Abstract

In gob-side entry retaining (GER) by roadway-side filling, the long cantilever beam structure formed by the goaf roof subjects the filling wall to significant compressive stress under its self-weight and overburden load, often resulting in severe deformations such as floor heave. The S1212 working face of the Ningtiaota Coal Mine was utilized as the engineering background for this study. Through field monitoring of deformations and support component loads, the study revealed the deformation and failure mechanisms of the surrounding rock. This analysis led to the proposal of a novel, optimized control technology centered on roof-dense drilling. In order to validate the efficacy of the proposed methodology, a numerical model was established to replicate field conditions. Various dense drilling parameter schemes were comprehensively evaluated through systematic simulation. The validity of the model was confirmed through the analysis of field monitoring data. The quantitative evaluation metrics were established, including the surrounding rock control rate and support force reduction rate. Subsequent analysis examined the impact of dense drilling angle and height on surrounding rock deformation. Additionally, the study elucidated the control mechanism of roof dense drilling technology in weakening the long cantilever beam and improving the surrounding rock stress environment. Preliminary field tests demonstrated that, in comparison with engineering practices that did not incorporate roof dense drilling, the implementation of this technology led to a substantial enhancement in the control of surrounding rock deformation. This enhancement was characterized by an increase in the control rate by 50.56%, as well as a reduction in the support force required on the filling wall by 60.45%. This approach effectively optimized the surrounding rock stress environment, achieving effective control of roadway stability. Consequently, this research provides a theoretical foundation and practical methodology for stability control in GER roadways under analogous mining conditions.

Similar content being viewed by others

Introduction

Gob-side entry retaining (GER) by roadway-side filling is a mining method that does not necessitate the use of coal pillars. The filling wall adjacent to the roadway will be constructed using the filling materials after mining. It has the capacity to preserve the roadway and serve as a support for the subsequent working face1,2,3,4,5. The implementation of this technology confers several benefits, including the enhancement of coal resource recovery, the reduction of roadway excavation, and the improvement of roadway ventilation. Its extensive utilization in the longwall coal mining method has been documented in numerous studies6,7,8,9. In recent years, a substantial volume of research has been undertaken on the subject of the control of surrounding rock in GER using roadway-side filling.

With respect to the control of surrounding rock in GER by the roadway-side filling, extant research primarily concentrates on enhancing the performance of filling materials, optimizing the width of roadway-side filling walls, and strengthening the surrounding rock support10,11,12,13,14,15,16. Thompson et al.11 examined the impact of varying binder contents on the support capacity of cement slurry filling materials through the implementation of field monitoring techniques. Xie et al.12 investigated the optimal width of roadway-side filling walls based on the mechanical properties of concrete under varying curing durations. Wu et al.13 examined the development of microcracks and macroscopic mechanical response characteristics of the roadway-side filling wall. The optimization method of the aspect ratio of the roadway-side filling wall was analyzed. While yieldable concrete walls can provide roof support, enhancing the performance and parameters of the roadway-side filling wall can improve the control effect of GER. However, the compression exerted on the filling wall by the bending and sinking of the roof is one of the essential reasons for stress concentration in the roadway17,18,19. The aforementioned study made no alterations to the structural design of the roadway-side filling walls.

The authors’ team has proposed a roadway control method involving roof cutting and pressure releasing, a technique that modifies the structure of the roadway roof. It has been demonstrated that this phenomenon can enhance the stress environment of the roadway and optimize the control effect of the surrounding rock20,21,22,23,24. Yang et al.25 demonstrated that roof cutting can reduce the compression of the roadway roof on the roadway-side filling walls and improve the stress environment of the surrounding rock through field experiments. In their study, Meng et al.26 found that the removal of the thick and hard roof can reduce the disturbance to the filling walls caused by the impact load of roof collapse through numerical simulation. Wang et al.27 investigated the impact of roof fracture location on the length of cantilever beams through numerical simulation. Their findings indicated that reducing the length of cantilever beams can mitigate stress concentration. Adequate roof cutting parameter design has been demonstrated to effectively improve the stress environment of the surrounding rock, thereby ensuring the control effect of the roadway. The prevailing roof-cutting methods encompass directional energy-gathering blasting, hydraulic fracturing, and dense drilling28,29,30,31,32. Directional energy-gathering blasting is characterized by its simplicity of operation and its ability to cover an extensive controllable range. However, it is imperative to acknowledge its specific influence on the safety of the mining space. While hydraulic fracturing is widely regarded as a relatively safe process, its viability is contingent on several factors, including the characteristics of the surrounding rock, the structural integrity of the formations, and the geologic stress within the area of interest. The implementation of dense drilling exhibits several notable advantages, including its cost-effectiveness, straightforward operational procedures, wide applicability, and its ability to minimally disturb the surrounding rock formations of roadways. However, research on optimizing the GER by using roof dense drilling remains limited.

