Abstract

Polymer skeleton porous concrete (PSPC) is an innovative type of pavement material combining the high strength of cement concrete with the high toughness of asphalt concrete. It is also characterized by excellent water permeability, noise reduction, construction efficiency, and driving comfort, leading to extensive practical applications. The authors found that incorporating rubber powder greatly enhances the mechanical properties of PSPC, including flexural strength, deformation resistance, and impact toughness. This paper investigated influences of five different proportions of rubber powder on PSPC. Results show that polymer skeleton porous rubber concrete (PSPRC) exhibits exceptional deformation capacity and toughness. When the rubber content is 10% of the cement mass, compared with PSPC without rubber content, the deformation performance of PSPRC increased by 49.4% and the impact toughness increased by 156.6%. Scanning Electron Microscopy (SEM) was also employed to elucidate how rubber power enhances the overall mechanical properties of PSPC.

Similar content being viewed by others

Introduction

Cement concrete pavement and asphalt concrete pavement are currently the two primary types of highway pavements1,2,3. The cement-based binder used in cement concrete pavement is characterized by high strength but poor fracture toughness. The asphalt-based binder used in asphalt concrete pavement has good deformation resistance but low strength, high plasticity, and poor stability. Due to the fundamental differences in the chemical and physical properties of the two types of binders, it is difficult to combine their advantages and overcome their disadvantages simultaneously4,5.

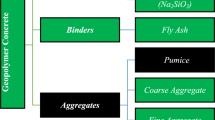

Polymer skeleton porous concrete (PSPC) is a new type of pavement material developed by the first author of this paper6,7,8,9,10,11,12. It is formed by mixing polymer-modified cement with single or gap-graded crushed stones. After setting, it forms a “skeleton-node-pore” spatial grid structure (as shown in Fig. 1). The polymer cement act as the material that connects the nodes between crushed stones, and thus is called the polymer cement binder by the authors.

PSPC combines the high strength and stability of cement concrete pavement with the high deformation resistance and toughness of asphalt concrete pavement, effectively avoiding the typical forms of failure associated with these two types of pavement. PSPC pavement has been successfully applied in several pilot projects and afterwards successfully implemented on highways such as Hubei’s Hurongxi Expressway, Shanxi’s Xinfu Expressway, and Jiangxi’s Jinggangshan-Mucun Expressway6.

In PSPC, the aggregates are in close contact with each other. Only a small amount of polymer cement binder is needed between the nodes of gravel particles to form high-strength and high-toughness consolidation, and the excess polymer cement binder is distributed on the surface of the aggregates. The skeleton formed by the aggregates and the polymer cement elastic nodes endows the material with strength and deformation properties, and the connected pores endow the material with the functions of water permeability and noise reduction7,8,9,10,11. It has high strength (more than 5–15 times the Marshall stability of asphalt mixtures at 60 °C under the same conditions), good deformation performance, large connected porosity (12–22%), good dry shrinkage (about 1/2 of the 180-day dry shrinkage rate of cement concrete and about 2/3 of the 180-day dry shrinkage rate of sand-free porous concrete), and good high-temperature stability. While ensuring excellent mechanical properties, it can achieve ecological, environmental-friendly and landscape functions such as water permeability, noise reduction and color marking, providing a new idea and choice for the construction of modern expressways to embark on the sustainable development path of resource conservation and environmental friendliness12.

On the premise of maintaining a certain flexural performance, improving its deformation capacity (ultimate strain) and toughness under impact load is the key to the design of PSPC materials. To optimize its mechanical properties, incorporating waste rubber particles as a modified material into PSPC has become a valuable research direction13,14,15. This approach can not only significantly improve the impact toughness of concrete, endow it with excellent energy dissipation and crack inhibition capabilities, but also realize the resource utilization of solid waste, which conforms to the concept of green and sustainable development. Therefore, rubber modification is undoubtedly an effective strategy to improve the comprehensive performance of PSPC to cope with special service environments.

Ordinary rubber concrete has advantages such as good toughness, light weight, shock absorption and noise reduction16,17,18,19,20,21. However, there is a significant difference in elastic modulus between rubber and concrete, resulting in serious deformation incoordination. In addition, the inert surface of rubber leads to weak interfacial bonding, forming initial defects and significantly reducing its compressive and flexural strength22,23,24,25,26,27,28,29,30. Existing studies31,32,33,34,35,36,37,38,39 have utilized coupling agents, organosilanes, acids, or alkalis to modify rubber; however, they have not addressed key issues, such as the inherent brittleness of concrete. Therefore, the flexural-tensile strength and deformation capacity of rubber concrete are still poor. To improve the inherent brittleness of concrete and enhance the interfacial bond strength between rubber and concrete, researchers have investigated polymer rubber concrete with a dense structure. Studies indicate that compared to rubber concrete, polymer rubber concrete exhibits superior deformation capacity, freeze resistance, and fatigue performance40,41,42. However, its dense structure suppresses cement hydration shrinkage during the hardening stage, leading to significant shrinkage stresses that may result in microcracks or even macroscopic cracking, ultimately becoming a weak point in mechanical performance43,44,45. Although various polymers have been applied and surface treatments of rubber have been attempted, the improvement on the strength of most polymer modified rubber remains insignificant46,47,48.

