Abstract

The current study focuses on the poly(ethylene terephthalate) (PET) powder degradation potential of a rhizobacterial consortium screened from the rhizosphere of plants growing at plastic-polluted sites. The rhizobacterial consortium were screened and ability of PET powder degradation was studied up to 18 days. For observing the efficiency of degradation, all three rhizobacterial strains with highest percentage of degradation were combined to formulate the consortium. The Response Surface Methodology (RSM) was used to optimize the process variables. The combinations demonstrating highest weight reduction percentage for PET were selected for further degradation studies. The changes in the structure and surfaces that occurred after biodegradation on the plastic were observed through SEM and FTIR analysis. The obtained results showed the disappearance and elongation of the peak, signifying that the rhizobacterial consortium could modify the PET plastic. The weight reduction percentage of PET powder (300 µm) was 71.12% at optimized conditions (29.8 °C, 7.02 pH and 1 g/L carbon source). The mathematical model developed through RSM is found to be significant (P < 0.05), and optimization and validation experiments were also well correlated for the process.

Similar content being viewed by others

Introduction

The plastic products are manufactured and used for several purposes in large quantities1. The gross manufacture of single-use packaging plastics is approximately 49%, emphasizing the disposal importance of plastic, primarily poly(ethylene terephthalate) (PET)2. In 2021, poly(ethylene terephthalate) (PET) packaging represented 44.7% of single-serve beverage containers in the United States and made up 12% of global solid waste3.

In environmental waste, plastic polymers are slowly degrading and pervasive, whose usage and demand are overgrowing due to their features such as low cost, high strength, and lightweight4,5.

Poly(ethylene terephthalate) is a polymer of thermoplastic comprising terephthalic acid and ethylene glycol monomers widely used to produce food and beverage packaging and packaging sheets. This plastic has high stability and is chemically inert; thus, it cannot participate in the biosphere’s cycle of degradation, which poses a serious problem for environmental pollution6. As a result of inappropriate recycling and management of plastic waste, it has accumulated in the surroundings and disturbs the soil fauna and flora, thus causing hazard to the ecosystem7. Biodegradation is a sustainable method among other degradation approaches, such as chemical and physical methods, to overcome this environmental issue6,8.

Various fungi and bacteria can degrade plastics, namely Halomonas sp., Azotobacter vinelandii, Pseudomonas sp., Ralstonia eutropha, and Bacillus megaterium9. Mostly the plastic-degrading microorganisms have been isolated from the mountain and landfill soils. Mountains such as Mount Jayawijaya, which has extreme weather conditions in the highlands, indicate the presence of bacteria capable of PET plastic degrading. Ruslan et al. isolated the bacteria Bacillus sp. from this region which was able to degrade the PET plastic up to 4.77% b/b10. From soil the bacteria is isolated namely Pseudomonas sp. which degrades the synthetic polyethylene plastic within one month by 11.7%11.

Plant-based remediation is an eco-friendly, sustainable technology that leverages the natural abilities of plants to absorb, break down, metabolize, transform, or eliminate harmful pollutants from different environments12. In the rhizosphere, microorganisms both on the surface and inside the plant provide protection while benefiting from root exudates and oxygen13. Rhizoremediation is among the most potent approaches for remediation in polluted soil. It is a specialized form of phytoremediation that involves plants and the microorganisms associated with their rhizosphere.

This study is an extension of our previous work14 and it emphasizes the biodegradation of the PET by using consortium of previously isolated strains isolated from plastic polluted sites capable of utilizing PET plastic as a sole source of energy. In the biodegradation test, the consortium showed the ability to break down PET plastic using minimal media. However, this research was prioritized to test the consortium of three bacterial isolates’ ability to degrade PET plastic at various parameters. Therefore, the bacteria’s ability to degrade PET plastic is expected to be enhanced.

Methodology

Reculturing of the previously isolated poly(ethylene terephthalate) degrading rhizobacteria

The three previously rhizobacteria isolates were revived from the glycerol stock. These rhizobacteria were revived as the procedure used in our previous studies14 with slight modifications used PET powder as a sole carbon source.15,16,17.

Formulation of the microbial consortium for PET degradation

From these three revived bacterial isolates, we formulated the bacterial consortium in a ratio of 1:1:1, further PET degradation percentage was evaluated. For formulating the consortium, a compatibility assay was performed. On plates of nutrient agar, cultures were streaked in such a way for every isolate, culture in plate’s center. The other cultures were streaked radiating from the center. The zones of inhibition were visible after incubation of 48 h at 37 °C for the plates18. For this purpose, a single colony from each bacterial strain was inoculated in nutrient broth and incubated at optimum pH (7 ± 0.02) and temperature (37 ± 1 °C). The flask was incubated at 37 °C for 16 h while being continuously shaken at 120 rpm to prepare the active cultures. The calculated amount (CFU m/L) of each strain was mixed to develop consortia19,20.