Based on this, the surrounding rock control method of roof dense drilling is proposed, aiming to enhance the control effectiveness of GER. Taking the S1212 working face of the Ningtiaota Coal Mine in Western China as the engineering background, research was conducted to optimize the control effect of GER using roof dense drilling. The failure characteristics of GER were analyzed, and the influence mechanism of roof dense drilling parameters on the roadway stability was clarified. A series of engineering recommendations has been put forth with the objective of enhancing the control efficacy of GER, with the implementation of roof-dense drilling being a key component of these recommendations. Furthermore, the implementation of dense drilling on the roof proved to be a successful field application. This method can provide a reference for similar engineering conditions.

The deformation mechanism and control methods of the roadway

Engineering background

(1) Overview of the working face.

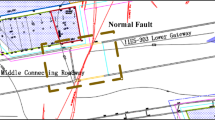

The Ningtiaota Coal Mine, located in western China, boasts a designed annual production capacity of 20 million tons. The S1212 working face extends 1991 m in strike length and 344 m in dip length, with the extraction of the No. 2–2 coal seam, which averages 4.1 m in thickness. As illustrated in Fig. 1, the working face layout and spatial relationships with adjacent workings are depicted. Subsequent to the extraction process, the haulage roadway will be maintained as a service entry for the adjacent working face.

The immediate roof of S1212 working face is primarily composed of siltstone, with an average thickness of 4.6 m. The basic roof is predominantly composed of medium sandstone, with an average thickness of 10.7 m. The immediate floor is chiefly constituted of fine sandstone, with an average thickness of 6.9 m. The basic floor is primarily comprised of siltstone, with an average thickness of 9.9 m. The coal seam dip angle is less than 2°. The geological structure is uncomplicated, and the average burial depth is 164 to 224 m.

(2) Supporting scheme for the gob-side entry retaining roadway.

The haulage roadway of the S1212 working face is designed as a rectangular section and is excavated along the coal seam floor. Its width is measured at 6200 mm, while its height is recorded at 3800 mm. The roof is supported by anchor cables and bolts. The roadway roof is composed of four rows of anchor cables, with a spacing of 1600 × 2400 mm. The anchor cables have a diameter of 21.8 mm and a length of 9,000 mm. The roadway roof is composed of a total of five rows of anchor bolts, with a spacing of 1400 × 1200 mm. The bolt types measure 22 mm in diameter and 2500 mm in length. The anchor bolts, with a diameter of 22 mm and a length of 2200 mm, are spaced at 1100 × 1200 mm. The width of the gob-side entry retaining roadway is 5000 mm. The yieldable concrete wall has a width of 1200 mm, and its concrete strength grade is C40. The configuration of the roadway’s supporting infrastructure is depicted in Fig. 1.

Analysis of roadway deformation mechanism

A comprehensive monitoring section was established 100 m ahead of the haulage roadway. It was to monitor the displacement of the surrounding rock and the forces exerted by the supporting components throughout the entire roadway retention process. The objective of this study was to elucidate the deformation and failure mechanisms of the roadway by employing the GER method. The specific layout of the monitoring section is as follows: Infrared anchor dynamometers were installed at the extremities of the roadway’s roof anchor bolts and cables to monitor force changes in the supporting components continuously. Displacement monitoring points were strategically positioned at the roof, floor, and midpoint of both sides of the roadway to ensure continuous monitoring of the convergence deformation of the roof and floor, as well as that of the two sides. Figure 2(a) illustrates the curve of displacement changes of the surrounding rock within the entire range of advance pressure influence, and Fig. 2(b) illustrates the curve of support force changes of the anchor cable and bolt. The minus sign in the figures indicates locations that are ahead of the working face. The second signifies locations situated behind the working face, that is, within the scope of the GER roadway.

By analyzing Fig. 2, the following conclusions can be drawn:

(1) With regard to the deformation of the roadway, the following observations can be made. As the mining process progresses, the convergence of the roof and floor, as well as the convergence of the two sides, undergo continuous escalation. In the context of mining operations, as the working face progresses towards the monitoring section, the maximum convergence deformation of the roof and floor is recorded at 45 mm, while the maximum convergence deformation of the two sides is determined to be 69 mm. The roadway surrounding rock has been disturbed by the working face mining. As the process of retaining the roadway progressed, the convergence of the two sides increased with the distance of the retaining roadway, and the surrounding rock remained relatively stable, exhibiting a maximum convergence of 140 mm. The convergence of the roadway roof and floor exhibited a direct correlation with the increase in retaining roadway distance. The maximum deformation of the roof and floor within the monitoring range was recorded at 616 mm. The roadway’s floor demonstrated a range of floor heave.

(2) With regard to the force of the supporting components: During the mining process of the working face, the support force of the anchor bolt and anchor cable remains relatively stable, exhibiting minimal fluctuations. As the working face progresses towards the monitoring section, the anchor bolt support force increases to 21 kN, and the anchor cable support force increases to 138 kN. In a manner analogous to the deformation of the surrounding rock, the anchor support force is less affected by mining disturbance during the working face mining process. As the process of retaining the roadway progressed, the support force of anchor bolts and anchor cables underwent a substantial increase. Subsequent to the stabilization of the roadway, the anchor bolt support force remained stable at 52 kN, and the anchor cable support force remained stable at 155 kN. When considered in conjunction with the laboratory-measured anchor bolt and anchor cable breaking forces of 213 kN and 320 kN, respectively.

