Abstract

Deep shale has obvious bedding structure, and its complex anisotropic mechanical characteristics bring challenges to the development of shale gas resources. In order to explore the effect of bedding on the mechanical properties and failure modes of shale. This paper takes the Longmaxi Formation shale in Changning, Sichuan Province as the research object, uniaxial compression tests were conducted on shale with different bedding angles, and acoustic emission (AE) signals were monitored during the loading process. The anisotropic mechanical properties of shale under loading were analyzed, and a further comprehensive evaluation of shale brittleness characteristics and rock burst tendency was conducted. Additionally, the evolution law of statistical parameters of AE and the mechanism of rock fracture were explored. The results showed that: (1) The deformation and mechanical properties of shale containing laminations during uniaxial compression show strong anisotropic characteristics, showing significant dip angle effect. (2) The fracture morphology of shale under uniaxial loading was complex, mainly characterized by splitting tensile failure and shear tensile failure, showing a strong tendency towards rockburst. (3) The Rickman brittleness index of shale attains 45.59, manifesting strong brittleness properties that are conducive to reservoir fracturing transformation. (4) During the loading process, there is good consistency between the AE signal and the stress–strain curve. The evolution of shale AE parameters corresponds to the rock damage and failure process, and the distribution characteristics of AE spectrum RA–AF data can distinguish the type of stress-generated cracks, and it is found that the shale under uniaxial compression was dominated by shear damage on the whole, and the proportion of shear damage increases firstly and then decreases with the increase of bedding angle. The research results can provide theoretical reference and guidance for the optimization design of hydraulic fracturing and the control of drilling stability during deep shale gas exploitation.

Similar content being viewed by others

Introduction

As an important unconventional energy source, shale gas is one of the most realistic alternative resources for conventional oil and gas. It has become a hot spot of development and research around the world. China is rich in shale gas resources, the recoverable reserves were second only to the United States, and has a wide distribution, with organic-rich shale widely developed in southwestern areas such as Sichuan, Chongqing and Guizhou. It is reported that currently, China’s shale gas production capacity has ranked second in the world. In 2023, its production has reached 25 billion cubic meters, accounting for half of the total natural gas production. It is expected that the production will reach 400 billion cubic meters in 2035. Shale gas is playing an increasingly important role in China’s energy structure. With the rapid development of the economy and society, the demand for energy has increased sharply, and the development of deep oil and gas resources has become an important direction of the energy field during the "14th Five-Year Plan" period in China and the practical need to achieve the ability to ensure energy supply. China urgently needs to break through related theories and technologies for shale gas development.

Under long-term geological stress conditions, shale reservoirs were formed into bedding structures through deposition or metamorphism, and appear obvious lamellar and non-homogeneous characteristics in the microstructure. This highly dense bedding structure can be observed through deep shale drilling cores, imaging logging, CT scanning and field outcrop, etc. The mechanical properties and cementation strength of bedding are much weaker than those of shale matrix, and its impact on the mechanical properties of shale cannot be ignored. In the process fracturing and reforming of shale reservoir, the mechanical properties of rocks with different lithologies and their differences are important influences on the ability of fracture expansion in the longitudinal direction of multi-layer stacked formations. In engineering practice and scientific research, the exploration of crack propagation and rock micro-failure mechanisms under the influence of bedding has received widespread attention. Cho et al.1 conducted electron microscope scanning tests on shale that parallel and perpendicular to the bedding plane, and found that the difference in microstructure was the root of the mechanical anisotropy. Chen et al.2 found that the essence of the damage effect of bedding on shale under uniaxial loading is the softening effect of the primary microfracture populations distributed along the bedding. The damage and destruction of rock are actually the phenomenon of gradual instability during the germination, propagation and penetration processes of internal microcracks. In order to explore the anisotropic mechanical properties of stratified rocks, many foreign and local scholars have analyzed the evolution laws of rock tensile strength, Young’s modulus, Poisson’s ratio and wave velocity under the influence of bedding3,4 through experiments and numerical simulation5,6 and observed obvious anisotropic failure modes and macroscopic crack morphology7, and analyzed the effects of burial depth8, temperature9 and loading rate10 on the anisotropic mechanical properties. In addition, some scholars have studied the anisotropic characteristics and laws of crack expansion, heat conduction, rockburst proneness, energy dissipation and transmission of stratified rocks under loading11,12,13. However, most of the existing research focuses on macro-strength and deformation damage characteristics of shale under the influence of bedding, but pays less attention to the brittleness characteristics and the analysis of the tendency of rock burst. In the field of geotechnical engineering, AE technology is capable of providing real-time monitoring and early warning for rock dynamic disasters. Recently, the AE waveform spectrum of rocks under loading has gradually attracted the attention of scholars in the field of rock mechanics, and related studies have shown that there is a one-to-one correspondence between the frequency distribution pattern of the AE spectrum and the cracking evolution mechanism, which can effectively explain the micro-damage mechanism of rocks. However, related research is generally focused on coal, marble and sandstone14,15,16,17. So far, there is still a lack of systematic studies on utilizing the AE spectrum characteristics to analyze the comprehensive effect of shale micro-damage under loading. In the process of deep shale reservoir reconstruction, its mechanical properties are the basis for evaluating fracability and crack propagation, as well as an important parameter for subsequent hydraulic fracturing theoretical calculation and rock fracture evolution simulation. In-depth research on the mechanical properties and fracture behavior of anisotropic shale rocks is of great guiding significance for the assessment of borehole stability, hydraulic fracturing and other aspects of underground energy development and design.

