Abstract

Because coal seam mining with high geostress and high gas pressure is prone to coal–rock–gas compound dynamic disasters, a disaster energy equation considering the influence of roof elastic energy is established, and a disaster energy criterion considering the influence of roof elastic energy is derived and introduced into COMSOL software to conduct numerical simulations of coal seam mining under different geostress and gas pressures. The study revealed that the increase of ground stress reduces the gas pressure required for disaster occurrence. When the gas pressure reaches a certain value, the disaster will occur even if the ground stress is very small. When the ground stress and gas pressure are very low, by changing the magnitude of ground stress or gas pressure, outburst, rockburst and coal‒rock‒gas composite dynamic disasters can transform into each other. As the depth of the excavated coal seam increases, the geostress‒gas pressure increases from 15‒0.5 MPa to 20‒0.74 MPa and 25‒1 MPa, the peak stress and peak gas pressure can reach maximum values of 39.61 MPa and 1.11 MPa, respectively, the difference between the elastic energy of the coal rock body and the expansion energy of the gas is not large, and the energy criterion is greater than 1 and increasing, which indicates that the occurrence of a compound dynamic disaster and the degree of hazard gradually increase. The high-pressure water jet slit technology can increase the average gas extraction volume by 3.6 times, the peak stress is transferred from 7 m away from the coal wall to 10 m, and the peak stress is transferred to the deep coal wall, which can effectively reduce the stress in the coal rock mass and the gas pressure in the coal seam.

Similar content being viewed by others

Introduction

With increasing coal mining depth, the number of coal rock bodies subjected to geostress and coal gas pressure increases1,2, the deep high geostress environment containing gas, coal and rock interactions becomes obvious, and rock bursts, coal outbursts and gas outbursts under the joint action of the two disasters, i.e., coal-rock‒gas complex dynamic disasters, and safety mining in coal mines have caused considerable threats3,4,5. At present, the most widely used theory of the coal rock gas dynamic disaster mechanism at home and abroad is the comprehensive role of the theory6,7. The theory that a disaster is the result of the combined effect of the geostress, gas pressure, and physical and mechanical properties of the gas-containing coal, of which the gas pressure and the geostress in the process of triggering the disaster play the role of the power source, so the geostress and the gas pressure are the two important factors affecting the coal rock dynamic disaster8,9,10. It is generally believed that coal and gas outbursts rely mainly on the role of gas, that rockbursts rely mainly on the role of geostress, that rockbursts are ignored, or that there is no role for gas outbursts11,12,13.

To address the situation in which deep high geostress and high gas pressure mines are prone to induce coal–rock–gas compound dynamic disasters, experts at home and abroad have focused on such problems through theoretical analyses, numerical simulations, and field experiments. He et al.14summarized the mechanism of rockburst occurrence from experimental, theoretical, and simulation aspects; Chen et al. 15, Zhao et al.16, Lu et al.17 used COMSOL simulation software to couple the coal-rock stress with the gas pressure during the mining process, and analyzed the distribution law of the gas pressure in the matrix and cracks; Hao et al.18 revealed the outburst mechanism of coal-rock gas catastrophe from the mechanical point of view; Wang et al.19 investigated the damage characteristics of coal dust under different gas pressures during coal and gas herniation; Du et al.20 discussed the influence of coal-rock assemblages and gas adsorption on the conditions and patterns of disaster occurrence using a true triaxial coal and gas protrusion experimental system; Dai et al.21 investigated the mechanical properties and energy evolution laws of coal-rock assemblages under different air pressures; An et al.22, Zhao et al.23 investigated the importance of gas expansion energy in coal-rock gas catastrophe; Wang et al.24 explored the occurrence conditions and energy criterion of the coal-rock-gas compound dynamic disaster through the physical simulation experiment of the destabilization of loaded gas-containing coal-rock assemblage to cause disaster; Xu25, Shu et al.26 conducted a study on the pore pressure evolution characteristics and permeability distribution characteristics of coal seams under the influence of mining; Zhang et al.27 studied the energy evolution mechanism of rockburst-induced outburst, and by analyzing the common energy release process of rockburst and outburst, they concluded that the coupled effects of gas internal energy, geostress, and strong perturbation are the energy sources of coal body destruction as well as dynamic phenomena in the process of compound dynamic disaster; Soleimani et al.28 studied the coal rock gas catastrophe mechanism from the perspective of energy balance; Lu et al.29 studied the outburst caused by shock wave caused by rockburst by microseismic and acoustic emission technology.

In the deep environment of high ground stress, the release of roof elastic energy in the compound disaster can accelerate the failure of coal mass and further aggravate the degree of disaster. However, the current research on roof elastic energy and its influence in the compound disaster is only ignored or only considered qualitatively but not truly quantified. Domestic and foreign experts mostly study the effects of ground stress and gas pressure on the combined dynamic disasters of coal, rock and gas from a qualitative perspective, and rarely quantitatively study the effects of different ground stress and gas pressure on the combined dynamic disasters of coal, rock and gas by numerical simulation coupled with multiple physical fields such as gas pressure and ground stress. Therefore, based on Comsol software, this paper constructs a gas–solid coupling model of gas-bearing coal rock structure with double pores and cracks, establishes the energy equation of coal and gas outburst considering the influence of elastic energy of roof, and puts forward the energy criterion. Qualitative and quantitative research is carried out on the stress field, gas flow field, plastic failure zone evolution law and energy distribution of coal seam under different initial geostress and gas pressure states, and the mechanism of coal-rock gas complex dynamic disaster induced by coal seam geostress and gas pressure is deeply analyzed. Finally, a coal, rock and gas combined dynamic disaster prevention and control measure applied to deep coal mining with high ground stress and high gas pressure is proposed to explain the disaster excitation phenomenon in deep coal mining and provide theoretical support for disaster prevention.

