Abstract

To explore the influence of water inflow on the safe and efficient tunneling construction of TBM in water-rich Luohe Formation sandstone. Based on the tunneling data at the main inclined shaft TBM construction site of Kekegai Coal Mine, a relationship model between tunneling speed and water inflow is established by using statistical analysis and machine learning theory; XRD and SEM tests on the microstructural components of Luohe Formation sandstone are carried out to analyze the mechanism of water inflow in argillaceous cemented sandstone affecting the tunneling speed of TBM. The Libsvm support vector machine (SVR) model is more effective than multiple regression and random forest (RF) models in evaluating nonlinear problems. When the Gaussian radial basis function (RBF) is selected as the kernel function, the prediction result R2 reaches 0.974, MAE is 0.699, and MAPE is 1.89%. When the water inflow is small, the mud cake formed by water–rock interaction and the roof fall phenomenon of surrounding rock are the main factors for the large fluctuation of tunneling speed. When the water inflow reaches 45–60 m3/h, the significant increase in tunneling speed is due to the fact that the water pressure seepage scouring greatly reduces the probability of mud cake and surrounding rock roof fall phenomena. This conclusion is verified by the engineering practice of the main inclined shaft of Kekegai Mine. The research results provide a reference for the control of water inflow during TBM tunneling under similar geological conditions.

Similar content being viewed by others

Introduction

Tunnel Boring Machine (TBM) has become an indispensable key technology in the construction of transportation tunnels, water conservancy and hydropower tunnels, as well as in mining and energy engineering. Its advantages include safety, economical, environmental protection, and high efficiency, leading to its widespread use in large and medium-sized engineering projects1,2,3. However, the advantages of TBM application in water-rich soft rock geological conditions, particularly in western China, are currently facing challenges4,5.

In terms of predicting TBM boring parameters, the research primarily concentrates on three major categories of methods: theoretical, empirical, and machine learning. The theoretical approach is grounded in physical principles and mathematical models, making it highly interpretable and suitable for theoretical researchand parameter analysis; however, it necessitates substantial a priori knowledge. The empirical type, which is grounded in historical data and the accumulation of experience, possesses practical utility; however, it has limited capacity for generalization. In contrast, the machine learning type is capable of learning complex patterns and relationships from data, demonstrating high adaptability. It can effectively manage large datasets and multivariate relationships, and its application in tunnel construction and technology is currently on the rise6,7,8,9.

The inability to effectively address the issue of water influx during tunnel boring has resulted in severe consequences10. The substantial volume of water within the tunnel not only significantly hindered the boring speed of the TBM but also precipitated a series of safety incidents, including equipment damage and injuries11. In the past decade, significant research has been conducted on the water-machine-rock interaction in tunnel boring, resulting in a series of notable achievements by scholars both domestically and internationally. For instance, Yan et al.12 found that as the water content increases in sandstone, the cutting force of the TBM hobbing cutter changes, leading to a decrease in the vertical propagation range of cracks. Notably, the horizontal propagation range decreases significantly once the water content exceeds 3%. Additionally, the peak normal force and the fluctuation range of the tangential force also decline, with the maximum tool force gradually diminishing. Similarly, Lin et al.13 conducted rock crushing tests using an electro-hydraulic servo rigidity testing machine and observed that with increasing water content, the peak penetration force, consumed energy, and specific energy exhibit a negative exponential trend, while the volume of rock chips increases with water content following a quadratic trend. It is well established that the compressive, shear, and tensile strengths, as well as the modulus of elasticity of rocks, decrease to varying extents as water content rises. Furthermore, Zhang et al.14 identified five primary mechanisms through which water weakens rocks: the swelling and dissolution of clay minerals, reduction of capillary tension, increase in pore pressure, reduction of fracture energy, and weakening of intergranular cohesion and friction.Water expands the pore structure of rocks, increases the connectivity of pores, further enlarges primary cracks, and enhances both porosity and permeability. Xu et al.15 investigated how water–rock interactions alter the morphology of rocks and influence the rate of crack expansion. Zeng et al.16 found that soft rocks typically contain silica-alumina salts, such as kaolinite and illite, which expand and disintegrate upon interaction with water, leading to asymmetric stresses and damage to the internal structural system of these rocks. This results in asymmetric stress within the soft rock, compromising the internal structural integrity and causing the rock particles to break and disperse. When the rock is subjected to stress, the movement of particle edges and the chemical actions of the solution contribute to a decrease in cohesion and internal friction, ultimately reducing the mechanical strength of the rock.

In the study of the significant deformation mechanisms of soft rock tunnels, Bian et al.17 attributed the large deformation of the Huangjiazhai Tunnel primarily to plastic flow resulting from tunnel excavation under high ground stress and low rock strength, as well as the water-force coupling process in the shale. Zhang et al.18 concluded that the length of bolts could be determined based on the radius of the plastic zone. Wang et al.19 found that the deformation mechanism of the tunnel is a composite mechanism, with CRLD bolts providing consistent resistance and accommodating large deformation during tensioning, thereby absorbing energy. Furthermore, CRLD bolts adapt to the requirements of soft rock tunnel support. Additionally, new support systems have been accumulated and summarized regarding ample deformation support for soft rock tunnels20,21,22.

The aforementioned scholars have made significant contributions to the study of water–rock and machine-rock interactions. However, current research on the mechanisms by which the formation and variation of water influx influence the parameters of TBM excavation and control strategies, particularly in the context of western water-rich and weakly cemented sandstone inclined shaft excavations, remains limited. With the advancement of underground mining development, research on TBM excavation has garnered increasing attention. However, previous studies have often inadequately explored and utilized comprehensive, multidimensional data from excavation sites to analyze the excavation process. This article focuses on the Luohe formation sandstone section of the main inclined shaft TBM construction at Kekegai Coal Mine. It innovatively integrates a comprehensive dataset encompassing various types of excavation parameters and detailed engineering geological data. Employing unique data preprocessing techniques, such as Savitzky–Golay filtering, the study conducts an in-depth analysis of the interrelationships among key parameters (including water inflow and cutterhead torque) and their impact on excavation speed. Additionally, the Libsvm model is innovatively introduced to analyze excavation parameters within this specific geological context. This model analyzes the mechanisms by which varying water influx influences changes in digging speed from the perspectives of seepage, water–rock interaction, and machine-rock interaction. It innovatively integrates a machine learning model with mechanistic analysis, effectively addressing the limitations associated with the “black-box” problem that is inherent in machine learning. In comparison to previous studies, this research has elucidated the underlying mechanisms influencing excavation efficiency under specific geological conditions in a more targeted manner, thereby offering precise guidance for future engineering practices.

