Abstract

We calculate the band structures of \(\hbox {Ge}_{1-x}\hbox {Sn}_{x}\) nanowires under the [110] direction stress via the effective-mass \({\textbf {k}} \cdot {\textbf {p}}\) theory. Interestingly, it is found that octuple equivalent indirect L-valleys can be split into \(L_1\)-valleys and \(L_2\)-valleys with quadruple degeneracy by the imposed stress, which results in the inflection point of electron filling ratio at the direct \(\Gamma \)-valley whether Sn content is low or high. Moreover, the optical gain along the z direction will not only appear an inflection point, but also can be enhanced several times with the increase of the stress, which will be much greater than that along the x direction. For \(\hbox {Ge}_{0.92}\hbox {Sn}_{0.08}\) nanowires, the result indicates that the z direction peak gain will invariably exceed the FCA loss as increasing the stress to 4 GPa when the total electron concentration reaches the order of \(10^{19}\) \(\hbox {cm}^{-3}\), which is obviously better than the case of \(\hbox {Ge}_{0.95}\hbox {Sn}_{0.05}\) nanowires due to the larger electron filling ratio at the \(\Gamma \)-valley. While for \(\hbox {Ge}_{1-x}\hbox {Sn}_{x}\) nanowires with high Sn contents, the FCA loss is almost negligible and the considerable positive net peak gain can be acquired under the stress even if the total electron concentration is as low as the order of \(10^{18} \, \hbox {cm}^{-3}\) . Therefore, in the field of silicon photonics, our researches manifest that [110] direction strained \(\hbox {Ge}_{1-x}\hbox {Sn}_{x}\) nanowires as lasers are advantageous over unstrained \(\hbox {Ge}_{1-x}\hbox {Sn}_{x}\) nanowires, but inferior to [100] direction strained \(\hbox {Ge}_{1-x}\hbox {Sn}_{x}\) nanowires because of the splitting of the L-valleys.

Similar content being viewed by others

Introduction

The search for economical and high-performance on-chip light emitters or lasers is extremely desirable, which has become to one of the ultimate goals in the filed of silicon (Si) photonics1. For a long time, unlike group III–V and II–VI semiconductor materials2,3, group IV materials such as Si, germanium (Ge) and SiGe have not been considered as the efficient light sources owing to their indirect bandgap characteristic4,5,6,7. However, in the past two decades, the requirement of compatible with Si complementary metal-oxide-semiconductor (CMOS) has made Ge material attract more and more attentions8,9,10. Moreover, the fact that the direct bandgap of Ge material is only 136 meV larger than its indirect bandgap enables it possible to reduce even reverse the indirect-direct bandgap difference by applying several methods. Two main methods toward realizing band-engineered Ge material and reversing the indirect-direct bandgap difference of Ge material are applying tensile strain11,12 and incorporating tin (\(\alpha \)-Sn)13,14. In addition, the growth of Ge/GeSn core-shell nanowires is also a recently adopted method15, because the tensile stress provided by the GeSn shell may transform Ge core into a direct-bandgap semiconductor naturally, and Ge/GeSn core-shell nanowires may constitute a dual direct-bandgap material. Nevertheless, despite these advantages, it is not until the total electron concentration reaches close to 1 × \(10^{20} \, \hbox {cm}^{-3}\) that the considerable optical gain can be achieved in strain-free Ge-related structures16, and the further researches demonstrate that when uniaxial stress along different directions is imposed, the electron concentration can only be decreased to \(10^{19}\, \hbox {cm}^{-3}\) order of magnitude to obtain a certain positive net gain value17,18. In this vein, the large free-carrier absorption (FCA) loss will be encountered, which is not conducive to the Ge-related structures as the effective Ge-on-Si light emitters. In order to overcome this problem, the idea of alloying tin (\(\alpha \)-Sn) into Ge to form GeSn material is proposed19,20. As a matter of fact, GeSn material with all group IV elements is not only compatible with Si-based CMOS, but also can lower the bandgap difference between the direct \(\Gamma \)-valley and indirect L-valley through incorporating \(\alpha \)-Sn21. Therefore, since the direct bandgap GeSn material was experimentally confirmed in 201422, it has been at the forefront of developing Si-based optoelectronic devices, then the light emitters made of GeSn material were attained extensively in several experimental groups23,24,25. As the development of growth technology, low dimensional GeSn nanowires or Ge/GeSn core-shell nanowires with different Sn contents, even as high as 20% Sn content, have been widely synthesized in the last decade26,27,28,29,30, which indicates that it will be possible to integrate ultra-miniaturized, low-cost and Si CMOS-compatible light sources into photonic circuits. Especially accompanied by a raising number of GeSn nanowires with direct bandgap and very small diameter have been reported31,32,33,34, short wave infrared cavity resonances based on single GeSn nanowires has also been observed in 202335, which provides powerful experimental evidence for the realization of group IV nanowire lasers. In stark contrast to the progress of experiments, there is little theoretical research on GeSn nanowires as light emitters. Only the recent calculation of optical gain shows that the peak gain of \(\hbox {Ge}_{1-x}\hbox {Sn}_{x}\) nanowires along the z direction can be enhanced greatly by the imposed stress along the [100] direction (perpendicular to the nanowire axis), which will far beyond the FCA loss even if the total electron concentration is reduced to the order of \(10^{18}\, \hbox {cm}^{-3}\) and Sn content is less than 10%36. Therefore, compared to unstrained \(\hbox {Ge}_{1-x}\hbox {Sn}_{x}\) nanowires, the [100] direction strained \(\hbox {Ge}_{1-x}\hbox {Sn}_{x}\) nanowires are obviously more suitable for lasers. However, what will happen when uniaxial stress is applied to \(\hbox {Ge}_{1-x}\hbox {Sn}_{x}\) nanowires except along the [100] direction? This stimulates us to conduct the following investigation.

In this paper, the electronic structures of \(\hbox {Ge}_{1-x}\hbox {Sn}_{x}\) nanowires with different Sn contents under uniaxial sterss \(U_{110}\) along the [110] direction are computed, and we find that eight degenerate indirect L-valleys of \(\hbox {Ge}_{1-x}\hbox {Sn}_{x}\) nanowires can be split into two sets of \(L_1\)-valleys and \(L_2\)-valleys by the stress regardless of the Sn composition and diameter of nanowires, which will lead to an inflection point of the filling ratio of electrons at the direct \(\Gamma \)-valley with the increase of stress. While for the case of exerting the [100] direction stress, the filling ratio of electrons at the direct \(\Gamma \)-valley will keep increasing due to the L-valley that will not split. Moreover, the calculations on the optical gain spectra manifest that the z direction peak gain will also exhibit an inflection point when \(U_{110}\) is up to 4 GPa, which makes it difficult to obtain the positive net peak gain in \(\hbox {Ge}_{1-x}\hbox {Sn}_{x}\) nanowires with low Sn contents (\(x\) 10%) because the total electron concentration should reach the order of \(10^{19} \, \hbox {cm}^{-3}\) . With regard to \(\hbox {Ge}_{1-x} \hbox {Sn}_{x}\) nanowires with high Sn compositions (\(x\) \(\ge \)10%), owing to the decrease of total electron concentration to \(10^{18} \, \hbox {cm}^{-3}\) order of magnitude and the enhancement of electron populated proportion at the \(\Gamma \)-valley, the sizable positive net peak gain can be obtained in \(\hbox {Ge}_{1-x}\hbox {Sn}_{x}\) nanowires. Our comprehensive researches of \(\hbox {Ge}_{1-x}\hbox {Sn}_{x}\) nanowires under the [110] direction stress further enriches the application of strained all-group IV \(\hbox {Ge}_{1-x}\hbox {Sn}_{x}\) nanowires as short wavelength infrared (SWIR) or mid-wavelength infrared (MWIR) lasers in Si-based photonics.

Theoretical model

Under uniaxial stress \(U_{110}\) along the [110] direction, the stress-induced Hamiltonian \(H_{100,\varepsilon }^{\Gamma }\) in Ref.36 should be replaced by \(H_{110,\varepsilon }^{\Gamma }\) to form the eight-band \({\textbf {k}}\) \(\cdot \) \({\textbf {p}}\) Hamiltonian of \(\hbox {Ge}_{1-x}\hbox {Sn}_{x}\) nanowires at the direct \(\Gamma \)-valley, namely,

where the matrixes \(H_{4\times 4}^{U}\), \(H_{4\times 4}^{L}\) and \(H_{so}\) are the same as the condition that the [100] direction stress is applied. In parallel, \(H_{110,\varepsilon }^{\Gamma }\) is an \(8\times 8\) block diagonalized matirx with \(H_{110,\varepsilon }^{\Gamma ,U}\) = \(H_{110,\varepsilon } ^{\Gamma ,L}\), and the matrix form of \(H_{110,\varepsilon }^{\Gamma ,U}\) is invariable as presented in Ref.36, which can be written as

In the above matrix, we shoud notice that although the calculated expressions of matrix elements \(P_{e\varepsilon }\), \(P_{1\varepsilon }\), \(P_{3\varepsilon }\) and \(T_{\varepsilon }\) are identical when the stresses along the [100] direction and [110] direction are imposed, the strain tensor matrix \(\varepsilon _{110}\) introduced by the stress \(U_{110}\) are different from that introduced by the stress \(U_{100}\), and we can express \(\varepsilon _{110}\) as

