Abstract

To identify the root cause of the abnormal 186Hz vibration amplitude in Stand S4 of a cold rolling mill, this study analyzes the statistical characteristics of two distinct transverse hardness profiles across the strip width. The influence of both individual hardness distributions and their interaction with strip surface morphology on the amplitude frequency response of the Stand S4 is systematically investigated. A novel finite element simulation model is proposed to represent the spatially varying hardness distribution across the strip width, overcoming the limitations of conventional models that assume uniform or single-value hardness. The results demonstrate that the transverse hardness profile is a primary contributor to the excessive vibration at 186Hz. While surface morphology can amplify the vibration amplitude, the degree of amplification is modulated by the underlying hardness statistics. Specifically, the vibration amplitude exhibits a negative correlation with the mean hardness and a positive correlation with the standard deviation of hardness, highlighting the critical role of both average material properties and local non-uniformity in dynamic excitation.

Similar content being viewed by others

Introduction

In the cold rolling process, vibration issues significantly impact product quality and production efficiency, involving complex interactions among mechanical, hydraulic, and frictional interface effects. In recent years, researchers have conducted extensive studies on the vertical and horizontal nonlinear vibration characteristics of cold rolling mills, proposing various dynamic models to elucidate vibration mechanisms and explore effective control strategies. Existing research has demonstrated that multiple factors–including the stability of the friction coefficient, servo-valve dynamics, bearing excitation, structural clearance, and parameter matching–play crucial roles in system stability. Additionally, advanced signal processing methods and control algorithms have been introduced for vibration identification and suppression. These findings provide a robust theoretical foundation and technical support for enhancing the dynamic performance and reliability of cold rolling system.

Xing Lu has established a new model based on mixed lubrication theory, incorporating friction curve monotonicity analysis to determine the minimum friction coefficient. This advancement enables accurate predictions of friction balance in tandem rolling mills. This model supports the design of optimal rolling conditions to enhance mill stability and expand the friction stability range. The study identifies third-octave mode chatter (150–250 Hz) as a critical factor affecting strip quality and production efficiency, emphasizing the need for effective detection and early warning methods. An adaptive cuckoo search algorithm variational mode decomposition method was developed to accurately extract chatter components from noisy industrial data, effectively avoiding mode mixing and endpoint effects. Transfer entropy analysis enabled root cause diagnosis, revealing that tension fluctuations exceeding 20% during steady rolling serve as a reliable early warning indicator for chatter onset1,2. Yeau-Ren Jeng has conducted research indicating that the surface quality of cold-rolled aluminum sheets–characterized by low roughness and high gloss–is significantly influenced by the rolling parameters. A mixed lubrication model and experimental validation on a laboratory-scale cold mill system reveal that higher reduction rates and lower roll speeds improve surface finish. Specifically, a lower proportion of protrusion in the bearing area ratio correlates with increased surface gloss3. Lei Cao’s research reveals that work roll bending has the most significant effect on the critical speed of the mill, followed by intermediate roll shifting and intermediate roll bending. During vibration, rapid fluctuations in friction stress and the occurrence of negative forward slip intensify instability. Analysis of energy dissipation at the rolling interface clarifies the vibration mechanism, providing insights for chatter suppression4. Xiaofei Chen’s research demonstrates that random fluctuations can significantly affect the dynamic behavior of a four-roller cold rolling mill, inducing stochastic transitions and bifurcations under combined harmonic and random excitation. Theoretical analysis using averaging and stochastic averaging methods, validated by numerical simulations, reveals how noise influences system stability and response characteristics5. Xingdou Jia has established a mechanical-hydraulic coupled vibration model of a cold rolling mill with a thickness control system incorporating dynamic stiffness compensation, revealing its significant influence on mill vibration behavior. Simulation results show that different control modes alter the vibration response characteristics of the mill structure, with dynamic stiffness compensation effectively suppressing vibration under specific operating conditions. Adjusting the dynamic stiffness compensation system and optimizing rolling speed can reduce outlet strip thickness variation and improve both vibration control and product surface quality6. Although scholars have proposed advanced methods for identifying the causes of abnormal vibration amplitudes at specific frequencies in rolling mills, no simulation model has yet been developed to fully capture the stochastic characteristics of strip steel properties.

