Abstract

As a new investigation for renewable energy generation, the recent three-layer solar structure is composited with three effective material usages of Al (resonator), InSb (substrate), and Ag (based). The overall wavelength of overall 2800 nm with the bandwidth order from 0.2 to 3.0 μm is 91.68%, the extracted percentage is 97.07% at 800 nm (1.41–2.21) µm, and the output is 95.02% with the 1420 nm wavelength by the bandwidth separation of 1.09 and 2.51 μm respectively. With the graphene accumulation in this absorber, the radiated output can be determined in the first visible area, the second ultraviolet region, and the near-infrared spectra respectively. The multi-step exploration of the absorbed rate in design performance, the selected materials and parameter assignments, and the analyzed parametric numbers for each layer will be included in the proposed presentation. The demonstrated solar structure can be performed at the low-temperate rate of less than 100 °C for heating processes of water or space, between 100 and 250 °C for industrial processes, and above 250 °C to release the steam for running turbines in the electricity generation.

Similar content being viewed by others

Introduction

With the advanced technology of solar energy systems, one of the ideal uses is the heating and cooling solar system by collecting the thermal energy (heat) from the sun to provide space heating, pool heating, hot water, and cooling processes in commercial, industrial applications, and commercial by converting the collected heat by the solar absorber1,2,3,4.

As a primary stage, the solar collector gets the necessary heat amount from the radiation (sun) of the solar system and then transfers it to the potable water5. This produced heat water flows from the proposed solar collector to the distributed hot water tank, and it can be used for various applications6,7. Solar collectors have several types of evacuated tubes, thermosiphon, flat plate, concentrating, and ICS (Integral Collector Storage)8,9. Concerning the production of energy from the thermal systems, there are two main effective ways active and passive10,11. In the process of active way, the system needs some moving parts such as pumps or fans to do the circulation of the heated fluids12. On the other hand, the passive system does not need mechanical components and it only relies on the system’s design to capture the heat13. The energy production by the thermal system can be grouped into three main categories low, medium, and high temperature14. With the creation of O. Alsalman and co-authors, the creation of absorber structure in Al top layer, can distribute the absorption percentage of 95.2% at the band limit of 600 nm15. The three-material composition of GaAs-Al-Zr in a three-layer absorber development can give the resulting amount of 98.2% at the bandwidth number of 700 nm16. With the broadband solar type structure, the development of the three-silver based (nanofluids) structure can achieve the efficiency of almost 85% by the distribution of B. Raj and co-authors17. With the combination of graphene and silver in the creation of the solar thermal conversion system, the collector can create an efficiency of 77% according to the demonstration of X. Xing and co-authors18. With the bloom-shaped solar structure in resonator structure with the creation of three materials Au-InSb-Al can achieve the resulting percentage of more than 97% at an 800 nm band rate19. B. Liu et al. and co-authors stated that the InSb substrate layer with the Al-based creation, can explore the output percentage of 96.6% by the effective bandwidth value of 1470 nm20. S. K. Patel and co-authors found that an absorption output exceeds 95% with a band rate number of 1400 nm with the aluminium design on the silver substrate section in the development of the graphene absorber21. With the effect of the stopped-trench (ST) metal deposition on the organic solar cells, it can give the efficiency (light absorption) of 77.01%22. In a perovskite solar cell with the applied nanotubes, we can achieve 29% and 24.3% enhancement factors23. The investigated LSPR CH3NH3PBX3 solar cell can raise the photocurrent ratio value of 22.67–47% and 50.63%24. With the developed cylindrical structure nanoparticles in the perovskite absorber, it can be improved the photocurrent amount of 17.71 to 19.67 mA/cm²25.

The recent creation of the graphene absorber applied with the three different materials combination of the Al-InSb-Ag is investigated. With the good resistance in corrosion property of aluminium, it is applied in the development of the resonator in this structure26,27. The second layer by the Indium antimonide material and it is a semiconductor type of crystalline form28,29. Silver is an excellent material type of heat and electricity and it is used in the ground section of the current structure investigation30,31. The following section of the current study will include the design showing and the assigned parameters presentation, an analysis of all of the used parameters, and the conclusion section.