Background of the study

Project profile

The main inclined shaft of the Coco Cover Coal Mine is situated approximately 32 km northwest of Yulin City in Shaanxi Province (see Fig. 1). This shaft, constructed using an open-type TBM, has a diameter of 7.13 m. The project for the main inclined shaft commenced in May 2021 and employs a combination of open trench excavation and TBM construction methods. The excavation of the sandstone from the Luohe Group extends 2338.09 m, while the sandstone from the Luohua Formation, which is characterized as water-rich, soft, and susceptible to significant deformations, measures 2200 m. The TBM excavation has a diameter of 7.13 m, a total length of 4770 m, and reaches a maximum shaft depth of 517.5 m23. This project represents the first instance of open-type TBM construction for long inclined shafts in the western region of China.

Geological condition

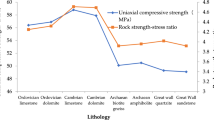

According to the geological data from the mine, the geological section of its main inclined shaft is illustrated in Fig. 2, where the thickness of the Cretaceous Luohe Formation ranges from 153.15 to 221.40 m. The burial depth reaches between 230 and 330 m below ground level24, exhibiting the typical geological characteristics of unstable strata and aquifers in the western region23. The rock mass within the wellbore is categorized into four primary structural types: discrete structure, fractured structure, laminated structure, and block structure (comprising the Anding Formation and Zhiluo Formation). The sandstone of the Cretaceous Luohe Formation, characterized by pore-fracture water retention, is situated within a strongly weathered zone, which is classified as a discrete-fractured structure of V rock type. The water richness is substantial, though the strength is relatively low, with compressive strength primarily ranging from 10 to 30 MPa and a softening coefficient between 0.45 and 0.75. The water-rich sandstone of the Luohe Formation exhibits an interlaced laminar structure with weak cementation of mud and calcium, while the fractured rock layer is notably complex. This complexity increases the likelihood of destabilization and damage to the surrounding rock of the inclined shaft. Additionally, when this layer serves as the roof of the tunnel, there is a heightened risk of large-scale roof collapse, presenting significant challenges for excavation.

Research process display

To clarify the analytical process of this study, the following flowchart has been created (Fig. 3). This visual representation is intended to improve readers’ comprehension of the logical relationships among the various components and the overall research methodology.

Overall idea of the study

The overall concept is illustrated in Fig. 3. Noise reduction during preprocessing employs a Savitzky–Golay (S–G) filter, which is a filtering method based on local polynomial least-squares fitting in the time domain. This approach has the advantage of preserving the trend of the signal throughout the smoothing process, effectively maintaining the essential features of the high-frequency signal components and enhancing the accuracy and reliability of the data compared to other filtering methods. To predict the digging speed for correlation analysis, a Libsvm model is established, and new data are utilized to validate the model. The performance of the Libsvm model is compared with that of multiple linear regression and random forest (RF) models, providing an in-depth analysis of how the model responds to variations in water influx and its impact on digging speed.

Data processing and analysis

Data collection

Source and scope: The data is derived from the excavation process of the Luohe Formation sandstone section at the TBM construction site of the main inclined shaft of the Kekegai Coal Mine. This includes excavation parameters such as penetration, total thrust, cutterhead speed, cutterhead torque, and propulsion speed, along with geological data encompassing geological structure and rock characteristics. This information serves as a foundation for analyzing the relationship between water inflow and excavation speed.

Data integrity considerations: This comprehensive collection of characteristic values and time series data represents stable sections of mainstream excavation under varying water inflow rates. It ensures an accurate reflection of both water inflow conditions and excavation circumstances, thereby enhancing the reliability of the research results.

Data preprocessing

Data cleaning and screening: Clean and remove abnormal data resulting from sensor failures, and filter specific water inflow data within the range of 0–60 according to research objectives to ensure accurate and targeted results.

Noise reduction processing: Savitzky–Golay filter is employed to denoise the filtered data. This method utilizes local polynomial least squares fitting, which smooths the data while preserving trends and high-frequency components, thereby enhancing data accuracy and facilitating subsequent analysis and modeling.

In this study, several key parameters significantly influence the final results:

Water inflow: As a primary influencing factor, its magnitude is directly related to the tunneling boring machine (TBM) excavation speed in the sandstone section of the Luohe Formation. Within various ranges of water inflow (e.g., 0–60 m3/h), the excavation speed exhibits notable phased changes, playing a crucial role in the construction of models and the analysis of excavation efficiency.

Excavation parameters:

Penetration: This parameter reflects the depth at which the cutting tool penetrates the rock and is closely associated with the excavation speed. Variations in penetration values can significantly affect the overall excavation efficiency of the TBM, thereby influencing the presentation of research results.

Total thrust: This is the essential force that propels the TBM forward during excavation. Its magnitude impacts the excavation capacity of the equipment under varying geological and water inflow conditions, thus exerting a significant influence on both excavation speed and subsequent analysis results.

Cutterhead speed: Determines the frequency of rock cutting by the cutterhead, and the speed has a mutually restrictive and influential relationship with excavation speed, cutterhead torque, etc. It is one of the important parameters for analyzing the excavation process and results.

Cutterhead torque: It reflects the resistance experienced by the cutterhead when cutting rocks, and its numerical changes reflect the comprehensive influence of rock characteristics, water inflow, and other factors on excavation, which has important reference value for result analysis.

Progress speed: It is not only the target variable for research, but also an intuitive indicator for measuring excavation efficiency. It is influenced by various factors such as other parameters and water inflow, and its changes are also the key to evaluating the effectiveness of the entire excavation process and model.