Qualitative research

Experts at home and abroad have qualitatively studied the occurrence mechanism of coal, rock and gas combined dynamic disasters through experimental studies. From the perspective of complex dynamic disasters caused by the instability failure of gas-bearing coal‒rock assemblies, Wang ang Du30 and Du et al.31,32 studied the mechanical characteristics and gas seepage laws of gas-bearing coal‒rock assemblies through conventional triaxial and true triaxial experiments and reported that rock bursts caused by roof and floor failure may induce low-gas coal seam outbursts (Fig. 1).

Through true triaxial experiment and coal mine disaster simulation test system, Zhou et al.33 and Du et al.26 analyzed the influence of ground stress and gas pressure on compound dynamic disasters. They reported that an increase in ground stress reduces the rate of gas pressure decline, an increase in gas pressure reduces the compressive strength of coal, and a compound dynamic disaster is the result of the mutual induction of high ground stress and high gas pressure (Fig. 2).

In summary, high ground stress, high gas pressure and roof and floor rocks all play an active role in the development of complex dynamic disasters.

Theoretical model construction

In this paper, the mechanism of coal-rock-gas dynamic disaster is quantitatively studied through numerical simulation, in which the actual situation of the simulation condition is mainly realized by inputting the following parameters and governing equations. The calculation formula of roof elastic energy is derived innovatively, and the roof elastic energy is incorporated into the energy balance system of coal and gas outburst, and then the mathematical expression of energy criterion is given.

Equation of control for gas transportation in coal seams

The transportation of gas can be mainly divided into three parts: Desorption, diffusion and seepage34,35, the diffusion of gas is in accordance with Fick’s law of diffusion, and the seepage of gas is in accordance with Darcy’s law of seepage36. The coal seam gas transportation mechanism is shown in Fig. 3.

The state of gas accumulation in coal seams

Gas in coal seams consists of fissure free gas, matrix pore free gas and matrix adsorbed gas.

The mass of free gas per unit volume of coal is:

Style: cf free gas concentration in the fissure; Mc denotes the molar mass of methane, kg/mol; R denotes the ideal gas constant, j/(mol∙ K); T expressed temperature, K.

The total gas mass per unit volume of coal matrix is37:

Style: VL indicates the maximum adsorption capacity of the monolayer, kg; PL indicates the adsorption equilibrium pressure at which the adsorption amount is half of the maximum adsorption amount, MPa; ρa is the apparent density of coal, kg/m3; VM is the molar volume of methane in the standardized state, m3/mol; Φm indicates matrix porosity; Φf indicates the fracture ratio.

Gas diffusion control equation

The flux equation for mass exchange between the coal matrix and the fissure system can be expressed as follows38:

Style: D denotes the diffusion coefficient of the gas, m2/s; L is the fracture spacing, m.

According to the law of conservation of mass, it is known that the rate of mass exchange between the matrix and the fissure is equal to the amount of change in the mass of the matrix with respect to time i.e.:

Substituting Eq. (2) into Eq. (4), the matrix gas pressure control equation can be obtained as39:

Equation of control for gas seepage

Gas flows slowly in coal seam fissures and gas seepage conforms to Darcy’s law. Its mass conservation equation is:

Style: υ is the gas seepage rate in the fissure, m/s; ke is the effective permeability of the coal seam,Md; μ is the gas dynamic viscosity coefficient, Pa∙s.

After finishing the equation of fissure gas pressure versus time can be obtained as40,41:

Ontological equations for gas-bearing coal bodies

The effective stress equation for a gas-bearing coal body is given by42:

Style: σij, σij0, pm, pf denote the stress tensor, effective stress tensor, matrix, and gas pressure in the fissure, respectively, MPa; αf, αm indicates the effective stress coefficient of the fracture and matrix.

The parameters K, Km, Ks, αf, αm in Eq. (1) can be expressed as43:

Style: Ecoal, Em, v denote coal modulus of elasticity, coal matrix modulus of elasticity, and coal Poisson’s ratio, respectively; K, Km, Ks denote the bulk modulus of the coal body, coal matrix, and coal skeleton, respectively, MPa.

The deformation control equations of gas-containing coal body are as follows44:

Style: G, Fi denote the shear modulus of coal, the volumetric stress in the i-direction, respectively, MPa; ν denotes poisson’s ratio; \({\varepsilon }_{\text{bmax}}^{\text{s}}\) denotes the adsorbed maximum volumetric strain; pc indicates adsorption deformation pressure.

Criterion equation for coal seam yield damage

Yield criterion for gas-bearing coal bodies using the Drucker-Prager criterion:

Style: σ1, σ2, σ3 are the three effective ground stresses of the coal body, MPa.

Coal rock gas catastrophe energy equation and criterion

Considering the influence of roof elastic energy, the elastic energy of coal, roof accumulation and gas expansion energy in coal are defined as outburst kinetic energy45. Crushing work, ejection work, heat energy, kinetic energy and roof plastic deformation energy are defined as outburst energy. Therefore, the dynamic disaster energy balance equation of coal, rock and gas considering the elastic energy of the roof is as follows46,47,48,49,50:

Style: Wcoal–elastic energy of the coal body; Wrock–elastic energy of the roof rock; N–gas expansion energy; W1–crushing power; W2–throwing function; W3–heat energy, kinetic energy, etc.

In order to simplify the analysis and calculation, only the crushing work is considered in this outburst energy consumption. When the outstanding kinetic energy is greater than the outstanding energy consumption, the coal will be unstable risk. Therefore, this paper defines the ratio of outburst kinetic energy to outburst energy consumption as an energy criterion, and the outburst energy criterion C of coal and gas is:

Elastic energy of the coal body

Style: Ecoal indicates the modulus of elasticity of coal, MPa; νcoal indicates the Poisson’s ratio of the coal; Vp indicates the volume of the plastic damage zone, m3.