Preliminary findings from field monitoring efforts suggest that the deformation of the roadway within the designated support control range can be effectively managed within the current support control parameters. However, due to the absence of adequate support for the roadway floor, it has become the primary pressure relief surface. The phenomenon of roadway floor heave, which is influenced by factors such as mining disturbance and roof collapse of the goaf, poses a significant challenge to the safe production of coal mines.

Control method

Preliminary research suggests that the termination of the working face roof in proximity to the coal seam will undergo fracturing as the working face undergoes mining, thereby forming a protracted cantilever beam structure. The high-level rock blocks undergo a gradual fracturing process, resulting in the formation of a hinged structure that exerts a compressive force on the long cantilever beam structure. This phenomenon can lead to the bending and sinking of the long cantilever beam structure located above the roadway, thereby exerting pressure on the roadway-side filling wall. This phenomenon is known to induce stress concentration in the roadway, thereby compromising the stability of the surrounding rock, as illustrated in Fig. 3(a).

The location of the roof fracture, in conjunction with the degree of bending and subsidence, will affect the stability of the roadway. The degree of bending and sinking of the roof can be mitigated by decreasing the length of the cantilevered roadway roof, transitioning from a long cantilever beam structure to a short cantilever beam structure, and modifying the position of the fixed roof fracture. The load transmitted from the surrounding rock of the roof to the roadway-side filling wall can be reduced, the stress environment of the roadway can be improved, and the stability of the roadway can be ensured, as demonstrated in Fig. 3(b).

The control mechanism of roof-dense drilling involves the utilization of advanced mining stress to expand the plastic zone within the drilling area, thereby inducing the continuous development and expansion of cracks. When the plastic zones of dense drilled boreholes overlap, the process of crack development and penetration continues, resulting in the formation of macroscopic cracks. These cracks, in turn, induce further expansion and the formation of weak planes. Subsequent to the mining of the working face, the roof of the goaf will collapse along the weak plane, thereby shortening the long cantilever beam structure of the roof, as illustrated in Fig. 4.

The specific process is as follows: roof dense drilling is carried out outside the advanced disturbance range, and a circular, elliptical, or butterfly-shaped plastic zone is formed near the drilling area based on the ratio of the maximum horizontal principal stress to the minimum horizontal principal stress. At this time, the plastic zone formed by dense drilling is not connected, so the impact on the stability of the roadway roof is relatively small. As the mining operation continues, the dense boreholes penetrate the range of advanced disturbance, thereby increasing the stress levels within this zone. At this time, the plastic zone between dense boreholes continues to expand, and the cracks in the plastic zone continue to develop until the plastic zones coincide and the cracks are connected. Subsequent to the establishment of connections between the cracks, the ongoing increase in disturbance stress will precipitate the continuous development of surrounding rock cracks, thereby forming macroscopic cracks. This will result in a reduction of the mechanical properties of the surrounding rock in the area, leading to the formation of a weakened zone in the surrounding rock strength. Dense drilling has been demonstrated to reduce the threshold for crack initiation in surrounding rock, guide the direction of crack propagation, promote the formation of weak planes, and mitigate the impact on roadway stability.

Control mechanism of roof dense drilling

According to the extant research on roof cutting20,21,22,23,24, the selection of roof cutting parameters is of critical importance for achieving the desired control effect on the roadway. A series of empirical tests was conducted in order to ascertain the most effective method for drilling in the presence of roof dense conditions. These tests were based on the results of field monitoring, the mining method employed at the working face, and the rock conditions of the roadway.

Schematic design

In order to ascertain the optimal parameters for roof-dense drilling, two types of numerical comparative experimental schemes were designed. The control effect of the surrounding rock with different dense drilling parameters was studied. The designed dense drilling parameters include Scheme A, which involves varying the drilling angles, and Scheme B, which involves varying the drilling heights.

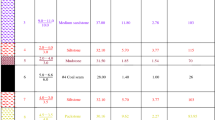

The establishment of 3DEC numerical calculation models with precise field dimensions, geomechanical parameters, and support parameters was achieved through the implementation of both types of experimental schemes. The mechanical parameters of the surrounding rock are shown in Table 1.

The immediate roof of S1212 working face is primarily composed of siltstone, with an average thickness of 4.6 m. The basic roof is predominantly composed of medium sandstone, with an average thickness of 10.7 m. The immediate floor is chiefly constituted of fine sandstone, with an average thickness of 6.9 m. The basic floor is primarily comprised of siltstone, with an average thickness of 9.9 m. The coal seam dip angle is less than 2°. The geological structure is uncomplicated, and the average burial depth is 164 to 224 m. The roadway section size, surrounding rock support strength, coal seam thickness, and yieldable concrete parameters of Ningtiaota Coal Mine are used as invariants, and the dense drilling angle and height are used as variables to simulate the control effect of different dense drilling parameters. The specific scheme is as follows:

(1) Dense drilling angle.

The following comparison schemes are to be considered for different dense drilling angles, designated hereinafter as Scheme A. This scheme involves the variation of the dense drilling angle, denoted as Ai, with i ranging from 0 to 7. In the context of the original field support control plan, specifically when i = 0, no roof-dense drilling operations were conducted. For this study, it is essential to note that when I equals 1–7, it corresponds to the following dense drilling angles: 0°, 5°, 10°, 15°, 20°, 25°, and 30°, respectively. The specific plan is delineated in Table 2.

