Abstract

The collapsible nature of loess soil can lead to issues such as additional settlement of pile foundations, reduced pile strength, and decreased bearing capacity, posing a significant threat to the safety of structures in loess regions. In this paper, considering the collapsibility of loess and the layered characteristics of foundation soil, a load transfer model for single piles in homogeneous layered soil was established using the load transfer method. Simultaneously, based on the elastoplastic theory, a differential equation controlling the negative skin friction of single piles caused by the collapsibility of loess was derived. A three-linear hardening model was selected to simulate the pile–soil interface interaction. By considering the boundary conditions, the pile side friction resistance, axial force, and pile displacement were calculated, and the nonlinear patterns of load transfer for single piles in layered soil foundations were obtained. The negative skin friction characteristics of a single pile in an actual engineering project were analyzed, and the results were compared with the finite element numerical simulation to verify the rationality of the model. The research results show that in the homogeneous layered soil foundation in the collapsible loess area, the negative skin friction caused by collapsibility cannot be ignored; the calculated results of the single-pile load transfer model are in good agreement with the numerical simulation results, verifying the rationality of the model; the model successfully reveals the load transfer patterns and negative skin friction characteristics of single piles in the layered soil foundation in the collapsible loess area. This study enriches the theoretical calculation of negative skin friction for single piles in the collapsible loess area, provides a theoretical basis for calculating the negative skin friction caused by loess collapsibility, and offers a theoretical calculation method for accurately evaluating the bearing capacity of single piles in the collapsible loess areas.

Similar content being viewed by others

Introduction

With the introduction of the Belt and Road Initiative and the continued advancement of the Western Development Strategy, China’s western regions are experiencing unprecedented opportunities for infrastructure development and economic growth. The implementation of these significant national strategies aims to integrate the western regions into the international economic system, enhance cooperation with neighboring countries, and elevate the level of development within the region. These strategies have become vital engines for China’s overall development. In this broader context, infrastructure construction, especially geotechnical engineering, plays a crucial role. The stability and safety of buildings, bridges, roads, and other infrastructure are essential to ensure the successful implementation of these national strategies. However, in western regions, particularly in loess areas, the collapsible nature of soils poses additional challenges for the design and construction of infrastructure projects. Collapsible soils often undergo volume expansion when subjected to water infiltration, resulting in additional settlement, reduced soil strength, and decreased bearing capacity of infrastructure. In such circumstances, especially in pile foundation engineering, the presence of negative friction resistance becomes particularly significant, greatly affecting the load-bearing performance of pile foundations. Therefore, effectively understanding and addressing the impact of collapsible soils on infrastructure projects have become one of the key issues in current research and practice.