Engineering geological parameters

Stratigraphic structure: The complexity of the stratigraphic structure of the Luohe Formation sandstone affects the excavation path and stability of TBM. Different stratigraphic layers and structural conditions can change the difficulty of excavation, which in turn affects the excavation speed and related research results.

Rock characteristics (such as pore and fracture characteristics, rock strength, and cementation type): These characteristics determine the rock’s machinability, as well as its ability to accommodate and conduct water inflow, fundamentally affecting the working conditions faced by TBM during excavation, and have a significant impact on the final excavation speed and research results.

Correlation analysis

To enhance the recognition of the degree of correlation among each feature, as well as between each feature and the target, and to improve the accuracy and stability of the modeling, we selected consistent data for the subsequent model establishment. This selection was based on the research needs of this paper, focusing on the sandstone section of the Luohe Formation. We analyzed 15 types of surges, corresponding to the original construction of 310 groups of ascending sections and stable sections. The digging parameters representative of the mainstream digging section and the stable section were chosen, specifically for the following characteristics: penetration (p), total propulsive force (F), cutter speed (n), cutter torque (T), and propulsive speed (v). A correlation analysis was conducted, as illustrated in Fig. 4.

The Pearson correlation coefficient (person correlation coefficient) R measures the linear relationship between two variables (X, Y) between − 1 and 1.

Corresponding to Fig. 4a–e, where R values are 0.954, 0.826, 0.84, 0.76, and 0.29, respectively, a robust positive correlation is observed between penetration, total propulsion force, and cutter rotation speed within the range of 0.8 to 1.0. Additionally, a strong positive correlation is noted between cutter torque and propulsion speed, indicated by an R value of 0.76. In contrast, Fig. 4e reveals a weak correlation between water influx and propulsion speed, with an R value of 0.29. As illustrated in Fig. 4d, an increase in torque enhances the cutting force exerted by the cutter plate on the rock, thereby increasing the digging speed. Initially, the torque of the TBM exhibits a positive correlation with cutting speed. However, as torque continues to rise, the rate of increase in cutting speed gradually diminishes, as the TBM road header requires more energy (due to cutter wear) to sustain the cutting process.

The scatter density plots in Fig. 5a to e visually represent the areas where data points are concentrated, and the experience of stable and safe passage through the crushing zone provides recommended ranges for various excavation parameters in TBM construction. Advancing speed: 26–50 mm/min, penetration: 6–8 mm/r, cutter torque: 360–845 kN m, rotational speed: 4.4–5.1 r/min.

The correlation between water inflow and TBM propulsion speed is weak (R = 0.29), primarily due to several influencing factors. The geological conditions are complex and varied, characterized by the unique pore and fracture structures, as well as the loose fragmentation properties of the Luohe Formation sandstone. These characteristics create a tortuous impact path for water inflow on propulsion speed. The process of water–rock interaction involves multiple mineral reactions, making it challenging to represent its comprehensive effect on propulsion speed as a straightforward linear relationship. Additionally, the TBM excavation process is affected by various factors, including penetration and total thrust, which are highly correlated with propulsion speed. The interplay of these multiple factors partially obscures the individual effect of water inflow, resulting in a seemingly weak direct correlation with propulsion speed. This weak correlation holds significant implications for model prediction. In constructing the model, it is essential to thoroughly consider the interaction effects of various factors. Traditional linear models, with their established theories and capacity to integrate multiple independent variables, can serve as the primary exploratory method for the subsequent phase. Moreover, nonlinear models such as Libsvm possess potential advantages in addressing complex relationships due to their distinctive algorithms and mechanisms. They may provide enhanced capabilities for managing intricate nonlinear relationships influenced by multiple factors, offering new avenues for consideration when selecting appropriate prediction models.

Multiple linear regression model

The multiple linear regression model was analyzed using SPSS to obtain a linear regression model of the independent variables (penetration, total propulsive force, cutter speed, and water influx) on the propulsion speed. The model showed that the fitted R2 of multiple linear regression of propulsion speed was 0.963, indicating a good prediction (see (2) for the formula). The unstandardized coefficients, t, showed a significant linear relationship between penetration, total propulsive force, cutter rotational speed, water influx, and propulsive velocity (t < 0.05). In contrast, the coefficient of cutter torque was not significant (t > 0.05).

The multiple linear regression equation is:

The meanings and functions of the symbols in formula (2) are shown in Table 1. It can be seen that the order of influence on digging parameters is cutter speed > penetration > water influx > total propulsion force > cutter torque. It can be seen that the effect of water influx on the digging speed begins to come to the fore. This is because the interaction between water influx and other variables affects the propulsion speed in the multivariate model. The multivariate linear regression model is based on the results of all the variables working together. In contrast, the univariate correlation analysis only considers the simple relationship between a single variable and the propulsion speed.

Libsvm regression model

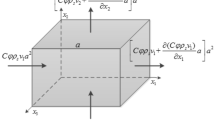

TBM parameter prediction belongs to the Support Vector Regression (SVR) regression problem in Support Vector Machines, which has been widely used in recent years25,26. Using Libsvm modeling, the goal of the SVR regression problem is to find the optimal hyperplane that minimizes the sum of the distances (here, distance refers specifically to the deviation between the predicted and actual values) of all data points and to construct a spacing band of width 2, as in Fig. 6, so that as much data as possible falls within the upper and lower decision boundaries. This is achieved by minimizing the total loss and the regularization term to fit as many data points as possible.SVR has an advantage in predicting concerning small sample data.

The insensitive loss function of SVR is:

The objective function of the SVR model is:

where C is a penalty factor (regularization parameter) characterizing the degree of importance given to outliers, data falling within the upper and lower decision boundaries are fitted with a curve with no loss in (\(\xi_{i} ,\;\xi_{i}^{*}\)). Data falling outside the upper and lower decision boundaries can be retained by giving some penalty through the slack variable (\(- \varepsilon ,\varepsilon\)).

