Abstract

The current study recommends a novel design that includes lightweight flapping gates that open when the convex side is facing the wind source in order to reduce negative torque and increase the efficiency of Savonius wind turbines. Very light leaf or torsional springs can be used to ensure that the gates close smoothly by returning them to their closed state. The efficiency of the turbine is increased when the flapping gates open because there is less drag force and resistive torque applied to the turbine shaft. Two turbines, one with the conventional shape and the other with flapping gates, were created in order to achieve this. The two turbines were then compared to one another under similar circumstances. To collect the necessary readings, an experimental setup with a variety of sensors was developed. Experiments were carried out at various air velocities to calculate the static torque coefficient and power coefficient. It was proved that the new design, which has a higher static torque and power coefficient, is more effective than the conventional design. The power coefficient increases by an average of 25% at middle speed ranges, but only by about 16.914% at higher tip speed ratios.

Similar content being viewed by others

Introduction

A wind turbine with a vertical rotor axis is known as a vertical axis wind turbine (VAWT). These turbines are beneficial for use on locations where the wind direction is highly variable since the rotor axis is vertical, meaning that they do not need to be directed into the wind in order to operate. They are especially helpful in urban and residential settings since they are much quieter than horizontal axis wind turbines. However, the added drag that the VAWTs create when their blades rotate into the wind makes them less efficient than the HAWTs. In order to increase the VAWT’s efficiency, attempts are being made to lower its drag coefficient. In recent years, the VAWTs have been tested on a number of factors, including solidity, wind velocity, tip speed ratio, and rotor blade finish. There are two main groups for vertical axis wind turbines: Savonius and Darrieus types of VAWT. By developing a novel geometry for the Savonius blade shape, the current effort aims to increase the performance of Savonius wind turbines.

Savonius wind turbine is an aerodynamic drag type configuration that is relatively suitable for low wind speed. Savonius rotor works due to the difference of drag force acting on the concave and convex parts of its blades. Based on the difference between the drag forces on the blades, Savonius wind turbine has poor aerodynamic performances, Menet [1] and Bhutta et al. [2]. Savonius wind turbine has a number of advantages over other wind turbines such as simplicity in design, ease of fabrication and installation in confined spaces, its operation is independent of wind direction, ability to operate under complex turbulent flows [3], low rotation speed and noise emission [4], and good starting performance [5]. On the other hand, disadvantages of Savonius rotor are: lower efficiency, low rotational speed, fluctuations in the torque during operation of the rotor and difficulty in designing high-power wind turbines. The conventional Savonius turbines have a low power coefficient, around 0.21, compared to other vertical axis turbines. Comprehensive studies were carried out to investigate the effect of various design parameters such as overlap [6], number of blades and number of stages [7,8,9], and endplates [10] on turbine performance using experimental and numerical methods. Additional types of equipment such as obstacle shielding at the returning blade side [11], curtain at upstream of the rotor turbine [12,13,14,15], deflector plate [16], and guide-box tunnel [17] can be used to improve the performance of the Savonius turbine. However, the use of additional equipment will make Savonius rotor more complex. Some researchers investigated the use of a helical-shape blade Savonius rotor [18,19,20,21,22,23,24]. It has many advantages such as simple construction, independence of wind direction and a good starting torque at lower wind speeds [19, 20]. Zhao et al. [21] and Damak et al. [22] studied four types of helical rotors with different twisted angles \(90^{o}\), \(180^{o}\), \(270^{o}\) and \(360^{o}\). They found that the best performance was obtained by a helical rotor of \(180^{o}\) twisted angle. The rotor has some downwind surface parts that are exposed to the wind speed at any rotational angles producing positive torque giving better performance than helical rotors with other twist angles. Darrieus-Savonius rotor was introduced by some researchers [25,26,27,28,29,30,31,32] to have the advantage of high starting torque of Savonius turbine and advantage of Darrieus rotor that is high power coefficient. Combined Savonius-Darrieus type vertical axis wind rotor has better efficiency than the Savonius rotor. There are many combined configurations of turbines and the overlap between Savonius blades increases the performance of the combined turbine. Sahim [33] showed that the gap distance between Savonius and Darrieus blades is an important parameter that affects the performance of the turbine. The flow field around the Savonius rotor is very complex and there is no integrated theoretical system to make a complete analysis and prediction of it. So, many researchers [34,35,36,37,38,39,40] carried out numerical simulations verified the results by experiments. Thotla [41] installed a semi-automatic valve device in the blades of Savonius turbine. A hole was made in the blade with a raxine-type cover to cover it on the concave side of the blade, acting as a valve. Under this condition, the rotor operates normally like a conventional Savonius turbine. When the convex side of blade is on the windward side, the raxine-type cover is blown open and the airflow goes through the hole in the convex side to reduce the negative torque of the rotor, resulting in a higher torque.

Numerous techniques have been employed to create novel rotor profiles, according to earlier studies. Table 1 describes how the Savonius turbine’s performance can be improved by altering the traditional profile, either by utilizing auxiliary blades or by altering the circular profile’s angle. The new Savonius profiles derived from parametric investigations are displayed in Table 2. Additionally, as indicated in Table 3, modified Savonius rotors were created using optimization algorithms.

The aim of the present study is to introduce a modified novel shape of the Savonius rotor blade to reduce/eliminate the negative torque when the convex side of blade is on the windward side. At a certain value of the wind speed, the negative torque on the convex blade may be converted to a positive torque and the performance of the Savonius turbine can be improved significantly.

