Abstract

Productivity prediction and dynamic description of carbonate gas reservoirs are very important to improving development efficiency. In this paper, we study the productivity evaluation and reasonable production allocation of the carbonate gas reservoir in the HS 4 block. Through gas test and production data, the dynamic productivity equation of a gas well is established using various equations. The influencing factors of productivity change are analyzed, and the main control effects of geological, engineering, and production factors on productivity are discussed. Based on the study of the main controlling factors of gas reservoir productivity, the one-point method is modified to establish the gas reservoir productivity equation, predict the new drilling productivity, and put forward reasonable production allocation suggestions. The seepage model of a single well and well group based on a fractured-vuggy gas reservoir is constructed, and the reservoir permeability characteristics of the gas reservoir are described in detail. Notably, this study innovatively modifies the traditional one-point method by classifying reservoir types (pore-type and fractured-vuggy) to establish targeted productivity equations, effectively addressing the accuracy limitations of single-method applications in complex carbonate gas reservoirs. Furthermore, the integrated use of grey correlation analysis, Pearson method, and fractured-vuggy seepage models realizes the comprehensive quantification of geological, engineering, and production factors on productivity, which fills the gap of lacking a unified and multi-method collaborative productivity prediction framework for such reservoirs in previous studies. The research shows that (1) The thickness and physical properties of fractured-vuggy reservoirs are positively correlated with gas well productivity, and the water production of gas wells is negatively correlated with productivity. (2) The modified one-point method and the dynamic model method can effectively predict the new drilling productivity and optimize the gas well production plan. (3) Wellbore pressure loss and near-well pressure loss are the main influencing factors of gas well productivity. (4) The analysis of the grey correlation method and the Pearson method shows that there is a significant correlation between geological, development, and engineering parameters and gas well productivity, which provides a basis for gas reservoir development.

Similar content being viewed by others

Introduction

Carbonate gas reservoir is one of the most important natural gas resources in the world, and its exploitation and development play an important role in the energy industry1. Due to the complex geological characteristics, heterogeneous reservoir structure, and complex seepage behavior of carbonate gas reservoirs, the application of traditional gas reservoir development methods and productivity prediction techniques in their development has certain limitations, especially in fractured-vuggy gas reservoirs. Gas well productivity is affected by many factors, such as geology, engineering, and production2,3. Therefore, it is very important for the rational utilization of resources and the economy of development to carry out research on the productivity prediction method of carbonate gas reservoirs and improve the development efficiency of gas reservoirs.

The productivity prediction and dynamic description of gas reservoirs are the basis for the efficient development. The core problem of productivity evaluation is how to accurately predict the productivity of gas wells and reveal the main controlling factors in the dynamic change process of gas reservoirs4. At present, the productivity prediction methods for carbonate gas reservoirs mainly include empirical formulas, productivity equations, numerical simulations, and dynamic models. Although these methods can reflect the productivity characteristics of gas reservoirs to a certain extent, there are still some errors and applicability limitations in dealing with complex reservoir structures and multi-factor effects. In addition, accurately evaluating the productivity change of gas wells at different development stages and determining a reasonable production allocation scheme are also important issues in gas reservoir development.

In recent years, with the progress of oil and gas field development technology, some progress has been made in the research of dynamic reserves evaluation, productivity prediction, and reasonable production allocation. Given the complexity of carbonate gas reservoirs, researchers have proposed a variety of productivity prediction methods suitable for different reservoir types and combined numerical simulation and dynamic model methods to gradually improve the accuracy of productivity prediction5. However, most of these studies focus on the discussion of theoretical models and the application of single methods, lacking a comprehensive analysis framework and a unified productivity prediction system suitable for different gas reservoir types.

Compared with published studies on carbonate gas reservoir productivity prediction, this work has two key innovations:

First, the traditional one-point method—widely used in productivity evaluation—adopts fixed empirical coefficients for all reservoir types in existing research, leading to large prediction errors in complex reservoirs. In contrast, this study modifies the one-point method by classifying reservoir types (pore-type and fractured-vuggy), which solves the poor adaptability of the traditional method to heterogeneous carbonate reservoirs, a gap in previous studies.

Second, most existing works rely on single methods to analyze productivity-influencing factors, failing to comprehensively quantify the combined effects of geological, engineering, and production parameters. This study innovatively combines grey correlation analysis and Pearson method to evaluate multi-factor correlations with productivity, and further integrates this analysis with fractured-vuggy seepage models. It also links the modified one-point equation with dynamic models to form an "evaluation-prediction-optimization" integrated framework for production allocation—an approach rarely reported in existing literature.