In the design of pile foundations in collapsible loess regions, it is typically necessary to consider the influence of soil collapsibility. To avoid the occurrence of uneven settlement of buildings in the later stages, pile foundations are commonly used for the foundation. When the foundation soil contains collapsible loess layers, the deformation of buildings on the collapsible loess foundation is influenced by the inherent strength of the foundation soil under non-immersed conditions. However, when the foundation is subjected to water infiltration, the deformation of buildings is affected by the characteristics of loess swelling when it encounters water. In this scenario, the range of negative friction resistance at the pile sides expands, and its numerical values increase. This is the most significant difference between collapsible loess foundations and ordinary foundations when subjected to water immersion1. When the negative frictional resistance on the pile side occurs, the positive frictional resistance on the pile side decreases and the range is narrowed, which directly leads to the increase of the vertical load on the pile foundation2, the bearing capacity of the soil around the pile is also greatly reduced3. The increase in negative friction resistance leads to downward loading on the pile, reducing the load-bearing capacity of the pile foundation. Additionally, it increases the axial force in the pile, with the maximum axial force typically occurring at the neutral point, making it the most critical location for the pile and potentially compromising the safety of the pile foundation. Furthermore, localized stresses on the pile increase, causing increased loading on the bearing layer at the pile tip. Excessive deformation and displacement may occur, potentially exceeding the design load-bearing capacity of the pile, resulting in cracking and failure of the pile and the bearing layer. Therefore, when constructing buildings on collapsible loess foundations, it is essential to consider the potential impact of loess collapsible settlement on the structures. Building on collapsible loess foundations necessitates a thorough understanding of how loess collapsible settlement can affect the structural integrity of the buildings. Pile–soil interaction, as a classic nonlinear problem, is characterized by complex mechanisms influenced by geological conditions, pile characteristics, as well as environmental factors like climate and groundwater. Numerous scholars both domestically and internationally have conducted extensive research in this field, including outdoor in-situ tests, laboratory single-axis tests, laboratory triaxial tests, classical theoretical studies, and numerical analysis. These efforts have yielded valuable insights and significant achievements4,5,6,7,8,9). However, due to the complexity of the pile–soil system, there has not been a very complete and comprehensive theoretical conclusion, and further research is needed. Among the classical theoretical studies, the elastic theory method has the longest development time, and the theoretical system is relatively complete. However, this theory assumes that the soil is an ideal uniform elastic body, which is suitable for the analysis of single-layer soil, while the research on layered soil is more complicated, and it is only suitable for the force analysis of end-bearing piles10,11,12. The shear displacement method gives the displacement change field of the soil within a certain range around the pile, and the pile group effect can be considered through the calculation of the superposition of soil layers between pile groups, which is simpler than the elastic theory method13,14,15. However, the shear displacement method cannot take into account the nonlinearity and inhomogeneity of soil, nor does it consider the support reaction force at the tip of the pile. In the load transfer method, the pile body is divided into several units, and the transfer function between each unit and the surrounding soil is independent of each other. In the multi-layer soil foundation, the transfer function of each layer of soil can be valued separately according to the properties of the surrounding soil layers, and then the soil layers can be distinguished. In the existing studies on the calculation of the lateral friction resistance of the pile body by the load transfer method, most of them assume that the soil displacement around the pile is a linear function distribution16,17,18. In actual engineering, the displacement of the formation is not linearly distributed19,20. According to the calculation of the soil position around the pile with a linear distribution, there are still defects. The theoretical calculation of negative friction resistance of pile foundations in collapsible loess strata still needs to be further studied. Therefore, starting from the mechanism of pile–soil interaction and considering the collapsibility of loess, this paper draws inspiration from the load transfer theory analysis proposed by Ye et al.21 related to single homogeneous soil layers. It further takes into account the presence of multiple soil layers and establishes a load transfer model for single piles in layered soil foundations, for which analytical solutions are derived. By comparing the theoretical calculations with finite element simulation results in conjunction with engineering examples, the results demonstrate a good agreement between the two. The outcomes of this study provide a theoretical foundation for understanding the load transfer patterns of pile foundations in thick collapsible loess foundations and offer important reference points for the design and engineering practice of pile foundations in collapsible loess regions.

Load transfer relationship between piles and soil

Basic differential equation and analytical solution of load transfer between pile and soil

It can be seen from the research of Ye’s research22 that for a single homogeneous soil layer, the load transfer method divides the pile into several elastic elements, assuming that each element is connected with the surrounding soil by nonlinear springs, as shown in Fig. 1 shown. The stress–strain relationship of a nonlinear spring expresses the relationship between the pile side resistance (pile end resistance) and the shear displacement (pile end displacement), which is called the load transfer function. The axial force of the pile body \(Q_{(z)}\) and the displacement of the pile body \(u_{p(z)}\) decrease with the pile body, and the side friction resistance of the pile body \(\tau_{(z)}\) first increases and then decreases along the pile body, and gradually develops from top to bottom. Finally, the basic differential equation of load transfer is obtained as: \(\tau_{(z)} = EA\frac{{d^{2} u_{p(z)} }}{{dz^{2} }}\). In the formula, \(E\) is the elastic modulus of the concrete of the pile body; \(A\) is the cross-sectional area of the pile body;\(\tau_{(z)}\) is the side friction resistance of the pile.

According to the basic differential equation of load transfer of a single homogeneous soil layer, considering the multi-layer soil factors, the soil around the pile is divided into n layers, the nth layer is the soil layer at the bottom of the pile, and the soil body of each layer is homogeneous and isotropic. The i layer is the analysis object. The calculation diagram is shown in Fig. 2. The basic differential equation of load transfer for multi-layer soil is obtained:

In the formula, \(E\) is the elastic modulus of the concrete of the pile body; \(A\) is the cross-sectional area of the pile body; \(U\) is the perimeter of the cross-section of the pile; \(\tau_{(z)}\) is the side friction resistance of the pile.

Analytical solution of load transfer law of multi-layer soil single pile

When considering a single homogeneous soil layer, only one transfer function model is used for the soil around the pile; this paper considers the layered soil foundation, and each layer of soil adopts a different transfer function model. The three-polyline model is also used as the transfer function model of the pile side and the pile end, as shown in Fig. 3. The soil transfer function at the pile tip is consistent with that of a single homogeneous soil layer, as shown in Fig. 4.

