic collectors. Sol. Energy 197, 411–432. https://doi.org/10.1016/j.solener.2020.01.025 (2020).

Chakraborty, O., Das, B., Gupta, R. & Debbarma, S. Heat transfer enhancement analysis of parabolic trough collector with straight and helical absorber tube. Ther. Sci. Eng. Progress 20, 100718 (2020).

Pandey, R. & Kumar, M. Efficiencies assessment of an indoor designed solar air heater characterized by V baffle blocks having staggered racetrack-shaped perforation geometry. Sustain. Energy Technol. Assess. 47, 101362 (2021).

Otanicar, T. P., Wingert, R., Orosz, M. & McPheeters, C. Concentrating photovoltaic retrofit for existing parabolic trough solar collectors: Design, experiments, and levelized cost of electricity. Appl. Energy 265, 114751 (2020).

Muñoz, J. & Abánades, A. Analysis of internal helically finned tubes for parabolic trough design by CFD tools. Appl. Energy 88, 4139–4149 (2011).

Manikandan, G. K., Iniyan, S. & Goic, R. Enhancing the optical and thermal efficiency of a parabolic trough collector—A review. Appl. Energy 235, 1524–1540. https://doi.org/10.1016/j.apenergy.2018.11.048 (2019).

Chang, C. et al. Enhanced heat transfer in a parabolic trough solar receiver by inserting rods and using molten salt as heat transfer fluid. Appl. Energy 220, 337–350 (2018).

Pandey, M., Padhi, B. N. & Mishra, I. Numerical simulation of solar parabolic trough collector with viscous dissipation in slits of arc-plug insertion. Sol. Energy 230, 810–824 (2021).

Tiwar, A. K., Kumar, V., Said, Z. & Paliwal, H. K. A review on the application of hybrid nanofluids for parabolic trough collector: Recent progress and outlook. J. Clean. Prod. https://doi.org/10.1016/j.jclepro.2021.126031 (2021).

Norouzi, A. M., Siavashi, M., Ahmadi, R. & Tahmasbi, M. Experimental study of a parabolic trough solar collector with rotating absorber tube. Renew. Energy 168, 734–749 (2021).

Abrofarakh, M. & Moghadam, H. Investigation of thermal performance and entropy generation rate of evacuated tube collector solar air heater with inserted baffles and metal foam: A CFD approach. Renew. Energy 223, 120022 (2024).

Byiringiro, J., Chaanaoui, M. & Halimi, M. Heat transfer enhancement of a parabolic trough solar collector using innovative receiver configurations combined with a hybrid nanofluid: CFD analysis. Renew. Energy 233, 121169 (2024).

Liu, P., Lv, J., Shan, F., Liu, Z. & Liu, W. Effects of rib arrangements on the performance of a parabolic trough receiver with ribbed absorber tube. Appl. Therm. Eng. 156, 1–13 (2019).

Bozorg, M. V., Coventry, J. & Torres, J. F. Thermal energy storage in a tightly packed bed with sodium as the heat transfer fluid: A numerical study. Appl. Energy 352, 121879 (2023).

Hassan, M. A., Al-Tohamy, A. H. & Kaood, A. Hydrothermal characteristics of turbulent flow in a tube with solid and perforated conical rings. Int. Commun. Heat Mass Transfer 134, 106000 (2022).

Sharaf, M. A. et al. Heat transfer enhancement in a double-pipe helical heat exchanger using spring wire insert and nanofluid. J. Therm. Anal. Calorim. 149, 5017–5033 (2024).

Abu-Hamdeh, N. H., Bantan, R. A. R., Khoshvaght-Aliabadi, M. & Alimoradi, A. Effects of ribs on thermal performance of curved absorber tube used in cylindrical solar collectors. Renew. Energy 161, 1260–1275 (2020).

Alnaqi, A. A., Alsarraf, J. & Al-Rashed, A. A. A. A. Effect of off-center finned absorber tube and nanoparticle shape on the performance of two-fluid parabolic solar collector containing nanofluid: An application of artificial neural network. Sustain. Energy Technol. Assess. 48, 101668 (2021).

Allam, M., Tawfik, M., Bekheit, M. & El-Negiry, E. Heat transfer enhancement in parabolic trough receivers using inserts: A review. Sustain. Energy Technol. Assess. https://doi.org/10.1016/j.seta.2021.101671 (2021).

Samiezadeh, S., Khodaverdian, R., Doranehgard, M. H., Chehrmonavari, H. & Xiong, Q. CFD simulation of thermal performance of hybrid oil-Cu-Al2O3 nanofluid flowing through the porous receiver tube inside a finned parabolic trough solar collector. Sustain. Energy Technol. Assess. 50, 101888 (2022).

Bashir, M. A. et al. Effect of phase change materials on the short-term thermal storage in the solar receiver of dish-micro gas turbine systems: A numerical analysis. Appl. Therm. Eng. 195, 117179 (2021).

Singla, M., Hans, V. S. & Singh, S. CFD analysis of rib roughened solar evacuated tube collector for air heating. Renew. Energy 183, 78–89 (2022).