In this study, the carbonate gas reservoir in HS 4 block is taken as the research object. According to the geological characteristics and engineering technical characteristics of the gas reservoir, the research on gas reservoir productivity evaluation, reasonable production allocation and dynamic reserves evaluation is systematically carried out. Firstly, based on the gas test and production data, the dynamic productivity equation of gas well is established by using various equations, the main influencing factors of gas well productivity change are analyzed, and the main controlling factors in gas reservoir development are revealed. Secondly, although the traditional one-point method is widely used in gas reservoir productivity evaluation, its applicability and accuracy are often insufficient in the face of complex reservoir conditions. In this paper, an improved one-point productivity equation is established according to different reservoir types, and an improved gas reservoir productivity prediction method is proposed. Combined with the dynamic model method, the production allocation scheme of gas wells is optimized. Finally, by constructing the seepage model of single well and well group of fractured-vuggy gas reservoir, the characteristics of reservoir permeability are described in detail, which provides a theoretical basis for the dynamic description of gas reservoir.

Gas well productivity analysis and dynamic evaluation

Based on the analysis of gas test and production data, a variety of equations are used to calculate the open flow of gas wells, establish the dynamic productivity equation of gas wells, track and evaluate the productivity changes of gas wells, use the theoretical model to reveal the influencing factors of gas well productivity, analyze the influence of geology, engineering, and production, and clarify the main controlling factors of productivity6.

Basic concept and calculation method of gas well productivity

Typical productivity evaluation methods for gas wells include empirical formula method, productivity equation method, numerical simulation method and dynamic model method (Table 1). Different productivity equations and analysis methods are different in well type, data source and applicability. Combined with the characteristics of fractured-vuggy gas reservoirs, the binomial productivity equation in the form of pseudo-pressure has good applicability and can provide more reliable evaluation results7.

Typical gas well productivity evaluation analysis uses a variety of methods and equations to calculate the dynamic, open flow rate of the gas tests and production tests. Taking TS 4 well as an example, the technical process of productivity evaluation and reasonable production allocation analysis is expounded in detail.

Four working systems were tested, and the corresponding wellhead Pressure were 58.2 MPa, 55.9 MPa, 50.6 MPa, and 38.7 MPa, respectively, and the wellhead static pressure was 60.6 MPa. According to the pipe flow equation and the average parameters, the calculated bottom hole flow pressures are 69.82 MPa, 68.49 MPa, 65.54 MPa, and 62.41 MPa, respectively, and the converted bottom hole static pressure is 71.8 MPa. The open-flow capacity is 356–567 × 104m3/d, which is analyzed by the pressure-square method, pseudo-pressure method, binomial, and exponential open-flow capacity formula12. Finally, it is recommended to use the binomial productivity equation in the form of pseudo-pressure to calculate the open flow capacity, and the result is 445 × 104m3/d (Table 2) .

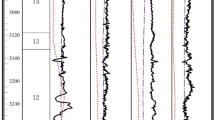

By using the pipe flow equation and the equilibrium parameter equation, the bottom hole flow pressure (Fig. 1) is converted, and the shut-in static pressure is calculated. The results show that the pressure drop per unit flow pressure and the cumulative gas production fluctuate significantly (Fig. 2), with an average of 0.26 × 108m3/MPa. The cumulative gas production per unit pressure drop in February 2024 is 0.44 × 108m3/MPa, and the cumulative gas production per unit pressure drop is 0.39 × 108m3/MPa.

In the gas test stage, the open flow capacity is slightly higher than that in the production stage, and it shows a downward trend after production. The open flow range of the gas test stage is 179–445 × 104m3/d, and the production stage is 329–301 × 104m3/d. The open flow capacity in the production stage is slightly lower than that in the gas test stage, which may be caused by the low flowback rate and the pollution at the bottom of the well.

One-point method open flow analysis, general one-point method productivity equation :

According to the data of 16 wells in 6 gas fields in China, Chen Yuanqian calcu-lated α = 0.25 and obtained the one-point productivity equation :

In the formula, QAOF is the open flow capacity of the gas well, 104m3/d; qg is the production of gas wells underground standard conditions, 104m3/d; α is the empirical coefficient; PD is dimensionless pressure; Pwf is bottom hole flowing pressure, MPa; Pe is formation pressure, MPa.

The open flow capacity calculated by the binomial formula of the productivity at the stable point is 304–267 × 104m3/d, which is gradually decreasing (Fig. 3) and has decreased by 12% so far. The reasons for the decrease in productivity are analyzed, mainly the decrease in formation pressure.

Numerical analysis method to calculate the current capacity : open flow 298–427 million square/day(cubic meters per day), recommended open flow value of 3.86 million square/day(cubic meters per day), numerical analysis method to calculate the current open flow: binomial method 298–386 × 104m3/d, exponential method 321–427 × 104m3/d.

Based on the comprehensive comparative analysis of multiple methods, the productivity equations of the gas test stage and the production test stage are determined. The open flow capacity in the gas test stage is 6.45 million square/day(cubic meters per day), and the open flow capacity in the production test stage is currently 4.05 million square/day(cubic meters per day) (Table 3).