The elements of matrix \(\varepsilon _{110}\) can be calculated as follows, which means that \(\varepsilon _{110}\) is not a diagonal matrix

in which \(C_{11}\), \(C_{12}\) and \(C_{44}\) are the elastic modulus of \(\hbox {Ge}_{1-x}\hbox {Sn}_{x}\) material. In Ref.36, the cylindrical symmetry of \(\hbox {Ge}_{1-x}\hbox {Sn}_{x}\) nanowires is destroyed under the stress \(U_{100}\) because the off-diagonal matrix element \(T_{\varepsilon }\) = \(1.5b_{v}(\varepsilon _{xx}-\varepsilon _{yy})\) \(\ne \)0, and the reason is that \(\varepsilon _{xx}\) is not equal to \(\varepsilon _{yy}\). Similarly, the exertion of the stress \(U_{110}\) also break the cylindrical symmetry of \(\hbox {Ge}_{1-x}\hbox {Sn}_{x}\) nanowires due to the off-diagonal matrix element \(T_{\varepsilon }\) = \(1.5b_{v}(\varepsilon _{xx}-\varepsilon _{yy})-i\sqrt{3}d_{v}\varepsilon _{xy}\) \(\ne \)0. Whereas, it should be noticed that the expression can be simplified to \(T_{\varepsilon }\) = \(-i\sqrt{3}d_{v}\varepsilon _{xy}\) owing to \(\varepsilon _{xx}\) = \(\varepsilon _{yy}\) in this case. Therefore, we can understand that the nonzero off-diagonal strain tensor \(\varepsilon _{xy}\) under \(U_{110}\) results in the broken symmetry of nanowires.

In order to calculate the stress-induced Hamiltonian \(H_{110,\varepsilon }^{\Gamma }\) in Eq. (1), the elastic modulus and deformation potentials of \(\hbox {Ge}_{1-x}\hbox {Sn}_{x}\) material need to be used, which can be established linearly via the following equations37

where \(a_{c}(\text{Ge}_{1-x}\text{Sn}_{x})\), \(a_{v}(\text{Ge}_{1-x}\text{Sn}_{x})\), \(b_{v}(\text{Ge}_{1-x}\text{Sn}_{x})\) and \(d_{v}(\text{Ge}_{1-x}\text{Sn}_{x})\) are four deformation potentials of \(\hbox {Ge}_{1-x}\hbox {Sn}_{x}\) material, and \(C_{11}(\text{Ge}_{1-x}\text{Sn}_{x})\), \(C_{12}(\text{Ge}_{1-x}\text{Sn}_{x})\) and \(C_{44}(\text{Ge}_{1-x}\text{Sn}_{x})\) are three elastic modulus of \(\hbox {Ge}_{1-x}\hbox {Sn}_{x}\) material. According to the above discussion, the nonzero off-diagonal strain tensor \(\varepsilon _{xy}\) introduced by the uniaxial stress \(U_{110}\) will destroy the cylindrical symmetry of \(\hbox {Ge}_{1-x}\hbox {Sn}_{x}\) nanowires, thus the envelope wavefunction of the carriers can be expanded as the following eight-component Bessel function form

where \(j_{m}(r)\) and \(A_{n,m}\) are the Bessel functions and their normalized coefficients, respectively.

At the indirect [111] L-valley, the single-band effective-mass Hamiltonian of \(\hbox {Ge}_{1-x}\hbox {Sn}_{x}\) nanowires under the uniaxial stress \(U_{110}\) can be written as

Clearly, besides the stress-induced Hamiltonian \(H_{110,\varepsilon }^{L}\), the other terms on the right side of Eq. (9) are identical to the case of imposition of the stress \(U_{100}\) in Ref.36. Additionally, we should note that \(k_z\) is defined relative to the minimum wave vector at the L-valley, and the strained Hamiltonian \(H_{110,\varepsilon }^{L}\) in Eq. (9) can be expressed as follows38

in which the meanings of the products \(\{\}\), \({\textbf {:}}\) and the unit vector \({\textbf {a}}_L^{i}\) (i = 1, 2, ......, 8) have been given in Ref.38, and \(\varepsilon _{110}\) is the above 3\(\times \)3 strain tensor matrix under the stress \(U_{110}\). Dissimilar to the condition that the stress \(U_{100}\) is exerted, the eight equivalent L-valleys of \(\hbox {Ge}_{1-x}\hbox {Sn}_{x}\) nanowires will be split into two groups under uniaxial stress \(U_{110}\), and we can take the L-valleys along the [111], \([11\overline{1}]\), \([\overline{1}11]\) and \([1\overline{1}1]\) directions as examples to clarify these splitting. For these four L-valleys, the strained Hamiltonians can be calculated as

where the deformation potentials \(\Xi _d^{L}\) and \(\Xi _u^{L}\) at the L-valley of \(\hbox {Ge}_{1-x}\hbox {Sn}_{x}\) material can also be obtained via the linear combination of those of Ge and Sn materials. From the above equations (11)\(\sim \)(14), it can be found that the degeneracy of these four L-valleys are split due to the nonzero strain tensor \(\varepsilon _{xy}\) under the stress \(U_{110}\). In parallel, the strained Hamiltonians of the L-valleys along the other four directions can also be calculated similarly, and as a result, the eight equivalent L-valleys are devided into two groups by the imposed stress \(U_{110}\). Namely, the first group is \(H_{110,\varepsilon }^{L,111}\) = \(H_{110,\varepsilon }^{L,11\overline{1}}\) = \(H_{110,\varepsilon }^{L,\overline{11}1}\) = \(H_{110,\varepsilon }^{L,\overline{111}}\), which is labeled as \(L_1\) group, while the second group is \(H_{110,\varepsilon }^{L,\overline{1}11}\) = \(H_{110,\varepsilon }^{L,1\overline{1}1}\) = \(H_{110,\varepsilon }^{L,\overline{1}1\overline{1}}\) = \(H_{110,\varepsilon }^{L,1\overline{11}}\), which is labeled as \(L_2\) group. Then, the electron energies at the \(L_1\)-valleys and \(L_2\)-valleys that ensure the convergence can be acquired via the same method in Ref.16, which are also in line with the results calculated by the \(sp^3d^5s^*\) tight-binding model in Ref.39.

Based on the electronic structures of \(\hbox {Ge}_{1-x}\hbox {Sn}_{x}\) nanowires, the quasi-Fermi level \(E_{fc}\) of the conduction band under the stress \(U_{110}\) can be determined by solving the following equation

where \(\Delta n\) is the total electron concentration, and \(f_{n_c}^{\sigma }(k_z)\) (\(\sigma \) = \(\Gamma \), \(L_1\) and \(L_2\)) are the Fermi-Dirac distribution functions of the electron states16. By the analogous method, the quasi-Fermi level \(E_{fv}\) of the valence band of \(\hbox {Ge}_{1-x}\hbox {Sn}_{x}\) nanowires under the stress \(U_{110}\) can also be obtained. Herein, we should illustrate the summation factor of four at the \(L_1\)-valley and \(L_2\)-valley in Eq. (15). As mentioned above, the eight equivalent L-valleys will be split into fourfold degenerate \(L_1\)-valleys and \(L_2\)-valleys by the stress \(U_{110}\). Since only half of each L-valley is contained in the first Brillouin zone, the number of equivalent \(L_1\)-valleys or \(L_2\)-valleys in the first Brillouin zone is actually two. However, it should be noted that each electron state at \(L_1\)-valleys and \(L_2\)-valleys is doube spin degeneracy, which leads to the summation factor of four for the electron states at \(L_1\)-valleys and \(L_2\)-valleys in Eq. (15).

Numerical results and discussions

The electronic structures and optical gain of \(\hbox {Ge}_{1-x}\hbox {Sn}_{x}\) nanowires with low Sn contents (\(x\) 10%) under uniaxial stress \(U_{110}\)

Generally speaking, less than 10% Sn composition in \(\hbox {Ge}_{1-x}\hbox {Sn}_{x}\) nanowires is considered to be relatively low15. We employ the effective-mass, elastic modulus and deformation paramters in Refs.36,40 to calculate the electron and hole energy levels of \(\hbox {Ge}_{1-x}\hbox {Sn}_{x}\) material with low Sn contents (\(x\) 10%) when the stress \(U_{110}\) is applied. As stated above, the off-diagonal element of the stress-induced Hamiltonian matrix \(H_{110,\varepsilon }^{\Gamma }\) and the strain tensor matrix \(\varepsilon _{110}\) are \(T_{\varepsilon }\) = \(-i\sqrt{3}d_{v}\varepsilon _{xy}\) and \(\varepsilon _{xy}\) = \(U_{110}/(4C_{44})\), respectively, thus an additional deformation potential \(d_{v}\) and elastic modulus \(C_{44}\) of \(\hbox {Ge}_{1-x}\hbox {Sn}_{x}\) material should be constructed by linear combination method, which can be seen in Eq. (6) and Eq. (7). In the calculation, these two parameters of Ge material and Sn material are taken from Refs.37,38,41,42,43,44,45 and listed in the following Table 1. Moreover, we can compute the direct and indirect bandgap of \(\hbox {Ge}_{1-x}\hbox {Sn}_{x}\) material at the temperature T = 300 K via the following formula36

where \(\sigma \) = \(\Gamma \) and L, and \(E_g^{\sigma }(\text{Ge})\) and \(E_g^{\sigma }(\text{Sn})\) are the bandgaps of Ge ans Sn materials at the room temperature, which can be adopted from the Ref.46. The bowing parameters \(b^{\Gamma }\) and \(b^{L}\) of \(\hbox {Ge}_{1-x}\hbox {Sn}_{x}\) material are adopted from Ref.36, which can guarantee the crosspoint of the direct bandgap and indirect bandgap of bulk \(\hbox {Ge}_{1-x}\hbox {Sn}_{x}\) material appears between 6% and 10% of Sn content47,48. The parameters of Ge material and \(\alpha \)-Sn material at the room temperature are listed in Table 1 below.