Novelty

The present invention introduces a novel and improved geometry of a Savonius turbine blade, which contains flapping gates that rotate around an axis parallel to the turbine’s axes of rotation. The suggested flap gates are evenly distributed across the blade’s surface area and are as small as possible. At different angles of rotation of the convex blade, the value of the pressure acting on the surface changes, causing the flaps to open and allow air to pass through the holes, but with varying openings depending on the pressure value, the mass of the flap, and the radial distance between the flap and the axis of rotation. Furthermore, the area of air leave from the flap gate is less than the area of air input into it, resulting in a large increase in air speed at the gate’s exit region resulting in the creation of a thrust in the direction of the turbine’s rotation. The thrust helps to raise the positive torque, which improves turbine performance. In some cases, the angle of the convex blade can cause the convex total torque acting on the turbine axis to be positive rather than negative, resulting in a significant improvement in turbine performance and efficiency. The present invention provides a new and improved Savonius wind turbine blade that is easily manufactured and does not require external mechanical assistance to reduce the negative torque produced by the convex blade.

Materials and methods

Detailed description of the modified turbine and the method of exploitation

The current study presents a novel and better Savonius wind turbine blade that is easy to fabricate and does not require extra mechanical help to lower the convex blade’s negative torque. The latest model also contains a new and improved wind turbine that can be disassembled quickly and easily, takes up minimal space, weighs as little as possible, and is readily transportable. Furthermore, the presence of opening holes in the convex Savonius turbine blade allows air to pass through, which reduces both the drag coefficient and also the drag force acting on it. As a result, the negative torque produced by the convex blade is decreased, enhancing turbine efficiency. According to prior research42,43,44,45,46, the pressure distribution on the surface of both the concave and convex blades during the rotation of the Savonius turbine varies with the angles of rotation, as illustrated in Fig. 1. In addition, the presence of flapped-gates in the convex Savonius turbine blade allows air to pass through, which reduces both the drag coefficient and the drag force acting on it. As a result, the negative torque produced by the convex blade is decreased, enhancing turbine efficiency. According to Fig. 1, the maximum pressure occurs near the axis of rotation at angle zero. As the blade angle increases, the area of the surface subjected to maximum pressure increases, until it reaches an angle of around 90 degrees. For angles between 90 and 180 degrees, the area along the axis of rotation gets low pressure values, while the area at the blade’s free edge receives larger pressure values.

The pressure distribution on the surface of the concave and convex blades of the S-shape Savonius turbine at various rotor position angles ranging from 0 to 150 deg. [42].

As illustrated in Fig. 2, each flap of the present turbine is subjected to the pressure force P and the centrifugal force component \(F_{c}\) as the turbine rotates. Because the concave blade’s pressure and centrifugal force component are in the same direction, the flapping gate remains closed. The gate flap in the convex blade is subjected to both pressure and centrifugal forces, but in different directions. The pressure force opens the flapping gate, while the centrifugal force closes it.

For the greatest advantage, the suggested flap gates are distributed throughout the blade’s surface area and are as small as possible. At different angles of rotation of the convex blade, the value of the pressure acting on the surface changes, causing the flaps to open and allowing air to pass through the holes, but with varying openings depending on the pressure value, the mass of the flap, and the radial distance between the flap and the axis of rotation. Figure 2 shows the pressure force P and centrifugal force component acting on a flap in both concave and convex blades. The pressure force and centrifugal force components are \(P = p\,A_{f}\) and \(F_{c} = m\,r\,\omega^{2} \,\cos \,(\alpha ) = m\,\omega^{2} \,d\,\cos^{2} \,(\alpha )\). p is the average pressure value working on the flap surface area, while P is the pressure force acting on the flap surface area \(A_{f}\). m is the flap mass, \(\omega\) is the turbine’s angular speed in rad/s, d is the half-cylinder blade diameter, and \(\alpha\) is the flap position angle. For the convex blade, when the pressure force P exceeds the centrifugal force component \(F_{c}\), the net force acting on the flap surface opens the flapped gate, whereas when the centrifugal force component \(F_{c}\) overcomes the pressure force P, the flapped gate closes. The characteristics of any flapped gate that opens at a specific convex blade position are determined by the pressure distribution values at the flap’s location, the flap’s surface area, mass, and position angle, which define the position of the flapped gate for a specific blade diameter (d) at a specific turbine rotation speed. Every flapped-gate opening on the convex blade surface has its own significance and is unlike any other flapped gate. By opening the gates, the drag force on the blade decreases, which lowers the quantity of negative torque produced at the turbine’s rotational axis. As a result, minimizing the negative torque improves both the turbine’s efficiency and the net torque acting on its axis.

As illustrated in Fig. 3, opening the flapping gate changes the area through which air passes, increasing air velocity at the exit region and producing a thrust force \(F_{th}\). This, in turn, creates positive torque acting on the turbine’s axis of rotation. A and B are two flapped gates depicted in Fig. 4. The position of flapped gate A is close to the turbine’s axis of rotation, whereas flapped gate B is close to the blade’s free end. The chance of the two flapping gates A and B opening is controlled by the pressure force P and the centrifugal force \(F_{c}\). The openings at each flapped gate control the generated thrust forces \(F_{th - A}\) and \(F_{th - B}\).If there is a thrust force, it is possible to produce positive torque at the turbine’s axis of rotation.

Due to the convex blade’s angle, there are situations where the convex blade’s torque operating on the turbine axis changes to a positive value instead of a negative one. The convex blade’s negative torque is replaced by a quantity of positive torque added to the concave blade’s torque under these circumstances, which results in a significant improvement in the turbine’s performance and efficiency, both the concave and convex blades cause a positive torque at the turbine axis.

Compared to other modified Savonius turbines described in prior researches, the proposed flapped-gates Savonius turbine design has a number of advantages. These advantages include a simple design, ease of fabrication and installation in confined spaces, the ability to operate under complex wind conditions, independence from wind direction, and good starting performance. An investigation into the potential benefits of using flapping gates Savonius turbine blades is carried out through the present experimental work.