Comparative analysis of gas well productivity: The gas well productivity in the production test stage is significantly lower than that in the gas test stage, and the productivity decreases significantly (Fig. 4). The average single well open-flow capacity of the block is 5.11 million square/day(cubic meters per day), and the production capacity in the production test stage (at present) is significantly lower than that in the gas test stage. The open flow rate in the gas test stage is 188–756 million cubic meters/day, with an average of 5.11 million cubic meters/day, and the open flow rate in the trial production stage (current) is 27–492 million cubic meters/day, with an average of 3.09 million cubic meters/day. At present, the average productivity of gas wells has decreased by 39%. The reasons for the decrease in gas well productivity include the decrease in formation energy and water production of gas wells.

The key factors that determine the productivity of gas wells and the stable production capacity of gas reservoirs are :

(1) Geology, engineering, development, and other aspects: common factors (geology): pressure, reservoir physical properties, fluid properties, skin factor (pollution, high-speed non-Darcy), supply radius, etc. ;

(2) Tight gas reservoir (geology): time-varying effect (transformation, stress sensitivity, and relative permeability, etc.), starting pressure gradient, physical properties, etc. ;

(3) Fractured-vuggy gas reservoir (geology): the development degree of cave and fracture, the development mode of fracture-vuggy body, the supply capacity of the matrix, etc. ;

(4) Non-uniform water invasion (development): too fast mining speed causes a series of problems, such as rapid water invasion of gas reservoirs, water-sealed gas, and increased water content, resulting in a decline in productivity ;

(5) Wellbore blockage (engineering) : reservoir sand production, wellbore scaling and other factors cause wellbore blockage, resulting in a decline in gas well productivity.

Gas well productivity influence and main control factor analysis

Wellbore pressure loss and near-well pressure loss are the key factors that directly affect the productivity of gas wells13,14,15,16,17. The larger the skin factor is, the more significant the non-Darcy flow effect is, resulting in an increase in near-well pressure loss and a significant decrease in gas well productivity (Fig. 5). At the same time, the decrease in the inner diameter of the production string and the increase of the relative density of the fluid will significantly increase the wellbore pressure loss (Fig. 6), further inhibiting the improvement of gas well productivity. These factors work together to determine the actual performance of gas well productivity.

Reservoir pressure loss is an inherent key factor in determining the productivity of gas wells, and some of these factors have certain controllability, such as optimization through reasonable well location deployment18. The reservoir pressure loss is mainly affected by the comprehensive influence of geological factors such as structural morphology, trap conditions, fault characteristics, reservoir development degree, and reservoir physical properties. These geological characteristics jointly determine the pressure distribution and productivity potential of gas wells (Fig. 7,8).

The main controlling factors of gas well productivity involve many aspects, including reservoir physical properties, thickness, type, transformation parameters, and production parameters19,20. In order to comprehensively analyze the influence of these factors, Grey Relation Analysis (GRA) is used to systematically study the correlation between 7 geological parameters, 3 development parameters and 2 engineering parameters and gas well productivity.

Grey Relation Analysis (GRA) is a method for analyzing the correlation between variables in ‘grey systems’ (systems with incomplete, small-sample, or uncertain data), which avoids the strict requirements of traditional statistical methods (e.g., large sample size, normal distribution) on data. The grey correlation analysis method is a multi-factor comprehensive statistical analysis method, which can effectively solve the uncertainty problem of influencing factors between multiple indicators and quantify the influence degree of each factor on gas well productivity (Fig. 9,10). Studies have shown that gas well water production, acid fracturing, reservoir thickness, and reservoir physical properties are important factors affecting gas well productivity.

By analyzing the influence degree of each factor, the following order is obtained :

Accumulative water production > acid fracturing fluid volume > gas layer thickness > flow back rate > porosity > saturation > well-controlled reserves > reservoir depth > cloud content.

Gas reservoir productivity evaluation and optimization

This section may be divided by subheadings. It should provide a concise and precise description of the experimental results, their interpretation, as well as the experimental conclusions that can be drawn.

Gas reservoir productivity equation and prediction analysis

In order to improve the accuracy and practicability of gas reservoir productivity evaluation, this paper improves the traditional one-point productivity equation (Table 4), and discusses the applicability of the classification reservoir type analysis method. Although the traditional one-point method is widely used in gas reservoir productivity evaluation, its applicability and accuracy are often insufficient in the face of complex reservoir conditions. Many scholars have improved the traditional one-point method to varying degrees, mainly by adjusting the model parameters in the equation or introducing reservoir heterogeneity factors to improve its accuracy. However, these improved methods generally have limitations, especially in the face of fractured-vuggy reservoirs or vuggy reservoirs, the traditional one-point method still has the problem of large prediction error. In recent years, some studies have tried to evaluate productivity by combining different reservoir types, but there is still a lack of comprehensive classification analysis of reservoir characteristics.