Design and parameters

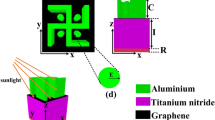

The current design is used the method of Finite Element (FEM) for calculating the absorbed percentages and COMSOL software (Multiphysics) for distributing the absorber design in this work32,33,34. As the first section of the presentation, the current design in different positions can be figured out (3-D design) in Fig. 1 (a), the assigned parametric numbers in the front view are H = 300 nm (Al resonator), O = 800 nm (InSb substrate), and M = 300 nm (Silver-based) as represented in Fig. 1 (b). The resonator side of the distributed absorber structure in Fig. 1 (c) with the recent design width of E = 400 nm as validated in Fig. 1 (c). Concerning the refractive amounts of the used materials in the proposed structure, the aluminium is 3.212, InSb is 1.617, and silver is 0.27732 respectively28,29,30.

The reported design for showing parametric values in each layer of the absorber. (a) The current design (one-unit cell) is in three-dimensional construction. (b) The parametric value of 300 nm for the Al resonator ‘H’ and Ag-based ‘M’, and the InSb substrate is O = 800 nm. The top section and the structure width of E = 400 nm.

Concerning the design declaration, the multistep presentation will be included in Fig. 2 according to the resulting absorption situation for each step performance. The illustrated absorption line for the construction of the silver-ground layer is exposed in Fig. 2 (a) with the deposited amount of 77.89% in 0.55 nm (λ1), 67.87% in 0.8 nm (λ2), 68.62% in 1.41 nm (λ3), and 83.04% in 1.88 nm (λ4) respectively. The absorption amount in the UV region declares 62.34%, the violet (V) area shows 63.4%, and the near-infrared spectrum devotes 70.1% to the ground section contribution. The contributed absorption line for the construction of the InSb substrate section is exposed in Fig. 2 (b) with the deposited amount of 80.1% at 0.55 nm, 75.8% at 0.8 nm, 60.5% at 1.41 nm, and 87.8% at 1.88 nm respectively. The absorption amount in the UV region declares 65.6%, the violet (V) area shows 66.7%, and the near-infrared spectrum devotes 77.9% for the InSb substrate layer demonstration. The contributed absorption line for the construction of the InSb substrate section (graphene combination) is exposed in Fig. 2 (c) with the deposited percentage of 81.32% in 0.55 nm, 76.06% in 0.8 nm, 62.5% in 1.41 nm, and 89.66% in 1.88 nm respectively. The absorption amount in the UV region declares 68.1%, the violet (V) area shows 67.66%, and the near-infrared spectrum devotes 78.72% for the InSb layer composited with the thin graphene demonstration. The contributed absorption line for the construction of the Al resonator is exposed in Fig. 2 (d) with the deposited amount of 98.1% in 0.55 nm, 99% in 0.8 nm, 97.6% in 1.41 nm, and 96.8% in 1.88 nm respectively. The absorption amount in the UV region declares 89%, the violet (V) area shows 90.2%, and the near-infrared spectrum devotes 93.8% for the Al resonator demonstration. The contributed absorption line for the construction of the complete structure (graphene combination) is exposed in Fig. 2 (e) with the deposited percentage of 99.4% in 0.55 nm, 99.08% in 0.8 nm, 98.87% in 1.41 nm, and 97.08% in 1.88 nm respectively. The absorption amount in the UV region declares 90.1%, the violet (V) area shows 91.2%, and the near-infrared spectrum devotes 94.2% to the InSb substrate (second layer) according to the graphene demonstration.

The reported absorption rates concerning the construction steps. (a) The resulting absorption line for the silver-based demonstration. (b) The demonstrated absorption for the InSb substrate part. (c) A 0.34 nm thin graphene inclusion on the InSb layer. (d) The final demonstration step with the Al resonator. (e) The final demonstration step with the Al resonator in graphene addition.