Polymer skeleton porous rubber concrete (PSPRC) not only improves the inherent excessive brittleness of concrete through polymers, but also effectively improves the bonding between rubber particles and cement paste, reducing defects in the interfacial transition zone (ITZ). At the same time, the high porosity reduces the shrinkage deformation of cement hydration, thereby significantly reducing the risk of cracking caused by shrinkage. The uniform dispersion of pores also weakens the deterioration effect of inherent concrete defects on macroscopic properties. PSPRC can compensate for the defects of both rubber concrete and dense polymer rubber concrete, considering both mechanical and functional requirements.

To improve the flexural performance and impact toughness of PSPC, this study conducted a trial production of PSPRC. Through the compressive and flexural performance experiments on polymer rubber cement binders, the rules governing the improvement of rubber cement binders by polymers were initially revealed. Further research was carried out on the mechanical properties and impact toughness of PSPRC to comprehensively evaluate the PSPRC with the optimal rubber content. Scanning Electron Microscopy (SEM) was used to observe the ITZ between rubber and polymer cement binders.

Materials

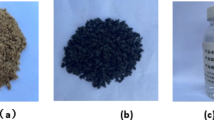

Cement: P.O 42.5 ordinary Portland cement produced by Huaxin Cement Co., Ltd. in Chongqing, China, is selected. Polymer: In this study, the polyacrylic acid polymer flexible emulsion (solid content: 38%) developed by the research team of Chongqing Jiaotong University in China is chosen as the liquid material49. Rubber: 80-mesh rubber powder produced from waste tires by Sitong Rubber and Plastic Co., Ltd. in Chengdu, China, with a particle size range of 180–200 µm, is used. Aggregate: Study show that when the maximum particle size of the aggregate is less than 13.2 mm, the gradation has a limited impact on the performance of polymer skeleton concrete, and the gradation is not a key control factor. Considering the construction performance and service function comprehensively, single-graded crushed pebbles and hard crushed stones such as basalt with a size of 4.75–9.5 mm are finally selected in our early research50. Thus, in this paper, single-graded crushed limestone with a size of 4.75–9.5 mm is used as the aggregate for PSPRC. The materials are shown in Fig. 2.

Experimental methods and results

In this study, the hydration law of the cementitious system was initially explored through the compressive and flexural strength tests of the polymer rubber cement binder. On this basis, the compressive and flexural strength, as well as the ultimate strain, tests of the PSPRC were further carried out. Taking the macroscopic mechanical properties as the criterion, the optimal rubber powder content was determined. Subsequently, the above-mentioned content was independently verified from the perspective of dynamic damage tolerance through the drop-weight impact test. Finally, the optimal rubber powder content, which takes into account both quasi-static strength, deformation performance, and impact performance, was obtained.

Strength and deformation performance of polymer cement binder

The principle of the mix-proportion design for the polymer cement binder is to enhance the ultimate deformation capacity while maintaining sufficient flexural strength.

Preparation of polymer cement binder specimens and polymer cement ratio

The polymer cement binder specimens were prepared by mixing cement, polymer emulsion and rubber powder. The uniformity of the polymer rubber cement binder directly affects its mechanical properties. The rubber powder has a small particle size and is prone to agglomeration in a humid environment. It needs to be manually kneaded and dispersed before pre-mixing and fully dry-mixed with cement. After ensuring the uniform dispersion of particles, the polymer emulsion is added and the mixture is continuously mechanically stirred. A small-scale laboratory cement mortar mixer was used for preparation. After the mixture was put into the mould, it was vibrated on a vibrating table and then moved to a standard curing room for curing. The flexural specimens were prismatic, measuring 40 mm × 40 mm × 160 mm, and the compressive specimens were cubic, measuring 40 mm × 40 mm × 40 mm. Based on previous research experience and tests, the polymer cement ratio (the ratio of the solid content of the polymer emulsion to the cement) was determined to be 0.15. The mechanical performance testing process is shown in Fig. 3.