In order to overcome these shortcomings, this paper establishes an improved one-point productivity equation according to different reservoir types, and classifies and analyzes the applicability of productivity evaluation method and gas well allocation analysis method21,22. Based on 32 test data points of 9 gas wells, the coefficients of one-point productivity equation (Fig. 11) are optimized by regression analysis. Specifically, this paper improves the one-point productivity equations suitable for pore-type and fracture-pore-type reservoirs. Through regression analysis, combined with the characteristics of the reservoir, the key parameters in the equation are adjusted to better reflect the influence of reservoir heterogeneity on productivity, thus improving the accuracy of productivity evaluation23.

The "hole-type" in this table refers to "porous-vesicular reservoir" (a carbonate reservoir type with pores and isolated vesicles as the main storage space), not well type (vertical/horizontal wells). It is classified with "fractured-vuggy reservoir" to optimize the one-point productivity equation for different reservoir characteristics of the HS 4 block.

Reservoir heterogeneity in the HS 4 block (carbonate gas reservoir) mainly manifests in two aspects: reservoir type differentiation and spatial variation of physical properties, both of which are verified to directly affect gas well productivity through well test data and productivity equation optimization.

Through the improved one-point productivity equation and steady-state productivity equation, the open flow capacity of new drilling under different parameters is predicted. Taking the average parameters of the block as the basic parameters of the new drilling, according to the two reservoir types of hole type and Fractured-vuggy (Fig. 12), the relationship between reservoir permeability and open flow capacity is established respectively.

Based on the dynamic model and chart prediction, the productivity of new drilling under the condition of average parameters is as follows: vuggy reservoir: open flow capacity is 2.18 million square/day(cubic meters per day); fracture-vuggy formation: open-flow capacity is 4.05 million square/day(cubic meters per day).

Comparative analysis of reasonable production allocation of gas wells

The equations should be inserted in editable format from the equation editor.

At present, the gas well production is close to the reasonable production allocation level, but the overall gas reservoir production is still lower than the reasonable production allocation target. At present, 7 wells have been opened (Wells TS 401 and 402 are in shut-in state). The average single well production is 270,000 cubic meters per day, the average wellhead wellhead Pressure is 47.2 MPa, and the total daily gas production is 1.92 million cubic meters per day.

In order to further optimize the production efficiency of gas wells, it is recommended that the reasonable single-well production allocation interval is 10–40 million square/day(cubic meters per day), and the average single-well production allocation is recommended to be 283,000 square/day(cubic meters per day) (Fig. 13). After adjustment according to this scheme, the total daily gas production can reach 2.55 million square/day(cubic meters per day), which is about 33% higher than the current.

According to the comprehensive analysis results of gas wells, the following suggestions for dynamic work of gas reservoirs are proposed to optimize the development effect and improve the management level of gas reservoirs :

(1) Strengthen dynamic monitoring data acquisition: Continue to strengthen the dynamic monitoring of gas reservoirs and comprehensively acquire key dynamic data such as production pressure, flow rate, and water production rate to provide a reliable basis for subsequent analysis.

(2) Combined with monitoring data and reservoir characteristics, an in-depth study of reservoir permeability, reserves distribution, and heterogeneity characteristics identifies reservoir dominant areas and potential problems.

(3) Strengthen the adjustment of technical countermeasures and measures according to the dynamic development of gas reservoirs, adjust the development strategy in time, focus on pressure drop management, production optimization, and water-bearing gas well management, and improve development efficiency.

(4) Optimized multi-well well test design: pay attention to multi-well joint test in well test design, optimize the coordinated development of productivity test, pressure recovery test and interference test, so as to obtain more comprehensive dynamic data.

Analysis of dynamic reserves and water invasion characteristics of gas reservoirs

Dynamic reserves evaluation method

The dynamic reserve evaluation of gas reservoirs is usually based on the material balance theory, and the applicability of different methods varies with gas reservoir characteristics and development conditions (Table 5)24. Dynamic reserves refer to the cumulative gas production of gas wells calculated by the gas reservoir engineering method when the production rate is reduced to zero, and the formation pressure is reduced to 1 standard atmospheric pressure within the affected range, based on the production dynamic data such as production and pressure of single well or gas reservoir, under the condition that the existing technology and well pattern mining method are unchanged.

The accuracy of dynamic reserves evaluation results is determined by the applicability, reliability, and parameter values of the evaluation method, and the accuracy of parameter values is particularly critical, which directly depends on the comprehensive admission and analysis of pressure, water invasion, and dynamic monitoring data. The original formation pressure and comprehensive compression coefficient are the core parameters affecting the calculation results, and they need to be calibrated in combination with reservoir lithology, gas physical properties, and dynamic data. The dynamic change of pressure and the degree of water invasion play a decisive role in the distribution and calculation accuracy of reserves, which must be fully grasped through high-quality dynamic monitoring data25,26,27. Different evaluation methods need to match the characteristics of gas reservoirs and development stages. The empirical formula method is suitable for the early development stage but has low accuracy. The material balance method shows high applicability in the stable development stage. The numerical simulation method is suitable for complex gas reservoirs and has high accuracy but relies on high-quality data and model calibration. Only by scientifically selecting evaluation methods, accurately determining key parameters, and strengthening dynamic monitoring can the accuracy of dynamic reserves evaluation be improved and a reliable basis for gas reservoir development be provided.