Optimization design of process variables using Response surface methodology (RSM)

In this study, we have chosen Box-Behnken Design (BBD) to optimize PET degradation process variables. RSM was utilized as the experimental design to predict the point values of variables that may produce the best response and to observe the relation between test variables and PET degradation. Table 1 represents the range chosen for the process variables at three different level. During the degradation experiment, temperature (°C, X1), pH (X2) and carbon source (g/L, X3) were selected as independent variables, whereas weight loss of PET powder (% degradation) was selected as response variables. Previous research on plastic degradation were the basis for selecting the values of process variables selected for current study21,22 and the effect of operating parameters on plastic degradation capabilities of bacterial strain23,24.

A second-order Eq. (1) of polynomial was chosen to fit the experimental results.

Here, predicted response (‘y’), xi is the input variables, \(a_{^\circ }\) is a constant term, \(a_{i}\), \(a_{ij}\) a \(a_{ii}\) are ith linear coefficient, cross product coefficient (ijth), and quadratic coefficient, respectively.

Equation 1 can be rewritten as follows considering three test variables and PET degradation rate as response variable-

Coefficients α0 is dimensionless coefficient; linear coefficients (α1, α2 and α3); quadratic coefficients (α11, α22 and α33) and the variables (α12, α13, and α23) responsible for studying the interactions.

Weight loss method for determining biodegradation percentage

For the extraction of PET residual, in powder degradation suspension toluene (5 ml) was added and centrifuged for 15 min at 4000 rpm. Using the Wattman filter paper, the organic phase of the solution was filtered. Before and after the filtration, weight of the filter paper was recorded. The filter paper was dried to obtain the weight of residual PET at 50 °C15. Afterwards, percentage of biodegradation was calculated using percentage formula mentioned below.

where, Xt = degradation percentage, mo = initial weight, mt = final weight.

Fourier transform infrared spectroscopy—attenuated total reflectance (FTIR–ATR)

In case of PET powder, for FTIR analysis filtrate liquid was used. To acquire the spectra at 4 cm−1 resolution from 4000 to 450 cm−1, an iS5 infrared spectrophotometer (Thermo Scientific) attached with id7 diamond-ATR was used. The strong N-B apodization with Mertz phase correction was used to transform the data. The plastic surface’s average condition was analyzed by taking the spectra of three areas of each sample. The peak intensity was normalized to C-H bending at 1409 cm−1 for PET spectral normalization25.

High-performance liquid chromatography

The extracted filtrate liquid was used for HPLC analysis to analyze the degree of degradation. The LC-2010CHT Shimadzu equipment with manual injector and column RP-C18 was used. The mobile phase was 20% water and 80% methanol, and separation was achieved at 240 nm wavelength17. The temperature of column was maintained at 40 °C. The volume of injection was set to 1 µL, and a flow rate of 1 mL/min was performed.

Scanning electron microscope

PET samples were buffered with 2% phosphate glutaraldehyde to fix the cells. Then samples were soaked in tetraoxoosmium (2%) for 3 h in an ice bath. Afterwards, samples were dehydrated in 50%, 75%, and 100% graded ethyl alcohol for 15 min before imaging samples were gold sputter coated using coater Leica ACE600. The voltage of accelerating was 2 kV, and 1 μs dwell time was maintained in ULTRA 55 FESEM Zeiss. The powder of PET was dried entirely at 50 °C in the oven for 4 h. Further, to check the rhizobacteria absorption, SEM was performed.

Results

Reculturing of the plastic-degrading rhizobacteria

The isolates were grown in minimal media, in which poly(ethylene terephthalate) plastic acted as the primary source of carbon. The PGPR characterization, revealed the siderophore, ammonia, and indole acetic acid production by isolates, which confirms that these bacteria are rhizobacteria. The 16 s rRNA sequencing of isolated rhizobacterial strains was submitted to National Center for Biotechnology Information (NCBI) as mentioned in our previous paper14. The compatibility potential of all the isolates were screened. It was found that all the inoculants were compatible with each other, simultaneously able to grow without any growth inhibition.

Compatibility between strains

For compatibility, all rhizobacterial cultures were screened within the isolates. All the isolates were found to be compatible and simultaneously grow without any inhibition in growth (Fig. 1).

Determination of biodegradation percentage

The degradation of 300 µm particle sizes of PET powder was carried out for 18 days with all three isolates in our previous studies. After the incubation period, 69%, 66%, and 64% degradation percentage of PET powder by VT3.12, VT3.15, and VT3.16 isolates were observed respectively14. Because of the increased surface area, powdering PET is quite effective. Therefore, the higher degradation percentage for PET plastic could be achieved by powdering it.

RSM for modeling for PET degradation rate

A degradation assessment of PET powder was done by measuring the weight loss after regular intervals. Afterward, weight loss (%) was calculated using experimental data. The BBD model was used to fit the experimental data related to temperature, pH and carbon source in the form of linear, quadratic, and cubic model respectively. A total of 15 experiments were performed at different combinations of test variables using the BBD approach. The response in the form of PET weight loss (%) is represented in Table 2.