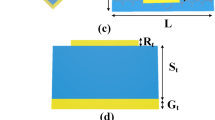

The design construction can also be expressed concerning the lithography including the deposited parts as validated in Fig. 3. Figure 3 (a) is the deposition of the first Ag-ground part with the parametric value of 300 nm, and Fig. 3 (b) expresses the deposition section of the InSb substrate with 800 nm on the previous Ag-based layer. The graphene part includes in Fig. 3 (c) and (d) displays the deposited part of the aluminium resonator section with a 300 nm and the front side of the final construction in lithography in Fig. 3 (e) respectively.

The contributed solar structure in deposited parts and lithography presentation. (a) The deposition of the first Ag-ground part construction. (b) The deposition section of the InSb substrate. (c) A 0.34 nm thickness graphene part inclusion on the InSb section. (d) The deposited part of the aluminium resonator section. (e) The front side of the final construction in lithography.

The extracted absorption can also be determined depending on the value of band rate (nm) and wavelength (µm) as declared in Fig. 4 (a) and the respective area of the absorbed, reflected part, AM situation in Fig. 4 (b). Figure 4 (a) configures the overall wavelength of 2800 nm with the bandwidth order from 0.2 to 3.0 μm the 91.68%, the extracted percentage is 97.07% at 800 nm (1.41–2.21) µm, and the output is 95.02% with the 1420 nm wavelength by the bandwidth separation of 1.09 and 2.51 μm respectively. The explored results and analysis of the absorber’s output will show in four wavelength rates (µm) of 0.55, 0.8, 1.41, and 1.88. Concerning the AM demonstration, the absorbed part by the current solar design is in yellow, the reflected part in blue color, and the AM part is represented in black color respectively.

The organized air mass production concerning the absorption, AM part, and reflected by the following air mass Eq. 135.

The used symbols from the above AM equation are \(\:{I}_{AM1.5}\) demonstrates the amount of radiated air mass, R means the reflection section, and \(\:{\eta\:}_{A}\) for the absorption for the reported design36.

Due to the help of a 0.34 thickness graphene in this design, the following graphene inclusion Eqs. (2–5) will be illustrated37.

With the used symbols from the above graphene equations, '\(\varDelta\)' means the parametric value of the used graphene, ‘\(\:Tg\)' for the demonstrated structure’s temperature, '\(\:\omega\:\)' recognizes the frequency, '\(\:\epsilon\:_{o}\)' illustrates the value of the deposited permittivity (in air), '\(\:{\:k}_{B}\)' and '\(\:\text{h}\)' for Boltzmann and Plank constant symbol, '\(\:{e}\:\)' shows the amount of the electron charge value, and '\(\:{\mu\:}_{C}\)' displays the graphene’s potential value38.

Results and discussions

The reported structure can be performed the outputs with the different parametric values for aluminium resonator, InSb substrate, silver-based, and the width of the structure in this section. The result explorations for the Al resonator ‘H’ and the InSb substrate ‘O’ layers with the color graphene verification can be contributed in Fig. 5. Figure 5 (a) contributes the analyzed parametric values of the Al resonator design ‘H’ with the varied numbers of 93.41% in 100 nm and 97.69% in 500 nm by 0.55 μm, reduced from 98.96 to 96.42% for 0.8 μm, developed from 94.55 to 96.92% for 1.41 μm, and deducted from 99.87 to 90.37% with 1.88 μm. The output rates in the ultraviolet part, visible area, and near-infrared area are figured out in the color graph as distributed in Fig. 5 (b). Figure 5 (c) presents the analyzed parametric values of the InSb second layer ‘O’ by the varied numbers of 99.73% in 600 nm and 96.6% in 1000 nm for 0.55 μm, from 99.57 to 98.16% by 0.8 μm, achieved from 97.21 to 99.42% at 1.41 μm, and from 95.5 to 94.91% with 1.88 μm. The output rates of the InSb substrate parameter variations in the ultraviolet part, visible area, and near-infrared area are figured out in the color graph as distributed in Fig. 5 (d).