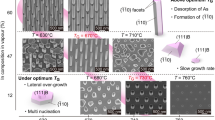

The diameter range of \(\hbox {Ge}_{1-x}\hbox {Sn}_{x}\) nanowires considered in the calculation is from 12 nm to 24 nm. On the one hand, the size range of nanowires we choose can cover both small diameter (12 nm) and large diameter (24 nm), thus the nanowires can exhibit different quantum confinement effect. On the other hand, the growth of \(\hbox {Ge}_{1-x}\hbox {Sn}_{x}\) nanowires in this diameter range has been reported in the experiments49,50. The several highest hole states and lowest electron states of unstrained \(\hbox {Ge}_{0.92}\hbox {Sn}_{0.08}\) nanowires with the diameter D of 12 nm at the \(\Gamma \)-valley are demonstrated in Fig. 1a and b, respectively. For the strain-free case in these two figures, the nanowires possess the cylindrical symmetry, which makes the total angular momentum J a good quantum number and each electronic state with same |J| doubly degenerate16. From Fig. 1a, it can be seen that the ground hole state at the center of Brillouin zone is \(h_0^{1/2}\) with the superscript J = 1/2, which will cross with the second excited hole state \(h_0^{3/2}\) with J = 3/2. Moreover, the hole states in Fig. 1a show the strong non-parabola and cross each other. While for the electron states in Fig. 1b, the energy-wave vector dispersion relation is only slightly non-parabolic. In Fig. 1c, the eight lowest electron states of \(\hbox {Ge}_{0.92}\hbox {Sn}_{0.08}\) nanowires at the L-valley when D = 12 nm and \(U_{110}\) = 0 GPa are presented, and we should recall that the electron states at the L-valley are not split for the unstrain case. Because the energy of the lowest electron state at the minimum L-valley is lower than that at the minimum \(\Gamma \)-valley by 55.09 meV, which indicates that the strain-free \(\hbox {Ge}_{0.92}\hbox {Sn}_{0.08}\) nanowires with the diameter D of 12 nm is an indirect bandgap semiconductor. When the stress \(U_{110}\) = 2 GPa is exerted, the corresponding hole states and electron states are plotted in Fig. 1d and e. In this vein, the superscript J cannot be used to label the hole states and electron states at the \(\Gamma \)-valley due to the broken symmetry of nanowires36. Comparing Fig. 1d with Fig. 1a, it can be clearly seen that the energy-wave vector dispersion relationship of the hole states have undergone the substantial changes under the stress. In contrast, as shown in Fig. 1b and e, the curve shape of each electron state hardly varies under \(U_{110}\). We shoud mind that the electron states \(e_1\), \(e_3\) and \(e_5\) are not displayed in Fig. 1e, because the splitting energy of each pair of degenerate electron states by the stress is too small to be distinguished. In Fig. 1f, a significant resut is that the electron states at the L-valley without the stress will be split into those at the \(L_1\)-valley and \(L_2\)-valley with the stress of 2 GPa, and the splitting energy is equal to \(\frac{4}{3}\Xi _u^{L}\varepsilon _{xy}\), which is proportional to the magnitude of the applied stress. In this case, the energy of the lowest electron state at the minimum \(L_1\)-valley is higher than that at the minimum \(\Gamma \)-valley by 77.48 meV, while the energy of the lowest electron state at the minimum \(L_2\)-valley is lower than that at the minimum \(\Gamma \)-valley by 74.1 meV. Therefore, under the stress of 2 GPa, \(\hbox {Ge}_{0.92}\hbox {Sn}_{0.08}\) nanowires still feature the characteristic of an indirect bandgap semiconductor.

(a) The 10 highest hole states at the \(\Gamma \)-valley of \(\hbox {Ge}_{0.92}\hbox {Sn}_{0.08}\) nanowires when the diameter D = 12 nm, the stress \(U_{110}\) = 0 GPa and the temperature T = 300 K; (b, c) are the same as (a) but for the six lowest electron states at the \(\Gamma \)-valley and the eight lowest electron states at the L-valley of \(\hbox {Ge}_{0.92}\hbox {Sn}_{0.08}\) nanowires, respectively; (d, e) are identical to the corresponding (a, b) with the stress \(U_{110}\) = 2 GPa, respectively; (f) is the same as (c) but for the stress \(U_{110}\) = 2 GPa, in which the solid line and dashed line represent the electron states at the \(L_1\)-valley and \(L_2\)-valley, respectively.

(a) The energy difference \(\Delta E_{e}^{\Gamma ,L_1}\) of \(\hbox {Ge}_{0.92}\hbox {Sn}_{0.08}\) nanowires versus the stress \(U_{110}\) and the diameter D, and the black thick line represents \(\Delta E_{e}^{\Gamma ,L_1}\) = 0; (b) is the same as (a) but for the energy difference \(\Delta E_{e}^{\Gamma ,L_2}\) of \(\hbox {Ge}_{0.92}\hbox {Sn}_{0.08}\) nanowires.

