Abstract

In the Guxu mining area, the mining of thin coal seams is complicated by the unknown migration structure of the roof overburden and severe mine pressure. Based on this, taking the 1599 working face as the research background, and using a method that combines theory with simulation, starting from the structural fracture of roof overburden rock in thin coal seams, the roof failure characteristics during the mining process are studied, and the roof caving shape and stress distribution characteristics under the influence of mining speed are studied is explored. The research results show that a cantilever beam with a short length forms in the overburden rock of the soft bedrock roof during thin coal seams mining. The roof strata 2,5 and 10 of the 1599 working face control the local overburden activity respectively. After fracture, the pressure increases obviously, and with the collapse of the upper strata controlled by it, the pressure phenomenon occurs in the working face. For thin coal seams, the peak value of supporting stress is slightly smaller than that of medium-thick coal seams, but the peak point of supporting stress is closer to the coal wall. When the advancing speed increases, the length of the cantilever beam will increase, the maximum stress concentration factor and the advance influence range will also increase, but the peak value will shift to the deep part. Therefore, the rapid advance will make the front high stress area away from the working face, and the slow advance will cause the roof overburden pressure relief time to become longer. For the composite bearing layer structure, the acceleration of the advancing speed will cause the bearing performance of the lower bearing layer to be weakened and the bearing performance of the upper bearing layer to be enhanced.

Similar content being viewed by others

Introduction

The coal resources in Southwest China are mostly inclined coal seams. Among them, thin coal seams are widely distributed in more than 80 mining areas, with a total of more than 750 mines. The industrial reserves are abundant, up to 9.83 billion tons, and the recoverable reserves account for about 20% of the total recoverable reserves1,2,3,4. However, the occurrence conditions of such coal seams are generally poor, the mining technology is more complex, and the mine pressure behavior is easily affected by external factors, resulting in the phenomenon of ' thin abandonment ' in various mining areas, causing a great waste of coal resources5,6. China ‘s coal resources have emerged. Backup shortage and imbalance of storage and mining ratio7,8. At the same time, as coal mining gradually enters the intelligent stage, such difficult-to-mine coal seams also need to enter the ranks of safe and efficient mining9,10. Therefore, it is an important way to study the law of mine pressure behavior and the influence of mining speed in inclined thin coal seams for improving the recovery rate of coal resources.

In view of the characteristics of mine pressure behavior and the influence of advancing speed in thin coal seams, many scholars have conducted certain research on this. ZHANG and JIANG11,12 found that the pressure of thin coal seams roof is a single elastic distribution, and the peak value is close to the coal wall. SUN13 believed that unlike others coal seams, due to the limitation of goaf space, the roof fracture of thin coal seams is mainly manifested as shear slip instability and collapse. YU and HE14,15 found that in the mining of thin coal seams, the roof control distance is positively correlated with the mining risk coefficient, When mining, the roof can be weakened by pre-splitting to reduce the roof hanging area, and the dynamic load disturbance of coal stress concentration and roof breaking can be reduced. Fu16 revealed the behavior law of roof strata in thin coal seam working face by comparing the control effect of two different support forms on roof. JIA17 found that the filling mining technology in thin coal seams can effectively reduce the advanced influence range and stress peak, and the stability time of overburden strata in goaf will be shortened, and there is no caving zone and obvious fault zone. HAN and DENG18,19 believed that the mining speed is an important factor affecting the mine pressure and overburden movement. The increase of the mining speed will cause the increase of the weighting step of the main roof, and the roof settlement, fracture angle and roof rotation angle and displacement decrease. Zhao20 found that the increase of advancing speed will cause the distribution height of ' three zones ' of roof overburden to decrease, the average weighting step increases, and the development range is small. Li21 found that the higher the mining speed, the smaller the development opportunity of the micro-cracks in the hard roof, which leads to the increase of the tensile strength of the roof overburden rock. CUI22 found that the energy released by the rock during this process is proportional to the mining speed through microseismic tests, and established a loading and unloading response ratio considering the mining speed and stop time.JIA23,24found that the increase of advancing speed will lead to the combination of dynamic and static loading of coal body at the same time. The peak stress, plastic failure zone and elastic energy under high speed advance are obviously larger, and the probability of dynamic disaster of surrounding rock will also increase. Yu25 studied the influence of mining speed on the deformation and energy release of overlying strata. It was found that the increase of mining speed would prolong the fracture distance of the main roof, and the rapid mining would increase the energy and frequency of overlying strata crushing. WANG26 found that the advancing speed will cause the subsidence and rotation angle of the key block to decay in an approximately negative exponential relationship, thereby increasing the degree of extrusion between the rock blocks and the horizontal thrust, which is conducive to controlling the sliding instability of the key block.