Parametric number demonstration in the Al resonator (top section) and the InSb substrate layers (second section). (a) Al resonator ‘H’ parametric values variations. (b) The resulting colour graph for the Al resonator analysis in different air regions. (c) InSb substrate ‘O’ parametric values variations. (d) The resulting colour graph for the InSb substrate analysis in different air areas.

The result explorations for the Ag-ground ‘M’ and the structure’s width ‘E’ with the graph verification can be contributed in Fig. 6. Figure 6 (a) contributes the analyzed parametric values of the Ag-ground section ‘M’ with the varied numbers of 99.73% by 100 nm and achieved 99.01% for 500 nm by 0.55 μm, from 99.57 to 97.98% with 0.8 μm, raised from 97.21 to 99.37% with 1.41 μm, and from 95.5 to 96.03% with 1.88 μm. The output rates of the Ag-ground section in the ultraviolet part, visible area, and near-infrared area are figured out in the color graph as distributed in Fig. 6 (b). Figure 6 (c) presents the analyzed parametric values of the structure’s width ‘E’ with the varied numbers of 99.49% at 400 nm and 97.94% at 440 nm by 0.55 μm, deducted from 99.11 to 96.84% with 0.8 μm, increased from 92.76 to 97.86% with 1.41 μm, and from 96.94 to 98.22% with 1.88 μm. The output rates of the structure’s width variations in the ultraviolet part, visible area, and near-infrared area are figured out in the color graph as distributed in Fig. 6 (d).

Contribution of the varied parametric values in the Ag-ground and the structure’s width. (a) Ag-ground ‘M’ parametric values variations. (b) The resulting color graph for Ag-ground layer analysis. (c) Structure’s width ‘E’ parametric values variations. (d) Resulting color graph for the structure’s width analysis.

With the effect of the thin graphene section performance, the chemical potential ‘µc’ variations need to be considered by changing the value from 0.1 to 0.9 eV as organized in Fig. 7. Figure 7 (a) validates the analyzed values of the graphene’s potential value ‘µc’ by the varied rates of 96.21% for 0.1 eV and 99.3% by 0.9 eV for 0.55 μm, developed from 85.62 to 98.76% by 0.8 μm, generated from 81.26 to 99.1% for 1.41 μm, and developed from 96.2 to 97.92% by 1.88 μm respectively. The output rates of the potential amount variations in the ultraviolet part, visible area, and near-infrared area are figured out in the color graph as distributed in Fig. 7 (b).

The resulting absorption outputs with the incidence angle changes can be attributed to the changed number from 0 to 80 degrees as represented in Fig. 8. To determine the polarization deposition in the proposed absorber, the angle (degree) variations will be included for the TE mode as distributed in Fig. 8 (a) and the color demonstration graph in Fig. 8 (b). Figure 8 (a) contributes the analyzed TE mode degree changes with the varied numbers of 99.49% at 0-degree and 17.6% at 80-degree with 0.55 μm, reduced from 99.11 to 52.79% with 0.8 μm, sharply deducted from 98.87 to 37.62% with 1.41 μm, and from 96.94 to 43.36% with 1.88 μm respectively. The output rates of the TE degree variation section in the ultraviolet part, visible area, and near-infrared area are figured out in the color graph as distributed in Fig. 8 (b). To determine the polarization deposition in the proposed absorber, the angle (degree) variations will be included for the TM mode as distributed in Fig. 8 (c) and the resulting color declaration graph in Fig. 8 (d). By the variation outputs from the TE and similar TM modes of the recent structure, the resulting rates are identical to each other and the polarization can be performed in the current structure.