Shale uniaxial compression test and analysis

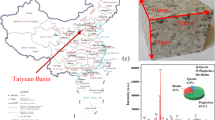

Shale specimen preparation

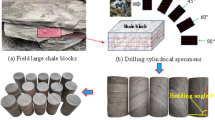

The Sichuan Basin and its surrounding areas play a very important position in China’s shale gas resource exploration and development pattern, with the highest resource and recoverable amount, and is the main battlefield for the strategic development of shale gas resources in the country. Currently, more than 95% of shale gas production comes from the Upper Ordovician Wufeng Formation and Lower Silurian Longmaxi Formation in this region, and these two main purpose formations are highly similar to the geological conditions of the Haynesville Shale in the United States, which is important guarantee for the sustainable development of China’s shale gas industry in the future. The shale samples in this experiment were collected from the outcrop stratum of black shale in Longtou Town, Changning, Sichuan Province. This outcrop is a natural extension of the shale reservoir of the Lower Silurian Longmaxi Formation. The Ning 201 shale gas well, which is 30 km away from this area in a straight line, is the first shale gas well with commercial value in China. Shale gas block of Changning is the earliest national-level shale gas demonstration zone in China. The shale reservoir thickness was between 100 and 500 m, where shales of Upper Ordovician Wufeng Formation and Lower Silurian Longmaxi Formation were widely developed, which has good resource development potential. These shales were formed in deep-water continental shelf sediment controlled by continental margin depression at a depth of 200 m. Shale reservoirs with dark mudstone debris deposition and highly developed bedding structures. The surface of the rock core shows obvious alternating layers of thin and thick layers, rich in biological fossils, and banded pyrite. Other interlayers such as calcium, siliceous, and fossils are interspersed inside. Under CT scanning, the layered structure of shale gray white alternation can be clearly seen, and rock minerals were mainly quartz and dolomite. The content of both was over 70%18. Large shale with clear stratification was selected and brought back to the laboratory (Fig. 1a), and the rock samples used for tests were drilled from the same full-diameter rock to ensure similar physical properties. To ensure the accuracy of the bedding inclination, we mainly prepare cubic shale specimens with bedding, and the angle between the bedding and the horizontal plane of the block is determined by a protractor. During the coring process of the standard specimen, we ensure that the drill bit remains consistent with the horizontal plane of the rock block to obtain shale specimens with different bedding angle (Fig. 1b). The machining accuracy of the sample strictly follows the testing standard of ISRM of the International Society of Rock Mechanics. The flatness of the two end faces is controlled within ± 0.05 mm, and the vertical deviation is controlled within ± 0.25°. The shale specimen of 50 mm*100 mm is prepared, then dried and sealed with plastic wrap.

Test results and analysis

The shale bedding inclination was set to 7 levels: 0°, 15°, 30°, 45°, 60°, 75° and 90°. Uniaxial compression used the MTS 815 rock mechanics test system of the State Key Laboratory of Coal Mine Disaster Dynamics and Control of Chongqing University. The loading pattern is axial displacement control, and the loading rate of displacement was 0.05 mm/min. A suitable amount of grease was applied to the upper and lower ends of the specimen to reduce the friction between the specimen and the indenter (end-effect). During the test, the axial stress, axial strain and circumferential strain were recorded in real time by the computer control system, and the data acquisition frequency was set at 10 Hz.