(2) Dense drilling height.

The following comparison schemes are to be considered for different dense drilling heights (Scheme B): This scheme involves the variation of the dense drilling height, denoted as Bi, with i ranging from 1 to 7. In the context of dense drilling, the parameters of height (i) and the drilling angle (α) are defined as follows: i = 1–7, corresponding to heights of 5 m, 6 m, 7 m, 8 m, 9 m, 10 m, and 11 m, respectively. The drilling angle, α, is set as an invariant, and the optimal drilling angle value of Scheme A is taken. The specific scheme is illustrated in Table 3.

Establishment of models and evaluation index

(1) Model establishment.

A numerical calculation model consistent with field geological conditions was established, with the calculation range of 200 × 120 × 120 m (width × height × thickness), as illustrated in Fig. 5. The lowermost boundary of the model is fixed vertically, while the frontal, posterior, lateral, and medial boundaries are fixed horizontally. The compensation stress is applied on the upper surface of the model. This approach ensures that the test face of the model attains the desired level of field stress. A monitoring section has been established at a distance of 60 m from the front surface of the model. This section is designed to monitor the displacement of the surrounding rock and the support force of the yieldable concrete.

The sequence of operations in the simulation is as follows: “roadway excavation → roof dense drilling → mining of working face → pouring of yieldable concrete wall.” The specific simulation process is carried out according to the following process. The first step is tunnel excavation and support. The tunnel is excavated step by step, with each excavation of 3 m, followed by support. Excavate until the tunnel is fully connected. The second step is to drill densely on the roof. The distance between each dense drilling step on the roof is 3 m. Before mining on the working face, 5 dense drilling steps are carried out for the first time, and then the dense drilling gradually advances to completion with the mining on the working face. The third step is the mining of the working face and the support of the roadway. The working face is mined at each step, with a depth of 3 m each time, and then a filling material is poured on the side of the roadway near the goaf for support. The second and third steps are repeated until the mining of the working face is completed. The displacement of surrounding rock and the support force of yieldable concrete walls throughout the entire process of the S1212 working face haulage roadway is monitored.

(2) Establishment of the quantitative evaluation index.

To compare and analyze the control effects of surrounding rock in various simulation schemes, the roadway deformation control rate was established as a quantitative evaluation index to optimize the parameters of roof dense drilling.

Where: S0—the design cross-sectional area of the roadway, m2; SA0—the roadway cross-sectional area of Scheme A0, Scheme A0 is the scheme without dense drilling, m2; SXi—the roadway cross-sectional area of Scheme Xi, X = A, B, i = 1, 2, 3, 4, 5, 6, 7 (for example, X = A, i = 1, represents the roadway cross-sectional area of Scheme A1), m2; LA0—convergence rate of roadway section in Scheme A0, %; \(\:{L}_{Xi}\)—convergence rate of roadway section in Scheme Xi, %; \(\:{\delta\:}_{Xi}\)—roadway deformation control rate in Scheme Xi, %.

At the same time, the support force of yieldable concrete walls is also an important indicator for evaluating the control effect of the surrounding rock. Therefore, the change rate of the support force of yieldable concrete walls was established to assist in evaluating the control effect of the surrounding rock.

Where: FA0—support force of yieldable concrete wall in Scheme A0, MPa; FXi—support force of yieldable concrete wall in Scheme Xi, MPa; \(\:{\delta\:}_{FXi}\)—the change rate of support force in Scheme Xi, %.

Result analysis

Comparison between numerical simulation and field monitoring

To validate the numerical model against field observations, the simulation results of Scheme A0 were rigorously compared and analyzed with the corresponding field monitoring data, as shown in Fig. 6. Figure 6 compares the convergence deformation of the roof and floor, as well as the deformation on both sides, when the working face is mining to the monitoring section, and the deformation of the surrounding rock during the stable stage of retaining the roadway.

Analysis of Fig. 6 reveals that the numerical simulation results for the convergence deformation of the roof and floor and the deformation on both sides closely matched the field measurements at the corresponding times. At the monitoring section stage, the simulated convergence deformation of the roof and floor, and the deformation on both sides values were 42.8 mm and 62.1 mm, respectively, exhibiting relative deviations of only 4.91% and 9.93% from the field measurements. At the stable stage, the simulated deformations increased to 606.5 mm and 139.7 mm, showing remarkably low relative deviations of 1.54% and 0.25%, respectively, compared to the field data. In summary, the relative deviations between the numerical predictions and field measurements were consistently below 10% across all monitored stages and deformation types.

This substantial degree of agreement indicates that the numerical model, which was calibrated using field-derived parameters in this study, accurately replicates the field behavior of the rock mass. Consequently, the model that has been validated provides a reliable foundation for the subsequent parameter optimization study of dense drilling, which is presented in the following section.

Analysis of different dense drilling angle schemes

In accordance with the experimental design, numerical comparative analyses were conducted for varying roof dense drilling angles. Figures 7 and 8 present the convergence of the roadway roof-to-floor and rib-to-rib, respectively, along with the effectiveness of surrounding rock control across various drilling angles. Figure 9 provides a detailed analysis of the yieldable concrete wall support forces.