In the analysis validation of the varied absorption, the electric effect and resulted magnetic field configurations need to be expressed by the demonstrated color as figured out in Figs. 9 and 10. In Fig. 9, the situation of the electric result illustration by the selected wavelength number of 0.55 μm in Fig. 9 (a) and (b), 0.8 μm describes in Fig. 9 (c) and (d) describes, Fig. 9 (e) and (f) for 0.8 μm, and 1.88 μm configured in Fig. 9 (g) and (h). Concerning the demonstrated color, some parts of the Al resonator show greater percentages than the other layers.

In Fig. 10, the situation of the magnetic amount with the selected wavelength value by 0.55 μm in Fig. 9 (a) and (b), 0.8 μm describes in Fig. 9 (c) and (d) describes, Fig. 9 (e) and (f) for 0.8 μm, and 1.88 μm configured in Fig. 9 (g) and (h). Concerning the demonstrated color, the amount of the deposited absorption rates in the Al resonator shows greater percentages than the other layers.

The magnetic field configuration for different layers. (a) and (b) describes the first selected wavelength value of 0.55 μm. (c) and (d) displays the resulting color for 0.8 μm. (e) and (f) demonstrates the color outputs for 1.41 μm. (g) and (h) contributes to the resulting color demonstration in 1.88 μm.

To determine the wavelength separation and the respective bandwidth of the proposed structure and the other work’s results, we can illustrate a comparative analysis shown as presented in Table 1.

Conclusion

The three-section (layers) composition in a graphene solar structure with the three different materials of aluminium (Al) for the proposed resonator design, indium antimonide (InSb) for the substrate section, and silver (Ag) as the based construction of the absorber respectively. The explored results and analysis of the absorber’s output are shown in four wavelength rates (µm) of 0.55, 0.8, 1.41, and 1.88. The overall wavelength of 2800 nm with the bandwidth separation from 0.2 to 3.0 μm is 91.68%, the extracted percentage is 97.07% at 800 nm (1.41–2.21) µm, and the output is 95.02% with the 1420 nm wavelength by the bandwidth separation of 1.09 and 2.51 μm respectively. With the graphene accumulation in this absorber, the radiated output has been determined in the first visible area, the second ultraviolet region, and the near-infrared spectra respectively. In the above-presented sections, the multi-step exploration of the absorbed rate in design performance, the selected materials and parameter assignments, and the analyzed parametric numbers for each layer have been included. The current demonstrated solar structure can be performed at a low-temperate (less than 100 °C) for heating processes of water or space and can able to release the steam for running turbines in the electricity generation with the high-temperature (above 250 °C).

Data availability

The data supporting the findings in this work are available from the corresponding author with reasonable request.

References

Khan, M. I., Asfand, F. & Al-Ghamdi, S. G. Progress in research and technological advancements of thermal energy storage systems for concentrated solar power. J. Energy Storage. 55. https://doi.org/10.1016/j.est.2022.105860 (2022).

Ye, Q., Chen, M. & Cai, W. Numerically investigating a wide-angle polarization-independent ultra-broadband solar selective absorber for high-efficiency solar thermal energy conversion. Sol Energy. 184, 489–496. https://doi.org/10.1016/j.solener.2019.04.037 (2019).

Ranabhat, K. et al. An introduction to solar cell technology. J. Appl. Eng. Sci. 14 (4), 481–491. https://doi.org/10.5937/jaes14-10879 (2016).

Yu, P. et al. Ultra-wideband solar absorber based on refractory titanium metal. Renew. Energy 158, 227–235. https://doi.org/10.1016/j.renene.2020.05.142 (2020).

Han, B. B., Patel, S. K., Jadeja, R. & Al-Zahrani, F. A. Design and analysis of multiple ring resonator solar thermal absorber for renewable energy harvesting. Int. J. Therm. Sci. 208, 109415. https://doi.org/10.1016/j.ijthermalsci.2024.109415 (2025).

Hao, W. et al. Crumpled graphene ball-based broadband solar absorbers. Nanoscale 10 (14), 6306–6312. https://doi.org/10.1039/c7nr09556b (2018).