After 28 days of specimen curing, according to the “Test method for strength of hydraulic cement mortar (ISO method)” GB/T 17671-202151, compression and flexural tests were carried out. The compressive loading rate is 2400 N/s ± 200 N/s, and the bending loading rate is 50 N/s ± 10 N/s. The experimental results of the 28-day compressive strength, flexural strength and ultimate flexural strain of ordinary cement binder and polymer cement binder are as follows, as shown in Table 1:

The experimental results show that: compared with ordinary cement binders, the flexural strength of polymer cement binders is increased by 52.6%, and the ultimate strain is increased by 10.4 times, with both improvement amplitudes being very significant. The most critical mechanical indicators of polymer cement binders are flexural strength and flexural ultimate strain. In particular, the improvement of ultimate strain is crucial for ensuring the flexural and tensile performance of the pavement. The fundamental improvement of the ultimate flexural strain of polymer cement binders reflects its deformation coordination ability and is the fundamental guarantee for its road-use performance. The addition of polymers will lead to a decrease in compressive strength, but its value still meets the requirements for the compressive bearing performance of the pavement (its compressive strength is still about one order of magnitude higher than that of general road-use asphalt mixtures).

Preparation of polymer rubber cement binder specimens and rubber powder content

After the polymer cement ratio (P/C) was fixed at 0.15, based on the mix proportion of the polymer cement binder described above, rubber was incorporated at 0%, 5%, 10%, 15%, and 20% of the cement mass to prepare specimens for flexural and compressive tests of the polymer rubber cement binder with the same dimensions as mentioned above. Since the rubber powder has a large number of micropores and fissure structures on its surface, which preferentially adsorb water in the concrete, the formability of the concrete can be adjusted during the specimen preparation process by adding water appropriately, while keeping the polymer cement ratio unchanged. The curing age is set to 28 days. Using the same experimental method as before, the compressive strength, flexural strength, and ultimate strain are obtained, as shown in Table 2. The large number of micropores and fissure structures on the surface of the rubber powder will preferentially adsorb the free water in the concrete, resulting in a decrease in the amount of water used to lubricate the aggregates and cement particles.

The test results in Table 2 indicate that flexural strength is maintained until the rubber powder content reaches 10%, but the ultimate strain increases significantly thereafter. This indicates that the addition of rubber powder significantly improves the deformation coordination performance of the cement binder, and further enhances its flexural and tensile bearing performance for road use. After adding rubber powder, the compressive strength shows a downward trend, but it still meets the road mechanical performance requirements, which is consistent with the research results of general literature52. However, when the rubber powder content reaches 15%, the overall mechanical performance of the binder declines. Comprehensively, the optimal addition amount of rubber powder in the polymer rubber cement binder is between 5 and 10%. It can not only maintain high flexural strength but also have better deformation coordination performance, while ensuring economic efficiency.

Strength and deformation performance of PSPRC

PSPC is a skeleton porous concrete formed by combining polymer cement binder with single-graded aggregate. Its preparation method involves placing cement and aggregate into a self-compacting concrete double-horizontal compulsory mixer for dry mixing until the aggregate surface is evenly coated with cement. Then, the broken rubber powder is slowly added in small amounts multiple times, and the mixture is continued to be dry mixed until it is evenly dispersed. Then, inject the polymer emulsion at a constant speed and stir until the polymer rubber cement slurry (polymer cement binder) evenly wraps all the crushed pebbles, at which point the mixing is considered complete. The size of the flexural test specimen is 100 mm × 100 mm × 400 mm, and the size of the compressive test specimen is 100 mm × 100 mm × 100 mm. PSPRC has a large porosity. After moulding, it is necessary to ensure that the polymer in the emulsion participates in the hydration process synchronously with the cement. During the curing stage, the humidity needs to be controlled to prevent water loss. The specific curing method is as follows: after molding in the test mould, cover it with a polyethylene film to prevent evaporation. After pouring, move it to a standard curing room (20 ± 3 °C, RH > 90%) for 24 h and then demold. After demolding, continue to place it in the curing room until the specified age. The formed specimens are shown in Fig. 4.

After the specimens reach the specified age, in accordance with the “Test Regulations for Cement and Cement Concrete in Highway Engineering” (JTG 3420—2020) of China, for the compressive strength test, a loading rate of 0.5 MPa/s is applied to test the 100 mm × 100 mm × 100 mm cube specimens; for the flexural-tensile strength test, third-point loading is adopted with a loading rate of 0.05 MPa/s, and the specimen size is 100 mm × 100 mm × 400 mm. The experimental process is shown in Fig. 5.

