Abstract

This study aimed to optimize the extraction process of total saponins from the stems and leaves of Panax zingiberensis (SLPZ) and analyze its chemical composition. This study investigated the optimal extraction conditions for total saponins from the stems and leaves of Panax zingiberensis (SLPZ) via single-factor experiments and response surface methodology (RSM) optimization, and the optimal parameters were determined as follows: cellulase-to-pectinase ratio of 1%:5%, enzymatic hydrolysis pH 4.5, ultrasound temperature 55 °C, and ultrasound time 28.88 min. Under these conditions, the total saponin extraction rate from SLPZ reached 37.12%. UHPLC-Q-TOF-MS/MS analysis identified 42 saponin compounds, including 28 dammarane-type triterpenes, 7 oleanane-type triterpenes, and 7 other saponins. Among them, triterpenes comprising the majority (51.07%) of the total compounds detected. Diterpenes, sesquiterpenes, and monoterpenes accounted for 18.26%, 17.74%, and 12.93%, respectively. This study provides a theoretical basis for the comprehensive utilization of SLPZ resources.

Similar content being viewed by others

Introduction

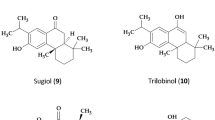

Panax zingiberensis, a member of the Araliaceae family, is primarily distributed in Yunnan Province, China, particularly in the Simao, Maguan, and Mengzi regions. It is also found in central Nepal, the high-altitude areas of Bhutan, and the Taunggyi and Shan States in Myanmar1. This plant is referenced in the traditional Chinese medical text Chinese Materia Medica for its historical use in treating conditions such as bruises, internal injuries, external bleeding, postpartum hemorrhage, lochia, exhaustion, cough, and anemia. Recent pharmacological studies have demonstrated that P. zingiberensis can reduce bleeding and clotting times, improve blood circulation, and stimulate the hematopoietic system2,3,4,5. It promotes the proliferation of various hematopoietic stem cells, resulting in a significant increase in blood cell production6. P. zingiberensis is also used as a substitute for Panax notoginseng in China.The primary active components of P. zingiberensis are triterpenoid saponins, which are categorized based on the structure of their aglycones into four types: protopanaxadiol (PPD), protopanaxatriol (PPT), oleanolic acid (OA), and octillol (OT)7,8,9. To date, more than 20 saponin compounds have been isolated and identified from the root and rhizome parts of P. zingiberensis, and research has mainly focused on the rhizomes of the plant, with little to no investigation into its aerial parts.

Studies on other Panax species suggest that their aerial parts are rich in saponins and flavonoids and possess notable anti-inflammatory and antioxidant activities. For instance, the leaves of Panax notoginseng and Panax quinquefolium have been widely used in functional products such as teas, fermented foods, surfactants, and instant beverages10,11,12. The stems and leaves (aerial parts) of P. zingiberensis may offer similar potential due to their substantial biomass and suitability for annual harvesting. Investigating these parts could thus support the comprehensive utilization of this valuable medicinal plant.

Regarding extraction methodologies, ultrasonic enzyme-assisted extraction has gained attention due to its efficiency, eco-friendliness, and ability to enhance the product quality. This method combines physical and enzymatic mechanisms to improve extraction yields, making it a promising approach in the green extraction technology field13,14,15.

Despite the known pharmacological potential of P. zingiberensis, research on the saponin content of its stems and leaves (SLPZ) is still limited. The present study aims to fill this gap by optimizing the extraction process of total saponins from the aerial parts of the plant. Utilizing a combination of enzymatic hydrolysis and ultrasound-assisted extraction, we employed single-factor experimentation and response surface methodology to determine the optimal conditions. Furthermore, ultra-performance liquid chromatography (UPLC) coupled with tandem mass spectrometry (MS/MS) was used to identify and quantify the extracted saponins. This comprehensive analysis provides new insights into the saponin profile of P. zingiberensis aerial parts and their pharmacological potential, laying the groundwork for future applications and resource development.

Materials and methods

Plant material

The stems and leaves of Panax zingiberensis were collected from Zhenyuan County, Yunnan Province, southwestern China, in June 2023. The P. zingiberensis collected this time is a cultivated variety. The plant material was taxonomically identified by Dr. Weiwei Jiang, and a voucher specimen (Accession No: PV20230601) was deposited at the Key Laboratory of Medicinal Plant Biology, Yunnan Agricultural University. All experimental research and field collection of P. zingiberensis specimens described in this manuscript comply with relevant institutional regulations, national laws of the People’s Republic of China, and international guidelines (including the IUCN Policy Statement on Research Involving Species at Risk of Extinction and the Convention on the Trade in Endangered Species of Wild Fauna and Flora, CITES).