Ravi Kumar, K., Krishna Chaitanya, N. V. V. & Sendhil Kumar, N. Solar thermal energy technologies and its applications for process heating and power generation – A review. J. Clean. Prod. 282. https://doi.org/10.1016/j.jclepro.2020.125296 (2021).

Mondry, M. J., Babic, D. I., Bowers, J. E. & Coldren, L. A. Refractive indexes of (Al, Ga, In)as epilayers on InP for Optoelectronic Applications. IEEE Photonics Technol. Lett. 4 (6), 627–630. https://doi.org/10.1109/68.141990 (1992).

Barnhart, J. Occurrences, Uses, and Properties of Chromium, Regul. Toxicol. Pharmacol., vol. 26, no. 1 I. https://doi.org/10.1006/rtph.1997.1132 (1997).

Alsharari, M. et al. Solar Thermal Plasmonic Absorber Design using graphene-based Zr-Fe-Ti materials for Industrial and Household Applications. Plasmon. Aug https://doi.org/10.1007/s11468-024-02493-0 (2024).

Zhang, M. et al. Antibacterial evaporator based on reduced graphene oxide/polypyrrole aerogel for solar-driven desalination. Nano Res. 16 (4), 4219–4224. https://doi.org/10.1007/s12274-021-4041-4 (2023).

Rossi, E., Romero Rodriguez, C., Jonkers, H. & Çopuroğlu, O. Assessment of the self-healing capacity of cementitious materials through active thin sections. J. Microsc. 286 (2), 58–62. https://doi.org/10.1111/jmi.13082 (2022).

Ren, Y. et al. Active spoof plasmonics: from design to applications. J. Phys. Condens. Matter 34. https://doi.org/10.1088/1361-648X/ac31f7 (2022).

Tisch, U., Meyler, B., Katz, O., Finkman, E. & Salzman, J. Dependence of the refractive index of AlxGa1 – xN on temperature and composition at elevated temperatures, J. Appl. Phys. 89(5), 2676–2685. https://doi.org/10.1063/1.1341212 (2001).

Alsalman, O., Han, B. B. & Patel, S. K. Graphene-based solar absorber structure using GaAs-Al-Zr materials for renewable energy application. Int. J. Therm. Sci. 200, 108979. https://doi.org/10.1016/j.ijthermalsci.2024.108979 (2024).

Almawgani, A. H. M. et al. Design of Surface Plasmon resonance–based solar absorber using Bloom-shaped Au-InSb-Al structure. Plasmonics. https://doi.org/10.1007/s11468-023-02003-8 (2023).

Raj, B., Angayarkanni, S. A. & Philip, J. Nanofluids for efficient heat transfer applications. Nanatechnol. Energy Sustain. 997–1028. https://doi.org/10.1002/9783527696109.ch40 (2017).

Xing, X., Sun, F., Qu, W., Xin, Y. & Hong, H. Numerical simulation and experimental study of a novel hybrid system coupling photovoltaic and solar fuel for electricity generation. Energy Convers. Manag. 255. https://doi.org/10.1016/j.enconman.2022.115316 (2022).

Almawgani, A. H. M. et al. Design of Surface Plasmon resonance–based solar absorber using Bloom-shaped Au-InSb-Al structure. Plasmon. Sep. https://doi.org/10.1007/s11468-023-02003-8 (2023).

Liu, B. et al. Optical properties and thermal stability evaluation of solar absorbers enhanced by nanostructured selective coating films. Powder Technol. 377, 939–957. https://doi.org/10.1016/j.powtec.2020.09.040 (2021).

Patel, S. K. et al. Graphene-based cross-shaped surface Plasmon Resonance Solar Absorber Design for Solar Thermal Energy converters. Plasmon. Oct. https://doi.org/10.1007/s11468-023-02091-6 (2023).

Asl, A. F., Heidarzadeh, H. & Bahador, H. Enhanced light absorption of organic solar cells based on stopped-trench metal grating, Opt. Express 31(6), 10554. https://doi.org/10.1364/OE.461126 (2023).