In order to evaluate the splitting energies of the electron states at the L-valley under the stress \(U_{110}\), two physical quantities \(\Delta E_{e}^{\Gamma ,L_1}\) and \(\Delta E_{e}^{\Gamma ,L_2}\) of \(\hbox {Ge}_{0.92}\hbox {Sn}_{0.08}\) nanowires as functions of \(U_{110}\) and the diameter D are plotted in Fig. 2a and b, respectively. In the figure, \(\Delta E_{e}^{\Gamma ,L_1}\) is defined as \(E_e^{\Gamma }\)-\(E_e^{L_1}\), and \(\Delta E_{e}^{\Gamma ,L_2}\) is defined as \(E_e^{\Gamma }\)-\(E_e^{L_2}\), where \(E_e^{\Gamma }\), \(E_e^{L_1}\) and \(E_e^{L_2}\) are the energies of the lowest electron state at the minimum \(\Gamma \)-valley, \(L_1\)-valley and \(L_2\)-valley, respectively. Through the calculation, we can find that \(E_e^{\Gamma }\) and \(E_e^{L_1}\) at the minimum \(\Gamma \)-valley and \(L_1\)-valley will go down and go up as the increase of \(U_{110}\) if D is fixed, respectively. Whereas, as shown in Fig. 2a, \(\Delta E_{e}^{\Gamma ,L_1}\) will decrease as the increment of \(U_{110}\), which means that the energy \(E_e^{\Gamma }\) reduces faster than the energy \(E_e^{L_1}\) increases. Moreover, with the increase of the stress, \(\Delta E_{e}^{\Gamma ,L_1}\) will experience the change from positive value to negative value. Therefore, \(E_e^{L_1}\) will be pushed close to \(E_e^{\Gamma }\) and surpass \(E_e^{\Gamma }\) by the increasing \(U_{110}\). For instance, \(\Delta E_{e}^{\Gamma ,L_1}\) is 55.09 meV when D = 12 nm and \(U_{110}\) = 0 GPa, which will become to -11.24 meV with \(U_{110}\) = 1 GPa and -77.48 meV with \(U_{110}\) = 2 GPa, respectively in case that D = 12 nm is kept unchanged. Similarly, for the diameter D = 24 nm, \(\Delta E_{e}^{\Gamma ,L_1}\) is 32.92 meV with \(U_{110}\) = 0 GPa, – 34.06 meV with \(U_{110}\) = 1 GPa and – 100.95 meV with \(U_{110}\) = 2 GPa, respectively, which manifests that \(\Delta E_{e}^{\Gamma ,L_1}\) will also turn from greater than zero to less than zero when \(U_{110}\) is between 0 GPa and 1 GPa. In Fig. 2b, although both \(E_e^{\Gamma }\) and \(E_e^{L_2}\) goes down with the increase of \(U_{110}\), \(E_e^{\Gamma }\) reduces more slowly than \(E_e^{L_2}\), resulting in the rise of the value \(\Delta E_{e}^{\Gamma ,L_2}\) at the same D. Taking D = 12 nm as an example, \(\Delta E_{e}^{\Gamma ,L_2}\) is equal to \(\Delta E_{e}^{\Gamma ,L_1}\) when \(U_{110}\) = 0 GPa, and it will be raised to 64.55 meV with \(U_{110}\) of 1 GPa and 74.10 meV with \(U_{110}\) of 2 GPa, which will cause \(E_e^{L_2}\) to be pushed away from \(E_e^{\Gamma }\) by the applied stress. For other diameters in Fig. 2b, such as D = 18 nm and 24 nm, \(\Delta E_{e}^{\Gamma ,L_2}\) will experience the same change law as well. Because the L-valley of \(\hbox {Ge}_{1-x}\hbox {Sn}_{x}\) nanowires with low Sn compositions will be split into \(L_1\)-valley and \(L_2\)-valley, and the electron energy levels at the \(L_1\)-valley and \(L_2\)-valley will approach even exceed and far from those at the \(\Gamma \)-valley under the stress \(U_{110}\), the filling ratio of the electrons at the \(\Gamma \)-valley will not increase monotonically with \(U_{100}\) as changed in Ref.36, but will first increase and then decrease with \(U_{110}\) as shown in Fig. 3. In the figure, \(N_e\) is the total electron concentration, \(N_e^{\Gamma }\) is the electron concentration filled at the \(\Gamma \)-valley, while \(N_e^{L_1}\) and \(N_e^{L_2}\) are the electron concentrations occpying the \(L_1\)-valley and \(L_2\)-valley, respectively. During the calculation of the filling ratios \(N_e^{\Gamma }\)/\(N_e\), \(N_e^{L_1}\)/\(N_e\) and \(N_e^{L_2}\)/\(N_e\), the total electron concentration \(N_e\) is chosen as 2 \(N_0\), and the value \(N_0\) is 1\(\times \) \(10^{19}\) \(\hbox {cm}^{-3}\). Obviously, the ratio \(N_e^{L_1}\)/\(N_e\) will drop rapidly as increasing \(U_{110}\) no matter how the Sn content is 0.05 or 0.08 in Fig. 3a, and the reason can be analyzed from Fig. 2a. In fact, the energy \(E_e^{L_1}\) will surpass the energy \(E_e^{\Gamma }\) and be much greater than \(E_e^{\Gamma }\) gradually, which can cause a very small proportion of the electrons at the \(L_1\)-valley, even less than 0.1% with \(U_{110}\) of 4 GPa. Accordingly, the energy \(E_e^{L_2}\) will become much lower than the energy \(E_e^{L_1}\) and \(E_e^{\Gamma }\) as the increase of \(U_{110}\), which leads to most electrons in \(\hbox {Ge}_{0.95}\hbox {Sn}_{0.05}\) or \(\hbox {Ge}_{0.92}\hbox {Sn}_{0.08}\) nanowires occpying the \(L_2\)-valley when \(U_{110}\) is in the range of 1 GPa\(\sim \)4 GPa. Especially, the ratio \(N_e^{L_2}\)/\(N_e\) is about 99.80% for \(\hbox {Ge}_{0.95}\hbox {Sn}_{0.05}\) nanowires and 98.88% for \(\hbox {Ge}_{0.92}\hbox {Sn}_{0.08}\) nanowires with the diameter of 12 nm, respectively. Therefore, the splitting of L-valley under the stress and the filling behaviors of electrons at the \(L_1\)-valley and \(L_2\)-valley will lead to variation rule of the ratio \(N_e^{\Gamma }\)/\(N_e\) at the \(\Gamma \)-valley with \(U_{110}\), as shown in the inset figure of Fig. 3a. From the inset figure, we can clearly find that an inflection point will appear at the stress \(U_{110}\) \(\approx \)1.5 GPa whether x is 0.05 or 0.08. Moreover, for \(\hbox {Ge}_{0.95}\hbox {Sn}_{0.05}\) nanowires, the ratio \(N_e^{\Gamma }\)/\(N_e\) is about 0.54% at \(U_{110}\) = 1.5 GPa, which is approximately twice that of the case \(U_{110}\) = 0 GPa. While for \(\hbox {Ge}_{0.92}\hbox {Sn}_{0.08}\) nanowires, the ratio \(N_e^{\Gamma }\)/\(N_e\) increases from about 1.38% at \(U_{110}\) = 0 GPa to about 2.37% at \(U_{110}\) = 1.5 GPa. Then, the ratio \(N_e^{\Gamma }\)/\(N_e\) will decrease when the stress goes up from 1.5 GPa to 4 GPa. Similar to Fig. 3a, the curve of the ratio \(N_e^{\Gamma }\)/\(N_e\) as \(U_{110}\) also have an inflection point in the inset figure of Fig. 3b with D = 18 nm and Fig. 3c with D = 24 nm, and the inflection point appears at \(U_{110}\) \(\approx \)1.5 GPa and \(U_{110}\) \(\approx \)1.0 GPa, respectively.

(a) The ratio of the electron concentration filled at the \(L_1\)-valley and \(L_2\)-valley to the total electron concentration versus the stress \(U_{110}\) in \(\hbox {Ge}_{0.95}\hbox {Sn}_{0.05}\) and \(\hbox {Ge}_{0.92}\hbox {Sn}_{0.08}\) nanowires with the diameter of 12 nm, and the inset figure is the ratio of the electron concentration filled at the \(\Gamma \)-valley to the total electron concentration versus the stress \(U_{110}\); (b) and (c) are in common with (a) but for the diameter of 18 nm and 24 nm, respectively.

As we know, the optical gain g(E) is closely related to the filling ratio \(N_e^{\Gamma }\)/\(N_e\) of the electrons at the \(\Gamma \)-valley16, thus g(E) along the z direction and x direction in \(\hbox {Ge}_{0.92}\hbox {Sn}_{0.08}\) nanowires with D of 12 nm as a function of \(U_{110}\) is computed and shown in Fig. 4a. In the figure, the solid line and dashed line stand for the optical gain g(E) along the z direction and x direction, respectively. During the calculation, the electron concentration \(N_e\) is chosen as 2 \(N_0\), which is the same as the value in Fig. 3. As seen in the figure, we can find that the peak gain along the z direction will be improved greatly, while the peak gain along the x direction is only increased a little by the increasing \(U_{110}\), which can cause the nearly negligible optical gain along the x direction under the stress \(U_{110}\). When \(U_{110}\) is 0 GPa, the peak gain along the z direction is 1031.53 \(\hbox {cm}^{-1}\) at the photon energy \(E\) \(\approx \)0.70 eV, and the peak originates from the optical transition \(e_0^{1/2}\) \(\Rightarrow \) \(h_0^{1/2}\). The peak gain will be enhanced to 3573.63 \(\hbox {cm}^{-1}\) at \(E\) \(\approx \)0.57 eV with 2 GPa stress and 2642.48 \(\hbox {cm}^{-1}\) at \(E\) \(\approx \)0.43 eV with 4 GPa stress, respectively. In the case of these two stresses, the peak all corresponds to the optical transitions \(e_0\) \(\Rightarrow \) \(h_0\) and \(e_1\) \(\Rightarrow \) \(h_1\). Moreover, the photon energies corresponding to the peaks under different stresses are invariably within the scope of SWIR band. Different from imposing [100] direction stress \(U_{100}\) in Ref.36, it is important that the peak gain does not always increase with the stress \(U_{110}\) in Fig. 4a, and the reasons can be analyzed as follows. As \(U_{110}\) rises from 0 GPa to 2 GPa, not only the value of \(f_{n_c}\) \((1-f_{n_v})\) in the formula g(E) will almost double, but also the ratio \(N_e^{\Gamma }\)/\(N_e\) goes up from 1.38% with 0 GPa stress to 2.17% with 2 GPa stress, and these two factors mainly determine the enhancement of the peak gain together. Accompanied by the slight reduction of \(f_{n_c}\) \((1-f_{n_v})\), the ratio \(N_e^{\Gamma }\)/\(N_e\) will be decreased to 1.12%, which primarily lower the peak gain with 4 GPa stress in converse. When the diameter D is increased to 18 nm, the optical gain of \(\hbox {Ge}_{0.92}\hbox {Sn}_{0.08}\) nanowires under the different \(U_{110}\) is displayed in Fig. 4b. Obviously, the peak gain along the z direction will also reach the maximum value 2489.77 \(\hbox {cm}^{-1}\) at \(E\) \(\approx \)0.51 eV under \(U_{110}\) = 2 GPa, and then reduces to 2052.86 \(\hbox {cm}^{-1}\) at \(E\) \(\approx \)0.37 eV under \(U_{110}\) = 4 GPa, thus the variation rule of the peak gain as a function of \(U_{110}\) is identical to that in Fig. 4a. When the diameter is increased to 24 nm in Fig. 4c, two optical gain peaks will show up under \(U_{110}\), and the inflection point of the peak gain also occurs at \(U_{110}\) = 2 GPa. In this case, the first peak originating from the optical transitions \(e_0\) \(\Rightarrow \) \(h_0\) and \(e_1\) \(\Rightarrow \) \(h_2\) is located at the photon energy \(E\) \(\approx \)0.48 eV in the SWIR band. As \(U_{110}\) increases to 4 GPa, the first peak will be red shifted to \(E\) \(\approx \)0.34 eV in the MWIR band. Therefore, the peak gain along the z direction in \(\hbox {Ge}_{1-x}\hbox {Sn}_{x}\) nanowires with low Sn contents can be enhanced substantially via the exertion of the stress \(U_{110}\), which will far exceed that along the x direction whether the diameter is 12 nm or 24 nm.