The objective function of the SVR model is further:

The constraints are:

The kernel function uses the radial basis kernel function Radial Basis Function (RBF):

The meanings and functions of the parameters in formulas (3) to (7) are shown in Table 2. γ is an important parameter of the kernel function that is closely related to the standard deviation, which determines the shape of the Gaussian kernel function, and adjusting the shape (bandwidth) of the Gaussian kernel function is one of the important strategies to optimize the model performance (generalization ability). The RBF has good nonlinear mapping and generalization ability, which enables the model to deal with nonlinear problems better, and therefore, it is chosen as the kernel function.

When Libsvm is used, the optimization parameters are obtained according to cross-validation: the penalty factor is 70, the radial basis function parameter is 0.7, and the loss function is taken as 0.01. The flow is shown in Fig. 7.

Model performance evaluation metrics:

The meanings and functions of the parameters in formulas (8) to (11) are shown in Table 3. The larger the R2, the better the fit, the smaller the MAE, MAPE, and RMSE error, and the closer the predicted value is to the true value.

Comparison between Libsvm model and multiple linear regression model

The Libsvm model uses the digging parameters of the rising section (training set) to predict the digging speed of the stabilized section (test set) and compares it with those above multiple linear regression models to plot the change of digging speed with the water influx, as shown in Fig. 8a. The number in each color block in the figure represents 1 type of water influx. The R2 of the training set of multiple linear regression and Libsvm model is 0.951, 0.997, MAE is 2.254, 0.542, and MAPE is 30.55%, 4.35%, respectively; the R2 of the test set of multiple linear regression and Libsvm model is 0.958, 0.974, MAE is 0.989, 0.699, respectively. MAPE was 2.75% and 1.89%, respectively. Another different influx volume (210 data sets) was selected for validation (Fig. 8b), and the R2 of the Libsvm model for the training and test sets were 0.998, 0.972, MAE 0.288, 0.354, and MAPE 1.613%, 1.081%, respectively. The goodness-of-fit of the Libsvm model with a small error indicates that the model has a good generalization ability and no overfitting phenomenon. Sound, and no overfitting phenomenon occurred.

Multivariate linear regression is interpretable for the relationship between propulsion speed and each digging parameter. However, support vector machine predicts better than multiple linear regression in training and test sets. Multiple linear regression assumes a linear relationship between the make features and the target variables. The support vector machine is a nonlinear model with a kernel function, which is more accurate in predicting nonlinear changes.

Comparison of Libsvm model with RF type

Random Forest (RF) is an algorithm that builds a Bagging classification tree based on a decision tree and further introduces a random selection of independent variables to achieve the de-correlation of the tree and realize the improvement of Bagging. RF can significantly improve prediction accuracy by integrating multiple decision tree models, and it also has the advantage of better robustness to noise and outliers. Trial and Error Method in the RF Model. The number of decision trees is 280, and the minimum leaf tree is 5. The prediction results of the advancing speed of each surge stabilization section of Libsvm and RF are averaged, displayed, and compared with the real values, as shown in Figs. 9 and 10.

From Figs. 9 and 10, the RF prediction effect is not as good as that of Libsvm, especially the error is more obvious after the water influx exceeds 47 m3/h. RF has low sensitivity to the changed data, and Libsvm can more accurately capture the nonlinear relationship of the data, and the prediction error is relatively small.

Digging speed mechanism analysis

There exists a strong positive correlation among penetration, total thrust, tool speed, and the propulsion speed of TBMs. The total thrust force, acting as an external force on the rock, directly determines the cutterhead’s and cutting tools’ ability to overcome rock resistance. A reasonable allocation and coordination of the total thrust force enable the various components of the TBM—such as the cutterhead, shield, and propulsion system—to work in unison and achieve optimal performance. Increased penetration and total thrust result in more energy being transferred to the rock, thereby enhancing the efficiency of the rock fragmentation process. As the degree of penetration increases, the interaction between the cutting tool and the rock intensifies, which improves energy utilization efficiency and contributes to higher propulsion speeds. The effect of tool speed is notable; higher tool speeds increase the frequency of contacts and the cutting length between the tool and the rock per unit time, akin to high-frequency cutting actions, which can more effectively fracture the rock and facilitate rapid TBM excavation. The overall collaborative working mechanism of TBM equipment ensures effective coordination among parameters such as total thrust, penetration, and tool speed. Under optimal conditions of total thrust, penetration, and tool speed, the cutterhead and tools achieve superior rock-breaking performance. Furthermore, the equipment’s power system provides stable support for these parameters, collectively fostering a strong positive correlation between thrust speed and these factors.

XRD and SEM results of Luohe formation sandstone

The source of the specimen (sandstone of Luohe Formation), the test apparatus, and the method are referred to the literature27, the mineral X-ray diffraction pattern is shown in Fig. 11a, and the results are shown in Fig. 11b. The content of quartz and feldspar in this sandstone is 73.1%, the colluvium montmorillonite, calcite, hematite, illite, chlorite, and hornblende, and the content of clay minerals is 26.9% more than 25% (with a higher probability of generating mud cake28) The type of colluvium is muddy colluvium, which belongs to the typical weakly colluvial sandstone. SEM test results of fine sandstone Fig. 12a, under different magnifications, the pore boundaries of the weakly cemented sandstone are evident in a profound shape, and many micrometer-sized pores are of different sizes. SEM experiment magnification Fig. 12b, the distribution of the colluvium between the quartz, feldspar, and other minerals skeleton particles show curly, fish scale porous characteristics, in a loose state, and the colluvium contains a large number of micropores. These will be the channels for crack expansion.

Roofing and mud-cake mechanism

From the XRD test, it can be seen that the muddy sandstone of the Luohe Formation in the main incline of the Coco Gai mainly consists of feldspar and quartz mineral grains and muddy colluvium. The muddy part includes a variety of minerals, such as clay minerals (illite, montmorillonite, etc.). Under the water-rich environment, water enters the pores and fissures of the rock and reacts with the muddy cement. The crystal structure of montmorillonite is a 2:1-type layered structure consisting of two layers of silica-oxygen tetrahedra sandwiching a layer of aluminum-oxygen octahedra, with exchangeable cations and water molecules existing between the layers. When montmorillonite absorbs water, the water molecules enter the interlayer and hold up the interlayer spacing, leading to a sharp expansion of the interlayer29. Equations (8), (9), (10), and (11) are the hydration reaction equations of calcium feldspar, sodium feldspar, potassium feldspar, and illite in the sandstone of Luohe Formation, respectively, which are kaolinite. Calcium feldspar, sodium feldspar, and potassium feldspar hydration are generated by kaolinite. A large amount of kaolinite forms a water film effect with water. It can be seen that the clay minerals montmorillonite, kaolinite, illite, and water action led to the expansion and disintegration of the crystal layer, the internal inhomogeneous stresses make the chondritic minerals volume significant expansion and deformation, and the microstructure shows that the rock particles are dispersed16.