Comprehensive analysis of Figs. 7, 8 and 9 reveals three key findings:

(1) With respect to the evolution trend of roadway displacement, the convergence deformation of the roadway roof and floor in different dense drilling angle schemes, as well as the convergence deformation of two sides, exhibited a trend of initially increasing slowly, subsequently increasing rapidly, and ultimately stabilizing with the working face mining. Specifically, before the arrival of the working face mining at the monitoring section, there is a gradual increase in the deformation of the roof and floor, as well as the deformation of the two sides. Subsequent to the mining of the working face through the monitoring section, the roof and floor of the roadway and the two sides rapidly converge, particularly with a substantial impact on the convergence of the roadway roof and floor. Convergence of the roof and floor, as well as the convergence of the two sides, has been observed to tend towards stabilization.

(2) With respect to the phenomenon of roadway displacement control, the implementation of roof dense drilling has been demonstrated to be an effective strategy for the management of deformation in the surrounding rock of the roadway. Among the various schemes involving dense drilling, the deformation of the surrounding rock in the roadway was found to be less pronounced in comparison to the roadway without dense drilling, particularly about the convergence deformation of the roof and floor. As the angle of dense drilling increases, the control rate of the surrounding rock shows a trend of first increasing and then decreasing. The control rate of the surrounding rock with a dense drilling angle of 15° reached a maximum of 50.56%. The schemes with a surrounding rock control rate greater than 45% are designated as A3, A4, and A5. Consequently, the range of dense drilling angles that can effectively control the deformation of the surrounding rock of the roadway is 10° to 20°.

(3) With respect to the reinforcement of yieldable concrete walls, the implementation of roof dense drilling has been demonstrated to be an effective strategy for reducing the support force of yieldable concrete walls. In various dense drilling angles, the support force of yieldable concrete walls is considerably lower than that of roadways without roof dense drilling. As the angle of roof dense drilling increases, the support force of yieldable concrete walls initially decreases and subsequently increases. In comparison with the support force devoid of dense drilling, the change rate of the support force demonstrates an initial increase followed by a subsequent decrease. In the scheme with the dense drilling angle of 15°, the support force of yieldable concrete walls was reduced by 59.79% compared to the roadway without dense drilling. This finding suggests that roof dense drilling can effectively optimize the support force of yieldable concrete walls.

According to the findings of the aforementioned analysis, it can be concluded that a drilling angle of 15° is the most effective strategy for achieving optimal control of the surrounding rock, while simultaneously maximizing the reduction of the support force in the yieldable walls. Therefore, under the optimal parameters, the numerical comparative experiments of scheme B were continued to study the control effect of different dense drilling heights on the surrounding rock of the roadway.

Analysis of different dense drilling height schemes

In accordance with the test protocols, numerical comparative tests were conducted with roof dense drilling of varying heights. The convergence deformation of the roadway roof and floor, the convergence deformation of the two sides, and the control effect of the surrounding rock under different dense drilling heights are demonstrated in Figs. 10 and 11. The support force of the yieldable concrete wall is illustrated in Fig. 12.

The following conclusions can be drawn from the comprehensive analysis of Figs. 10, 11 and 12:

(1) With respect to the roadway displacement control effect, the implementation of roof dense drilling has been demonstrated to be an effective strategy for the management of deformation in the surrounding rock of the roadway. Among the various schemes involving dense drilling, the deformation of the surrounding rock in the roadway is less pronounced compared to the case without dense drilling, particularly about the convergence deformation of the roof and floor. As the height of dense drilling increases, the control rate of surrounding rock in the roadway shows a pattern of rapid increase followed by a slow increase. As the drilling height increases from 5 to 11 m, the control rate of the surrounding rock increases from 30.86% to 51.61%. The findings suggest that augmenting the height of dense drilling may potentially enhance the efficacy of controlling the surrounding rock of the roadway.

(2) With respect to the reinforcement of yieldable concrete walls, the implementation of roof dense drilling has been demonstrated to be an effective strategy for reducing the support force of yieldable concrete walls. In various scenarios involving dense drilling at different heights, the support force of yieldable concrete walls is found to be considerably lower in comparison to that of roadways devoid of a roof dense drilling structure. As the height of the roof increases, the support force of yieldable concrete walls shows a trend of continuously decreasing, from 50.34 MPa without drilling to 19.91 MPa. In comparison with the support force devoid of dense drilling, the change rate of the support force exhibited an increase from 53.23% to 60.45%. It has been demonstrated that increasing the height of the roof can effectively optimize the support force of yieldable concrete walls through dense drilling.

(3) With respect to the adequate selection of dense drilling height, an augmentation in the drilling height from 5 to 8 m has been demonstrated to result in a substantial diminution of the deformation of the roadway surrounding rock. Concurrently, the rock control rate has been shown to escalate from 30.86% to 50.56%, while the support force reduction rate of the yieldable walls has undergone an increase from 53.23% to 59.79%. These findings signify a substantial control effect. An increase in the height of dense drilling from 8 to 11 m has been observed to result in a negligible decrease in the deformation of the surrounding rock. The control rate of the surrounding rock has been found to increase by a mere 1.05%, while the reduction rate of the support force has shown a modest increase of 0.66%. This finding suggests that once the height of dense drilling reaches a certain threshold, the subsequent continuous increase in height exerts minimal influence on the control effect. Furthermore, the height of dense drilling has been demonstrated to directly correlate with construction cost and difficulty.