Through the analysis of the dynamic reserves of the block, it is found that the characteristics of inter-well interference are obvious, and the degree of inter-well interference is about 12%. The superimposed dynamic reserves of the single well are 25 billion cubic meters, and the evaluated dynamic reserves of the well group are 22 billion cubic meters. The difference between the two is 3 billion cubic meters, and the ratio is about 1.2, which reflects the significant influence of inter-well interference on dynamic reserves.

Based on a variety of methods, the dynamic reserves of a single well control and well group are evaluated. The results show that there are great differences between wells: the dynamic reserves of a single well range from 2.6 to 6.26 billion cubic meters, a total of 25.04 billion cubic meters; the dynamic reserves of the well group range from 2.6 to 9.21 billion cubic meters, a total of 22.02 billion cubic meters (Table 6). The ratio of the single well superimposed dynamic reserves to the dynamic reserves of the good group after considering the inter-well interference is 1.14, and the difference is 3.02 billion square, which further verifies the existence and influence of the inter-well interference. Taking the HS 4–401-402 well group as an example, the ratio is 1.15, and the difference is 1.36 billion square; the ratio of the TS 4–401-402 well group is 1.21, and the difference is 1.66 billion cubic meters, all of which show a certain degree of inter-well interference (about 12%) (Table 6).

Inter-well interference has a certain impact on the evaluation results of dynamic reserves. It is necessary to strengthen the analysis of dynamic characteristics of well groups and the management of interference effects in the development process to improve the accuracy of reserves evaluation and the scientificity of development decisions.

At present, the dynamic and static reserves ratio of the block is 19.8%, indicating that the degree of reserve utilization is low. According to the data of proven geological reserves of natural gas reported in 2022, the total reserves of the block are 111.459 billion cubic meters, of which the reserves of the second member of the Maoshan Formation are 800.28 billion cubic meters, and the reserves of the second member of the Qishan Formation are 354.67 billion cubic meters. Through the evaluation of dynamic reserves, the current dynamic reserves controlled by the block are 22 billion cubic meters. Compared with the total geological reserves, the dynamic and static reserves ratio is 19.8%, indicating that the development and utilization rate is low.

At present, the block is mainly developed in the Mao 2 section, and 9 gas wells have been put into production (Fig. 14). According to the reserves analysis of the Maoer member, the dynamic and static reserves ratio is 27.5%, and the development degree is relatively high, but the overall reserves utilization rate still needs to be further improved.

Combined with the above analysis results, the overall reserves utilization degree of the block is low, especially the development and utilization of the reserves of the second member of Qigehai Formation has not been fully developed (Table 7). The development plan should be further optimized to improve the reserves utilization rate and provide support for the efficient development of gas reservoirs.

By investigating the dynamic model of water invasion and its theoretical basis, its applicable conditions and characteristics are analyzed22. The commonly used water invasion dynamic models include the Pod model, Schilthuis stable flow model, Hurst modified stable flow model, Van Everdingen-Hurst unstable flow model, Carter-Tracy unstable flow model, and Fetkovich model. These models provide important theoretical support for the dynamic analysis of water invasion in typical well groups. In the dynamic analysis of water invasion in typical well groups, the water breakthrough characteristics, water energy, and driving types of gas wells are mainly concerned.

According to the investigation, the types of water in the well group are divided into two categories: condensate water and formation water. Well, six mainly produces formation water, while other wells mainly produce condensate water. HS 6 well (Maokou formation and Qixia combination mining) obviously produces formation water. At present, the daily water production is 33 m3/day; the salinity range is 103.72–158.87 g / L, and the water–gas ratio is 7.9 m3/104m3. The average water–gas ratio of other wells is 0.1 m3/104m3, and the water production is mainly condensate water, which is characterized by a low water–gas ratio.

The water production changes of 9 wells were investigated and analyzed. It was found that only the formation water production of the HS 6 well was significant, and the water production of other wells was small and stable, which further indicated that the water production characteristics of this well were significantly different from other wells (Table 8).