The above studies have carried out meaningful work on the influence of mine pressure law and mining speed in nearly horizontal thin coal seams. However, there are few studies on the structural evolution of soft bedrock roof overburden and the influence of advancing speed on the law of rock pressure in thin coal seams. Therefore, this paper starts with the fracture characteristics of soft bedrock roof, analyzes the failure characteristics of roof overburden rock in the process of thin coal seams mining, and studies the influence of advancing speed on the structural evolution of roof, in order to provide insights for mines with similar mining conditions.

Engineering situations

The Guxu mining area in Sichuan belongs to the typical gently inclined thin coal seams in the southern Sichuan coalfield in China, and the thickness of the main coal seam is generally about 1.0 m. For a long time, owing to the special occurrence conditions and slow mining speed, the working face exhibits the characteristics of mine pressure behavior of “small mining height but rapid pressure and intense mine pressure”. Taking the 1599 working face as an example, the average thickness of the coal seam is merely 1.2 m. However, due to the poor roof and floor conditions, since the commencement of formal mining, the roof pressure of the working face has been con-tinuously and significantly increasing. Roof breakage and caving phenomena have occurred. The pressure range is large and the occurrence time is short, which leads to difficulties in the large-scale passage of the hydraulic support. As a result, problems such as roof cutting, support crushing, coal wall spalling, end face leakage and caving arise, and water disasters in the roof of the working face are caused. Relevant research shows that27,28, appropriately increasing the advancing speed can improve the roof stability to a certain extent, but the insufficient research on the internal relationship between the advancing speed and the activity law of the roof strata in the inclined thin coal seams will also affect the mine production.

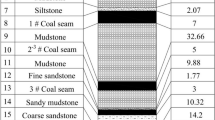

The 1599 working face mainly mines C19 coal seam in Guxu mining area, with an average dip angle of 14 °, an average coal thickness of 1.2 m, and a mining height of 1.4–1.6 m. It is an intelligent working face for the key construction of the mine. The working face adopted the intelligent comprehensive mechanized longwall backward mining method (two-way automatic memory coal cutting of shearer), and installed ZY4000 / 08 / 18 D shield hydraulic support with the center distance of 1.75 m. The overburden strata of the coal seam are mainly sandstone and sandy mudstone, and the geological boreholes are columnar as shown in Fig. 1 (a). The results of borehole peeping in 1599 air roadway are shown in Fig. 1 (b). The hole wall at 2.73 m of the roof is seriously broken, and a large number of cracks of different degrees are bred. There are more cinders at 4.67 m and 4.95 m, and there are different degrees of longitudinal cracks. There are obvious circumferential cracks in the hole wall at 7.25 m. If the roof is not properly controlled, the location of obvious circumferential cracks will face the risk of roof separation.

Based on the theory of key strata29, it can be seen that it will control the activity of all strata in the overburden strata of the stope or up to the surface, which are usually thicker than other similar lithologic strata, and the strength is greater than other strata. However, for the 1599 working face, the overburden rock is mostly sandy mudstone, and there is no obvious key stratum in the traditional definition. During the mining period, due to the unknown law of overburden caving, unlike the traditional thin coal seams, although the average mining height is only 1.5 m, the pressure is relatively rapid, and the support resistance increases sharply, resulting in serious roof caving, roof cutting and support pressing, coal wall spalling and other strata control problems, as shown in Fig. 1 (c). Therefore, it is urgent to grasp the evolution of roof structure in inclined thin coal seams mining, and to clarify the characteristics of overburden fracture instability and the law of mine pressure. At the same time, the reasonable advancing speed is determined to ensure the safe mining of coal seam.

Material and models

Physical similarity Simulation

As shown in Fig. 2, the similar material test was conducted on a test bench with length × width × height = 3000 × 200 × 1800 mm, and the similarity ratio was determined based on the similarity law (geometry : C1 = 1 / 50; bulk density: Cγ = 0.64; stress : Ca = C1Cγ = 0.0128; time : Cr = C11/2= 0.1414). To minimize the impact of boundary effect, 300 mm boundary coal pillars are retained on both sides of the model along the strike direction.