Elastic energy of the rock mass

The derivation process of elastic strain energy of roof rock is shown as follows.

When gas effects are considered, Ecoal is substituted by ΠEcoal, σ by τσ, and n by n/Π, where 0 < τ < 1 and0 < Π < 1; Let σz = τAσ, so that A ≥ 1.

Style: Ucoal is the elastic energy per unit volume of coal; Ucoal+rock elastic energy of coal and rock; σz is the strength of coal and rock mass, MPa; Ez the elastic modulus; Ecoal the elastic modulus; 0 < Π < 1; m is the ratio of rock-coal thickness; n is the ratio of the modulus of elasticity of rock and coal;β contribution rate of roof elasticity.

By combining formula (15), we can get:

It can be concluded that:

In summary, the roof rock increases the elastic energy of the system at least Πm/n times of that of pure coal.The elastic strain energy of the rock mass is approximated as:

Gas expansion energy

The gas stored in the coal seam mainly consists of free gas and adsorbed gas51.

1) Free state gas expansion energy

Style: patm indicates atmospheric pressure, take a value of 0.1 MPa; n retrieve a value1.25.

2) Expansion energy of gas in the adsorbed state

So the total gas expansion energy is expressed as:

Work of crushing coal

The coal body crushing work equation can be expressed as :

Style: s indicates the new surface area of the coal body, m2; f indicates coefficient of robustness.

By substituting Eqs. (14), (18), (21) and (22) into Eq. (13), the criterion C of coal, rock and gas dynamic disaster considering the elastic energy of the roof as follows:

When the energy criterion C > 1, coal outburst occurs in front of the roadway, and the greater the energy criterion C is, the greater the outburst damage is. When energy criterion C < 1, coal body in front of roadway does not protrude. When the energy criterion C = 1, the coal body in front of the roadway is in the limit equilibrium state, and the coal body is about to become unstable.

Multi-physical field coupling relations

Coal rock gas dynamic catastrophe involves stress field, gas pressure field, seepage field, fissure field and other multi-physical fields, multi-physical fields coupled with each other, the coal stress state, physical and mechanical properties, and gas pressure in the process of outburst will occur in a series of changes in the physical field control equations and mutual coupling relationship is shown in Fig. 4.

Numerical simulation analysis

Engineering background

Xinji No. 2 mine is located in Huainan, Anhui Province, China, it is an outburst mine. The buried depth of the working face of 220,108 is 570 ~ 650 m, the coal seam inclination of the first coal seam is 3° ~ 8°, the average is 5°, the measured maximum gas pressure is 1.65 MPa, the coal thickness is 3.4 m, the uniaxial compressive strength is 13.47 MPa and the elastic energy index is 3.11, the impact energy index is 3.07, the sandstone roof with a thickness of 26 m exists above the coal seam, and the working face has the conditions of outburst and rockburst coal-rock-gas composite dynamic disaster.

Numerical simulation establishment

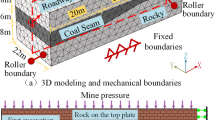

This numerical simulation takes the coal seam of 220,108 working face of Xinji No. 2 mine as the prototype and carries out simplified modeling according to a certain proportion. Comsol multi-physics field coupled numerical simulation software is used to simulate the mining process of the coal seam under different initial geostress and gas pressure. In which the solid mechanics module and the PDE module can solve the stress–strain relationship, gas seepage and gas diffusion in the gas-containing coal-rock structure. The volume fraction with damage variable greater than 0 is taken as the plastic deformation volume of coal. A monitoring line is set in the center of the thin coal seam and the rock 1 m away from the upper part of the coal seam to obtain the distribution curve of elastic energy, gas expansion energy and energy criterion. The whole solution process adopts steady state. The geometric model and boundary conditions are shown in Fig. 5, and the model parameters are determined on the basis of reference 17 and in combination with the engineering site, as shown in Table 1.

1) Geometric feature.

The dimensions of the geometric model are: x = 60 m, y = 22 m, z = 22 m, where the top and bottom of the model are 9 m thick rock, the middle is 4 m thick coal seam, the height of the mining roadway is 4 m, the width is 4 m, and the horizontal cyclic excavation footage is 5 m.

2) Initial and boundary conditions.

Solid module: The bottom boundary is a fixed boundary; the left, right, and front and back boundaries are roller boundaries.

PDE module: The upper, lower and right-hand boundaries of the coal seam are zero-flow boundaries, and the roadway within the seam is a pressure boundary, with an absolute pressure of atmospheric pressure of 0.1 MPa.

3) Simulation scenario.

Three excavation scenarios were developed for this simulation, the different excavation scenarios are shown in Table 2.

Numerical simulation results

Abutment pressure distribution in coal seam

From Fig. 6 and Fig. 7, it can be seen that the stress near the working face of the excavation is very small, but with the increase of the distance from the working face, the stress gradually rises up to the peak, and then the stress gradually decreases to the initial original rock stress, so it can be classified into unloading zone, concentration zone, and original zone of the coal seam in front of the working face.

Figure 6(a) ~ (c) and Fig. 7(a) show Scenario 1, when the gas pressure is 0.5 MPa and the geostress increases from 15 to 25 MPa, the peak stress in the concentrated stress zone continues to increase, and the maximum value is 34.47 MPa at geostress 25 MPa; Fig. 6(d) ~ (f) and Fig. 7(b) show Scenario 2, when the geostress is 15 MPa and the gas pressure increases from 0.5 MPa to 1.0 MPa, the peak stress in the concentrated stress zone continues to increase, and the maximum value is 32.15 MPa at gas pressure 1.0 MPa, it can be seen that the internal stress state of coal seam is jointly controlled by geostress and gas pressure and other factors; Fig. 6(g) ~ (i) and Fig. 7(c) show Scenario 3, with the ground stress and the gas pressure increasing, the peak stress also increases continuously.