The plant materials were washed, air-dried, crushed, and sieved to obtain a uniform powder for further analysis, hereafter referred to as SLPZ (stems and leaves of P. zingiberensis).

Experimental equipments and reagents

Ultrasound-assisted extractor (KQ-500DE, Kunshan Ultrasonic Instrument Co., Ltd., China ), High-performance liquid chromatography (HPLC) (Agilent 1260 Infinity II, Agilent Technologies, USA); Ultra-high performance liquid chromatography-quadrupole time-of-flight mass spectrometry (UHPLC-Q-TOF-MS/MS); (Waters Xevo G2-XS QTof, Waters Corporation, USA.); pH meter (PB-10, Sartorius AG, Germany). The ginsenoside Rg1 reference standard was obtained from Yunnan Yingge Biotechnology Co., Ltd. Cellulase (11 U/mg) and compound pectinase (60 U/mg) were supplied by Changzhou Xiasheng Enzyme Biotechnology Co., Ltd. Vanillin was purchased from Yuanye Biotechnology Co., Ltd.; glacial acetic acid was from Chongqing Chuandong Chemical Co., Ltd.; perchloric acid was from City Cologne Chemical Co., Ltd.; and absolute ethanol was from Tianjin Zhiyuan Chemical Reagent Co., Ltd. Methanol and acetonitrile were supplied by Merck, and formic acid was sourced from Aladdin. All reagents used for extraction are of analytical grade. The reagents used for liquid chromatography-mass spectrometry (LC-MS) are of chromatographic grade. All solutions were prepared using purified water.

Determination of total saponins in SLPZ

Total saponins were quantified using a spectrophotometric method. To prepare the standard curve, 10 mg of ginsenoside Rg1 was accurately weighed and dissolved in ethanol in a 10 mL volumetric flask, then diluted to volume and mixed thoroughly. Aliquots of 0, 0.4, 0.6, 0.8, 1.0, 1.2, and 1.4 mL of the standard solution were transferred into separate 10 mL test tubes. After evaporating the solvent from each tube, 0.2 mL of freshly prepared 5% vanillin–glacial acetic acid solution and 0.8 mL of concentrated hydrochloric acid were added. The mixtures were then heated in a 60 °C water bath for 15 min, rapidly cooled in cold water, and diluted to a final volume of 10 mL with glacial acetic acid. After standing for 20 min, the absorbance was measured at 544 nm. A standard curve was constructed by plotting the ginsenoside Rg1 concentration (x-axis) against the corresponding absorbance (y-axis)16.

For the sample analysis, 1 mL of the extract solution was transferred to a test tube and evaporated in an 80 °C oven. Subsequently, 0.2 mL of 5% vanillin–glacial acetic acid solution and 0.8 mL of perchloric acid were added. The mixture was shaken thoroughly and incubated in a 60 °C water bath for 15 min, then immediately cooled in cold water for 10 min. Afterward, 9 mL of analytical-grade glacial acetic acid was added. The solution was mixed well and allowed to stand for 20 min, using the reagent as a blank. The absorbance was measured at 544 nm17.

The total saponin content was calculated using the following formula:

Total saponins/% = (C × D × V) / m × 100,

where C is the concentration determined from the standard curve (mg/mL), D is the dilution factor, V is the volume of the tested solution (mL), and m is the mass of the sample (g).

Extraction methods for total saponins from SLPZ

Five extraction methods were compared to evaluate their efficiency at extracting total saponins from SLPZ18. In the ethanol reflux extraction method, 2 g of SLPZ was soaked in 30 mL of 70% ethanol for 1 h, followed by refluxing for an additional hour. The extract was centrifuged (rotational speed 4000 rpm, 5 min) and filtered, and 1 mL of the filtrate was diluted to 10 mL for analysis.

In the ultrasound-assisted extraction method (ultrasonic power 200 W, ultrasonic frequency 40 kHz), 2 g of SLPZ was soaked in 30 mL of 70% ethanol for 1 h, then subjected to ultrasonic extraction at 50 °C for 1 h. The extract was centrifuged, filtered, and diluted similarly.

In the ultrasound-assisted cellulase extraction method, 2 g of SLPZ was mixed with cellulase (11 U/mg) in 70% ethanol, adjusted to pH 5 (5% acetic acid). After 1 h of soaking, the sample underwent ultrasonic extraction for 30 min. The extract was filtered and diluted as above. In the ultrasound-assisted pectinase extraction, the same procedure was done, replacing cellulase with pectinase (60 U/mg).