Influenced by the bedding structure, the mechanical and deformation characteristics of rock exhibited different when subjected to external loads. Figure 2 shows the uniaxial stress–strain curve of shale, and Table 1 shows the related parameters of rock mechanics calculated by the stress–strain curve. It can be seen that the uniaxial strength of shale is very high, the linear elastic stage is relatively long, and it does not show obvious yield characteristics. Moreover, with the sudden and rapid linear drop of post-peak stress in a very short period of time, it does not show residual stress, and the brittleness characteristics are obvious. It is generally believed that the brittle rock is prone to form complex fracture network, and the effect of reservoir fracturing transformation is better. Under different bedding angles, the uniaxial compressive strength of shale ranges from 179.11 to 256.85 MPa, the elastic modulus ranges from 22.31 to 26.37 GPa, and Poisson’s ratio ranges from 0.173 to 0.292. The mechanical parameters of shale have great differences (Fig. 3). The peak strength generally presents a U-shaped change with the increase of bedding angle, exhibiting strong anisotropic mechanical characteristics, mainly because the bedding is a weak plane, and its existence has a significant impact on the mechanical state. The Poisson ratio of shale is larger in the range of 30°–60°, which is due to the partial shear slip along the bedding plane of rock during loading, resulting in large circumference deformation. When θ is near 30°, the rock is most prone to shear slip along the bedding plane, which also reflects the ability of the rock structural plane to resist shear slip14,17,19.

The existence of bedding not only has a significant impact on the strength and deformation of shale, but also has a remarkable influence on the fracture mode. The macro-failure modes of shale under different bedding angles are shown in Fig. 4. It can be found that shale has obvious brittle fracture characteristics and serious fragmentation, mostly showing flaky spalling accompanied by a lot of rock powdery fragments, which is the result of rapid expansion and connectivity of internal micro-cracks inside the rock under the influence of bedding during loading. When shale burst, it emits a “crisp” and violent sound, and a large quantity of debris is ejected rapidly. It shows a strong tendency towards rockburst and is prone to rockburst disaster.

Fracture morphology of shale

Fracture morphology and fracture degree of rock are the essential manifestation of rock deformation and brittleness. The macro-crack morphology of shale is significantly affected by bedding structure. Without lateral constraints, rock will deform freely and spalls outward. The failure pattern of shale under uniaxial compression is shown in Fig. 1. (1) When the bedding inclination is 0°, the shale is mainly damaged by tension splitting along the bedding plane. Multiple micro-cracks are formed along the bedding, and most of them expand and crack into sheets. (2) When the bedding inclination is 15°, the failure mode is shear failure along the bedding plane and a small amount of tensile failure along the axial direction, which is due to the formation of tensile cracks is affected by the sliding of the bedding plane, thus forming a complex crack pattern. (3) When the bedding inclination is 30°, the fracture is shear-slip failure mode along and across the bedding plane. The fracture is relatively complex, and obvious compressive fragmentation and flake spalling phenomena can be seen. (4) When the bedding inclination is 45°, the fracture mode is composite shear tensile damage along and across the weak bedding plane. It can be clearly observed that the large angle inclined fracture plane develops at a certain angle with the weak bedding plane, and the local cracks break into several large pieces along the bedding plane, and the cracks are few and simple. (5) When the bedding inclination is 60° and 75°, the fracture mode of the shale is vertical splitting shear failure through the bedding. The fractures are relatively complex, and multiple oblique shear cracks extend from both sides of the upper part of the sample. (6) When the bedding inclination is 90°, the shale failure is greatly influenced by the matrix. The macro-failure mode is mainly vertical splitting cracks through the bedding plane, and the overall shear failure mode is obvious “V-shaped conical”, accompanied by small rock caving. Because of the high cementation strength of bedding, the influence of bedding on shale break mode is not significant at this time. In summary, under uniaxial compression, with the increase of the bedding angle, the macro-failure mode of shale mainly changes from split-tensile failure along the bedding plane, gradually develops to mixed tensile shear failure, and finally changes to split-shear failure through the matrix and bedding plane.