According to the findings of the aforementioned analysis, it can be concluded that as the height of the roof dense drilling increases, the control effect of the surrounding rock becomes more pronounced, and the support force of the yieldable wall decreases significantly. Upon attaining a specific height, the ongoing augmentation of the height of dense drilling becomes ineffective in significantly impacting the control effect of the surrounding rock and the support force of the yieldable wall. In selecting a dense drilling of 8 m, the optimal surrounding rock control effect can be achieved for the overall roadway under these working conditions. This approach also minimizes the support force of the yieldable wall to the greatest extent.

Engineering suggestions and field applications

Engineering suggestions

The following engineering recommendations are proposed to optimize roadway control through roof dense drilling, as indicated by integrated numerical simulations and field tests:

(1) An analysis of roadway deformation characteristics, derived from field monitoring and numerical simulations, indicates that roof dense drilling exerts a substantial control on roadway deformation, concurrently reducing the necessary support forces in yieldable concrete walls. Consequently, the implementation of this technique provides effective roadway stabilization.

(2) A thorough examination of the numerical tests conducted on various dense drilling angles reveals a sequential pattern. Initially, the efficiency of surrounding rock control demonstrates an upward trend. However, as the angle of the dense boreholes increases, this efficiency undergoes a decline. Concurrently, support force requirements in yieldable concrete walls demonstrate an inverse trend. This finding indicates the presence of an optimal angular control range for the execution of dense drilling operations on roofs. In the context of analogous geotechnical conditions, the optimal drilling angle range is determined to be 10°−20°.

(3) An analysis of the numerical tests conducted on varying dense drilling heights reveals a correlation between enhanced surrounding rock control and corresponding reductions in required support forces for yieldable concrete walls as height increases. Beyond critical heights, both control efficiency and support force reduction demonstrate a marked decline in effectiveness. Consequently, an optimal control height for roof-dense drilling is determined. In analogous engineering scenarios, the optimal height range is delineated as 8 to 10 m.

Field application

A field test of roof-dense drilling was conducted at the S1212 working face in the Ningtiaota Coal Mine, guided by the research findings and engineering suggestions. The designed roof dense drilling height was 8.0 m, with an angle of 15°. The design scheme is illustrated in Fig. 13. To this end, displacement monitoring stations were installed at strategic locations along the roadway to monitor convergence deformation of both the roof-to-floor and rib-to-rib. The evolution curves of surrounding rock deformation recorded at these monitoring stations are presented in Fig. 13.

From Fig. 13, it can be seen that:

(1) The roof-to-floor and rib-to-rib convergence deformation exhibited a characteristic trend: an initial phase of slow increase, followed by a period of rapid acceleration, ultimately stabilizing as mining of the working face progressed. This overall trend was analogous to that observed in roadways without dense drilling. However, the magnitudes of deformation were found to be considerably mitigated.

(2) In comparison with sections lacking roof dense drilling, the technique achieved substantial reductions in convergence deformation. The roof-to-floor convergence was 54.6%, while the rib-to-rib convergence was 32.1%. The phenomenon of floor heave has not been observed in the roadway. The performance of the gob-side entry retaining method was found to be exceptional, thereby substantiating the efficacy of roof-dense drilling as a means to regulate surrounding rock deformation.

Conclusion

(1) The S1212 working face of Ningtiaota Coal Mine was selected as the engineering background, and a comprehensive monitoring and analysis were conducted on the deformation behavior and support force characteristics in the GER roadway. The deformation and failure mechanism of the roadway was analyzed, leading to the proposal of a targeted control method involving roof dense drilling. This approach utilizes mining-induced pressure to promote the development of microcracks between adjacent boreholes, facilitating their coalescence into macroscopic weak planes. This phenomenon enables the directional collapse of the goaf roof under mining pressure, thereby transforming the roof structure from a long cantilever beam to a short cantilever beam. This structural transformation modifies the surrounding rock stress environment, thereby enhancing roadway stability.

(2) A numerical model consistent with field conditions was established, and its subsequent validation and calibration were performed using field monitoring data. Accordingly, comparative numerical simulations were conducted for the purpose of evaluating various roof dense drilling parameters. These simulations were based on a validated model. Quantitative evaluation indicators, specifically the surrounding rock control rate and the change rate of the support force on the roadway-side yieldable wall, were established. The control effectiveness of the surrounding rock under different dense drilling parameters was analyzed. The simulation results demonstrated that roof dense drilling significantly increased the surrounding rock control rate by 50.56% and reduced the support force of the yieldable wall by 60.45%. These findings substantiate the efficacy of roof-dense drilling in regulating the GER roadway.

