Abstract

Raised bed planting offers numerous benefits on soil health, drainage, water savings, and improved economic and energy use efficiency. The dimension of raised bed especially top width vary for different crops according to specific growth habits, space need, and irrigation requirement of the crop, which require specialized bed former suitable for multiple crops. Considering these views in mind, the present study was undertaken on development and performance evaluation of variable width raised bed former under soil bin and field conditions. The soil bin experiments were conducted according to factorial completely randomized design with three replications to examine the effect of soil moisture content (11, 13 and 15% on wet basis), working width (0.70, 0.80 and 1.0 m) and forward speed (0.42, 0.56 and 0.69 m s− 1) on draft force of test rig. The soil bin data were used to build regression and radial basis function (RBF) neural network models to predict the specific draft and optimizing the input parameters using RBF neural network-particle swarm optimization (PSO) technique. Both, regression and RBF neural network models predicted the specific draft of test rig with good accuracy (R2 value > 0.98) in both training and testing phases. In soil bin, actual specific draft of 4002.4 N m− 1 was observed against the predicted value of 4056.6 N m− 1 with optimal input parameters given by RBF neural network-PSO technique. A variation of ± 7.2% was observed between predicted and actual value of specific draft for tractor operated variable width raised bed former in the field conditions with similar input settings. The findings of the study suggest that use of modern techniques such as neural network and particle swarm optimization might be a good approach for optimizing the input parameters and diminishing the energy expenditure during the field operation of tillage machinery.

Similar content being viewed by others

Introduction

Tillage is a crucial field operation in primary agricultural production which plays a key role in improving the soil structure and creating the optimal conditions for plant growth1,2. However, intensive tillage involving repeated movement of heavy machinery in conventional farming methods often leads to soil compaction which can restrict the growth of plant roots if penetration resistance exceeds 1.5 MPa3,4,5,6. Such problems need to be avoided using modern tillage and planting techniques which allow limited tillage, restricted movement of machinery or movement of machinery in the specified areas. One of such techniques is raised bed farming which allows farmers to maintain the designated pathways between rows, preventing the direct pressure on crop-growing area, while furrows aid in managing tractor and human traffic during various farm operations such as spraying, weeding, and harvesting7,8,9. Raised bed farming practice also helps in maintaining the soil porosity and promoting the better root penetration10. Moreover, it is one of the contemporary farming practices, which enhances soil structure, improves drainage and boosts the crop’s growth11. It is particularly beneficial in regions prone to waterlogging or soil compaction and is widely used for growing crops such as wheat, rice, and vegetables12. Raised bed former helps to shape the soil into elevated beds, allowing excess water to drain away efficiently and thereby, reducing waterlogging and its negative impact on root growth and crop productivity13. The properly structured raised bed directs the water to plant roots, minimizes wastage, improves water use efficiency and uses significantly lesser water than conventional flat-bed methods, thus making it ideal for water-scarce regions as well14,15. Long-term field measurements on contrasting soil types have shown that raised beds can decrease surface runoff by roughly 15–20 mm in Alfisols and 35–40 mm in Vertisols, accompanied by 30–60% reductions in soil loss when compared with flat beds16. In irrigated maize–wheat rotations, permanent raised beds achieved approximately 8% higher water use efficiency (WUE) in maize and 22% higher WUE in wheat relative to flat bed planting17. Similarly, other researchers reported that furrow irrigated raised bed systems reduced irrigation requirements by 18–20% and increased WUE by 8–23% in wheat production18,19. Despite multiple benefits, the adoption of raised bed farming practice by farmers is low due to limited availability of suitable raised bed former and lack of awareness. Several researchers developed raised bed former suitable for various crops. Dixit et al.8 developed a wide raised bed former for vegetable cultivation, comprising of rotary tiller and bed shaper, which could form bed top width of 1000 mm, height of 130 mm and trapezoidal furrow of 330 mm top and 40 mm bottom width. In a different study, Meselhy20 developed integrated unit for raised bed forming, drip lateral and plastic mulch laying operations. The equipment could form the raised bed of dimensions of 900 mm width and 300 mm height to facilitate plastic mulch laying firmly along with placement of surface and subsurface drip irrigation pipes underneath the plastic film simultaneously. Kumar et al.21 designed a raised bed former having two furrowers on its both sides for scouring of the soil and inclined plate planter for onion seed planting, which could form bed of 1000 mm top width. Several other studies have been conducted on development of raised bed former, either alone or in combination with a rotary tiller, seeder, planter, or fertilizer applicator8,21,22. Raised bed based crop cultivation resulted into reduced operational costs, fuel consumption and time while increased yield compared to flatbed system22.

The raised bed forming is helpful in making the soil quality better by enhancing drainage, aeration, and allowing for superior control of soil temperature and moisture, leading to healthier plant growth and greater water management16. In wheat-maize cropping system, He et al.23 found several benefits viz. increased macro-aggregates, enhanced distribution of pore size classes, higher hydraulic conductivity, 4.2% more crop yield and 21.3% increase in water use efficiency under raised bed system over flat bed method. In a different study, Garg et al.16 reported 30–60% lesser soil loss from raised bed method as compared to traditional system. Despite multiple benefits, the higher energy consumption associated with movement of bulk soil volume during the bed forming process after the tillage operation is considered as an energy exhaustive step24. It opens the research gap to reduce the energy consumption in terms of draft force and fuel consumption during the raised bed forming operation. The energy required for raised bed forming is directly linked to the forces involved, such as draft force and vertical force, making these as significant contributors in overall energy consumption within the system25,26. The draft force and bed uniformity are further dependent on various major factors such as soil moisture content, bed width, forward speed during the operation and weight of the machine27,28. The raised bed forming process performed with optimal conditions of these parameters might be an economical and energy efficient strategy. The authors found limited literature available on optimization of soil, machine and operational parameters of raised bed former. Rajesh and Jayan29 conducted field experiments with various speed of operation (1.0–2.0 km h− 1) and depth of operation (10–20 cm), and found lesser draft of bed former at a forward speed of 1.5 km h− 1 and depth of operation as 15 cm, while bed height was maximum at 2 km h− 1 speed and 20 cm depth of operation. It is always not necessary that optimum settings of input parameters are found at the levels on which experiment has been performed which calls the use of modern techniques for precise prediction and optimization of parameters for raised bed former. A few researchers applied modern techniques such as artificial neural network, particle swarm optimization (PSO), genetic algorithm (GA), response surface methodology (RSM), etc., for building the prediction models and optimization of parameters of agricultural equipment and processes, and reported good results30,31,32,33. Anantachar et al.34 established artificial neural network (ANN) model for determining the optimum design and operational parameters of an inclined plate seed metering device under sticky belt method. RSM technique is helpful for building the model up to cubic terms, while ANN technique can handle non-linear and complex problems easily in a faster way. Moreover, ANN model outperformed classical regression methods in complex problems35. Pareek et al.36 used neural network model coupled with PSO technique for optimization of parameters of a pneumatic planter and found a variation of −2.1 to 5.4% between actual and predicted values of quality feed index and precision index of the planter. On optimization aspect, both GA and PSO are population-based meta-heuristic algorithms which can handle both discrete and continuous variables in complex nonlinear optimization problems; however, PSO offers faster convergence and comparatively better accuracy37,38. Therefore, such techniques might be helpful for optimization of parameters and cutting down the energy expenditure during the raised bed forming process.

