Abstract

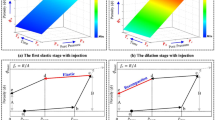

Shale reservoirs commonly contain numerous geological discontinuities, such as natural fractures, faults, and lithological interfaces. These discontinuities significantly influence the formation of hydraulic fracture networks. Therefore, to investigate the impact of different natural fracture parameters on fracture network development, this study establishes a stress-seepage-fracture multi-field coupling model for fractured reservoirs based on the continuous-discontinuous algorithm. The effects of natural fracture angle, stress difference, natural fracture strength, and injection rate on fracture network morphology, injection pressure, and fracture complexity are systematically analyzed. The results indicate that the natural fracture angle and stress difference jointly control fracture propagation patterns. At high natural fracture angles and high stress differences, hydraulic fractures tend to directly cross natural fractures. Additionally, as natural fracture strength increases, the difficulty of natural fracture activation gradually rises, while the number of branch fractures increases. Under high injection rates, the fluid pressure builds up rapidly, facilitating better activation of natural fractures. Meanwhile, as the injection rate increases, the growth rate of fracture complexity accelerates significantly. However, under the same injected volume, the fracture complexity is highest at 0.001 m³/s and lowest at 0.01 m³/s. This study aims to provide guidance for understanding the interaction mechanisms between hydraulic and natural fractures and optimizing fracturing design parameters.

Similar content being viewed by others

Data availability

The data that support the findings of this study are available from the corresponding authors upon reasonable request.

References

Yu, J. et al. Experimental simulation of fracture propagation and extension in hydraulic fracturing: A state-of-the-art review. Fuel 363, 131021 (2024).

Yang, P. et al. Numerical simulation of integrated three-dimensional hydraulic fracture propagation and proppant transport in multi-well pad fracturing. Comput. Geotech. 167, 106075 (2024).

Huang, G., Li, M., Chu, J., Zhou, F. & Lu, G. Longitudinal propagation mechanisms of multiple fractures in heterogeneous multi-lithology stacked reservoirs: A continuum-discontinuum simulation study. Eng. Fract. Mech. 322, 111181 (2025).

Guo, Y., Huang, L. & Li, X. Experimental and numerical investigation on the fracture behavior of deep anisotropic shale reservoir under in-situ temperature. Energy 282, 128969 (2023).

Xia, Y., Yao, M., Li, T., Yang, H. & Tang, C. Numerical analysis of hydraulic fracture propagation in deep shale reservoir with different injection strategies. J. Rock Mech. Geotech. Eng. 16 (9), 3558–3574 (2024).

Barale, L. et al. Estimation of natural asbestos content in rocks by fracture network modeling and petrographic characterization. Eng. Geol. 271, 105566 (2020).

Jinzhou, Z., Wang, Q., Yongquan, H., Chaoneng, Z. & Jin, Z. Prediction of pore Pressure–Induced stress changes during hydraulic fracturing of heterogeneous reservoirs through coupled fluid Flow/Geomechanics. J. Eng. Mech. 145 (12), 05019001 (2019).

Weng, X. Modeling of complex hydraulic fractures in naturally fractured formation. J. Unconv. Oil Gas Resour. 9, 114–135 (2015).

Zheng, H., Pu, C. & Sun, C. Study on the interaction between hydraulic fracture and natural fracture based on extended finite element method. Eng. Fract. Mech. 230, 106981 (2020).

Bakhshi, E. et al. Lattice numerical simulations of Lab-Scale hydraulic fracture and natural interface interaction. Rock. Mech. Rock. Eng. 52 (5), 1315–1337 (2019).

Xiong, D. & Ma, X. Influence of natural fractures on hydraulic fracture propagation behaviour. Eng. Fract. Mech. 276, 108932 (2022).

Merzoug, A., Pandey, V., Rasouli, V., Damjanac, B. & Pu, H. Comparison of lattice and Pseudo 3D numerical simulation of tip screen out operation. Petroleum 9 (3), 454–467 (2023).

Geertsma, J. & De Klerk, F. A rapid method of predicting width and extent of hydraulically induced fractures. J. Petrol. Technol. 21 (12), 1571–1581 (1969).

Perkins, T. K. & Kern, L. R. Widths of hydraulic fractures. J. Petrol. Technol. 13 (09), 937–949 (1961).

Zolfaghari, N. & Bunger, A. P. Numerical model for a penny-shaped hydraulic fracture driven by laminar/turbulent fluid in an impermeable rock. Int. J. Solids Struct. 158, 128–140 (2019).

Barbosa, L. G. et al. Simulation of the natural fractures influence on hydraulic fractures propagation using high aspect ratio interface elements. Comput. Geotech. 179, 107026 (2025).

Li, Y. et al. Numerical simulation of limited-entry multi-cluster fracturing in horizontal well. J. Petrol. Sci. Eng. 152, 443–455 (2017).