Experimental study

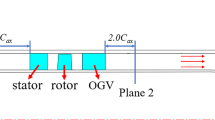

An investigation into the potential benefits of using flapping gates Savonius turbine blades is carried out through an experimental study. Based on our current capabilities, it is challenging to construct a modified Savonius turbine blade with a large number of small-area flapping gates originally spread throughout the whole surface of the blade. Thus, two sets of experiments are to be carried out. The first set will determine whether the flapping gate enhances the performance of the traditional Savonius turbine, and if so, by how much. This series of experiments are to be carried out using a small turbine that can be installed within the test section’s open circuit wind tunnel and has one flapping gate in each concave and convex blade. Experiments are to be conducted at various air speed values inside the test section of the wind tunnel. The second set of experiments is to be conducted on a relatively larger Savonis turbine placed behind the exit section of the wind tunnel, after placing a set of screens to improve the air flow condition, which is to lower its turbulence level before entering the Savonius turbine. This is in addition to designing and creating the device on which the Savonius turbine will be installed. This is whether it is normal or modified, with the possibility of placing the measuring devices required to conduct the experiments. This is in addition to those required to carry out the process of increasing the load on the turbine shaft during the operation process. A schematic representation of the experimental setup used in the second set of tests is shown in Fig. 5.

Equipments

The main equipments to be used are the low speed wind tunnel of open circuit type, a pitot static probe, a load cell of beam type to measure the tensile force in the highest side of the nylon string, a torque sensor, a load cell of S type to measure the tensile force in the slack side of the nylon string, a structural test bench carrying the Savonius wind rotor and a CPU unit.

Wind tunnel

The Hampden Model H-6910–12-150-CDL wind tunnel is equipped with the basic facilities for generating air flows which are to be used in the experiments. The wind tunnel including an inlet cone, a test section of \(0.3 \times 0.3\,m\), an outlet cone diffuser with a fan and a main AC circuit breaker. The wind tunnel’s exit section has a circular cross section of 0.7 m in diameter. The air velocity downstream of tunnel exit section could also be changed by the use of suitable turbulence damping screens.

Pitot static tube (Air velocity measurements)

Pitot static tube of a modified Prandtl type is used to measure the total and static pressure at the same point in moving air stream, inside the test section or at the downstream exit section. If the temperature of the fluid is known, the density and flow velocity can be calculated. The air velocity is measured using the pitot static tube connected to an inclined manometer and is controlled by the variation of the speed of the blower fan. The experiments were carried out for different values of the fan speed and the corresponding values of the air velocity were reported. In the second set of experiments, to ensure uniform air flow, the Savonuis wind rotor should be located around 5 m away from the wind tunnel exit. Due to space constraints downstream of the wind tunnel exit in the laboratory, two screens were utilized to ensure uniform air flow, and the wind rotor was installed at a distance of 1 m measured from the last turbulence screen. Screens with a grid of 10 × 10 mm and a space of 120 mm between them are employed as shown in Fig. 6. The Savonuis rotor shaft is supported by two anti-friction bearings in a cantilever arrangement. To reduce the friction torque acting on the rotor, the bearing seals are removed and each bearing is sprayed with W-D 40 (a commercially available spray) lubricant before collecting each reading.

Load cells and speed sensor (Torque and power measurements)

A brake drum (pulley) dynamometer is used to measure the torque of the turbine shaft by creating frictional resistance to the shaft’s motion using a nylon wire. Two load cells were used to measure the forces \(F_{1} \,\,and\,\,F_{2}\) in the nylon wire’s tight and slack sides respectively, see Fig. 7. The first load cell is of the beam type with a capacity of 200 N to measure \(F_{1}\) acting on the tight side. The second load cell is of S-type to measure the force \(F_{2}\) acting on the slack side of the nylon string. The gauges are linked to a Wheatstone bridge as well as a.

HX711 Load Cell Amplifier Interface with Arduino. HX711 was used to magnify the load cell’s output signal. The HX711 is a 24-bit precision analogue to digital converter (ADC) designed for industrial control applications that interface directly with a bridge sensor. Rotational speed of the rotor is recorded by a speed sensor of type DC5V-24V 600P/R.

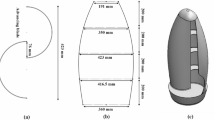

Blade description

Conventional Savonius turbine: For the first series of experiments, the traditional Savonius rotor is made up of two semi-cylinder-shaped blades without end plates; for the second set of examinations, it has endplates. The two blades of the traditional Savonius turbine used in the first set of experiments are each half-cylinders of 100 mm in diameter and 100 mm in height. The blades are made from aluminum sheets that are 1 mm thick. In the second set of experiments, the traditional Savonius rotor is made up of two half-cylinder blades, Fig. 10a, that are supported by two endplates, as illustrated in Fig. 11a. The blade’s height after being inserted into the endplates is 324 mm, which is also the diameter of the traditional turbine rotor. The rotor’s S shape was formed using a transparent acrylic sheet that was 4 mm thick, and each endplate has a diameter of 350 mm and a thickness of 4 mm.

Modified Savonius turbine: Each Savonius blade has the same dimensions as the conventional one, but as shown in Fig. 8, which shows two perspectives of a single flapped-gate on the turbine blade’s surface, one flapped-gate is used for the first set of experiments within the test section of the wind tunnel; the blade has no endplates, and the flapper rotates around a vertical axis parallel to the turbine’s axis of rotation, with the flapper axis supported near the turbine axis. Figure 9 shows the turbine blade’s size that includes the flapped-gate. The turbine in the second set of experiments has the same primary features as the conventional Savonius rotor in terms of diameter, height, and endplates. However, as illustrated in Fig. 10b, each blade has two flapped-gates, each measure 80 mm in length and 40 mm in arc. To create the flapped-gates, which have two on the concave side and two on the convex side, the flappers—which are composed of the same material as the blade—are secured in place by tiny hinges. The complete flapping gates Savonius rotor is shown in Fig. 11b.