Nallaperumal, T. N., Sellapandiyan, R. K., Vishnu, S. K. & Senthil, R. Numerical and experimental analysis of a cross-finned solar receiver for parabolic dish collectors. Appl. Therm. Eng. 248, 123329 (2024).

Pazarlioğlu, H. K., Tepe, A. Ü. & Arslan, K. Optimization of parameters affecting anti-icing performance on wing leading edge of aircraft. Eur. J. Sci. Technol. https://doi.org/10.31590/ejosat.1062495 (2022).

Pazarlıoğlu, H. K., Tepe, A. Ü. & Arslan, K. Thermohydraulic performance assessment of new alternative methods for anti-icing application against current application in an aircraft. Proc. Inst. Mechan. Eng. Part E: J. Process Mechan. Eng. 239, 1477–1493 (2025).

Sajjad, R. et al. CFD analysis for different nanofluids in fin prolonged heat exchanger for waste heat recovery. S. Afr. J. Chem. Eng. 47, 9–14 (2024).

Chekifi, T. & Boukraa, M. CFD applications for sensible heat storage: A comprehensive review of numerical studies. J. Energy Storage https://doi.org/10.1016/j.est.2023.107893 (2023).

Shaker, B., Gholinia, M., Pourfallah, M. & Ganji, D. D. CFD analysis of Al2O3-syltherm oil Nanofluid on parabolic trough solar collector with a new flange-shaped turbulator model. Theoret. Appl. Mechan. Lett. 12, 100323 (2022).

El-Sebaey, M. S., Ellman, A., El-Din, S. S. & Essa, F. A. Thermal performance evaluation for two designs of flat-plate solar air heater: An experimental and CFD investigations. Processes 11, 1227 (2023).

Breussin, F., Pigari, F. & Weber, R. Predicting the near-burner-one flow field and chemistry of swirl-stabilied low-Nox flames of pulveried coal using the RNG-k-ε, RSM and k-ε turbulence models. Sympos. Int. Combust. 26, 211–217 (1996).

Yakhot, V., Orszag, S. A., Thangam, S., Gatski, T. B. & Speziale, C. G. Development of turbulence models for shear flows by a double expansion technique. Phys. Fluids A 4, 1510–1520 (1992).

Yakhot, V. & Orszag, S. A. Renormalization group analysis of turbulence. I. Basic Theory J. Sci. Comput. 1, 3–51 (1986).

Dittus, F. W. & Boelter, L. M. K. Heat transfer in automobile radiators of the tubular type. Int. Commun. Heat Mass Transfer 12, 3–22 (1985).

Lorenzini, M., Morini, G. L. & Salvigni, S. Laminar, transitional and turbulent friction factors for gas flows in smooth and rough microtubes. Int. J. Therm. Sci. 49, 248–255 (2010).

Benoit, H., Spreafico, L., Gauthier, D. & Flamant, G. Review of heat transfer fluids in tube-receivers used in concentrating solar thermal systems: Properties and heat transfer coefficients. Renew. Sustain. Energy Rev. 55, 298–315 (2016).

Singh, H., Saini, R. P. & Saini, J. S. Performance of a packed bed solar energy storage system having large sized elements with low void fraction. Sol. Energy 87, 22–34 (2013).

Kline, S. & McClintock, F. Describing uncertainties in single-sample experiments. Mechan. Eng. 75, 3–8 (1953).

Luan, N. T. & Phu, N. M. Thermohydraulic correlations and exergy analysis of a solar air heater duct with inclined baffles. Case Stud. Therm. Eng. 21, 100672 (2020).

Singh, S., Suman, S., Mitra, S. & Kumar, M. Thermo-hydraulic performance enhancement of a solar air heater using rotating cylindrical turbulators. Appl. Therm. Eng. 236, 121748 (2024).

Acknowledgements

The authors express their gratitude to Prof. Kamil Urbanowicz from the West Pomeranian University of Technology in Szczecin, Faculty of Mechanical Engineering and Mechatronics, for his valuable suggestions to the work. The authors acknowledge the Ongoing Research Funding program, (ORF-2025-999), King Saud University, Riyadh, Saudi Arabia for this research project.

Author information

Authors and Affiliations

Contributions

Conceptualization, A.K. and R.K.; methodology, R.K. and N.K.; software, A.K.; validation, A.K., T.A. and R.K.; formal analysis, N.K. and M.I.H.S.; investigation, A.K.; resources, R.K. and N.K.; data curation, R.K. and N.K.; writing—original draft preparation, A.K. and D.D.; writing—review and editing, D.D.; supervision, D.D.; project administration, T.A. and D.D.; funding acquisition, D.D. and M.I.H.S. All authors have read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Kumar, A., Kunwer, R., Kanojia, N. et al. Thermal and hydrodynamic characteristics of Therminol VP-1 oil flow across perforated conical hollow turbulence promoter in Scheffler dish receiver tube. Sci Rep 15, 45720 (2025). https://doi.org/10.1038/s41598-025-28251-8

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-28251-8