Heidarzadeh, H. Effect of parasitic absorption of the plasmonic cubic nanoparticles on the performance of a plasmonic assisted halide thin-film perovskite solar cell. Sol Energy. 223, 293–301. https://doi.org/10.1016/j.solener.2021.05.081 (2021).

Heidarzadeh, H. & Tavousi, A. Design of an LSPR-Enhanced Ultrathin CH3NH3PbX3 Perovskite Solar Cell Incorporating Double and Triple Coupled Nanoparticles, J. Electron. Mater. 50(4), 1817–1826. https://doi.org/10.1007/s11664-020-08612-x (2021).

Heidarzadeh, H. Simulation and analysis of the performances of a thin plasmonic-based perovskite absorber by subtracting the parasitic absorption of nano-cylinders. Opt. Quantum Electron. 53(10), 552. https://doi.org/10.1007/s11082-021-03205-2 (2021).

Cao, F. et al. Enhanced thermal stability of W-Ni-Al2O3 Cermet-based spectrally selective solar absorbers with tungsten infrared reflectors. Adv. Energy Mater. 5(2). https://doi.org/10.1002/aenm.201401042 (2015).

Zhang, P. et al. IEEE Draft Standard for Spectrum Characterization and Occupancy Sensing, in IEEE Access, pp. 1–6. [Online]. http://ieeexplore.ieee.org/document/9946717%0Ahttp://ieeexplore.ieee.org/document/9823213%0Ahttp://ieeexplore.ieee.org/document/9740281%0Ahttp://ieeexplore.ieee.org/document/9823279%0Ahttp://ieeexplore.ieee.org/document/9821542%0Ahttp://ieeexplore.ieee.or (2019).

Cheng, Y., Li, Z. & Cheng, Z. Terahertz perfect absorber based on InSb metasurface for both temperature and refractive index sensing. Opt. Mater. (Amst). 117. https://doi.org/10.1016/j.optmat.2021.111129 (2021).

Fritzsche, H. & Lark-Horovitz, K. Electrical properties of p-type indium antimonide at low temperatures. Phys. Rev. 99 (2), 400–405. https://doi.org/10.1103/PhysRev.99.400 (1955).

Ren, K. et al. Realizing significant dielectric dispersion of composites based on highly conducting silver-coated glass microspheres for wide-band non-magnetic microwave absorbers. J. Mater. Chem. C. 7(3), 528–542. https://doi.org/10.1039/c8tc03594f (2019).

Chen, H. L. et al. A 19.9%-efficient ultrathin solar cell based on a 205-nm-thick GaAs absorber and a silver nanostructured back mirror. Nat. Energy 4 (9), 761–767. https://doi.org/10.1038/s41560-019-0434-y (2019).

Sahu, N. K. & Kaviti, A. K. A review of use FEM techniques in modeling of human knee joint. J. Biomimetics Biomaterials Biomedical Eng. 28, 14–25. https://doi.org/10.4028/www.scientific.net/JBBBE.28.14 (2016).

Han, B. B., Patel, S. K. & Baz, A. Highly efficient broadband solar thermal absorber for domestic renewable energy solutions. Int. J. Therm. Sci. 206, 109346. https://doi.org/10.1016/j.ijthermalsci.2024.109346 (2024).

Gerlich, V., Sulovská, K. & Zálešák, M. COMSOL multiphysics validation as simulation software for heat transfer calculation in buildings: building simulation software validation. Meas. J. Int. Meas. Confed. 46 (6), 2003–2012. https://doi.org/10.1016/j.measurement.2013.02.020 (2013).

Wang, Z. et al. Organic photovoltaic cells offer ultrahigh VOC of ∼ 1.2 V under AM 1.5G light and a high efficiency of 21.2% under indoor light. Chem. Eng. J. 451. https://doi.org/10.1016/j.cej.2022.139080 (2023).