Chaofan Sun has investigated the stability of horizontal nonlinear vibrations in a four-high cold rolling mill, taking into account gyro-precession and roll eccentricity. He established the chaotic threshold using the Melnikov method, which was validated through fractal basin analysis. Bifurcation and Lyapunov exponent analyses reveal that increased horizontal force fluctuation reduces system stability, with significant parameter sensitivity when the fluctuation amplitude exceeds 3.5, indicating the need for stiffness adjustment. The research identifies optimal parameter pairs that allow for a balance between average horizontal force and eccentricity, offering theoretical guidance for enhancing the dynamic reliability and service stability of rolling mill systems7. Li Jiang has introduced fractional-order damping into a nonlinear horizontal vibration model of a cold rolling mill roller system, revealing new resonance phenomena under high- and low-frequency excitations. By analyzing the amplitude-frequency response and equilibrium points, it is found that the system exhibits single or double resonance depending on the fractional order, with critical resonance amplitudes influenced by both damping strength and fractional order8. Hongbin Zhang has established a vertical nonlinear vibration model of a precision cold rolling system that accounts for structural gaps and dynamic rolling forces. He employs the Magnus series method to accurately analyze the system’s bifurcation characteristics and chaotic behavior. Results reveal regions of bifurcation and chaos, including a transition from period-3 motion to chaos, which are critical for understanding instability mechanisms in cold rolling systems. By identifying optimal two-parameter matching regions involving structural gap and dynamic force, the research provides theoretical guidance for enhancing system stability and reducing vibration in cold rolling processes9. While existing models address various sources of vibration excitation, the combined role of spatially varying strip hardness and surface topography in driving abnormal 186Hz vibrations in the S4 stand has not been systematically studied.

Yujie Liu has identified backup roll bearings as a significant source of vibration in a five-stand tandem cold rolling mill. Field tests demonstrated a 30% reduction in vibration amplitude following the replacement of these bearings. A dynamic model of the four-row cylindrical roller bearing and the mill’s vertical system was developed, revealing that fault-free bearings can still generate periodic excitation and amplified vibrations through bifurcation mechanisms. The results also show that when multiple excitation frequencies are close, energy can be transmitted between different vibration modes, contributing to system instability. The study identifies 80 Hz vibrations in the top of the cold rolling mill and servo valve pressure during production, highlighting the need to understand their hydro-mechanical coupled vibration mechanism. Dynamic models of the valve spool, 8-DOF mill structure, and hydraulic system were developed, revealing that the dynamic characteristics of the servo-valve significantly influence system vibrations. By optimizing the servo-valve’s dynamic performance, the coupled vibrations can be effectively damped10,11. Li Li has established a nonlinear vertical vibration model for the working roll system based on dynamic rolling force. This model demonstrates that nonlinear stiffness has a significant impact on system stability, while increased damping reduces vibration amplitude and narrows the resonance region. Using averaging and singular value methods, the stability of the system under both autonomous and non-autonomous states is analyzed, leading to the design of an effective combined time-delay feedback controller. Simulation results confirm the controller’s ability to suppress large-scale vibrations by tuning control gain and time delay, offering theoretical support for vibration prediction and mill system design12. Qianyi Wang has established a dynamic rolling force optimization model that considers small vertical and horizontal displacements of the rolled strip. This advancement enhances the accuracy of rolling analysis by addressing variations in the rolling zone caused by mill vibrations. A coupled vertical–horizontal vibration model was developed using the dynamic rolling force model and lumped mass method, revealing that internal resonance triggered by similar excitation frequencies is a primary cause of roller distance vibrations. The results demonstrate that the optimized model effectively captures complex vibration patterns and shows high precision in analyzing coupled vibrations, providing a theoretical basis for vibration suppression through parameter adjustment and improved system design13. The development of finite element models that integrate real-world strip surface features–such as morphology and hardness variation–remains critical for bridging the gap between theoretical analysis and industrial vibration phenomena.

During on-site vibration monitoring of the S4 cold rolling mill, it was observed that significant vibrations were generated during the production of strip steel composed of cold rolling hot-rolled steel plate and strip intended for automotive structural applications (QStE420TM) with a specification of 0.5\(\times\)1300 mm. A comprehensive review of the batch production monitoring signal data revealed distinct amplitude and frequency characteristics associated with the operation of the S4 cold rolling mill, as shown in Fig. 1.

The results indicate that the vibration amplitude of the mill reaches its peak at a frequency of 186 Hz. Identifying the key factors influencing this vibration frequency has become a pressing priority, as it will provide essential theoretical support for the enterprise to optimize operational efficiency and reduce production costs.

