Abstract

This study presents a comprehensive investigation into the free vibration behaviour and optimization of natural fibre-based laminated sandwich (NFLS) structures, with a focus on enhancing both damping capacity and structural stiffness. The NFLS beam consists of two isotropic elastic face sheets and a viscoelastic core reinforced with Jute–Polyurethane, a sustainable material offering favourable energy dissipation characteristics. Experimental modal analysis is conducted using the impact hammer technique to find the natural frequencies and modal loss factors. A detailed finite element model is developed incorporating shear and compressive damping effects, with the governing equations formulated through Hamilton’s principle. Numerical results shows that a strong agreement with experimental results, validating the accuracy and robustness of the proposed model. A parametric study is carried out to find out the effect of core thickness, skin thickness and core loss factor on the dynamic responses of the NFLS beam. Also, the Taguchi optimization method is used to identify the optimal configuration for maximizing the signal-to-noise (S/N) ratio. This analysis shows that a core thickness of 10 mm, a skin thickness of 2.5 mm, and a core loss factor of 0.8 gives the best combination for superior dynamic performance.

Similar content being viewed by others

Introduction

In recent years, natural fibre-based laminated sandwich (NFLS) structures have emerged as a promising solution for many engineering application due to their unique combination of sustainability, mechanical performance, and cost-effectiveness. Researchers and engineers have increasingly focused on these materials as industries seeks alternatives to synthetic composites to meet environmental and regulatory demands. NFLS structures offer distinct advantages, including excellent specific stiffness, high strength-to-weight ratio, and anisotropic properties, which allow engineers to tailor their mechanical behaviour to specific design requirements. Their lightweight nature, combined with superior energy absorption capabilities, makes them particularly attractive for industries where weight reduction and impact resistance are critical, such as aerospace, automotive, military, naval, and civil engineering sectors. In automotive parts, such composites not only reduce the mass of the component but also reduce the production cost by 80%1. Bio-based composite sandwich structures are compatible with the environment, their resources are renewable and also they are considered neutral toward CO2 emissions2. Davoodi et al.3 have designed the hybrid kenaf/glass fibre for the car bumper beam and evaluated their mechanical properties. Kumar et al.4 worked on the orthopaedic implant which is based on flax and ramie-reinforced green composites. The static and fatigue features of flax fibre-reinforced polymer structure with and without a scoop of the natural viscoelastic layer were deliberated by Mahi et al.5. Mohanty et al.6 studied the buckling and free vibration response of a viscoelastic core with a functionally graded sandwich plate under a temperature environment. Obada et al.7 introduced the coir and coconut husk powder-reinforced polymer composites and their viscoelastic properties. As the percentage of jute fibre in nonwoven composites increased, the magnitudes of the peak storage modulus and loss modulus improved8. Mohanty et al.9 concluded that the improvement in the melt viscosity by the addition of the sisal fibres and MAPP was an enhancement in the fibre-matrix adhesion properties. Thomas et al.10 examined the dynamic characteristics of natural rubber and short-coir fibre-reinforced composites. Genc11 proposed the alternative bio composite which was Luffa cylindrica and did their dynamic analysis. He found that the damping characteristics of Luffa cylindrica composite are better than those of glass fibre composite materials. Teimouri et al.12 optimized the 3D-printed sandwich beams incorporating auxetic cores via deep neural network. Four key design variables were considered: core thickness, width, and two specific geometric parameters related to the auxetic core–the cell’s wall thickness-to-length ratio and the cell angle. Sahu et al.13 adopted the ANFIS model to predict the first three modes of the natural frequencies of the carbon/basalt reinforced hybrid face layers and PET foam core-based skew sandwich plates. They observed that the natural frequency obtained through finite element simulation and ANFIS were very consistent to each other’s. Hadiji et al.14 experimented to calculate modal frequencies and damping factors of nonwoven natural fibre-reinforced polypropylene composites. The higher damping factors were observed in natural fibre-reinforced polymer composites as compared to glass-PP composites. By different chemical treatments, the adhesion between the natural fibres (jute, ramie, sisal, and curaua) and the polymer matrix can be improved15. Zhang et al.16 observed that bamboo/cotton hybrid composites are a worthy candidate for engineering-demanding applications with high bending strength, high damping and vibration quality. Acharya et al.17 presented the effect of stacking sequence on the tribological behaviour of jute-glass hybrid epoxy composite. Mohanty et al.18 proposed the mathematical formulation based on higher-order shear deformation theory in conjunction with Green-Lagrange-type geometric nonlinearity for functionally graded skew plates under thermal conditions.