Brittleness evaluation of shale

Brittleness is one of the very important mechanical properties of rock materials. It refers to the property that rock materials suddenly fail and lose bearing capacity after small deformation under the action of external forces. It directly determines the deformation and fracture mechanical behavior of rocks under stress, which is the key parameter for evaluation of rockburst tendency. The mechanical parameter of shale is an important index to evaluate its brittleness, the poisson’s ratio reflects the rock rupture ability, and the elastic modulus reflects the support ability of rock after rupture. Brittleness controls the fracturing ability of rock reservoirs. Rocks with high elastic modulus and low Poisson’s ratio are strongly brittle and prone to sudden rupture. There are many methods to evaluate rock brittleness, mainly based on rock mineral composition, stress–strain curve, residual stress after peak, etc. In 2008, Rickman proposed an evaluation method to calculate rock brittleness by using rock elastic parameters20, that is, Young’s modulus and Poisson’s ratio obtained from rock mechanics tests were used to calculate rock brittleness index. The results calculated by this method were highly consistent with those obtained from field imaging logging, thereby confirming its effectiveness. For the rock reservoir with small elastic modulus and high poisson ratio, its plasticity (ductility) is strong. As a result, it is difficult to carry out reservoir stimulation. This brittleness index is calculated as follows:

In the formula, B is the brittleness index of the rock, dimensionless; \(E\) is the average elastic modulus, [GPa]; \({\text{E}}_{\text{R}}\) represents the normalized elastic modulus, [GPa]; \(v\) is the average Poisson ratio, dimensionless; \({v}_{R}\) represents the normalized Poisson’s ratio, dimensionless. If B > 40, the rock is brittle; if B > 60, the rock is considered to be strongly brittle.

Shale brittleness, an important indicator of reservoir fracturability, significantly affects the stability of wellbore and hydraulic fracturing effect. It is an important basic parameter for the design of fracturing scheme and also one of the five key evaluation techniques for shale oil and gas selection. Brittleness evaluation is of great significance for shale gas resource development. Rickman et al.20 found through a large number of fracturing tests that the brittleness index of rock affected the fracture pressure and fracture width, however, and the anisotropy of rock structure truly affects the morphology of fracturing cracks. The cracks induced by hydraulic fracturing in shale reservoirs are greatly affected by rock brittleness. Rocks with strong brittleness are prone to fracture, and the hydraulic fracturing cracks are more likely to extend forward and further away. Conversely, the energy required to generate cracks is greater, making it less likely to undergo fracturing. In addition, as the brittleness increases, the initiation pressure of rock crack shows a decreasing trend, indicating that the stronger the brittleness of rock, the easier it is to crack. Furthermore, rock brittleness can increase the turning angle of fractures, enhance the possibility of hydraulic fractures turning and extending along natural fractures, and make it easier to form complex crack network21, which has been found in experiments and numerical simulations22. Shale contains a large number of quartz, calcite and other brittle minerals. Under external loading, it is very easy to have brittle failure and form cracks, which is conducive to improving the permeability of the reservoir.

The fracture of rock is closely related to its brittleness index, and for rocks with high brittleness, the reservoir can rupture even with low displacement during fracturing. Evans defined material failure with deformation less than 1% as brittle, 1–5% as brittle ductile transition, and greater than 5% as ductile23. According to the stress–strain curve of shale obtained from the test, both axial and radial strains of the sample are about 1%, which indicates that shale has obvious brittleness characteristics under uniaxial compression10. According to the elastic modulus and poisson’s ratio obtained by uniaxial mechanical test, the brittleness index of this region can be calculated as 45.59. The greater the B value, the stronger the brittleness is. High brittleness is one of the necessary conditions for the formation of fracture networks during hydraulic fracturing. Practice has shown that formations with higher brittleness are easier to fully transform during fracturing, leading to the formation of complex crack network. Fracturing experience of shale in North America shows that reservoirs with B value greater than 40 have frackability. For rock reservoirs with brittleness index greater than 50, complex fracture networks are easy to form20, indicating that the shale in this region has strong brittleness, which is conducive to reservoir fracturing reform.

