Abstract

The Doubly Fed Induction Generator (DFIG)-based Wind Energy Conversion System (WECS) has gained significant attention due to its capability to operate efficiently over a wide range of wind speeds and in various modes. To enhance the performance and reliability of such systems, advanced control strategies are essential. This study introduces a Hybrid Fennec Fox–Sand Cat Optimization Algorithm (HFFSCOA) integrated with a Cascaded Adaptive Neuro-Fuzzy Inference System (ANFIS) for Maximum Power Point Tracking (MPPT) control of DFIG-based WECS. The proposed hybrid algorithm adaptively tunes ANFIS membership functions and parameters, improving its learning capability and ensuring accurate maximum power tracking with minimal oscillations. The coordinated control of the Rotor Side Converter (RSC) and Grid Side Converter (GSC) maintains a stable DC-link voltage and facilitates smooth power delivery to the grid. Moreover, d–q transformation is employed for harmonic suppression, enhancing overall power quality and ensuring compliance with grid standards. Simulation results in MATLAB/Simulink demonstrate the proposed controller’s effectiveness in minimizing active (Ps) and reactive (Qs) power fluctuations while achieving a remarkably low total harmonic distortion (THD) of 0.09%. Consequently, the proposed HFFSCOA-Cascaded ANFIS MPPT offers an intelligent, efficient, and scalable solution for sustainable wind energy systems seamlessly integrated into modern smart grids.

Similar content being viewed by others

Introduction

The production of toxic gases like\(\:{\:CO}_{2}\) and \(\:CO\:\) from fossil fuels contributes to environmental contamination and global warming. However, there are plenty of renewable resources that are widely available everywhere in the world1. Therefore, the best alternative to natural fossil fuels is renewable energy. The best approach to mitigate the issue of global warming and widely promote ecologically friendly energy is through renewable energy2,3. This emphasis on wind power is in accordance with the widespread acknowledgement that wind energy is an essential renewable resource because of its affordability, sustainability, cleanliness and environmental friendliness4,5. Vertical and horizontal axis wind turbines are the 2 categories of wind turbines6,7. Because they only require small converters, double-fed induction generator (DFIG)-based units are popular among different wind turbine (WT) technologies. This lowers costs in comparison to other variable speed WTs while maintaining the capability to independently control reactive and active power8,9.

Since a power electronic converter separates its rotating mass from the grid, DFIG is unable to use the kinetic energy that is naturally stored in its revolving masses to provide additional power10. The stator is attached to the grid, where the rotor winding is fed by a voltage source converter that utilizes pulse width modulation (PWM)11. Among the DFIG and the grid, the RSC keeps the flow of active and reactive power12. A faster response and lower steady-state error are demonstrated using an MPPT13 controller based on an Artificial Neural Network (ANN). In order to properly reflect wind speed variations, turbine features, and environmental factors, ANN models need large datasets14. Fuzzy logic15 monitors the system’s nonlinearity and produces the maximum output given the wind speed. The FLC approach enhances the fuzzy system’s membership parameters, enabling it to achieve the highest output power. Its intricate rule design necessitates precise tuning and in-depth domain knowledge to generate an efficient fuzzy rule base and membership functions, which take a lot of effort.

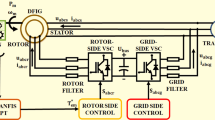

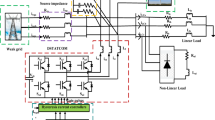

To raise the DFIG system’s performance, the MPPT is employed that has the ability to track the utmost power. An ANFIS16 that uses fuzzy logic in a sophisticated, networked ANN to make it easier to transform system inputs into desired outputs. Furthermore, the quality and diversity of training data have a significant impact on ANFIS performance; if the dataset is insufficient in capturing wind condition variability, the system is not be able to monitor the maximum power point, in rapid variations in wind speed. The metaheuristic algorithm is employed to increase the performance of MPPT approach. The robust global search ability of grey wolf optimization17 helps steer clear of local optima and guarantees highest power’s accurate tracking even in wind circumstances that change quickly. Minor power losses are result from oscillations near the ideal point. Fast convergence, fewer power fluctuations and improved energy capture efficiency are benefits of the crow search algorithm18. Particularly when used in real-time systems with constrained processing power, it is computationally demanding. Because of its well-balanced exploration and exploitation approach, the Equilibrium Optimizer Algorithm19 is effectively traverse intricate solution spaces without experiencing premature convergence. Real-time implementation in low-resource situations is hampered by its processing cost and the requirement for meticulous parameter tuning. The common block diagram of proposed DFIG system is depicted in Fig. 1.

