Abstract

Red mud (RM), a solid waste byproduct of the alumina industry, has accumulated in significant global stockpiles. Currently, the primary application of RM involves magnetic separation to recover iron oxides, while the residual RM is predominantly landfilled. Due to its strong alkalinity, RM can serve as a substitute for strong alkalis or sodium salts in the alkali activation of concrete, thereby accelerating setting time and improving early-age strength. Building on this property, this study designs and develops an RM based rapid setting filling support material, primarily composed of RM, which features rapid setting and high early strength. This material is intended as a substitute for high-water-content materials in gob-side entry retaining for coal mining. Experimental results demonstrate that when RM content reaches 70% and cement content is 10%, the Rapid-Setting Filling Support Material (RSM) achieves satisfactory compressive strength and initial setting time, coupled with excellent economic performance. The compressive strengths at 1 day, 3 days, 7 days, and 28 days are 6.12 MPa, 8.97 MPa, 11.25 MPa, and 12.33 MPa, respectively, meeting all requirements specified in the 'Technical Requirements for Roadside Bag Filling for Gob-side Entry Retaining with High-Water Material' (GB/T 39336-2020). The RSM also exhibits good durability, with primary hydration products including C–S–H gel, ettringite, and calcium carbonate, all of which contribute to strength development. Leaching tests reveal that heavy metal ion concentrations in the RSM leachate comply with integrated emission standards for Class III groundwater and wastewater, confirming its safe application. Considering the annual increase of approximately 13,000 km in roadway length for coal mining in China, the demand for filling and support materials is substantial. Consequently, the findings of this study hold significant economic and environmental value, with the potential to promote green mining practices and the circular economy.

Similar content being viewed by others

Introduction

RM, the waste residue generated during alumina extraction in the aluminum industry, appears red due to its high iron oxide content. Approximately 0.8 to 1.5 tonnes of RM are produced for every tonne of alumina extracted, resulting in global annual emissions exceeding 200 million tonnes1. With a high alkalinity (pH 9–12.5), RM is classified as a corrosive hazardous material in certain countries2. Its storage occupies valuable agricultural land, contaminates soil, air, and water, and poses risks such as debris flows3,4,5. The safe and effective disposal and utilization of RM remain critical challenges for the sustainable development of the aluminum industry.

Gob-side entry retaining is a vital technique in coal pillar-free roadway protection. This method enables coal mining without the need for pillars, providing notable advantages, including improved resource recovery rates, reduced roadway excavation requirements, optimized ventilation at the workface, modified stress distributions in subsequent workfaces, and alleviated stress concentrations6. It has been widely adopted in underground coal mining operations. During mining processes involving gob-side entry retaining and filling support, a range of filling materials is employed7,8, such as paste backfill9, high-water materials10, coal gangue11, and various industrial wastes12,13,14. Currently, high-water materials are frequently utilized due to their short initial setting time, high early strength, and excellent fluidity. However, the primary component of high-water filling materials, sulfate aluminate cement, has notable disadvantages, including high cost and susceptibility to strength degradation, which may result in roadway deformation15. Therefore, there is an urgent need to explore cost-effective alternative materials with superior strength properties.

The use of RM in mine filling materials not only addresses RM accumulation but also provides structural support during underground mining, thereby mitigating surface subsidence and protecting the natural environment16. For example, Zhaowen D et al.17 reported that the addition of CaO and CaSO4 significantly improves the strength of backfill materials when RM is used. Shuai L et al.18, in a feasibility study on RM as a filling material, observed that conventional backfill reduces compressive stress on pillars and effectively prevents roof subsidence. Tang L R et al.13 demonstrated that composite gelling materials containing RM (with an RM content of 9.4%) achieved a compressive strength of 6.4 MPa after 28 days of curing, with heavy metal ion leaching results meeting Class III groundwater quality standards. Zhikai W et al.19 investigated the effects of environmental factors on the setting properties of RM-based filling materials and found that their prepared RM filling material (with an RM content of 34.2%) effectively stabilized heavy metals and minimized environmental pollution during the filling process. Current research on RM-based filling materials primarily targets gob area filling in mines, with limited focus on gob-side entry retaining and filling support. Moreover, RM utilization rates remain relatively low (typically below 70%), and the strength of the filling bodies is insufficient. Consequently, developing RM-based quick-setting filling and supporting materials with high strength for gob-side entry retaining is of great importance and holds promise for large-scale applications. In this study, RM was employed as the primary raw material to develop a quick-setting material with high strength, offering a potential alternative to high-water materials for gob-side entry retaining and filling support. The durability and ion leaching behavior of the material were systematically investigated. The findings provide valuable insights into the resource utilization of solid wastes, such as RM, in gob-side entry retaining technology.

Materials and methods

Materials

RM

The RM utilized in this study was sourced from an alumina plant in Guiyang City, Guizhou Province, and its chemical composition is summarized in Table 1. The primary components of the RM are Al2O3, Fe2O3, SiO2, and TiO2, along with minor amounts of Na2O, MgO, and K2O. The X-ray diffraction (XRD) pattern of the RM, shown in Fig. 1, reveals that the major mineral phases present are cancrinite, hydrogarnet, calcite, mica, kaolinite, and hematite.