Although raised bed systems and their associated equipments have been widely studied for their agronomic benefits, very limited research has been focused on optimization of design and operating parameters of raised bed former to reduce its energy demand particularly draft force, and fuel consumption during the bed formation process. Existing studies provide only isolated insights into how factors such as soil moisture, bed width, and forward speed influence draft and bed quality, and most of these studies do not apply modern predictive or meta-heuristic optimization tools. Moreover, there is little empirical evidence on the development and performance evaluation of variable-width raised bed formers optimized using advanced machine-learning or hybrid techniques such as ANN-PSO. This leaves a significant gap in engineering-focused research aimed at enhancing the energy efficiency, operational performance, and overall better adoptability of raised bed formation technique. Therefore, the present study aims to develop a variable width raised bed former and to evaluate its performance with optimal input parameters predicted by RBF neural network-PSO framework.

Materials and methods

Experimental set-up for laboratory experiments

The laboratory experiments on developed test rig of variable width raised bed former were performed in an indoor soil bin facility of ICAR-Central Institute of Agricultural Engineering, Bhopal, India (23°18’35"N, 77°02’41"E and 498.7 m above sea level). The region falls in humid sub-tropical climate with annual rainfall of 1100 mm. The laboratory tests were conducted on black cotton soil as present in the field. The soil bin comprised a stationary bin, soil processing trolley, tool carrier, test rig, rotary to linear movement transmission system, control panel, and data acquisition system (Fig. 1). The top rails mounted on each side of soil bin were used to guide the linear movement of soil processing trolley, tool carrier and test rig. Rotary tiller and leveler were attached in soil processing trolley followed by hydraulically operated press roller for compaction of the soil during the bed preparation. Tool carrier and soil processing trolley were connected by rectangular bars and mounting plates. Soil processing trolley was also equipped with water sprinkler unit in order to vary the moisture content of the soil. The test rig was mounted on tool carrier through draft measuring system. The vertical adjustment of soil processing tools and test rig was done with the help of single acting hydraulic cylinder and steering wheel with chain and sprocket mechanism in the system, thereby enabling the controlled adjustment and secure positioning of the tools and test rig as per requirement. The linear to and fro movement of soil processing trolley and tool carrier at different speeds was done with the help of variable frequency drive three phase induction motor (power: 15 kW, max speed: 1445 rpm) connected to intermediate shaft through a speed reducing chain-sprocket combination. Two chains, whose one ends are connected to soil processing trolley at front while other ends to tool carrier at rear, rotate over the sprockets mounted at both ends of the intermediate shaft and similar sprockets mounted on the opposite end of the soil bin. Control panel was employed for the movement of soil processing trolley and test rig at the required speed in the forward and backward directions.

Soil bin

To replicate the field conditions, the soil bin was prepared to match the soil characteristics (moisture content, bulk density and cone index) of the field. The soil bin comprised a fixed soil container having 16 m length, 2 m width and 1 m depth as shown in Fig. 1. The soil bin was occupied with black cotton soil (sand: 19.2%, silt: 27.6% silt, and clay: 52.3%) having a bulk density of 1.37 g cm− 3 and field capacity of 30.6%.

Instrumentation and measurements in soil bin tests

The instrumentation setup having two horizontally placed S-type load cells (IPA Pvt. Ltd., Bangalore) was used for measuring the draft of test rig. All load cells were calibrated for both tensile and compressive loading prior to the experiment. The calibration of S-type load cells for tensile load was performed on calibration setup having the mechanical floor crane, a certified load cell and digital display. S-type load cell was placed in between of certified load cell with display and pulley of the crane. The tensile load was gradually increased through ratchet pinion of mechanical crane and output of S-type load cell was recorded with help of data logger and laptop. The calibration of S-type load cell for compressive load was done on bench vice type calibration setup having the loading plate and arrangement for mounting the load cell. After mounting the load cell on calibration setup, the compressive load was increased gradually by means of adding standard weights on the loading plate and corresponding output was recorded. In soil bin, each load cell was designed with a fixed end connected to the toolbar carrier while free end attached with test rig. The tool carrier velocity was regulated by a three-phase induction motor and it was calculated according to distance measured by a laser displacement sensor (SICK AG, Germany, DT500) and time counter option in the data logger. A Quantum X 840 A, 16-channel universal data acquisition system (Hottinger Baldwin Messtechnik, Germany) was employed to capture the data of multiple sensors installed in the soil bin.

Test rig

Soil bin experiments were carried out with the developed test rig of variable width raised bed former as shown in Fig. 2. It consisted of main frame assembly, adjustable side wings, bed top shaper and single hitch point. The test rig was made of mild steel with overall dimension of 1600 mm × 329 mm × 822 mm. This was the initial version, which was further intended to upgrade to raised bed former-cum-mulch laying machine and then to raised bed former-cum-mulch laying-cum-punch planting machine with the same basic configuration in the future. The test rig was attached to draft measuring system mounted on the tool carrier. The vertical adjustment of the test rig was done using steering wheel with chain and sprocket mechanism in the system as detailed in section 2.1.