The compressive strength, flexural strength, and ultimate strain of PSPRC at the 28-day age under the conditions of rubber contents of 0, 5%, and 10% respectively are as follows in Table 3:

The experimental results show that when the rubber powder content is 5% and 10%, the ultimate strain increases by 22.9% and 49.4%, respectively, and the compressive strength decreases by 15.9% and 21.3%, respectively. PSPRC significantly improves the ultimate strain of polymer skeletal concrete while maintaining the flexural strength basically unchanged and losing a small amount of compressive strength. The fundamental improvement in the ultimate flexural strain of PSPRC not only reflects the excellent combination ability of the polymer and rubber powder, but also the deformation coordination ability between the rubber powder and the PSPC is the fundamental guarantee for its use under various road conditions. The addition of rubber powder will lead to a further decrease in the compressive strength of PSPC; however, its value still meets the requirements for the compressive bearing performance of the pavement.

Impact toughness of polymer skeleton pore rubber concrete

The specimens for the impact test were formed with the same mix proportion as those in the aforementioned flexural and compressive strength tests. The specimens had a diameter of 150 mm and a height of 63 mm. After the curing was completed, the surface moisture was wiped off, and the specimens were placed in the center of the chassis of the impact frame. The impact test was conducted using a fully automated electronic drop-weight impact testing machine. After the concrete was impacted, cracks appeared, and it was damaged. The ability to resist impact can be evaluated by the initial cracking impact energy consumption \({W}_{1}\) and the final cracking impact energy consumption \({W}_{2}\), which are calculated according to Formulas (1) and (2).

In the formula, \({N}_{1}\) is the initial cracking impact time when the first crack appears; \({N}_{2}\) is the final cracking impact time when the crack of the specimen penetrates and contacts any three of the four baffles of the impact frame; \(m\) is the mass of the impact hammer, taking 4.54 kg; \(g\) is the gravitational acceleration, taking 9.81 m/s2; \(h\) is the falling height of the impact hammer, taking 500 mm; \({W}_{1}\) and \({W}_{2}\) are the initial cracking and final cracking impact energy consumptions, respectively, with the unit of \(J\). After sorting out, the initial cracking times, final cracking times, initial cracking impact energy consumption and final cracking impact energy consumption of the rubber powder and polymer skeleton pore rubber concrete specimens under different dosages are shown in Table 4 and Fig. 6 below:

The experimental results show that: Adding an appropriate amount of rubber powder to PSPC can significantly improve the impact toughness of the concrete. When the dosages of other materials remain unchanged, when the rubber dosage is 5% and 10%, the initial cracking impact energy consumption of PSPRC increased by 145.7% and154.4%, respectively, and the final cracking impact energy consumption increased by 147.2 and 156.6%, respectively. The presence of the polymer enhances the interface strength between the rubber particles and the concrete. Therefore, the PSPRC exhibits better ductility. The incorporation of rubber powder alters the internal structure of the concrete and enhances its impact resistance to a certain extent. Rubber powder is an elastic material with a good energy-absorbing effect and a strong ability to undergo compression and deformation. When cracks occur in the concrete, the rubber particles can reduce stress concentration at the crack tip, play a role in unloading and energy absorption, thereby inhibiting the development of cracks and significantly enhancing the impact toughness of the concrete53,54,55. Road pavements are repeatedly subjected to impact loads such as heavy loads and sudden braking, as well as environmental stresses like temperature and humidity fluctuations. They also endure long-term influences from factors including subgrade settlement. Improving the energy dissipation performance of pavement materials and enhancing their impact toughness have a significant importance for extending service life and elevating overall pavement performance56,57.

SEM analysis

SEM analysis as shown in Fig. 7a indicates that, the surface of ordinary rubber cement binder is angular, while that of polymer rubber cement binder is smooth. In the ordinary rubber cement binder, the interface between the rubber particles and the cement matrix is clear, and the bonding is poor; significant interface defects form after cement hydration. When the material is under stress, these defects are likely to initiate microcracks and expand into macrocracks, resulting in a decrease in strength as the rubber powder content increases. In contrast, for the polymer rubber cement binder with the same rubber powder content, the polymer significantly improves the cement matrix (Fig. 7b). The rubber particles are embedded in the matrix, resulting in a more compact bonding. The rubber particles and the polymer matrix exhibit a high degree of compatibility in their microscopic morphology, indicating that the polymer forms a continuous coating layer on the surface of the rubber, effectively suppressing interface defects. Under external loads, this system exhibits excellent deformation coordination. The matrix and rubber particles deform cooperatively, thereby significantly delaying the cracking process, which is manifested as an increase in the material’s macroscopic strength.