In the ultrasound-assisted composite enzyme extraction ,2 g of SLPZ was mixed with both cellulase (11 U/mg) and pectinase (60 U/mg) under the same extraction conditions as the enzyme-assisted methods described above.

Each extract was processed and analyzed using the spectrophotometric method described in Sect. 2.3.

Single-factor experiments

To investigate the key parameters that influence the extraction of total saponins from SLPZ, single-factor experiments were conducted under fixed baseline conditions:2.0 g of SLPZ, a material liquid ratio of 1:30, ultrasound-assisted power at 200 W, extraction temperature of 50 °C, extraction duration of 60 min, ethanol concentration of 70%, enzymatic hydrolysis pH of 5.0, and a pre-soaking period of 1 h.

Refer to the extraction method proposed by Cui Xiao’ao et al. and adjust it to set the gradient range of enzyme concentration19. For cellulase, six dose levels were tested: 1%, 3%, 5%, 7%, 9%, and 11% (‘%’ represents the mass fraction of the enzyme preparation in the total mass of the reaction system, meaning 1% indicates the addition of 1 g of enzyme preparation per 100 g of the reaction mixture.). The same gradient was applied for pectinase. Each treatment was evaluated by determining the total saponin content to calculate the extraction efficiency. Subsequently, the optimal cellulase-to-pectinase ratio in the composite enzyme system was assessed by testing various combinations under otherwise identical conditions20.

Further single-factor experiments were performed to evaluate the influence of individual process variables, such as ultrasound-assisted extraction time (10, 20, 30, 40, 50, and 60 min), material liquid ratio (1:15, 1:20, 1:25, 1:30, 1:35, and 1:40), ethanol concentration (40%, 50%, 60%, 70%, 80%, and 90%), and enzymatic hydrolysis pH (4.0, 4.5, 5.0, 5.5, and 6.0). Each parameter was varied independently while keeping the other conditions constant16. The total saponin content was analyzed spectrophotometrically to determine the extraction rate under each condition.

All single-factor experiments were conducted in triplicate. Statistical analysis was performed using Excel.

Response surface optimization experiment

Based on the results of the single-factor experiments, the response surface methodology (RSM) was employed to optimize the extraction parameters. The experiment focused on three critical independent variables with significant influence on the total saponin yield. The total saponin extraction rate (Y) was set as the response variable. A Box–Behnken design (BBD) was adopted for the experimental setup, incorporating three factors at three levels. This design enabled the modeling of quadratic relationships and interactions between the variables.

Component analysis of total saponins from SLPZ

The chemical composition of the total saponins extracted from SLPZ was analyzed using ultra-performance liquid chromatography coupled with tandem mass spectrometry (UPLC-MS/MS)21.

Sample preparation

Total saponins were extracted using a 70% methanol–water (v/v) solution pre-cooled to -20 °C. A volume of 600 µL of the extraction solution was added to 50 mg of the lyophilized sample. The mixture was vortexed for 15 min and centrifuged at 12,000 rpm at 4 °C for 3 min. The supernatant was filtered through a 0.22 μm microporous membrane and transferred to sample vials for UPLC-MS/MS analysis.

UPLC conditions

Chromatographic separation was carried out using an Agilent SB-C18 column (2.1 mm × 100 mm, 1.8 μm). The mobile phase system consisted of 0.1% formic acid in ultrapure water as phase A and 0.1% formic acid in acetonitrile as phase B. A gradient elution program was applied, beginning with 5% phase B at 0.00 min, followed by a linear increase to 95% phase B over 9.00 min. This composition was maintained from 9.00 to 11.10 min before being reduced back to 5% and held until 14.00 min. The flow rate was set at 0.35 mL/min, the column temperature was maintained at 40 °C, and the injection volume was 2 µL.

Mass spectrometry conditions

An electrospray ionization (ESI) source was employed in both positive and negative ion modes for the mass spectrometric analysis. The source temperature was maintained at 550 °C, with an ion spray voltage of + 5500 V in positive mode and − 4500 V in negative mode. The gas settings were configured as follows: ion source gas 1 (GS1) at 50 psi, ion source gas 2 (GS2) at 60 psi, and curtain gas (CUR) at 25 psi. The collision-induced dissociation (CID) was set to a high level. The instrument operated in multiple reaction monitoring (MRM) mode using a triple quadrupole (QQQ) analyzer, with nitrogen serving as the collision gas. For each MRM ion transition, the declustering potential (DP) and collision energy (CE) were individually optimized to ensure maximum sensitivity and specificity.