AE characteristics of shale under uniaxial loading

AE evolution characteristics of shale

Rock deformation and failure are often accompanied by energy release. The AE signal released during rock loading contains important information about its internal damage and failure mechanism. The stress inside the rock is relaxed during the deformation process, and the energy stored in the rock is released in the form of elastic waves. AE is based on this principle to analyze the change process of crack initiation, expansion and damage inside the rock, which can be used to analyze the progressive damage process, evaluate the degree of damage, and determine the type of rock failure24,25. The AE monitoring equipment used the American PCI-2 multi-channel AE signal acquisition system, the threshold value was set to 40 dB. AE parameters such as the number of events, impact, and energy during the loading process were monitored in real time and the entire process was evaluated at an acquisition frequency of 0.5 Hz. The AE probe was coupled with the rock surface with vaseline to improve the signal quality, and was symmetrically fixed on both sides of the specimen with tape to reduce the end effect and energy loss of the specimen.

There was a one-to-one correspondence between the distribution pattern of AE spectrum and the evolution of rock cracks, and this characteristic can essentially reveal the process of internal crack propagation and development in rocks, can be used to predict rock bursts and analyze the mechanism of rock micro-damage. AE ringing count refers to the frequency of signal deviation beyond AE threshold, which can reflect the active degree of rock crack propagation. The AE energy reflects the release rate of energy inside the rock, and both of them can accurately reflect the fracture characteristics inside the rock under loading. Figure 5 shows the changes of axial stress, cumulative ringing count and absolute energy with time during shale uniaxial compression under different bedding angles. It can be observed that all specimens exhibit significant AE phenomena, and the changes of AE characteristics correspond well with the deformation and failure process of the rock. According to the AE characteristics of the specimen, the process can be divided into four stages. During the compaction and elastic deformation stages, AE is in a relatively long quiet period, AE energy and count are at a low level, and the cumulative ringing count is small and sparse. This is because the shale is dense, cracks are not closed much when subjected to external loads, and energy consumed by shale deformation is stored in the form of elastic energy, thereby resulting in less AE activities. With load further increases, the damage stage of microcrack development and stable expansion is entered, and the AE energy and ringing count both increase rapidly. At this time, macro-crack in shale begins to germinate and expand. During this process, a major portion of energy is released through dissipated energy, and the accumulated energy rises slowly. When entering the crack unstable growth stage (i.e., the yield stage), with the increase of the load, the elastic energy stored inside the rock is instantaneously released. In a short time, the AE energy and cumulative ringing count exhibit a step explosive exponential rise and are accompanied by the generation of ultra-high frequency signals. The AE signal is most significant when the load drops, indicating that the rock has been severely damaged and the cracks inside the rock have germinated, expanded, and penetrated, demonstrating a strong burst tendency of shale. Since the yield stage of the sample is very short and brittle, it undergoes macroscopic fracture and completely destroyed when reaching peak stress and there is no obvious post-peak deformation, so there is no AE signal after the peak.

Fracture mechanism of shale

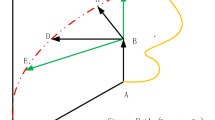

Rock rupture can be divided into two types: tension crack and shear crack, and the failure mechanism of rock crack can be analyzed by AE waveform parameters. AE waveform parameters include AE count, amplitude (A), rise time (RT) and duration (Fig. 6a). Rock cracks can be divided into tensile cracks and shear cracks by using the distribution characteristics of AE parameters AF and RA (Fig. 6b). The effectiveness of this classification method has been validated by the results of moment tensor inversion26, providing a pathway for identifying rock failure processes and mechanisms under complex stress conditions. The calculation methods of AF and RA values are shown in formula (4) and formula (5), respectively16,27. The region above the diagonal corresponds to the tension crack, while the region below the diagonal corresponds to the shear crack27, and this relationship is based on a large number of experiments and statistical analysis of data16. The RA value is the ratio of the rise time to the amplitude, measured in μs/mV, while the AF value (average frequency) is the ratio of the AE count to the duration, measured in kHz.

Typical AE parameters: (a) AE waveform; (b) classification of tensile and shear cracks; (c) tensile events; (d) shear events27.