First set of experiments: verification of the proposed idea

The conventional Savonius turbine has two blades, each of which is a half-cylinder with a diameter of 100 mm and a height of 100 mm. Aluminum sheets with a thickness of t = 1 mm are used to make the blades. The novel blade configuration is of the same size as the traditional one, but it has a flapped-gate, as shown in Fig. 12. The flapped-gate has an arc length of 52.36 mm and a height of 80 mm, and is positioned in the middle of the turbine’s blade, as shown in Fig. 9. The gate of the concave blade is closed, whereas the gate of the convex blade can be opened to allow air to pass through, resulting in an area change through the gate. Using the structure support as shown in Fig. 16A, the turbine was fixed inside the test section of the wind tunnel. The generator and the turbine shafts are connected, and the generator output is connected to a multimeter so that the voltage (V) and current (I) can be measured. The power \(P_{t} = V\,I\) in Watt can be used to calculate the power generated. For different values of air velocity, the power is estimated for both the traditional and flapped-gates Savonius turbines.

Second set of experiments: turbine performance using the proposed model

In the second set of experiments, the static torque generated by Savonius blade rotors for various angular positions and wind speeds is measured. Both regular and modified Savonius blade rotors are used in the studies. Figure 13 depicts the test bench that was designed, manufactured, and assembled. Figure 13a shows a photograph of the test bench used in the second set of experiments, identifying the key elements used to load the turbine shaft as well as the sensors used to detect the various parameters throughout the experimentations. Figure 13b depicts the loading mechanism and the speed sensor. The photo in Fig. 13c shows the two-bearing housing holding the turbine shaft after removal of the bearing seals, as well as the upper plate of the construction and how the rotor blade is supported. Figure 14 shows a photograph of all of the elements and the layout of the experiment components for the second set of experiments.

Experiment (2–1): bearing friction and aerodynamic effect

The first group of tests is carried out to determine one of the important characteristics of the test bench at different operating wind speeds. The friction in bearings, aerodynamic effects, friction power loss and free braking time are to be evaluated in order to understand the behavior of the system at different values of wind speed. The test procedure for experiment (2–1) may be summarized as follows:

-

1. Disconnecting the resisting mechanism at the end of the rotor assembly

-

2. Starting the wind tunnel and controlling the speed of the fan.

-

3. Adjusting the speed of fan and measure the wind speed.

-

4. Using the speed sensor attached to the rotor to measure the rotor speed at no load till reaching the steady state condition, \(\omega_{\,1}\) at time \(t = 0\)

-

5. Stopping the stream of the turbine rotor by cutting the air flow using a movable barrier.

-

6. Recording the variation of the rotor speed with time and estimate the free braking time \(t_{o}\) at \(\omega_{2} = 0\).

-

7. Determining the average value of angular acceleration of the rotor \(\alpha_{f} = \frac{{\omega_{\,1} - \omega_{\,2} }}{{t_{o} }} = \frac{{\omega_{\,1} }}{{t_{o} }}\).

-

8. Estimating the friction and aerodynamic resistance torque \(T_{f} = - \alpha_{f} \,J_{eq}\); where \(J_{eq}\) is the polar moment of inertia of the rotor in \(kg\,m^{2}\).

-

9. Repeating the steps 4–6 at different operating wind speeds and reporting the outputs.

Experiment (2–2): static torque produced by savonius rotor for different angular position at various wind speeds.

A set of experiments were carried out to evaluate the static torque produced by traditional and modified wind mill. Using the brake drum measuring system, Fig. 7, a set of tests were performed to evaluate the static torque and static torque coefficient of the rotor at a given rotor angle. The static torque of the rotor is measured at every 30° of the rotor angle, and the use of a worm gear box made the loading of the rotor easy to obtain and control at any given wind velocity. The test procedure for experiment (2–2) may be summarized as follows:

-

1.

Adjusting the rotor blades to be at the specified position 0,30,60,90,120,150 and 180 deg.

-

2.

Rotating the worm to increase the forces \(F_{1} \,\,and\,\,F_{2}\) loading the break drum sufficiently to prevent rotation at a specified value of air velocity and a certain rotor position.

-

3.

Starting the wind tunnel and adjusting the speed of the fan to obtain the required value of the air velocity downstream from the wind tunnel exit section.

-

4.

Using the pitot static tube which is connected to the inclined manometer to measure the velocity of the free air stream upstream of the rotor position.

-

5.

Making a fine turning for the fan speed to get the desired value of the free air velocity.

-

6.

Gradually releasing the load until the rotor begins to move. At that instance, \(F_{1}\) and \(F_{2}\) forces are to be measured and recorded using the load cells.

-

7.

Determining the values of static torque \(T_{s}\) and static torque coefficient \(C_{ts}\) using the relations: \(T_{s} = (F_{1} - F_{2} )\,\left( {\frac{{D_{pully} + D_{wire} }}{2}} \right)\) and \(C_{ts} = \frac{{4\,T_{s} }}{{\rho \,U^{2} D^{2} H}}\).

-

8.

Repeating the experiment for different angular position at various wind speeds

Experiment (2–3): torque coefficient and power coefficient

A series of experiments are conducted to determine the torque, torque coefficient, power, and power coefficient produced by conventional and modified rotors at various wind speeds. The procedure of the experiment may be summarized as follows:

-

1.

To set the rotor at the desired position

-

2.

To set the pitot static probe upstream of the rotor to measure the velocity of the stream of the air

-

3.

To start the wind tunnel and adjust the speed of the fan to obtain the required air velocity.

-

4.

To adjust speed of the rotor by changing the resisting moment acting on the rotor by changing the forces \(F_{1}\) and \(F_{2}\) through the rotation of the worm

-

5.

To measure the values of rotor speed in RPM, the force \(F_{1}\) and \(F_{2}\) in tight side and slack side of the nylon string, respectively.