When the maximum geostress and gas pressure are 25 MPa and 1.0 MPa, respectively, the stress peak is the largest, the maximum value is 39.61 MPa, indicating that with the increase of the depth of the excavated coal seam, the geostress and gas pressure interact with each other in a coupled manner, and the possibility of the occurrence of the coal-rock-gas dynamics disaster is greatly increased.

Gas pressure distribution in coal seams

For the fissure and matrix gas pressure distribution, the difference between the two model calculations is very small, but the matrix gas pressure is slightly higher than the fissure gas pressure, in view of the space limitation, only the cloud diagram of matrix gas pressure distribution is given for the case of the same ground stress with different initial gas pressures as shown in Fig. 8. From the analysis of Fig. 8(a) ~ (c), the distribution of gas pressure in the coal seam in front of the working face is similar to the distribution of stress, and it is also divided into unloading zone, concentration zone, and original zone. The gas pressure at the coal wall of the working face is much lower than the initial gas pressure, and with the increase of the distance between the coal body and the working face, the gas pressure increases and reaches the peak value, and then gradually decreases to the initial value. Except for a small area around the excavation face, there is no significant change in matrix gas pressure.

When the initial gas pressure is 0.5 MPa, the peak stress is 0.55 MPa, which does not exceed the critical value of 0.74 MPa, which is safer; When the initial gas pressure is 0.74 MPa, the peak stress is 0.82 MPa, which exceeds the critical value of 0.74 MPa, and there is a risk of disaster; When the initial gas pressure is 1.0 MPa, the peak stress is 1.11 MPa, far exceeding the critical value of 0.74 MPa, and the possibility of coal and rock gas dynamic disaster is great.

Distribution of plastic damage zones in coal seams

The plastic deformation volume of coal was obtained by numerical simulation of the volume fraction of damage variables greater than zero, and the distribution of plastic damage zones of coal seams under three excavation scenarios is given in Fig. 9. The results show that the plastic deformation volume of coal increases significantly with the increase of ground stress and gas pressure. When the maximum ground stress and gas pressure are 25 MPa and 1 MPa, respectively, the plastic deformation volume of the coal body is the largest, and it is most likely to occur in the coal-rock-gas dynamic disaster accident.

Outburst energy evolutionary features

Coal and rock body elastic energy(W) and gas expansion energy(N) are the main energies contributing to the coal-rock-gas compound dynamic disaster. From Fig. 10(a) ~ (i), it can be seen that the elastic energy contained in the rock body is about 1/3 of the elastic energy contained in the coal body, the elastic energy contained in the rock body is larger, and the effect of the elastic energy of the roof rock on the catastrophe is non-negligible; with the increasing of the ground stress and gas pressure, the elastic energy of the coal and rock body and the gas expansion energy are also accumulating. Scenario 1: W and N are not very different in Fig. 10(a), W is about 7 times as large as N in Fig. 10(b), and W is about 13 times as large as N in Fig. 10(c); Scenario 2: W and N are not very different in Fig. 10(d), N is about 6 times as large as W in Fig. 10(e), and N is about 12 times as large as W in Fig. 10(f); and Scenario 3: W and N are not very different in Fig. 10(g) ~ (i), but are larger than those in Scenarios 2 and Scenario 3.

Dynamical disaster energy criterion

The energy criterion (C) couples multiple physical fields such as stress, gas pressure, plastic damage zone, etc. The energy criterion (C) calculated by numerical simulation is compared with 1 to analyze the possibility of the occurrence of coal-rock gas dynamics catastrophe, and the following conclusions can be drawn by combining the above part of the protruding energy distribution (It is generally believed that when W and N differ by an order of magnitude, rockburst or coal and gas outburst occurs; when the difference between W and N is not much, within an order of magnitude, the compound dynamic disaster occurs). Scenario 1 from Fig. 11 can be seen: When the gas pressure is constant at 0.5 MPa, with the increase of the geostress, C also increases, the geostress is 15 MPa, C is less than 1, did not occur disaster; the geostress is 20 MPa, C is slightly greater than 1, and because W is about 7 times N, not more than 10 times more than that, it can be assumed that this time the coal-rock-gas compound dynamic disaster; the geostress is 25 MPa, C is greater than 1, and because W is about 13 times N, more than 10 times more, can be considered to occur at this time rockburst.

Scenario 2 in Fig. 12 shows that: When the geostress is constant at 15 MPa, as the gas pressure increases, C also increases; when the gas pressure is 0.5 MPa, C is less than 1, and no catastrophe occurs; when the gas pressure is 0.74 MPa, C is slightly larger than 1, and because N is about 6 times of W, and does not exceed more than 10 times, it can be assumed that coal-rock-gas compound dynamic disaster occurs at this time; when the gas pressure is 1 MPa, C is larger than 1, and because N is about 12 times of W, and more than 10 times over, it can be assumed that coal and gas outburst occurs at this time.

Scenario 3 in Fig. 13 shows that: With the increase of geostress and gas pressure, C also increases, when the geostress is 15 MPa and gas pressure is 0.5 MPa, C is less than 1, and no catastrophe occurs; when the geostress is 20 MPa and gas pressure is 0.74 MPa, C is greater than 1, and there is not much difference between W and N, which can be regarded as the occurrence of the coal-rock-gas compound dynamic disaster at this time; when the geostress is 25 MPa and gas pressure is 1 MPa, C is greater than 1 and C is the largest among the three scenarios, and there is little difference between W and N, it can be considered that the coal-rock-gas complex dynamic disaster occurs at this time, and the disaster intensity is the largest among the three scenarios.