Figure 2 presents the scanning electron microscope (SEM) analysis of the microstructure of RM particles. The RM exhibits a heterogeneous morphology, comprising flaky, spherical, and various irregularly shaped particles20. Smaller particles tend to aggregate into larger agglomerates, with numerous voids observed among the smaller particles.

Sample preparation and maintenance

The RM used in our research originated from the RM storage yard of Guizhou Guanglv Aluminum Co., Ltd. The recovered RM slurry was uniformly dispersed in an open area to allow for natural air-drying for 7 days. Afterwards, it underwent grinding and passes through a 0.25 mm sieve, as finer RM possesses better mechanical strength21. The cement utilized was 525 Portland cement, and the machine-made sand ranged from 20 to 40 mesh, equivalent to a diameter of 0.85 mm to 0.425 mm. The additives, provided by Guizhou Guanglv Aluminum Co., Ltd., were a mixture of building gypsum, silica fume, and lime in a specific proportion. We substituted cement with RM, starting from a 10% substitution rate and gradually increasing until full replacement, to observe the impact of RM addition on the blocks. Through processability tests and mechanical performance experiments, we determined the optimal ratio for the RM rapid-setting filling support material. Additionally, we conducted microstructural performance analysis, durability testing, and heavy metal leaching analysis on the most suitable ratio. The schematic diagram of RM composites preparation and testing is shown in Fig. 3.

The ratio of the RM composite material is shown in Table 2. After mixing according to the ratio in Table 2, pour it into the mold and let it cure for 4 h before demolding. The demolded samples were then transferred to a SHBY-40B standard constant temperature and humidity curing chamber set at 95% humidity and 20 ± 3 °C for curing durations of 1 d, 3 d, 7 d, and 28 d. Finally, the compressive strength and flexural strength of the samples were measured in compliance with JC/T 683-2005 standards.

Performance testing and test methods

This study proposes a series of experimental methods to evaluate the performance of RM composites. Firstly, the feasibility of using RM as a filler in RM composites is assessed through wet packing density test. Secondly, the workability of RM composites in engineering applications is evaluated by measuring slump and setting time. Thirdly, mechanical properties and durability tests are conducted to investigate the impact of RM composites on strength when applied in underground filling. Fourthly, morphological changes in RM composites during underground filling are theoretically analyzed using XRD and SEM, further demonstrating how the addition of RM influences performance. Finally, heavy metal ion leaching tests are conducted on the target RM composites to evaluate their environmental feasibility for filling applications.

Machinability test

The wet method for measuring filler density16,22 was utilized to analyze the effect of RM on the structure of the filler during the filling process. The wet filler density of the rapid-setting backfill support material was calculated using Eqs. (1) and (2):

In this study, Vc denotes the volume of solids in the slurry, and Mmax represents the maximum mass of the slurry. The components w, s, and x correspond to water, sand, and binder, respectively. The densities of these components are denoted as ρw, ρs, and ρx. Additionally, Rw, Rs, and Rx represent the volumetric ratios of water, sand, and binder to the solid materials, respectively. V is the volume of sample mold, and Φ refers to the packing density.

The slump test is conducted following the SL/T131-2017 slump testing protocol.

The setting time is assessed as per GB/T 1346-2011, beginning when the RM composite interacts with water, documenting both initial and final setting times.

Durability test

During the transportation of RM composite materials to the gob-side entry retaining area and the subsequent curing process, prolonged exposure to groundwater may adversely affect the mechanical properties of the filling material, potentially compromising mining safety. Therefore, durability tests were conducted on the filling material to simulate the performance changes of the RM composite material in an underground water environment.

In the immersion test, during the filling process, RSM inevitably becomes immersion with groundwater, which can affect its performance and microstructure23,24. Therefore, it is essential to conduct soaking experiments on it. In this experiment ,the optimally proportioned blocks, which exhibited the highest RM recovery rate and satisfactory mechanical properties, were immersed in deionized water with a liquid-to-solid ratio of 1:10. The samples were cured at a constant temperature of 20 °C for durations of 1 day, 3 days, 7 days, 28 days, 60 days, and 90 days. After the curing period, the samples were removed, dried, and left to air dry for 1 h before their mechanical properties were tested.

In the eluviation test, due to the geological structure of gob-side entry retention in the goaf area, numerous fractures can occur, through which groundwater flows out to erode the backfill material. This may result in impacts on the performance, microstructure of RSM, and the leaching of heavy metal ions9. Therefore, for this experiment, a custom-built immersion test apparatus was designed and utilized to conduct immersion tests on RSM. Optimally proportioned blocks were placed under an eluviation device maintained at a constant temperature of 20 °C, with a water flow rate of 0.01 cm3/min. The samples were rinsed for varying curing durations: 1 day, 3 days, 7 days, 28 days, 60 days, and 90 days. After the rinsing period, the samples were removed, dried, and left to air dry for 1 h before their mechanical properties were tested.