The expression of the tri-polyline load transfer function of the pile side soil is:

In the formula: \(\tau_{i}\) is the frictional resistance at the pile–soil interface of the i-th soil layer; \(k_{i1}\) s the stiffness coefficient of the elastic interface of the i-th soil layer; \(k_{i2}\) is the stiffness coefficient of the pile–soil interface in the plastic stage of the i-th soil layer; \(u_{i}\) is the pile displacement at the midpoint of the i-th soil layer; \(u_{ia}\) is the elasto-plastic critical displacement of the i-th soil layer; \(u_{ib}\) is the critical displacement in the plastic-slip stage of the i-th soil layer.

The expression of the load transfer function of the pile end soil tri-polyline is:

In the formula: \(k_{4}\) is the elastic stiffness coefficient when the pile end soil layer is in the elastic stage; \(k_{5}\) is the plastic stiffness coefficient when the pile end soil is in the plastic stage; \(u_{c}\) is the critical displacement in the elasto-plastic stage of the pile end soil; \(u_{d}\) is the critical displacement when the pile end soil is in the plastic-failure stage.

Basic assumptions

In this paper, the distribution law of pile side friction resistance in collapsible loess area is studied through three cases: (1) only under the vertical load on the top of the pile, (2) only under the action of flooding load, (3) only under the action of flooding load The vertical load on the top of the pile and the flooding load around the pile act simultaneously (considering the collapsibility of loess). It is mainly based on the following assumptions:

-

1.

The pile is a concrete pile of constant section. The pile body is in the elastic stage without damage. The plastic deformation of concrete is not considered during loading.

-

2.

The soil around the pile is distributed in layers, and each layer of soil is homogeneous and isotropic.

-

3.

Trilinear transfer functions are used for both the pile side and the pile end, and the elastic–plastic, softening and hardening conditions of the soil are considered.

Research on negative friction resistance of pile

Load transfer law of single pile in layered soil foundation under vertical load

Full-elastic stage

When the load on the top of the pile is small, the pile body and surrounding soil are in the elastic deformation stage. Only considering the vertical load, the soil displacement around the pile is 0. At this time, the load transfer function of the pile side is:

The pile end load transfer function is:

According to the basic differential equation of load transfer in Eq. (1) into Eq. (4), let \(\alpha_{i1} = \sqrt {\frac{{k_{i1} }}{EA}}\), the basic differential equation of multi-layer soil is obtained:

The general solution of formula (6) is taken as:

At this time, the axial force and displacement conditions of pile top and pile end and the displacement conditions at the interface of adjacent soil layers are:

Substituting the general solution into the boundary conditions, let \(\gamma_{4n1} = \frac{{k_{4} }}{{EA\alpha_{n1} }}\), \(\eta_{n} = \frac{{\gamma_{4n1} {\text{sh}} (\alpha_{n1} l) + {\text{ch}} (\alpha_{n1} l)}}{{\gamma_{4n1} {\text{ch}} (\alpha_{n1} l) + {\text{sh}} (\alpha_{n1} l)}}\), we can get:

Semi-elastic and semi-plastic stage

Based on the analysis of Ye’s research22, as the load on the top of the pile gradually increases, the soil around the pile gradually undergoes plastic deformation from top to bottom. At this time, an elastic–plastic interface appears in the soil around the pile, that is, an elastic–plastic interface appears in the mth layer. The surrounding soil of pile m layer and above is in the plastic zone,the soil surrounding the pile below m layer is still in the elastic zone. At this time, the load transfer function of pile side and pile end is:

According to the basic differential equation of load transfer in Eq. (1), and substituting Eq. (10) into Eq. (10), we can get:

Let \(\alpha_{i2} = \sqrt {\frac{{k_{i2} }}{EA}}\), \(U_{i} = \frac{{\alpha_{i2}^{2} - \alpha_{i1}^{2} }}{{\alpha_{i2}^{2} }}u_{ia}\),the general solution is:

At this time, the axial force and displacement boundary conditions of pile top and pile end are:

Substituting the general solution Eq. (13) into the boundary condition Eq. (14), we can get:

Full-plastic stage

With the gradual increase of the pile top load, the pile body and the pile end soil are all in the plastic stage. At this time, the pile side and pile end load transfer functions are:

According to the basic differential equation of load transfer in Eq. (1), the differential equation of the full plastic stage is obtained:

The general solution of formula (18) is:

At this time, the axial force and displacement boundary conditions of pile top and pile end are:

Substitute the general solution Eq. (19) into the boundary condition Eq. (20), let \(\gamma_{4n2} = \frac{{k_{4} }}{{EA\alpha_{n2} }}\), 4\(\gamma_{5n2} = \frac{{k_{5} }}{{EA\alpha_{n2} }},\) we can get:

Load transfer law of single pile under water immersion

In the actual project, the top of the pile foundation is not free from the load, but for the convenience of research, it is assumed that the top of the pile is not subject to the load, and only the impact of the immersion displacement around the pile exists. In the research on the force of pile foundation using the load transfer method, most of the researches simplified the displacement and settlement of the soil around the pile into a linear shape, or even simplified it into a unified constant, which is greatly inconsistent with the settlement behavior of the soil around the pile in actual engineering. The key influencing factor of the negative friction resistance of the pile is the change of the settlement and displacement of the soil at the pile position. It is not accurate enough to use a linear function to simulate the settlement of the surrounding soil. Especially for collapsible loess, there are many factors that affect the additional displacement caused by water collapsibility, which are affected by many factors such as soil quality, precipitation, groundwater, region, soil age, etc., especially the uncertainty of water collapsibility. It is unreasonable to use a linear function to simulate the displacement curve of loess collapse. Therefore, according to Zhang’s research23, the settlement-displacement curve of collapsible loess can be simplified as an exponential function: \(v_{(z)} = A_{0} \cdot e^{{A_{1} \cdot z}} + A_{2}\) into the analytical equation of load transfer, where A0, A1 and A2 are experimental Fitting parameters.

Full-elastic stage

When there is only vertical load, since the displacement of the surrounding soil is 0, \(u\) in the transfer function represents the compressive displacement of the pile body; when there is water immersion collapsibility, \(u\) in the transfer function represents the displacement of the pile body and the displacement of the surrounding soil. difference between.

At this time, the load transfer function of the pile side is:

The pile end load transfer function is:

According to the basic differential equation of load transfer in Eq. (1), into Eq. (23), let \(\alpha_{i1} = \sqrt {\frac{{k_{i1} }}{EA}}\), the basic differential equation of multi-layer soil is obtained:

Since \(v(z)\) is an exponential function of z, let \(Y_{1(z)} = \frac{{A_{0} A_{1}^{2} }}{{\alpha_{1}^{2} - A_{1}^{2} }}e^{{A_{1} z}}\), The general solution of formula (25) is taken as:

At this time, the axial force and displacement conditions of pile top and pile end and the displacement conditions at the interface of adjacent soil layers are:

Substituting the general solution into the boundary conditions, we get:

Semi-elastic and semi-plastic stage

Based on the analysis of Ye’s research22, as the load on the top of the pile gradually increases, the soil around the pile gradually undergoes plastic deformation from top to bottom. At this time, an elastic–plastic interface appears in the soil around the pile, that is, an elastic–plastic interface appears in the mth layer. The surrounding soil of pile m layer and above is in the plastic zone; the soil surrounding the pile below m layer is still in the elastic zone. At this time, the load transfer function of pile side and pile end is:

According to the basic differential equation of load transfer in Eq. (1), and substituting Eq. (29) into Eq. (29), we can get:

Let \(\alpha_{i2} = \sqrt {\frac{{k_{i2} }}{EA}}\), \(U_{i} = \frac{{\alpha_{i2}^{2} - \alpha_{i1}^{2} }}{{\alpha_{i2}^{2} }}u_{ia}\), \(Y_{i1} (z) = \frac{{A_{i0} A_{i1}^{2} }}{{\alpha_{i1}^{2} - A_{i1}^{2} }}e^{{A_{i1} z}}\), \(Y_{i2(z)} = \frac{{A_{i0} A_{i1}^{2} }}{{\alpha_{i2}^{2} - A_{i1}^{2} }}e^{{A_{i1} z}}\),the general solution is:

At this time, the axial force and displacement boundary conditions of pile top and pile end are:

Substituting the general solution Eq. (32) into the boundary condition Eq. (33), we can get:

Full-plastic stage

With the gradual increase of the pile top load, the pile body and the pile end soil are all in the plastic stage. At this time, the pile side and pile end load transfer functions are:

According to the basic differential equation of load transfer in Eq. (1), the differential equation of the full plastic stage is obtained:

The general solution of formula (37) is:

At this time, the axial force and displacement boundary conditions of pile top and pile end are:

Substitute the general solution (38) into the boundary condition (39), let \(\gamma_{4n2} = \frac{{k_{4} }}{{EA\alpha_{n2} }}\), \(\gamma_{5n2} = \frac{{k_{5} }}{{EA\alpha_{n2} }}\),we can get:

Load transfer law of single pile in layered soil foundation under the action of load + water immersion

Full-elastic stage

When the load on the top of the pile is small, the pile body and surrounding soil are in the elastic deformation stage. Only considering the vertical load, the soil displacement around the pile is 0. At this time, the load transfer function of the pile side is:

The pile end load transfer function is:

According to the basic differential equation of load transfer in Eq. (1) and into Eq. (42), the basic differential equation of multi-layer soil is obtained:

Let \(Y_{i1} (z) = \frac{{A_{i0} A_{i1}^{2} }}{{\alpha_{i1}^{2} - A_{i1}^{2} }}e^{{A_{i1} z}}\), the general solution of formula (43) is taken as:

At this time, the axial force and displacement conditions of pile top and pile end and the displacement conditions at the interface of adjacent soil layers are:

Substitute the general solution into the boundary conditions, let \(\gamma_{4n1} = \frac{{k_{4} }}{{EA\alpha_{n1} }}\),\(\eta_{n} = \frac{{\gamma_{4n1} {\text{sh}} (\alpha_{n1} l) + {\text{ch}} (\alpha_{n1} l)}}{{\gamma_{4n1} {\text{ch}} (\alpha_{n1} l) + {\text{sh}} (\alpha_{n1} l)}}\), we can get:

Semi-elastic and semi-plastic stage

Based on the analysis of Ye’s research22, as the load on the top of the pile gradually increases, the soil around the pile gradually undergoes plastic deformation from top to bottom. At this time, an elastic–plastic interface appears in the soil around the pile, that is, an elastic–plastic interface appears in the mth layer. The surrounding soil of pile m layer and above is in the plastic zone,the soil surrounding the pile below m layer is still in the elastic zone. At this time, the load transfer function of pile side and pile end is:

According to the basic differential equation of load transfer in Eq. (1), and substituting Eq. (47) into Eq. (47), we can get:

Let \(U_{i} = \frac{{\alpha_{i2}^{2} - \alpha_{i1}^{2} }}{{\alpha_{i2}^{2} }}u_{ia}\), \(Y_{i1} (z) = \frac{{A_{i0} A_{i1}^{2} }}{{\alpha_{i1}^{2} - A_{i1}^{2} }}e^{{A_{i1} z}}\), \(Y_{i2} (z) = \frac{{A_{i0} A_{i1}^{2} }}{{\alpha_{i2}^{2} - A_{i1}^{2} }}e^{{A_{i1} z}}\), the general solution is:

At this time, the axial force and displacement boundary conditions of pile top and pile end are:

Substituting the general solution (50) into the boundary condition (51), we can get:

Full plastic stage

With the gradual increase of the pile top load, the pile body and the pile end soil are all in the plastic stage. At this time, the pile side and pile end load transfer functions are:

According to the basic differential equation of load transfer in Eq. (1), the differential equation of the full plastic stage is obtained:

The general solution of formula (55) is:

At this time, the axial force and displacement boundary conditions of pile top and pile end are:

Substituting the general solution (56) into the boundary condition (57), let \(\gamma_{4n2} = \frac{{k_{4} }}{{EA\alpha_{n2} }}\), \(\gamma_{5n2} = \frac{{k_{5} }}{{EA\alpha_{n2} }},\) we can get:

Case analysis

Project overview and laboratory test

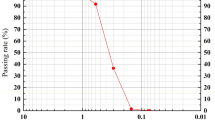

This paper relies on the pile foundation project in a collapsible site in Lanzhou City, Gansu Province, China, and selects 220# piles located in the southwest of the site for theoretical calculation. The surface layer of the foundation is covered with a mixed fill layer (Q4ml) with a thickness of about 2 m; the underground 2-10 m is a loess-like silt layer (Q42al+pl); due to the influence of the groundwater level, the loess-like silt layer is saturated with a thickness of about 2 m. Silt layer (Q42al+pl); 12-14 m underground is pebble layer (Q42al+pl), with hard texture as the bearing layer of pile foundation; below 14 m underground is Cretaceous mudstone (K). The diameter of the pile is 0.8 m, the length of the pile is 12 m, and the elastic modulus of the pile body is \(E = 3.25 \times 10^{4} {\text{ MPa}}.\) First, according to the indoor uniaxial compression test (Fig. 5), the stiffness coefficient of each soil layer is obtained as shown in Table 1. Secondly, the relationship between the calculated value of the collapsible amount and the depth was obtained according to the indoor collapsibility test, as shown in Fig. 6. The load on the top of the pile is applied 900kN, and the exponential function fitting can be used to obtain the distribution function of the collapse amount along the z direction: \(\Delta_{s} = 935 \times e^{0.1895 \cdot z}\).