SEM analysis as shown in Fig. 8a, b indicates that when the rubber powder content is 5% and 10%, the rubber in the polymer rubber cement binder is closely bonded with the binder, and the ITZ is not distinct. As the rubber powder content increases to 15%, the SEM images show that the grayscale contrast of the ITZ between the rubber particles and the polymer cement matrix is significantly enhanced (Fig. 8c). This indicates that as the rubber powder content increases, the wetting ability of the polymer cement hydration products on the hydrophobic rubber surface decreases, the development degree of micro-pores and micro-cracks at the interface intensifies, and the attenuation of the interfacial bond strength leads to a linear downward trend in the material strength. When the rubber powder content is increased to 20% (Fig. 8d), the spacing between rubber particles approaches the critical value, and the process of local micro-cracks penetrating through the ITZ and evolving into macroscopic main cracks accelerates. The polymer cannot coat all the rubber particles; the interfacial bond between the rubber and the polymer cement matrix weakens, and interfacial defects appear again. The rubber particles no longer appear to be embedded in the binder, and interfacial debonding causes the rubber particles to be damaged through disconnection, resulting in a sudden drop in macroscopic strength.

The SEM images are consistent with the macroscopic observations of compressive strength, flexural strength, and impact toughness. The PSPRC with 5% and 10% rubber powder content both exhibit good performance, with the latter being superior.

Conclusions

Incorporating rubber powder derived from scrap tires into PSPC not only provides an effective means for large-scale consumption of waste rubber but also enhances the mechanical properties of the PSPC. The following conclusions are drawn through the investigation of the mechanical properties of PSPRC:

-

(1)

Compared with ordinary cement binders, the flexural strength and ultimate strain of polymer cement binders are fundamentally improved. In particular, the ultimate strain is increased by 10.4 times, which fully reflects the excellent deformation coordination ability of polymer cement binders and is also the fundamental guarantee for it to meet the road-use performance.

-

(2)

When the polymer cement ratio is fixed, the flexural strength of the polymer rubber cement binder with rubber powder added is essentially the same as that of the polymer cement binder, but the ultimate strain is further enhanced. The best improvement is achieved when the rubber powder addition amount is 10%, resulting in a 29.7% increase. This shows that the addition of rubber powder significantly improves the deformation coordination performance of the polymer cement binder, and its road-use flexural and tensile bearing performance is further improved. The addition of rubber powder will cause a decline in the compressive performance of the polymer cement binder, but it can still meet the basic road-use performance requirements. The optimal rubber powder content is between 5 and 10%, which not only maintains high flexural strength but also exhibits better deformation coordination performance.

-

(3)

The strength change rule of PSPRC is consistent with that of the polymer rubber cement binder. Compared with PSPC, when the rubber powder content is 5% and 10%, the ultimate strain increases by 22.9% and 49.4%, respectively, and the compressive strength decreases by 15.9% and 21.3%, respectively. The impact toughness test shows that the addition of rubber powder can significantly improve the impact toughness of concrete. When the rubber powder content is between 5%-10%, the initial cracking energy consumption and the final cracking impact energy consumption increase by 145.7% and 147.2, respectively.

-

(4)

Through SEM microstructure analysis, it is found that the polymer effectively improves the cement matrix structure and enhances its ability to coat rubber particles. At an appropriate content, the bond between the rubber particles and the polymer cement matrix is tight, and the interfacial bond is significantly better than that of the ordinary cement rubber interface. This structure enables the rubber particles to deform coordinately with the matrix during the stress process, allowing their deformation ability to be fully utilized.

Data availability

All data generated or analyzed during this study are included in this published article.

References

Cudworth, D. & Rahman, M. Pavement analysis and design. In Deterioration and Maintenance of Pavement Chapter 4 (ICE Publishing, 2023). https://doi.org/10.1680/dmp.65086.031.

Sinha, K. C. & Samuel, L. Highway Engineering (McGraw Hill, 2021). https://doi.org/10.1036/1097-8542.318700.

Rogers, M. & Bernard, E. Highway Engineering (Wiley, 2023).

Miller, J. S. & Bellinger, W. Y. Distress Identification Manual for the Long-Term Pavement Performance Program (United States. Department of Transportation. Federal Highway Administration. Office of Infrastructure Research and Development, 2003). https://rosap.ntl.bts.gov/view/dot/40882

Ioannides, A. M. Concrete pavement analysis: The first eighty years. Int. J. Pavement Eng. 7(4), 233–249. https://doi.org/10.1080/10298430600798481 (2006).

Yi, Z. J. et al. Application of polymer skeleton porous concrete pavement in the supporting project. In Proceedings of the Symposium on New Technologies for Transportation Resource Conservation and Environmental Protection 28–32 (China Communications Press, 2007). (In Chinese).

Yi, Z. J. et al. Routine mechanical properties of polymer skeleton porous concrete. Proceedings of the Symposium on New Technologies for Transportation Resource Conservation and Environmental Protection 21–23 (China Communications Press, 2007). (In Chinese).