Soil bed preparation, experimental design and procedure

Prior to the experimental study, the known amount of irrigation was sprinkled uniformly throughout the soil bin and the soil was tilled deeper at 250 mm to achieve the required soil moisture content and uniform tilth. The soil moisture content was measured as per Indian Standard [IS: 2720 (Part II)−2010]. To maintain the consistent and repeatable conditions, soil bin was reconditioned after each experimental trial to simulate the real field conditions and ensuring the reliability and reproducibility of the experimental results. A factorial completely randomized design (CRD) involving three levels of soil moisture content (11, 13 and 15% on wet basis), three levels of working width (0.7, 0.8 and 1.0 m) and three levels of forward speed (0.42, 0.56 and 0.69 m s− 1) was employed to assess the effects of dependent variables on draft force as given in Table 1. The lower speed range (1.5–2.5 km h− 1) in this experiment was selected to suit for raised bed former and mulch laying-cum-punch planting machine. For each treatment, the experiment was replicated thrice and these data were used to develop regression and radial basis function (RBF) neural network models for prediction of specific draft (draft per unit width) and optimization of parameters using RBF neural network-particle swarm optimization (RBF neural network-PSO) technique for minimum specific draft.

Development of regression and RBF neural network models

Regression model

The data of soil bin experiments (soil moisture, working width, operational speed and specific draft) were subjected to analysis of variance performed at 5% level of significance (α = 0.05). The main factors and their interaction identified as significant terms (p-value < 0.05) were used for building the regression model. The developed regression model can be mathematically represented as given in Eq. 1. Based on the values of regression coefficients (\(\:{{\upbeta\:}}_{0}\), \(\:{{\upbeta\:}}_{1},\:\dots\:)\), specific draft was predicted for a given set of conditions and it was compared with actual specific draft. Various key indices such as mean square error (MSE), root mean square error (RMSE), mean absolute error (MAE), mean absolute percent error (MAPE) and coefficient of determination (R2) used for performance evaluation of the model were computed using Eqs. 2–6.

where \(\:\widehat{\text{Y}}\) is predicted value of specific draft, \(\:{{\upbeta\:}}_{0}\) is the model intercept, \(\:{{\upbeta\:}}_{\text{m}}\) is the coefficient for \(\:{\text{m}}^{\text{t}\text{h}}\) input parameter, \(\:{{\upbeta\:}}_{\text{m}\text{n}}\) is the coefficient for interaction of \(\:{\text{m}}^{\text{t}\text{h}}\) and \(\:{\text{n}}^{\text{t}\text{h}}\) input parameters, \(\:{\text{X}}_{\text{m}}\)is \(\:{\text{m}}^{\text{t}\text{h}}\) input parameter and \(\:{\text{X}}_{\text{n}}\) is \(\:{\text{n}}^{\text{t}\text{h}}\) input parameter.

where, \(\:\text{Y}\)i is actual value of specific draft N m− 1; \(\:\widehat{\text{Y}}\)i is predicted value of specific draft N m− 1; \(\:\overline{\text{Y}}\) is mean value of specific draft N m− 1, and n is the sample size. MSE represents mean square error. RMSE denotes the standard deviation of the residuals, used for evaluating the quality of predictions. MAE indicates mean absolute error. MAPE represent the accuracy in percentage, and R2 value represents the variance of experimental data explained by the model.

RBF neural network model

Radial function based neural networks are considered alternative to multilayer perceptron feed forward neural network and widely used due to their ability to approximate complex functions and handle non-linear data. RBF neural network consists of three layers namely input layer, hidden layer and output layer. The input variables are allocated to each neuron present in the input layer, which then pass the input information to hidden layer. In next (hidden) layer, each neuron calculates the Euclidean distance between input data and centre of the neuron. This distance is then transformed by radial activation function (usually Gaussian) in the hidden layer. The transformed values from all neurons of hidden layer are multiplied by different weights and linearly aggregated in an output layer to produce the final output. A RBF neural network model with architecture of 3–12-1 having three, twelve and one neuron in input, hidden and output layers of the network, respectively, is depicted in Fig. 3. RBF neural network model with input vector x produces the output y using the following relations:

where, \(\:{\text{w}}_{\text{i}}\) represents the weight for \(\:{\text{i}}^{\text{t}\text{h}}\) neuron in hidden layer,\(\:\:{\varnothing}(\:.)\) is a radial basis function, \(\:\parallel\:\:.\parallel\:\) represents the Euclidean distance, \(\:{\text{c}}_{\text{i}}\) represents the centre of \(\:{\text{i}}^{\text{t}\text{h}}\) neuron and \(\:{\upbeta\:}\) is the spread constant.

The model was trained with randomly selected 70% data of total dataset and rest data were considered for testing of the model. In model, soil moisture, working width and operational speed were utilized as input parameters, while specific draft was considered as output parameter. Initially, spread constant and number of neurons in the model were varied to build a well-trained model having low mean square error (MSE) value. After fixing the number of neurons and spread constant, performance indices RMSE, MAE, MAPE and R2 were used for performance evaluation of the model. The well-trained RBF neural network model was then integrated with PSO technique and named as RBF neural network-PSO model for optimization of input parameters.