Microstructure analysis

The samples meeting the maintenance criteria should be placed in a vacuum drying oven for the drying process. After drying, grind the samples and sieve them through a 200-mesh sieve to obtain the test samples. Microstructural analysis will be performed using a Tescan-vega3 scanning electron microscope, while phase analysis will be conducted with an Ultima IV X-ray diffractometer at a scanning speed of 1° per minute.

Ion leaching analysis

Toxicity leaching, immersion, and eluviation tests were conducted on the standard solidified RSM after 90 days of curing, following the procedure outlined in HJ-T 299-2007. Heavy metal ion concentrations were measured over a 90-day period. The results were compared with the limits specified in the 'Standards for Groundwater Quality' (GB 14848-2017) and the 'Integrated Wastewater Discharge Standard' (GB 8978-1996) to assess the environmental impact of ion leaching from the material. If the concentration during testing was below 0.0001 mg/L, the specific ion concentration, undetectable by ICP, was denoted as '–'.

Results and analysis

Machinability test

Packing density in wet state

The filling ability of RM was evaluated using wet packing density, with the results shown in Fig. 4. In the RM composite mixture with a 10% RM addition, the minimum filler density is 0.7703. As the RM content increases to 20%, 30%, 40%, 50%, 60%, 70%, and 80%, the corresponding filler densities are 0.7703, 0.7805, 0.7808, 0.7872, 0.7915, 0.7924, and 0.7931, respectively. It can be concluded that the filler density increases as the RM content rises. This may be due to the agglomeration of smaller RM particles into larger clusters, which increases the space between particles, thereby significantly enhancing the filling capacity of the RM composite slurry.

Considering both economic benefits and the utilization rate of RM, selecting a mixture with a high RM content as the filling material formulation is reasonable, provided the required strength is achieved. This approach not only maximizes the utilization of RM resources but also ensures the efficiency and cost-effectiveness of the filling material.

Slump and setting time

The slump and setting time tests conducted on RM composites can be used to evaluate the effect of RM incorporation on machinability properties and performance. The results regarding the influence of RM addition on slump are shown in Fig. 5a. It is evident that the slump flow decreases significantly as the RM content increases. However, when the RM content is at its lowest (C7R1), the slump reaches its maximum value of 312 mm. In contrast, when the RM content reaches 70% (C1R7), the slump decreases to 204 mm, representing a reduction of 34.6%. The gradual increase in RM content has a negative impact on workability, potentially due to the specific surface area of the RM used in this experiment being 113.20m2/g, while the specific surface area of the cement is 321.18m2/kg, indicating that the specific surface area of the RM is much larger than that of cement. As the RM content increases, the number of micropores and specific surface area in the composite material also increase, thereby enhancing the overall water absorption capacity. This increased water absorption capacity consumes more free water, reducing the thickness of the water film between particles and weakening the water binding force, which leads to decreased fluidity25,26.

The experimental results regarding the influence of RM addition on the setting time of the slurry are shown in Fig. 5b. The data indicate that both the initial and final setting times of RM composites decrease as the RM content increases. Specifically, at an RM ratio of 10%, the initial setting time is 452 min and the final setting time is 706 min, serving as the control group. However, when the RM content reaches 70%, the initial setting time decreases to 30 min and the final setting time decreases to 135 min. Compared to the control group, the initial and final setting times are reduced by 93.36% and 80.87%, respectively. This reduction in setting time may be attributed to the high alkalinity (pH ≥ 11) of RM, which induces an alkali-activation effect27. This effect promotes the early formation of materials such as ettringite (AFt) and calcium silicate hydrate (C–S–H) gels in RM composites, accelerates the hydration process, and leads to a shorter setting time26,28.

When the RM content reaches 70%, the slump measures 204 mm, in accordance with the requirements specified in the "Technical Specification for Paste Filling Roadway Retaining in Coal Mine" (NB/T 10728-2021). Moreover, the initial and final setting times are 30 min and 135 min, respectively, meeting the engineering requirements for short-term filling support in gob-side entry retaining in coal mining. This achievement not only improves construction efficiency but also enhances the utilization of industrial waste materials, offering an innovative solution for resource recycling and environmental protection.

Mechanical properties

Strength tests were conducted on the prepared samples under consistent curing conditions and a fixed water-cement ratio. Figure 6a,b show the compressive and flexural strengths, respectively, of samples containing different percentages of RM at curing ages of 1 d, 3 d, 7 d, and 28 d. As illustrated in Fig. 6a, using the compressive strength of the specimen with 10% RM as the control, the highest strength at 1 d was observed in the composite with 40% RM addition, which was 59.48% higher than the control. At 3 d, the composite with 30% RM addition exhibited the highest strength, an increase of 18.59% compared to the control. However, after 7 d and 28 d of curing, the control group showed the highest strength, while the composite with 80% RM addition demonstrated the lowest strength, with reductions of 87.63% and 90.53% respectively, compared to the control. Figure 6b indicates that the flexural strength follows a similar trend to the compressive strength with increasing RM content.