The simulation results show that Scenario 1: The increase of the geostress will lead to the decrease of the gas pressure required for the catastrophe, the lower gas pressure (0.5 MPa) will also induce the catastrophe; Scenario 2: The catastrophe will occur even if the geostress is very small when the gas pressure reaches a certain value (0.74 MPa); Scenario 3: As the depth of the excavated coal seam increases, the geostress and gas pressure keep increasing, and the frequency of coal-rock-gas compound dynamic disaster increases significantly. When the geostress is 25 MPa, gas pressure is 0.5 MPa, rockburst will occur, then increase the gas pressure to 1 MPa, rockburst into compound dynamic disaster; when the geostress is 15 MPa, gas pressure is 1 MPa, outburst will occur, then reduce the gas pressure to 0.5 MPa, outburst into compound dynamic disaster.

Mechanism analysis of coal-rock-gas complex dynamic disaster

On the basis of the qualitative research of the first part of the laboratory experiment, the two important influencing factors of ground stress and gas pressure, as well as the influence of roof and floor rocks on inducing complex dynamic disasters, are analyzed in detail combined with the numerical simulation quantitative research in this paper, and the unified occurrence mechanism of coal, rock and gas complex dynamic disasters in deep roadway is further clarified52.

Dividing the coal-rock-gas compound dynamic disaster into four stages: Gestation, stimulation, development, as shown in Fig. 14.

Cataclysmic gestation stage: When the coal mine is mined to the deep area of high in-situ stress, the local coal body will be stressed beyond its strength limit, deformation and destruction will occur, forming a plastic deformation zone. The greater the initial stress-gas pressure is, the larger the plastic deformation zone will be (the largest when the initial geostress-gas pressure is 25 MPa-1.0 MPa), as shown in Fig. 9 and Fig. 14, where cracks and fractures are dense. The gas in the surrounding coal seam will enter this area through cracks, forming a high-pressure gas accumulation area, and the surrounding coal and rock masses accumulate elastic energy, forming an elastic deformation area, and forming coal and rock masses with disaster tendency.

Cataclysmic motivation stage: as shown in Fig. 6 and Fig. 7, the peak stress in front of the excavation face is the largest when the geostress -gas pressure is 25 MPa-1 MPa. When the coal seam is disturbed by mining, the original stress balance of coal and rock mass is most easily destroyed. As shown in Fig. 10–14, when the geostress -gas pressure is 25 MPa-0.5 MPa, C is greater than 1, W is about 13 times of N, and more than 10 times, the accumulated elastic energy of coal and rock mass in the elastic deformation area is released, and the coal and rock mass only break and rockburst occurs. When the geostress -gas pressure is 15 MPa-1 MPa, C is greater than 1, N is about 12 times of W, and more than 10 times, the gas stored in the plastic deformation zone of coal seam can be released, throw out coal, and outburst occurs. When the geostress -gas pressure is 20 MPa-0.74 MPa and 25 MPa-1.0 MPa, C is greater than 1, and the difference between W and N is less than 10 times, the elastic energy of coal and rock mass in the elastic deformation area and the gas expansion in the plastic deformation area can boost each other and release, resulting in a coal-rock-gas compound dynamic disaster.

Cataclysmic progression stage: After the disaster is triggered, the free gas in the roadway is transferred to the outside world in the form of two-phase flow with the pulverized coal body, and the coal body in front of the excavation work continuously releases the elastic energy and gas expansion energy, which is transferred to the inside in the form of laminar cracks in the coal seams. In the process of disaster, outburst, rockburst and coal-rock-gas compound dynamic disaster can be transformed into each other, as shown in Fig. 10–14, when the geostress is 25 MPa and the gas pressure is 0.5 MPa, the rockburst will occur, at this time, the gas pressure is increased to 1.0 MPa, and the rockburst will be transformed into composite dynamic disaster; When the geostress is 20 MPa and the gas pressure is 0.5 MPa, the composite dynamic disaster will occur, at this time, the geostress is increased to 25 MPa, the composite dynamic disaster will be transformed into rockburst; When the geostress is 15 MPa and the gas pressure is 1.0 MPa, the outburst will occur, at this time, the gas pressure will be reduced to 0.5 MPa, and the outburst will be transformed into compound dynamic disaster; When the geostress is 15 MPa and the gas pressure is 0.74 MPa, the composite dynamic disaster will occur, at this time, the gas pressure is increased to 1.0 MPa, the composite dynamic disaster will be transformed into outburst.

Cataclysmic termination stage: When the energy released by the deformation and destruction of the coal body is less than the energy consumed by the catastrophe, the catastrophe will be terminated.

Prevention and control of compound dynamic disaster

Protective measures

Numerical simulation analysis revealed that high gas pressure in coal seams and high ground stress in coal rock masses are strongly correlated with coal rock gas dynamic disasters in deep roadways, which are the main factors controlling disaster occurrence. Therefore, the focus of disaster prevention and control is to reduce the gas pressure in coal seams and the near-field stress in coal rock masses. We mainly control the gas pressure and stress in coal rock structures through high-pressure water jet slicing and drilling technology53,54.

High pressure water jet slit drilling technology can depressurize coal seams with low permeability and effectively reduce the expansion energy of gas in coal seams with high efficiency and low cost55,56. The specific prevention and control measures include the use of high-pressure water jet cutting slit drilling technology to cut the coal seam in the horizontal direction to unpressurize and increase penetration. A schematic diagram of the coal–rock–gas dynamic disaster prevention and control model is shown in Fig. 15.

Prevention and control effects

In the 220,108 working face of the Xinji No. 2 Mine, 40 drilling holes with high-pressure water jets were constructed to carry out joint drilling tests, and 40 ordinary drilling holes were constructed for comparison. Then, the effect of using high-pressure water jet joint drilling technology on coal seam pressure relief and gas extraction was investigated and analyzed.

According to the engineering geological conditions and test experience of the test site, the selected parameters of high-pressure water jet slot drilling are as follows: slot spacing of drilling 3 m, hole spacing of drilling 6 m, drill pipe rotation speed of 80 r/min, single-tool slot cutting time of 7 min, average single-hole slot cutting time of 2.5 h, slot cutting pressure of 80 MPa, and hole depth of bedding drilling 80 m.