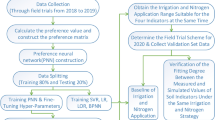

Particle swarm optimization

Particle swarm optimization technique is inspired from the social behavior of fish or birds moving in a group and searching for food. This technique works effectively in global maximization or minimization problem having variables of discrete and continuous nature39. Moreover, it has good search ability, faster convergence and lesser parameters to tune37,40. The major steps or processes involved in working of PSO technique are shown in Fig. 4. In this technique, swarm is depicted as a group of particles, each representing a potential solution, which move through a multidimensional search area by altering their positions and velocities according to their own experience and information shared by neighboring particles. The algorithm is started with random position of particles which are accelerated towards their personal best and global best positions according to velocity. At each point, data of position as well as velocity of all particles are retained in the algorithm. The movement (position and velocity) of each particle is decided according to cognitive component, representing the personal best position of the particle, and social component, reflecting the best position in the entire swarm. The position and velocity of particles are modified according to the following equations:

where \(\:{v}_{m}^{n}\) denotes the velocity of \(\:m\)th particle at iteration n, \(\:w\:\)indicates inertia weight factor, \(\:{c}_{1}\) and \(\:{c}_{2}\) represent individual and social learning parameter, respectively, \(\:{pb}_{m}\) shows the position of \(\:m\)th particle at its personal best value, \(\:{gb}_{m}\) indicates the position of \(\:m\)th group at its global best value, \(\:{x}_{m}^{n}\) denotes the position of \(\:m\)th particle at iteration n, and \(\:{r}_{1}\) and \(\:{r}_{2}\) represent uniformly distributed random numbers.

A value of 1.05 was assigned to each learning parameters (\(\:{c}_{1}\) and \(\:{c}_{2}\)). The value of inertia weight parameter was varied from 1.0 to 0.3. The design problem in the present study was a minimization problem involving continuous type control parameter namely soil moisture and discrete type control parameters namely working width and operational speed which are denoted as \(\:{X}_{1},\:{X}_{2}\:\)and \(\:{X}_{3}\), respectively. The designed problem can be defined as given below:

\(\:\underset{X\:\in\:\:{X}^{T}}{\text{min}}f\left(X\right)\) subject to

Development of tractor operated variable width raised bed former and its working

The tractor operated variable width raised bed former was developed (Fig. 5) and its performance was evaluated in the field with optimal parameters as determined from soil bin experiments. It consisted of main frame, adjustable side wings, bed top shaper, three point linkage, depth adjustment link and deadweight. The side wings of the variable width raised bed former can be adjusted from both sides with nut and bolt to achieve the desired bed width ranging from 700 mm to 1000 mm in a step of 100 mm. For making of 1000, 800 and 700 mm bed top, the front side (side wing to side wing) of variable width raised bed former was set at 1700, 1600, 1400 mm while rear side (side wing to side wing) was set at 1130, 1030 and 830 mm, respectively, with a height of 150 mm. The tractor operated variable width raised bed former collects the soil present inside the wide wings at front and converges it to narrow section at rear along with compression from bed top shaper to form a bed of trapezoidal shape. The depth adjustment link was provided to increase or decrease height of the bed. The dead weight of 160 kg was attached at the rear top side of variable width raised bed former to match the weight of experimental setup and for uniform bed top formation.

Field evaluation of the tractor operated variable width raised bed former

The performance of tractor operated variable width raised bed former was evaluated at the experimental farm of ICAR-CIAE, Bhopal. The field had clayey textured soil (sand: 30.9%, silt: 11.2% and clay: 57.9%). Prior to the field evaluation, a good tilth of the soil was achieved with one pass of mould board plough, cultivator and rotavator each. The soil had mean clod diameter (determined by sieve analysis) of 22 mm, and a bulk density of 1.46 g cm-3 after tilling operation. When moisture of field soil was about 13.25%, variable width raised bed former with 1.0 m working width was operated in the field for its performance evaluation using a 55 hp tractor (make: New Holland, model: 3630 TX Plus) running at a forward speed of 2 km h− 1 (0.56 m s− 1). The performance parameters such as draft, fuel consumption, field capacity and field efficiency were measured in accordance with the established procedures outlined in Indian Standard (IS: 7640 − 1999). The draft was measured by dynamometer (make: Novatech, model: F-256TFROKN, Capacity: 2 tonne) using auxiliary tractor method. The theoretical field capacity was calculated according to Eq. 11. The effective field capacity was determined by operating the implement in a known area and recording the operational time using stopwatch as per Eq. 12. The field efficiency of the implement was calculated using Eq. 13. The fuel consumption of tractor was measured using auxiliary tank method in which tank was filled with fuel to an upper mark (near neck) before start of the operation. After completion of the operation, the required amount of fuel was measured and put in the auxiliary tank till its level reaches the upper mark. The bed quality was also assessed in terms of slant angle to ensure the uniformity of bed dimensions and levelness of the bed’s top surface.

Data analysis

The experimental data of the study were statistically analyzed using SPSS® (version 22.0) software at a significance level of 5% (α = 0.05). Analysis of variance (ANOVA) was performed to identify the significant terms, useful for building the regression model. MATLAB® platform R2014 (8.3.0.532) was used for executing RBF neural network-PSO technique.

Results and discussion

Regression model

An analysis of variance (ANOVA) was performed to find out the significance status of input parameters and their interactions, affecting the specific draft of test rig (Table 2). The results of ANOVA suggested that soil moisture, working width, operational speed and soil moisture × working width introduced significant (p < 0.05) effect on specific draft of test rig. The other interaction terms were non-significant (p > 0.05). Multiple linear regression model was built using SPSS® (version 22.0) software by considering the significant factors as witnessed in ANOVA analysis. The developed regression model can be expressed as given in Eq. 14.

where, draft⁄width is in N m− 1; soil moisture is in percentage (wet basis); working width is in m; operational speed is in m s− 1 and \(\:{\text{C}}_{\text{i}}\) = regression coefficients (for i = 0, 1, 2, 3, 4). The values of regression coefficients along with standard error are presented in Table 3.

The values of regression coefficients along with standard error for developed regression model are shown in Table 3. ANOVA results of developed regression model are given in Table 4. It is evident from the presented results that developed regression model indicated high R2 value which underpins the accuracy of model and explaining the variability of experimental data.

RBF neural network model

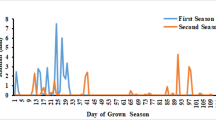

The model was trained using 70% of the total data. During the initial phase of the model, spread constant was varied while fixing the maximum number of neurons as 15. The model with spread constant of 1.0e1 exhibited good results. Now, the numbers of neurons were varied while fixing the spread constant as 1.0e1 to get the mean square error (MSE) in the lower range as shown in Fig. 6. Initially, MSE decreased rapidly with number of neurons but it was in narrow range when numbers of neurons were 17 to 21. The lowest value of MSE was observed with 20 number of neurons and it was slightly increased with number of neurons exceeding 21 (Fig. 6).