Muddy sandstone has been subjected to hydration and expansion in a water-rich environment to undergo complex physicochemical processes, leading to rock fragmentation and adventitious fall under mechanical perturbation. The formation mechanism is shown in Fig. 13. The hydration reaction forms internal expansion30,31. When TBM boring disturbance, tunnel excavation, breaks the original relatively stable and slowly changes the balance of the natural equilibrium state of equilibrium, so that the flow path of groundwater, pressure distribution, etc. changes, the surrounding rock stress state is also due to the excavation and redistribution, thus exacerbating the intensity and complexity of water–rock action.

The influence of water pressure on tunnel performance and potential roof collapse of surrounding rock:

-

(1)

25–45 m3/h water inflow stage.

Within this range of water inflow, the water pressure gradually increases, exerting various impacts on the rock layers. This pressure facilitates deeper penetration of water into rock pores and fractures, thereby accelerating water–rock interactions. These interactions result in the expansion of mineral volumes, propagation of fractures, and a loosening of the rock formation. While this alteration reduces the risk of mud cake formation, it simultaneously compromises the stability of the rock formation itself. Under the disturbance caused by TBM excavation, the surrounding rock becomes more susceptible to small-scale rockfalls. Although the scale of these rockfalls is smaller than during periods of low water inflow, they still significantly reduce the fluctuations in excavation speed. The increase in water pressure alters the internal stress state of the rock, disrupting the original balance of the surrounding rock and heightening the potential for roof collapse. However, at this stage, the water inflow has not yet reached a high level, and the destructive effects of water pressure remain relatively limited, resulting in only minor roof collapse.

-

(2)

45–60 m3/h water inflow stage.

When the inflow is within this range, the water pressure increases further, intensifying the erosion effect of the water flow. The elevated water pressure enables the flow to carry away more cementing material, exacerbating the loosening of rock and forming larger cavities or cracks. This process facilitates rock breaking at the tunnel excavation face, significantly enhancing excavation speed and effectively eliminating the occurrence of mud cake. However, as water inflow and pressure continue to rise, the stability of the surrounding rock faces increased challenges. When the water pressure exceeds the bearing capacity of the rock layer, it can cause serious damage to the rock structure, greatly heightening the potential risk of rock collapse and jeopardizing the safety of tunnel excavation. If support measures are not implemented timely or are inadequate, the combination of water pressure and rock damage may lead to large-scale roof collapse incidents. At this stage, it is essential to reinforce support measures and optimize excavation parameters by leveraging water pressure to facilitate rock breaking, thereby ensuring safe and efficient excavation.

Engineering practice verification

The sandstone of water-rich weakly cemented Luohe Formation in the central well of Kekegai Coal Mine has a loose and poorly cemented structure, with obvious particle boundaries and pore structures, which provides a good channel for groundwater and has strong permeability and hydraulic conductivity. TBM digging process to form the peripheral rock air space, breaking the original rock equilibrium state, the original closed groundwater system is disturbed, and the water on the surrounding rock body produces pressure changes (fracture zone or weak peripheral rock is primary). It leads to the expansion of cracks and the generation of new cracks in the rock body, and the groundwater gushes out through the pores and cracks of the rock, forming gushing water. In this paper, in order to rationalize the concept, the TBM digging speed is divided into micro-digging speed and macro-digging speed; the so-called macro-digging speed is the distance of forward digging per unit of time, including various reasons for downtime calculated, which is the embodiment of the efficiency of rock-breaking and refers to this paper to study the digging speed is a microscopic digging speed, referring to the equipment in the normal working condition, non-stopping state of the distance of forward digging per unit of time. According to the prediction results of the Libsvm model mentioned before, the relationship between the average value of the digging speed and the variation of water influx for each digging section in Fig. 7 is extracted as Fig. 14.

From the analysis of Fig. 14, it can be concluded that in the initial stage of water inflow (0–25 m3/h), the fluctuation value of excavation speed (between AB) is between 28 and 38 mm min−1. The record of the Kekegai main inclined shaft project is as follows: when the water inflow is 5 m3/h, a large-scale collapse occurred on July 10, 2022, with an area of 49.44 m2. On July 17, when the mud cake appeared, the temperature of the cutter head increased by more than 50 °C. The most significant scale collapse occurred from July 18 to 20th, with an area of 77.7 m2, indicating that the coexistence of mud cake and collapse is an essential reason for the decrease in excavation speed, as shown at point B in Fig. 14, which is the lowest point of the advance speed. Upon investigation, the hydration of clay minerals in the sandstone of the Luohe Formation is prone to the formation of mud cakes due to the combined effects of water disturbance during excavation and excavation temperature. At the same time, if the support during excavation is not timely or the support method is improper, it cannot effectively resist rock deformation and stress concentration, leading to roof collapse. It can be seen that during the low water inflow stage, the phenomenon of roof caving and mud cake formation is more severe, causing potential difficulties in advancing, rather than the smaller the water inflow, the more advantageous it is.