Seifu et al.19 proposed new polymer composites consisting of sisal fibres and false banana (Ensete) as reinforcement. They have used linear low-density polyethene (LLD-PE) and low-density polyethene (LD-PE) as matrix and kaolin clay as a filler. Sahu et al.20 investigated the tensile, flexural and vibrational characteristics of the carbon/basalt fibre-based hybrid face layers and PET foam-based sandwich structures through experimental and numerical simulation. They obtained the highest natural frequency for carbon-basalt-basalt-carbon layup-based sandwich plates. Patel et al.21 proposed the hybrid Bauhinia-valid-weight/sisal (BVWS) and Bauhinia-valid-weight (BVW) fibre-reinforced hybrid composites. Balaji et al.22 manufactured the snake grass (SG) and banana fibre-reinforced polyester composites by hand layup method and tested their mechanical properties. They found that the tensile and flexural strength were improved with fibre volume fraction. The increase in density, toughness, tensile strength, and bending strength by the jute and glass fibre with epoxy23. Manral et al.24 the fabricated hybrid composite consists of jute/flax/PLA and obtained higher flexural strength and modulus while the flax/PLA composite possesses higher tensile strength. Arif et al.25 experimented to evaluate the drop weight impact hammer and flexural for different weight percentages of jute and glass fibre-reinforced epoxy composites. Yahaya et al.26 proposed Kevlar/Cocos nucifera sheath (CS)/epoxy composites with graphene nanoplatelets (GNP) to enhance their thermal and mechanical properties. GNP at various weight percentages (0.25, 0.5, and 0.75) were ultrasonically incorporated with epoxy resin. The properties of red banana peduncle fibre were enhanced by the chemical treatment and their Physico-chemical properties were studied by Pillai et al.27. Cavalcanti et al.28 characterized the novel hybrid composites by tensile, flexural and impact tests according to ASTM standards. Bavan et al.29 presented the mechanical and thermal stability of coir fibre epoxy hybrid composites with fly ash or TiC nanoparticles or both. The vibration and sound properties were investigated of kenaf/bamboo fibre-reinforced epoxy hybrid composites with different weight ratios of 30:70, 50:50 and 70:30 by Jawaid et al.30. Hybrid kenaf/bamboo composites had better tensile, vibration, and acoustic properties and relatively low void contents. Sathish et al.31 studied the mechanical and thermal aspects of Jute/Aloevera hybrid polymer composites. Marichelvam et al.32 developed the hybrid composite which is based on the palm sheath and sugarcane bagasse fibres. ASTM standards were used to evaluate the tensile, flexural, hardness, and impact properties.

Some recent research highlights advanced strategies for improving vibration resistance in composite structures. Studies on functionally graded coated honeycomb shells show enhanced damping and stability. Fiber-reinforced sandwich plates with viscoelastic square honeycomb cores effectively reduce vibrations through energy dissipation. Multi-objective optimization of graded composite shells achieves a balance between vibration suppression and weight reduction33,34,35.

Similarly other works focus on nonlinear vibration behavior in advanced composite and viscoelastic structures. Studies on all-composite honeycomb-core panels reveal strong nonlinear effects influenced by core geometry. Fractional viscoelastic plates show improved modeling of damping and energy dissipation. Research on composite conical-cylindrical shells with bolt looseness highlights nonlinear coupling due to joint imperfections36,37,38. Apart from these deterministic analysis, some other researcher worked on stochastic free vibration analysis of FGM and other materials39,40,41,42,43.

Despite increasing interest in sustainable sandwich composites, previous research has largely overlooked the detailed dynamic characterization and optimization of NFLS structures. Most existing studies either simplify the damping behaviour or neglect the combined effects of shear and compressive damping. Moreover, there is a lack of integrated experimental–numerical approaches that systematically explore the influence of key design parameters on both stiffness and damping performance. The present study addresses these gaps by combining experimental modal analysis with a finite element model that incorporates both shear and compressive damping mechanisms, enabling a more realistic representation of the structural dynamics. A comprehensive parametric study is undertaken to examine the effects of core thickness, skin thickness and core loss factor on the free vibration behaviour. Additionally, the Taguchi method is employed to optimize these variables for maximum dynamic performance. The novelty of this work lies in its holistic approach to characterizing and optimizing NFLS beams, offering validated insights and practical design guidelines for developing lightweight, high-damping, and eco-friendly structural components suitable for vibration-sensitive applications. In particular, this study uniquely integrates rheological modelling of natural fibre-based viscoelastic cores with design optimization through Taguchi analysis, establishing a direct link between material damping characteristics and structural performance. This combined framework provides a new pathway for designing next-generation bio-composite sandwich structures with tailored dynamic behaviour and sustainability.

Mathematical formulations

The mathematical formulations for the sandwich structures are explained in this section. Both the base beam and the constraining layer are modeled using Euler–Bernoulli beam theory and possess independent out-of-plane displacements. The linear interpolation between the constraining layer and base beam results in the viscoelastic layer’s transverse displacement. The shear and compression deformations are responsible for damping in the viscoelastic layer. The relative sliding between the layers is prohibited as there is perfect bonding between them.