Comparative performance of regression and RBF neural network models

The comparative performance of developed regression and RBF neural network models was evaluated using training and testing phase data. The values of specific draft predicted by both the models are compared with actual specific draft using data points (total = 19) of training period as shown in Fig. 7. A good agreement was found between actual and predicted specific draft by both the models. Similar trend was observed for data points (total = 9) of testing period as depicted in Fig. 8. It is understood that both models performed superiorly with R2 value more than 0.98; however, RBF neural network predicted specific draft more close to actual ones (R2 > 0.99) with lesser MPAE (≤ 1.02) and RMSE (≤ 41.40) in training as well as testing phase as compared to the regression model. The results of the present study are similar to report given by Bayat et al.41 who reported better performance of ANN model over regression model in predicting the cone index using bulk density, gravimetric soil water content, total porosity and relative saturation of the soil. Similarly, Çarman et al.42 reported superior performance of ANN model compared to regression model in prediction of draft and soil area disturbed by chisel tine under the soil bin conditions.

Optimal input parameters predicted by RBF neural network-PSO

A good performing RBF neural network model (as discussed in section 3.3) was integrated with PSO technique for predicting the optimal input parameters (soil moisture, working width and operational speed) of raised bed former. Algorithm of RBF neural network-PSO was run multiple times to produce different combinations of optimal soil moisture, working width and operational speed as shown in Table 5 by considering the fact that some combinations may have such setting of discrete type parameters which are not feasible in this experiment. The predicted specific draft was compared with actual specific draft either available from standard run or by evaluating the performance of test rig at the desired settings. In all feasible combinations, variation between predicted and actual specific draft was observed within ± 3.62%. In other fields also, researchers reported good prediction results with neural network models having lesser than 10% variation from actual data32,43. The combination having the soil moisture of 13.25%, working width of 1.0 m and operational speed of 0.56 m s− 1 was selected in which variation between predicted and actual specific draft was found as 1.34%. In the selected combination, RBF neural network demonstrated good performance indices viz. RMSE, MAE, MAPE and R2 having values of 5.78, 17.88, 0.40 and 0.998, and 21.19, 50.13, 1.02 and 0.994 during the training and testing phase, respectively. The mean fitness value of all particles coincided with global best fitness value within 10 iterations as shown in Fig. 9, which is the benefit of PSO technique37.

Field evaluation of the variable width raised bed former

The performance of tractor operated variable width raised bed former was evaluated with optimal input settings under field conditions (Fig. 10). After preparing the field, soil bulk density was found to be 1.46 g cm-3. When moisture of the soil reached about 13.25%, field operation of tractor operated variable width raised bed former with 1.0 m width and 0.56 m s− 1 forward speed was done and its draft was measured. The measured draft was found as 4349 N and 4349 N m− 1 in term of per unit width. This shows a 7.21% variation in predicted value of specific draft for soil bin condition and actual specific draft of variable width raised bed former measured in the field. This variation could be due to more heterogeneity in term of soil moisture, clod size and compactness across the field. Nevertheless, the results of predicted optimal input parameters were reasonably good, which shows the applicability of such technique in agricultural operations. Sarkar and Raheman44 used radial basis function neural network integrated with PSO for optimization of operational parameters of a laboratory setup for harvesting the cabbage and found a variation of −5.1 to 10.7% between actual and predicted values of cutting torque. In the present study, field capacity and field efficiency of variable width raised bed former were calculated as 0.23 ha h− 1 and 72%, respectively, with a fuel consumption of 4.5 L h− 1. In the field performance evaluation of a 2.0 m wide raised bed seed-cum-fertilizer drill, Shrivastava et al.45 observed field capacity of 0.82 ha h− 1, field efficiency of 86.8% and draft force of 3450 N at the forward speed of 5.2 km h− 1. Saha et al.46 evaluated the field performance of 2.0 m wide rotary-assisted broad bed former-cum-seeder at 2.5 km h− 1 speed and found effective field capacity of 0.325 ha h− 1 and fuel consumption of 7.1 L h− 1. In a different study, Fouda et al.47 evaluated the performance of raised bed machine at different speeds (2.0, 3.5 and 4.5 km h− 1) and reported that increase in speed from 2 km h− 1 to 4.5 km h− 1 led to 42.9% increase in effective field capacity and 68.8% rise in fuel consumption, while 47.7% reduction in field efficiency. In present study, the mean bed slant angle was determined to be 60°. The bulk density of soil increased to 1.57 g cm-3³ after the formation of bed. Dixit el al8 also reported that bulk density of soil increased to 1.63 g cm− 3 from 1.46 g cm− 3 after formation of bed possibly due to compaction of soil from side wings and top bed shaper48,49. Dixit et al.8 reported good formation of bed with 1.0 m width at top, 1.31 m width at bottom, 0.13 m height and slant angle of 41° in sandy loam soil when operated at a speed of 0.76 m s− 1 (2.75 km h− 1). In present study, the tractor operated variable width raised bed former with 1.0 m width was also operated at 1.25 m s− 1 forward speed and found that the bed was successfully formed with 180 mm bed height, 0.90 m top width and 1.1 m bottom width. With this pseed, the top and bottom width of bed were reduced under the field conditions compared to bed formed in soil bin, which might be due to greater forward speed and varying soil tilth. The mean field capacity, field efficiency and fuel consumption at this speed was observed to be 0.45 ha h− 1, 62.5% and 5.7 L h− 1 , respectively. Irrespective of the bed width, variable width raised bed former could form the raised beds of 165 ± 15 mm in height and furrows with 350 mm bottom width and 550 mm top width. It indicates the effective working of variable width raised bed former across the width range and at higher speeds as well. Total labour requirement in the operation of variable width raised bed former was 0.56 man-day ha− 1. Pagare et al.50 also reported 0.09 ha h− 1 field capacity, 59% field efficiency and 780–845 N draft of a 0.65 m wide animal drawn raised bed former-cum-planter. Dixit et al.8 found a field capacity of 0.31 ha h− 1, fuel consumption of 5.9 L h− 1 and labour requirement of 2.48 man-day ha− 1, when wide bed former was operated at an optimum speed of 2.75 km h− 1. Shrivastava et al. 51 also indicated 58.4–61.7% field efficiency and 29.7–35.4 L ha− 1 specific fuel consumption for various raised bed former-cum-planters (working width: 1.13–2.22 m). Therefore, field operation of variable width raised bed former with optimal input parameters can ensure the quality work output while minimizing the energy demand, thereby reducing the fuel consumption and its associated harmful impact on the environment.