(a) The optical gain along z direction and x direction of \(\hbox {Ge}_{0.92}\hbox {Sn}_{0.08}\) nanowires with the diameter D of 12 nm under the different stress \(U_{110}\). The solid line and dashed line represent the z direction and x direction, respectively; (b, c) are in common with (a) but for the diameter D of 18 nm and 24 nm, respectively.

(a–c) represent the FCA loss, z direction peak gain and net peak gain of \(\hbox {Ge}_{0.95}\hbox {Sn}_{0.05}\) nanowires as a function of the stress \(U_{110}\) when the diameter D = 12 nm, 18 nm and 24 nm, respectively; (d–f) are in common with the corresponding (a–c), respectively but for \(\hbox {Ge}_{0.92}\hbox {Sn}_{0.08}\) nanowires.

Because the order of magnitude of the total electron concentration \(N_e\) is \(10^{19}\) \(\hbox {cm}^{-3}\), the FCA loss of \(\hbox {Ge}_{1-x}\hbox {Sn}_{x}\) nanowires with low Sn compositions under the stress \(U_{110}\) is expected not to be ignored, which can be computed as

where \(N_h\) is the hole concentration, and \(\lambda \) is the free space wavelength of \(\hbox {Ge}_{0.92}\hbox {Sn}_{0.08}\) or \(\hbox {Ge}_{0.95}\hbox {Sn}_{0.05}\) nanowires under \(U_{110}\). Besides those, the physical meanings represented by other quantities in Eq. (17) have also been clarified in Refs.16,17. The relationship between the z direction peak gain and net peak gain, the FCA loss of \(\hbox {Ge}_{0.95}\hbox {Sn}_{0.05}\) nanowires with \(U_{110}\) when D = 12 nm and \(N_e\) = 2 \(N_0\) is presented in Fig. 5a. In the figure, the peak gain refers to the maximum value in the optical gain g(E). As discussed above, the optical gain along the x direction can almost be neglected with increasing \(U_{110}\), thus only the peak gain along the z direction is drawn. Evidently, as the increase of \(U_{110}\), the peak gain will not always rise monotonically, while the FCA loss will experience a continuous increment mainly due to the redshift of the wavelength \(\lambda \). At the beginning, the FCA loss is 297.57 \(\hbox {cm}^{-1}\), which is far greater than the peak gain 11.35 \(\hbox {cm}^{-1}\) with 0 GPa stress, thus the negative net peak gain occurs for unstrained \(\hbox {Ge}_{0.95}\hbox {Sn}_{0.05}\) nanowires. The net peak gain will reach the positive maximum value with 1.5 GPa stress, and under this stress, the FCA loss and peak gain are 391.73 \(\hbox {cm}^{-1}\) and 491.57 \(\hbox {cm}^{-1}\), respectively. Ultimately, the FCA loss will be increased to 706.80 \(\hbox {cm}^{-1}\) with 4 GPa stress, which is far beyond the falling peak gain. Let us analyze the cases of D = 18 nm in Fig. 5b and D = 24 nm in Fig. 5c. From Fig. 5b, it can be found that there will be an inflection point at \(U_{110}\) = 1.5 GPa in the curves of the peak gain and net peak gain, and the net peak gain is greater than 0 only under three stresses \(U_{110}\) = 1 GPa, 1.5 GPa and 2 GPa. Whereas in Fig. 5c, the inflection point will appear at \(U_{110}\) = 1 GPa in the curve of the net peak gain, which is related to the FCA loss of 468.30 \(\hbox {cm}^{-1}\) and peak gain of 554.47 \(\hbox {cm}^{-1}\) in this case. Therefore, it is difficult to obtain the positive net peak gain for [110] direction strained \(\hbox {Ge}_{0.95}\hbox {Sn}_{0.05}\) nanowires no matter the diameter. However, for \(\hbox {Ge}_{0.92}\hbox {Sn}_{0.08}\) nanowires under the stress \(U_{110}\), the situation may be different, and the calculated results are demonstrated in Fig. 5d–f. In Fig. 5d with D of 12 nm and x = 0.08, the peak gain is 1031.53 \(\hbox {cm}^{-1}\), which is still larger than the FCA loss 386.61 \(\hbox {cm}^{-1}\) even though \(U_{110}\) = 0 GPa. Dissimilar to the constant increase of the FCA loss, the peak gain will go up at first and then go down, resulting in an inflection point in the curve of the net peak gain at \(U_{110}\) = 1.5 GPa. Moreover, the peak gain is 3547.06 \(\hbox {cm}^{-1}\) at the inflection point, which is about seven times that in Fig. 5a under the same stress. The reason is that the increment of Sn content can lead to the enhancement of electron filling proportion at the \(\Gamma \)-valley of \(\hbox {Ge}_{1-x}\hbox {Sn}_{x}\) nanowires, as shown in Fig. 3a. In contrast, the FCA loss has only increased a little when Sn content x changes from 0.05 in Fig. 5a to 0.08 in Fig. 5d, thus the net peak gain under the different \(U_{110}\) all exceeds 1500 \(\hbox {cm}^{-1}\) except \(U_{110}\) = 0 GPa. In Fig. 5e with D = 18 nm and x = 0.08, an inflection point in the curve of the net peak gain can also be clearly seen. Compared with Fig. 5d, the net peak gain is reduced under the same \(U_{110}\) due to the increase of FCA loss and decrease of the peak gain. Even though, the net peak gain all exceeds 600 \(\hbox {cm}^{-1}\) in the figure. As seen in Fig. 5f, the variation rule of the net peak gain with \(U_{110}\) equals to that in Fig. 5e, but the net peak gain will be smaller than that in Fig. 5e when \(U_{110}\) remains the same and it will be less than 0 with 4 GPa stress in the figure. By virtue of the above analysis, unlike the [100] direction strained \(\hbox {Ge}_{1-x}\hbox {Sn}_{x}\) nanowires with low Sn compositions in Ref.36, we can conclude that the FCA loss cannot be ignored since the order of the total electron concentration is \(10^{19}\) \(\hbox {cm}^{-3}\). Moreover, the net peak gain will exhibit an inflection point under the stress \(U_{110}\), which collectively cause the positive net peak gain can be acquired in [110] direction strained \(\hbox {Ge}_{0.92}\hbox {Sn}_{0.08}\) nanowires but hardly in strained \(\hbox {Ge}_{0.95}\hbox {Sn}_{0.05}\) nanowires.

The electronic structures and optical gain of \(\hbox {Ge}_{1-x}\hbox {Sn}_{x}\) nanowires with high Sn contents (\(x\) \(\ge \)10%) under uniaxial stress \(U_{110}\)

With further increasing the Sn composition to above 10%, the energy difference between the indirect bandgap L-valley and direct bandgap \(\Gamma \)-valley of bulk \(\hbox {Ge}_{1-x}\hbox {Sn}_{x}\) material will continue to reduce or even reverse. Therefore, it can be expected that the filling ratio of the electrons at the \(\Gamma \)-valley in \(\hbox {Ge}_{1-x}\hbox {Sn}_{x}\) nanowires with high Sn contents (\(x\) \(\ge \)10%) will be larger than that in \(\hbox {Ge}_{1-x}\hbox {Sn}_{x}\) nanowires with low Sn contents (\(x\) 10%) under the same stress \(U_{110}\). In view of this, we calculate the electronic structures of unstrained and strained \(\hbox {Ge}_{1-x}\hbox {Sn}_{x}\) nanowires with D = 12 nm and x = 0.11 at the \(\Gamma \)-valley and L-valley in Fig. 6. As seen in Fig. 6a, similar to the case in Fig. 1a, the curve of each hole state also demonstrates the strong non-parabola, and the order of the three lowest hole states at the center of Brillouin zone is still \(h_0^{1/2}\), \(h_1^{1/2}\) and \(h_0^{3/2}\). For the electron states at the \(\Gamma \)-valley in Fig. 6b and at the L-valley in Fig. 6c, although the curve shape of each electron state is identical to that in figure 1(b) and Fig. 1c, respectively, it is important that \(\hbox {Ge}_{0.89}\) \(\hbox {Sn}_{0.11}\) nanowires is about to be transformed into an direct bandgap semiconductor even if the stress \(U_{110}\) is 0 GPa. The reason is that the lowering energy of the lowest electron state at the minimum \(\Gamma \)-valley is 87.2 meV, while that of the lowest electron state at the minimum L-valley is 38.22 meV when Sn content x increases from 0.08 to 0.11, which makes \(E_{e}^{\Gamma }\) only above \(E_{e}^{L_1}\) 6.1 meV for unstrained \(\hbox {Ge}_{0.89}\) \(\hbox {Sn}_{0.11}\) nanowires with D = 12 nm. Let us focus on the elelctronic structures at the \(\Gamma \)-valley and L-valley of strained \(\hbox {Ge}_{0.89}\) \(\hbox {Sn}_{0.11}\) nanowires under the stress \(U_{110}\) = 2 GPa, as presented in Fig. 6d–f. From Fig. 6d and a, it is obvious that the curve shapes of the hole states are greatly changed by the applied stress. Regarding the electron states, compared Fig. 6b with Fig. 6e, the reduction of the energy \(E_{e}^{\Gamma }\) is 70.55 meV when \(U_{110}\) is from 0 GPa to 2 GPa. Whereas, \(E_{e}^{L_2}\) is 22.72 meV lower than \(E_{e}^{\Gamma }\) because the L-valley can be split into \(L_1\)-valley and \(L_2\)-valley under \(U_{110}\) = 2 GPa in Fig. 6f, which indicates that the indirect bandgap nature of strained \(\hbox {Ge}_{0.89}\) \(\hbox {Sn}_{0.11}\) nanowires are more prominent than that of unstrained \(\hbox {Ge}_{0.89}\) \(\hbox {Sn}_{0.11}\) nanowires.