In the mid-term stage of water inflow (25–45 m3/h), Fig. 14 shows a significant decrease in the fluctuation of excavation speed (28–34 mm min−1 between CD), with a decrease of 40% compared to the initial stage. This is due to the increased permeability of the rock layers, increased water pressure, and intensified hydration reactions, resulting in significant changes in the rock structure, including an increase in mineral volume expansion and fracture propagation. The rock layers are looser, reducing the risk of mud cake formation. In the later stage of water inflow (45–60 m3/h), the excavation speed rises to 48 mm min−1 (point E). The mechanism of the turning point in excavation speed is mainly attributed to the seepage and erosion of groundwater. The more considerable water inflow intensifies the scouring and erosion of rock layers, the loss of cementing material intensifies rock loosening, the infiltration effect triggers rock particle movement, the infiltration flow accelerates dissolution and erosion, intensifies the expansion of water inflow channels, forms larger cavities or cracks, and makes it easier to break the rock in the tunnel excavation face, and less likely to produce mud cake phenomenon. The footage from December 1st and 3rd, in the later stages of water inflow, reached more than 35 m, which is well verified.

However, suppose the water inflow increases to 60 m3/h, as shown in Fig. 14. In that case, the water pressure will continue to increase, exceeding the bearing capacity of the rock layer, leading to further damage to the rock structure and posing more significant safety risks to the tunnel excavation face. Reducing the excavation rate and further strengthening the surrounding rock support is necessary. The total sandstone excavation in the Luohe Formation of the Kekegai central well is 2338 m, accounting for 49% of the total TBM excavation. The sandstone of the Luohe Formation in the Fushui section accounts for 94.1% of the total length of the Luohe Formation sandstone, and the range of collapse and fragmentation accounts for 68.9% of the Fushui section (with a fragmentation area accounting for 65.7%). A large-scale and long-distance "anchor net cable spraying + steel arch + advanced pre-grouting" combined support method is adopted24. The fact that the water inflow of the Luohe Formation on site is strictly controlled below 60 m3/h is an interpretation of this mechanism.

Extracting the statistics of intelligent TBM instrumentation records before and after the emergence of mud cake in the surging volume of 5.0 m3/h on July 17, the changes of mud cake digging parameters are shown in Fig. 15. In Fig. 15, SD1 and SD2 represent the speed before and after the mud cake formation, TL1 and TL2 represent the thrust before and after the mud cake formation, and NJ1 and NJ2 represent the torque before and after the mud cake formation. From Fig. 15a box plot and Fig. 15b histogram, it can be concluded that from the pre-mud cake period (smooth section) to the eve of mud cake, the median values of digging parameters: propulsion speed decreases by 43.74%, the torque of cutter plate increases by 72.13%, and the total thrust force increases by 26.85%. Considering the mean values of the horizontal information reflecting the overall level: propulsion speed decreased by 38.72%, cutter torque increased by 161.41%, and total thrust increased by 18.46%. July 17, 7:50 a.m. shutdown to 1:00 p.m., used to cool down and clean up the mud cake, occupied five hours. The emergence of this monitoring temperature rises sharply (after the shutdown of the slow decline in temperature), the propulsion speed drops significantly, the total thrust of the cutter plate rises significantly, cutter torque rises sharply, the typical characteristics of the mud cake, the cutter plate mud cake occurs after the occurrence of the phenomenon of the peripheral rock bubbling and falling in the literature2 has been fully verified.

Discussion

Collect the CAD write-up statistics of the TBM excavation process in the main inclined shaft of Coco Cover Mine, organize and draw the change of water influx during the construction of the main inclined shaft of TBM (Fig. 16), and find that the water influx of the water-rich Luohe group is instead minimal, the reason is that, the high-intensity anchor spray grouting fluid diffuses and penetrates deep into the plastic zone of its fractured structure that is over the porosity4 (25.6%), which strengthens the crushed area of the surrounding rock to form a more closed waterproof structure Circle stabilized group, Zhi Luo group surge water is getting bigger and bigger. Because of the layer and block structures of the Anding Group and Zhi Luo Group, the anchor spraying support slurry injection cannot fill their microscopic fissures, resulting in the generation of gushing channels under dynamic water pressure, and the amount of gushing water is getting bigger and bigger.

The daily progress of construction is shown in Fig. 17, from which it can be seen that, but the advancing speed of stabilizing group Zhiluo group is basically the same as that of Luohe group, mainly because the supporting strength of stabilizing group Zhiluo group is not as muscular as that of the peripheral rock of water-rich Luohe group, so in order to ensure the stability of peripheral rock, the advancing speed of stabilizing group and Zhiluo group must be controlled; in addition, stabilizing group and Zhiluo group have a large amount of surging water, and the advancing speed is influenced by the fact that when surging water causes the equipment to operate under full load in the course of excavation (without In addition, when the water influx causes the equipment itself to run at total capacity during the digging process (without stopping the machine), it will take up specific resources and time to deal with the water influx problem, thus affecting the speed of advancement, so it is not that the larger the water influx is, the more favorable it is. It is not the case that the smaller the water influx, the more favorable it is. However, the water influx under medium conditions can achieve better propulsion speed, indicating that controlling the range of water influx is significant.

This study analyzes in detail the existence of a close correlation between propulsion speed and water influx. It considers the existence of a coupling between the relationship between propulsion speed and each digging parameter. This provides a more comprehensive perspective for further understanding and controlling the water influx in coal mine TBM inclined shaft projects. When the propulsion speed increases, it generates more excellent disturbance to the surrounding rock mass, which changes the rock mass’s permeability and pore pressure distribution. This will not only lead to an increase in water influx but, more importantly, will trigger the stability of the weakly cemented sandstone surrounding rock, with the risk of roof collapse or even jamming. Geologic conditions are an important influencing factor. Different geological formations, rock types, and aquifer characteristics will significantly impact the relationship between advancement speed and water influx. The main inclined shaft of Coco Cover Mine has adopted effective peripheral rock support measures, and over-advanced water discharge, drainage measures, and water-stopping technology to reduce the water influx in the sandstone of the water-rich Luohe Formation, which guarantees the safety of digging is a successful experience worth recommending.

Despite collecting a substantial amount of data, some bias or incompleteness may still be present. The TBM boring parameters for this project are recorded solely in minutes, which may have influenced the accurate understanding of the overall relationship.

The next step involves conducting in-depth research on the mechanisms that influence propulsion speed and water influx under various geological conditions. It is essential to perform additional field tests and monitoring to acquire more accurate and comprehensive data, which will help verify and enhance the findings of this study. Furthermore, exploring more effective techniques for controlling water influx and implementing construction strategies will be crucial in mitigating the impact of groundwater on propulsion speed, thereby ensuring the safety and smooth progress of the coal mine TBM inclined shaft project.