Zhang, C. Y., Yi, Z. J., Yan, W. & Xu, P. Experimental study on the early shrinkage performance of porous concrete. In Proceedings of the 2009 Annual Academic Conference of Chongqing Mechanics Society 73–76 (China Communications Press, 2009). (In Chinese).

Yi, Z. J. et al. Service functions and resource conservation of polymer skeleton porous concrete pavement. In Proceedings of the Symposium on New Technologies for Transportation Resource Conservation and Environmental Protection 3–5 (China Communications Press, 2007). (In Chinese).

Yi, Z. J. et al. Multifunctional polymer skeleton porous concrete pavement. In Proceedings of the Symposium on New Technologies for Transportation Resource Conservation and Environmental Protection 16–20 (China Communications Press, 2007). (In Chinese).

Yi, Z. J. et al. Construction technology of polymer skeleton porous concrete pavement. Proceedings of the Symposium on New Technologies for Transportation Resource Conservation and Environmental Protection 24–27 (China Communications Press, 2007). (In Chinese).

Yi, Z. J. et al. Study on the drying shrinkage performance of polymer skeletal porous concrete for road use. J. Chongqing Jiaotong Univ. (Nat. Sci. Ed.) 28(03), 534–536 (2009) (In Chinese).

Formela, K. Sustainable development of waste tires recycling technologies–recent advances, challenges and future trends. Adv. Ind. Eng. Polym. Res. 4(3), 209–222. https://doi.org/10.1016/j.aiepr.2021.06.004 (2021).

Wang, Q. Z. et al. Waste tire recycling assessment: Road application potential and carbon emissions reduction analysis of crumb rubber modified asphalt in China. J. Clean. Prod. 249, 119411. https://doi.org/10.1016/j.jclepro.2019.119411 (2020).

Bu, C. et al. Research progress on rubber concrete properties: A review. J. Rubber Res. 25(2), 105–125. https://doi.org/10.1007/s42464-022-00161-8 (2022).

Shen, H., Ji, H., Peng, X., Tian, Z. & Su, G. Dynamic mechanical behavior and constitutive relationship of rubber fiber concrete after high temperature. Sci. Rep. 15(1), 25764. https://doi.org/10.1038/s41598-025-09160-2 (2025).

Mathew, L. A. & Joseph, G. Natural rubber latex modified high performance concrete. Iran. J. Sci. Technol. Trans. Civ. Eng. 49(4), 3511–3527. https://doi.org/10.1007/s40996-024-01656-7 (2025).

Zang, R. et al. Triaxial mechanical behaviour and constitutive response of rubberised concrete materials. Constr. Build. Mater. 450, 138635. https://doi.org/10.1016/j.conbuildmat.2024.138635 (2024).

Ecemiş, A. S. et al. Bending performance of reinforced concrete beams with rubber as form of fiber from waste tires. Materials 17(20), 4958. https://doi.org/10.3390/ma17204958 (2024).

Yang, G., Chen, X. & Xu, J. Molecular dynamics simulation of interfacial mechanical properties of crumb rubber concrete. Constr. Build. Mater. 438, 137336. https://doi.org/10.1016/j.conbuildmat.2024.137336 (2024).

Ge, J., Mubiana, G., Gao, X., Xiao, Y. & Du, S. Research on static mechanical properties of high-performance rubber concrete. Front. Mater. 11, 1426979. https://doi.org/10.3389/fmats.2024.1426979 (2024).

Sherbini, A. S. & Abou El-Mal, H. S. S. Assessment of rubberized concrete as a promising green building material. J. Umm Al-Qura Univ. Eng. Archit. https://doi.org/10.1007/s43995-025-00176-3 (2025).

Moolchandani, K. & Sharma, A. State-of-the-art review on the influence of crumb rubber on the strength, durability, and morphological properties of concrete. Sci. Eng. Compos. Mater. 32(1), 20250060. https://doi.org/10.1515/secm-2025-0060 (2025).

Han, X. et al. Experimental and analytical evaluation of mechanical properties of rubberized concrete incorporating waste tire crumb rubber. Case Stud. Constr. Mater. https://doi.org/10.1016/j.cscm.2025.e04970 (2025).

Gruszczyński, M., Kowalska-Koczwara, A. & Tatara, T. Effect of rubber granulate content on the compressive strength of concrete for industrial vibration-isolating floors. Materials 18(13), 3134. https://doi.org/10.3390/ma18133134 (2025).

Elbaz, Y., Mwafy, A., El-Hassan, H. & El-Maaddawy, T. Advancements in characterization and potential structural seismic performance of alkali-activated concrete incorporating crumb rubber: A state-of-the-art review. Sustainability 17(13), 6043. https://doi.org/10.3390/su17136043 (2025).