S4 simulation modeling of a cold rolling mill

The modeling process for the Stand S4 of the cold rolling mill follows a systematic two-step methodology. First, thorough investigations were conducted to determine the spatial distribution of Vickers hardness across the width of the strip. This was accomplished by implementing a computational model to characterize the variation pattern of hardness within the strip’s width. Second, a comprehensive finite element-based structural model for the S4 mill stand was developed, incorporating detailed structural components and operational dynamics to accurately represent the system’s behavior under various loading conditions.

The first step

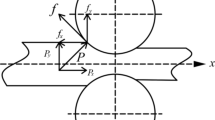

In this paper, we present a Vickers hardness measurement scheme for strips, designed to assess hardness along the width direction, as illustrated in Fig. 2.

The strip is divided into three sections: the operating side, the central and the drive side. Within each region, hardness measurements are taken at intervals of 1 mm, resulting in 200 measurement points per section (N=200). A total of two pieces of strip steel are evaluated; the first is referred to as Strip 1#, and the second as Strip 2#. Measured Vickers hardness of strips in the attached Excel files. The unit of the Vickers hardness measurements is HV.

The Vickers hardness values were analyzed using Gaussian statistical methods, and the corresponding mean values and standard deviations were calculated, as presented in Table 1.

As shown in Table 1, the first strip exhibits a lower mean Vickers hardness value but a higher standard deviation, whereas the second strip displays the opposite statistical characteristics. Although the strip steel samples are fabricated from the same material (QStE420TM) and possess identical nominal dimensions (0.5 × 1300 mm), significant variations in hardness are observed across the strip width. In such cases, identifying the underlying patterns of their collective influence on rolling mill vibration is essential for understanding and mitigating dynamic instabilities in the rolling process. The same strip is utilized for the operating side, the central and the drive side, with all sections being cut into equally spaced segments. Following the measurement process, each segment is further divided into smaller, uniformly spaced pieces.

The second step

The three-dimensional solid modeling of key components was conducted using SpaceClaim software, based on the structural drawings of the vertical system of the Stand S4 in the cold rolling mill. The modeled components primarily include the work rolls, intermediate rolls, backup rolls, work roll bearing housings, intermediate roll bearing housings, backup roll bearing housings, piston rods of the hydraulic cylinders, hydraulic cylinders, pads, and plaques. All of the aforementioned parts were assembled according to the design annotations provided in the drawings to accurately constrain the spatial relationships between the key components. The resulting three-dimensional structural model of the vertical system of the cold rolling mill is illustrated in Fig.3.

The positive direction of the X-axis (red coordinate axis) represents the operating side, while the negative direction corresponds to the drive side. The strip is subsequently cut along its width direction, as depicted in the spatial segmentation schematic of the finite element model shown in Fig. 3. The strip, divided into equal segments, is merged into a single part using DesignModeler software. This approach enables the assignment of individual hardness values to each segment while preserving the option to model the strip as a homogeneous entity.

The material properties of the key components in the vertical structural system of the cold rolling mill are detailed in Table 2. The unit of density is kg/m3, and the unit of elasticity modulus is GPa.

Since the actual measurement of strip surface topography includes numerous surface features, the strip mesh must undergo a two-dimensional surface stretching operation before analysis to generate a three-dimensional solid mesh model. This process ensures that the surface topography characteristics are represented as comprehensively as possible. Specifically, the element size is set to 0.01 in both the rolling and width directions, and 0.1 in the thickness direction. The mesh type is defined as a hexahedral element, and the mesh quality is controlled to be above 0.96. The final mesh model of the strip is shown in Fig. 4.

Figure 4 is divided into two parts. The upper section presents the mesh discretization of the strip surface morphology along the rolling direction. To balance computational efficiency and numerical accuracy, the mesh quality was optimized to approach unity. The lower section shows the overall mesh configuration of the strip surface employed in the numerical simulations. By using various meshing methods such as automatic tetrahedral, sweeping, multi-zone, and hexahedral mesh, the mesh quality of the vertical structural system of the cold rolling mill is 0.94. The holistic mesh model consists of a total of 142,628 elements and 492,786 nodes.