Conclusion

-

(1)

The water-rich fractured strata formed infiltration pressure due to the disturbance of TBM excavation, which led to the increase of pore water pressure, the aggravation of loss of cementing material, the rock became loose, the infiltration triggered the movement of rock particles, the infiltration flow accelerated the dissolution and erosion, and the accelerated seepage of groundwater led to the surge of water. The TBM excavation redistributes the stress state of the surrounding rock, thus exacerbating the intensity and complexity of the water–rock interaction, with water influx being a potentially significant influence.

-

(2)

The stability of surrounding rock severely restricts the drilling speed of open-type TBM in soft rock geology. The mud cake topping phenomenon is complicated, among which the mineral composition and the role of groundwater are important intrinsic factors. Under the influence of groundwater, different mineral compositions trigger a series of physical and chemical reactions, making the rock structure unstable. The vibration generated by the TBM in the working process will break the original rock structure’s closed equilibrium state, accelerating the emergence of mud cake topping and other problems, which is the intrinsic cause of the impact on the digging speed. The extrinsic factor is mainly the vibration of the machine digging.

-

(3)

The rock layer is loose and permeable, and the water surge causes feldspar’s hydration reaction in the muddy sandstone to form a kaolinite water film effect. At the same time, the hydration reaction of clay minerals such as montmorillonite and illite causes their internal expansion. When the water influx is 0–25 m3/h, it is easy to form mud agglomeration and bubbling down phenomenon, significantly affecting the TBM digging speed. When the water influx is 25–45 m3/h, water erosion reduces the fluctuation of digging speed. When the water influx reaches 45–60 m3/h, water erosion forms larger cavities or fissures, which reduces the risk of mud cakes as the water influx increases. Significantly improve the digging speed, low water influx stage of the roof mud cake, high water influx of the risk of perimeter rock support and drainage are profound impact on the advancement speed, while the water influx of the medium conditions, but to achieve a better advancement speed, indicating that the control of the range of the influx of water is significant.

-

(4)

Multiple linear regression shows a coupling between the relationship between the advance rate and each digging parameter. libsvm has a higher prediction accuracy for nonlinear, small-sample data. A more than 60 m3/h water influx will lead to extreme instability of the working face and increase various safety risks. In the main inclined shaft of Cocogee Mine, the water influx is strictly controlled within 60 m3/h, TBM advance speed: 26–50 mm/min, penetration: 6–8 mm/r, cutter torque: 360–845 kN m, rotational speed: 4.4–5.1 r/min. Safe tunneling has been successfully realized, which is a model for tunneling in similar geological environments.

-

(5)

The effectiveness of the Libsvm model has been validated through various methods. Compared to the multiple linear regression model, the Libsvm model demonstrates superior performance in terms of the goodness of fit index, exhibiting higher coefficients of determination for both training and testing sets. Additionally, the error indicators, specifically the mean absolute error (MAE) and mean absolute percentage error (MAPE), are lower for the Libsvm model, indicating improved prediction accuracy and data fitting capabilities. As a nonlinear model, it adeptly manages nonlinear relationships between data. In contrast, the multiple linear regression model presumes a linear relationship between features and target variables, which renders the Libsvm model more advantageous for handling complex relationships. When compared to the Random Forest (RF) model, the Libsvm model surpasses it in prediction accuracy, particularly in scenarios of high water inflow, where its predictions align more closely with actual values and exhibit greater sensitivity to data variations, thereby better capturing non-linear relationships within the data. Furthermore, utilizing actual data from the main inclined shaft project at Kekegai Coal Mine, the Libsvm model effectively predicts trends in excavation speed changes that correspond with variations caused by different factors at various stages of engineering practice. This further substantiates the model’s effectiveness in engineering applications, as it accurately reflects the impact of water inflow on excavation speed and is well-suited for predicting excavation speed in this specific engineering context.

Data availability

All data generated or analysed during this study are included in this published article.

References

Yang, Y. et al. Research on prevention and control technology of classified rockburst in TBM construction of deeply buried tunnels. Sci. Rep. 14, 333. https://doi.org/10.1038/s41598-024-51228-y (2024).

Fu, J., Xia, Y., Lian, H., Wu, D. & Lin, L. A case study on TBM cutterhead temperature monitoring and mud cake formation discrimination method. Sci. Rep. https://doi.org/10.1038/s41598-021-99439-x (2021).

Ma, Y. et al. Safety and environmental impact control of cross passage construction in soft soil strata using tunnel boring machine method. Sci. Rep. https://doi.org/10.1038/s41598-023-42082-5 (2023).

Wang, Z., Jiang, Y., Shao, X. & Liu, C. On-site measurement and environmental impact of vibration caused by construction of double-shield TBM tunnel in urban subway. Sci. Rep. https://doi.org/10.1038/s41598-023-45089-0 (2023).

Zhao, H., Quan, Y., Zhou, J., Wang, L. & Yang, Z. Key technology of TBM excavation in soft and broken surrounding rock. Appl. Sci. https://doi.org/10.3390/app13137550 (2023).

Guo, D. et al. Advance prediction of collapse for TBM tunneling using deep learning method. Eng. Geol. https://doi.org/10.1016/j.enggeo.2022.106556 (2022).

Wang, X., Yuan, Y., Mu, X., Sun, W. & Song, X. Sensitivity of TBM’s performance to structural, control and geological parameters under different prediction models. IEEE Access https://doi.org/10.1109/access.2019.2894462 (2019).

Chen, X., Liu, X., Wang, E. & Wang, S. Prediction of tunnel boring machine operating parameters using various machine learning algorithms. Tunn. Undergr. Space Technol. https://doi.org/10.1016/j.tust.2020.103699 (2021).

Liu, B. et al. Improved support vector regression models for predicting rock mass parameters using tunnel boring machine driving data. Tunn. Undergr. Space Technol. https://doi.org/10.1016/j.tust.2019.04.014 (2019).