(3) The efficacy of roadway control is significantly influenced by the parameters associated with dense drilling of the roof. Both considerably and insufficiently small dense drilling angles have been demonstrated to adversely affect surrounding rock control. An insufficiently small angle results in high frictional resistance along the pre-splitting surface, whereas an extensive angle increases the cantilever beam length, inducing significant rotational deformation of the roadway roof. As the magnitude of the drilling height increases, the effectiveness of the surrounding rock control initially demonstrates significant optimization before reaching a state of stability. It has been demonstrated that, in the context of dense drilling, the attainment of a specific height threshold results in the cessation of substantial enhancement in surrounding rock control. Subsequent increases in drilling height, therefore, are predicted to yield no significant improvements in this regard. Consequently, for conditions analogous to this project, the optimal ranges for roof dense drilling height and angle are determined to be 8–10 m and 10–20°, respectively. The implementation of this technology at the S1212 working face of the Ningtiaota Coal Mine was met with success, resulting in the effective control of the surrounding rock. This study offers substantial theoretical underpinnings for the optimization of GER roadway control through roof dense drilling.

Data availability

The datasets used and/or analysed during the current study available from the corresponding author on reasonable request.

References

Wang Qi, H. et al. Study of a no-pillar mining technique with automatically formed gob-side entry retaining for Longwall mining in coal mines. Int. J. Rock Mech. Min. Sci. 110, 1–8. https://doi.org/10.1016/j.ijrmms.2018.07.005 (2018).

Xie Shengrong, P. et al. Stability analysis of integral load-bearing structure of surrounding rock of gob-side entry retention with flexible concrete formwork. Tunn. Undergr. Space Technol. 103, 103492. https://doi.org/10.1016/j.tust.2020.103492 (2020).

Fu Jianhua, C., Deyou, Li, X., Shumin, L. H. L., Changqing, L. & Zhang Junwei. Research on the technology of gob-side entry retaining by pouring support beside the roadway in three soft coal seam: A case study. Phys. Fluids. 36 (1), 017123. https://doi.org/10.1063/5.0186678 (2024).

Luan Hengjie, J., Yujing, Z. & Lujie, L. Huili. Stability control and quick retaining technology of gob-side entry: a case study. Advances in Civil Engineering. 2018: 7357320. (2018). https://doi.org/10.1155/2018/7357320

Tian Zhijun, Z., Zizheng, D., Min, Y., Shuai, B. & Jianbiao Gob-side entry retained with soft roof, floor, and seam in thin coal seams: A case study. Sustainability 12 (3), 1197. https://doi.org/10.3390/su12031197 (2020).

Shen Fuxin, S. et al. Research on novel method of Gob-Side entry retaining under the synergistic effect of roof cutting and roadside filling in Thick coal seams. Rock Mech. Rock Eng. 56 (10), 7217–7236. https://doi.org/10.1007/s00603-023-03385-1 (2023).

Wang Qi, W. et al. Dynamic impact simulation tests of deep roadways affected by high stress and fault slip. Int. J. Min. Sci. Technol. 35 (4), 519–537. https://doi.org/10.1016/j.ijmst.2025.03.005 (2025).

Zhang Xingyu, C. et al. Study of an innovative approach of roof presplitting for gob-side entry retaining in Longwall coal mining. Energies 12 (17), 3316. https://doi.org/10.3390/en12173316 (2019).

Tan Yunliang, M. et al. Cooperative bearing behaviors of roadside support and surrounding rocks along gob-side. Geomech. Eng. 18 (4), 439–448. https://doi.org/10.12989/gae.2019.18.4.439 (2019).

Huang Wanpeng, W., Xuewen, Shen, Yusan, F., Kai, F. W. & Li, C. Application of concrete-filled steel tubular columns in gob-side entry retaining under Thick and hard roof stratum: A case study. Energy Sci. Eng. 7 (6), 2540–2553. https://doi.org/10.1002/ese3.442 (2019).

Thompson, B. D., Bawden, W. F. & Grabinsky, M. W. In situ measurements of cemented paste backfill at the Cayeli mine. Can. Geotech. J. 49 (7), 755–772. https://doi.org/10.1139/T2012-040 (2012).

Xie Shengrong, W. et al. Failure analysis and control mechanism of gob-side entry retention with a 1.7-m flexible-formwork concrete wall: A case study. Eng. Fail. Anal. 117, 104816. https://doi.org/10.1016/j.engfailanal.2020.104816 (2020).

Bowen, W., Xiangyu, W., Jianbiao, B., Wenda, W. & Xiangxiang, Z. Study on crack evolution mechanism of roadside backfill body in gob side entry retaining based on UDEC trigon model. Rock Mech. Rock Eng. 52, 3385–3399. https://doi.org/10.1007/s00603-019-01789-6 (2019).

Wang Qi, G. & Hongke, Feng, F. Research progress on rotary cutting drilling testing method for rockmechanics parameters. J. Green. Mine. 2 (4), 333–343 (2024).

Zhang Nong, Y., Liang, H., Changliang, X., Junhua, K. & Jiaguang Stability and deformation of surrounding rock in pillarless gob-side entry retaining. Saf. Sci. 50 (4), 593–599. https://doi.org/10.1016/j.ssci.2011.09.010 (2012).