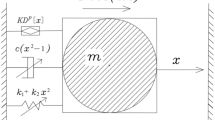

The Johnson-Cook constitutive model is employed to describe the material’s elastic-plastic response, with the yield stress expressed as a function of strain, strain rate, and temperature according to Equation 1.

where,

\(\varepsilon _{p}\) = effective plastic strain

\(\varepsilon _{p}^{*}\) = normalized effective plastic strain rate

\(T_{H}\) = homologous temperature = (T-\(T_{room}\))/(\(T_{melt} -T_{room}\))

The five material parameters A, B, C, n, and m are listed in Table 3.

Uniaxial tensile tests were conducted on QSTE420TM steel strip specimens to obtain stress-strain curves, which were fitted to the Johnson-Cook constitutive model to calibrate parameters A, B, and n via nonlinear regression. The remaining JC parameters (C, m) were established by cross-referencing commercial material databases and literature values for comparable high-strength steel(e.g. S460). The JC parameters were then assigned as a weighted average of Vickers hardness measurements across the first and second longitudinal sections, with spatially varying values for individual sub-segments determined proportionally based on their relative hardness ratios to the global average.

Set the tensile yield strength of the strip steel to 2.5 \(\times 10^8\) Pa; the compressive yield strength to 2.73 \(\times 10^8\) Pa; and the tensile ultimate strength to 4.96 \(\times 10^9\) Pa.

Model simulation analysis

The three-dimensional model of the vertical structural system of the cold rolling mill is imported into the geometric analysis module of the ANSYS Workbench simulation platform. To establish an effective simulation and analysis process, the finite element modeling procedure is followed, which includes geometric model simplification, contact definition, mesh generation, application of constraints, and setup of boundary conditions14. The simulation analysis is conducted under two distinct operating conditions. The first condition considers roll vibration excited solely by the transverse variation in strip hardness, assuming a smooth strip surface morphology (Fig. 3); this is referred to as Condition I. The second condition incorporates coupled excitation from both the transverse hardness variation and the actual measured surface morphology of the strip (Fig. 4), with the experimentally acquired topography superimposed onto the model; this is designated as Condition II.

Condition I

The simulation model was imported into ANSYS Workbench software to compute the vibration response of the cold rolling mill. A power spectral density contour plot of the overall structural vibration velocity for Stand S4 was generated to characterize the dynamic behavior of the rolling mill. Based on the simulation results, the vibration amplitude-frequency characteristics were further processed and analyzed using MATLAB. The structural vibration velocity response cloud diagrams for Strip 1# and Strip 2# are presented in Figs. 5 and 6, respectively.

From Figs. 5 and 6, applying the 3-sigma principle (corresponding to a 99.73% confidence level) to the vibration velocity response data reveals that the maximum structural vibration velocity amplitude of the rolling mill excited by Strip 1# reaches 3.7e10 mm/s, whereas the maximum amplitude under excitation by Strip 2# is 5.2e10 mm/s. Further analysis indicates that the transverse distribution of strip hardness significantly influences the dynamic response of the rolling mill, with notable differences in vibration magnitude attributable to variations in material uniformity across the strip width.

To investigate the amplitude-frequency characteristics and the influence of the random spatial distribution of strip hardness along the width direction on the structural vibration behavior of the vertical system in a cold rolling mill, the response characteristics at the central point on the upper surface of the lower work roll bearing seat were extracted using the post-processing tools provided by the software. The amplitude-frequency diagrams for the vertical system structure of the cold rolling mill for strips 1# and 2# are shown in Figs. 7 and 8, respectively.

As illustrated in Figs. 7 and 8, both strips induce a vibration frequency of 186 Hz in the vertical structural system of the cold rolling mill, which aligns with the vibration frequency recorded during field measurements. In addition to the dominant vibration component at 186Hz, an increase in the average hardness of the strip steel leads to a reduction in vibration amplitudes at 35Hz, 119Hz, and 296Hz, with the maximum amplitude decrease reaching approximately 50%. Conversely, the vibration amplitude at 164Hz exhibits a slight increase of 8%. Although the transverse hardness distribution of the strip induces multiple excessive vibration amplitudes, the vibrations at 35Hz, 119Hz, and 164Hz are primarily excited by strip caused morphology or longitudinal hardness variations along the rolling direction. Therefore, this study focuses on identifying the mechanisms responsible for the 186Hz vibration component14,15.

The 186Hz vibration amplitude decreases by 29% with increasing mean strip hardness, demonstrating a negative correlation. A further reduction is observed as the standard deviation of hardness decreases, revealing a positive correlation between vibration intensity and hardness variability.