When wind conditions changed, the Modified Golden Section20 has dynamic adaptation. Limited scalability in highly nonlinear or multi-variable systems is one of its disadvantages. High flexibility to nonlinear and changing wind circumstances, strong tracking capability and quick convergence speed are all features of the African Vulture Optimization21. Its performance is also susceptible to parameter adjustment, and instability or less-than-ideal tracking result from incorrect configuration. By reducing the searching space, the searching space minimization-PSO (SSM-PSO) scheme reduces the tracking time. Additionally, because of its straightforward searching mechanism, the SSM-PSO have reduced oscillation and is simple to implement. Under quickly shifting wind conditions, it is incapable to track the upmost power point due to premature convergence22. Significantly less oscillations, quicker transient response, more efficiency and enhanced speed tracking are the benefits of EVOA. Slow convergence is a problem for Energy Valley Optimization (EVO) in DFIG-based wind systems, especially when wind conditions change quickly23. To reduce sub synchronous torsional oscillations in series-compensated induction generator-based wind turbines, STATCOM-based damping controllers optimised using the Bacterial Foraging Optimisation Algorithm (BFOA) is developed in24. The Whale Optimisation Algorithm (WOA) have increased oscillation damping and system stability25. In order to preserve overall stability and control in multimachine power systems, hybrid wind-photovoltaic farms employed as static compensators26. Furthermore, sub-synchronous oscillations in DFIG-based wind farms have been effectively suppressed by damping controllers based on battery energy storage. Although these methods significantly improve certain aspects of wind power regulation, they frequently lack integrated solutions for real-time flexibility and optimal MPPT under quickly changing wind conditions27.

Due to their early convergence, susceptibility to parameter adjustment, and inadequate balance between exploration and exploitation, earlier hybrid controllers resulted in local optima and unstable MPPT tracking under different wind conditions. These problems are addressed by the HFFSCOA, which combines the fine local exploitation of the Sand Cat optimizer with the robust global search capability of the Fennec Fox algorithm. Faster convergence, improved stability, and avoidance of local minima are all guaranteed by this approach. Thus, the Hybrid Fennec Fox-Sand Cat Optimized Cascaded ANFIS MPPT control method is exploited in this research. The key objectives are:

-

The DFIG-based WECS is incorporated owing to its capability to function efficiently across an extensive range of wind speeds while ensuring grid compatibility.

-

To improvise the performance of DFIG system, the Cascaded ANFIS MPPT control approach is exploited, and its parameters are tuned by Hybrid Fennec Fox-Sand Cat optimization algorithm.

Proposed methodology

The turbine blades absorb wind energy, which is then conveyed via the gearbox to power the DFIG. By joining the DFIG’s stator directly to the transformer and subsequently to the grid, partial direct power is transferred. An RSC converts the AC to DC power and controls rotor currents, guarantee torque control and support reactive power. The RSC is controlled by a cascaded ANFIS MPPT algorithm that is tuned for hybrid Fennec Fox–Sand Cat, ensuring optimal power extraction in fluctuating wind situations. The DFIG-WECS’s block diagram is presented in Fig. 2.

Then, the GSC transforms this DC power back to a synchronized AC form to given into the grid. Between the GSC and the RSC, the DC-link capacitor keeps the steady voltage balance. Along with controlling the flow of reactive and active power, the GSC steadies the DC-link voltage. Harmonic distortions are reduced to electricity injection into the grid due to the addition of filters. The quality and stability of grid power are improved by GSC control. The transformer raises the voltage level for seamless grid integration and long-distance transmission. This hybrid control structure enhances the wind system’s efficiency, flexibility and dynamic performance.

DFIG based wind system

The DFIG is exploited to produce and deliver power in a constant frequency. Figure 3 displays the circuit for the DFIG in the \(\:d-q\) frame.

The self-inductance coefficients of rotor and stator side windings are represented by\(\:{L}_{r}\) and\(\:{L}_{s}\), whereas the rotor and stator’s resistances are indicated by \(\:{R}_{r}\:\)and\(\:\:{R}_{s}\). The mutual coupling coefficient among the rotor and stator sides is \(\:{L}_{m}\).