Strain-displacement relations

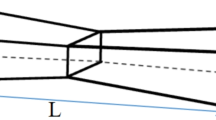

The longitudinal, transverse, and angular displacements are the primary variables for the sandwich beam. Fig. 1 depicts the undeflected and deflected conditions of the EVE sandwich beam. The mid-planes of layers are represented by the dashed lines. The main geometrical parameters have having following meanings: The length of the sandwich beam is L. The thicknesses of the constraining layer, base layer and viscous layer are\({t_c}\),\({t_b}\) and \({t_v}\) respectively; The constraining layer and base layer’s transverse deflection are measured as\({w_c}\)and \({w_b}\); \(\psi\)is rotation angle and \(\varphi\)represents a shear strain of viscoelastic layer; \({w_{c,x}}\)and \({w_{b,x}}\) are the rotational angle of the constraining layer and base layer respectively. The constraining layer and base beam are stiff and obey Euler-Bernoulli hypothesis also these have very low shear deformation.

(a) Undeflected (b) deflected configuration of the sandwich beam44.

The \({u^{\left( m \right)}}\)and \({w^{\left( m \right)}}\)are the axial and out-of-plane displacements at any point of the \({m^{th}}\) face layer as follows44.

The coordinate systems for sandwich beam44.

The bottom surface of the constraining layer in the z-coordinate is \({h_c}= - {{{t_c}} \mathord{\left/ {\vphantom {{{t_c}} 2}} \right. \kern-0pt} 2}\)and the top surface of the base beam in the z-coordinate is \({h_b}={{{t_b}} \mathord{\left/ {\vphantom {{{t_b}} 2}} \right. \kern-0pt} 2}\) (Fig. 2). The viscoelastic layer’s displacement at the top and bottom surface can be obtained by putting the values of hc and hb expressed as.

The mid-plane displacement of the viscoelastic layer in the longitudinal direction is expressed as follows:

Finite element formulations

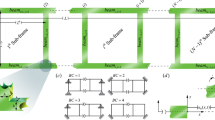

The finite element formulation of the sandwich beam element is done by discretizing the length of the beam into many line elements. Each element has two nodes and has six degrees of freedom per node and these are axial, out-of-plane and rotational displacement of the constraining layer and base beam layer Fig.3.

Free body diagram of sandwich beam element44.

The nodal displacement vectors \(\left\{ {{\delta ^e}} \right\}\) of beam elements with nodes \(i\) \(j\) are

The six displacements vector, \(\left\{ \delta \right\}={\left[ {\begin{array}{*{20}{c}} {{w_c}}&{{\theta _c}}&{{u_c}}&{\begin{array}{*{20}{c}} {{w_b}}&{{\theta _b}}&{{u_b}} \end{array}} \end{array}} \right]^T}\). The relationship between the nodal displacement vector and shape functions is given below.

Governing equation of motion

Hamilton’s principle in conjunction with the finite element method provokes equations of motion for the EVE sandwich beam element.

The global form of the equation of motion can be written as

Complex eigenvalue problem of the sandwich beam

Since the sandwich beam has a viscoelastic core, the global stiffness matrix has two components one is real and another is imaginary

For the viscoelastic model, the shear modulus\({G^*}\)of the sandwich beam can be expressed as

\({G_{real}}\) is the real part known as the storage modulus generally indicates the stiffness of the sandwich beam and the energy dissipation capacity of the beam is represented by the imaginary part (loss modulus \({G_{imaginary}}\)) and \({\eta _v}\)is the loss factor.

Thus, the governing equation of motion for the complex eigenvalue problem can be expressed as,

where, \(\left[ K \right]\)and \(\left[ M \right]\)denote the global stiffness and mass matrices, \(\left\{ \delta \right\}\)is the global displacement vector and \(\left\{ {{\omega ^*}} \right\}\)represents the complex eigenfrequency of the sandwich beam.

The modal frequency and modal loss factor of the sandwich beam are calculated by the following formula.

The NFLS beam is modeled using a self-developed MATLAB program based on the finite element formulation to analyze its natural frequencies and modal loss factors. The finite element procedure involves the following steps: (a) assigning material and geometric properties, (b) establishing the geometric relationships, (c) defining the shape functions, (d) computing the element-level mass and stiffness matrices, (e) assembling the global system matrices, (f) applying the appropriate boundary conditions, and (g) solving the resulting eigenvalue problem.