Condition II

To more accurately represent the actual condition of the strip steel, a coupled analysis of surface topography and transverse hardness distribution was conducted to investigate their combined influence on cold rolling mill vibrations under the this specified operating condition. Simulation results for two distinct hardness distribution patterns were analyzed using the processing method for Operating Condition 1, producing the overall structural vibration velocity response of the cold rolling mill, as shown iin Figs. 9 and 10, respectively.

As shown in Figs. 9 and 10, the peak vibration velocity responses of the rolling mill under surface morphology superposition conditions are 3.7e13mm/s for Strip 1# and 6.13e5mm/s for Strip 2#. These results indicate that the vibration amplitude decreases with increasing mean strip hardness, demonstrating a negative correlation. Furthermore, the amplitude also decreases as the standard deviation of hardness decreases, revealing a positive correlation between vibration intensity and the spatial variability (non-uniformity) of hardness across the strip width.

Comparative analysis of Figs. 5, 6, 9, and 10 reveals that the combined effects of strip surface morphology and hardness distribution have a negligible influence on the vibration amplitude for Strip 1#. In contrast, for Strip 2#, the vibration amplitude is reduced by approximately five orders of magnitude, indicating a significant damping effect induced by the interaction of these material properties.

The vibration velocity characteristics of Strip 1# and Strip 2# from Stand S4 of the rolling mill under strip morphology superposition conditions are presented in Figs. 10 and 11, respectively.

As shown in Figs. 11 and 12, the amplitude of the 186Hz vibration component decreases by 34% with increasing mean strip hardness, indicating a negative correlation between vibration amplitude and average material hardness. In contrast, the amplitude also diminishes as the standard deviation of hardness decreases, revealing a positive correlation between vibration intensity and the degree of hardness non-uniformity across the strip. The 186Hz vibration velocity response results from Figs. 7, 8, 11, and 12 are summarized in Fig. 13, providing a comparative overview of the effects of strip hardness and surface morphology on the dynamic response of the rolling mill.

The 186Hz vibration amplitudes presented in Fig. 13 demonstrate that the inclusion of strip surface morphology amplifies the structural vibration response in all cases. For Strip 1#, the amplitude increases by over 8%, whereas for Strip 2#, the increase is less than 1%. These results suggest that the influence of surface morphology on vibration excitation is significantly attenuated under conditions of high and uniform strip hardness, indicating a negligible contribution to overall vibration amplitude in such scenarios.

Conclusion

This study investigates the excessive vibration amplitude observed at 186Hz in Stand S4 of a cold rolling mill, based on field measurements. The Vickers hardness of two steel strips (material: QStE420TM, specification: 0.5\(\times\)1300 mm) was measured and integrated with an established vertical structural dynamic model of the Stand S4. Using this coupled approach, the influence of transverse hardness distribution within individual strips, as well as the combined effects of hardness variation and surface morphology, on the vibration amplitude and frequency response of the mill structure was systematically analyzed. The key findings are summarized as follows:

-

(1)

A novel finite element simulation model for the spatial distribution of strip hardness along the width direction is proposed, overcoming the limitations of traditional methods that rely on a single, uniform hardness value for the entire strip.

-

(2)

This study investigates the influence of two distinct statistical characteristics of transverse strip hardness distribution on the vibration behavior of Stand S4 in a cold rolling mill. The results demonstrate that the spatial variation of hardness across the strip width is the primary factor driving the increased vibration amplitude at 186Hz.

-

(3)

This study investigates the combined influence of transverse hardness distribution and strip surface morphology on the vibration behavior of Stand S4 in a cold rolling mill. The results show that the inclusion of surface morphology amplifies the 186Hz vibration amplitude; however, the extent of this amplification depends on the statistical characteristics of the strip hardness. Notably, regardless of whether excitation is modeled under single or superimposed (morphology + hardness) conditions, the vibration amplitude exhibits a negative correlation with the mean hardness and a positive correlation with the standard deviation of hardness–indicating that both the average material property and its spatial variability significantly affect the dynamic response of the mill stand.

-

(4)

Through the investigation of the amplitude-frequency characteristics of the Stand S4 excited by the spatial distribution of strip hardness along the width direction, the study not only successfully reproduced the vibration phenomena observed in the field, but also identified additional frequency components with significant vibration amplitudes. These findings provide new insights and a theoretical basis for further research into the vibration mechanisms of cold rolling mills.