Here, \(\:{I}_{qs},{I}_{ds},{V}_{qs},{V}_{ds},{{I}_{qr},{I}_{dr},V}_{qr}\) and \(\:{V}_{dr}\) represents the current and voltage components of stator and rotor. It is assumed that the EM torque expression in the d-q frame as,

The reactive and active stator powers are,

The active and reactive rotors’ power are,

The number of pole sets is represented by p. The stator and rotor side current’s \(\:q\:and\:d\:\)components are \(\:{I}_{qs}\) and \(\:{I}_{qr}\) and stator voltage are \(\:{V}_{qs}\:\)and\(\:{V}_{ds}\). The EM torque and the stator and rotor side’s flux linkages are,

These flux and torque correlations serve as state equations in the optimization framework that connect the electrical behavior of the DFIG to the MPPT controller’s decision.

The control strategy utilizes a combination of RSC and GSC techniques to manage power flow and assure smooth incorporation by the grid. Subsequently, the regulation of RSC and GSC in DFIG based WECS is discussed in the next section.

Control of RSC and GSC

The RSC sustains DC-link voltage stability, where the GSC facilitates power transmission to the grid and regulates voltage.

Control of GSC

Figure 4 illustrates the GSC’s control system. The grid-side PWM converter’s vector-control strategy aims to regulate the flow of reactive power into the grid though sustaining a steady DC link voltage. By aligning the reference frame with the grid voltage position, it is possible to decouple the regulation of the reactive power flow and DC-link voltage among the grid and the GSC. The voltage balance between the across the inductor is,

Where, \(\:L\:and\:R\) denotes the inductance and resistance.

The active power and reactive power are,

The grid voltage’s angular position is,

Ignoring the switching-related harmonics as well as losses in the converter and inductor resistance, the DC-link voltage and current expressions are,

Reference values for the stator side converter is,

Where, the GSC’s reference values are denoted by \(\:{v}_{dl}^{*}\) and \(\:{v}_{ql}^{*}.\) The instantaneous power errors that are fed into the ANFIS-based MPPT controller are produced by these control loops.

Control of RSC

The structure of RSC control is displayed in Fig. 5. The actuation is provided by the rotor-side PWM converter. Since the stator is grid-connected and the stator resistance has no effect, the stator magnetizing current \(\:{i}_{ms}\) is regarded as constant. The stator and rotor flux expressions under stator flux orientation are expressed as,

The rotor flux expression as,

The reference voltage comprises,

The flux angle on stator is,

Where, the stator flux vector’s position is indicated by \(\:{\theta\:}_{s}.\) To raise the DFIG system’s performance, the HFFSCOA based cascaded ANFIS MPPT controller is utilized.

HFFSCOA based cascaded ANFIS MPPT controller

The HFF-SCO algorithm is presented to tune the cascaded ANFIS parameters, such as duty cycle adjustment, widths, rule weights, membership function centers and scaling gains to enhance accuracy and convergence speed. The ability of each pair of input variables to lower the Root Mean Square Error (RMSE) among the estimated and actual outcomes is evaluated in a consecutive feature selection process. For each pair, an ANFIS model with 2 inputs is trained and assessed. By contrasting the expected and actual results, the RMSE for each data pair is calculated. The specified optimization problem is,

Where, the input variables are indicted as\(\:{Z}_{1},{Z}_{2},{Z}_{3}\) and \(\:{Z}_{4}\), actual results is \(\:A\), predicted outcomes is P and sample size is \(\:N.\) Fuzzification, rule generation, normalization, defuzzification, and output are the five levels that make up each ANFIS in the two-stage hierarchical structure of the cascaded ANFIS MPPT controller. Gaussian membership functions with three MFs per input are used to process four important inputs rotor speed error, change in speed of rotor, DC-link voltage error, and change in active power. This results in 81 fuzzy rules. The final MPPT control signal is produced by refining the initial duty cycle produced by the first ANFIS. While the Sand Cat Optimization (SCO) offers global exploration capacity by imitating prey finding and attacking mechanisms utilizing adaptive auditory sensitivity, the Fennec Fox Optimization (FFO) guarantees powerful local exploitation by fine-tuning parameters through its digging and escape behaviours. By combining these two approaches, a balance between local and global searches is maintained, allowing the cascaded ANFIS MPPT controller to achieve strong tracking efficiency, minimal oscillations, and fast convergence. The FFO initializes all parameters of cascaded ANFIS-MPPT controller like as membership function centers, widths, rule weights, output scaling gains and the duty cycle factor by encoding them into candidate solutions. Each fox indicates a parameter set and is randomly located in the search space.