The excavation height of the model is 30 mm, and the open-off cut is arranged on the left side with a width of 60 mm (representing the actual width of 3 m). In the process of simulation, cyclic excavation is carried out from left to right. The test uses river sand as aggregate, and gypsum, white powder and mica powder as bonding materials and layered materials. The specific model parameters and material matching are shown in Table 1.

Because there are many rock strata in the roof overburden rock, in order to facilitate the clear description of the roof breaking characteristics, the overburden rock is numbered, and the direct jacking is 1–16 respectively.

Numerical Simulation Experiment Model

The 3DEC discrete element software is used for numerical simulation. The model size is 140 m × 105 m × 140 m (X × Y × Z), as shown in Fig. 3. The model simulates the mining dip angle of 15 °.There are displacement constraint boundaries around the model and fixed support boundaries at the bottom. An equivalent uniform load of 7.5 MPa is applied to the upper surface of the model. The parameters of each layer of the model are shown in Table 2.

In the simulation scheme, three advancing speed levels are set up, which are 4 m / d, 4.8 m / d and 8 m / d, corresponding to 5 knives / d, 6 knives / d and 10 knives / d respectively (the cutting depth footage is 0.8 m). Due to the grid accuracy of the calculation model, 4.8 m / d is approximately used as 5 m / d for mining.

Theory

Roof pressure distribution characteristics of thin coal seams

The surrounding rock stress before and after the goaf will be redistributed with the coal seam mining, forming the abutment pressure zone. According to the limit equilibrium condition30, the stress distribution in the inelastic region can be obtained as follows:

If the σy of the limit equilibrium zone is equal to the bearing pressure of the elastic zone, the distance x0 from the coal wall is the width of the inelastic zone12 :

In the formula, σy is the bearing pressure, N0 is the residual strength, taking 60% ~ 80% ; f is the interlayer friction coefficient ; x is the distance from the coal wall ; m is the mining height ; φ is the internal friction angle of coal ; γ is the maximum stress concentration factor ; q is the original rock stress.

From the expression (1) ~ (2), it can be seen that the peak value of abutment pressure in the inelastic zone and the width of the inelastic zone are positively correlated with the mining height. The peak value increases with the increase of mining height, and the distance between the peak point and the coal wall also increases gradually, as shown in Fig. 4.

Therefore, due to the small mining height of the thin coal seams, the peak point of the supporting stress is close to the coal wall. In order to protect the normal mining, the advanced stress concentration area should be transferred to the deep part to ensure that there is a sufficient range of pressure relief protection zone in front of the working face.

Effect of advancing speed of roof Overburden structure

During the mining of thin coal seams, the rock layer at the coal wall will form a ' short cantilever beam ' structure. From the previous text, it can be seen that the peak point of advanced stress in the thin coal seams is close to the coal wall, causing the short cantilever beam structure to quickly cut off, affecting the normal mining. The change of advancing speed will change the stress environment and stress time of the roof, which makes the movement and failure of the roof strata have obvious time effect30,31,32.

For the convenience of analysis, the cantilever beam structure model formed above the coal wall is shown in Fig. 5.

Assuming that the working face is advancing at a constant speed, the length of the cantilever section x2 is approximately the time function of the advancing speed v and the mining time t:

The maximum advance abutment pressure concentration factor is expressed as33 :

Let 1 + sinφ / 1-sinφ = ζ, by substituting formula ( 4 ) into formula ( 2 ), we obtain:

In the formula : δ is the attenuation coefficient of bearing pressure, take 0.23.

The comprehensive expression (3) ~ (5), when the advancing speed increases, the length of the cantilever beam will increase in a single caving period of the main roof. The peak value of the advanced stress will increase, the distance between the peak point and the coal wall will increase, and the advanced influence range will increase, as shown in Fig. 6.

In summary, for thin coal seams, the stress peak point is closer to the coal wall. When the advancing speed is accelerated, the cantilever length will increase significantly, the peak stress concentration factor and the distance between the stress peak point and the coal wall will increase, and the influence range of the advanced supporting stress will increase, so that the peak stress position will shift to the deep.