-

6.

To calculate the value of the torque T, \(T = (F_{1} - F_{2} )\,\left( {\frac{{D_{pully} + D_{wire} }}{2}} \right)\).

-

7.

To calculate the tip speed ratio, \(TSR = \frac{\omega \,(D/2)}{U}\), where \(\omega = \frac{2\,\pi \,N}{{60}}\,\,.\)

-

8.

To calculate the torque coefficient and power coefficient using the relations:

$$C_{t} = \frac{4\,T}{{\rho \,U^{2} D^{2} H}}\,\,\,\,and\,\,\,\,C_{p} = TSR\, \times \,C_{t} \,\,.$$ -

9.

To repeat the steps from 4 to 9 for various values of wind speed ranging from 5 m/s to 9 m/s. T

-

10.

The findings can be obtained through adjusting the braking drum system using the worm-gearbox to change rotor speed. The torque coefficient and power coefficient are to be determined for rotor tip speed ratio ranging from 0.2 to 1.2 and air velocity ranging from 5 to 9 m/s.

Data reduction

-

The turbine’s performance can be expressed in terms of dimensionless quantities based on the outcomes of the experiments. The data reduction can be introduced by the following dimensionless quantities:

-

Reynolds number is calculated based on the diameter of the rotor D using the following definition \(R_{e} = \frac{\rho \,U\,D}{\mu }\) with \(\rho = 1.225\,{{\,\,\,kg} \mathord{\left/ {\vphantom {{\,\,\,kg} {m^{3} }}} \right. \kern-0pt} {m^{3} }}\). U is the free stream air velocity in m/s, D is the rotor diameter of 0.324 m and \(\mu\) is the absolute viscosity of air, \(\mu = 1.525 \times 10^{ - \,5} \,Pa\,s\,\,at\,\,20\,\,{}^{o}C\).

-

Tip speed ratio is given by \(TSR = \frac{\omega \,D}{{2\,U}}\); where \(\omega\) is the angular velocity of the rotor.

-

To determine the torque coefficient, use \(C_{t} = \frac{4\,T}{{\rho \,U^{2} D^{2} H}}\); where H is the turbine height of 0.324 m and the torque \(T_{r}\) is the resisting load acting on the rotor of the turbine calculated as \(T_{r} = (F_{1} - F_{2} )\,\left( {\frac{{D_{pully} + D_{wire} }}{2}} \right)\). The diameter of the pully is 0.05 m and the diameter of the wire is 2 mm.

-

Power coefficient can be obtained using \(C_{p} = TSR\, \times \,C_{t}\).

-

Balance ratio B is given by \(B = \frac{D\,\,H}{{A_{exit} }}\). \(A_{exit}\) is the area of the wind tunnel exit section. The effect of blockage ratio is negligible on \(C_{p} ,\,C_{t} \,\,and\,\,C_{ts}\) for open wind tunnel as reported by Kemoji [47]. In the present study, blockage ratio is negligible where the tests are out in downstream of the wind tunnel exit section.

-

Aspect ratio is the ratio of the rotor height to rotor diameter, \(AR = \frac{H}{D}\,\,.\)

Results and discussion

The first set of experiments were conducted to validate the concept of the suggested modification to the Savonius turbine blade, which contains a single flapping gate that revolves about an axis parallel to the turbine’s axis of rotation. The turbine is installed in the wind tunnel’s test section area, and its output power is to be estimated. The data is gathered and reported in Table 4, where the percentage power difference is indicated as follows,

The findings reveal that using a modified Savonius turbine with flapping gates increases output power by an average of 16.233 percent over velocity ranges of 6.3 to 11.5 m/s. The percentage starts at 17.572% at an air velocity of 6.3 m/s; increasing the air velocity value causes an increase in the rate of rotation of the rotor, which impacts the opening of the flapping gates as the centrifugal force increases. When the air velocity is sufficiently high, the centrifugal force exceeds the pressure force, and the gate closes. The modified blade then performs similarly to the traditional blade.

The second set of tests involves changing the blade shape to a half-cylinder with a diameter of 162 mm and a height of 324 mm. S-shape of the original and modified Savonius rotor has a rotor aspect ratio of \(AR = {H \mathord{\left/ {\vphantom {H {D = }}} \right. \kern-0pt} {D = }}1\). The initial group of experiments, Experiment (2–1), was carried out to evaluate the friction in bearings, aerodynamic effects, friction power loss, and free braking time to understand the behavior of the system at different wind speeds. The Savonuis rotor shaft is supported in a cantilever configuration by two bearings with extremely low friction. The experiments were carried out for the typical Savonius rotor before removing the seals of the bearings, and after their removal and spraying each bearing with a lubricant before each reading. Table 5 presents the rotor speed and free breaking time for the two examinations. The findings of the experiment demonstrate that it is essential to lower the friction torque acting on the rotor by removing the bearing seals and spraying each bearing with W-D 40 (an available commercial spray) lubricant before each reading.

\(\alpha_{f}\) is the angular acceleration of the rotor, \(t_{o}\) is the breaking time.

In the second set of experiments, Experiment (2–2), a series of tests were carried out on both traditional and modified rotors to determine the static torque and static torque coefficient of the rotor at a specific angle. For a conventional rotor, Fig. 11a, the static torque is measured for every 30 degrees of rotor angle. Figure 15a shows how the static torque fluctuates with different wind speeds (U = 5.7, 7.57, and 8.1 m/s), whereas Fig. 15b shows how the static torque coefficient varies with turbine angular position for the same wind speed. The obtained experimental points are fitted with the 6th polynomial fit. The results are in good qualitative match with previous investigations. Static torque and its coefficient behave in a similar way to angular position, but their values vary depending on wind speed. For both the conventional savonius rotor and the modified flapped-gates Savonius turbine at air speeds of 5.6 m/s and 7.57 m/s, Figs. 16 and 17 depict the variation of the static torque and static torque coefficient at various turbine locations from 0 to 360 degrees at wind speeds U = 5.6 m/s and 7.57 m/s. Compared to the old design, the new one has a higher available static torque and coefficient of static torque. This demonstrates the design’s effectiveness.