Data processing

All experiments were repeated three times, and data analysis and plotting were conducted using Excel 2021 and Origin 2024 software, with variance analysis performed via ANOVA. A p-value of less than 0.05 was considered statistically significant. Mass spectrometry data were processed using the k-nearest neighbors (KNN) algorithm to impute missing values. The coefficient of variation (CV) was calculated for the quality control (QC) samples, and only compounds with a CV < 0.5 were retained for downstream analysis. This filtering ensured reliable quantification of individual saponin components.

Results and discussion

Ginsenoside Rg1 standard curve

A standard calibration curve for ginsenoside Rg1 was constructed by plotting the absorbance values on the y-axis against the corresponding ginsenoside Rg1 concentrations (mg) on the x-axis (Fig. 1). This standard curve served as the basis for accurately quantifying the ginsenoside Rg1 content in the sample extracts during subsequent analyses.

Extraction rates using different methods

The extraction efficiency of total saponins from the SLPZ was evaluated using various methods. The ethanol reflux method yielded a totole saponin content of 9.54%, while the ultrasound-assisted extraction resulted in a lower yield of 7.46%. Enhanced yields were observed with enzyme-assisted techniques: the ultrasound-assisted cellulase method yielded 10.96%, and the ultrasound-assisted pectinase method achieved 10.37%. Notably, the ultrasound-assisted composite enzyme method produced the highest extraction rate at 13.57%. The total saponin extraction yield of SLPZ is primarily determined by cell wall disruption degree and intracellular saponin dissolution efficiency across different extraction methods. The ethanol reflux method (extraction yield: 9.54%) dissolves only surface saponins via solvent thermal effects, failing to penetrate intracellular components. The ultrasound-assisted method (7.46%) induces mild cell structure disruption through cavitation but lacks targeted degradation of cell wall components, both yielding low extraction efficiencies. In contrast, enzyme-assisted extraction employs cellulase and pectinase for specific degradation of cell wall components, coupled with ultrasound-mediated physical disruption, thereby markedly increasing intracellular saponin exposure–ultrasound-assisted single-enzyme methods achieve yields of 10.37%–10.96%. Notably, the ultrasound-assisted composite enzyme method leverages synergistic degradation of multiple cell wall components by mixed enzymes, combined with ultrasound-induced cavitation and stirring effects to enhance dissolution. This synergy maximizes saponin release, ultimately attaining the highest extraction yield of 13.57%.These results suggest that the composite enzyme method, when combined with ultrasonic assistance, is the most effective and holds promise for further optimization in the saponin extraction process (Fig. 2).

Results of single-factor experiments

The extraction rates of total saponins varied depending on the concentrations of cellulase and pectinase. For cellulase additions of 1%, 3%, 5%, 7%, 9%, and 11%, the corresponding extraction rates were 30.14%, 29.58%, 28.58%, 28.54%, 28.30%, and 28.54%, with the highest extraction rate observed at 1%, followed by 3%. Similarly, pectinase doses of 1%, 3%, 5%, 7%, 9%, and 11% produced extraction rates of 28.22%, 28.54%, 29.45%, 29.22%, 29.13%, and 29.24% respectively, with the optimal yields occurring at 5% and 11% (Fig. 3a,b).

Cellulase and pectinase promote the breakdown of plant cell walls, thereby enhancing the release of saponins. The most effective extraction was achieved using 1% cellulase combined with 5% pectinase, while the next-best combination was 3% cellulase with 11% pectinase. These findings suggest a synergistic interaction between the enzymes at specific ratios, improving the overall extraction efficiency.

Further optimization involved varying the total enzyme additions to 6%, 8%, 10%, and 12%, corresponding to cellulase–pectinase ratios of 1:5, 3:5, 5:5, and 1:11, respectively. The extraction rates under these conditions were 30.72%, 30.26%, 29.73%, and 29.65%. The highest extraction rate was observed with a total enzyme addition of 6% at a cellulase–pectinase ratio of 1:5 (Fig. 3c).

Additionally, single-factor experiments assessed the influences of the ultrasound-assisted time, material-to-liquid ratio, ethanol concentration, and pH on the saponin extraction. The optimal extraction conditions were determined to be an ultrasound-assisted duration of 30 min, a material liquid ratio of 1:30, an ethanol concentration of 70%, and an enzymatic hydrolysis pH of 4.5 (Fig. 4a–d).