Results

Failure characteristics of soft bedrock roof in thin coal seams

The Caving form of roof Overburden Rock

As shown in Fig. 7, the roof overburden rock gradually breaks and collapses with the mining of the working face. According to the collapse form of the roof overburden rock, the mining process is divided into four stages.

Initial stage: this stage is the direct roof (rock 1) caving stage. Due to the sufficient space in the goaf, the fractured rock blocks cannot form an articulated structure, and are distributed in a massive tiled distribution in the goaf .

The second stage: this stage is the caving stage of rock strata 2 ~ 4. Due to the small mining height, the fracture rock block of the immediate roof quickly plays a supporting role in the filling degree of the goaf, and the fracture rock block begins to appear as a ' masonry beam ' structure. At this stage, the rock layer 2 ~ 4 simultaneously breaks and collapses, and is limited by the space of the goaf. The fracture development of the upper rock layer is not obvious, and the fracture morphology of the roof rock layer at the coal wall is ' trapezoidal ' distribution.

The third stage: this stage is the collapse stage of rock stratum 5 ~ 9. With the complete cutting of rock strata 2 ~ 4, rock strata 5 first formed a continuous ' voussoir beam ' structure, and the roof strata at the coal wall formed a ' cantilever beam ' structure with different lengths. Since then, rock strata 6 ~ 9 also broke synchronously in a short time, forming a common bearing structure with rock strata 5. The overburden rock at the coal wall is distributed in a ' ladder-like ' distribution after the fracture, and the top of the fractured rock layer in the goaf and the upper rock layer form a sepa-ration fracture.

The fourth stage: this stage is the collapse stage of rock strata 10 and above. As the rock layer 5 ~ 9 breaks and completely loses its bearing capacity, the rock layer 10 breaks, and the upper rock layer is displaced as a whole, and the separation cracks in the vertical direction gradually become smaller. The caving form of the overburden rock is ' stepped ' distribution, and there is a large fracture line in front of the coal wall, and the space of the overburden rock separation layer is narrowed.

As shown in Fig. 8, the ' stable structure-fracture instability ' process of rock strata 2,5 and 10 controls the overburden strata activity of the roof at different stages of working face mining. In this process, the short cantilever rock beam formed by the overburden strata and the strata 2,5 and 10 gradually breaks as a whole. In summary, in the early stage of soft bedrock thin coal seams mining, the space range of the goaf is small, and the soft bedrock roof is easy to collapse, and the goaf will be completely filled in a short time. In the middle stage, the relatively hard rock strata in the roof overburden are broken at different stages. Under the restriction of the friction force of the sur-rounding rock on the other side, a stable ' beam ' structure with integrity is formed to continue to play a bearing role. In the later stage of mining, after the uppermost relatively hard rock layer in the roof overburden is destabilized, the overburden collapse and longitudinal cracks gradually spread to the surface.

In summary, the roof overburden of soft bedrock thin coal seams mining will form a short cantilever beam structure, and due to the slow advancing speed, the weak overburden has sufficient time to relieve pressure and fully collapse, resulting in the support to bear the full weight of the caving overburden at the coal wall, which is prone to the phenomenon of support crushing.

Distribution characteristics of Abutment pressure

The distribution curve of roof abutment pressure when the working face advances at different distances is shown in the Fig. 9 (the upper figure is a 3D surface figure, and the lower figure is a horizontal projection figure).

As shown in Fig. 9, there are three times of obvious advance abutment pressure increase in the process of mining. When advancing 55 cm, the abutment pressure increases obviously for the first time, the peak value is 275.1 N, which is located at 8 cm in front of the working face. When advancing 88 cm, the abutment pressure rises again, the peak value is 352.8 N, and the peak point moves far to 11 cm in front. When advancing 115 cm, the abutment pressure surges again, the peak value is 443.0 N, and the peak point moves closer to 8 cm again, as shown in the Table 3.

According to the previous research, when the rock strata 2,5 and 10 are completely broken and collapsed, the bearing pressure increases significantly. With the collapse of the rock strata above it, the pressure phenomenon appears on the working face. The peak point of stress will be far away from the working face with the fracture of rock stratum 5, until the rock stratum 10 is cut backward and moved closer again, but the peak influence range remains basically unchanged. Therefore, it is considered that the rock strata 2,5 and 10 play a controlling role in the local rock strata activity of the stope, and different structural forms are used as the bearing body of the control area before and after the fracture.