Aliqab, K. et al. Graphene-based highly efficient surface Plasmon Resonance Solar Absorber Design using Zr-GaAs-Cr materials for renewable Energy Generation. Plasmon. Nov https://doi.org/10.1007/s11468-024-02634-5 (2024).

Marconcini, P. & MacUcci, M. The k•p method and its application to graphene, carbon nanotubes and graphene nanoribbons: the Dirac equation. Rivista Del. Nuovo Cimento 34, 8–9. https://doi.org/10.1393/ncr/i2011-10068-1 (2011).

Ghosh, G. Dispersion-equation coefficients for the refractive index and birefringence of calcite and quartz crystals. Opt. Commun. 163(1), 95–102. https://doi.org/10.1016/S0030-4018(99)00091-7 (1999).

Zhao, X. G. et al. Cu-In Halide Perovskite Solar absorbers. J. Am. Chem. Soc. 139, 6718–6725. https://doi.org/10.1021/jacs.7b02120 (2017).

Alsharari, M., Han, B. B., Patel, S. K., Armghan, A. & Aliqab, K. Design and investigation of Surface Plasmon Resonance Solar Absorber based on Graphene for renewable energy applications. Plasmonics https://doi.org/10.1007/s11468-024-02660-3 (2024).

Liu, Z. et al. Truncated titanium/semiconductor cones for wide-band solar absorbers. Nanotechnology 30(30). https://doi.org/10.1088/1361-6528/ab109d (2019).

Rangasamy, S., Khansadurai, A. M., Venugopal, G. & Udayakumar, A. K. Graphene-based O-shaped metamaterial absorber design with broad response for solar energy absorption. Opt. Quantum Electron. 55(1). https://doi.org/10.1007/s11082-022-04315-1 (2023).

Yu, P. et al. A numerical research of wideband solar absorber based on refractory metal from visible to near infrared. Opt. Mater. (Amst) 97. https://doi.org/10.1016/j.optmat.2019.109400 (2019).

Alsharari, M. et al. Graphene-based metasurface solar absorber using Fe–Fe2O3–Ti multilayer structure, Opt. Quantum Electron. 56(12), 1914. https://doi.org/10.1007/s11082-024-07767-9 (2024).

Obaidullah, M., Esat, V. & Sabah, C. Multi-band (9,4) chiral single-walled carbon nanotube based metamaterial absorber for solar cells. Opt. Laser Technol. 134. https://doi.org/10.1016/j.optlastec.2020.106623 (2021).

Wu, P. et al. Design of ultra-high absorptivity solar absorber based on Ti and TiN multilayer ring structure. Int. J. Therm. Sci. 183. https://doi.org/10.1016/j.ijthermalsci.2022.107890 (2023).

Gao, S., Wang, Q., Lin, Y., Yang, H. & Wang, L. Flower-like Bi0.9La0.1FeO3 microspheres modified by reduced graphene oxide as a thin and strong electromagnetic wave absorber. J. Alloys Compd. 781, 723–733. https://doi.org/10.1016/j.jallcom.2018.11.327 (2019).

Acknowledgements

This research is funded by the Deanship of Graduate Studies and Scientific Research at Jouf University through the Fast-Track Research Funding Program.

Funding

This research is funded by the Deanship of Graduate Studies and Scientific Research at Jouf University through the Fast-Track Research Funding Program.

Author information

Authors and Affiliations

Contributions

Conceptualization, M.A and S.K.P.; methodology, B.B.H, M.A and S.K.P.; software, M.A, B.B.H. and S.K.P.; investigation, N.B.A, K.A and A.A.; Formal Analysis, N.B.A, K.A and A.A.; writing—original draft preparation, All authors; writing—review and editing, All Authors.;; All authors have read and agreed to the published version of the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Alsharari, M., Han, B.B., Patel, S.K. et al. Ultrabroadband solar absorber design using graphene-based Al-InSb-Ag MIM structure for renewable energy generation. Sci Rep 15, 6101 (2025). https://doi.org/10.1038/s41598-025-90059-3

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-90059-3