Finite element model establishment

The pile is numerically simulated by PLAXIS 3D (2020 version) finite element software. The size of the model is 10 × 10 × 20 m, the soil constitutive relationship adopts HSS model, and the pile body adopts embedded beam elements. First, apply a pile top of 900kN to the model, and calculate the force of the model when only the pile top load is applied; since it is difficult to simulate soil subsidence in water with finite element software, a uniform load is set to simulate the collapse displacement. According to Zhang24 about The calculation method of stress and settlement in soil under large-area heap load assumes that 60kN/m2 of soil around the pile is applied to the model, and the stress of the model is calculated when only the displacement of the soil around the pile is applied; finally, 900kN and 900kN of pile top and The soil around the pile is applied with 60kN/m2, and the force of the model is calculated when it is subjected to two actions of the pile top load and the water immersion displacement around the pile. The 3D finite element model is divided into unit diagram and model section as shown in Fig. 7.

Comparative analysis of calculation results

Comparative analysis of calculation results under vertical load

Through the theoretical derivation results, that is, the model of the pile top load is calculated, and the changes of the axial force and lateral friction resistance of the pile body are shown in Fig. 8. This paper selects the research theory of He25 for comparative analysis.

Under the action of the pile top load, the axial force and lateral friction resistance of the pile body obtained in the full elastic stage are roughly in an ideal linear distribution. At the junction of the soil layer, the slope of the curve changes slightly, but the overall change trend is roughly similar. The axial force gradually decreases from 900kN at the top of the pile, and most of the axial force is distributed in the upper part of the pile. The side friction resistance of the pile body does not change much, and it is roughly and straight.

The calculation results of the semi-elastic and semi-plastic stages are similar to the numerical simulation results. The axial force curves are basically the same, and they are all quadratic curves that gradually decrease along the pile body. At the first soil layer change interface at the -2 m position of the pile body, the axial force changes more slowly above -2 m, and at -2 m Hereinafter, the change tendency of the axial force increases. The frictional resistance increases gradually along the pile body in the elastic–plastic region. Since the position of the elastic–plastic interface is clarified by the theoretical calculation method, the lateral friction resistance curve obtained by the theoretical calculation has a sudden change at the elastic–plastic interface. Due to the clear boundaries of the multi-layer soil layers established in the numerical simulation, there is a sudden change in the lateral friction resistance at the soil layer interface, and the trend is that the lateral friction resistance gradually increases down the pile body. The calculation results of the three stages all show that the axial force is uniformly distributed along the pile body, mainly concentrated in the upper part of the pile body, the lateral frictional resistance is positive, and evenly distributed along the pile body downward, showing a trend of small upwards and large downwards. The friction resistance is the largest, which is consistent with the existing theoretical results. The calculation results in this section are consistent with the conclusions of He25, and the theoretical derivation results are similar to the simulation results, which proves the accuracy of the theoretical derivation results.

Comparative analysis of calculation results under water immersion load

Through the theoretical derivation results, that is, the model of the submerged collapse around the pile is calculated, and the changes of the axial force and lateral friction resistance of the pile body are shown in Fig. 9. It can be seen from Fig. 9a that under the action of water immersion, the change of the axial force of the pile body is different from that of the vertical load only. The axial force at the top and the end of the pile is smaller, and the axial force in the middle of the pile body is the largest, with obvious negative friction effect. The influence of soil layer change on the axial force is manifested at -2 m of the pile body, and the slopes of the upper and lower curves at this point are slightly different. Since the top of the pile is not affected by the vertical load at this time, the axial force on the top of the pile is 0. The theoretical calculation results are basically consistent with the numerical simulation results. The peak position of the axial force is at the midpoint of the pile, and the peak size is similar, about 600kN.

It can be seen from Fig. 9b that since only the soil around the pile bears the load and displacement, the upper half of the pile is negative friction and the lower half presents positive friction. At the soil layer change of -2 m, since the strength of the plain fill is lower than that of the loess-like silt, after receiving the top load, the displacement and deformation of the plain fill is larger, and there is a sudden decrease at the − 2 m. The change trend of negative friction resistance above − 2 m is large, and the change trend of negative friction resistance from − 2 m to the neutral point is small. In the full elastic stage and the full plastic stage, the same deformation stage is set along the whole length of the pile body. Since the calculation of the semi-elastic and semi-plastic stages gives a clear elasto-plastic interface position, the side friction resistance of the pile body suddenly appears at − 5 m. The variation trend of the lateral friction resistance in the semi-elastic and semi-plastic stages is closer to the numerical simulation results.

Comparative analysis of calculation results under vertical and water immersion loads

Through the theoretical derivation results, that is, the model that is subjected to the load on the top of the pile and the collapsible subsidence around the pile is calculated, and the changes of the axial force and lateral friction resistance of the pile body are shown in Fig. It can be seen from Fig. 10a that the changes of the axial force of the pile body from the theoretical calculation and the simulation results are roughly similar. The change of the axial force of the pile body is similar to that at the top of the pile. little. The end of the pile is the smallest, followed by the top of the pile, and the axial force in the middle of the pile body is the largest. At the junction of soil layers, the slope of the axial force curve changes slightly, but the overall change trend is roughly similar.