Xue, Y. et al. Water and mud inrush hazard in underground engineering: Genesis, evolution and prevention. Tunn. Undergr. Space Technol. https://doi.org/10.1016/j.tust.2021.103987 (2021).

Wang, X. et al. Geohazards, reflection and challenges in Mountain tunnel construction of China: A data collection from 2002 to 2018. Geomat. Nat. Hazards Risk. 11, 766–785. https://doi.org/10.1080/19475705.2020.1747554 (2020).

Yan, C., Wang, T., Zheng, Y., Zheng, H. & Ali, S. Insights into the effect of water content on mudstone fragmentation and cutter force during TBM cutter indentation via the combined finite-discrete element method. Rock Mech. Rock Eng. 57, 2877–2912. https://doi.org/10.1007/s00603-023-03700-w (2024).

Lin, Q., Zhang, S., Liu, H. & Shao, Z. Water saturation effects on the fracturing mechanism of sandstone excavating by TBM disc cutters. Arch. Civ. Mech. Eng. https://doi.org/10.1007/s43452-024-00964-z (2024).

Zhang, C. et al. Strength weakening and its micromechanism in water–rock interaction, a short review in laboratory tests. Int. J. Coal Sci. Technol. https://doi.org/10.1007/s40789-023-00569-6 (2023).

Xu, J., Zhang, J. & Liu, T. Mesoscopic weakening feature of marble during water rock interaction. Geotech. Geol. Eng. 37, 121–128. https://doi.org/10.1007/s10706-018-0596-6 (2019).

Zeng, Q. et al. Interaction between soft rocks and water and its application to engineering. IOP Conf. Ser. Earth Environ. Sci. 570, 052033. https://doi.org/10.1088/1755-1315/570/5/052033 (2020).

Bian, K. et al. Mechanisms of large deformation in soft rock tunnels: A case study of Huangjiazhai tunnel. Bull. Eng. Geol. Environ. 78, 431–444. https://doi.org/10.1007/s10064-017-1155-8 (2017).

Zhang, H., Chen, L., Zhu, Y., Zhou, Z. & Chen, S. Stress field distribution and deformation law of large deformation tunnel excavation in soft rock mass. Appl. Sci. 9(5), 865. https://doi.org/10.3390/app9050865 (2019).

Wang, D., Jiang, Y., Sun, X., Luan, H. & Zhang, H. Nonlinear large deformation mechanism and stability control of deep soft rock roadway: A case study in China. Sustainability 11(22), 6243. https://doi.org/10.3390/su11226243 (2019).

Kang, X. et al. A new stage control device for open TBM tunnel lining support in water-rich weakly cementing soft rock. Int. J. Rock Mech. Min. Sci. 179, 105754. https://doi.org/10.2139/ssrn.4559642 (2024).

Hou, T. et al. TBM rapid tunneling roadway support parameters design and process research. Processes 11(9), 2708. https://doi.org/10.3390/pr11092708 (2023).

He, M., Sui, Q. & Tao, Z. Excavation compensation theory and supplementary technology system for large deformation disasters. Deep Undergr. Sci. Eng. 2(2), 105–128. https://doi.org/10.1002/dug2.12043 (2023).

Wang, Q. et al. Feasibility analysis of excavation with open full section boring machine for ultra-long distance slant in coal mine. Coal Sci. Technol. 51, 310–320 (2023).

Li, A., Zhang, K., Xu, J., Xie, X. & Kang, Y. Stability of surrounding rock and support optimization of a broken soft-rock-inclined shaft bored by tunnel boring machine: A case study of Kekegai sub-inclined shaft. Tunn. Constr. 43(11), 1924–1934 (2023).

Ding, X., Yang, H. & Shi, Y. Genetic analysis and evaluation model construction of EPB cutterhead mud cake. J. South China Univ. Technol. (Nat Sci Ed) 52(5), 71–83 (2024).

Li, J. et al. Prediction of TBM construction parameters based on local linear embedding and support vector machine regression. J. Zhejiang Univ. 55(8), 1426–1435. https://doi.org/10.3785/j.issn.1008-973x.2021.08.003 (2021).

Yang, Q. et al. Study on crack growth in fine sandstone under different wedge loading rates. China Work Saf. Sci. Technol. 19(12), 93–101. https://doi.org/10.11731/j.issn.1673-193x.2023.12.012 (2023).

Liu, B. et al. Improved support vector regression models for predicting rock mass parameters using tunnel boring machine driving data. Tunn. Undergr. Space Technol. 91, 102958. https://doi.org/10.1016/j.tust.2019.04.014 (2019).

Liu, B. Research on hob mud-forming effect and TBM drilling parameters in Mudstone Formation. Ph.D. Dissertation, Chongqing University. Learned scholar, https://doi.org/10.27670/d.cnki.gcqdu.2021.000615 (2021).

Brochard, L. Swelling of montmorillonite from molecular simulations: Hydration diagram and confined water properties. J. Phys. Chem. C. 125(28), 15527–15543. https://doi.org/10.1021/acs.jpcc.1c02659 (2021).

Underwood, T., Erastova, V. & Greenwell, H. Wetting effects and molecular adsorption at hydrated kaolinite clay mineral surfaces. J. Phys. Chem. C. 120(21), 11433–11449. https://doi.org/10.1021/acs.jpcc.6b00187 (2016).

Acknowledgements

This study was supported by the Postgraduate Research Fund of Colleges and Universities in Anhui Province, China (Grant No. YJS20210385) and the 2020 Fund of the Engineering Research Center of Underground Mine Engineering of the Ministry of Education of Anhui University of Science and Technology (Grant No. JYBGCZX2020209).

Author information

Authors and Affiliations

Contributions

M.L.: Provide field data of TBM construction site. Q.Y.: Data processing and manuscript writing. Professor C.R.: Review and check. X.W.: Assist in editing. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Yang, Q., Rong, C., Li, M. et al. A comprehensive investigation of the relationship between propulsion speed and water influx in coal mine TBM inclined shaft projects. Sci Rep 15, 6332 (2025). https://doi.org/10.1038/s41598-025-89704-8

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-89704-8