Conclusions

The raised bed farming has huge potential for water management, improving the soil physical health and augmenting the crop yield pertinent to water logging prone areas. Keeping variable size requirement of bed by different crops in mind, a variable width raised bed former was developed and its test rig was evaluated for draft requirement at various levels of soil moisture (11, 13 and 15%, wet basis), working width (0.7, 0.8 and 1.0 m) and operational speed (0.42, 0.56 and 0.69 m s− 1) under the soil bin condition. The experimental data were used to develop regression and RBF-neural network models for prediction of specific draft and finding out the optimal input parameters for minimum specific draft using RBF neural network-PSO technique. The performance of test rig in soil bin and tractor operated variable width raised bed former with similar configuration in field condition was evaluated using optimal parameters. The results of the present study led to the following concluding remarks:

-

The effect of soil moisture, working width, operational speed and soil moisture × working width on specific draft of test rig was significant (p < 0.05).

-

Both regression and RBF neural network predicted specific draft of test rig with good accuracy (R2 > 0.98) in training as well as in testing phase; however, RBF neural network model performed superiorly over regression model.

-

RBF neural network-PSO optimized the input parameters as 13.25% soil moisture, 1.0 m working width and 0.56 m s−1 operational speed for predicted specific draft of test rig as 4056.6 N m−1against the actual value of 4002.4 N m−1. In all combinations of input parameters, variation between predicted and actual specific draft of test rig was observed within ± 3.62%.

-

The performance of tractor operated raised bed former evaluated at optimal input parameters showed specific draft of 4349 N m−1 against the predicted value of 4056.6 N m−1 along with 0.23 ha h−1 field capacity, 72% field efficiency and fuel consumption of 4.5 L h−1.

-

In terms of quality of bed formation, slant angle was measured to be 60°, while the bulk density of soil increased to 1.57 g cm-³ from 1.46 g cm-³ after formation of the bed.

Scope for future work

It can be understood that modern techniques such artificial neural network, particle swarm optimization, etc., offer good potential for application in agriculture sector. Such techniques need to be adopted for prediction and optimization of operational parameters of agricultural machinery in order to diminish the energy expenditure and reducing the input cost especially in energy-intensive operations such as land and seed bed preparation. The findings of the present study are limit bound and these may be applicable for similar settings and input conditions. Future study on development of variable width raised bed former of broad working width range (0.7–1.7 m) can expand the applicability of such implements to various cropping systems. Moreover, performance of such configured implements needs to be evaluated in various textured soils to reach the broadly applicable optimal input conditions given by the optimization techniques.

Data availability

The data that support the findings of this study are available from the corresponding author upon reasonable request.

References

Hobson, D., Harty, M., Tracy, S. & McDonnell, K. The effect of tillage depth and traffic management on soil properties and root development during two growth stages of winter wheat (Triticum aestivum L). SOIL. Discuss. 2021, 1–32. https://doi.org/10.5194/soil-8-391-2022 (2021).

Gao, P. J. et al. Effect of planting methods and tillage practices on soil health and maize productivity. Front. Plant Sci. 15, 1436011. https://doi.org/10.3389/fpls.2024.1436011 (2024).

Horn, R. & Fleige, H. A method for assessing the impact of load on mechanical stability and on physical properties of soils. Soil Tillage. Res. 73 (1–2), 89–99. https://doi.org/10.1016/S0167-1987(03)00102-8 (2003).

Hakansson, I. Machinery-induced compaction of arable soils: incidence, consequences, counter-measures. SLU, department of soil Sciences, division of soil management. Rep. No 109. https://pub.epsilon.slu.se/5517/1/hakansson_i_101206.pdf (2005).

Chan, K. Y. et al. Agronomic consequences of tractor wheel compaction on a clay soil. Soil Tillage. Res. 89 (1), 13–21. https://doi.org/10.1016/j.still.2005.06.007 (2006).

Nassir, A. J., Mishall, A. A. H., Sabah, Q. S., Almtherfe, A.A.A.K., Awad, A. H. & Alwan, A. A. M. Soil compaction induced by different tillage systems and its impact on growth and yield of maize (zea Mays l.): A review. Univ. Thi-Qar J. Agricultural Res. 13 (1), 185–200. https://doi.org/10.54174/szm42027 (2024).

McPhee, J. E., Aird, P. L., Hardie, M. A. & Corkrey, S. R. The effect of controlled traffic on soil physical properties and tillage requirements for vegetable production. Soil Tillage. Res. 149, 33–45. https://doi.org/10.1016/j.still.2014.12.018 (2015).

Dixit, A., Khurana, R., Verma, A., Singh, A. & Manes, G. S. Development and evaluation of a wide-bed former for vegetable cultivation in controlled tractor traffic. J. Institution Eng. (India): Ser. A. 99 (3), 449–452. https://doi.org/10.1007/s40030-018-0305-8 (2018).

Jacobs, A. A. et al. Tillage and cover crop systems alter soil particle size distribution in Raised-Bed-and-Furrow Row-Crop agroecosystems. Soil. Syst. 8 (1), 6. https://doi.org/10.3390/soilsystems8010006 (2024).

Bakker, D. M., Hamilton, G. J., Houlbrooke, D. J. & Spann, C. The effect of Raised beds on soil structure, waterlogging, and productivity on duplex soils in Western Australia. Soil. Res. 43 (5), 575–585. https://doi.org/10.1071/SR03118 (2005).