A set of tests are carried out in Experiment (2–3) in order to evaluate the power, power coefficient, torque, and torque coefficient produced at different wind speeds by both modified and standard rotors. After the torque and power coefficient values for the conventional turbine are compared to numerous earlier studies, a good agreement is found. Compared to the original design, the new one has a higher available static torque and coefficient of static torque, as shown in Figs. 16 and 17. This demonstrates the design’s effectiveness. For both the conventional turbine and the turbine with the modified blade, Fig. 18 illustrates how the torque and power coefficients change with the tip speed ratio. The torque coefficient decreases as the tip speed ratio increases, Fig. 18a, but it is higher with the modified blade geometry than with the conventional one. At a tip speed ratio of 0.2, the torque coefficient improves by 23.833%, and at a tip speed ratio of 0.865, it improves by 16.668%. On the other hand, the power coefficient was improved roughly by 16.914% at higher tip speed ratio of 0.865, according to the data on the change of the power coefficient in Fig. 18b, which shows an average increase of 25% at middle speed ranges. The flapping gates open and air flows through the holes in the convex side of the blade when it is on the windward side, reducing the negative torque operating on the turbine rotor and increasing the overall torque. This was good since the gates opened less widely due to the stronger centrifugal force acting on them.

Static testing, which disregards centrifugal force, demonstrated the design’s effectiveness. To reduce the effects of centrifugal force, it is advised that the mass of the gates should be kept as low as possible.

Conclusions

The current research offers an innovative design that consists of lightweight flapping gates that open when the convex side is facing the wind source in order to reduce negative torque and improve the efficiency of Savonius wind turbines. Very light leaf or torsional springs can be employed to ensure that the gates close smoothly by returning them to their closed condition. When the flapping gates open, less drag force and resistive torque are transferred to the turbine shaft, increasing the turbine’s efficiency. To do this, two turbines were designed, one with flapping gates and the other with the conventional shape. Then, under the same circumstances, the two turbines were examined. A variety of sensors were used in an experimental setup to gather the required readings. To determine the static torque coefficient and power coefficient, experiments were conducted at different air velocities. It was demonstrated that the new design outperforms the traditional design due to its higher static torque and power coefficient. The following is a summary of the main conclusions:

-

The use of the modified flapping gates Savonius turbine blades resulted in a significant increase in the effectiveness of the conventional Savonius turbine. When the blade is on the windward side, the flapping gates open and air passes through the holes in the convex side, decreasing the negative torque acting on the turbine rotor and raising the total torque.

-

At higher tip speed ratios, the power coefficient improves only by around 16.914%, but at medium speed ranges, it increases by an average of 25%.

-

However, more comprehensive research is required to determine the ideal mass, size, and distribution of the gates all over the entire surface of the Savonius turbine blade.

Data availability

All data generated or analyzed during this study are included in this published article, no supplementary information files.

References

Menet, J. L. A double-step Savonius rotor for local production of electricity: A designstudy. Renew. Energy 29, 1843–1862 (2004).

Bhutta, M. M. A. et al. Verticalaxis wind turbine—A review of various configurations and design techniques. Renew. Sustain. Energy Rev. 16, 1926–1939 (2012).

Pope, K., Dincer, I. & Naterer, G. Energy and energy efficiency comparison of horizontal andvertical axis wind turbines. Renew. Energy 35, 2102–2113 (2010).

Shigetomi, A., Murai, Y., Tasaka, Y. & Tasaka, Y. Interactive flow field around two savonius turbines. Renew. Energy 36, 536–545 (2011).

Sivasegaram, S. Design parameters affecting the performance of resistance-type, vertical-axisWind rotors—An experimental investigation. Wind Energy 1, 207–217 (1977).

Akwa, J., Junior, G. & Petry, A. Discussion on the verification of the overlap ratio influence on performance coefficients of a Savonius wind rotor using computational fluid dynamics. Renew. Energy 38, 141–149 (2012).

Saha, U., Thotla, S. & Maity, D. Optimum design configuration of Savonius rotor through windtunnel experiments. J. Wind Eng. Ind. Aerodyn. 2008(96), 1359–1375 (2008).

Hayashi, T., Li, Y. & Hara, Y. Wind tunnel tests on a different phase three-stage Savonius rotor. JSME Int. J. 48, 9–19 (2005).

Sharma, K. K., Gupta, R. & Biswas, A. Performance measurement of a two-stage two-bladed Savonius rotor. Int. J. Renew. Energy Res. 4(1), 115–120 (2014).

Krzysztof, R. & Ryszard, M. CFD computation of the Savonius rotor. J. Theor. Appl. Mech. 53(1), 37–45 (2015).

Mohamed, M. H., Janiga, G., Pap, E. & Thévenin, D. Technical Note Optimization of Savonius turbines using an obstacle shielding the returning blade. Renew. Energy 35, 2618–2626 (2010).

Deda, B., Wind energy and increasing the performance of Savonius wind rotors. MSc. Thesis in Mechanical Engineering,Graduate School of Natural and Applied Sciences, Pamukkale University, Denizli, Turkey (2000).

DedaAltan, B., Performance investigation of Savonius wind rotor with curtaining method, PhD. Thesis in Mechanical Engineering, Graduate School of Natural and Applied Sciences, Pamukkale University, Denizli, Turkey, (2006).

Altan, B. D. & Atilgan, M. The use of a curtain design to increase the performance level of a Savonius wind rotors. Renew. Energy 35, 821–829 (2010).