Yang Jun, H., Manchao, C. & Chen Design principles and key technologies of gob side entry retaining by roof pre-fracturing. Tunn. Undergr. Space Technol. 90, 309–318. https://doi.org/10.1016/j.tust.2019.05.013 (2019).

Wenda, W. et al. Failure characteristics and cooperative control strategies for gob-side entry driving near an advancing working face: A case study. Processes 12 (7), 1398. https://doi.org/10.3390/pr12071398 (2024).

Sun Qiang, Z., Jixiong, H., Yanli, Y. & Wei Failure mechanism and deformation characteristics of gob-side entry retaining in solid backfill mining: A case study. Nat. Resour. Res. 29 (4), 2513–2527 (2019).

Shihao, G. et al. Stability control technology for surrounding rocks in gob-side entry driving with small coal pillars under dynamic pressure. Energies 16 (23), 7887. https://doi.org/10.3390/en16237887 (2023).

He Manchao, M. & Xingen, Y. Bin. Analysis of strata behavior process characteristics of gob-side entry retaining with roof cutting and pressure releasing based on composite roof structure. Shock and Vibration. 2019: 2380342. (2019). https://doi.org/10.1155/2019/2380342

He Manchao, W. Rock dynamics in deep mining. Int. J. Min. Sci. Technol. 33 (9), 1065–1082. https://doi.org/10.1016/j.ijmst.2023.07.006 (2023).

Wang Qi, H., Manchao, W., Yuncai, L., Jiting & Xue Haojie. Research progress and prospect of automatically formed roadway by roof cutting and pressure relief without pillars. J. Minging Saf. Eng. 40 (3), 429–447 (2023).

Wang Qi, J. et al. Ground control method of using roof cutting pressure release and energy-absorbing reinforcement for roadway with extra-thick hard roof. Rock Mech. Rock Eng. 56 (10), 7197–7215. https://doi.org/10.1007/s00603-023-03461-6 (2023).

Wang Qi, W., Yuncai, J., Bei, J., Zhenhua, X. & Haojie Geomechanics model test research on large deformation control mechanism of roadway disturbed by strong dynamic pressure. Geohazard Mech. 1, 140–152. https://doi.org/10.1016/j.ghm.2023.06.002 (2023).

Xiaojie, Y. et al. A case study on optimization and control techniques for entry stability in non-pillar Longwall mining. Energies 12, 1–17. https://doi.org/10.3390/en12030391 (2019).

Meng Ningkang, B., Jianbiao, C., Yong, W., Xiangyu, W. & Wenda, W. Stability analysis of roadside backfill body at gob-side entry retaining under combined static and dynamic loading. Eng. Fail. Anal. 127, 105531. https://doi.org/10.1016/j.engfailanal.2021.105531 (2021).

Wang Haosen, W. et al. Ground response mechanism of entries and control methods induced by hard roof in Longwall top coal caving panel. Eng. Fail. Anal. 144, 106940. https://doi.org/10.1016/j.engfailanal.2022.106940 (2023).

Kang Hongpu, L., Huawen, G., Fuqiang, M., Xianzhi & Feng Yanjun. Understanding mechanisms of destressing mining-induced stresses using hydraulic fracturing. Int. J. Coal Geol. 196, 19–28. https://doi.org/10.1016/j.coal.2018.06.023 (2018).

Kang Hongpu, X., Yongxue, F., Meihua, L. & Chuang Gao Fuqiang. Case study of hydraulic fracturing for coal burst risk mitigation. Int. J. Coal Sci. Technol. 12 (1), 61. https://doi.org/10.1007/s40789-025-00812-2 (2025).

He Manchao, W. & Qi, W. Innovation and future of mining rock mechanics. J. Rock Mech. Geotech. Eng. 13 (1), 1–21. https://doi.org/10.1016/j.jrmge.2020.11.005 (2021).

Zhan Kai, W., Xiaotao, W., Xuben, K. & Chao A method for characterization of stress concentration degree of coal mine roadway surrounding rock. J. Geophys. Eng. 20 (4), 699–711. https://doi.org/10.1093/jge/gxad040 (2023).

Shao Chun, X., Lin, C., Xiaojun, C., Zhiwei, Y. & Baolin Factors affecting received signal intensity of electromagnetic measurement-while-drilling during underground in-seam horizontal drilling. J. Nat. Gas Sci. Eng. 56, 212–221. https://doi.org/10.1016/j.jngse.2018.06.002 (2018).

Acknowledgements

The research has obtained permission from relevant authorities and support from the management of Ningtiaota Coal Mine.

Funding

This work was supported by the National Natural Science Foundation of China (Grant Nos. 42307213), the National Key Research and Development Program of China (Grant No. 2024YFC2909500).

Author information

Authors and Affiliations

Contributions

Z.T. and Y.W. wrote the main manuscript text. Y.W., L.G.and D.L. were responsible for figure and table making and data analysis. G.K., C.H., S.W., and Y.H. were responsible for supplying the data of coal mines. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Tan, Z., Wang, Y., Gao, L. et al. Research on the pressure relief mechanism and application of roof dense drilling of gob side entry retaining by roadway-side filling. Sci Rep 16, 5411 (2026). https://doi.org/10.1038/s41598-025-32678-4

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-32678-4