Here, the number of decision variables are denoted by \(\:m,\) total population of foxes are \(\:N\) and\(\:\:{ub}_{j}\) and \(\:{lb}_{j}\)are upper and lower bounds. The population matrix is,

Each row indicates a single fennec fox with a ANFIS parameter set whereas the each column corresponds to a candidate value of a specific parameter. The objective function is evaluated as,

In the exploitation phase of FFA, it refines the parameters by performing local search in the neighbourhood of each candidate solution. Every fennec fox indicates a membership function centers, widths, rule weights, output scaling gains and the duty cycle factor. The digging behavior fine tunes the parameters within a localized search radius assuring that the solution converges to the global optimum of MPPT. The local update of each parameter dimension is,

Where, the updated value of \(\:{j}^{th}\)parameter is \(\:{x}_{i,j}^{P1},\) adaptive search radius is \(\:{R}_{i,j}\) and random number is \(\:r\).

The flowchart of HFFSCO based Cascaded ANFIS MPPT controller is revealed in Fig. 6. Where, the total number of iterations are \(\:T.\) The update rule for new solution is,

Here, the new parameter set is \(\:{X}_{i}^{P1}\)and its fitness value is \(\:{F}_{i}^{P1}.\) In this phase, membership functions are shifted and resized, rule weights are adjusted, output scaling gains are more precisely tuned and duty cycle control step is refined. It assures that the MPPT parameters converge toward an accurate MPP under dynamic operating conditions. In the exploration phase, it improves the global search ability to evade being trapped in local optima while tuning the cascaded ANFIS parameters. It simulates the fox’s sudden change of position when escaping predators that corresponds to moving ANFIS parameter sets toward diverse regions of search space. The target position is randomly selected from the population as,

Where, the escape target is denoted by \(\:{X}_{i}^{rand}\) and selected parameter dimension is \(\:{x}_{i,j}^{rand}.\) The actual update of each parameter is,

Where, the random integer is denoted by \(\:I.\)

Here, the new parameter set is denoted by \(\:{X}_{i}^{P2}\) and its fitness function is \(\:{F}_{i}^{P2}.\) The algorithm efficiently explores the unexplored region of parameter space assures that the MPPT converge toward the global MPP rather than stuck in local solution.

In the initialization phase of SCO, each sand cat denotes a parameter of cascaded ANFIS MPPT controller. In the beginning, the positions of sand cats are randomly generated within their allowable limit to assure diversity in the search population.

Here, the lower and upper bounds are denoted by \(\:{d}_{j}^{max}\) and \(\:{d}_{j}^{min}\). This phase offers a diverse set of MPPT parameters where some sand cats indicate parameter sets with broader membership functions. In the exploration phase, the MPPT parameters are tuned by simulating the auditory based hunting ability of sand cats.

Where, the maximum number of iterations are \(\:{nter}_{max},\) maximum auditory sensitivity is \(\:SM\:\)and current iteration number is \(\:n.\:\) The efficient auditory range of each sand cat is randomized to sustain diversity in search space as,

It assures that distinct sand cats explore and exploit distinct neighbours of the MPPT parameter space. The exploration phase enables the algorithm to search broadly for global optima of MPPT parameters while the exploitation phase assures fine-tuning around the best solution. In the searching and attacking prey phase, the MPPT parameters are tuned based on the balance among the global exploitation and exploration.

Since R reduces with time, the algorithm transits from global searching to local attacking assuring a smooth convergence process. If \(\:\left|R\right|>1,\) it explores new regions of parameter space to avoid local optima.

Here, the cat’s current position is \(\:{d}_{c}\left(n\right)\) and new position is \(\:d\left(n+1\right).\:\) If \(\:\left|R\right|\le\:1,\) the cat switches to attack mode.

Where, the global best parameter set is \(\:{d}_{b}\left(n\right).\) The new position is updated as,

Here, the randomly selected angle is \(\:\theta\:\) permits the cat to approach the global best solution from multiple directions. In search mode, it diversifies candidate ANFIS MPPT parameters to prevent premature convergence while in attack mode, it exploits the neighbourhood of global best solution. It assures that the MPPT parameters quickly converge and yield high tracking accuracy in fluctuating environmental conditions. Combining these two approaches allows the algorithm to strike a compromise between local fine-tuning and global search, guaranteeing reliable ANFIS parameter optimization. By avoiding local optima and avoiding premature convergence, it iteratively converges toward the optimal parameter set with less computational cost. With fewer oscillations, this hybrid technique offers better steady-state accuracy, faster dynamic responsiveness and increased MPPT efficiency. In the end, robust grid integration, dependable maximum power extraction, and improved wind energy system performance are all guaranteed by the HFFSCO based cascaded ANFIS MPPT controller.

Result and discussions

The analysis of DFIG based WECS with HFFSCO algorithm based Cascaded ANFIS MPPT controller in in MATLAB/Simulink tool is added in this section. The parameters of specification are depicted in Table 1.