Figures 2, 3 and 4 represents 3 D response surface plots and 2 D contour plots of biodegradation of PET powder showing the interactive effect of test variables, viz. incubation temperature, carbon source and pH. Figure 2 depicts surface plots and contour plots, respectively, to understand the interactive effects of temperature and pH on the biodegradation of PET powder by using the rhizobacterial consortium. The 3D response surface plots are used to predict the optimum values for independent variables (temperature and pH), which are interpolated through the plane of zero slopes. As in Fig. 2a, the highest degradation value was seen at the peak region of central point, where temperature and pH were 30 °C and 7, respectively. The contour plots of PET degradation versus temperature and pH (Fig. 2b) were curved in the working range, indicating a significant effect of their interaction on PET degradation.

Figure 3a demonstrate the surface curve of carbon source concentration and temperature along with constant value of pH. The closed boundary of the core region makes it evident that the optimum biodegradation of PET plastic was within the design boundary. The maximum degradation of PET was obtained at the optimum temperature and carbon source concentration at 30 °C and 1 g/L, respectively, keeping pH constant at 7. The interaction effect of temperature and carbon source was not significant based on corresponding P-values. The contour plot between temperature and carbon source (Fig. 3b) was elliptical, which signifies their nonsignificant interactive effect on the PET degradation rate.

As shown in Fig. 4a, at constant temperature value of 30 °C, degradation of PET was found to be increased on increasing the pH upto 7. The contour plot between temperature and pH (Fig. 4b) was elliptical, implying their nonsignificant effect on the response.

The final quadratic model on the basis of BBD results using the software Minitab 16.0 (USA) in coded and uncoded form (Eqs. 4 and 5) is shown as below-

The maximum experimental weight loss (%) for PET powder was observed to be 73.52% (Table 2). The predicted weight loss by quadratic model was found to be 71.12% at 29.8 °C, 7.02 pH and 1 g/L carbon source.

Further, the experiments for validating PET powder’s predicted value of biodegradation by formulated rhizobacterial consortium were performed in triplicates using 29.8 °C, 7.02 pH and 1 g/L carbon source. At these optimum conditions, 73.07% weight loss was obtained with experimental PET powder biodegradation, which matches with the predicted value of 71.12%. This close relation between predicted and experimental value validates the use of regression model in current work for PET powder biodegradation.

Statistical analysis

Analysis of variance (ANOVA) is used to determine the importance of each model term present in quadratic model on plastic degradation system as explained in Table 3. Given the P value for PET powder was less than 0.05, the model was considered significant (Table 3). As per the rule, a model exhibits a lack of fit when it flops to describe the adequate data fitting with the model. In the present study, the lack of fit P-value was higher than 0.05 (0.226 for PET powder), which confirms the better fitting of experimental values with the model. The R-squared value was found to be 0.9974 for PET powder, which means that the model can explain 99.74% variation in the plastic degradation system. Generally, a model can be considered reasonably reliable if the CV is not greater than 10%26. A CV of 8.65% suggests that the selected model is accurate enough for the optimization work. It was observed that for the degradation of PET powder, the linear effect of carbon source concentration and quadratic effect of all three model parameters are significant having P value ˂ 0.05. The adj. R-squared for PET powder was found to be 0.9928, which signifies the close proximation regression model with experimental data.

After that, regression Eq. 5 was solved, and maximum predicted values for weight loss corresponding to PET powder degradation of 73.52% were obtained at an optimized temperature of 30 °C, pH of 7 and carbon source concentration of 1 g/L.

Quadratic model validation

Predicted weight loss in PET powder was calculated using the quadratic regression equation (Eq. 5). An excellent correlation between experimental and predicted values was obtained, having R2 value of 0.98 (Fig. 5). Further, Normality test or Anderson Darling statistic test was performed to confirm the normal distribution of residual error, i.e. the difference between experimental and predicted weight loss percentages.

Figure 6 shows that all of the data points fall in a somehow straight line. Based on P value for normal probability plot (0.940), which is greater than α-level of 0.05, the residual error was found to be distributed in factorial space region. The residual plot for quadratic model (Fig. 7) varies in irregular pattern around the central line thus confirming the suitability of regression model for better prediction of highest weight loss of PET powder.

Fourier transform infrared spectroscopy—attenuated total reflectance (FTIR-ATR)

In rhizobacterial consortium-treated PET powder, FTIR spectra indicated the formation of a new peak at 2980 cm−1 wavelength (Fig. 8). The shift in FTIR peaks was also observed. In the degradation process, the absorption bands disappeared later compared to pristine PET with degradation degree, which proves the biodegradation efficiency27. The spectroscopy study of FTIR was conducted in the 400–4000 cm−1 range. The stretching of the C=C aromatic bond refers to 866 cm−1. Slowly, with time in the treated PET powder sample, it becomes less intense, which may indicate that unsaturation reduction or oxidation occurs in the PET sample.