Response surface optimization results

Based on the findings of the single-factor experiments, a response surface methodology (RSM) was applied to optimize the extraction conditions for total saponins from the SLPZ. The experimental design employed an enzyme dose of 6%, with a cellulase – pectinase ratio of 1:5. The ethanol concentration, ultrasound-assisted time, and solid-to-liquid ratio were selected as the three independent variables to assess their impacts on the saponin extraction rate (Table 1). The response variable was the total saponin extraction rate (Y), with the corresponding data shown in Table 2.

The regression model established from the response surface analysis was as follows:

Y = 37.06 + 0.34 A − 0.27B − 0.43 C − 0.80AB + 0.43AC + 0.67BC − 2.14 A² − 1.85B² − 2.15 C²

The ANOVA results indicate that the regression model was statistically significant (P = 0.0001), demonstrating strong model reliability. In contrast, the lack-of-fit was not significant (P = 0.21), suggesting that the model appropriately fits the experimental data (F = 71.90) (Table 3). The model exhibited a high coefficient of determination (R² = 0.9893) and an adjusted R² of 0.9755, reflecting strong predictive power. Statistically significant effects were observed for the linear terms of ethanol concentration and ultrasound-assisted time (P < 0.001), The P-value corresponding to the lack-of-fit term of the model is 0.2102 (greater than 0.05), indicating that the lack-of-fit term is not significant. This suggests that the regression model established in this study can well describe the response relationship between ethanol concentration, ultrasound time, solid-to-liquid ratio, and total saponin extraction rate, with good fitting effect and high prediction reliability of the model. as well as for their quadratic terms (P < 0.0001). Additionally, the interaction between the ethanol concentration and material liquid ratio was highly significant (P < 0.01). The regression analysis revealed that the material liquid ratio had the greatest influence on the saponin extraction rate, followed by the ethanol concentration. Based on the response surface analysis and F-values, the relative influence of each factor on the total saponin extraction is ranked as follows: material liquid ratio > ethanol concentration > ultrasound-assisted time (Table 3).

The response surface analysis, depicted in the spatial diagram below using Design-Expert 8.0.6 software, illustrates the relationship between the response value (Y) and the independent variables, highlighting their effects on the total saponin extraction rate from the SLPZ. This analysis considered three key factors: ethanol concentration, ultrasound-assisted time, and material liquid ratio (Fig. 5).

A validation experiment was conducted using the optimal extraction conditions: ethanol concentration of 70.90%, ultrasound time of 28.88 min, and solid-to-liquid ratio of 29.45:1. Three replicates yielded an average saponin extraction rate of 36.74%, which was only 0.38% below the predicted value of 37.12%, confirming the model’s reliability. In traditional ginsenoside extraction, the ultrasonic method is conducted under the conditions of 70%–75% ethanol and 60–70 °C for 30 min, with the maximum extraction rate of total ginsenosides reaching 42.34 mg/g (approximately 4.23%)22,23,24; the microwave-assisted extraction method, applied in an ethanol-hydrochloric acid system, achieves an extraction rate of ginsenoside Rg5 of 3.14%25. In contrast, the optimized process targeting the stems and leaves of Panax zingiberensis in this study yields a higher extraction rate (37.12%) than the aforementioned traditional ginsenoside extraction methods. Some ginsenoside extraction processes rely on organic solvents, which pose risks of toxicity and volatility26,27. However, this study employs a 70.90% ethanol system combined with enzymatic hydrolysis assistance, ensuring a high extraction rate while reducing the potential hazards of solvents. Most traditional ultrasonic or microwave extraction methods require an extraction time of more than 30 min and have limitations in single-batch extraction quantity22,25. In this study, the ultrasonic time is optimized to 28.88 min, and meanwhile, the cell wall structure is disrupted through the synergistic effect of a composite enzyme (cellulase: pectinase = 1%:5%), significantly improving the extraction rate. Through the optimization of the ultrasound-assisted composite enzyme method, this study achieves a 37.12% extraction rate of total saponins from the stems and leaves of P. zingiberensis. This result demonstrates significant advantages in the saponin extraction of Panax species, and the optimized process holds clear application value.

Component analysis of total saponins from SLPZ

The chemical composition of total saponins extracted from the SLPZ was characterized using UPLC-MS/MS. A total of 239 terpenoids were identified, consisting of 168 triterpenes, 20 diterpenes, 20 sesquiterpenes, and 31 monoterpenes, accounting for 51.07%, 28.26%, 17.74%, and 12.93% of the total content, respectively. Among them, triterpenoid saponins were the most abundant, with 139 identified compounds, including 40 PPD, 44 PPT, 10 OA, 10 OT, and 35 other saponins. The relative proportions of these subtypes were 21.22%, 25.37%, 12.08%, 9.12%, and 32.21%, respectively. The PPT-type saponins exhibited the greatest diversity, whereas the other saponins showed the highest relative content, highlighting the complexity and richness of SLPZ saponins in dammarane-type tetracyclic triterpenoids (Figs. 6 and 7).