When the curing durations are 1d and 3d, and the content of RM is less than that of cement, the strength initially increases and then decreases with the increasing amount of RM. This behavior can be attributed to the high alkalinity of RM, which acts as an alkali activator during the reaction process of the RM composite. It promotes the formation of gelling materials such as AFt and C–S–H gels within the composite, thereby accelerating the early-stage binding of these materials. Additionally, it facilitates the dissolution and polymerization of aluminosilicates and other gelling components in Portland cement, enhancing the overall hydration process of the system. Consequently, a more compact and dense structure forms in the slurry during the initial stages of solidification29. However, when the content of RM exceeds that of cement, the early-stage strength begins to decline due to the relatively low reactivity of RM. At this point, strength is primarily governed by the gelling materials, such as AFt, produced in Portland cement26,30,31. As the curing duration extends to 7 days or longer, the material strength shows a decreasing trend with increasing RM content. This is because RM mainly functions as an alkali activator and fine aggregate in the RM composite, promoting the formation of gelling materials such as AFt and C–S–H gels during the early solidification stages, thus enhancing early strength32. As the content of RM increases, the amount of Portland cement decreases accordingly, leading to a reduction in the production of AFt and C–S–H gels per unit volume of the RM composite, The reduction in the production of these hydration products per unit volume leads to an increase in voids within the material, making the structure porous and weakening the binding force between particles, ultimately resulting in decreased strength33.

Table 3 compares the technical requirements for bag filling with high-water materials in gob-side entry retaining and those for the rapid-setting filling material derived from RM. The results show that C1R7 satisfies the strength requirements outlined in the 'Technical Requirements for Roadside Bag Filling in Gob-side Entry Retaining with High-Water Material' (GB/T 39336-2020). When the RM content reaches 70%, the material meets the strength criteria specified in the technical standard for high-water material bag filling in gob-side entry retaining. Based on the processability tests presented in Sections "Packing density in wet state" and "Slump and setting time", the sample with 70% RM content is identified as the optimal formulation and designated as RSM. This material not only demonstrates excellent processability and mechanical properties but also achieves a dual benefit in terms of economic and environmental performance.

Durability analysis

Analysis of the mechanical properties of durability test samples

Figure 7 illustrates the variation in compressive strength of RSM samples subjected to durability treatments. As shown in the figure, regardless of whether the samples underwent immersion or leaching testing, the compressive strength of the RSM blocks initially increased and then decreased. At the 60-day mark, the strength was still rising, likely due to the pozzolanic reaction of Ca(OH)2 formed during the later stages of cement hydration. This reaction with Si and Al compounds in the RM led to the formation of additional hydration products, thereby improving the mechanical properties34. However, after 90 days, the strength began to decrease, possibly due to the complete reaction of the gelling materials. Once the gel material has fully reacted, its capacity to fill voids reaches its limit, and it is no longer able to further increase the material’s density. Additionally, when the sample is immersed in water, the water penetrates into the pores, increasing the bound water within the pore structure. This reduces the forces between the particles, resulting in a decrease in compressive strength. This suggests that there is an upper limit to enhancing mechanical properties through the hydration reaction of the cementitious material.

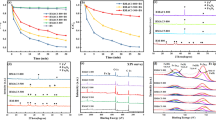

XRD analysis of durability samples

Figure 8 presents the XRD results for RSM samples that were cured for 3 days and 28 days under standard conditions, as well as those subjected to immersion and leaching tests for the same durations. As shown in Fig. 8, the type of hydration products do not vary with the treatment methods; however, their peak intensities are influenced. The main hydration products of RSM include A (ettringite), Ca (calcite), Cs (calcium silicate hydrate, C–S–H), P (calcium hydroxide), and Ca (calcite, for clarity). The strength of RSM is primarily determined by the quantity of hydration products such as A and Cs35,36. These minerals exhibit strong cementation capabilities for heavy metals and soluble salts37,38,39. As the curing time increases in Fig. 8, the peak intensity of P decreases, indicating that P undergoes transformation during the later stages of hydration, possibly forming Na–A–S–H gel and C–A–S–H gel40,41. The combination of these minerals with C–S–H and A hydration products contributes to the favorable mechanical properties of the RSM samples. Comparison of the peak intensities at 32.52°, 39.75°, and 58.75° in Fig. 7 with those in Fig. 1 reveals no significant changes, suggesting the presence of low-reactivity RM that remains unreacted.

Microstructural analysis of durability

Figure 9 presents the microstructural morphologies of samples cured for 28 days under different conditions. The SEM images show the formation of short rod-like and needle-like AFt (ettringite) structures, flocculent C–S–H gel, and platelet-like monocarbonate aluminates in the paste, resulting from hydration reactions. The mortar strength primarily depends on the structure formed by AFt and C–S–H crystals7,42. Figure 9a–c show RSM samples that were cured under standard, immersion, and leaching conditions for 28d, respectively. In Fig. 9a, a significant amount of needle-like AFt and flocculent C–S–H gel combine to form numerous porous structures. In contrast, Fig. 9b,c clearly show that the samples cured under immersion conditions for 28d exhibit fewer needle-like AFt and flocculent C–S–H gel structures compared to those eluviation 28d, and both have fewer of these microstructures than the samples standardly cured for 28d. Moreover, it is evident that the microstructure of the immersion samples for 28 days is less abundant than that of the eluviation samples for the same duration. This may be due to water infiltrating the immersion samples and cementing the inert components, which are less reactive, together with the hydration products. The microstructure of the eluviation samples is less pronounced than that of the immersion samples, possibly because eluviation involves water flushing into the samples, introducing more fresh water and consequently more inert components. The incorporation of these inert components leads to a reduction in ettringite and flocculent C–S–H gel structures, thereby decreasing strength. This result aligns with the durability and mechanical properties observed.