Migration Law of roof Overburden Rock

Coal seam mining causes the fracture and instability of overburden strata, resulting in vertical subsidence of the roof and vertical displacement. The trend of displacement (negative downward) at different advancing distances is shown in Fig. 10 (the upper figure is a 3D surface map, and the lower figure is a horizontal projection map).

As depicted in Fig. 10 (a), advancement of the working face by 55 cm was accompanied by sharp sinking of the rock stratum 2 (fine sand rock stratum), indicating whole-rock stratum breakage and the initial pressure of the working face. Thereafter, the rock stratum displacement developed in the direction of advancement, with a maximum subsidence of 25 mm reached in the middle. The goaf was in a stable state, compacting from left to right.

Figure 10 (b) shows the change trend of rock stratum 5 and its controlled rock stratum. In the figure, the subsidence of the left and right ends is zero, and the subsidence in the middle increases gradually, and the subsidence in the middle of the rock layer increases with the advance of the working face, indicating that the middle of the rock layer first enters the stable state of compaction, and then gradually compacts to the right. The roof subsidence curve is in a ' concave ' shape as a whole, showing a sharp decline-stability (maximum subsidence) -sharp rise-stability (zero value).

In summary, during the mining process, the rock layer 2 is unstable and fractured, the abutment pressure distribution zone moves with it, and the roof weighting phenomenon occurs with the roof sinking by a large margin. At the same time, the goaf is almost completely filled, and the broken rock block is almost completely compacted, which leads to the limited displacement of the broken body of rock stratum 5 in a narrow space, and its displacement is greatly reduced compared with that of rock stratum 2. Therefore, rock layer 2 can be regarded as the main control rock layer for the caving deformation of roof overburden in 1599 working face.

Roof Migration characteristics under different advancing speeds

The Caving form of roof Overburden Rock

The failure modes of roof overburden under different advancing speeds are obtained as shown in Fig. 11. The roof of the goaf will gradually collapse, sink, horizontal migration and fracture under the combined action of its own gravity and horizontal stress, until it forms a balance state again, and the overburden fractures show dynamic development. Part of the cracks are re-compacted and closed, and the development range of some cracks gradually expands above the goaf. The extended cracks are divided into transverse separation fracture cracks and vertical fracture cracks.

When advancing slowly, the overburden strata of the goaf are broken in turn, the rock blocks are hinged each other, and the ‘masonry beam’ structure is formed, as shown in Fig. 11 (a). When advancing 16 m, the roof of the goaf bends and sinks, showing a ' concave ' shape, in contact with the floor. There are obvious transverse cracks in the overburden rock, and longitudinal cracks appear in the direct roof at the leading position. Since then, the subsidence degree of the roof in the excavation has remained unchanged, and it is still in contact with the floor. The cracks in the roof overburden have increased significantly, and are mainly distributed near the coal wall, and the height of crack development has gradually increased.

When the normal speed is advanced, the roof of the goaf is ‘exposed structure’ in the initial stage, and the degree of bending subsidence is obviously smaller than that when the advancing speed is 4 m / d. After that, the degree of roof subsidence in the goaf gradually increases and gradually contacts with the floor, as shown in Fig. 11 (b). When advancing 15 m, the roof of the goaf sinks slightly, and the broken rock blocks are hinged to form a ‘suspended structure’. There are some cracks in the overburden rock, and there are no obvious longitudinal cracks in the immediate roof. When is advanced to 40 m, the direct roof and the basic roof of the goaf are obviously separated, and the cracks in the overburden rock and their development height continue to increase. When it is pushed to 65 m, the roof of the excavation is in contact with the floor, and the separation position is moved up to the deep rock layer of the roof.

During the rapid advance, the roof of the goaf also gradually transits from the ‘suspended structure’ to the contact with the floor, but its subsidence degree is greater than that of the advancing speed of 4.8 m / d, as shown in Fig. 11 (c). When advancing 16 m, the roof of the excavation is ‘suspended structure’, and there are small longitudinal cracks in the middle of the direct roof, and there obvious separation phenomenon in the upper part. When advances 48 m, the coal wall side of the roof of the goaf breaks and basically contacts with the floor. At the same time, the cracks in the overburden rock increase and the development height also increases. When advances 64 m, the roof and floor of the goaf are completely in contact, and the height of fracture development is further increased.