(a–c) repesent the several highest hole states and lowest electron states at the \(\Gamma \)-valley and L-valley, which are the same as those in the corresponding Fig. 1a–c, respectively except for \(\hbox {Ge}_{0.89}\) \(\hbox {Sn}_{0.11}\) nanowires under the stress \(U_{110}\) = 0 GPa; (d–f) are the same as the corresponding (a–c) but for \(\hbox {Ge}_{0.89}\) \(\hbox {Sn}_{0.11}\) nanowires under the stress \(U_{110}\) = 2 GPa.

(a) The energy difference \(\Delta E_{e}^{\Gamma ,L_1}\) of \(\hbox {Ge}_{0.89}\) \(\hbox {Sn}_{0.11}\) nanowires versus the stress \(U_{110}\) and the diameter D, and the black thick line represents \(\Delta E_{e}^{\Gamma ,L_1}\) = 0; (b) is in common with (a) but for the energy difference \(\Delta E_{e}^{\Gamma ,L_2}\) of \(\hbox {Ge}_{0.89}\) \(\hbox {Sn}_{0.11}\) nanowires, and the black thick line represents \(\Delta E_{e}^{\Gamma ,L_2}\) = 0.

Figure fig7a displays the relationship between the energy difference \(\Delta E_{e}^{\Gamma ,L_1}\) and the stress \(U_{110}\), diameter D in \(\hbox {Ge}_{0.89}\) \(\hbox {Sn}_{0.11}\) nanowires. From the figure, we can distinctly see that \(\Delta E_{e}^{\Gamma ,L_1}\) is nearly always less than zero regardless of \(U_{110}\) and D. Moreover, \(E_e^{L_1}\) will be pushed away from \(E_e^{\Gamma }\) by the increasing stress if the diameter is kept unchanged, which makes \(\Delta E_{e}^{\Gamma ,L_1}\) drop substantially, even down to -256.41 meV with D = 12 nm and \(U_{110}\) = 4 GPa or -272.66 meV with D = 24 nm and \(U_{110}\) = 4 GPa. Nevertheless, \(\Delta E_{e}^{\Gamma ,L_1}\) only decreases slightly by the diameter augment if the stress remians constant. For example, \(\Delta E_{e}^{\Gamma ,L_1}\) = – 59.65 meV with D=12 nm, which will reduce to – 75.17 meV with D = 24 nm under \(U_{110}\) = 1 GPa. On the contrary, for the \(L_2\)-valley, \(\Delta E_{e}^{\Gamma ,L_2}\) is almost greater than zero constantly in Fig. 7b. In this vein, except for a few data points, \(E_e^{L_2}\) lies below \(E_e^{\Gamma }\) unchangeably, which will be pushed away from \(E_e^{\Gamma }\) by the rasing stress at the same diameter. From the figure, it is found that \(\Delta E_{e}^{\Gamma ,L_2}\) is 6.10 meV with \(U_{110}\) = 0 GPa and D = 12 nm, which can be pushed to 39.69 meV with \(U_{110}\) = 4 GPa and D = 12 nm. When \(U_{110}\) is fixed, \(\Delta E_{e}^{\Gamma ,L_2}\) will drop slightly as the increment of D, which means that the decrease of \(E_{e}^{\Gamma }\) by the weakening of quantum confinement effect is greater than that of \(E_{e}^{L_2}\). As discussed above, for \(\hbox {Ge}_{1-x}\hbox {Sn}_{x}\) nanowires with high Sn contents, the electron levels of the \(L_2\)-valley are closer to those of the \(\Gamma \)-valley, resulting in the filling ratio of the electron at the \(\Gamma \)-valley higher than that of \(\hbox {Ge}_{1-x}\hbox {Sn}_{x}\) nanowires with low Sn contents. In Fig. 8a, the filling ratio of the electron at the \(\Gamma \)-valley, \(L_1\)-valley and \(L_2\)-valley of \(\hbox {Ge}_{0.89}\) \(\hbox {Sn}_{0.11}\) nanowires or \(\hbox {Ge}_{0.86}\) \(\hbox {Sn}_{0.14}\) nanowires as a function of the stress is shown, and the total electron concentration is chosen as \(N_e\) = 0.8 \(N_0\) = 8\(\times \) \(10^{18}\) \(\hbox {cm}^{-3}\) in the figure, which is lower than the value \(N_e\) = 2\(\times \) \(10^{19}\) \(\hbox {cm}^{-3}\) in Fig. 3. Similar to Fig. 3a, an inflection point also occurs at \(U_{110}\) = 1 GPa in the curve of the ratio \(N_e^{\Gamma }\)/\(N_e\) whether x is 0.11 or 0.14. However, compared to Fig. 3a, more electrons will populate the \(\Gamma \)-valley in Fig. 8a even though \(N_e\) is reduced. The calculated data shows that the maximum value of \(N_e^{\Gamma }\)/\(N_e\) is about 6.45% when x = 0.11, which is an order magnitude greater than that of \(N_e^{\Gamma }\)/\(N_e\) when x=0.05 in Fig. 3a, and the ratio \(N_e^{L_2}\)/\(N_e\) at the \(L_2\)-valley in Fig. 8a is less than that in Fig. 3a under the same \(U_{110}\), because the raise of Sn content makes the energies of the electron states at the \(L_2\)-valley closer to those at the \(\Gamma \)-valley. In Fig. 8b with the diameter of 18 nm, compared with Fig. 8a, the filling ratio of the electrons at the \(L_2\)-valley is slightly enhanced, which leads to a little decrease of the ratio \(N_e^{\Gamma }\)/\(N_e\) at the inflection point. Moreover, as D increases to 24 nm in Fig. 8c, the ratio \(N_e^{\Gamma }\)/\(N_e\) at the inflection point of \(U_{110}\)=1 GPa will further go down, but its value is still several times higher than that of \(\hbox {Ge}_{1-x}\hbox {Sn}_{x}\) nanowires with low Sn contents in Fig. 3c.

(a) The ratio \(N_e^{L}\)/\(N_e\) versus the stress \(U_{110}\) in \(\hbox {Ge}_{1-x}\hbox {Sn}_{x}\) nanowires with x = 0.11 and 0.14 when D = 12 nm, and the inset figure is the ratio \(N_e^{\Gamma }\)/\(N_e\) versus the stress \(U_{110}\); (b, c) are in common with (a) but for the diameter of 18 nm and 24 nm, respectively.

(a) The optical gain along z direction and x direction of \(\hbox {Ge}_{1-x}\hbox {Sn}_{x}\) nanowires when x = 0.11 and D = 12 nm under the different stress \(U_{110}\). The solid line and dashed line represent the z direction and x direction, respectively; (b, c) are in common with (a) but for the diameter D of 18 nm and 24 nm, respectively.

(a–c) represent the FCA loss, z direction peak gain and net peak gain of \(\hbox {Ge}_{0.89}\) \(\hbox {Sn}_{0.11}\) nanowires as functions of the stress \(U_{110}\) and the diameter D; (d–f) are in common with the corresponding (a–c), respectively but for \(\hbox {Ge}_{0.86}\) \(\hbox {Sn}_{0.14}\) nanowires.