It can be seen from Fig. 10b that the side friction resistance of the pile body is negative friction resistance in the upper half of the pile body, and the lower half is the positive friction resistance of the pile body, and the position of the neutral point corresponds to the maximum value of the axial force. The curve of the calculated lateral friction resistance is relatively smooth, and there is no obvious abrupt change. The lateral friction resistance in the simulation results is because the position of the pile bottom is the interface between the structure and the soil, and the pile-soil-relative interface cannot be established on this surface, so the lateral friction resistance at the pile bottom is greatly retracted. But the general trend is consistent with the theoretically calculated curve. All are the smallest at the top of the pile, gradually increase along the pile body, and reach a peak value near the bottom of the pile. The slope of lateral friction resistance varies slightly between different soil layers. The theoretical derivation results are similar to the software simulation results, which proves the accuracy of the theoretical derivation results.

Conclusions

In this paper, the load transfer method is used to deduce and analyze the force of pile foundation in multi-layer soil foundation. Through the research, the following conclusions are drawn:

-

(1)

Based on the load transfer method, a mechanical analysis model of a single pile under the condition of multi-layered soil foundation was successfully established. Considering that the collapsible displacement around the pile is distributed in an exponential curve, the analytical solutions of load transfer in the three stages of the pile body being fully elastic, semi-elastic and semi-plastic, and fully plastic were derived, providing a theoretical basis for in-depth understanding of the mechanical behavior of pile foundations in collapsible loess areas.

-

(2)

In the analysis of pile load transfer, the influence of layered soil was fully considered. Each layer of soil in the foundation was treated separately, and the independent transfer function and the exponential curve of collapsible displacement were given. Under certain conditions, the analytical solution of the basic equation for calculating each layer of soil was derived, which improved the calculation accuracy and reliability.

-

(3)

Combining with the actual engineering case, the finite element software PLAXIS 3D was used to numerically simulate the stress of the pile body in the multi-layered soil site. Through the comparison and verification of the theoretical results and the simulation results, it shows that the established model has high rationality and provides effective theoretical support for engineering practice.

Data availability

The datasets used and/or analysed during the current study available from the corresponding author on reasonable request.

References

Gao, X. J., Wang, J. C. & Zhu, X. R. Static load test and load transfer mechanism study of squeezed branch and plate pile in collapsible loess foundation. J Zhejiang Univ. Sci A 8(7), 1110–1117. https://doi.org/10.1631/jzus.2007.A1110 (2007).

Terzaghi, K., Peck, R. B. & Mesri, G. Soil Mechanics in Engineering Practice (Wiley, 1996). https://doi.org/10.5860/choice.34-0331.

Zhao, Z. F., Ye, S. H., Zhu, Y. P., Tao, H. & Chen, C. L. Scale model test study on negative skin friction of piles considering the collapsibility of loess. Acta Geotechnica 12(6), 1–11. https://doi.org/10.1007/S11440-021-01254-1 (2021).

Hanna, A. M. & Sharif, A. Drag force on single piles in clay subjected to surcharge loading. Int. J. Geomech. 6(2), 89–96. https://doi.org/10.1061/(ASCE)1532-3641(2006)6:2(89) (2006).

Huang, F. Y., Li, L., Zhang, F. & Lin, Y. W. Study on calculation method of internal force of integral abutment-pile–soil interaction. J. Phys. Conf. Ser. https://doi.org/10.1088/1742-6596/2158/1/012005 (2022).

Mashhour, I. & Hanna, A. Drag load on end-bearing piles in collapsible soil due to inundation. Can. Geotech. J. 53(12), 2030–2038. https://doi.org/10.1139/cgj-2015-0548 (2016).

Mahdi Taha, K., Al-Neami Mohammed, A. & Rahil Falah, H. Experimental and numerical study on the winged pile–soil interaction under lateral loads. IOP Conf. Ser. Earth Environ. Sci. https://doi.org/10.1088/1755-1315/961/1/012063 (2022).

Lu, S. L., Zhang, N. & Shen, S. L. Deep learning evaluation method for side friction resistance of cast-in-place piles in reclaimed strata based on field test. J. Zhejiang Univ. Sci. A Appl. Phys. Eng. 21(06), 496–508 (2022).

Zahid, M. A. et al. Tunnel progression effects to the ground surface and the adjacent pile. IOP Conf. Ser. Earth Environ. Sci. https://doi.org/10.1088/1755-1315/971/1/012027 (2022).