Bušić, R., Gazić, G., Guljaš, I. & Miličević, I. Experimental determination of double-K fracture parameters for self-compacting concrete with waste tire rubber and silica fume. Theor. Appl. Fract. Mech. https://doi.org/10.1016/j.tafmec.2025.105021 (2025).

Naresh, T., Murthy, N. D., Mallik, M. & Singh, V. Performance assessment of concrete incorporating waste rubber powder as partial cement replacement. J. Build. Pathol. Rehabil. 10(2), 138. https://doi.org/10.1007/s41024-025-00646-0 (2025).

Wei, W., Cai, S. & Li, Y. Fatigue bond behavior of steel rebars in recycled aggregate concrete containing recycled rubber. Build. 15(12), 2102. https://doi.org/10.3390/buildings15122102 (2025).

Rajaa, N., Alharishawi, S. S. C. & Faris, H. A. Experimental study of shear stresses of solid and hollow concrete beams made with waste tire rubber. J. Appl. Eng. Sci. 23(2), 208–219. https://doi.org/10.5937/jaes0-52938 (2025).

Eldin, N. N. & Senouci, A. B. Rubber-tire particles as concrete aggregate. J. Mater. Civ. Eng. 5(4), 478–496. https://doi.org/10.1061/(ASCE)0899-1561(1993)5:4(478) (1993).

Mohammadi, I. & Khabbaz, H. Shrinkage performance of crumb rubber concrete (CRC) prepared by water-soaking treatment method for rigid pavement. Cem. Concr. Compos. 62, 106–116. https://doi.org/10.1016/j.cemconcomp.2015.02.010 (2015).

Segre, N. & Joekes, I. Use of tire rubber particles as addition to cement paste. Cem. Concr. Res. 30(9), 1421–1425. https://doi.org/10.1016/s0008-8846(00)00373-2 (2000).

Dong, Q., Huang, B. & Shu, X. Rubber modified concrete improved by chemically active coating and silane coupling agent. Constr. Build. Mater. 48, 116–123. https://doi.org/10.1016/j.conbuildmat.2013.06.072 (2013).

He, L. et al. Research on the properties of rubber concrete containing surface-modified rubber powders. J. Build. Eng. 35, 101991. https://doi.org/10.1016/j.jobe.2020.101991 (2021).

Xu, Y., Wang, J., Zhang, P., Guo, J. & Hu, S. Enhanced effect and mechanism of colloidal nano-SiO2 modified rubber concrete. Constr. Build. Mater. 378, 131203. https://doi.org/10.1016/j.conbuildmat.2023.131203 (2023).

Ming, P. et al. Research on physical and mechanical properties of alkaline-modified self-compacting rubber concrete. Constr. Build. Mater. 489, 142251. https://doi.org/10.1016/j.conbuildmat.2025.142251 (2025).

Zhang, Y. C. & Gao, L. L. Mechanical performance test of rubber-powder modified concrete. In E3S Web of Conferences vol. 38, p. 03006 (2018). https://doi.org/10.1051/e3sconf/20183803006.

Sukmak, G. et al. Physical and mechanical properties of natural rubber modified cement paste. Constr. Build. Mater. 244, 118319. https://doi.org/10.1016/j.conbuildmat.2020.118319 (2020).

Huang, Z. D. & Yin, X. Research on the frost resistance of geopolymer rubber concrete. Plast. Sci. Technol. 53(3), 64–70. https://doi.org/10.15925/j.cnki.issn1005-3360.2025.03.012 (2025) (In Chinese).

Zhang, G. B. et al. Research on the fatigue performance of rubber-modified ultra-high performance geopolymer concrete. Concrete 2024(12), 243–247. https://doi.org/10.3969/j.issn.1002-3550.2024.12.043 (2024) (In Chinese).

Deredas, K., Kępczak, N. & Urbaniak, M. Influence of doping with styrene-butadiene rubber on dynamic and mechanical properties of polymer concrete. Compos. Struct. 268, 113998. https://doi.org/10.1016/j.compstruct.2021.113998 (2021).

Lv, J. F. et al. Effects of waste rubber powder and resin content on the free shrinkage of polymer concrete. Constr. Build. Mater. 381, 131307. https://doi.org/10.1016/j.conbuildmat.2023.131307 (2023).

Wang, J., Dai, Q., Guo, S. & Si, R. Mechanical and durability performance evaluation of crumb rubber-modified epoxy polymer concrete overlays. Constr. Build. Mater. 203, 469–480. https://doi.org/10.1016/j.conbuildmat.2019.01.085 (2019).