The waveform of wind system is presented in Fig. 7. The wind’s speed is stabilized at \(\:15\left({\text{m}/\text{s}}\right)\) while the rotor speed is maintained a steady value at\(\:1.2\left({\text{m}/\text{s}}\right)\), assures the synchronized operation with minimal fluctuations. Then, the torque has sustained at a less value and the pitch angle is gradually raised and settled at 5 rad, representing the active pitch control mechanism that regulates blade orientation to control power capture and defend the turbine.

The waveform of DFIG is illustrated in Fig. 8. The output current is sustained at 0.8 A, replicating effective current regulation and reduced harmonic distortion. Subsequently, the output voltage is maintained at 1 V, indicating the proper synchronization with the grid. The output voltage of PWM rectifier is randomly increased and settled at 600 V, endorsing effective DC-link regulation for power conversion.

Figure 9 depicts the waveform of grid. The grid’s voltage is stabilized at 320 V, denoting the stable voltage delivery in the system while grid’s current is randomly fluctuated in the beginning and maintained at 20 A, ensuring reliable power injection under varying dynamics.

The waveform of power is shown in Fig. 10. The real power is slowly increased and settled at 1000 W and reactive power is settled at a reduced value, indicating the reliable power transfer and strong grid compliance is attained.

The waveform of direct and quadrature axis current is represented in Fig. 11. The current of direct axis is reduced and sustained at 20 A, ensuring effective regulation of the reactive power. Consequently, the current of quadrature axis is suddenly increased and settled at less value, managing the active power flow.

Figure 12 reveals the waveform of reference and actual current. The reference current is gradually reduced and sustained at 20 V while the actual current has minimal deviation after the initial transient period and settled at 20 A, denotes the improved stability of DFIG system.

The waveform of grid under 7KW load condition is depicted in Fig. 13. The voltage of grid is maintained at 320 V and current of grid is settled at 10 A, representing the system maintains voltage stability at rated conditions and efficiently controls grid currents.

Figure 14 illustrates the waveform of power, and the real power is gradually raised and sustained at 1000 W with no oscillations and reactive power is settled at a small value that improves the performance of system.

Figure 15 reveals the waveform of direct and quadrature axis current, in which the current of direct axis is suddenly reduced and sustained at 10 A and current of quadrature axis is stabilized at a small value.

The waveform of reference and actual current is represented in Fig. 16. The reference current is maintained at 20 A while the actual current is suddenly reduced and sustained at 10 A throughout the system.

Figure 17 presents the waveform of grid under 9KW load conditions. The voltage of grid is sustained at 320 V throughout the system and current of grid is settled at 10 A with no oscillation in the complete system.

The waveform of real and reactive power is displayed in Fig. 18. The real power is slowly increased and stabilized at 1000 W, and reactive power is maintained at small value throughout the system.

Figure 19 presents the waveform of direct and quadrature axis current, in which current of direct axis is stabilized at 20 A while the current of quadrature axis is sustained at small value in the entire system.

The waveform of reference and actual current is displayed in Fig. 20. The reference current is stabilized at 10 A while actual current is sustained at 20 A throughout the system.

The waveform of THD is represented in Fig. 21. For the R, Y, and B phases, the suggested HFFSCOA–Cascaded ANFIS controller achieves THD values of 0.18%, 0.17% and 0.15%, well within IEEE and IEC limits. Therefore, the developed controller validates its efficacy and grid compliance by achieving a 94–98% reduction in harmonic distortion when compared to the IEEE 519 benchmark.

Higher oscillations and inadequate reactive power control are indicated by the ISMC approach with PS = 0.5 and QS = 0.71. With lower PS = 0.22 and QS = 0.26 values, the PPFC approach performs better, indicating improved dynamic response and partial stability, as seen in Table 2. But the best results are obtained by the proposed approach, which achieves PS = 0.07 and QS = 0.06, indicating fewer fluctuations and accurate power regulation, demonstrate that the developed controller maintains balanced power quality while improving the DFIG system’s stability and efficiency.

An analysis of Total Harmonic Distortion (THD) for several control strategies is depicted in Fig. 22. With a THD value of 3.26%, the DTC28 method exhibits the highest harmonic content and low power quality. The highest THD is attained by the IVC-ANFIS29 than others. The THD of 0.83% and 0.77% is attained by the Third Order Sliding Mode Control (TOSMC)30 and PPFC31 approaches significantly improve waveform quality and performance. However, the developed method’s greater capacity to minimize harmonic distortions is demonstrated by its lowest THD of 0.15%.