The microcracks inside rocks can be simplified into tensile cracks (Type I) and shear cracks (Type II), and the formation process of these two types plays an important controlling role in macroscopic rock rupture. AE waveform contains rich information of rock mechanical state. Due to the different propagation speeds of longitudinal wave (tension) and shear wave (shear), AE waveform parameters can evaluate rock fracture mode to a certain extent (Fig. 6b). The tensile mode of the crack is mainly the opposite movement on both sides of the crack, resulting in a short rise time and high frequency of AE waveform. The waveform has the characteristics of burst signal and will release a large amount of energy instantaneously (Fig. 6c). On the contrary, the shear pattern of cracks generally results in longer waveforms, lower frequencies, and relatively long rise times (Fig. 6d), mainly due to the slower propagation speed of shear waves28. Therefore, tensile cracks exhibit lower RA and higher AF, while shear cracks exhibit higher RA and lower AF. Through these two parameters, the fracture mechanism of rocks can be quantitatively analyzed29.

For different types of rocks, the dividing line between tension and shear cracks is different. In this study, the ratio in shale was set as 200:1 according to previous studies by scholars as the reference line for crack classification30. Figure 7presents the scatter diagram of RA–AF value distribution of shale. It can be seen that the spatial distribution characteristics of all data points in the diagram are basically the same. On the whole, the distribution points of AF and RA values of AE are concentrated near the origin and have a wide distribution range (RA values are 0–10 ms/V and AF values are 0–500 kHz). RA/AF values are distributed in both shear and tension regions, indicating that both rock tension and shear failure occur under loading, and AF values of most data points are below 300 kHz and low RA values (less than 3 ms/V). In other words, the data points are mainly concentrated on high RA and low AF, indicating that shear cracks are dominant, while tensile cracks are relatively less, suggesting that shale will produce relatively more shear cracks and fewer tensile cracks under uniaxial loading, leading to a failure mode dominated by shear, which is basically consistent with Yao’s research results31.

By determining the crack pattern, the ratio of tension crack and shear crack can be calculated. Figure 8shows the percentages of the two kinds of cracks under uniaxial load at different bedding angles of shale. It can be found that shale bedding has a significant impact on the ratio of tensile or shear failure, and the proportion of tensile failure is lower than that of shear failure under different bedding angles of shale, which is similar to that in uniaxial compression conditions as reported by Zhang and Deng26. Furthermore, the proportion of tensile failure decreases first and then rises with the increase of bedding angle, because the existence of bedding leads to more shear failure. This is because the presence of bedding leads to more shear failure. The mineral composition in shale is not uniform, and the coupling strength between crystals is different, which leads to different generation mechanisms of tensile and shear cracks. The micro-cracks in the process of tensile failure mainly propagate along the surface of the internal microstructure, so the tensile cracks are mainly intergranular cracks. In the process of shear failure, there are both intergranular cracks and transgranular cracks32. Therefore, under the same conditions, the elastic strain energy released by shear crack is greater than that by tension crack. The morphology of the specimen after rupture can also reflect the fracture mechanism of the rock. As can be seen in Fig. 4, a large number of cracks formed by shear failure can also be observed. And there is a high consistency between crack type discrimination based on AE signals and rock failure modes. In addition, we also observed that some rock powder was formed during the rock failure process, which further indicates the existence of friction sliding between rock shear fractures.

Conclusion

In this paper, uniaxial compression and AE tests of shale under different bedding angles are carried out. The anisotropic mechanical properties, macro-failure modes, brittleness index and AE evolution characteristics of shale are analyzed, and the failure mechanism of shale is analyzed based on the AE waveform parameter RA–AF value. The main conclusions are as follows:

-

(1)

The uniaxial compression strength, deformation characteristics and failure modes of shale show obvious anisotropy under different bedding angles. The uniaxial compression strength in vertical bedding direction is greater than that in parallel bedding direction, and shows a U-shaped trend, manifesting a strong rockburst tendency.

-

(2)

The crack mode of shale under uniaxial loading is relatively complex, and it is closely related to the bedding angle. Macroscopically, it shows a transition from a shear-tension failure along the bedding plane to a mixed shear-tension failure, and finally to a shear-tension failure that penetrates the matrix and bedding plane. The Rickman brittleness index is 45.59, which shows strong brittleness characteristics and is easy for reservoir fracturing and modification.

-

(3)

AE signals can reflect the microscopic damage evolution characteristics of shale under uniaxial loading to some extent, and the changes of AE signals have a good correspondence with the deformation and failure process of rock. The proportion of tensile and shear failure modes of shale under uniaxial loading can be identified using the RA–AF crack classification criteria based on AE waveform parameters. As a whole, uniaxial compression of shale is mainly dominated by shear failure, and the proportion of shear failure increases firstly and then decreases with the increase of bedding angle.