High-performance liquid chromatography

The biodegradation percentage of PET powder was also observed through high-performance liquid chromatography (HPLC). In the culture medium, PET powder was the sole carbon and energy source incubated with the consortium. The peak shift indicates PET powder degradation. Using the formula of degradation percentage, the percentage of degradation was calculated. The decrement in the peak area in the treated PET powder sample was observed compared to the control sample. However, the peak retention time remains similar, which is 10.81 for the consortium and 10.85 for the controlled. The area of treated PET powder with consortium was found to be 8,075,801, whereas the controlled area was 30,311,898. Thus, this area change confirms PET polymer breakdown into its monomers. The rate of degradation was found to be 73.4% which shows that formulated rhizobacterial consortium capability of PET plastic degrading exists in the environment.

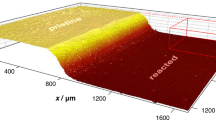

Scanning electron microscope

For the effective degradation of plastic, the formation of biofilm by microorganisms is essential. SEM allows the visualization of microbial colonization and the formation of biofilm. The absorption of rhizobacteria on PET powder was analyzed using SEM. This showed a significant difference between PET powder samples of degraded and native (Fig. 9). The rhizobacteria degraded the PET surface and formed biofilm on the surface.

Discussion

The consortium (Priestia aryabhattai VT 3.12, Bacillus pseudomycoides VT 3.15, and Bacillus pumilus VT 3.16) was able to grow only in the presence of a carbon source and PET plastic. Out of three rhizobacterial isolates, Priestia aryabhattai VT 3.12 was found to show considerably high degradation potential compared to other isolates14 as reported previously. The molecular characterization determined that all three isolates belong to the family Bacillaceae. The optimum conditions from RSM based on the Box-Behnken Design method (BBD) were a carbon source of 1 g/L, pH 7, and incubation temperature of 37 °C increased the degradation efficiency of bacteria. The formulated consortium was able to degrade up to 73.4% of PET powder, which is an efficient percentage of degradation in accordance over the observation of 168 days of incubation by the consortium 17% PET microplastic degradation28. The predicted versus actual plot indicated that the degradation percentage of the consortium was accurate. The PET powder degradation percentage was determined as 69% by VT3.12, 66% by VT3.15 and 64% by VT 3.16 post 18 days of incubation in our previous studies14. Based on this study, rhizobacterium are promising microbes for PET biodegradation. The post-consumer poly(ethylene terephthalate) plastic does not degrade easily, hence requires strategies to be implemented to enhance the degradation process. Skariyachan et al. formulated the thermophilic consortium, which involves Aneurinibacillus aneurinilyticus btDSCE04, Brevibacillus sp. btDSCE03, Brevibacillus agribt DSCE02 and Brevibacillus brevis btDSCE04 strains for degrading the high- and low-density polyethylene (HDPE, LDPE) and polypropylene (PP) pellets and films29. The consortium degraded the PP, HDPE and LDPE pellets up to 44.2 ± 3%, 37.2 ± 3% and 45.7 ± 3%, whereas films degradation percentage was determined to be 56.3 ± 2%, 46.6 ± 3% and 58.21 ± 2% post-incubation of 140 days respectively. The optimized temperature was 50 °C, and the pH was maintained at 7.2. Taniguchi et al. studied the degradation of low crystallinity (1.9%) films of PET using microbial consortium no. 46 (bacteria, protozoa & yeast-like cells), which stably adheres to the surface & causes changes in the morphology at ambient temperature30. They have isolated the consortium from the sediment region of Sakai city, Japan. The degradation rate of PET film is 0.13 mg/(cm2 day). In this study the capability of rhizobacterial consortium of three bacterial species to degrade the PET plastic in powder form of 300 µm size was evaluated. It was found that consortium was able to adhere to PET particle surfaces and cause morphological changes at optimum temperature which is clearly corroborated in SEM images. The formulated consortium was able to degrade the PET plastic by 73.4% in 18 days. In another study, the researchers have formulated the marine bacterial consortium capable of degrading PET which includes the species of Exiguobacterium, Halomonas, and Ochrobactrum from the sedimentary samples and reconstituted into a consortium with a ratio of 1:1:1. They treated the PET square sheets of dimensions 30 mm × 20 mm with the consortium in the minimal media and incubated for four weeks31. They have used three different types of PET plastic, i.e., type ES301005 (0.0005 mm thickness), type ES301450 (0.25 mm thickness and plastic drinking bottles in their study. Their FTIR data revealed that a distinct peak in the spectra was observed at 3318 cm−1 wavelength. It denotes two functional groups, namely alcohol and carboxylic acid, as well as stretches the R-OH bond. The density and thickness of a microbial layer on PET increased with culture time, and SEM confirmed the colonization of bacteria. Another study by Liu et al. in which they have investigated the biodegradation of PET polymer and its Diethyl terephthalate (DET) monomer by Delftia specie WL-332. They incubated the PET film (2 × 2 cm) with 10 ml bacterial suspension at 180 rpm and 30℃ for two months. The cracks were observed on the surface of the PET film using SEM. The strain WL-3 degraded the DET up to 94% with a 671.43 mg (1 day)−1 degradation rate within seven days. Along with TA, protocatechuic acid was also identified after DET degradation. Roberts et al. degraded the PET plastic by a consortium of five strains, including Bacillus and Pseudomonas species33. The consortium synergistically degraded the PET into the cleaved product, bis(2-hydroxyethyl) terephthalic acid (BHET). The consortium was able to further convert BHET product fully into its monomers, i.e. ethylene glycol and terephthalic acid. The strategies for PET biodegradation require a concerted effect of bacterial consortium. It is desired to degrade plastic at a faster rate either by formulating the consortia or individual microbial species4,34. On a monumental scale, the pollution cleanup based on the bioaugmentation approach using consortium was successfully achieved in the deepwater horizon oil spill35. The biodegradation of different types of polyesters using a range of microorganisms’ consortia might be possible in the future. This eco-friendly approach could reduce plastic pollution from the environment. In our study, only three rhizobacterial species (i.e., Bacillus pumilus, Bacillus pseudomycoides, and Priestia aryabhattai) were able to degrade PET plastic with a high rate of degradation after formulating the consortium (Table 4).