The analysis of tracking efficiency for methods used for MPPT in a DFIG system is shown in Fig. 23. With the lowest tracking efficiency of 89%, the AD-HCS32 approach and ADPO33 has 91%, shows its limitations in terms of maximizing power extraction under dynamic wind conditions. With an efficiency of 98%, the Adaptive MPPT34 approach outperforms the others, demonstrating better response while still need for improvement. With the highest tracking efficacy of 99.90%, the developed approach beats both and guarantees almost optimal power extraction from the wind system.

An analysis of response time for ISMC14, IVC –ANFIS29 and proposed approach is shown in Fig. 24, which reveals the proposed approach has the lowest response time of 0.015s, offers reliable incorporation into the grid.

The proposed approach is compared with PSO35 and BFO36 in terms of ITAE is displayed in Fig. 25. The ITAE for PSO and BFO and proposed approach are 582.48, 1.63 and 0.05, assures the upmost power is extracted from WECS.

The settling time analysis of two methods for managing the DFIG system is displayed in the Table 3. With id = 0.891 s and iq = 1.8 s, the settling times in the traditional MPPT approach37 are high, denoting a slower dynamic response. The developed approach has a notable improvement, obtaining significantly shorter settling times of id = 0.05 s and iq = 0.06 s. This notable decrease demonstrates the controller’s capacity for quicker convergence. It guarantees increased adaptation in a range of wind situations and enhanced transient performance. During transient conditions, the controller maintained a steady DC-link voltage and accurate MPPT tracking, with an output power deviation of less than 2%. The THD showed good harmonic suppression, staying below 0.2% even during abrupt load fluctuations. These findings reveals that the ANFIS parameters to system nonlinearities, guaranteeing grid stability, high tracking efficiency and robustness in real-time DFIG–WECS operation.

Conclusion

By combining a cascaded ANFIS-based MPPT approach with a HFFSCO algorithm, this paper presents a control mechanism for DFIG-based WECS. By constantly adjusting ANFIS parameters, it efficiently optimizes wind power extraction, leading to precise tracking and quick response in a range of wind conditions. The system guarantees balanced power flow and reliable operation by combining the GSC for active power supply and grid support with the RSC for reactive power and DC-link voltage stability. Grid current quality is further enhanced by the use of d-q based harmonic mitigation, which guarantees adherence to IEEE standards. The proposed approach performs better than traditional control schemes in terms of power extraction efficiency, harmonic reduction and grid support capabilities, according to simulation data from MATLAB/Simulink tool with lowest THD of 0.15%. It reveals an improved dynamic stability during disturbances and high adaptability to wind changes. Because several parameters must be tuned simultaneously, the HFFSCOA- cascaded ANFIS controller has a high computational load, which could make real-time implementation difficult. ANFIS’s broad parameterization raises the possibility of over fitting, especially when training data is sparse or noisy, which could impede generalization under different wind and grid conditions. Although the optimization increases accuracy and convergence, it need a lot of iterations, which would increase runtime and energy usage.

Data availability

The datasets used and/or analysed during the current study available from the corresponding author on reasonable request.

References

Sami, I. et al. Nasim Ullah, and JongSuk Ro. Convergence enhancement of super-twisting sliding mode control using artificial neural network for DFIG-based wind energy conversion systems. IEEE Access. 10, 97625–97641 (2022).

Babu, D. et al. IoT interfaced improved smart P&O MPPT assisted PV-wind based smart grid monitoring system. In 7th International Conference on Circuit Power and Computing Technologies (ICCPCT), vol. 1, pp. 1078–1084 (IEEE, 2024).

Sahri, Y. et al. New intelligent direct power control of DFIG-based wind conversion system by using machine learning under variations of all operating and compensation modes. Energy Rep. 7, 6394–6412 (2021).

Bessy, T. C. et al. Optical, structural, morphological, antibacterial, and photodegradation characteristics of Ba x Mg0. 8 − x Fe2O4 (x = 0.2, 0.4, and 0.6) nanocrystalline powders synthesized by combustion method. Phys. Status Solidi (a) 219(24), 2200366 (2022).

Likhitha Chowdary, N. & Surya Kalavathi, M. Enhancing the performance of integrated solar wind and battery system with grid using fuzzy based MPPT. Int. Trans. Electr. Eng. Comput. Sci. 3 (4), 163–172 (2025).

Priyadarshi, N., Bhaskar, M. S. & Almakhles, D. A novel hybrid whale optimization algorithm differential evolution algorithm-based maximum power point tracking employed wind energy conversion systems for water pumping applications: Practical realization. IEEE Trans. Ind. Electron. 71(2), 1641–1652 (2024).