Effectiveness of coal seam gas extraction

Figure 16 gives a schematic diagram of the change of the average extraction pure volume of ordinary drill holes and high-pressure water jet slit drill holes within 60 days of coal seam extraction, from which we can see that the average extraction pure volume of gas of high-pressure water jet slit drill holes is 0.202 m3/min, and the average extraction pure volume of gas of ordinary drill holes is 0.056 m3/min, and the average extraction pure volume of high-pressure water jet slit drill holes is 3.6 times higher than that of ordinary drill holes.

Coal seam unloading effect

Figure 17 shows that the peak stress concentration coefficients after unpressurization, unpressurization by ordinary drilling holes and unpressurization by high-pressure water jet slit drilling are 2.25, 1.82 and 1.48, respectively, the peak stress concentration coefficients of unpressurization by ordinary drilling holes are reduced by approximately 19.1%, and the peak stress concentration coefficients of unpressurization by high-pressure water jet slit drilling holes are reduced by approximately 34.2%. The peak stresses correspond to distances of 4 m, 7 m and 10 m from the working face, and the peak stresses are gradually transferred to the deeper part. Both ordinary drilling and high-pressure water jet slit drilling have a certain degree of decompression effect, but the decompression effect of high-pressure water jet slit drilling technology is more obvious.

The experimental results have proved that the use of high-pressure water jet cutting slit drilling technology to cut the coal seam in the horizontal direction can effectively reduce the near-field stress in the coal-rock structural body, and the gas pressure in the coal seam, and at the same time, it can serve the purpose of anti-rockburst and anti- outburst.

Conclusion

Based on Comsol software, we constructed a gas–solid coupling model of dual pore-fracture gas-containing coal-rock structural body, and coupled multi-physical fields, such as stress field, damage field, gas flow field and energy distribution, to quantitatively study the effects of different geostresses and gas pressures on the coal-rock-gas dynamic disaster, and to explore the mechanism of the coal-rock gas-compound dynamic disaster. The main conclusions are as follows:

(1) The distribution of coal seam abutment pressure and gas pressure in front of the excavation face can be divided into a pressure relief zone, a concentration zone and an original zone. With increasing ground stress and gas pressure, the peak stress and peak gas pressure in the concentration area of the coal seam increase; the maximum values can reach 39.61 MPa and 1.11 MPa, respectively, the amount of plastic deformation of the coal body increases, and the risk of occurrence of dynamic coal‒rock‒gas disaster increases.

(2) A high geostress effect decreases the gas pressure required for a coal‒rock–gas catastrophe; that is, a lower gas pressure can also induce a catastrophe. When the gas pressure reaches a certain value, even if the geostress is very small, a catastrophe will occur. In the case of different ground stresses and gas pressures, by changing the magnitude of ground stress or gas pressure, outbursts, rockbursts and coal‒rock‒gas composite dynamic disasters can be transformed into each other.

(3) The simulated elastic energy of the roof rock is approximately 1/3 of the elastic energy of the coal body, and the influence of the elastic energy of the roof rock on the catastrophe cannot be ignored. The energy equation of coal and gas outbursts considering the influence of the elastic energy of the roof rock is established, and the energy criterion is proposed. This study reveals that, with increasing excavation depth, the energy criterion is greater than 1 when the geostress and gas pressure increase from 15–0.5 MPa to 20–0.74 MPa and 25–1 MPa, respectively, the difference between the elastic energy of the coal rock body and the expansion energy of the gas is not large, and the energy criterion is greater than 1 and increasing, which indicates that the occurrence of compound dynamic disasters and the degree of hazard gradually increase.

(4) Adopting high-pressure water jet cutting slit drilling technology to prevent and control coal–rock–gas compound dynamic disasters can effectively reduce the stress in the coal–rock body and the gas pressure in the coal seam. In practice, the average pure volume of extracted gas is increased by 3.6 times, the stress peak is further reduced, and the stress peak is shifted from 7 m from the coal wall to 10 m from the coal wall and further shifted to the deeper part of the coal seam compared with ordinary drilling and high-pressure water jet slit drilling.

Data availability

The data that support the findings of this study are available from the corresponding author T.C.L.

References

Lei, Y. et al. The energy principle of coal and gas outbursts: Experimentally evaluating the role of gas desorption. Rock Mech. Rock Eng. 54, 11–30 (2021).

Fan, C., Li, S., Luo, M., Du, W. & Yang, Z. Coal and gas outburst dynamic system. Int. J. Min. Sci. Technol. 27, 49–55 (2017).

Zhang, C. et al. Prediction of rockbursts in a typical island working face of a coal mine through microseismic monitoring technology. Tunn. Undergr. Space Technol. 113, 103972 (2021).

Chen, L. & Liu, Q. A Gas Pressure prediction model of the excavation face based on gas emission. Int. J. Environ. Res. Public Health 19, 4891 (2022).

Xue, Y., Ranjith, P. G., Gao, F., Zhang, Z. & Wang, S. Experimental investigations on effects of gas pressure on mechanical behaviors and failure characteristic of coals. J. Rock Mech. Geotech. Eng. 15, 412–428 (2023).

Tang, S. H. et al. Control and prevention of gas explosion in soft ground tunneling using slurry shield TBM. Tunn. Undergr. Space Technol. 113, 103963 (2021).

Zhang, X., Tang, J., Pan, Y. & Yu, H. Experimental study on intensity and energy evolution of deep coal and gas outburst. Fuel 324, 124484 (2022).

Gao, F., Kang, H. & Yang, L. Experimental and numerical investigations on the failure processes and mechanisms of composite coal–rock specimens. Sci. Rep. 10, 13422 (2020).