A detailed breakdown of the top 30 terpenoids by relative abundance is presented in Table 4 and visualized in Fig. 8.

UPLC-MS/MS analysis was employed to identify terpenoids in the SLPZ, which revealed that the compounds primarily comprised dammarane-type tetracyclic triterpenoid saponins, octillol-type tetracyclic triterpenoids, oleanolic acid-type pentacyclic triterpene saponins, and other saponin variants. Extensive research has demonstrated that these saponins exhibit a broad spectrum of pharmacological activities, including anti-tumor, antioxidant, anti-inflammatory, and anti-apoptotic effects, largely through modulation of multiple signaling pathways. Importantly, they are characterized by a low chemical toxicity and have shown therapeutic potential in a variety of conditions such as myocardial ischemia–reperfusion injury, diabetes, inflammation, cancer, neurological disorders, and Alzheimer’s disease28,29. Notably, Momordin Ic has been found to inhibit the proliferation and migration of head and neck cancer cells while promoting apoptosis30. Ginsenoside Rg2 exhibits a wide range of pharmacological activities related to inflammation, cancer, and other diseases31. Additionally, ginsenoside F1 has been shown to inhibit peripheral neurodegeneration and protect blood cells from neural damage, while notoginseng saponin Rb1 helps to alleviate morphological damage and improve cognitive and sensorimotor function following an ischemic stroke32,33,34.

For the 139 identified triterpene saponins, we analyzed their structural features and inferred potential properties. Dammarane-type triterpenes, mostly contain 2–3 sugar chains (glucose, rhamnose) at the C3 and C20 positions. Literature indicates that more sugar chains enhance water solubility35, which explains why these saponins were efficiently extracted by our aqueous-ethanol solvent system. Oleanane-type triterpenes are characterized by a carboxyl group at the C28 position. This acidic group may interact with the hydroxyl groups of plant cell wall polysaccharides, reducing their extraction efficiency—consistent with our result that oleanane-type saponins accounted for only 25% of total triterpene saponins. The high proportion of water-soluble dammarane-type saponins means our extraction process requires less organic solvent, supporting P. zingiberensis as a green resource for saponin production.

Conclusions

This study addressed the underutilization of SLPZ and the lack of efficient saponin extraction methods for these parts. By combining single–factor experiments and response surface methodology (RSM), an optimized ultrasound-assisted enzymatic extraction process was established-with key parameters including cellulase-to-pectinase ratio 1%:5%, enzyme dosage 6%, ethanol concentration 70.90%, enzymatic hydrolysis pH 4.5, ultrasound time 28.88 min, and material liquid ratio 29.45:1-and the total saponin extraction rate reached 37.12%. Its key innovations include: breaking the focus on Panax rhizomes to explore high-biomass SLPZ as a new saponin source; using composite enzyme-ultrasound assisted extraction to shorten time and reduce solvent risks (in line with green extraction); and identifying 239 terpenoids (139 triterpenoid saponins) via UPLC-MS/MS to fill the gap in SLPZ aerial part saponin research. Practically, this study provides a technical route for industrial SLPZ development (promoting P. zingiberensis from “rhizome-only use” to whole-plant utilization) and a basis for screening bioactive components for functional foods/pharmaceuticals, supporting the sustainable high-value use of this endangered resource.

Data availability

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

References

Hara, H. On the Asiatic species of the genus Panax. J. Jap Bot. 45, 197–212. https://doi.org/10.51033/jjapbot.45_7_5946 (1970).

Meng, G. Y., Guo, W. J., Fu, J. F., Gao, L. & Xu, Y. F. Study on the blood-activating and stasis-resolving effect of aqueous extract from Panax zingiberensis. Chin. J. Ethnomed. Ethnopharmacy. 33 (10), 46–49 (2024).

Guo, P. L. et al. Study on the protective effect of Panax zingiberensis saponin R1 against LPS/D-GalN-induced acute liver injury. China J. Traditional Chin. Med. Pharm. 39 (05), 2287–2291 (2024).

Shen, X. J., Wang, Y. Y., Zhang, G. H., Yang, S. C. & Jiang, W. W. Research progress on chemical constituents and Pharmacological effects of Panax zingiberensis. Chin. Archives Traditional Chin. Med. 41 (12), 57–63 (2023).