Kavin, K. S., Subha Karuvelam, P., Devesh Raj, M. & Sivasubramanian, M. A novel KSK converter with machine learning MPPT for PV applications. Electr. Power Compon. Syst. 1–19 (2024).

Anil, N. et al. FOPID controlled indirect matrix converter for wind energy conversion system. In 7th International Conference on Circuit Power and Computing Technologies (ICCPCT), vol. 1, pp. 1097–1102 (IEEE, 2024).

Priyadarshi, N., Padmanaban, S., Bhaskar, M. S., Blaabjerg, F. & Sharma, A. Fuzzy SVPWM-based inverter control realisation of grid integrated photovoltaic‐wind system with fuzzy particle swarm optimisation maximum power point tracking algorithm for a grid‐connected PV/wind power generation system: hardware implementation. IET Electr. Power Appl. 12 (7), 962–971 (2018).

Priyadarshi, N., Sharma, A. K. & Azam, F. A hybrid firefly-asymmetrical fuzzy logic controller based MPPT for PV-wind-fuel grid integration. Int. J. Renew. Energy Res. (IJRER). 7 (4), 1546–1560 (2017).

Vardia, M., Priyadarshi, N., Ali, I., Azam, F. & Bhoi, A. K. Maximum power point tracking for wind energy conversion system. In Advances in Greener Energy Technologies 631–640 (Springer Singapore, 2020).

Priyadarshi, N., Padmanaban, S., Ionel, D. M., Mihet-Popa, L. & Azam, F. Hybrid PV-wind, micro-grid development using quasi-Z-source inverter modeling and control—experimental investigation. Energies 11(9), 2277 (2018).

Priyadarshi, N., Ramachandaramurthy, V. K., Padmanaban, S. & Azam, F. An ant colony optimized MPPT for standalone hybrid PV-wind power system with single Cuk converter. Energies 12(1), 167 (2019).

Chojaa, H. et al. Integral sliding mode control for DFIG based WECS with MPPT based on artificial neural network under a real wind profile. Energy Rep. 7, 4809–4824 (2021).

Karthikeyan, S. & Ramakrishnan, C. A hybrid fuzzy logic-based MPPT algorithm for PMSG-based variable speed wind energy conversion system on a smart grid. Energy Storage Sav. 3 (4), 295–304 (2024).

Mehta, M. & Mehta, B. Control strategies for grid-connected hybrid renewable energy systems: Integrating modified direct torque control based doubly fed induction generator and ANFIS based maximum power point tracking for solar PV generation. e-Prime-Adv. Electr. Eng. Electron. Energy 8, 100575 (2024).

Rashmi, G. & Mary Linda, M. A novel MPPT design for a wind energy conversion system using grey wolf optimization. Automatika: časopis za automatiku, mjerenje, elektroniku, računarstvo i komunikacije 64, no. 4 : 798–806. (2023).

Smida, M. B. & Sakly, A. A novel crow search algorithm-based maximum power point tracking method for wind energy conversion systems. Adv. Sci. Technol. Res. J. 19 (9), 189–202 (2025).

Nguyen, T. N. A., Pham, D. C., Chan Thanh, N. H. & Nguyen, A. N. Implementation of equilibrium optimizer algorithm for MPPT in a wind turbine with PMSG. WSEAS Trans. Syst. Control 16, 216–223 (2021).

Yazıcı, İ, Yaylacı, E. K. & Yalçın, F. Modified golden section search based MPPT algorithm for the WECS. Eng. Sci. Technol. Int. J. 24(5), 1123–1133 (2021).

Kathiravan, K. & Rajnarayanan, P. N. Enhancing Wind Energy Harnessing with an Intelligent MPPT Controller Using African Vulture Optimization Algorithm. In Soft Computing in Renewable Energy Technologies 165–188 (CRC, 2024).

Sai, B. S. V., Chatterjee, S., Mekhilef, S. & Wahyudie, A. An SSM-PSO based MPPT scheme for wind driven DFIG system. IEEE Access. 10, 78306–78319 (2022).

Elnaghi, B. E., Ismaiel, A. M., El Sayed Abdel-Kader, F., Abelwhab, M. N. & Mohammed, R. H. Validation of energy Valley optimization for adaptive fuzzy logic controller of DFIG-based wind turbines. Sci. Rep. 15(1), 711 (2025).