Li, M. H. et al. Numerical simulation on the multiple planar fracture propagation with perforation plugging in horizontal wells. Pet. Sci. 19 (5), 2253–2267 (2022).

Chen, B., Li, S. & Tang, D. Numerical simulation study on hydraulic fracture propagation of multi-cluster fracturing of horizontal well in deep fractured coal seams. Eng. Fract. Mech. 318, 110983 (2025).

Wang, S. et al. Three-Dimensional lattice modeling of interaction behavior between hydraulic fractures and natural fractures with varied morphologies in hot dry rock. Rock. Mech. Rock. Eng. 58 (3), 2971–2998 (2025).

Zhou, J., Zhang, L., Pan, Z. & Han, Z. Numerical studies of interactions between hydraulic and natural fractures by smooth joint model. J. Nat. Gas Sci. Eng. 46, 592–602 (2017).

Wu, K., Olson, J., Balhoff, M. T. & Yu, W. Numerical analysis for promoting uniform development of simultaneous Multiple-Fracture propagation in horizontal wells. SPE Prod. Oper. 32 (01), 41–50 (2017).

Cheng, W., Lu, C. & Xiao, B. Perforation optimization of Intensive-Stage fracturing in a horizontal well using a coupled 3D-DDM fracture model. Energies 14 (9), 2393 (2021).

Gutierrez Escobar, R., Mejia Sanchez, E. C., Roehl, D. & Romanel, C. Xfem modeling of stress shadowing in multiple hydraulic fractures in multi-layered formations. J. Nat. Gas Sci. Eng. 70, 102950 (2019).

Yang, D. et al. Extended finite element modeling nonlinear hydro-mechanical process in saturated porous media containing crossing fractures. Comput. Geotech. 111, 209–221 (2019).

Chong, Z., Yao, Q., Li, X. & Liu, J. Investigations of seismicity induced by hydraulic fracturing in naturally fractured reservoirs based on moment tensors. J. Nat. Gas Sci. Eng. 81, 103448 (2020).

Fatahi, H., Hossain, M. M. & Sarmadivaleh, M. Numerical and experimental investigation of the interaction of natural and propagated hydraulic fracture. J. Nat. Gas Sci. Eng. 37, 409–424 (2017).

Lyu, S. et al. Natural fractures in soft coal seams and their effect on hydraulic fracture propagation: A field study. J. Petrol. Sci. Eng. 192, 107255 (2020).

Zheng, P. et al. Formation mechanisms of hydraulic fracture network based on fracture interaction. Energy 243, 123057 (2022).

Shi, F., Wang, X., Liu, C., Liu, H. & Wu, H. An XFEM-based method with reduction technique for modeling hydraulic fracture propagation in formations containing frictional natural fractures. Eng. Fract. Mech. 173, 64–90 (2017).

Zhang, J. et al. A hybrid numerical approach for hydraulic fracturing in a naturally fractured formation combining the XFEM and phase-field model. Eng. Fract. Mech. 271, 108621 (2022).

Zhu, X., Feng, C., Cheng, P., Wang, X. & Li, S. A novel three-dimensional hydraulic fracturing model based on continuum–discontinuum element method. Comput. Methods Appl. Mech. Eng. 383, 113887 (2021).

Zhang, B. et al. Effect of bedding planes and property contrast between layers on the propagation mechanism of hydraulic fracture height in shale reservoirs. Comput. Geotech. 175, 106715 (2024).

Ren, Q. et al. CDEM-based simulation of the 3D propagation of hydraulic fractures in heterogeneous coalbed methane reservoirs. Comput. Geotech. 152, 104992 (2022).

Huang, G. et al. A new Multi-Cluster fracturing simulation model coupled with perforation erosion: based on the Continuous–Discontinuous method. Rock. Mech. Rock. Eng. 56 (6), 3887–3901 (2023).

Geuzaine, C., Remacle, J. F., Gmsh & A 3-D finite element mesh generator with built-in pre- and post-processing facilities. Int. J. Numer. Methods Eng. 79 (11), 1309–1331 (2009).

Funding

Supported by the National Natural Science Foundation of China (No. 52174045, No. U23B2084 and No.5241002).

Author information

Authors and Affiliations

Contributions

K.Y: Writing – review & editing, Writing – original draft,, Software, Formal analysis, Data curation. G.H. : Writing – review & editing, Software, Resources, Methodology, Data curation. F.Z. : Writing – review & editing, Supervision, Resources, Methodology, Funding acquisition. T.L. & J.Z.: review & editing, Software, Data curation. M.L.: Formal analysis, Data curation.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Yang, K., Huang, G., Zhou, F. et al. Numerical simulation of hydraulic–natural fracture interaction based on the continuous–discontinuous element method. Sci Rep (2026). https://doi.org/10.1038/s41598-025-34508-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-34508-z