Experimental investigations

The sandwich beam specimens used in this study are fabricated with aluminum face sheets and a viscoelastic core made from a natural fibre-reinforced composite. The core material selected is Jute-Polyurethane, owing to its favorable combination of damping capability and environmental sustainability. Jute fibres are uniformly dispersed in a polyurethane matrix and cured under controlled conditions to form the viscoelastic core layer. After proper curing, the core layer is adhesively bonded between two aluminum face sheets using a high-strength epoxy adhesive. A commercial-grade epoxy system (Araldite AW106/HV953U) is used, which provides high interfacial strength and excellent resistance to dynamic loading. The adhesive layer, though very thin (~ 0.1 mm), ensures effective stress transfer between the aluminum face sheets and the viscoelastic core, thereby enhancing the overall stiffness and maintaining good damping efficiency of the structure. The bonding process is carried out under moderate pressure and ambient temperature to ensure uniform adhesion and dimensional accuracy. Care was taken to avoid voids and ensure consistent thickness across all specimens. The viscoelastic properties of the core material are determined through Dynamic Mechanical Analysis using the shear test configuration. The geometrical and material properties of the fabricated sandwich beams are summarized in Table 1.

To investigate the dynamic behavior of the sandwich beams, experimental modal analysis is performed using an impact hammer testing approach. The experimental setup used for vibration testing is depicted in Fig. 4. Structural excitation is applied through low-energy impacts delivered by a modal hammer. The roving hammer technique is adopted, wherein the hammer is moved sequentially across predefined impact points while the accelerometer remains fixed at a selected reference location. This technique allows multiple excitation points to be tested using a single fixed response location, effectively capturing the system’s transfer functions and enabling the accurate extraction of mode shapes and natural frequencies. It also minimizes measurement errors associated with mass loading that may arise from using multiple sensors. The response of the beam to each impact is recorded using the accelerometer mounted to measure the out-of-plane acceleration. The output signal from the accelerometer is passed to a data acquisition system, which processes the time-domain signals using Fast Fourier Transform to generate frequency response functions (FRFs). Modal testing is conducted using the PULSE LabShop software, which includes an integrated impact testing module. For each test configuration, five consecutive impacts are applied at each location to ensure repeatability and reliability of the FRFs. These FRFs are further analyzed using the MEscope software to extract key dynamic properties such as natural frequencies and modal loss factors. To ensure statistical reliability and minimize experimental uncertainties, three identical specimens are tested under the same conditions, and the average values of the measured dynamic responses are then considered for analysis.

Results and discussion

Validation of the proposed finite element model

First, a convergence study is conducted to determine the appropriate mesh size for the FEM model. Based on this study, the sandwich beam is discretized into 30 elements, and this mesh configuration is used consistently throughout the subsequent analyses. To validate the accuracy of the proposed FEM model, a benchmark study is performed using the material and geometrical properties reported by Arvin et al.45. The natural frequencies obtained from the present FEM model are compared with those available in literature. The comparative results, presented in Table 2, show excellent agreement across the first three modes. The minimal deviation between the two sets of results confirms the validity of the developed formulation.

Further validation is carried out by comparing the numerically predicted natural frequencies with those obtained from experimental modal analysis of the fabricated NFLS beam specimens. The comparison, summarized in Table 3, demonstrates a strong correlation between the experimental and the present FEM model results. The observed deviations are within acceptable limits, indicating the effectiveness of the modelling approach in replicating real-world dynamic behaviour. These findings confirm that the developed finite element model reliably captures both stiffness and damping characteristics of the natural fibre-based sandwich structures.

Parametric study

Effect of boundary conditions

The dynamic response of the NFLS beam is significantly influenced by the applied boundary conditions. In this study, the influence of three boundary conditions, Clamped-Free (CF), Simply-Supported (SS), and Clamped-Clamped (CC), on the natural frequencies and modal loss factors of the NFLS beam is analyzed, as illustrated in Figs. 5 and 6. The natural frequencies of the NFLS beam increase progressively from CF to SS to CC conditions. The CC configuration, being the most constrained, offers the highest stiffness, thereby resulting in the highest natural frequencies. The SS condition provides moderate constraint, leading to intermediate frequencies, while the CF configuration exhibits the lowest frequencies due to reduced structural restraint and higher flexibility. Conversely, the modal loss factors show an inverse trend. The CF condition yields the highest modal loss factors due to the larger deflection and shear strain in the viscoelastic core, which promotes greater energy dissipation. The SS condition results in moderate damping, while the CC configuration, due to limited deformation, produces the lowest loss factors.

Effect of core loss factors

This section presents the effect of the core loss factor on the dynamic response of the NFLS beam under clamped-free (CF) boundary conditions. As depicted in Fig. 7, a slight but consistent increase in natural frequencies is observed with the rise in core loss factor. This marginal increase can be attributed to the complex interplay between damping and stiffness, where the energy dissipation slightly alters the effective stiffness of the structure without significantly adding mass. In contrast, Fig. 8 shows a pronounced enhancement in modal loss factors as the core loss factor increases from 0.1 to 1.0. This trend highlights the improved energy dissipation within the viscoelastic core, leading to superior damping performance.