Holland, J. E., White, R. E. & Edis, R. Improved drainage and greater air-filled porosity of Raised beds in south-western Victoria. Soil. Res. 46 (4), 397–402. https://doi.org/10.1071/SR08003 (2008).

Du, X. et al. Raised bed planting reduces waterlogging and increases yield in wheat following rice. Field Crops Res. 265, 108119. https://doi.org/10.1016/j.fcr.2021.108119 (2021).

Manik, S. N. et al. Soil and crop management practices to minimize the impact of waterlogging on crop productivity. Front. Plant Sci. 10, 140. https://doi.org/10.3389/fpls.2019.00140 (2019).

Pramanik, S. C., Singh, N. B. & Singh, K. K. Yield, economics and water use efficiency of Chickpea (Cicer arietinum) under various irrigation regimes on Raised bed planting system. Ind. J. Agron. 54 (3), 315–318. https://doi.org/10.59797/ija.v54i3.4796 (2009).

Sawant, C. P. et al. Irrigation and conservation agricultural practices improve crop yield, water productivity and energetics of Chickpea (Cicer arietinum L.) in vertisols of central India. Irrig. Sci. 72 (3), 664–681. https://doi.org/10.1002/ird.2817 (2023).

Garg, K. K. et al. Impact of Raised beds on surface runoff and soil loss in Alfisols and vertisols. Catena 211, 105972. https://doi.org/10.1016/j.catena.2021.105972 (2022).

Ram, H. et al. Agronomic and economic evaluation of permanent Raised beds, no tillage and straw mulching for an irrigated maize-wheat system in Northwest India. Exp. Agric. 48 (1), 21–38. https://doi.org/10.1017/S0014479711000809 (2012).

Behera, U. K. & Sharma, A. R. Productivity and water use efficiency of wheat (Triticum aestivum) under different resource conservation techniques and irrigation regimes. Cereal Res. Commun. 42 (3), 439–449. https://doi.org/10.1556/CRC.2013.0072 (2014).

Singh, Y., Kukal, S., Jat, M. L. & Sidhu, H. S. Improving water productivity of wheat-based cropping systems in South Asia for sustained productivity. In D. Sparks (Ed.), Advances in Agronomy (Vol. 127, pp. 157–258). Academic Press. (2014). https://doi.org/10.1016/B978-0-12-800131-8.00004-2

Meselhy, A. A. Development the wide ridges machine for laying drip irrigation tubes and plastic mulch in Ras Sudr-South of Sinai. Int. J. Appl. Agricultural Sci. 6 (5), 135–147. https://doi.org/10.11648/j.ijaas.20200605.15 (2020).

Kumar, R., Sahoo, P. K., Choudhary, A. K. & Indramani, I. Design, development and performance evaluation of tractor-drawn raised-bed pulse-planter for precision sowing of pigeon pea (Cajanus cajan). Indian J. Agricultural Sci. 90 (9), 1800–1809. https://doi.org/10.56093/ijas.v90i9.106631 (2020).

Singh, K. P. et al. Performance evaluation of tractor operated Raised bed Former-cum-Seeder for Maize-Chickpea cropping sequence. J. Agricultural Eng. 53 (1), 1–8. https://doi.org/10.52151/jae2016531.1592 (2016).

He, J. et al. Permanent Raised beds improved soil structure and yield of spring wheat in arid north-western China. Soil Use Manag. 28 (4), 536–543 (2012).

Oduma, O. et al. Modelling of the effects of working width, tillage depth and operational speed on draft and power requirements of disc plough in sandy-clay soil in South-East Nigeria. Sci. Afr. 21, e01815. https://doi.org/10.1016/j.sciaf.2023.e01815 (2023).

Sadek, M. A., Chen, Y. & Zeng, Z. Draft force prediction for a high-speed disc implement using discrete element modelling. Biosyst. Eng. 202, 133–141. https://doi.org/10.1016/j.biosystemseng.2020.12.009 (2021).

Bae, B. M. et al. The development of a draft force prediction model for agricultural tractors based on the discrete element method in loam and clay loam. Agriculture 13 (12), 2205. https://doi.org/10.3390/agriculture13122205 (2023).

Abbaspour-Gilandeh, Y. et al. Effect of different working and tool parameters on performance of several types of cultivators. Agriculture 10 (5), 145. https://doi.org/10.3390/agriculture10050145 (2020).

Ketena, S. et al. Soil tillage interactions study based on workability and draft power efficiency. Discov Agric. 3, 182. https://doi.org/10.1007/s44279-025-00350-0 (2025).

Rajesh, A. N. & Jayan, P. R. Development and testing of tractor operated bed former for seed bed preparation in Kaipad region. Retrieved September 9, 2025, from (2012). https://krishikosh.egranth.ac.in/server/api/core/bitstreams/676127fe-8261-444d-ab4d-91bc7d7ae350/content

Hosseini, M., Naeini, S. A. M., Dehghani, A. A. & Khaledian, Y. Estimation of soil mechanical resistance parameter by using particle swarm optimization, genetic algorithm and multiple regression methods. Soil Tillage. Res. 157, 32–42. https://doi.org/10.1016/j.still.2015.11.004 (2016).

Kumar, N. & Raheman, H. Characterization of nano-oxide added water emulsified biodiesel blend prepared with optimal emulsifying parameters. Renew. Energy. 145, 308–317. https://doi.org/10.1016/j.renene.2019.06.009 (2020).

Sawant, C. P. et al. Optimization of operational parameters of site-specific pesticide spray module for young pomegranate orchards using RSM and RBFNN-PSO techniques. J. Biosystems Eng. 48 (2), 225–241. https://doi.org/10.1007/s42853-023-00185-x (2023).

Wang, Z. et al. Prediction and calibration of black soil modeling parameters based on response surface methodology and machine learning algorithms. Part. Sci. Technol. 43 (4), 534–545. https://doi.org/10.1080/02726351.2025.2476672 (2025).