Data availability

The datasets used and/or analysed during the current study available from the corresponding author on request.

References

Cho, J. W., Kim, H., Jeon, S. & Min, K. B. Deformation and strength anisotropy of Asangneiss, Boryeong shale, and Yeoncheon schis. Int. J. Rock Mech. Min. Sci. 50(2), 158–169 (2012).

Chen, H., Di, Q. Y., Zhang, W. X., Li, Y. & Niu, J. R. Effects of bedding orientation on the failure pattern and acoustic emission activity of shale under uniaxial compression. Geomech. Geophys. Geo. 20, 7 (2021).

Zhao, B. Y., Li, Y. F., Huang, W., Wang, X. P. & Chen, C. Experimental study on mechanical properties of shale rock and its strength criterion. Arab. J. Geosci. 14(4), 264 (2021).

Wang, Y. S. et al. Correlating mechanical properties to fractal dimensions of shales under uniaxial compression tests. Environ. Earth Sci. 82, 2 (2023).

Dou, F. K., Wang, J. G. & Leung, C. F. The impacts of bedding strength parameters on the micro-cracking morphology in laminated shale under uniaxial compression. Appl. Sci. 10, 5469 (2020).

Liu, Y., Ma, T. S., Wu, H. & Chen, P. Investigation on mechanical behaviors of shale cap rock for geological energy storage by linking macroscopic to mesoscopic failures. J. Energy Storage 29, 101326 (2020).

Huang, B. X., Li, L. H., Tan, Y. F., Hu, R. L. & Li, X. Investigating the meso-mechanical anisotropy and fracture surface roughness of continental shale. J. Geophys. Res.-Solid Earth 125, 017828 (2020).

Wang, Y. & Han, J. Q. Geomechanical and ultrasonic characteristics of black shale during triaxial deformation revealed using real time ultrasonic detection dependence upon bedding orientation and confining pressure. Geotech. Geol. Eng. 38, 6773–6794 (2020).

Fan, X. R. et al. Dynamic breakage characteristics of shale with different bedding angles under the different ambient temperatures. Rock Mech. Rock Eng. 54(6), 3245–3261 (2021).

He, J. M. et al. Efect of strain rate on anisotropic mechanical behavior of the shale under uniaxial compression conditions. Rock Mech. Rock Eng. 55, 5297–5305 (2022).

Kim, H., Cho, J. W., Song, I. & Min, K. B. Anisotropy of elastic moduli, P-wave velocities, and thermal conductivities of Asan Gneiss, Boryeong Shale, and Yeoncheon Schist in Korea. Eng. Geol. 148(5), 68–77 (2012).

Si, X. F., Huang, L. Q., Li, X. B., Gong, F. Q. & Liu, X. L. Mechanical properties and rockburst proneness of phyllite under uniaxial compression. Trans. Nonferr. Metal Soc. 31(12), 3862–3878 (2021).

Sun, Z. H., Li, M. H., Yuan, S., Zhou, F. J. & Fei, R. J. The effect of the fracture geometries from different stratification angle on the imbibition recovery of Jimusar shale oil: A comprehensive experimental study. Geoenergy Sci. Eng. 229, 212067 (2023).

Li, L. R., Deng, J. H., Zheng, L. & Liu, J. F. Dominant frequency characteristics of acoustic emissions in white marble during direct tensile tests. Rock Mech. Rock Eng. 50(5), 1337–1346 (2017).

Liu, H. X., Jing, H. W., Xu, X., Yin, Q. & Zhang, L. Study on mechanical and fracture characteristics of inclined weak-filled rough joint rock-like specimens. Theor. Appl. Fract. Mech. 125, 103660 (2023).

Hou, P. et al. Infuence of liquid nitrogen freeze–thaw cycles on mechanical behaviors and permeability properties of coal under diferent confning pressures. Rock Mech. Rock Eng. 57, 2625–2644 (2024).

Li, X., Duan, Y. T., Li, S. D. & Zhou, R. Q. Study on the progressive failure characteristics of longmaxi shale under uniaxial compression conditions by X-ray micro-computed tomography. Energies. 10(3), 303 (2017).