Data availability

The inconvenience in sharing the data arises from the following factors: (1) Vibration test data require specialized software and encrypted hardware for access, and their large volume significantly hinders efficient transmission; (2) To ensure the integrity and validity of the simulation results, the mesh discretization was performed using encrypted procedures, which complicates the transfer of simulation output files; (3) All data presented in this study have been archived with the corresponding author. For data access or collaboration, interested parties are encouraged to contact the corresponding author directly. Given the aforementioned constraints, the second and fourth options in the “Data Availability Statement” were deemed most appropriate and has been included in the manuscript.

References

Lu, X., Sun, J., Wei, Z., Li, G. & Zhang, D. Effect of minimum friction coefficient on vibration stability in cold rolling mill. Tribol. Int. 159, 106958 (2021).

Lu, X., Sun, J., Cheng, Q. & Zhang, D. Application of mill chatter component extraction and root cause diagnosis in the industrial cold rolling mill. Shock. Vib. 2024, 1109551 (2024).

Jeng, Y.-R., Lee, J.-T., Hwu, Y.-J., Liu, L.-C. & Lu, C.-Y. Effects of operation parameters of cold rolling on surface finish of aluminum. Tribol. Int. 148, 106321 (2020).

Cao, L., Li, X. & Zhang, D. Research into the effect of flatness control actuators on vibration stability in cold rolling using the finite element method. Int. J. Adv. Manuf. Technol. 125, 245–266 (2023).

Chen, X., Li, J. & Ma, J. Dynamical responses for a vertical vibration model of a four-roller cold rolling mill under combined stochastic and harmonic excitations. Probab. Eng. Mech. 73, 103480 (2023).

Jia, X., Wang, S., Yan, X., Wang, L. & Wang, H. Research on dynamic response of cold rolling mill with dynamic stiffness compensation. Electronics 12, 599 (2023).

Sun, C., Zhao, W., Huang, D. & Zhang, H. Stability of nonlinear vibrations induced by rolling force in a precise cold mill system. Appl. Math. Model. 119, 196–217 (2023).

Jiang, L., Wang, T. & Huang, Q.-X. Resonance analysis of horizontal nonlinear vibrations of roll systems for cold rolling mills under double-frequency excitations. Mathematics 11, 1626 (2023).

Zhang, H., Zhao, W., Huang, D., Sun, C. & Fan, J. Vertical nonlinear vibration analysis of cold rolling mill considering structural gap and dynamic rolling force. J. Manuf. Process. 108, 280–291 (2023).

Liu, Yu.-jie, Wang, Shen, Qi, Jie-bin & Yan, Xiao-qiang. Vibrations of tandem cold rolling mill: Coupled excitation of rolling force and variable stiffness of fault-free back-up roll bearing. J. Iron. Steel Res. Int. 30, 1792–1802 (2023).

Liu, Y., Wang, S., Qi, J., Wang, X. & Yan, X. Study on the influence of dynamic characteristics of servo valve on coupling vibration of cold rolling mill. Int. J. Precis. Eng. Manuf. 25, 1557–1570 (2024).

Li, L. & Zhong, C. Research on nonlinear dynamic vertical vibration characteristics and control of roll system in cold rolling mill. Sci. Rep. 14, 29503 (2024).

Wang, Q. Y., Zhang, Z., Zhang, L. K. & Tao, P. Coupled vertical-horizontal vibration characteristics of a cold rolling mill based on an optimized Karman differential equation. Iran. J. Sci. Technol. Trans, Mech. Eng. 48, 1745–1761 (2024).

Weiquan, S. et al. Random vibration study of cold rolling mill excited by different morphology of strip surface. Adv. Mech. Eng. 17, 16878132251339338 (2025).

Sun, W. et al. Random vibration study of cold rolling mill excited by different hardness of strip steel. Appl. Eng. Sci. 22, 100213 (2025).

Funding

No Funding.

Author information

Authors and Affiliations

Contributions

Weiquan Sun: Conceptualization, formal analysis, methodology, writing-original draft preparation. Xiaoqiang Yan: Project administration, supervision, writing-review and editing. Lirong Sun: Resource. Shen Wang: Software, validation. Zongqing Yan: Investigation. Yuchen Chen: Data curation. Weijing Yun: Visualization.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Sun, W., Yan, X., Sun, L. et al. Study on the transverse hardness distribution in strip-induced vibration of the Stand S4 cold rolling mill. Sci Rep 16, 1392 (2026). https://doi.org/10.1038/s41598-025-31129-4

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-31129-4