Environmental performance analysis

Leaching concentration of heavy metal ions

According to Table 4 the results of the toxicity characteristic leaching procedure (TCLP) for the raw RM exceed nearly all the limits specified in the 'Standards for Groundwater Quality' (GB 14848-2017) for Class III groundwater and the 'Integrated Wastewater Discharge Standard' (GB 8978-1996). For high-water materials with a water-cement ratio of 1.5:1, the toxicity leaching test results after standard curing for 90 days (RSM-90d), immersion-cured RSM samples (I-RSM-90d), and leaching-cured RSM samples (E-RSM-90d) exhibited ion leaching concentrations well below the standard limits, fully complying with both the Class III groundwater standards and the integrated wastewater discharge standards. The ion leaching concentrations from both immersion and leaching tests were lower than those from the toxicity leaching test conducted after standard curing for 90 days. Among the high-water materials tested, specifically those with a water-cement ratio of 1.5:1, the concentrations of Cd, B, Ca, and Ba ions were found to be higher than those observed in the toxicity leaching test conducted after standard curing for 90 days. This indicates that, in terms of environmental impact, RSM used for filling perform slightly better than high-water materials with a water-cement ratio of 1.5:1.

Combining XRD and SEM analyses, RSM contains hydrated products such as ettringite and C–S–H gel, which effectively immobilize heavy metals present in RM43. Ettringite incorporates heavy metal ions into its crystal lattice and transforms RM into compact aggregates through physical encapsulation or adsorption, thereby preventing the leaching of heavy metals44. Under the action of water dissolution, harmful substances, including heavy metals in RM, may dissolve or migrate. In addition to being encapsulated in ionic form, Cr3⁺, Cd2⁺, and Pb2⁺ can also be immobilized as solid precipitates45. Due to the ionization equilibrium between positively charged heavy metal ions and negatively charged ions, coupled with the alkaline nature of RM composites, Hg and Cr3⁺ can form HgO and Cr(OH)₃ with OH⁻, achieving a stable state46. Cement contains significant amounts of calcium compounds that dissolve in water, releasing large quantities of Ca2⁺, which can form stable C–(A)–S–H compounds with Al or Si47. The combined effect of setting action and cation–anion balance in RSM enables the formation of stable structures by heavy metals and harmful substances in RM, effectively inhibiting their leaching. This finding provides an environmental theoretical basis for the application of RM-based materials in filling.

Analysis of heavy metal immobilization mechanisms

Previous studies have shown48,49,50 that the immobilization of heavy metal ions in cement-based materials primarily involves processes such as adsorption, dissolution, precipitation, ion binding, and solidification. The raw materials utilized in this experiment are mainly RM and cement; therefore, the immobilization mechanism of heavy metal ions in RSM can be explained by referring to the solidification mechanisms of cement-based materials.

The primary immobilization mechanism observed in this experiment is adsorption. SEM analysis reveals that the main hydrated products of RSM materials are C–S–H gel and AFt , with AFt predominantly exhibiting an acicular morphology. As C–S–H gel is primarily amorphous and layered (as shown in Fig. 10a), its cementing action incorporates numerous micropores, providing excellent adsorption capacity51. Furthermore, C–S–H gel carries a negative charge, enabling it to adsorb positively charged heavy metal ions and stabilize them on its surface52. The reaction equation for this process is shown in Eq. (3) 53. The microstructure of AFt is acicular (as depicted in Fig. 10b), and it functions as an anion exchanger in alkaline environments, exhibiting significant adsorption capacity for alkaline salts54. The reaction equation for AFt’s adsorption is given in Eq. (4) and Eq. (5)54,55. The combined effect of C–S–H gel and AFt can effectively balance the cations and anions of heavy metal elements, thereby inhibiting their leaching. This finding is consistent with the results from the leaching experiments.

In this study, \(\equiv \text{SOH}\) denotes the chemisorption site for solid particles; M + represents heavy metal ions; M + adsorbed on the surface of solid particles is indicated by \(\equiv \text{SO}\cdot \text{M}\); \(\equiv \text{AFt}\) represents the adsorption site for ettringite; \({\text{MO}}^{-}\) stands for oxide anions; and adsorbed on the AFt surface is represented by \(\equiv {\text{AFtMO}}^{-}\); bs denoting alkaline salts;\(\equiv \text{AFtbs}\) represents alkaline salt adsorbed on the surface of AFt .

Based on the analysis of XRD, SEM, and leaching experiments, it can be concluded that the relatively low leaching concentration of heavy metal ions in RSM materials is attributed to the adsorption properties of hydrated products, particularly C–S–H gel and AFt, which act as adsorbents, facilitating the adsorption of heavy metal ions and alkaline salts from RM into the microporous structure, thereby maintaining a relatively stable ionic state.