Zhu, Z. R., Jia, P., Liu, Y. & Ma, L. Research progress on resource distribution, components and Pharmacology of medicinal plant Panax zingiberensis. Cent. South. Agricultural Sci. Technol. 44 (07), 203–205 (2023).

Quan, L. T. et al. Wild ginseng grows in Myanmar. Chem. Pharm. Bull. 51, 679–682. https://doi.org/10.1248/cpb.51.679 (2003).

Li, X., Zhang, G. J., Jiang, W. W., Zhang, G. H. & Yang, S. C. Saponins from rhizomes of Panax zingiberensis. J. Trop. Subtropical Bot. 30 (6), 884–889. https://doi.org/10.11926/jtsb.4525 (2022).

Liu, H. Y. & Wang, C. X. Study on the process of microwave-assisted degradation of total saponins from Panax Notoginseng stems and leaves to generate ginsenoside Rg5. Chin. J. Traditional Chin. Med. 49 (14), 3245–3251. https://doi.org/10.7501/j.issn.0253-2670.2018.14.009 (2018).

Xian, X. Y. et al. 2025.Research progress on utilization of Panax germplasm resources. Chin. J. Traditional Chin. Med. 56 (01), 360–373. https://doi.org/10.7501/j.issn.0253-2670.2025.01.034

Yang, F. F. et al. Integrating enhanced profiling and chemometrics to unveil the potential markers for differentiating among the leaves of Panax ginseng, P. quinquefolius, and P. notoginseng by Ultra-High performance liquid Chromatography/Ion Mobility-Quadrupole Time-of-Flight mass spectrometry. Molecules 27 (17), 5549–5549. https://doi.org/10.3390/molecules27175549 (2022).

Cao, J. et al. Comprehensively qualitative and quantitative analysis of ginsenosides in Panax Notoginseng leaves by online two-dimensional liquid chromatography coupled to hybrid linear ion trap orbitrap mass spectrometry with deeply optimized Dilution and modulation system. Anal. Chim. Acta. 1079 (C), 237–251. https://doi.org/10.1016/j.aca.2019.06.040 (2019).

Zheng, W. L. et al. Bioactive components in Panax Notoginseng and Panax quinquefolium leaves and their antioxidant, antihypertensive and anti-inflammatory capacities. Ind. Crop Prod. 210118079 https://doi.org/10.1016/j.indcrop.2024.118079 (2024).

De Zhou, Y., Li, H. R., He, J., Zhao, M. & Tang, Q. Optimization of ultrasound-assisted compound enzyme extraction process, structural characterization, and antioxidant activity of Gastrodia Elata polysaccharides. J. Mol. Struct. 1327, 141214. https://doi.org/10.1016/j.molstruc.2024.141214 (2025).

Pham, M., Tuan, Trang, H. D., Nguyen, N. T. & Ngan, Danh, C. V. Comparative analysis of phenolics and in vitro bioactivities of sphagneticola calendulacea (L.) Pruski extracts obtained by conventional solvent, ultrasonic agitation, and enzyme assisted extractions. J. Indian Chem. Soc. 102 (1), 101556. https://doi.org/10.1016/j.jics.2024.101556 (2025).

Qiming Chu, S. et al. Enzyme-assisted ultrasonic extraction of total flavonoids and extraction polysaccharides in residue from Abelmoschus manihot (L). Ultrason. Sonochem. 104, 106815. https://doi.org/10.1016/j.ultsonch.2024.106815 (2024).

Guo, Z. et al. Optimization of extraction and separation process of notoginsenoside Fc from Panax notoginseng leaves. Molecules 28, 3915. (2023). https://doi.org/10.3390/molecules28093915

Kabadayı, S. N., Sadiq, N. B., Hamayun, M., Park, N. I. & Kim, H. Y. Impact of sodium silicate supplemented, IR-treated panax ginseng on extraction optimization for enhanced anti-tyrosinase and antioxidant activity: a response surface methodology (RSM) approach. Antioxidants 13, 54. https://doi.org/10.3390/antiox13010054 (2024).

Jin, Y. et al. Response surface optimization for water-assisted extraction of two saponins from Paris polyphylla var. yunnanensis leaves. Molecules 29, 1652. https://doi.org/10.3390/molecules29071652 (2024).

Cui X A, Qin Y Q, Lan, W. et al. Optimization of ultrasound assisted enzymatic extraction of blueberry polysaccharides and its structural characteristics. China Food Addit. 34 (08), 78–86 (2023).

Gao, W., Wang, Y., Lu, F. & Liu, F. Ultrasound-assisted enzymatic extraction of polysaccharides from tricholoma matsutake: optimization, structural characterization, and inhibition of α-synuclein aggregation. Foods 13, 4150. https://doi.org/10.3390/foods13244150 (2024).