Effect of core-to-base layer thickness ratio

This section presents a detailed analysis of the effect of the viscoelastic core-to-base beam thickness ratio on dynamic responses of the NFLS beam under CF boundary condition. Figures 9 and 10 illustrate the variation of these dynamic characteristics, with the core-to-base layer thickness ratio represented along the horizontal axis, and the corresponding natural frequencies and modal loss factors plotted on the vertical axis. It is observed that the natural frequencies for all three modes decrease as the thickness of the viscoelastic core layer increases. This reductions in frequency is attributed to the reduction in overall stiffness of the structure due to the softer core material, while the added mass has a relatively lesser impact. In contrast, the modal loss factors initially increase with an increase in the core-to-base thickness ratio. This enhancement in damping is due to greater energy dissipation within the thicker viscoelastic core. However, beyond this optimal thickness ratio, the modal loss factors begin to decrease. This decline is likely due to a significant reduction in stiffness outweighing the damping contribution of the core, leading to less effective vibration energy dissipation.

Effect of constraining-to-base layer thickness ratio

This section investigates the effect of the constraining-to-base layer thickness ratio on dynamic responses of the NFLS beam under CF boundary condition. Figures 11 and 12 illustrate the relationship, with the thickness ratio plotted along the horizontal axis and the corresponding natural frequencies and modal loss factors on the vertical axis.

As the thickness of the constraining layers increases relative to the base layer, a consistent increase in natural frequencies is observed across all modes. This behaviours can be attributed to the enhanced bending stiffness provided by the thicker constraining layer, which reinforces the overall structural rigidity of the sandwich beam. However, a contrasting trend is observed in the modal loss factors, which exhibit a decreasing pattern with increasing constraining-to-base thickness ratio.

Taguchi method for optimization of performance parameters

Taguchi Method is a statistical technique used to optimise performance parameters. It focuses on robust design principles to ensure products resilient to variations in manufacturing or environmental conditions46. The Taguchi method provides a structured and efficient approach for optimizing performance parameters by focusing on quality, reducing variability, and improving robustness. It has gained widespread use due to its cost-effectiveness, simplicity, and ability to handle multiple factors simultaneously. The impact of various input parameters on the natural frequency of the hybrid laminated composite structures is investigated by analysis of variance (ANOVA) and signal-to-noise (S/N) ratio. The S/N ratio characteristics is categorized into three groups, each aligned with enhancing the key features: (1) higher values being preferable, (2) nominal values being optimal, and (3) lower values being advantageous. The performance characteristic remains more significant than the S/N ratio, irrespective of the specific performance attribute considered. For the present investigation, the higher is good principle is adopted for the natural frequency of the hybrid laminated composite structures. The mathematical expression of the S/N ratio for higher is good is expressed as follows47

Here, y represents the output response for a given combination of factor levels, and n denotes the number of responses corresponding to that combination. In Taguchi’s design method, all factors are varied simultaneously as per the design array and the responses are recorded. Table 4 shows the layout of the 25 experiments and Table 5 represents the input parameters with their levels.

Taguchi method is adopted to enhance the sandwich beam parameters on the larger is better criteria. For the present research work, L25 orthogonal arrays are employed to develop and analyze the dynamic performance of the sandwich beam. The dynamic performance such as natural frequencies and loss factors is influenced by core thickness, core loss factors and skin thickness. The S/N ratio of the dynamic performance of the sandwich beam is used to maximize “The Larger is Better” using Minitab 20. The natural frequencies and loss factor of the sandwich beam of L25 orthogonal arrays under CF, SS and CC are shown in Table 6.

Figures 13 and 14 present the S/N ratio analysis for the natural frequencies and modal loss factors of the NFLS beam, highlighting the effect of key input parameters, core thickness, skin thickness, and core loss factor. The results reveal that the maximum natural frequency is achieved under the optimal configuration of 10 mm core thickness, 2.5 mm skin thickness, and a core loss factor of 1.0. In contrast, the maximum modal loss factor occurs at the same core and skin thicknesses but with a core loss factor of 0.8, indicating a trade-off between stiffness and damping. Insights from Tables 7 and 8 further indicate that core thickness is the most influential parameter affecting both natural frequency and modal loss factor, while the core loss factor has comparatively less influence. These findings suggest that core geometry plays a dominant role in tuning the dynamic response of NFLS beams. The optimal parameter combination for achieving superior dynamic performance, balancing high natural frequencies with effective damping, is identified as a core thickness of 10 mm, skin thickness of 2.5 mm, and a core loss factor of 0.8. The surface plots illustrating the interaction effects on natural frequencies and modal loss factors are shown in Fig. 15.