In summary, for thin coal seams, when advancing slowly, the working face has a longer res-idence time at the same position, and the roof overburden pressure relief time is longer, resulting in its complete pressure relief and collapse with mining ; when advancing rapidly, the immediate roof of the goaf will break earlier than when advancing normally.

Roof stress distribution characteristics

Figure 12 shows the vertical stress distribution of the roof of the goaf under different ad-vancing speeds. With the advancement, different ranges of stress concentration areas will be formed at both ends of the goaf. When the advancing speed is 4 m / d, the advance bearing stress of the coal wall is relatively small; with the increase of advancing speed, the stress concentration degree of advance support of coal wall increases.

Figure 13 is the vertical stress distribution curve of roof strata 2 and strata 5 at different ad-vancing speeds. When the propulsion speed is 8 m / d, the peak value of the advanced support pressure of the rock layer 2 is 50.07 MPa, which is 45.56% and 67.79% higher than that of the propulsion speed 5 m / d and 4 m / d, respectively. The peak point is located in front of 6.08 m, which is far away by 84.24% and 218.32% respectively when advancing slowly by 5 m / d and 4 m / d, and the influence range of stress advance increases accordingly. When the propulsion speed is 8 m / d, the peak abutment pressure of rock stratum 5 is reduced by 14.91% and 24.30% compared with the propulsion speed of 5 m / d and 4 m / d. Therefore, with the increase of advancing speed, the peak stress of the lower bearing layer of the roof increases, and the peak stress of the upper bearing layer decreases. In other words, the acceleration of the advancing speed will weaken the bearing performance of the lower bearing layer and strengthen the bearing performance of the upper bearing layer.

In summary, the acceleration of the propulsion rate will reduce the retention time of the working face in the same position, which is conducive to mining management. At the same time, the high stress area in front will be far away from the working face, which will reduce the stress concentration near the coal wall, delay the roof collapse and improve the support efficiency.

Engineering practice

The 1599 working face adopts 50 shield hydraulic supports of ZY4000 / 08 / 18D, and its rated working resistance is 40 MPa. Based on the research results, the advancing speed of 1599 working face is increased from 4 m / d to 4.8 m / d, and the support resistance in the serious area of the support crushing accident is monitored. The results are presented in Fig. 14.

The monitoring results show that the increase of the advancing speed prolongs the time interval between the support and the roof caving-compaction, so that part of the roof pressure is unloaded into the rear goaf, and the working resistance of the support is maintained within a reasonable range, which is below the rated working resistance.

Conclusions

(1)The soft bedrock roof overburden of thin coal seams will form a short cantilever beam. The complete fracture of roof strata 2,5 and 10 in 1599 working face will cause the bearing pressure of overburden rock to increase significantly, which is 275.1 N, 352.8 N and 443.0 N, respectively. The rock layer 2,5 and 10 respectively control the local rock activity of the stope. At the same time, before and after its fracture, different structural forms are used as the main bearing body of the local rock layer.

(2)In the inelastic zone, the width and abutment pressure peak are proportional to the mining height. For thin coal seams, the peak stress point is closer to the coal wall. When the advanc speed is accelerated, the cantilever length increases obviously, and the peak stress concentration factor and the distance between the peak point and the coal wall will increase.

(3)The slow advance will cause the thin coal seams working face to stay at the same position for a long time, and the overburden pressure relief time will be longer, resulting in the roof falling with mining due to complete pressure relief. For the composite bearing layer structure of the roof, the acceleration of the mining speed at the working face will lead to an increase of 67.79% and 45.56% in the peak stress of the lower bearing layer, respectively. At the same time, the peak stress of the upper bearing layer will decrease by 24.30% and 14.91%.

Data availability

The datasets used and analysed during the current study available from the corresponding author on reasonable request.

References

Zhao, T., Zhang, Z. & Tan, Y. An innovtive approach to thin coal seams mining of complex geoloical conditions by pressure repulation. Int. J. Rock Mech. Min. Sci. 71, 249–257 (2014).

Tu, H., Tu, S., Yuan, Y., Wang, F. & Bai, Q. Present situation of fully mechanized mining technology for steeply inclined coal seams in China. Arab. J. Geosci. 8 (7), 4485–4494. https://doi.org/10.1007/s12517-014-1546-0 (2015).