Based on the calculation of the key parameters of water invasion in Well HS 6 ( well-controlled fracture-cavity unit ), the water body energy characteristics were systematically evaluated (Fig. 15 ). As an important index reflecting the relative relationship between water influx and natural gas expansion volume, the water drive index is a key parameter for gas reservoir classification, which reflects the influence of water influx on gas reservoir driving capacity. The water invasion replacement coefficient is used to calibrate the recovery rate, reflecting the relative relationship between the net water invasion and the residual gas expansion volume of the reservoir, which is an important basis for the recovery analysis. The calculation results show that the current water influx of Well HS 6 is 170,000 m3, and the dynamic water body multiple is 1.3, indicating that the water influx degree of the well-controlled fracture-cavity unit is more significant, and the water body energy plays an important role in driving the gas reservoir pressure and affecting the remaining gas productivity (Fig. 16). The above analysis provides a scientific basis for clarifying the dynamic characteristics of water invasion and optimizing the development strategy of gas reservoirs. At the same time, it is suggested that further monitoring of dynamic parameters and improving the evaluation method of water invasion energy are suggested to improve the accuracy and efficiency of gas reservoir development.

Combined with the key parameters of the HS 6 well (well-controlled fracture-cavity unit), the driving type and water body energy characteristics are systematically analyzed. The current water flooding index is 0.68, indicating that the gas reservoir has obvious elastic water flooding characteristics, and the water body plays an important role in driving the pressure recovery process of the gas reservoir. The water invasion replacement coefficient is 0.74, which further shows that the well is under the condition of an active water body, and the water invasion energy is strong, which has a significant substitution effect on the expansion volume of the remaining gas in the reservoir.

The comprehensive evaluation shows that the HS 6 well is a typical elastic water drive gas reservoir, with obvious strong water drive characteristics and strong water energy. The above analysis results provide a scientific basis for an in-depth understanding of the driving mechanism of gas reservoirs and optimizing the development plan. At the same time, it is recommended that water invasion dynamics and water body energy changes continue to be paid attention to in subsequent development to ensure the high efficiency and stability of gas reservoir development (Table 9).

Through the flow simulation experiment of the combined long core, the water invasion characteristics under different water body scales and physical conditions were systematically studied (Table 10, Fig. 17,18). The results show that in fractured-vuggy reservoirs, limited-scale water has a significant positive effect on gas reservoir energy supplement, which is helpful to maintain gas reservoir pressure and improve development effect. However, when the water body is too large, water invasion may aggravate the phenomenon of water channeling, resulting in a decline in gas reservoir development efficiency.

The experiment further reveals that there is a balance point between energy supplement and water channeling inhibition in finite-scale water bodies. Reasonable control of the water body scale is particularly important for the development of gas reservoirs in fractured-vuggy reservoirs. The above research provides an experimental basis for optimizing the development strategy of gas reservoirs and enhancing the energy management of gas reservoirs. At the same time, it emphasizes the need to formulate targeted development plans in combination with the specific physical conditions of the reservoir to achieve efficient development of gas reservoirs.

Conclusion

It should be noted that the models proposed in this study have specific limitations and acceptable conditions based on the HS 4 block’s characteristics: For the modified one-point productivity equation, it is only applicable to pore-type and fractured-vuggy carbonate reservoirs (consistent with the block’s main reservoir types) with ≥ 4 valid single-well gas test data (measurement error ≤ 3%), and cannot be used for tight carbonate reservoirs or those with insufficient test data. For the fractured-vuggy seepage model, it fits reservoirs with moderate heterogeneity (no isolated super-large vugs) and weak water invasion (water–gas ratio ≤ 8 m3/104m3, similar to most wells in the block except HS 6), but fails to describe extreme heterogeneity or severe water invasion scenarios. For the dynamic reserves and production allocation model, it is suitable for blocks with inter-well interference ≤ 15% (close to the block’s ~ 12%) and average single-well open flow ≥ 1.5 × 104m3/d; large errors may occur in blocks with severe interference or low formation energy.

Further development directions: 1) Expand the modified one-point method and seepage model to tight carbonate reservoirs, integrating machine learning to use multi-source data (e.g., real-time pressure) and reduce test data reliance. 2) Deepen water invasion-productivity model coupling based on long core experiments (Chapter 8) to study extreme conditions (high salinity/temperature). 3) Develop a field-oriented dynamic production allocation system linked to real-time monitoring28.

Practical significance: Solve poor adaptability of existing methods for multi-type carbonate reservoirs, guide targeted water control to reduce productivity loss, and improve the HS 4 block’s 19.8% reserve utilization rate and economic benefits.

(1) Productivity evaluation method: The pseudo-pressure binomial productivity equation is more applicable in the productivity evaluation of fractured-vuggy gas reservoirs. The reasonable production can be determined by dynamic model method, indication curve method and critical liquid carrying method. The dynamic reserve evaluation method based on modern numerical well test and material balance equation can more accurately characterize the complex dynamic characteristics of reservoirs and the influence of inter-well interference.

(2) Productivity change in the gas reservoir development stage: the open flow capacity of the gas well in the gas test stage is 5.11 million square/day(cubic meters per day), and the open flow capacity of the gas well in the production test stage decreases to 3.09 million square/day(cubic meters per day), and the productivity decreases by an average of 39%. This change is mainly caused by formation energy attenuation and gas well water production. The analysis shows that reservoir pressure loss, near-well pressure loss and wellbore pressure loss are the main determinants of gas well productivity.