Huang, M. S. & Mu, L. L. Vertical response of pile raft foundations subjected to tunneling-induced ground movements in layered soil. Int. J. Numer. Anal. Meth. Geomech. 36(8), 977–1001. https://doi.org/10.1002/nag.1035 (2011).

Poulos, H. G. A practical design approach for piles with negative friction. Geotech. Eng. 1(161), 19–27. https://doi.org/10.1680/geng.2008.161.1.19 (2008).

Zhang, C. R., Yu, J. & Huang, M. S. Effects of tunnelling on existing pipelines in layered soils. Comput. Geotech. 43, 12–25. https://doi.org/10.1016/j.compgeo.2012.01.011 (2012).

Wang, D. D. & Sun, J. Long-term settlement of pile foundation of bridges based on generalized shear displacement method. Chin. J. Geotech. Eng. 33(2), 47–53 (2011) (in Chinese).

Zhao, M. H., Lei, Y. & Liu, X. M. Settlement calculation of single pile’s negative skin friction with shear displacement method. J. Hunan Univ. Nat. Sci. 37(7), 1–6 (2008) (in Chinese).

Zhao, M. H., Zhang, L. & Yang, M. H. Settlement calculation of the long-short-pile composite foundation with shear displacement method. Chin. J. Geotech. Eng. 27(9), 994–998. https://doi.org/10.3321/j.issn:1000-4548.2005.09.004 (2005).

Carrubba, P. Skin friction of large-diameter piles socketed into rock. Can. Geotech. J. 34(2), 230–240 (1997).

Ng, C. W. W., Yau, T. L. Y., Li, J. H. M. & Wilson, H. Side resistance of large diameter bored piles socketed into decomposed rocks. J. Geo Tech. Geoenviron. Eng. 127(8), 642–657. https://doi.org/10.1061/(ASCE)1090-0241(2001)127:8(642) (2001).

Dyson, G. J. & Randolph, M. F. Monotonic lateral loading of piles in calcareous sand. J. Geotech. Geoenviron. Eng. 127(4), 346–352. https://doi.org/10.1061/(ASCE)1090-0241(2001)127:4(346) (2001).

Kim, H. J., Mission, J. L. C. & Park, I. S. Analysis of static axial load capacity of single piles and large diameter axial s using nonlinear load transfer curves. KSCE J Civ Eng 11(6), 285–292. https://doi.org/10.1007/BF02885899 (2007).

Maugeri, M. & Castelli, F. Discussion: Negative skin friction on piles in layered soil deposits. Geotech. Eng. 122(12), 1020–1023. https://doi.org/10.1061/(ASCE)0733-9410(1996)122:12(1020) (1996).

Tan, S. A. & Fellenius, B. H. Negative skin friction pile concepts with soil–structure interaction. Geotech. Res. 3(4), 137–147. https://doi.org/10.1680/jgere.16.00006 (2016).

Ye, S. H., Zhao, Z. F. & Zhu, Y. P. Study on negative friction of pile foundation in single homogeneous soil layer in collapsible loess area of Northwest China. Arab. J. Geosci. https://doi.org/10.1007/S12517-021-07508-2 (2021).

Zhang, Y. Q. Study on Side Friction Characteristics of Pile Foundation in Collapsible Loess Site of Lanzhou (Lanzhou University of Technology, 2020) (in Chinese).

Zhang, X. F. Experimental Study on Negative Friction of Pile Foundation (Tongji University, 2007) (in Chinese).

He, J. Theoretical and Application Research on Load Transfer Method of Vertical Loading Pile (Changan University, Xi’an, 2015).

Acknowledgements

The authors gratefully acknowledge the financial support provided by the National Natural Science Foundation of China (No. 52168050), and the Key Science and Technology Foundation of Gansu Province (Project No. 24YFFA070).

Author information

Authors and Affiliations

Contributions

Zhiquan Wang: Conceptualization, Methodology, Supervision, Writing—review & editing, Funding acquisition, Project administration. Liangliang Xin: Conceptualization, Methodology, Software, Validation, Formal analysis, Writing—review & editing. Shuaihua Ye: Methodology, Validation, Data curation, Software. Wu jian: Methodology, Validation, Data curation. Weina Ye: Methodology, Jingbang Li: Validation.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Wang, Z., Xin, L., Ye, S. et al. Study on negative friction of pile foundation in homogeneous layered soil in collapsible loess area. Sci Rep 15, 6540 (2025). https://doi.org/10.1038/s41598-025-86942-8

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-86942-8

Keywords

This article is cited by

-

Settlement Analysis of Single Piles Incorporating Effective Pile Length and Interface Behavior

Geotechnical and Geological Engineering (2025)