Ren, Q. & Cao, J. Characteristics of coal crack development and gas desorption in the stress affected zone of rock pillar. Sci. Rep. 14, 24551 (2024).

Sun, H. et al. Modelling of enhanced gas extraction in low permeability coal seam by controllable shock wave fracturing. Sci. Rep. 14, 24155 (2024).

Xu, C. et al. Experimental study on mechanical properties and failure behaviours of new materials for modeling rock bridges. J. Mater. Res. Technol. 23, 1696–1711 (2023).

Li, F., Yin, D., Wang, F., Jiang, N. & Li, X. Effects of combination mode on mechanical properties of bi-material samples consisting of rock and coal. J. Mater. Res. Technol. 19, 2156–2170 (2022).

Kang, H., Gao, F., Xu, G. & Ren, H. Mechanical behaviors of coal measures and ground control technologies for China’s deep coal mines - A review. J. Mech. Geotech. Eng. 15, 37–65 (2023).

He, M., Cheng, T., Qiao, Y. & Li, H. A review of rockburst: Experiments, theories, and simulations. J. Rock Mech. Geotech. Eng. 15, 1312–1353 (2023).

Chen, Y., Chu, T., Chen, X. & Chen, P. Coupling of stress and gas pressure in dual porosity medium during coal seam mining. Powder Technol. 367, 390–398 (2020).

Zhao, Y. et al. Mechanism of multifield coupling-induced outburst in mining-disturbed coal seam. Fuel 272, 117716 (2020).

Lu, S. et al. Numerical assessment of the energy instability of gas outburst of deformed and normal coal combinations during mining. Process. Saf. Environ.Prot. 132, 351–366 (2019).

Hao, Z., Jian, K., Peng, S. & Xu, J. Numerical investigation of coal and gas outbursts under different in situ stresses and gas pressures and the physical characteristics of coal. ACS Omega 6, 13260–13274 (2021).

Wang, Y., Li, C., Hao, M., Zhang, H. & Sun, X. Damage characteristics of pulverized coal under different gas pressures in coal and gas outbursts. Energy Sour.Part A: Recov. Utilizat. Environ. Eff. 44, 9385–9394 (2022).

Du, F. et al. Experimental study of coal-gas outburst: Insights from coal–rock structure, gas pressure and adsorptivity. Nat. Resour. Res. 29, 2481–2493. https://doi.org/10.1007/s11053-020-09621-7 (2020).

Dai, L., Zhang, Z., Sun, H. & Gao, H. Research on mechanical properties and energy evolution law of coal–rock assemblage with different gas pressures. Sustainability 14, 9904 (2022).

Du, X. et al. Damage and energy characteristics of coal rock combinations with inclined coal seams under axial loading. Sci. Rep. 14, 21881 (2024).

Shu, L. et al. Response characteristics of gas pressure under simultaneous static and dynamic load: Implication for coal and gas outburst mechanism. Int. J. Min. Sci. Technol. 33, 155–171 (2023).

Hao, T., Wang, G., Li, F., Tang, Y. & Yuan, M. Study on the characteristics of acoustic-thermal precursors of destabilization damage in coal-rock combination bodies with different proportions. Sci. Rep. 14, 25661 (2024).

Xu, C., Yang, G., Wang, K. & Fu, Q. Uneven stress and permeability variation of mining-disturbed coal seam for targeted CBM drainage: A case study in Baode coal mine, eastern Ordos Basin. China. Fuel 289, 119911 (2021).

Du, F. & Wang, K. Unstable failure of gas-bearing coal-rock combination bodies: Insights from physical experiments and numerical simulations. Process. Saf. Environ. Prot. 129, 264–279 (2019).

Yu, Y. et al. Failure energy evolution of coal–rock combination with different inclinations. Sci. Rep. 12, 19455 (2022).

Soleimani, F., Si, G., Roshan, H. & Zhang, Z. Numerical modelling of coal and gas outburst initiation using energy balance principles. Fuel 334, 126687 (2023).

Lu, C. P., Dou, L. M., Zhang, N., Xue, J. H. & Liu, G. J. Microseismic and acoustic emission effect on gas outburst hazard triggered by shock wave: A case study. Nat. Hazard. 73, 1715–1731 (2014).

Wang, K. & Du, F. Coal-gas compound dynamic disasters in China: A review. Process. Saf. Environ. Prot. 133, 1–17 (2020).

Du, F. et al. Investigation of the acoustic emission characteristics during deformation and failure of gas-bearing coal-rock combined bodies. J. Loss. Prev. Process. Ind. 55, 253–266 (2018).

Du, F., Wang, K., Wang, G., Huang, Y. & Yi, L. The mechanism of damage in gas-bearing coal-rock combination bodies and gas seepage in coals. Energy Sour. Part A: Recover. Utilizat. Environ. Eff. 43, 1181–1201 (2021).

Zhou, B. et al. Effects of geo-stress on the dynamic response of multi-physical field parameters during coal and gas outbursts under true triaxial stress. Int. J. Rock Mech. Min. Sci. 142, 104759 (2021).

Si, L., Li, Z., Yang, Y. & Gao, R. The stage evolution characteristics of gas transport during mine gas extraction: Its application in borehole layout for improving gas production. Fuel 241, 164–175 (2019).

Liu, H., Lin, B., Mou, J. & Yang, W. Mechanical evolution mechanism of coal and gas outburst. Rock Mech. Rock Eng. 52, 1591–1597 (2019).

Zhang, B., Wang, H., Wang, P., Yu, G. & Gu, S. Experimental and theoretical study on the dynamic effective stress of loaded gassy coal during gas release. Int. J. Min. Sci. Technol. 33, 339–349 (2023).

Langmuir, I. The adsorption of gases on plane surfaces of glass, mica and platinum. J. Am. Chem. Soc. 40, 1361–1403 (1918).