(3) Analysis of influencing factors of productivity: The influence of multiple geological, development and engineering parameters on gas well productivity is analyzed by grey correlation method and Pearson method. It is clear that water production, acid fracturing, reservoir thickness and reservoir physical properties are the main controlling factors of productivity. Based on the dynamic model fitting, a reliable method for gas reservoir dynamic reserve evaluation and new drilling productivity prediction is proposed.

(4) Dynamic reserves evaluation: The results of dynamic reserves evaluation show that the dynamic reserves range of single well is 2.6–6.26 billion squares, and the dynamic reserves range of well group is 2.6–9.21 billion squares. There is a significant difference between single well superposition reserves and well group reserves, and the degree of interference is about 12%. Inter-well interference has an important impact on reserves assessment. Based on the dynamic characteristics of the reservoir and the development effect of the well group, it is suggested that the reasonable production allocation interval is 10–400,000 m3/d, and the average production allocation of single well is 283,000 m3/d.

(5) Analysis of water invasion influence: Through water invasion dynamic model and long core flow simulation experiment, the influence of water body energy on gas reservoir development is analyzed. Well 6 is a strong water drive gas reservoir, which proves that it belongs to elastic water drive gas reservoir. The results highlight the importance of dynamic monitoring of chloride concentration and risk management of water intrusion.

Data availability

The datasets used and/or analysed during the current study available from the corresponding author on reasonable request.

References

Wang, B. et al. Characteristics and main controlling factors of carbonate reservoirs in Qixia Formation, Longnvsi-Hechuan block, central Sichuan Basin. Nat. Gas Explor. Dev. 47(05), 64–75. https://doi.org/10.12055/gaskk.issn.1673-3177.2024.05.008 (2024).

Men, C., Zhang, Q. & He, S. Dynamic prediction model of horizontal wells in carbonate fractured-vuggy gas reservoirs. Sci. Technol. Eng. 13(17), 4783–4786. https://doi.org/10.12055/gaskk.issn.1673-3177.2024.03.002 (2013).

Niu, X. et al. Breakthrough and significance of natural gas exploration for Ordovician subsalt fracture-cavities in Ordos Basin. Acta Petrolei Sinica. 45(12), 1715–1727. https://doi.org/10.7623/syxb202412002 (2024).

Yang, X., Yan, W., Zhou, C. & Yin, S. Experiment-based reserve calculation for carbonate gas reservoirs: Taking X gas reservoir as an example. Nat. Gas Explor. Dev. 47(03), 12–22 (2024).

Guo, X. et al. Hydrocarbon accumulation and orderly distribution of whole petroleum system in marine carbonate rocks of Sichuan Basin SW China. Pet. Explor. Dev. 51(04), 743–758. https://doi.org/10.11698/PED.20240022 (2024).

Wang, L. et al. Investigation of productivity prediction model and influencing factors of ultradeep carbonate gas reservoir. Pet. Geol. Recov. Effic. 31(3), 88–98. https://doi.org/10.13673/j.pgre.202304030 (2024).

Liu, R., Zhang, W. & Leng, Y. Steady productivity evaluation method of fractured-porous carbonate gas reservoirs. Special Oil Gas Reserv. 29(02), 122–127. https://doi.org/10.3969/j.issn.1006-6535.2022.02.018 (2022).

Qiao, Z., Shuai, J., Dong, H., Ye, C. & Wang, Y. Establishment of dynamic one-point productivity equation in changxing formation gas reservoir of Yuanba. Nat. Gas Technol. Econ.. 8(05), 25–27. https://doi.org/10.3969/j.issn.2095-1132 (2014).

Lu, J., Tu, M., Liu, X. & Xiao, Q. Binomial productivity equation of stable point of water-producing gas well and its application. Sci. Technol. Eng. 16(06), 66–69. https://doi.org/10.3969/j.issn.1671-1815.2016.06.011 (2016).

Cheng, S., Li, J., Li, X., Yang, F. & Wang, Y. Using material balance-binomial productivity equation to calculate the dynamic reserves of gas wells. Xinjiang Pet. Geol. 26(02), 181–182 (2005).

Pan, Z. et al. Deviation analysis of binomial and exponential productivity equations for gas wells. Oil Gas Well Test 16(04), 8–9 (2007).

Martyushev, D. A. & Mordvinov, V. A. Productivity of wells at oil and gas field while reducing the bottomhole and formation pressure. Neftyanoe Khozyaystvo - Oil Ind. 1, 67–69 (2014).

Li, R., Yang, G. & Hu, Q. Study of production capacity of carbonate reservoirs with well logging in Ordos basin. Prog. Exp. Geophys. 02, 109–113 (2003).