It is evident that rhizobacterial species are abundant in soils; therefore, it is a viable option for plastic biodegradation38. Hence, we have isolated the rhizobacterial species capable of degrading the PET plastic from the plastic polluted sites of Jalandhar. In this report, the rhizobacterial consortium degraded the poly(ethylene terephthalate), which involves the growth on the surface of PET as evidence to utilize the PET plastic as a sole carbon source. The hydroxyl group formation along with the cleavage of C=C and C–O bonds was observed in treated PET powder samples14.

The species belonging to Bacillus genus are more efficient in degrading PET plastic as compared to other microorganisms39. The species of Bacillus has ability to utilize the PET as a sole carbon source and energy as they are adapted to PET plastic contaminant environment40,41. This genus has specific characteristic ability of forming the biofilm on the colonize surfaces which allow them to survive in nutrient depleted environment such as PET polymer surface42. Another important key factor of Bacillus species is that they have the ability to adapt the hostile environment so they survive upon limited source of carbon due to its cell wall which is relatively hydrophobic39.

Rhizobacterial consortium is usually more effective than pure culture in degrading PET plastic. First, the rhizobacteria in consortium caused visible surface changes in the PET plastic. Second, FTIR analysis indicated possible ester functional group hydrolysis along with breakage of carbon backbone present in PET after incubation. The degradation extent of PET by this consortium was quite significant compared with previous study based on SEM43. The structural changes in PET plastic after degradation by consortium were analysed by FTIR. Several functional groups present in PET plastic had different intensities after incubation with rhizobacterial consortium as compared to the control44. The functional group present on the substrate changed due to the process of oxidation or reduction in degradation process, thus increases wettability and contributes bacterial attachment45.

The degradation parameters such as temperature, pH, and carbon source were further optimized to investigate the maximum weight loss percentage of PET. Several studies have been carried out on optimization of PET plastic biodegradation. Meng et al. optimized the pH and temperature conditions for the biodegradation of polystyrene plastic using Bacillus aryabhattai isolate24. They quantified the activity of biodegradation using a simple colorimetric method. On methylene blue dye polystyrene film, B. aryabhattai was inoculated. The conditions were optimized using RSM software. The release of entrapped methylene blue dye was measured photometrically. The desirability of the highest dye absorbance was 75.9% at 25 °C temperature and pH 9. Nehal and Singh reported that Bacillus sp. MZ540316 strain can degrade polyethylene plastic with a maximum degradation of 14.33% in 70 days21. They optimized the cultural conditions of nutrient media using a central composite design method and fermentation conditions. It was observed that the biosurfactant lipopeptide yield was improved after optimizing the cultural conditions and media component by 1.42-fold. Rani et al. isolated the SARR1 bacterial isolate and optimized media conditions for the effective degradation of LDPE22. The bacteria converted triphenyl tetrazolium chloride into triphenyl formazan, red-coloured and insoluble after seven days of incubation. In this study, the formulated rhizobacterial consortium composed of Bacillus species degraded the PET plastic more efficiently at optimal pH seven and 30 °C. We have optimized only the degradation conditions, such as temperature, pH, and a carbon source, to enhance the degradation rate. Various researchers also discovered that most Bacillus species worked effectively at neutral pH, for example, Bacillus subtilis and Bacillus cereus sp. BNPI-92 and Bacillus megaterium46,47,48. The experiment was performed at optimal conditions based on the RSM results for model validation, and the experimental results proved that model is reasonable. Likewise, the weight loss in PET plastic under the optimal conditions by the rhizobacterial consortium had increased and was found to be 73.4% for powder (300 µ).