Economic benefit analysis of RSM materials in filling applications

Based on a market survey, the price of high-water material is approximately 2,000 CNY per ton. With a water-cement ratio of 1.5:1, each ton of high-water material can fill a volume of 1.6 ± 0.5 m3, which corresponds to a cost of 1,250 CNY/m3. When calculated using the optimal ratio of 70% RM content (C1R7) in the composite material, and assuming the RM is untreated and essentially cost-free, the cost components include 70 CNY/t for fine sand, 1,500 CNY/t for Portland cement, and additional costs for additives. Considering these factors, the minimum cost of the C1R7 composite material is 457 CNY/ton, with a filling capacity of 0.9 m3/t, resulting in a cost of 507.8 CNY/m3. This indicates that the filling cost per cubic meter of C1R7 is only 40.6% of that of the high-water material. Therefore, taking into account both the mechanical properties and economic benefits, it is feasible to investigate the use of the C1R7 RM composite material as a backfill material to replace high-water material.

Conclusion

In this study, Processability tests, mechanical property tests, microstructure analysis, and leaching experiments were conducted on the RM composite material, leading to the following conclusions:

-

1.

With 70% RM content, the slump of the RM Solidified Fill (RSM) was 204 mm, with an initial setting time of 30 min and a final setting time of 135 min, fully meeting the requirements for filling construction. The compressive strengths of the RSM at 1 day, 3 days, 7 days, and 28 days were 6.12 MPa, 8.97 MPa, 11.25 MPa, and 12.33 MPa, respectively. Its mechanical properties exceeded the strength requirements specified in GB/T 39336-2020 for high-water materials with a water-cement ratio of 1.5:1.

-

2.

The RSM demonstrated good durability. XRD analysis revealed the presence of key phases, including C–S–H gel, AFt, and CaCO3, which contributed to the stable long-term performance of the RSM.

-

3.

Leaching experiments indicated that the concentrations of heavy metal ions in the leachate of RSM complied with the Class III groundwater and integrated wastewater discharge standards. The C–S–H gel and AFt phases in RSM effectively adsorbed heavy metals, rendering the material environmentally friendly.

-

4.

The cost of the RM quick-setting material was only 40.6% of that of high-water filling materials per ton.

The mechanical properties and production costs of RSM developed in this study are superior to those of high-water materials, indicating its potential to replace them in applications involving retention at the side entry of drill bits. However, it is worth noting that, due to RSM’s rapid setting time, it can only be utilized under strictly controlled construction conditions and within specific environmental parameters to ensure the full exertion of its properties. Additionally, since this experiment had a relatively brief research period focusing on RSM, future research endeavors will concentrate on designing RSM for extended durations, thereby enabling its application in an even broader range of working environments. Given its unique performance characteristics, RSM holds vast application prospects in specialized working environments. This study offers a novel direction for the comprehensive utilization of RM.

Data availability

All data generated or analysed during this study are included in this published article.For data requests, please contact the first author or the corresponding author.

References

Zhang, Z. Research and development of red mud resource utilization technology. Guangzhou Chem. 41(6), 29–31 (2013).

He, S., Jiang, S., Wang, W. Research progress on building materials resources of red mud in China. Light Met. (12), 1–5 (2007).

Pengfei, W. et al. Properties of red mud-filled and modified resin composites. Constr. Build. Mater. 409, 133984 (2023).

Emile, M. et al. Preparation and characterization of a red mud-based road base material: Strength formation mechanism and leaching characteristics. Constr. Build. Mater. 220, 297–307 (2019).

Zhang, J. Z. et al. Environmental aspects and pavement properties of red mud waste as the replacement of mineral filler in asphalt mixture. Constr. Build. Mater. 178, 288–300 (2018).

Zhang, X. et al. Research and development of steel fiber reinforced concrete filling material and its application in gob-side entry retaining technology in deep mines. Buildings 14(3), 722 (2024).

Zhang, J. et al. Resource utilization potential of red mud: A study on the micro-mechanism of the synergistic effect of multiple solid waste filling materials. Sustainability 15(21), 15532 (2023).

Zhen, L. et al. Layered re-breaking behavior of gangue backfilling materials and inspirations for protecting mined ecological environments. Constr. Build. Mater. 368, 130477 (2023).

Wang, Z. et al. Effect and mechanism of time-dependent and economical expansion materials in improving the active roof-contact for cemented paste backfill. Constr. Build. Mater. 439, 137339 (2024).

Zhang, F. et al. Post-peak mechanical characteristics of the high-water material for backfilling the gob-side entry retaining: From experiment to field application. Arab. J. Geosci. 13(7), 183–186 (2020).

Xiaoxuan, W. et al. Rheological and mechanical performance analysis and proportion optimization of cemented gangue backfill materials based on response surface methodology. Environ. Sci. Pollut. Res. Int. 30(58), 122482–122496 (2023).

Li, Q. et al. Recycling multisource industrial waste residues as green binder for cemented ultrafine tailings backfill: Hydration kinetics, mechanical properties, and solidification mechanism. Powder Technol. 441, 119799 (2024).