Kang L. Flow Model and Productivity Prediction Methods of Typical Carbonate Gas Reservoir. China University of Petroleum. (2019).

Xia, Y. Water production regularity and productivity evaluation of carbonate gas reservoirs (China University of Petroleum, 2019).

Cai, J. et al. Present situation and prospect of productivity evaluation of key marine carbonate gas reservoirs in Sichuan Basin. Fault-Block Oil Gas Field 28(05), 655–660. https://doi.org/10.6056/dkyqt202105015 (2021).

Galkin, V. I. et al. Developing features of the near-bottomhole zones in productive formations at fields with high gas saturation of formation oil. J. Min. Inst. 249, 386–392 (2021).

Cheng, Y., Guo, C., Xing, Y. & Cheng, M. Study on the main controlling factors of single well productivity in complex carbonate bottom water gas reservoirs-Taking B gas field on the right bank of Amu Darya in Turkmenistan as an example. Sci. Technol. Eng. 16(36), 20–24 (2016).

Zhang, K., Yang, S., Zhao, X., Yan, Y. & Peng, X. Evaluation method of gas well productivity in early stage of strong heterogeneous carbonate gas reservoir development. Technol. Ind. 21(01), 231–234 (2021).

Chen, G. et al. A new method for optimal production allocation in low permeable and strongly heterogeneous carbonate gas reservoirs. Fault-Block Oil Gas Field. 31(01), 154–159. https://doi.org/10.6056/dkyqt202401019 (2024).

Tang, H., Huang, B., Liu, Z. & Yi, J. Study on dynamic optimization of gas well (reservoir) production allocation. Nat. Gas Ind. 18, 57–60 (1998).

Huang, X., Zeng, X. & Yang, Y. Dynamic evaluation method of reserves and analysis of influencing factors. Oil Gas Geol. Recovery https://doi.org/10.13673/j.cnki.cn37-1359/te.2003.02.006 (2003).

Rashid, M. et al. Reservoir quality prediction of gas-bearing carbonate sediments in the qadirpur field: Insights from advanced machine learning approaches of som and cluster analysis. Minerals 13, 29 (2023).

Li, Z., Qi, Z., Su, Y., Li, J. & Yan, W. Dynamic prediction model of edge-water gas reservoir based on water invasion early warning. J. Southwest Pet. Univ. (Sci. Technol. Edit.). 36(03), 87–92. https://doi.org/10.11885/j.issn.1674-5086.2014.02.13.05 (2014).

Yu, Q. et al. Research of mathematical model and influencing factors of water invasion performance for horizontal well in fractured-vuggy gas reservoirs with bottom water. Geoscience 31(03), 614–622 (2017).

Wu, T. et al. Water-invasion patterns and ways to deal with water in ultra-deep carbonate gas reservoirs with multiple fractures. Nat. Gas Exp. Dev. 46(03), 49–58. https://doi.org/10.12055/gaskk.issn.1673-3177.2023.03.006 (2023).

Feng, X. et al. Influence of reservoir heterogeneity on water invasion differentiation in carbonate gas reservoirs. Nat. Gas. Ind. 38(06), 67–75 (2018).

Ma, T. et al. Fully coupled thermo-hydro-mechanical model for wellbore stability analysis in deep gas-bearing unsaturated formations based on thermodynamics. Rock Mech. Rock Eng. 58, 33–64 (2025).

Funding

Chongqing Municipal Education Commission Science and Technology Research Plan Project (No.KJQN202301537); the General Program of Chongqing Natural Science Foundation (No.CSTB2022NSCQ-MSX1423); the General Program of National Natural Science Foundation of China (52274034); National Natural Science Foundation of China (Grant No.52174022 , Grant No.52074088 ); Development of western oil fields special project (Grant No.XBYTKT202001); Heilongjiang Province postdoctoral Research initiation project (LBH-Q21086); Basic Research Expenses of Heilongjiang provincial Colleges and Universities: Northeast Petroleum University Control Science and Engineering Team Special Project (2022TSTD-04); ‘Open bidding for selecting the best candidates’ Heilongjiang Province Science and Technology Research Project (DQYT-2022-JS-758); Open Project of National Engineering Laboratory for Exploration and Development of Low Permeability Oil and Gas Fields (KFKT2023-10).

Author information

Authors and Affiliations

Contributions

QX, YG: Writing–original draft, Writing–review and editing. YG, FF: Writing–review and editing. YG, FF, JZ: Formal Analysis, Methodology. YG, CX, WJ, HC: Writing–review and editing, Methodology. AS, XL, YX, SH: Writing–review and editing, Methodology.All authors reviewed the manuscript."

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Xu, Q., Gong, Y., Fang, F. et al. Productivity prediction, dynamic evaluation and reservoir heterogeneity analysis of HS 4 block carbonate gas reservoir. Sci Rep 16, 1650 (2026). https://doi.org/10.1038/s41598-025-31158-z

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-31158-z