Conclusions

The present study explores the potential of the novel rhizobacterial consortium (three strains) screened from the plastic-polluted sites towards PET biodegradation. The formulated consortium biodegradation potential showed effective degradation towards PET powder. Weight loss methods have determined the degraded PET plastic powder. The weight loss percentage for PET powder was 73.4%. The degraded samples of PET powder have been analyzed by weight loss, HPLC, FTIR and SEM analysis. The maximal rate of degradation was found at an optimal temperature of 30 °C, pH 7 and carbon source 1 g/L. The smaller the particle size, higher will be degradation rate. This research presents a novel eco-friendly approach to managing PET plastic waste by utilizing a rhizobacterial consortium for biodegradation. Our findings suggest that this consortium could play a crucial role in the sustainable breakdown of PET plastics, a critical environmental challenge. This approach not only provides a promising alternative to conventional methods of plastic waste disposal but also emphasizes the potential of microbial communities in producing enzymes that facilitate biodegradation. We believe that our study offers a valuable reference for future research and efforts aimed at reducing plastic waste, particularly through the use of biological processes for waste management. These innovations present a forward-thinking approach to addressing plastic pollution in a sustainable and environmentally responsible manner. In future work, PET-targeted degrading enzymes from Bacillus species can be extracted to study deep insight. A promising or eco-friendly strategy is needed to reduce PET plastic waste from water and land.

Data availability

Correspondence and requests for materials should be addressed to Joginder Singh.

References

Ghosh, S. K., Pal, S. & Ray, S. Study of microbes having potentiality for biodegradation of plastics. Environ. Sci. Pollut. Res. 20, 4339–4355 (2013).

Peixoto, J., Silva, L. P. & Krüger, R. H. Brazilian Cerrado soil reveals an untapped microbial potential for unpretreated polyethylene biodegradation. J. Hazard Mater. 324, 634–644 (2017).

Benyathiar, P., Kumar, P., Carpenter, G., Brace, J. & Mishra, D. K. Polyethylene terephthalate (PET) bottle-to-bottle recycling for the beverage industry: A review. Polymers https://doi.org/10.3390/polym14122366 (2022).

Wilkes, R., Aristilde, L., Ludmilla Aristilde, C. & Hall, R.-R. Degradation and metabolism of synthetic plastics and associated products by Pseudomonas sp.: Capabilities and challenges. J. Appl. Microbiol. 123, 582–593 (2017).

Stagner, J. Methane generation from anaerobic digestion of biodegradable plastics—A review. Int. J. Environ. Stud. 73, 462–468 (2016).

Singh, J. J. & Gupta, K. Screening and identification of low density polyethylene (LDPE) degrading soil fungi isolated from polythene polluted sites around Gwalior city (MP) (2014).

Krueger, M., Harms, H. & Schlosser, D. Prospects for microbiological solutions to environmental pollution with plastics. Appl. Microbiol. Biotechnol. 99, 8857–8874 (2015).

Dhaka, V. et al. Occurrence, toxicity and remediation of polyethylene terephthalate plastics. A review. Environ. Chem. Lett. https://doi.org/10.1007/S10311-021-01384-8 (2022).

Yee Chee, J. et al. Bacterially produced polyhydroxyalkanoate (PHA): Converting renewable resources into bioplastics. researchgate.net.

Ruslan, R., Iqbal, M., Pekey, A. Y., Dewi, A. P. & Djamaan, A. Isolation and characterization of polystyrene-degrading bacteria Bacillus sp. ITP 10.1. 1 from soil sample of Jayawijaya Mountains, Papua, Indonesia. Int. Res. J. Pharm. (2018).

Agustien, A. Screening polyethylene synthetic plastic degrading-bacteria from soil endophytic bacteria view project second author view project Miptahul Jannah Sriwijaya State Polytechnic (2016).

Jha, S. Progress, prospects, and challenges of genetic engineering in phytoremediation. Bioremediation of Pollutants: From Genetic Engineering to Genome Engineering 57–123 (2020) https://doi.org/10.1016/B978-0-12-819025-8.00004-1.

Chamkhi, I. et al. Is——the rhizosphere a source of applicable multi-beneficial microorganisms for plant enhancement?. Saudi J. Biol. Sci. 29, 1246–1259. https://doi.org/10.1016/j.sjbs.2021.09.032 (2022).

Dhaka, V. et al. Biological degradation of polyethylene terephthalate by rhizobacteria. Environ. Sci. Pollut. Res. 2022, 1–10. https://doi.org/10.1007/S11356-022-20324-9 (2022).

Farzi, A., Dehnad, A. & Fotouhi, A. F. Biodegradation of polyethylene terephthalate waste using Streptomyces species and kinetic modeling of the process. Biocatal. Agric. Biotechnol. 17, 25–31 (2019).