Burҫin, D. A. & Mehmet, A. A study on increasing the performance of Savonius wind rotors. J. Mech. Sci. Technol. 26(5), 1493–1499 (2012).

Golecha, K., Eldho, T. I. & Prabhu, S. V. Influence of the deflector plate on the performance of modified Savonius water turbine. Appl. Energy 88, 3207–3217 (2011).

Irabu, K. & Roy, J. N. Characteristics of wind power on Savonius rotor using a guide-box tunnel. Exp. Ther. Fluid Sci. 32, 580–586 (2007).

Kamoji, M. A., Kedare, S. B. & Prabhu, S. V. Performance tests on helical Savonius rotors. Renew. Energy 34, 521–529 (2009).

Driss, Z., Mlayeh, O., Driss, D. & Abid, M. S. Numerical simulation and experimental validation of the turbulent flow around a small incurved savonius wind rotor. Energy 74, 506–517 (2014).

Driss, Z., Mlayeh, O., Driss, S., Maaloul, M. & Abid, M. S. Study of the incidence angle effect on the aerodynamic structure characteristics of an incurved savonius wind rotor placed in a wind tunnel. Energy 113, 894–908 (2016).

Zhao, Z., Zheng Y., Xu X., and Hu G., Research on the improvement of the performance of savonius rotor based on numerical study. International Conference on Sustainable Power Generation and Supply, 6–7 April, Nanjing, China, pp. 1–6 (2009).

Damak, A., Driss, Z. & Abid, M. S. Experimental investigation of helical savonius rotor with a twist of 180’. Renew. Energy 52, 136–142 (2013).

Lee, J. H., Lee, Y. T. & Lim, H. C. Effect of twist angle on the performance of Savonius wind turbine. J. Renew. Energy 89, 231–244 (2016).

Kumar, A. & Saini, R. P. Performance analysis of a single stage modified Savonius hydrokinetic turbine having twisted blades. J. Renew. Energy 113, 461–478 (2017).

Bhuyan, S. & Biswas, A. Investigations on self-starting and performance characteristics of simple Hand hybrid H-Savonius vertical axis wind rotors. Energy Convers. Manag. 87, 859–867 (2014).

Siddiqui A., Hameed A., Mian S. N., and Khatoon R., Experimental Investigations of Hybrid Vertical Axis Wind Turbine, in Proceeding of the 4th International Conference on Energy, Environment and Sustainable Development (EESD ’16) (2016).

Mahmoud, N. H., El-Haroun, A. A., Wahba, E. & Nasef, M. H. An experimental study on improvement of Savonius rotor performance. Alex. Eng. J. 51(1), 19–25 (2012).

Gupta, R., Biswas, A. & Sharma, K. K. Comparative study ofa three-bucket Savonius rotor with a combined three-bucketSavonius-three-bladed Darrieus rotor. J. Renew. Energy 33(9), 1974–1981 (2008).

Kaprawi, S., Santoso, D. & Sipahutar, R. Performance of combinedwater turbine darrieus-savonius with two stage savoniusbuckets and single deflector. Int. J. Renew. Energy Res. 5(1), 217–221 (2015).

Ghosh, A., Biswas, A., Sharma, A. A. & Gupta, R. Computationalanalysis of flow physics of a combined three bladedDarrieus Savonius wind rotor. J. Energy Inst. 88(4), 425–437 (2015).

Kyozuka, Y. An experimental study on the darrieus-savoniusturbine for the tidal current power generation. J. FluidSci. Technol. 3(3), 439–449 (2008).

Xiaoting, L. et al. A computational study of the effects ofthe radius ratio and attachment angle on the performanceof a darrieus-savonius combined wind turbine. Renew. Energy 113, 329–334 (2017).

Gupta, R. & Sharma, K. K. Flow physics of a combined Darrieus-Savonius rotor using computational fluid dynamics (CFD). Int. Res. J. Eng. Sci. Technol. Innov. 1(1), 1–13 (2012).

Altan, B. & Atilgan, M. An experimental and numerical study on the improvement of the performance of Savonius wind rotor. Energy Convers. Manag. 49, 3425–3432 (2008).

McTavish, S., Feszty, D. & Sankar, T. Steady and rotating computational fluid dynamicssimulations of a novel vertical axis wind turbine for small-scale power generation. Renew. Energy 41, 171–179 (2012).

Kacprzak, K., Liskiewicz, G. & Sobczak, K. Numerical investigation of conventional and modifiedSavonius wind turbines. Renew. Energy 60, 578–585 (2013).

Tian, W., Song, B. & Mao, Z. Numerical investigation of a Savonius wind turbine with elliptical blades. Proc. CSEE 34, 796–802 (2014).

Tian, W., Song, B., VanZwieten, J. H. & Pyakurel, P. Computational fluid dynamics prediction of a modified savonius wind turbine with novel blade shapes. Energies 8(8), 7915–7929 (2015).

Sharma, S. & Sharma, R. K. Performance improvement of Savonius rotor using multiple quarter blades—A CFD investigation. Energy Convers. Manag. 127, 43–54 (2016).

Roy, S. & Ducoin, A. Unsteady analysis on the instantaneous forces and moment arms acting on a novel Savonius-style wind turbine. Energy Convers. Manag. 121, 281–296 (2016).

Thotla S., Optimum design configuration of Savonius rotor through wind tunnel testing, M. Tech. Thesis, Department of Mechanical Engineering, IIT Guwahati, India (2006).

Mansour, H. & Afify, R. Design and 3D CFD static performance study of a two-blade Icewind turbine. Energies 13(20), 5356 (2020).

Zhou, T. & Rempfer, D. Numerical study of detailed flow field and performance of savonius wind turbines. Renew. Energy 51, 373–381 (2013).