The optical gain of \(\hbox {Ge}_{0.89}\) \(\hbox {Sn}_{0.11}\) nanowires with D of 12 nm as a function of \(U_{110}\) is presented in Fig. 9a, and the total electron concentration \(N_e\) is 0.8 \(N_0\) in the calculation. Evidently, the peak gain along the z direction becomes much larger than that along the x direction when the stress is imposed, and the peak gain will not be improved monotonously with increasing \(U_{110}\), which equals to the condition in Fig. 4a. In the figure, the peak gain along the z direction will go up from 140.91 \(\hbox {cm}^{-1}\) at the photon energy \(E\) \(\approx \)0.60 eV under \(U_{110}\) = 0 GPa to 2555.26 \(\hbox {cm}^{-1}\) at \(E\) \(\approx \)0.41 eV under \(U_{110}\)=3 GPa, then reduce to 2388.05 \(\hbox {cm}^{-1}\) at \(E\) \(\approx \)0.34 eV under \(U_{110}\)=4 GPa, and the peak position will shift from SWIR band to MWIR band. As a matter of fact, the maximum value of peak gain only decreases from 3573.63 \(\hbox {cm}^{-1}\) in Fig. 4a with x=0.08 to 2579.50 \(\hbox {cm}^{-1}\) in Fig. 9a with x=0.11 even though the total electron concentration decreases from 2 \(N_0\) to 0.8 \(N_0\). Because the energy difference of the electron states between the \(\Gamma \)-valley and \(L_2\)-valley in \(\hbox {Ge}_{0.89}\) \(\hbox {Sn}_{0.11}\) nanowires is less than that in \(\hbox {Ge}_{0.92}\hbox {Sn}_{0.08}\) nanowires, which results in a greater probability of electrons occupying the \(\Gamma \)-valley of \(\hbox {Ge}_{0.89}\) \(\hbox {Sn}_{0.11}\) nanowires and offsets the falling of the electron concentration in \(\hbox {Ge}_{0.89}\) \(\hbox {Sn}_{0.11}\) nanowires. In Fig. 9b with D of 18 nm and Fig. 9c with D of 24 nm, the variation trend of the optical gain as the stress \(U_{110}\) is in common with that in Fig. 9a. Nevertheless, the maximum peak gain will be reduced slightly by the increasing diameter. The FCA loss, z direction peak gain and net peak gain of \(\hbox {Ge}_{0.89}\) \(\hbox {Sn}_{11}\) nanowires with D of 12 nm as a function of \(U_{110}\) is shown in Fig. 10a, and we should note the total electron concentration \(N_e\) is set as 0.8 \(N_0\). From the figure, it can be found that the peak gain exceeds the FCA loss even if \(U_{110}\)=0 GPa. Moreover, the peak gain will be sharply enhanced to 2579.50 \(\hbox {cm}^{-1}\) at the inflection point of \(U_{110}\)=2.5 GPa by the applied stress, while the FCA loss only increases to 267.95 \(\hbox {cm}^{-1}\) at the same \(U_{110}\). Until \(U_{110}\) is increased to 4 GPa, although the peak gain will be reduced a little, its value is still much greater than the corresponding FCA, thus the considerable positive net peak gain can be acquired and the maximum net peak gain can reach 2311.56 \(\hbox {cm}^{-1}\) at \(U_{110}\)=2.5 GPa in Fig. 10a. In Fig. fig10b and c, compared with Fig. fig10a, the peak gain and FCA loss at the same \(U_{110}\) will undergo the reduction and increase, which together leads to the decline of the net peak gain. Even though, the net peak gain of \(\hbox {Ge}_{0.89}\) \(\hbox {Sn}_{11}\) nanowires is invariably larger than zero irrespective of \(U_{110}\) and D. In Fig. fig10d with x=0.14 and D=12 nm, an inflection point does not appear in the curve of the peak gain. The reason may be that \(E_{e}^{\Gamma }\) is always lower than \(E_{e}^{L_2}\) in \(\hbox {Ge}_{0.86}\) \(\hbox {Sn}_{14}\) nanowires whether \(U_{110}\) is 0 GPa or 4 GPa, which indicates that unstrained and strained \(\hbox {Ge}_{0.86}\) \(\hbox {Sn}_{14}\) nanowires are all direct bandgap semiconductor, and the filling of electrons at the \(\Gamma \)-valley of \(\hbox {Ge}_{0.86}\) \(\hbox {Sn}_{0.14}\) nanowires is different from those of \(\hbox {Ge}_{1-x}\hbox {Sn}_{x}\) (x=0.05, 0.08 and 0.11) nanowires. In comparison with Fig. fig10a, although the FCA loss has increased at the same \(U_{110}\), the substantial enhancement of the peak gain under the stress still makes the FCA loss almost negligible in Fig. fig10d. As seen in Fig. fig10e with D=18 nm, an inflection point in the curve of the peak gain also disappears, the redshift of the peak gain position caused by the diameter augment makes the FCA loss exceed 1000 \(\hbox {cm}^{-1}\) under \(U_{110}\)=4 GPa, but it is still far less than the corresponding peak gain of 4859.33 \(\hbox {cm}^{-1}\). In Fig. fig10f, the peak gain position will be further red shifted compared to Fig. fig10e, and the FCA loss can go up to 1776.57 \(\hbox {cm}^{-1}\) with 4 GPa stress. Accordingly, the net peak gain has sharply decreased to 1502.26 \(\hbox {cm}^{-1}\) under \(U_{110}\)=4 GPa. In view of the above analysis, it can be inferred that the sizable positive net peak gain along the z direction can be obtained in [110] direction strained \(\hbox {Ge}_{1-x}\hbox {Sn}_{x}\) nanowires with high Sn compositions (\(x\) \(\ge \)10%) despite the total electron concentration is decreased to the order of \(10^{18} \, \hbox {cm}^{-3}\).

Conclusion

In summary, the electronc structures of \(\hbox {Ge}_{1-x}\hbox {Sn}_{x}\) nanowires with low Sn contents (\(x\) 10%) and high Sn contents (\(x\) \(\ge \)10%) under the stress \(U_{110}\) are calculated on the basis of the effective-mass theory, and we find a significative phenomenon that the eight equivalent indirect bandgap L-valleys of \(\hbox {Ge}_{1-x}\hbox {Sn}_{x}\) nanowires can be split into fourfold degenerate \(L_1\)-valleys and \(L_2\)-valleys by the applied \(U_{110}\), which leads to an inflection point appearing in the curve of \(\Gamma \)-valley filling ratio-stress whether Sn composition is 0.05 or 0.14. However, this situation will not occur in [100] direction strained \(\hbox {Ge}_{1-x}\hbox {Sn}_{x}\) nanowires36. Moreover, the first gain peak of \(\hbox {Ge}_{1-x}\hbox {Sn}_{x}\) nanowires with x ranging from 0.05 to 0.14 will be red shifted to the SWIR or MWIR band by the imposed stress. For \(\hbox {Ge}_{1-x}\hbox {Sn}_{x}\) nanowires with low Sn contents, the calculated results manifest that a certain peak gain along the z direction will be acheived only when the total electron concentration reaches the order of \(10^{19} \, \hbox {cm}^{-3}\), which can result in the large and not negligible FCA loss. Therefore, the positive net peak gain is hardly obtained in \(\hbox {Ge}_{0.95}\hbox {Sn}_{0.05}\) nanowires, which is contrary to the case in \(\hbox {Ge}_{0.98}\) \(\hbox {Sn}_{0.02}\) nanowires due to the improved occupancy rate of electrons at the direct \(\Gamma \)-valley. For \(\hbox {Ge}_{1-x}\hbox {Sn}_{x}\) nanowires with high Sn contents, even if the total electron concentration is as low as the order of \(10^{18} \, \hbox {cm}^{-3}\) , the peak gain along the z direction will exceeds the FCA loss no matter what the stress and diameter, which can cause the the considerable positive net peak gain, especially in \(\hbox {Ge}_{0.86}\) \(\hbox {Sn}_{0.14}\) nanowires with small diameters. In light of the studies in the paper, we can conclude that [110] direction strained \(\hbox {Ge}_{1-x}\hbox {Sn}_{x}\) nanowires does not demonstrate advantage over [100] direction strained \(\hbox {Ge}_{1-x}\hbox {Sn}_{x}\) nanowires as SWIR or MWIR lasers owing to the L-valley splitting. Whereas, [110] direction strained \(\hbox {Ge}_{1-x}\hbox {Sn}_{x}\) nanowires is superior to unstrain \(\hbox {Ge}_{1-x}\hbox {Sn}_{x}\) nanowires, because the z direction peak gain can be enhanced many times by applying the stress. Our investigations have deepened the understanding of strained \(\hbox {Ge}_{1-x}\hbox {Sn}_{x}\) nanowires as optoelectronic devices.

Data availability

The data presented in this study are available on request from the corresponding author.

References

Siew, S. Y. et al. Review of silicon photonics technology and platform development. J. Light. Technol. 39(13), 4374–4389 (2021).

Vyas, K. et al. Group III–V semiconductors as promising nonlinear integrated photonic platforms. Adv. Phys. X 7(2097020), 1–39 (2022).

Zhang, X., Wu, D. & Geng, H. Heterojunctions based on II–VI compound semiconductor one-dimensional nanostructures and their optoelectronic applications. Crystals 7(307), 1–24 (2017).

Von Den Driesch, N. et al. Direct bandgap group IV epitaxy on Si for laser applications. Chem. Mater. 27(13), 4693–4702 (2015).

Fadaly, E. M. et al. Direct-bandgap emission from hexagonal Ge and SiGe alloys. Nature 580(7802), 205–209 (2020).

Mungua, J. et al. Temperature dependence of the indirect bandgap in ultrathin strained silicon on insulator layer. Appl. Phys. Lett. 100, 102107 (2012).

Sun, G. Intersubband approach to silicon based lasers-circumventing the indirect bandgap limitation. Adv. Opt. Photon. 3(1), 53–87 (2010).

Toriumi, A. & Nishimura, T. Germanium CMOS potential from material and process perspectives: Be more positive about germanium. Jpn. J. Appl. Phys. 57(010101), 1–44 (2017).

Zhou, Z. P., Yin, B. & Michel, J. On-chip light sources for silicon photonics. Light Sci. Appl. 4(e358), 1–13 (2015).

De Kersauson, M. et al. Direct and indirect band gap room temperature electroluminescence of Ge diodes. J. Appl. Phys. 108(023105), 1–4 (2010).

Petykiewicz, J. et al. Direct bandgap light emission from strained germanium nanowires coupled with high-Q nanophotonic cavities. Nano Lett. 16(4), 2168–2173 (2020).

Armand Pilon, F. T. et al. Lasing in strained germanium microbridges. Nat. Commun. 10(2724), 1–8 (2019).