Zhang, Y. F., Zhao, Y., Long, A. F., Wang, C. L. & Bi, J. Combined effects of bedding anisotropy and matrix heterogeneity on hydraulic fracturing of shales from Changning and Lushan, South China: An experimental investigation. J. Asian Earth Sci. 259, 105908 (2024).

Wang, X. L., Zhao, Y. X., Jiang, Y. D., Liu, B. & Teng, T. Anisotropic characteristics of crack initiation and damage thresholds of deep black shale in Longmaxi formation. J. China Coal Soc. (in Chinese with English abstract). 46(s1), 231–240 (2021).

Rickman, R., Mullen, M., Petre, E., Grieser, B. & Kundert, D. A practical use of shale petrophysics for stimulation design optimization: All shale plays are not clones of the barnett shale. In SPE Annual Technical Conference & Exhibition (2008).

Zhang, J. Study on the effect of reservoir rock’ brittleness on initiation and propagation mechanism of hydraulic fracture. Northeast Petroleum University (in Chinese with English abstract) (2019).

Feng, H. X. Characterization of rock local brittleness and study on fracture propagation mechanism of hydraulic fracturing in dense rock mass. Northeast Petroleum University (in Chinese with English abstract) (2022).

Evans, B., Fredrich, J. T. & Wong, T. F. The brittle-ductile transition in rocks: Recent experimental and theoretical progress. In The Brittle-Ductile Transition in Rocks Vol. 56 1–20 (American Geophysical Union, 1990). https://doi.org/10.1029/GM056p0001.

Huang, L. Q., Guo, Y. D. & Li, X. B. Failure characteristics of shale after being subjected to high temperatures under uniaxial compression. Bull. Eng. Geol. Environ. 81, 33 (2022).

Zhao, T. B. et al. Master crack types and typical acoustic emission characteristics during rock failure. Int. J. Coal Sci. Technol. 10(1), 73–86 (2023).

Zhang, Z. H. & Deng, J. H. A new method for determining the crack classification criterion in acoustic emission parameter analysis. Int. J. Rock Mech. Min. Sci. 130, 104323 (2020).

Li, Z. Z. et al. Damage evolution of rock salt under multilevel amplitude creep–fatigue loading with acoustic emission monitoring. Int. J. Rock Mech. Min. Sci. 164, 105346 (2023).

Aggelis, D. Classification of cracking mode in concrete by acoustic emission parameters. Mech. Res. Commun. 38, 153–157 (2011).

Yachen, X., Hou Michael, Z. & Cunbao, L. Anisotropic characteristics of acoustic emission and the corresponding multifractal spectrum during progressive failure of shale under cyclic loading. Int .J. Rock Mech. Min. 165, 105364 (2023).

Dong, L. J., Chen, Y. C., Sun, D. Y. & Zhang, Y. H. Implications for rock instability precursors and principal stress direction from rock acoustic experiments. Int. J. Rock Mech. Min. Sci. 31(5), 789–798 (2021).

Yao, Q. L., Chen, T., Tang, C. J., Sedighi, M. & Huang, Q. X. Influence of moisture on crack propagation in coal and its failure modes. Eng. Geol. 258, 105156 (2019).

Dong, L. J. et al. Uncertainty investigation for the classification of rock micro-fracture types using acoustic emission parameters. Eng. Fract. Mech. 162, 105292 (2023).

Acknowledgements

This work was supported by the Science and Technology Project of the Education Department of Jiangxi Province (No.GJJ2200871), Doctoral Scientific Research Foundation of Jiangxi University of Science and Technology (No.205200100605), the National Natural Science Foundation of China (No. 52204219 and 52304224), the Natural Science Foundation of Sichuan Province (No.2024NSFSC0971), the China Postdoctoral Science Foundation (No.2021M691390), the Innovation and Entrepreneurship Science and Technology Project of Chinese Institute of Coal Science (No.2021-KXYJ-005) .

Author information

Authors and Affiliations

Contributions

Z.S., L.Z. and C.J. wrote the main manuscript text; Q.L., L.Z. and D.L. prepared Figs. 1–8; All authors reviewed the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Shen, Z., Zhang, L., Lin, D. et al. Study on anisotropic mechanics and acoustic emission response characteristics of layered shale under uniaxial compression. Sci Rep 15, 11317 (2025). https://doi.org/10.1038/s41598-025-88832-5

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-88832-5