Zheng, S. Y., Li, F. D. & Jiang, W. W. Optimizing the extraction process of total saponins from Panax Vietnamensis based on response surface analysis and backpropagation neural network-genetic algorithm. Industrial Crops Prod. 220 (2024), 119252. https://doi.org/10.1016/j.indcrop.2024.119252 (2024).

Zhao, L. C. & Liu, J. Y. Optimization of extraction process for ginsenosides Rg1, re and Rb1 by Box-Behnken method. Food Ind. 41 (1), 162–167 (2020).

LI, H. et al. Effects of different extraction methods in pharmacopoeia on the content and structure transformation of ginsenosides. Molecules 27 (14), 4347 (2022).

Zhang, R. et al. Optimization of extraction process for total saponins from Panax ginseng adventitious roots by response surface methodology. Nat. Prod. Res. Dev. 27 (4), 726–731 (2015).

Guo, D. D. et al. Optimization of Preparation process for ginsenoside Rg5 from Panax ginseng fibrous root powder by response surface methodology. Food Ind. 38 (9), 51–56 (2017).

Lin, H. et al. Study on extraction process of diol-type ginsenosides by alkaline water ultrasonic method. Shandong Chem. Ind. 51 (7), 40–42 (2022).

Tu, Y. J. et al. Development of green and efficient extraction of bioactive ginsenosides from Panax ginseng with deep eutectic solvents. Molecules 27 (14), 4339 (2022).

Wang, T. et al. Traditional uses, botany, phytochemistry, Pharmacology and toxicology of Panax Notoginseng (Burk.) F.H. Chen: A review. J. Ethnopharmacol. 188, 234–258. https://doi.org/10.1016/j.jep.2016.05.005 (2016).

Xu, C. C. et al. Analytical methods and biological activities of Panax Notoginseng saponins: recent trends. J. Ethnopharmacol. 236, 443–465. https://doi.org/10.1016/j.jep.2019.02.035 (2019).

Wang, W. W. Study on the Inhibition of head and neck cancer cell proliferation and mechanism by saponin Ic from Fructus Kochia. Dali Univ.. https://doi.org/10.27811/d.cnki.gdixy.2020.000124 (2020).

Xue, Q. Q. et al. Protective effect and mechanism of ginsenoside Rg2 on atherosclerosis. J. Ginseng Res. 47 (2), 237–245. https://doi.org/10.1016/j.jgr.2022.08.001 (2023).

Chun, Y. L. et al. Protective and therapeutic effect of (S)-ginsenoside F1 on peripheral nerve degeneration targeting Schwann cells: a pharmaco-neuroanatomical approach. Anat. Sci. Int. 97 (1), 79–89. https://doi.org/10.1007/s12565-021-00630-x (2022).

Kwon, H. J. et al. Ginsenoside F1 promotes cytotoxic activity of NK cells via Insulin-Like growth Factor-1-Dependent mechanism. Front. Immunol. 9, 2785. https://doi.org/10.3389/fimmu.2018.02785 (2018).

an, Y. T. et al. Panax notoginsenoside saponins Rb1 regulates the expressions of Akt/ mTOR/PTEN signals in the hippocampus after focal cerebral ischemia in rats. Behav. Brain Res. 345, 83–92. https://doi.org/10.1016/j.bbr.2018.02.037 (2018).

Chang, T. S. Glycosylationof Ganoderic acid F by Bacillus glycosyltransferase. Agrochemicals 1, 17–21. https://doi.org/10.3390/agrochemicals1010003 (2022).

Funding

This project was supported by the General Project for Basic Research in Yunnan (202201AT070266), the Yunnan Province Agricultural Basic Research Joint Project (202401BD070001-012), and the Independent Research Fund of Yunnan Characteristic Plant Extraction Laboratory (2022YKZY001).

Author information

Authors and Affiliations

Contributions

Conceptualization, Weiwei Jiang; Data curation, Yunmei Wang and Xiaona Luo; Formal analysis, Denghui Cui and Fuman Yang; Funding acquisition, Weiwei Jiang; Methodology, Xiaojing Shen; Supervision, Weiwei Jiang; Writing—original draft, Xiaojing Shen; Writing—review and editing, Weiwei Jiang.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Shen, X., Wang, Y., Deng, H. et al. Optimization of ultrasound-assisted enzymatic extraction of saponins from Panax zingiberensis stems and leaves. Sci Rep 16, 3348 (2026). https://doi.org/10.1038/s41598-025-33315-w

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-33315-w