Conclusions

This study presents a comprehensive investigation into the free vibration behaviour and optimization of NFLS beams incorporating a Jute–Polyurethane viscoelastic core. Both experimental and numerical method are used to characterize and predict the dynamic response of the NFLS beam. Experimental modal analysis, performed using the impact hammer technique, provided reliable data for natural frequencies and modal loss factors. A finite element model results showed excellent agreement with experimental observations, validating the model’s accuracy and robustness. The key findings of this study are summarized as follows:

-

1.

Boundary conditions strongly influence dynamics — Clamped-Clamped (CC) plates show the highest natural frequencies, while Clamped-Free (CF) plates exhibit the greatest damping due to higher core deformation.

-

2.

Increasing the core loss factor enhances damping with little impact on natural frequencies.

-

3.

A core-to-skin thickness ratio of 1.4 gives maximum damping before stiffness reduction lowers performance.

-

4.

Thicker constraining layers raise natural frequencies but reduce damping by limiting viscoelastic shear.

-

5.

Taguchi optimization determined the optimal setup as 10 mm core, 2.5 mm skin, and 0.8 loss factor.

Overall, this work provides valuable insights into the design and optimization of sustainable NFLS structures for vibration-sensitive applications. The validated model and findings can serve as a guideline for developing lightweight, high-performance, and eco-friendly sandwich composites with tailored dynamic properties.

Data availability

The datasets used and/or analysed during the current study available from the corresponding author on reasonable request.

References

Malkapuram, R., Kumar, V. & Negi, Y. S. Recent development in natural fibre reinforced polypropylene composites. J. Reinf. Plast. Compos. 28 No (10), 1169–1189 (2009).

Assarar, M., Zouari, W., Sabhi, H., Ayad, R. & Berthelot, J. M. Evaluation of the damping of hybrid carbon-flax reinforced composites. Compos. Struct. 132, 148–154 (2015).

Davoodi, M. M. et al. Mechanical properties of hybrid kenaf/glass reinforced epoxy composite for passenger car bumper beam. Mater. Des. 31 No (10), 4927–4932 (2010).

Kumar, S., Zindani, D. & Bhowmik, S. Investigation of mechanical and viscoelastic properties of flax- and ramie-reinforced green composites for orthopedic implants. J. Mater. Eng. Perform. 29 No (5), 3161–3171 (2020).

El Mahi, A. et al. Damage mechanisms characterization of flax fibers–reinforced composites with interleaved natural viscoelastic layer using acoustic emission analysis. J. Compos. Mater. 53 No (18), 2623–2637 (2019).

Joseph, S. V. & Mohanty, S. C. Temperature effects on buckling and vibration characteristics of sandwich plate with viscoelastic core and functionally graded material constraining layer. J. Sandwich Struct. Mater. 21 No (4), 1557–1577 (2019).

Obada, D. O. et al. Effect of variation in frequencies on the viscoelastic properties of Coir and coconut husk powder reinforced polymer composites. J. King Saud Univ. - Eng. Sci. 32 No (2), 148–157 (2020).

Karaduman, Y., Sayeed, M. M. A., Onal, L. & Rawal, A. Viscoelastic properties of surface modified jute fiber/polypropylene nonwoven composites. Compos. Part. B. 67, 111–118 (2014).

Mohanty, S. & Nayak, S. K. Dynamic and steady-state viscoelastic behaviour and morphology of MAPP treated PP/sisal composites. Mater. Sci. Eng., A. 443 No (1–2), 202–208 (2007).

Geethamma, V. G., Kalaprasad, G., Groeninckx, G. & Thomas, S. Dynamic mechanical behavior of short Coir fiber reinforced natural rubber composites. Compos. Part A: Appl. Sci. Manufac. 36 No (11), 1499–1506 (2005).

Genc, G. Dynamic properties of luffa cylindrica fiber reinforced bio-composite beam. J. Vibroeng. 17(4), 1615–1622 (2015).

Teimouri, A. et al. Design optimization of additively manufactured sandwich beams through experimentation, machine learning, and imperialist competitive algorithm. J. Eng. Des. 35 No (3), 320–337 (2024).

Sahu, D. P., Das, R., Prusty, J. K. & Mohanty, S. C. Frequency analysis of skew sandwich plates with polyethylene terephthalate foam-core and carbon/basalt fiber-reinforced hybrid face layers using ANFIS model and experimental validation 1–23 (Mechanics of Advanced Materials and Structures, 2024).

Hadiji, H. et al. Damping analysis of nonwoven natural fibre-reinforced polypropylene composites used in automotive interior parts. Polym. Test. 89, 106692 (2020).