Margetis, M. et al. Si-Based GeSn lasers with wavelength coverage of 2–3 µm and operating temperatures up to 180 K. ACS Photon. 5(3), 827–833 (2018).

Zheng, J. et al. Growth of high-Sn content (28%) GeSn alloy films by sputtering epitaxy. J. Cryst. Growth 492(15), 29–34 (2018).

Meng, A. C. et al. Growth mode control for direct-gap core/shell Ge/GeSn nanowire light emission. Mater. Today 40, 101–113 (2020).

Xiong, W., Wang, J. W., Fan, W. J., Song, Z. G. & Tan, C. S. The theoretical direct-band-gap optical gain of Germanium nanowires. Sci. Rep. 10(32), 1–13 (2020).

Xiong, W., Gong, L. L., Chen, W. S. & Wang, Z. W. The variation of optical gain in Ge nanowires induced by the \(\Delta \)\(E_{e}^{\Gamma, L}\) and symmetry of hole states under the axial stress. J. Appl. Phys. 128(094304), 1–9 (2020).

Xiong, W., Ye, G. P., Xu, Q. Y., Gong, L. L. & Wang, Y. The optical gain of Ge nanowires engineered by the [100] direction uniaxial stress perpendicular to the nanowire axis. Phys. Lett. A 409(127526), 1–10 (2021).

Sun, G., Soref, R. A. & Cheng, H. H. Design of an electrically pumped SiGeSn/GeSn/SiGeSn double-heterostructure midinfrared laser. J. Appl. Phys. 108(033107), 1–6 (2010).

D’Costa, V. R. et al. Sn-alloying as a means of increasing the optical absorption of Ge at the C-and L-telecommunication bands. Semicond. Sci. Technol. 24(115006), 1–8 (2009).

Wirths, S. et al. Lasing in direct-bandgap GeSn alloy grown on Si. Nat. Photon. 9(2), 88–92 (2015).

Ghetmiri, S. A. et al. Direct-bandgap GeSn grown on silicon with 2230 nm photoluminescence. Appl. Phys. Lett. 105(151109), 1–5 (2014).

Kong, Z. Z. et al. Growth and strain modulation of GeSn alloys for photonic and electronic applications. Nanomaterials 12(981), 1–15 (2022).

Cong, H. et al. Multilayer graphene-GeSn quantum well heterostructure SWIR light source. Small 14(1704414), 1–5 (2018).

Moutanabbir, O. et al. Monolithic infrared silicon photonics: The rise of (Si) GeSn semiconductors. Appl. Phys. Lett. 118(110502), 1–10 (2021).

Azrak, E. et al. Growth of in-plane \(\text{ Ge}_{1-x} \text{ Sn}_{x}\) nanowires with 22 at.% Sn using a solid–liquid–solid mechanism. J. Phys. Chem. C 122(45), 26236–26242 (2018).

Azrak, E. et al. Low-temperature plasma-assisted growth of core-shell GeSn nanowires with 30 % Sn. J. Phys. Chem. C 124(1), 1220–1226 (2019).

Singh, S. et al. Ge-\(\text{ Ge}_{0. 92} \text{ Sn}_{0. 08}\) core-shell single nanowire infrared photodetector with superior characteristics for on-chip optical communication. Appl. Phys. Lett. 120(171110), 1–6 (2022).

Assali, S. et al. Strain engineering in Ge/GeSn core/shell nanowires. Appl. Phys. Lett. 115(113102), 1–4 (2019).

Gong, R., Zheng, L., Roca i Cabarrocas, P. & Chen, W. H. Rational control of GeSn nanowires. Phys. Status Solidi RRL 16, 2100554 (2022).

Fan, Q. et al. Direct and quasi-direct band gap of novel Si–Ge alloys in P-3m1 phase. J. Phys. Condens. Matter 33(385702), 1–13 (2021).

Moontragoon, P., Soref, R. A. & Ikonic, Z. The direct and indirect bandgaps of unstrained \(\text{ Si}_{x} \text{ Ge}_{1-x-y} \text{ Sn}_{y}\) and their photonic device applications. J. Appl. Phys. 112(073106), 1–8 (2012).

Kang, Y. Y. et al. \(\text{ Ge}_{0. 95} \text{ Sn}_{0. 05}\) gate-all-around p-channel metal-oxide-semiconductor field-effect transistors with Sub-3 nm nanowire width. Nano Lett. 21(13), 5555–5563 (2021).

Chen, G. et al. High-speed photodetectors on silicon photonics platform for optical interconnect. Laser Photon. Rev. 16(2200117), 1–39 (2022).

Kim, Y. M. et al. Short-wave infrared cavity resonances in a single GeSn nanowire. Nat. Commun. 14(4393), 1–7 (2023).

Xiong, W., Qiu, J. A., Wen, Z. Q., Zhu, H. Y. & Wang, F. The [100] direction strained \(\text{ Ge}_{1-x} \text{ Sn}_{x}\) nanowires with low Sn contents towards the application of SWIR or MWIR lasers. Phys. Lett. A 519(129716), 1–7 (2024).

Albani, M. et al. Critical strain for Sn incorporation into spontaneously graded Ge/GeSn core/shell nanowires. Nanoscale 10(15), 7250–7256 (2018).

Van de Walle, C. G. Band lineups and deformation potentials in the model-solid theory. Phys. Rev. B 39(3), 1871–1883 (1989).

Mugny, G., Li, J., Triozon, F. & Niquet, Y. M. Electronic structure and electron mobility in \(\text{ Si}_{1-x} \text{ Ge}_{x}\) nanowires. Appl. Phys. Lett. 110(052102), 1–4 (2017).

Low, K. L. et al. Electronic band structure and effective mass parameters of \(\text{ Ge}_{1-x} \text{ Sn}_{x}\) alloys. J. Appl. Phys. 112(103715), 1–9 (2012).

Rainko, D. et al. Investigation of carrier confinement in direct bandgap GeSn/SiGeSn 2D and 0D heterostructures. Sci. Rep. 8(15557), 1–13 (2018).

Fischetti, M. V. & Laux, S. E. Band structure, deformation potentials, and carrier mobility in strained Si, Ge, and SiGe alloys. J. Appl. Phys. 80(4), 2234–2252 (1996).

Roman, B. J. & Ewald, A. W. Stress-induced band gap and related phenomena in grey tin. Phys. Rev. B. 5(10), 3914–3932 (1971).

Zhang, Q. F. et al. Tensile-strained mid-infrared GeSn detectors wrapped in \(\text{ Si}_{3} \text{ N}_{4}\) liner stressor: Theoretical investigation of impact of device architectures. IEEE J. Photon. 7(6803208), 1–26 (2015).

Adachi, S. Properties of Semiconductor Alloys: Group-IV, III–V and II–VI Semiconductors (Wiley, 2009).

Zhu, Y. H., Xu, Q., Fan, W. J. & Wang, J. W. Theoretical gain of strained \(\text{ GeSn}_{0.02}\)/\(\text{ Ge}_{1-x-y^{\prime }}\)\(\text{ Si}_{x}\)\(\text{ Sn}_{y^{\prime }}\) quantum well laser. J. Appl. Phys. 107(073108), 1–8 (2010).

Zelazna, K. et al. Electronic band structure of compressively strained \(\text{ Ge}_{1-x}\)\(\text{ Sn}_{x}\) with \(x\)\(<\)0.11 studied by contactless electroreflectance. Appl. Phys. Lett. 106(142102), 1–5 (2015).

Eckhardt, C., Hummer, K. & Kresse, G. Indirect-to-direct gap transition in strained and unstrained \(\text{ Sn}_{x}\)\(\text{ Ge}_{1-x}\) alloys. Phys. Rev. B 89(165201), 1–9 (2014).

Seifner, M. S., Biegger, F., Lugstein, A., Bernardi, J. & Barth, S. Microwave-assisted \(\text{ Ge}_{1-x}\)\(\text{ Sn}_{x}\) nanowires synthesis: Precursor species and growth regimes. Chem. Mater. 27(17), 6125–6130 (2015).

Biswas, S. et al. Stretching the equilibrium limit of Sn in \(\text{ Ge}_{1-x}\)\(\text{ Sn}_{x}\) nanowires: Implications for field effect transistors. ACS Appl. Nano Mater. 4(2), 1048–1056 (2021).

Acknowledgements

This work was supported by the National Natural Science Foundation of China (Nos. 62074021 and 52472051) and the Natural Science Foundation Project of CQ CSTC (Nos. cstc2020jcyj-msxmX0822 and CSTB2023NSCQ-MSX0971).

Author information

Authors and Affiliations

Contributions

W. Xiong conceived the project, developed the computation code, analyzed the data and edited the paper. J. A. Qiu wrote the original paper and analyzed the data. H. Y. Zhu and Z. Q. Wen conducted the investigation and took part in the discussions. Z. Y. Hu helped to visualize the figures. X. Li contributed to paper revisions and put forward constructive opinions. All authors reviewed the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Qiu, JA., Zhu, HY., Wen, ZQ. et al. The indirect L-valleys splitting inductive optical gain variation of \(\hbox {Ge}_{1-x}\hbox {Sn}_{x}\) nanowires caused by [110] direction uniaxial stress. Sci Rep 15, 5864 (2025). https://doi.org/10.1038/s41598-025-89005-0

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-89005-0