Michna, J. & Rogowski, K. CFD calculations of average flow parameters around the rotor of a savonius wind turbine. Energies 16, 281. https://doi.org/10.3390/en16010281 (2023).

Kerikous, E. & Thévenin, D. Optimal shape of thick blades for hydraulic savonius turbine. Renew. Energy 134, 629–638. https://doi.org/10.1016/j.renene.2018.11 (2019).

Nasef, M. H., Awad, B. N. A. & EL-Askary, W. A. Installing new additional blades arrangement for improving Savonius rotor performance. Wind Eng. https://doi.org/10.1177/0309524X241258478 (2024).

Kamoji, M. A., Kedare, S. & Prabhu, S. Experimental investigations on single stage, two stage and three stage conventional savonius rotor. Int. J. Energy Res. 32, 877–895 (2008).

Mao, Z. & Tian, W. Effect of the blade arc angle on the performance of a Savonius wind turbine. Adv. Mech. Eng. 7(5), 1–10 (2015).

Abdelaziz, K. R., Nawar, M. A. A., Ramadan, A., Attai, Y. A. & Mohamed, M. H. Performance investigation of a Savonius rotor by varying the blade arc angles. Ocean Eng. 260, 112054 (2022).

Driss, Z. et al. Study of the bucket design effect on the turbulent flow around unconventional Savonius wind rotors. Energy 89, 708–729 (2015).

Abdelaziz, K. R., Nawar, M. A., Ramadan, A., Attai, Y. A. & Mohamed, M. H. Performance improvement of a Savonius turbine by using auxiliary blades. Energy 244, 122575 (2022).

Altan, B. D., Altan, G. & Kovan, V. Investigation of 3D printed Savonius rotor performance. Renew. Energy 99, 584–591 (2016).

Sharma, S. & Sharma, R. K. Performance improvement of Savonius rotor using multiple quarter blades—a CFD investigation. Energy Convers. Manag. 127, 43–54 (2016).

Sharma, S. & Sharma, R. K. CFD investigation to quantify the effect of layered multiple miniature blades on the performance of Savonius rotor. Energy Convers. Manag. 144, 275–285 (2017).

Al-Ghriybah, M., Zulkaflia, M. F., Didane, D. H. & Mohd, S. The effect of inner blade position on the performance of the Savonius rotor. Sustain. Energy Technol. Assess. 36, 100534 (2019).

Al-Ghriybah, M., Zulkaflia, M. F., Didane, D. H. & Mohd, S. Performance of Savonius wind rotor with two inner blades at low tip speed ratio. CFD Lett. 3, 11–21 (2020).

Haddad, H. Z., Elsayed, K., Shabana, Y. M. & Mohamed, M. H. Comprehensive influence of the additional inner blades with different configurations on the performance of a Savonius wind turbine. Energy Sour. Part A Recovery, Util. Environ. Eff. https://doi.org/10.1080/15567036.2021.1956645 (2021).

Patel, V. & Patel, R. Free energy-extraction using Savonius hydrokinetic rotor with dual splitters. Mater. Today Proc. 45(6), 5354–5361 (2021).

Shashikumar, C. M., Honnasiddaiah, R., Hindasageri, V. & Madav, V. Experimental and numerical investigation of novel V-shaped rotor for hydropower utilization. Ocean Eng. 224, 108689 (2021).

Shashikumar, C. M., Hindasageri, V. & Madav, V. Numerical investigation of conventional and tapered Savonius hydrokinetic turbine for low-velocity hydropower application in an irrigation channel. Sustain. Energy Technol. Assessm. 43, 100871 (2021).

Absi, S. M. A., Jabbar, A. H., Mezan, S. O., Rawi, B. A. & Attabi, S. T. An experimental test of the performance enhancement of a Savonius turbine by modifying the inner surface of a blade. Mater. Today Proc. 42(5), 2233–2240 (2021).

Tian, W., Song, B., Vanzwieten, J. H. & Pyakurel, P. Computational fluid dynamics predictions of a modified Savonius wind turbine with novel blade shapes. Energies 8, 7915–7929 (2015).

Mahrous, A. F. Computational fluid dynamics study of a modified Savonius rotor blade by universal consideration of blade shape factor concept. J. Adv. Res. Fluid Mech. Ther. Sci. 85(1), 22–39 (2021).

Roy, S. & Saha, U. K. Wind tunnel experiments of a newly developed two-bladed Savonius-style wind turbine. Appl. Energy 137, 117–125 (2015).

Mohamed, M. H., Janiga, G., Pap, E. & Thevenin, D. Optimal blade shape of a modified Savonius turbine using an obstacle shielding the returning blade. Energy Convers. Manag. 52, 236–242 (2011).

Chan, C. M., Bai, H. L. & He, D. Q. Blade shape optimization of the Savonius wind turbine using a genetic algorithm. Appl. Energy 213, 148–157 (2018).

Kerikous, E. & Thévenin, D. Optimal shape of thick blades for a hydraulic Savonius turbine. Renew. Energy 134, 629–638 (2019).

Tian, W., Mao, Z., Zhang, B. & Li, Y. Shape optimization of a Savonius wind rotor with different convex and concave sides. Renew. Energy 117, 287–299 (2018).

Funding

Open access funding provided by The Science, Technology & Innovation Funding Authority (STDF) in cooperation with The Egyptian Knowledge Bank (EKB).

Author information

Authors and Affiliations

Contributions

R.A., E.S., and H.A. contributed to the design and implementation of the research, to the analysis of the results and to the writing of the manuscript. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Afify, R., Saber, E. & Awad, H. Investigation of an innovative savonius turbine in practice. Sci Rep 15, 6937 (2025). https://doi.org/10.1038/s41598-025-88544-w

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-88544-w

Keywords

This article is cited by

-

Advanced blade profiles for improved efficiency in Savonius wind turbines: the aeroleaf case study

Scientific Reports (2025)