Liu, H., Zhang, R., Han, Z., Zhou, G., Han, Z., Zhang, H., Liu Q. & Chen, Z. Asymmetric deformation and Stability Control of the Roof Plate of a Return Mining Roadway through a normal Fault. Rock Mech. Rock Eng. https://doi.org/10.1007/s00603-024-04284-9 (2024).

Li, J. The coal pillar design method for a deep mining roadway based on the shape of the plastic zone in surrounding rocks. Arab. J. Geosci. 13 (12), 1–12. https://doi.org/10.1007/s12517-020-05501-9 (2020).

Zhao, T., Zhang, Z., Tan, Y., Shi, C., Wei, P., & Li, Q. An innovative approach to thin coal seam mining of complex geological conditions by pressure regulation. Int. J. Rock Mech. Min. Sci. 71, 249–257. https://doi.org/10.1016/j.ijrmms.2014.05.021 (2014).

Huang, B., Xie, P., Wu, Y., Lin, W., Luo, S., Wang, S., … Chen, J. (2024). The effect of overlying rock fracture and stress path evolution in steeply dipping and large mining height stope.Geomechanics and Geophysics for Geo-Energy and Geo-Resources, 10(1), 1–19. https://doi.org/10.1007/s40948-024-00803-8.

Liu, F., Ma, Z., Han, Y. & Huang, Z. Deformation rules for surrounding Rock in Directional weakening of end roofs of thin bedrocks and Ultrathick seams. Adv. Civil Eng. https://doi.org/10.1155/2020/8882374 (2020).

Lu, Z., Ju, W., Gao, F. & Du, T. Numerical analysis on the factors affecting post-peak characteristics of coal under uniaxial compression. Int. J. Coal Sci. Technol. 11 (1), 1–19. https://doi.org/10.1007/s40789-023-00626-0 (2024).

Tian, Z., Zhang, Z., Deng, M., Yan, S. & Bai, J. Gob-Side Entry retained with soft roof, floor, and Seam in thin coal seams: a Case Study. Sustainability 12 (3), 1197. https://doi.org/10.3390/su12031197 (2020).

Huang, B., Xie, P., Lin, W., Wu, Y., Luo, S., Ye, X., Nan, C., & Zhao, W. Study on the evolution mechanism of gangue filling and overlying rock spatial structure in steeply dipping stope. Eng. Fail. Anal. 166, 1–20. https://doi.org/10.1016/j.engfailanal.2024.108884 (2024).

Zhang, X. C., Qin, Z. C. & Li, Q. H. & N. Zhang. Study on Movement Law of Overburden Strata during shallow thinner Seam Mining in Shendong Mining Area. Adv. Mater. Res., 361–363, 188-192 (2012).

Jiang, J. Q., Dai, J., Li, H. & Qu, H. Failure law and application of complex structure thin coal seams mining face. J. China Coal Soc. 38 (11), 1912–1916 (2013).

Sun X. M., Liu X., Liang G.F., Wang D. & Jiang Y. L. Key parameters of gob–side entry retaingin formed by roof cut and pressure releasing in thin coal seams. Chinese Journal of Rock Mechanics and Engineering, 33 (07), 1449–1456 (2014)

Yu, W. J., Wu G. S., Liu H., Wang P., An B. F., Liu Z., Huang Z. & Liu F. F. Deformation characteristics and stability control of soft coal-rock mining roadway in thin coal seams. J. China Coal Soc. 43 (10), 2668–2678 (2018).

He, J., Dou, L. M., Gong, S. Y., Mao, W. M. & Wang, G. F. Research on rock burst prevention technology of roof-cutting roadway in inclined thin coal seams. J. China Coal Soc. 40 (6), 1347–1352 (2015).

Kai, F. & Cheng-dong, S. Study on strata behavior regularity of the working-face with thin coal seam and stiff roof. J. Jiaozuo Inst. Technol. (2004).

Jia, K. J., Feng, G. M., Li, H. J. & Li, J. Research on superhigh-water material filling mining in thin coal seams through similar simulation experiment. J. China Coal Soc. 38 (S2), 267–271 (2013).