Ma, C., Zhu, C., Zhou, J., Ren, J. & Yu, Q. Dynamic response and failure characteristics of combined rocks under confining pressure. Sci. Rep. 12, 12187 (2022).

Lim, K. T. & Aziz, K. Matrix-fracture transfer shape factors for dual-porosity simulators. J. Pet. Sci. Eng. 13, 169–178 (1995).

Cui, G., Liu, J., Wei, M., Shi, R. & Elsworth, D. Why shale permeability changes under variable effective stresses: New insights. Fuel 213, 55–71 (2018).

Fan, Y., Shu, L., Huo, Z., Hao, J. & Li, Y. Numerical simulation of sectional hydraulic reaming for methane extraction from coal seams. J. Nat. Gas Sci. Eng. 95, 104180 (2021).

Hosking, L. J., Chen, M. & Thomas, H. R. Numerical analysis of dual porosity coupled thermo-hydro-mechanical behaviour during CO2 sequestration in coal. Int. J. Rock Mech. Min. Sci. 135, 104473 (2020).

Wu, Y. et al. Dual poroelastic response of a coal seam to CO2 injection. Int. J. Greenh. Gas Control. 4, 668–678 (2010).

Li, W. et al. A fully coupled multidomain and multiphysics model considering stimulation patterns and thermal effects for evaluation of coalbed methane (CBM) extraction. J. Pet. Sci. Eng. 214, 110506 (2022).

Ye, D., Liu, G., Gao, F., Hu, Y. & Yue, F. A fractal model of thermal-hydrological-mechanical interaction on coal seam. Int. J. Therm. Sci. 168, 107048 (2021).

Wu, K., Chen, F., Lin, J., Zhao, J. & Zheng, H. Experimental study on the interfacial bond strength and energy dissipation capacity of steel and steel fibre reinforced concrete (SSFRC) structures. Eng. Struct. 235, 112094 (2021).

Tu, Q., Cheng, Y., Xue, S., Ren, T. & Cheng, X. Energy-limiting factor for coal and gas outburst occurrence in intact coal seam. Int. J. Min. Sci. Technol. 31, 729–742 (2021).

Hanak, D. P., Biliyok, C., Yeung, H. & Białecki, R. Heat integration and exergy analysis for a supercritical high-ash coal-fired power plant integrated with a post-combustion carbon capture process. Fuel 134, 126–139 (2014).

He, H. et al. Microseismic and electromagnetic coupling method for coal bump risk assessment based on dynamic static energy principles. Saf. Sci. 114, 30–39 (2019).

Meng, X., Chang, H. & Wang, X. Methane concentration prediction method based on deep learning and classical time series analysis. Energies 15, 2262 (2022).

Lu, S. et al. Damage-induced permeability model of coal and its application to gas predrainage in combination of soft coal and hard coal. Energy Sci. Eng. 7, 1352–1367 (2019).

Lu, Z. et al. Numerical analysis on the factors affecting post-peak characteristics of coal under uniaxial compression. Int. J. Coal Sci. Technol. 11, 2 (2024).

He, Y., Pang, J., Sun, X. & Sun, L. Scale parameters of soft structures for surrounding rock erosion prevention in rockburst-prone roadways. Sci. Rep. 14(1), 19890 (2024).

He, Y., Sun, L. & Xing, X. Study on the cyclic impact mechanical characteristics of coal under confining pressure. ACS omega 9(38), 40110–40121 (2024).

Sun, Z., Liu, Y., Qi, Q., Chai, J. & Gu, B. The influence of high-pressure water jet cutting parameters on the relief of pressure around the coal slot. Processes 11, 2071 (2023).

Jun, X., Yunpei, L., Quanle, Z., Lei, L. & Xuelong, L. Elimination of coal and gas outburst risk of low-permeability coalseam using high-pressure water jet slotting technology: A case study in Shihuatian Coal Mine in Guizhou Province. China. Energy Sci. Eng. 7, 1394–1404 (2019).

Acknowledgements

The authors would like to thank the Shandong postdoctoral innovation project (SDCX-ZG-202400203), Qingdao postdoctoral funding program (QDBSH20230202074), National natural science foundation of China (NSFC) (52278359), and Project funded by open fund of state key laboratory of coal mine disaster dynamics and control (2011DA105287-FW202203) for funding provided to this work.

Funding

Shandong Provincial Postdoctoral Science Foundation,SDCX-ZG-202400203,SDCX-ZG-202400203,Qingdao postdoctoral funding program,QDBSH20230202074,Project funded by open fund of state key laboratory of coal mine disaster dynamics and control,2011DA105287-FW202203,National Natural Science Foundation of China,52278359

Author information

Authors and Affiliations

Contributions

W. X.: Conceptualization, Methodology, Writing—Original Draft, Writing—Review & Editing, Visualization. T.C.L.: Supervision, Project administration. W.Q.B.: Investigation, Resources. S.Z.Y.: Supervision, Project administration. S.Y.: Supervision, Funding acquisition. W.K.Y.: Supervision, Funding acquisition, Validation.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Wang, X., Tian, C., Wang, Q. et al. Study on influencing factors and prevention measures of coal-rock-gas compound dynamic disaster in deep coal mine mining. Sci Rep 15, 2080 (2025). https://doi.org/10.1038/s41598-025-85296-5

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-85296-5

Keywords

This article is cited by

-

Numerical analysis of coal rock gas dynamics disaster risk in coal thickness variation area and research on prevention and control

Scientific Reports (2025)

-

Competitive Effects of Gas Pressure and Confining Pressure on Crack Deformation and Failure Characteristics in Gas-Bearing Coal

Rock Mechanics and Rock Engineering (2025)

-

Text Mining and Early Warning Key Information Identification of Coal Mine Major Disasters Utilizing Pre-trained Language Model

Natural Resources Research (2025)