Kumar, V., Maitra, S. S., Singh, R. & Burnwal, D. K. Acclimatization of a newly isolated bacteria in monomer tere-phthalic acid (TPA) may enable it to attack the polymer poly-ethylene tere-phthalate(PET). J. Environ. Chem. Eng. 8, 103977 (2020).

Gong, J., Li, Y., Wang, H., Li, H. & Zhang, J. Depolymerization and assimilation of poly(ethylene terephthalate) by whole-cell bioprocess. in IOP Conference Series: Materials Science and Engineering vol. 394 022047 (Institute of Physics Publishing, 2018).

Prasad, A. A. & Babu, S. Compatibility of Azospirillum brasilense and Pseudomonas fluorescens in growth promotion of groundnut (Arachis hypogea L.). An. Acad. Bras. Cienc. 89, 1027–1040 (2017).

Goel, R., Jayal, P., Negi, H., Saravanan, P. R. & Zaidi, M. G. H. Comparative in situ PET biodegradation assay using indigenously developed consortia. Int. J. Environ. Waste Manag. 13, 348–361 (2014).

Negi, H., Gupta, S., Zaidi, M. G. H. & Goel, R. Studies on biodegradation of LDPE film in the presence of potential bacterial consortia enriched soil. Biologija 57, 141–147 (2011).

Nehal, N. & Singh, P. Optimization of cultural condition of Bacillus sp. MZ540316: Improve biodegradation efficiency of lipopeptide biosurfactant against polyethylene. Biomass. Convers. Biorefin. https://doi.org/10.1007/S13399-021-02042-3 (2021).

Rani, R., Singh, N. P. & Santal, A. R. Isolation, characterization and optimization of bacterial isolate SARR1 for biodegradation of pretreated low density polyethylene. J. Appl. Nat. Sci. 13, 561–570 (2021).

Sawiphak, S. & Wongjiratthiti, A. Optimisation of culture conditions for PLA-food-packaging degradation by Bacillus sp. SNRUSA4. Pertanika J. Sci. https://doi.org/10.47836/pjst.29.1.23 (2021).

Meng, T. K. et al. Optimization of polystyrene biodegradation using response surface methodology (RSM) measured by simple colorimetric method high pressure processing view project dielectric elastomers view project optimization of polystyrene biodegradation using response surface methodology (RSM) measured by simple colorimetric method. Int. J. Eng. Technol. 7, 216–220 (2018).

Vague, M., Chan, G., Roberts, C., Swartz, N. A. & Mellies, J. L. Pseudomonas isolates degrade and form biofilms on polyethylene terephthalate (PET) plastic. bioRxiv https://doi.org/10.1101/647321 (2019).

Ries, E. F., Macedo, G. A. & Vermelho, A. B. Improvement of phytase activity by a new Saccharomyces cerevisiae strain using statistical optimization. Enzyme Res. 2011 (2011).

Umamaheswari, S. & Margandan, M. M. FTIR spectroscopic study of fungal degradation of poly(ethylene terephthalate) and polystyrene foam. Elixir. Chem. Eng. 64, 19159–19164 (2013).

Torena, P., Alvarez-Cuenca, M. & Reza, M. Biodegradation of polyethylene terephthalate microplastics by bacterial communities from activated sludge. Can. J. Chem. Eng. 99, S69–S82 (2021).

Skariyachan, S. et al. Enhanced polymer degradation of polyethylene and polypropylene by novel thermophilic consortia of Brevibacillus sps. and Aneurinibacillus sp. screened from waste management landfills and sewage treatment plants. Polym. Degrad. Stab. 149, 52–68 (2018).

Taniguchi, I. et al. Biodegradation of PET: Current status and application aspects. ACS Catal 9, 4089–4105 (2019).

Gao, R. & Sun, C. A marine bacterial community capable of degrading poly(ethylene terephthalate) and polyethylene. J. Hazard. Mater. 416, 125928. https://doi.org/10.1016/j.jhazmat.2021.125928 (2021).

Liu, J. et al. Biodegradation of diethyl terephthalate and polyethylene terephthalate by a novel identified degrader Delftia sp. WL-3 and its proposed metabolic pathway. Lett. Appl. Microbiol. 67, 254–261 (2018).

Roberts, C. et al. Environmental consortium containing pseudomonas and bacillus species synergistically degrades polyethylene terephthalate Plastic. mSphere 5 (2020).

Pathak, V. M. & Navneet. Review on the current status of polymer degradation: a microbial approach. Bioresour. Bioprocess. 4 (2017).

Dombrowski, N. et al. Reconstructing metabolic pathways of hydrocarbon-degrading bacteria from the Deepwater Horizon oil spill. nature.com 1 (2016).

Chaisu, K., Charles, A. L., Guu, Y.-K. & Chiu, C.-H. Optimization of poly lactic acid (PLA) plastic degradation by Aneurinibacillus migulanus using response surface methodology. In International Conference on Biological and Life Sciences (2012).