Montalvão, D., Karanatsis, D., Ribeiro, A. M., Arina, J. & Baxter, R. An experimental study on the evolution of modal damping with damage in carbon fiber laminates. J. Compos. Mater. 49 No (19), 2403–2413 (2015).

Khalid, M. Y. et al. Developments in chemical treatments, manufacturing techniques and potential applications of natural-fibers-based biodegradable composites. Coatings 11(3), 293 (2021).

Acharya, S. K., Bera, T., Prakash, V. & Pradhan, S. Effect of stacking sequence on the tribological behaviour of jute-glass hybrid epoxy composite. Materials Today: Proceedings 28, 936–939 (2019).

Parida, S. & Mohanty, S. C. Thermoelastic vibration analysis of functionally graded skew plate using nonlinear finite element method. J. Therm. Stresses. 40 No (9), 1111–1133 (2017).

Seifu, B., Singh, B., Gutu, J. M. & Legesse, D. Mechanical behaviours of hybrid ensete/sisal fiber reinforced polyethylene composite materials for injection moulding. SN Appl. Sci. 2 No (5), 1–25 (2020).

Sahu, D. P., Das, R., Prusty, J. K. & Mohanty, S. C. Flexural and dynamic characterization of carbon/basalt hybrid laminated composite sandwich plates with PET foam core: a numerical and experimental approach.. Structures 72, 108204 (2025).

Kumar, S., Mer, K. K. S., Gangil, B. & Patel, V. K. Synergy of rice-husk filler on physico-mechanical and tribological properties of hybrid Bauhinia-vahlii/sisal fiber reinforced epoxy composites. J. Mater. Res. Technol. 8 No (2), 2070–2082 (2019).

Balaji, D. et al. Experimental investigation on mechanical properties of banana/snake grass fiber reinforced hybrid composites. Materials Today: Proceedings 42, 350–355 (2020).

Braga, R. A. & Magalhaes, P. A. A. Analysis of the mechanical and thermal properties of jute and glass fiber as reinforcement epoxy hybrid composites. Mater. Sci. Eng., C. 56, 269–273 (2015).

Manral, A., Ahmad, F. & Chaudhary, V. Static and dynamic mechanical properties of PLA bio-composite with hybrid reinforcement of flax and jute, Materials Today: Proceedings, Vol. 25, pp. 577–580. (2019).

Khalid, M. Y., Arif, Z. U., Sheikh, M. F. & Nasir, M. A. Mechanical characterization of glass and jute fiber-based hybrid composites fabricated through compression molding technique. Int.J. Mater. Form. 14 No (5), 1085–1095 (2021).

Jesuarockiam, N., Jawaid, M., Zainudin, E. S., Sultan, M. T. H. & Yahaya, R. Enhanced thermal and dynamic mechanical properties of synthetic/natural hybrid composites with graphene nanoplatelets, Polymers. Polymers 11(7), 1085 (2019).

Pitchayya Pillai, G., Manimaran, P. & Vignesh, V. Physico-chemical and mechanical properties of alkali-treated red banana peduncle fiber. J. Nat. Fibers. 18 No (12), 2102–2111 (2021).

Cavalcanti, D. K. K. et al. Mechanical characterization of intralaminar natural fibre-reinforced hybrid composites. Compos. Part. B: Eng. 175, 107149 (2019).

Kavya, H. M. et al. Effect of Coir fiber and inorganic filler on physical and mechanical properties of epoxy-based hybrid composites. Polym. Compos. 42 No (8), 3911–3921. https://doi.org/10.1002/pc.26103 (2021).

Ismail, A. S., Jawaid, M. & Naveen, J. Void content, tensile, vibration and acoustic properties of kenaf/bamboo fiber reinforced epoxy hybrid composites. Materials 12(13), 2094 (2019).

Chandramohan, D., Sathish, T., Kumar, S. D. & Sudhakar, M. Mechanical and thermal properties of jute/aloevera hybrid natural fiber reinforced composites, AIP Conference Proceedings, Vol. 2283, No. October. (2020). https://doi.org/10.1063/5.0024976

Marichelvam, M. K. et al. A novel palm sheath and sugarcane Bagasse fiber-based hybrid composites for automotive applications: an experimental approach. Polym. Compos. 42 No (1), 512–521. https://doi.org/10.1002/pc.25843 (2021).

Cao, J. et al. Optimal design of vibration resistance of fiber-reinforced composite sandwich plates embedded in a viscoelastic square honeycomb core. Appl. Math. Model. 137, 115731. https://doi.org/10.1016/j.apm.2024.115731 (2025).

Li, H., Cao, J., Han, J., Li, J. & Yang, Y. Dynamic modeling and vibration suppression evaluation of composite honeycomb hemispherical shell with functional gradient protective coating. Thin-Walled Struct. 202, 112066. https://doi.org/10.1016/j.tws.2024.112066 (2024).