Kumar, R., Singh, R. & Ashfaq, H. Stability enhancement of induction generator–based series compensated wind power plants by alleviating subsynchronous torsional oscillations using BFOA-optimal controller tuned STATCOM. Wind Energy. 23 (9), 1846–1867 (2020).

Kumar, R., Singh, R., Ashfaq, H., Singh, S. K. & Badoni, M. Power system stability enhancement by damping and control of Sub-synchronous torsional oscillations using Whale optimization algorithm based Type-2 wind turbines. ISA Trans. 108, 240–256 (2021).

Kumar, R. et al. An intelligent hybrid Wind–PV farm as a static compensator for overall stability and control of multimachine power system. ISA Trans. 123, 286–302 (2022).

Verma, N., Kumar, N. & Kumar, R. Battery energy storage-based system damping controller for alleviating sub-synchronous oscillations in a DFIG-based wind power plant. Prot. Control Mod. Power Syst. 8 (2), 1–18 (2023).

Mahfoud, S., Derouich, A., Ouanjli, N. E. & El Mahfoud, M. Enhancement of the direct torque control by using artificial neuron network for a doubly fed induction motor. Intell. Syst. Appl. 13, 200060 (2022).

Ouhssain, S. et al. Enhancing the performance of a wind turbine based DFIG generation system using an effective ANFIS control technique. Int. J. Rob. Control Syst. 4, 4 (2024).

Kadi, S., Benbouhenni, H., Abdelkarim, E., Imarazene, K. & Berkouk, E. M. Implementation of third-order sliding mode for power control and maximum power point tracking in DFIG-based wind energy systems. Energy Rep. 10, 3561–3579 (2023).

Mossa, M. A., Echeikh, H. & Iqbal, A. Enhanced control technique for a sensor-less wind driven doubly fed induction generator for energy conversion purpose. Energy Rep. 7, 5815–5833 (2021).

Alrowaili, Z. A. et al. Robust adaptive HCS MPPT algorithm-based wind generation system using model reference adaptive control. Sensors 21(15), 5187 (2021).

Essam et al. An efficient maximum power point tracking algorithm for DFIG based wind energy conversion system. J. Control Instrum. Eng. 7 (2) (2021).

Sreenivasulu, P. & Hussain, J. Design of cascaded control loops for the implementation of adaptive MPPT control algorithm on doubly fed induction generator-based wind energy conversion system. Results Eng. 25, 104384 (2025).

Mezaache, M., Babes, B. & Chaouch, S. Optimization of welding input parameters using PSO technique for minimizing HAZ width in GMAW. Period Polytech. Mech. Eng. 66, 99–108. https://doi.org/10.3311/PPME.14127 (2022).

Hamouda, N., Babes, B., Boutaghane, A. & Hamouda, C. A robust PIλDµ controller for enhancing the width of the molten pool and the tracking of welding current in gas metal Arc welding (GMAW) processes. Int. J. Model. Simul. 1–15. (2023).

Yonis, S. A., Yusupov, Z., Habbal, A. & Toirov, O. Control approach of a grid connected DFIG based wind turbine using MPPT and PI controller. Adv. Electr. Electron. Eng. 21(3), 157–170 (2023).

Acknowledgements

The authors extend their appreciation to the Deanship of Scientific Research at Northern Border University, Arar, KSA, for funding this research (through the project number NBU- FFR -2025-2115-02).

Funding

This research was funded by the Deanship of Scientific Research at Northern Border University, Arar, KSA, for funding this research (through the project number NBU-FFR-2025-2115-02).

Author information

Authors and Affiliations

Contributions

Prashanth Rajanala: Conceptualization, methodology development, simulation, and data analysis. Malligunta Kiran Kumar: Supervision, validation, and technical guidance. K. V. Govardhan Rao: Investigation, software implementation, and results interpretation. Ch. Rami Reddy: Review of control algorithms, system modeling, and manuscript revision. D. Ravi Kumar: Data curation, visualization, and preparation of simulation results. A. Giri Prasad: Formal analysis, result verification, and editing of the manuscript. Jamal Aldahmashi: Critical review, improvement of presentation quality, and coordination with co-authors. Ahmed Emara: Conceptual supervision, overall project administration, writing—review and editing, and correspondence. All authors contributed to manuscript revision, approved the final version, and agreed to be accountable for all aspects of the work.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Rajanala, P., Kumar, M.K., Rao, K.V.G. et al. Hybrid Fennec Fox–Sand Cat optimized cascaded ANFIS MPPT for enhanced control of DFIG-based WECS with grid support. Sci Rep 16, 2500 (2026). https://doi.org/10.1038/s41598-025-32357-4

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-32357-4