Chaudhuri, S., Chakraborty, R. & Bhattacharya, P. Optimization of biodegradation of natural fiber (Chorchorus capsularis): HDPE composite using response surface methodology. Iran. Polym. J. (Engl. Ed.) 22, 865–875 (2013).

Ruley, J. et al. Rhizobacteria communities of phytoremediation plant species in petroleum hydrocarbon contaminated soil of the Sudd ecosystem, South Sudan. Int. J. Microbiol. (2020).

Fernandez, C., Paola Guzman Castillo, M., Silvia Andrea, Q. & Carvajal, V. Microbial degradation of polyethylene terephthalate: a systematic. SN Appl. Sci. 4 (2022).

Auta, H. S., Emenike, C. U. & Fauziah, S. H. Screening of Bacillus strains isolated from mangrove ecosystems in Peninsular Malaysia for microplastic degradation. Environ. Pollut. 231, 1552–1559 (2017).

Galicia-Jiménez, M. M., López-Garrido, S. J., Ávila-Serrano, N. Y. & Murialdo, S. E. (20) (PDF) TWO-component system: A molecular dialogue between ruminal bacteria and feed particles (forage plants). https://www.researchgate.net/publication/322400988_TWO-Component_System_A_molecular_dialogue_between_ruminal_bacteria_and_feed_particles_forage_plants.

Zeigler, D. & Microbiology, W.N.-E. Experimental evolution of Bacillus subtilis. Environ. Microbiol. 19, 3415–3422 (2017).

Gu, J. D. Biodegradability of plastics: the issues, recent advances, and future perspectives. Environ. Sci. Pollut. Res. 28, 1278–1282 (2021).

Cheng, Y., Chen, J., Bao, M., & Li, Y. Surface modification ability of Paracoccus sp. indicating its potential for polyethylene terephthalate degradation. Int. Biodeterior. Biodegrad. (2022).

Cheng, Y. et al. The proliferation and colonization of functional bacteria on amorphous polyethylene terephthalate: Key role of ultraviolet irradiation and nonionic surfactant. Chemosphere (2022).

Ock Kim, Y. et al. Growth promoting activity of Penaeus indicus by secondary metabolite producing probiotic bacterium Bacillus subtilis isolated from the shrimp gut. J. King Saud. Univ. Sci. 32, 1641–1646 (2020).

Mohanrasu, K. et al. Optimization of media components and culture conditions for polyhydroxyalkanoates production by Bacillus megaterium. Fuel 271, 117522 (2020).

Mohammed, S., Behera, H. T., Dekebo, A. & Ray, L. Optimization of the culture conditions for production of Polyhydroxyalkanoate and its characterization from a new Bacillus cereus sp. BNPI-92 strain, isolated from plastic waste dumping yard. Int. J. Biol. Macromol. 156, 1064–1080 (2020).

Acknowledgements

Authors are highly grateful to the Head, Department of Microbiology, School of Bioengineering and Biosciences, Lovely Professional University for providing necessary research facilities. Dr. Singh would like to acknowledge DBT HRD Project & Management Unit, Regional Center for Biotechnology, NCR Biotech Science Cluster, Faridabad, Haryana for Research Associateship (DBT-RA), funding under award letter No DBT-RA/2022/July/N/2044 dated January 12, 2023. The authors wish to express their gratitude to the Ministry of Education (MoE) for their support under the grant MoE-STARS/STARS-2/2023-0714, dated September 26, 2023. Also, would like to thank ICWaR and IISc for laboratory and instrumentation facilities. The authors extend their appreciation to the deanship of research and graduate studies at King Khalid University for funding the work through large research project under grant number RGP2/32/46.

Funding

No funding was received for this work.

Author information

Authors and Affiliations

Contributions

VD and SS have contributed in experimental work and writing. JS and VD conceptualized, and acquired the entire concept and guided all the authors. VD, SS, RR, SG, JSa, NAK and PCR have made the contributions including drafting and data verification under the leadership of Prof. JS (Corresponding author). All authors read and approved the final manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Ethical approval

This article does not contain any studies with animals performed by any of the authors.

Consent to participate

No consent to participate is required for this work.

Consent for publication

On behalf of author’s, Prof. Joginder Singh has been given authorization to submit and correspond.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Dhaka, V., Singh, S., Rao, R. et al. Statistical optimization of process variables for improved poly(ethylene terephthalate) plastic degradation by a rhizospheric bacterial consortium. Sci Rep 15, 14813 (2025). https://doi.org/10.1038/s41598-025-88084-3

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-88084-3

Keywords

This article is cited by

-

Biodegradation of plastics by a novel microorganism isolated from the working area of a plastic recycling company in Gebze, Kocaeli, Türkiye

Scientific Reports (2026)

-

Biocatalytic innovations in PETase for sustainable polyethylene terephthalate plastic recycling

Discover Applied Sciences (2025)