Han, P., Zhang, C., Ren, Z., He, X. & Jia, S. The influence of advance speed on overburden movement characteristics in longwall coal mining: insight from theoretical analysis and physical simulation. J. Geophys. Eng. 18 (1), 163–176. https://doi.org/10.1093/jge/gxab005 (2021).

Deng, Z., Wang, S., Mo, Y. & Liu, W. Influence of mining speed on Stope Energy in Deep Mines. Appl. Geophys. 21 (2), 1–9. https://doi.org/10.1007/s11770-024-1065-z (2024).

Zhao, P. , Zhuo, R. , Li, S. , Shu, C. M. , & Suo, L. . Analysis of advancing speed effect in gas safety extraction channels and pressure-relief gas extraction. Fuel 265, 1–12 (2020).

Li, W., Tu, S. & Zhao, T. Study on the Tensile failure characteristics and energy calculation model of coal Seam hard roof considering the mining speed. Appl. Sci. 14 (13), 5734. https://doi.org/10.3390/app14135734 (2024).

Cui, F., Yang, Y., Lai, X., Jia, C. & Shan, P. Experimental study on the Effect of advancing speed and Stoping Time on the Energy Release of Overburden in an Upward Mining Coal Working face with a hard roof. Sustainability 12 (1), 37. https://doi.org/10.3390/su12010037 (2019).

Jia, C., Lai, X. P., Cui, F., Feng, G. G., He, S. F., Gao, Y. J., & Tian, M. Q. Study on Multisize Effect of Mining Influence of Advance Speed in Steeply Inclined Extrathick Coal Seam, Lithosphere, 1–18 (2022).

Cui, F. Jia C., Lai X., Chen J., Zhang S., & He S. Study on advancing rate of steeply inclined extra-thick coal seam in rock burst mine based on loading-unloading response ratio. J. China Coal Soc. 47 (2), 745–761 (2022).

Yu, X., Gao, M., Zhao, H., Zhao, S. & Zhao, H. Research on the laws of Overlying Rock Fracture and Energy Release under different mining speeds. Appl. Sci. 14 (8), 3222. https://doi.org/10.3390/app14083222 (2024).

Wang, M., Song Z. F., Gou P. F., Li J., Zhang S. & Zheng D. J. Effect of advancing speed on stability control of overb-urden structure in fully mechanized coal face. J. China Univ. Min. Technol. 49 (3), 463–470 (2020).

Xie, G. X., Chang, J. C. & Hua, X. Z. Influence of mining velocity on mechanical char-acteristics of surrounding rock in fully mechanized top-coal caving face. Chin. J. Geotech. Eng. 07, 963–967 (2007).

Liang, D. M. & Chi, X. L. Influence of advancing speed on roof overburden activity. Safe-ty Coal Mines. 49 (09), 276–279 (2018).

Qian, M. G., Shi, P. W. & Xu, J. L. Rock pressure and strata control. Xuzhou: China Univ. Min. Technol. Press., 113–115 (2010).

Ren, Y. F. & Li, Z. J. Experimental study on time series character of roof cutting in shallow working face. J. China Coal Soc. 44 (S2), 399–409 (2019).

Wang, X. Z., Xu, J. L., Zhu, W. B. & Ju, J. F. Influence of high mining velocity on periodic weig-hting during fully-mechanized mining in a shallow seam. J. China Univ. Min. Technol. 41 (03), 349–354 (2012).

Li, W. L., Tu, S. H., Hao, D. Y., Liu, X. & Miao, K. J. Influence of advancing speed and filling ratio on energy accumulation and release of thick and hard roof in deep backfilling working face. J. China Univ. Min. Technol. 50 (03), 498–506 (2021).

Jiang, J. Q. Stress and Movement of Surrounding rock (Coal Industry, 1993).

Author information

Authors and Affiliations

Contributions

X.Q.: Writing-Original Draft, Conceptualization, Methodology, Software, Validation, Data curation, Formal analysis, Visualization.J.L.: Conceptualization, Supervision, Project administration, Funding acquisition, Review & Editing.Y. W.: Conceptualization, Funding acquisition, Review & Editing.C.C.: Data curation, Project administration.J.D.: Resources, Visualization.All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Qiang, X., Li, J., Wu, Y. et al. Study on migration instability characteristics and mine pressure control of roof overburden rock in thin coal seams mining. Sci Rep 15, 8212 (2025). https://doi.org/10.1038/s41598-025-88953-x

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-88953-x