Shen, Y. N., Huang, J. T., Ma, X. B., Hao, F. & Lv, J. F. Experimental study on the free shrinkage of lightweight polymer concrete incorporating waste rubber powder and ceramsite. Compos. Struct. 242, 112152. https://doi.org/10.1016/j.compstruct.2020.112152 (2020).

Al-Kahtani, M. S. M., Zhu, H., Haruna, S. I. & Shao, J. W. Evaluation of mechanical properties of polyurethane-based polymer rubber concrete modified ground glass fiber using response surface methodology. Arab. J. Sci. Eng. 48(4), 4695–4710. https://doi.org/10.1007/s13369-022-07112-w (2023).

Su, Y. W., Yang, Q. S. & Gao, M. Q. Study on the properties of rubber concrete modified by the combination of NaOH and polymer emulsion. Concr. Cem. Products 2023(6), 94–97. https://doi.org/10.19761/j.1000-4637.2023.06.094.04 (2023) (In Chinese).

Kevin, B., Sarker, P. K. & Madhavan, M. K. Performance assessment and microstructural characterization of combined surface, chemical and polymer treated crumb rubber concrete. Sci. Rep. 15(1), 15853. https://doi.org/10.1038/s41598-025-97189-8 (2025).

Wu, W. W. et al. Flexural fatigue behaviors of high-content hybrid fiber-polymer concrete. Constr. Build. Mater. 349, 128772. https://doi.org/10.1016/j.conbuildmat.2022.128772 (2022).

Gu, J. Y., Huang, F., Yi, Z. J., Yang, Q. G. & Zhao, C. H. Research on the influence of aggregates on the mechanical properties of polymer skeleton concrete. Highw. Eng. 40(3), 9–12. https://doi.org/10.3969/j.issn.1674-0610.2015.03.003 (2015) (In Chinese).

GB/T 17671-2021. Test method for strength of hydraulic cement mortar (ISO method) (China Standards Press, 2021). (In Chinese).

Barbuta, M. et al. Effects of tire wastes on the mechanical properties of concrete. Procedia Eng. 2017(181), 346–350. https://doi.org/10.1016/j.proeng.2017.02.399 (2017).

Zhang, L. L., Feng, M. Y., Liu, B. D., Geng, G. Q. & Lin, B. H. Multi-scale study on the crack resistance and energy dissipation mechanism of modified rubberized concrete. Constr. Build. Mater. 457, 139448. https://doi.org/10.1016/j.conbuildmat.2024.139448 (2024).

Zhao, X., Su, P. F., Xie, J. K. & Dai, Q. L. Experimental and numerical investigation of concrete properties and crack propagation in concrete incorporating different sizes of recycled tire rubber particles. Constr. Build. Mater. 499, 144117. https://doi.org/10.1016/j.conbuildmat.2025.144117 (2025).

Ho, A. C., Turatsinze, A., Hameed, R. & Vu, D. C. Effects of rubber aggregates from grinded used tyres on the concrete resistance to cracking. J. Clean. Prod. 23(1), 209–215. https://doi.org/10.1016/j.jclepro.2011.09.016 (2012).

Aghamohammadi, O., Mostofinejad, D., Mostafaei, H. & Abtahi, S. M. Mechanical properties and impact resistance of concrete pavement containing crumb rubber. Int. J. Geomech. 24(1), 04023242. https://doi.org/10.1061/IJGNAI.GMENG-7620 (2024).

Hu, C., Weng, X. Z. & Yan, X. C. A review of surface properties enhancement of pavement concrete. In IOP Conference Series: Earth and Environmental Science. IOP Publishing. 638(1): 012101. https://doi.org/10.1088/1755-1315/638/1/012101 (2021).

Funding

The financial support for this research comes from the Youth Science Fund Project titled “Research on the Realization Mechanism of FRP Crack Resistance and Reinforcement Polymer Skeleton Concrete Steel Bridge Deck Pavement”, with the project approval number of NSFC51408091.

Author information

Authors and Affiliations

Contributions

Zhijian Yi: conceptualization, methodology, formal Analysis, experiment, writing, validation, project administration, supervision; Jiaming Zhang: methodology, formal Analysis, experiment, writing, validation; Chaohua Zhao: methodology, data curation, writing; Ya Li: methodology, data curation, writing; Jie Liu., Zhixiang Wang., Kang Su., Nan Ru., Chunhui Qi.: experiment, data curation. All authors approve the manuscript before submission.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Yi, Z., Zhang, J., Zhao, C. et al. Mechanical performance of polymer skeleton porous concrete incorporated with rubber aggregates. Sci Rep 16, 3973 (2026). https://doi.org/10.1038/s41598-025-34102-3

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-34102-3