Tang, L. R. et al. Multisolid waste collaborative production of aeolian sand-red mud-fly ash cemented paste backfill. Case Stud. Constr. Mater. 20, e02843 (2024).

Zude, P. et al. Study on application and environmental effect of phosphogypsum-fly ash-red mud composite cemented paste backfill. Environ. Sci. Pollut. Res. Int. 30(50), 108832–108845 (2023).

Yaohui, Z. & Xiaolei, W. Modification test of high-water packing material and application in the gob-side entry retained engineering. Arab. J. Geosci. 15(7), 579 (2022).

Jiwei, B., Shuai, L. & Qinli, Z. Experimental investigation on red mud from the bayer process for cemented paste backfill. Int. J. Environ. Res. Public Health 19(19), 11926–11926 (2022).

Zhaowen, D., Shouqian, S. & Jiaxing, G. Effect of composite activators on mechanical properties, hydration activity and microstructure of red mud-based geopolymer. J. Mater. Res. Technol. 24, 8077–8085 (2023).

Shuai, L. et al. Feasibility of recycling bayer process red mud for the safety backfill mining of layered soft bauxite under coal seams. Minerals 11(7), 722–722 (2021).

Zhikai, W. et al. Effective reuse of red mud as supplementary material in cemented paste backfill: Durability and environmental impact. Constr. Build. Mater. 328, 127002 (2022).

Wang, J. et al. Synergistic utilization, critical mechanisms, and environmental suitability of bauxite residue (red mud) based multi-solid wastes cementitious materials and special concrete. J. Environ. Manag. 361, 121255 (2024).

Mehdipour, I. & Khayat, H. K. Effect of particle-size distribution and specific surface area of different binder systems on packing density and flow characteristics of cement paste. Cem. Concr. Compos. 78, 120–131 (2017).

Wong, C. H. H. & Kwan, H. K. A. Packing density of cementitious materials: part 1—Measurement using a wet packing method. Mater. Struct. 41(4), 689–701 (2008).

Chen, J., Bai, B. & Du, Q. Durability evaluation of a high-performance red mud-based composite material. Mater. Today Commun. 39, 108684 (2024).

Singh, S., Kumar, A. & Sitharam, T. G. Investigating the strength and durability properties of alkali activated red mud for tailings pond embankment material. Geomech. Energy Environ. 36, 100500 (2023).

Chang, N. et al. Improved macro-microscopic characteristic of gypsum-slag based cementitious materials by incorporating red mud/carbide slag binary alkaline waste-derived activator. Constr. Build. Mater. 428, 136425 (2024).

Cui, W. et al. Current research status and emerging trends in utilization of red mud resources: A study based on bibliometric network analysis. Constr. Build. Mater. 442, 137605 (2024).

Tang, W. C., Wang, Z., Liu, Y. & Cui, H. Z. Influence of red mud on fresh and hardened properties of self-compacting concrete. Construct. Build. Mater. 178, 288–300 (2018).

Lawrence, P., Cyr, M. & Ringot, E. Mineral admixtures in mortars—Effect of inert materials on short-term hydration. Cem. Concr. Res. 33(12), 1939–1947 (2003).

Xianhai, L. & Qin, Z. Influence behavior of phosphorus slag and fly ash on the interface transition zone in concrete prepared by cement-red mud. J. Build. Eng. 49, 104017 (2022).

Wei, C. & Jiusu, L. Effects of different silicon sources on the properties of geopolymer planting concrete mixed with red mud. Sustainability 15(5), 4427–4427 (2023).

Dongshuai, H. et al. Sustainable use of red mud in ultra-high performance concrete (UHPC): Design and performance evaluation. Cem. Concr. Compos. 115, 103862 (2021).

Pan, Z. et al. Hydration products of alkali-activated slag–red mud cementitious material. Cem. Concr. Res. 32(3), 357–362 (2002).

Xing, W. et al. Alkali-activated red mud in stabilizing marine dredged clay with low amount of cement. Eur. J. Environ. Civ. Eng. 27(16), 4598–4612 (2023).

Mousa, I. M. et al. Self-curing concrete types: Water retention and durability. Alex. Eng. J. 54(3), 565–575 (2015).

Yue, L. et al. Micro-chemomechanical properties of red mud binder and its effect on concrete. Compos. Part B 258, 110688 (2023).

Song, Z. et al. Solidification mechanism of bayer red mud under the action of calcium hydroxide. Sustainability 16(11), 4770 (2024).

Yong, L. et al. Preparation, characterization and application of red mud, fly ash and desulfurized gypsum based eco-friendly road base materials. J. Clean. Prod. 284, 124777 (2020).

Zhang, N. et al. Hydration characteristics and environmental friendly performance of a cementitious material composed of calcium silicate slag. J. Hazard. Mater. 30, 667–676 (2016).

Zajac, M. et al. Influence of limestone and anhydrite on the hydration of Portland cements. Cement Concr. Compos. 46, 99–108 (2014).

Chen, T. et al. The strength, reaction mechanism, sustainable potential of full solid waste alkali-activated cementitious materials using red mud and carbide slag. Constr. Build. Mater. 449, 138454 (2024).