Cao, J. et al. Multi-objective optimization for vibration suppression and weight reduction in composite sandwich shallow-spherical shells with functionally graded coating. Mech. Syst. Signal Process. 236, 113049. https://doi.org/10.1016/j.ymssp.2025.113049 (2025).

Xu, Z. et al. Nonlinear vibration characteristics of all-composite honeycomb-core sandwich panel: Theoretical and experimental investigation. Int. J. Struct. Stab. Dyn. https://doi.org/10.1142/S0219455426500045 (2024).

Amabili, M., Balasubramanian, P. & Ferrari, G. Nonlinear vibrations and damping of fractional viscoelastic rectangular plates. Nonlinear Dyn. 103 No (4), 3581–3609. https://doi.org/10.1007/s11071-020-05892-0 (2021).

Xu, Z. et al. Nonlinear vibration characteristics of fiber-reinforced composite thin-walled conical-cylindrical coupled shells under partial bolt looseness. Thin-Walled Struct. 209, 112874. https://doi.org/10.1016/j.tws.2024.112874 (2025).

Raturi, H. P., Kushari, S., Karsh, P. K. & Dey, S. Evaluating stochastic fundamental natural frequencies of porous functionally graded material plate with even porosity effect: a multi-machine learning approach. J. Vib. Eng. Technol. 12 No (2), 1931–1942. https://doi.org/10.1007/s42417-023-00954-0 (2024).

Vaishali, Kushari, S., Kumar, R. R., Karsh, P. K. & Dey, S. Sensitivity analysis of random frequency responses of hybrid multi-functionally graded sandwich shells. J. Vib. Eng. Technol. 11 No (3), 845–872. https://doi.org/10.1007/s42417-022-00612-x (2023).

Karsh, P. K., Mukhopadhyay, T. & Dey, S. A stochastic investigation of effect of temperature on natural frequencies of functionally graded plates, in Advances in Structural Engineering and Rehabilitation: Select Proceedings of TRACE 2018, pp. 41–53, Singapore: Springer Singapore. (2019). https://doi.org/10.1007/978-981-13-7615-3_3

Vaishali, Karsh, P. K., Kushari, S., Kumar, R. R. & Dey, S. Stochastic free vibration and impact responses of functionally graded plates: A support vector machine learning model approach. J. Vib. Eng. Technol. 11 No (7), 2927–2943. https://doi.org/10.1007/s42417-022-00721-7 (2023).

Karsh, P. K., Raturi, H. P., Kumar, R. R. & Dey, S. Parametric uncertainty quantification in natural frequency of sandwich plates using polynomial neural network, IOP Conference Series: Materials Science and Engineering, Vol. 798 No. 1, p. 012036, IOP Publishing. (2020). https://doi.org/10.1088/1757-899X/798/1/012036

Huang, Z., Qin, Z. & Chu, F. A compression shear mixed finite element model for vibration and damping analysis of viscoelastic sandwich structures. J. Sandwich Struct. Mater. 21 No (6), 1775–1798. https://doi.org/10.1177/1099636218794576 (2019).

Arvin, H., Sadighi, M. & Ohadi, A. R. A numerical study of free and forced vibration of composite sandwich beam with the viscoelastic core. Compos. Struct. 92 No (4), 996–1008 (2010).

Jacob, M., Francis, B., Thomas, S. & Varughese, K. T. Dynamical mechanical analysis of sisal/oil palm hybrid fibre-reinforced natural rubber composites. Polym. Compos. 27 No (6), 671–680 (2006).

Agrawal, T. et al. Optimization of engine performance parameters and exhaust emissions in compression ignition engine fueled with biodiesel-alcohol blends using Taguchi method, multiple regression and artificial neural network, Sustainable Futures, Vol. 2 No. September, p. 100039. (2020). https://doi.org/10.1016/j.sftr.2020.100039

Author information

Authors and Affiliations

Contributions

**Dhaneshwar Prasad Sahu** contributed to the experimental setup and execution of the modal analysis, data acquisition and interpretation of results.**J. Peter Praveen** was responsible for the formulation and validation of the finite element model.**Jagesh Kumar Prusty** supervised the numerical simulations and contributed to the parametric and optimization study using the Taguchi method.**Ramyaranjan Das** assisted in the design and fabrication of the natural fibre-based sandwich specimens and supported experimental work.**Pradeep Kumar Karsh** conceived the overall research idea, and contributed to final manuscript writing and editing.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Sahu, D.P., Praveen, J.P., Prusty, J.K. et al. Modal analysis and design optimization of natural fibre-based sandwich structures for enhanced damping and stiffness. Sci Rep 15, 44594 (2025). https://doi.org/10.1038/s41598-025-28325-7

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-28325-7