Anantachar, M., Kumar, P. G. & Guruswamy, T. Neural networkprediction of performance parameters of an inclined plate seed metering device and its reverse mapping for the determination of optimum design and operational parameters. Comput. Electron. Agric. 72 (2), 87–98. https://doi.org/10.1016/j.compag.2010.03.001 (2010).

Agrawal, K., Panda, A. & Sahoo, A. K. Advancements in tool wear monitoring in turning operations: digital image processing and AI techniques. In Journal of Physics: Conference Series (Vol. 2818, No. 1, p. 012040). IOP Publishing. (2024).

Pareek, C. M., Tewari, V. K. & Machavaram, R. Multi-objective optimization of seeding performance of a pneumatic precision seed metering device using integrated ANN-MOPSO approach. Eng. Appl. Artif. Intell. 117, 105559. https://doi.org/10.1016/j.engappai.2022.105559 (2023).

Parrott, D. & Li, X. Locating and tracking multiple dynamic Optima by a particle swarm model using speciation. IEEE Trans. Evol. Comput. 10 (4), 440–458. https://doi.org/10.1109/TEVC.2005.859468 (2006).

Ding, Y., Zhang, W., Yu, L. & Lu, K. The accuracy and efficiency of GA and PSO optimization schemes on estimating reaction kinetic parameters of biomass pyrolysis. Energy 176, 582–588. https://doi.org/10.1016/j.energy.2019.04.030 (2019).

Kundu, P., Paul, V., Kumar, V. & Mishra, I. M. Formulation development, modeling and optimization of emulsification process using evolving RSM coupled hybrid ANN-GA framework. Chem. Eng. Res. Des. 104, 773–790. https://doi.org/10.1016/j.cherd.2015.10.025 (2015).

Gad, A. G. Particle swarm optimization algorithm and its applications: a systematic review. Arch. Comput. Methods Eng. 29 (5), 2531–2561. https://doi.org/10.1007/s11831-021-09694-4 (2022).

Bayat, H., Neyshaburi, M. R., Hajabbasi, M. A., Mahboubi, A. A. & Mosaddeghi, M. R. Comparing neural networks, linear and nonlinear regression techniques to model penetration resistance. Turkish J. Agric. Forestry. 32 (5), 425–433 (2008).

Çarman, K., Marakoğlu, T., Taner, A. & Çıtıl, E. Prediction of draft force and disturbed soil area of a chisel tine in soil bin conditions using draft force and its comparison with regression model. Selcuk Journal of Agriculture and Food Sciences, 35 (1), 56–63. https://doi.org/10.15316/SJAFS.2020.229 (2021).

Kumar, N., Raheman, H., & Machavaram, R. Performance of a diesel engine with water emulsified diesel prepared with optimized process parameters. International Journal of Green Energy, 16 (9), 687–701. https://doi.org/10.1080/15435075.2019.1618309 (2019).

Sarkar, P. & Raheman, H. Optimization of cutting torque in a laboratory setup for harvesting cabbage following an AI-based approach. Smart Agricultural Technol. 5, 100278. https://doi.org/10.1016/j.atech.2023.100278 (2023).

Shrivastava, A. K., Alok, D. & Naik, R. K. Tractor drawn Raised bed seed drill under vertisol. Agricultural Mechanization Asia Afr. Latin Am. 43 (4), 16–19 (2012).

Saha, K. P., Singh, D., Jat, D. & Singh, K. P. Performance evaluation of tractor operated rotary assisted broad bed former-cum-seeder for wheat sowing. J. Agricultural Eng. (India). 55 (3), 1–11. https://doi.org/10.52151/jae2018553.1656 (2018).

Fouda, T., Abdelsalam, A., Swilam, A., Didamony, E. & M Development and evaluation of Raised bed machine to suit Faba bean planting. Sci. Papers Ser. Manage. Economic Eng. Agric. Rural Dev. 24 (1), 427–442 (2024).

Correa, J., Postma, J. A., Watt, M. & Wojciechowski, T. Soil compaction and the architectural plasticity of root systems. J. Exp. Bot. 70 (21), 6019–6034. https://doi.org/10.1093/jxb/erz383 (2019).

Shaheb, M. R., Venkatesh, R. & Shearer, S. A. A review on the effect of soil compaction and its management for sustainable crop production. J. Biosystems Eng. 1–23. https://doi.org/10.1007/s42853-021-00117-7 (2021).

Pagare, V., Dubey, U. C., Wahid, A. & Khadatkar, A. Comparative assessment of the developed animal drawn broad bed former cum planting system with existing planting methods for sowing of pea crop. Biol. Forum – Int. J. 15 (7), 185–192 (2023).

Shrivastava, P., Khandelwal, N. K., Jat, D. & Narwariya, B. S. Techno–economic evaluation of tractor operated Raised bed planters and seed drills for cultivation of wheat crop. Int. J. Agricultural Sci. Res. 7 (2), 349–362 (2017).

Acknowledgements

Research was supported by the Indian Council of Agricultural Research, Department of Agricultural Research and Education, Government of India.The authors thank ICAR-Central Institute of Agricultural Engineering, Bhopal and Consortia Research Platform on Precision Farming, ICAR, New Delhi, India for providing all financial, technical and research facilities for the successful completion of the research work.

Author information

Authors and Affiliations

Contributions

Conceptualization, Methodology, Investigation, Writing – original draft: **CPS**; Conceptualization, Methodology, Investigation: **BBG**; Methodology, Investigation: **APM**; Data collection, Formal analysis: **AK**; Writing – original draft, Formal analysis, Writing – review & editing: **NK**; Conceptualization, Writing – review & editing: **KVRR**; Writing – review & editing, Supervision: **VPC**.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Ethics

This study was conducted in accordance with relevant institutional and national guidelines for soil and environmental research. No human or animal subjects were involved. The work is original and not under consideration elsewhere.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Sawant, C.P., Gaikwad, B.B., Magar, A.P. et al. Development and performance evaluation of variable width raised bed former with optimal parameters predicted by RBF neural network-PSO technique. Sci Rep 16, 3655 (2026). https://doi.org/10.1038/s41598-025-33706-z

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-33706-z