Cao, Y. et al. Mechanical and microstructural characterization of one-part binder incorporated with alkali-thermal activated red mud. Case Stud. Constr. Mater. 21, e03634 (2024).

Wang, S., Zou, F. & Luo, H. An all solid waste CO2 sequestration material consist of multiple calcium silicate clinkers by carbide slag, copper tailing and red mud: Clinker crystal transformation and carbonation hardening properties. Constr. Build. Mater. 450, 138534 (2024).

Zhong, W. et al. Transferring red mud to efficient adsorbent for the adsorption and immobilization of Ni(II) from aqueous solution. Colloids Surf. C Environ. Asp. 2, 100045 (2024).

Zhang, Y. et al. Preparation of road base material by utilizing electrolytic manganese residue based on Si-Al structure: Mechanical properties and Mn 2+ stabilization/solidification characterization. J. Hazard. Mater. 390, 122188 (2020).

Zhang, M. et al. Immobilization of Cr(VI) by hydrated Portland cement pastes with and without calcium sulfate. J. Hazard. Mater. 342, 242–251 (2018).

Yang, J. et al. Rapid wet grinding carbonation of sintering red mud for highly efficient CO2 sequestration and Cr solidification. Chem. Eng. J. 488, 151134 (2024).

Li, Y. et al. Preparation of environmental-friendly cementitious material from red mud and waste glass sludge by mechanical activation. Constr. Build. Mater. 423, 135861 (2024).

Duo-Rui, Z. et al. Novel adsorbent synthesized from red mud and acid mine drainage for enhanced contaminant removal: Industrial waste transformation, adsorbent performance and metal(loid) removal mechanisms. Chem. Eng. J. 465, 142867 (2023).

Liu, J. et al. Effect of thermal pretreatment on the reactivity of red mud valorized as aluminosilicate precursor for geopolymer production. Constr. Build. Mater. 445, 13794 (2024).

Guo, L. et al. A comprehensive investigation of the adsorption behaviour and mechanism of industrial waste sintering and bayer red muds for heavy metals. Environ. Geochem. Health 46(11), 434 (2024).

Wu, B. et al. Modeling of multilayer water adsorption and condensation in slits of cement minerals by molecule simulation and adsorption isotherm. Constr. Build. Mater. 421, 135571 (2024).

Jinbo, Y. et al. Effects of C–S–H gel surface structure on sodium chloride evaporation crystallization in C–S–H gel nanopores with molecular dynamics analysis. Appl. Surf. Sci. 639, 158159 (2023).

Chen, Q. et al. Immobilisation of heavy metal in cement-based solidification/stabilisation: A review. Waste Manag. 29(1), 390–403 (2008).

Meng, D. et al. Effect of anionic charge quantity on adsorption properties of PCE molecules on ettringite surface: A molecular dynamic simulation method. J. Nanopart. Res. 25(8), 161 (2023).

Chrysochoou, M. & Dermatas, D. Evaluation of ettringite and hydrocalumite formation for heavy metal immobilization: Literature review and experimental study. J. Hazard. Mater. 136(1), 20–33 (2005).

Acknowledgements

The authors acknowledge the support of the 2024 Central Government-guided Local Science and Technology Development Fund Project: Extraction and Industrialization of Gallium and Lithium from RM and Its Production Process (Qianke He Zhong Yidi [2024]029); 2023 Guizhou Provincial Key Scientific and Technological Achievements Transformation Project: Integration and Application of RM "Rock-forming" Composite Materials for Mine Restoration and Road Construction (Qianke He Chenguo [2023] Major 009); 2022 Guiyang Science and Technology Plan Project: Demonstration of Filling Application of RM-Phosphogypsum Support Material in Gob-side Entry Retaining (Zhuke Hetong [2022] No. 2-6); Supported by Project of the Key Laboratory of Light Metal Materials Processing of Guizhou Province(Qian Ke He Platform and talent [2016]5104); 2025 Central Government-guided Local Science and Technology Development Fund Project: Integration and Application of Intelligent Modification and Rock Formation Filling of Red Mud, a By-product of the Aluminum Industry, in Abandoned Open-pit Mines (Qianke He Zhong Yidi [2025]028).

Author information

Authors and Affiliations

Contributions

Xiang Yang(First Author): Writing–original draft, Methodology, Investigation, Formal analysis, Conceptualization. Jiangang Zhang(corresponding author): Writing–review & editing, Supervision, Resources, Funding acquisition, Conceptualization Xiangdong Su(corresponding author): Supervision, Methodology. Zhiwei Huang: Supervision, Methodology Haijia Li: Supervision, Methodology.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Yang, X., Zhang, J., Su, X. et al. Feasibility evaluation of mechanical and environmental properties for red mud based rapid setting filling support material. Sci Rep 15, 7255 (2025). https://doi.org/10.1038/s41598-025-90570-7

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-90570-7

Keywords

This article is cited by

-

Green Process for Red Mud Utilization: Iron Recovery and Cement Precursor Synthesis

Journal of Sustainable Metallurgy (2025)

-

Treatment Methods and Influence of Red Mud and Phosphogypsum on Pavement Composite Performance: A State of the Art Review

Indian Geotechnical Journal (2025)