Abstract

Acidizing boosts healthy production, while microwave radiation techniques and hybrid methods are emerging to enhance hydrocarbon extraction and oil production efficiency. This research systematically investigated the interaction between microwave radiation and working acid on crude oil. Crude oil samples were positioned adjacent to an acid solution and subsequently subjected to microwave radiation at power levels of 1300 W (100% Microwave) and 780 W (60% Microwave) for durations of 1, 2, and 3 min. A comprehensive suite of analyses was performed, including viscometric assessments, interfacial tension measurements, density measurements, asphaltene quantification via extraction tests, sludge analysis, nuclear magnetic resonance (NMR) spectroscopy, pH measurements, and Fourier transform infrared spectroscopy (FTIR). The results indicate that the polarity of both the crude oil and the acid solution enhances the absorption of microwave radiation. FTIR analysis revealed an increase in polar functional groups relative to non-polar groups, suggesting significant molecular interactions; the NMR test also proves this trend. Furthermore, viscometric and surface tension tests demonstrated that increased polarity correlates with enhanced microwave absorption. The combined method, which is characterized by the simultaneous presence of polar acid solution and an electromagnetic field, led to alternating fluctuations (increase and decrease) of surface tension, viscosity, density, pH, and sludge during the tested process. It also caused a decrease in the concentration of asphaltene hydrocarbons; the reason for these intermittent changes is the simultaneous effects of changes in the strength of acid solutions and increasing or decreasing the power of microwave radiation at a particular time.

Similar content being viewed by others

Introduction

Upon contact between the acid and crude oil, asphaltene becomes unstable within the crude oil, leading to coagulation and precipitation, potentially blocking the formation of pores. The temperature was maintained at 26 °C, which is a standard ambient temperature that provides a stable environment for the asphaltene interactions in crude oil. The pressure was set to 1 atm (atmospheric pressure) to simulate typical environmental conditions without introducing significant deviations that might affect the coagulation and precipitation processes. These conditions were chosen because they represent typical operational conditions under which asphaltene behavior is commonly studied in crude oil processing, ensuring that the results are both relevant and applicable to practical scenarios in the oil industry.The rapid reaction between the injected acid and crude oil initiates the formation of an initial layer of acid sludge, followed by its growth. This sludge, comprising paraffin, resin, asphaltene, and other materials like wax and solid particles, forms complex structures with molecules strongly bonded to each other. The quantity of sludge formed is not solely dependent on the asphaltene content. Asphaltene content plays a significant role in sludge formation; however, several other factors also contribute, including pH, temperature, interfacial tension, viscosity, and salinity. These parameters were quantitatively measured through precise experimental setups. pH was monitored using a calibrated pH meter to account for treatment-induced changes. Temperature variations were controlled and continuously monitored using a thermocouple to isolate their effects. Interfacial tension was measured with a drop shape analyzer to evaluate oil–water interactions during treatment. Viscosity changes, which influence sludge formation, were observed using a rotational viscometer. Lastly, salinity was controlled by adding precise amounts of salt to simulate different water chemistries, enabling a comprehensive analysis of its impact on the process. While typically associated with asphaltene, sludge can also form in crude oils without asphaltene, known as non-asphaltic sludge. Asphaltic sludge particles are small but aggregate into larger entities that can block perforations due to swelling from water, acid, and oil presence1,2,3. Acidizing is a technique used to enhance hydrocarbon production in carbonate reservoirs, but its effectiveness can be influenced by different factors4.

Chemical analysis of the sludge indicates acid without the necessity of water molecules. Factors affecting acid sludge formation include acid type and concentration, temperature, gaseous components, total base number (TBN), SARA components of crude oil, and the presence of ferric and ferrous ions. Heavier crude oils may not produce acid sludge unless certain conditions, like iron ion presence in an acidic medium, are met5.

Initially, asphaltene molecules in crude oil interact with hydrogen ions from the acid, leading to their attraction to the interface between the acid and crude oil phases. Acid–base reactions occur at this interface based on the chemistry of asphaltene molecules and their heteroatoms (O, N, S), causing the migration of asphaltenes and their accumulation at the interface. This process results in the formation of a strong layer around the acid droplets, preventing their contact. The layer continues to grow, increasing in thickness and compactness over6. Petroleum products are known for the hydrocarbon materials obtained from the well, which occur in either the form of crude oil or crude gas7.

Naim et al. (2021) proposed a green and efficient acid system for carbonate reservoir stimulation, offering a safer and more environmentally friendly alternative to conventional acids like HCl. The system is biodegradable, non-corrosive, and performs comparably to traditional methods in enhancing reservoir permeability. Its operational advantages include reduced equipment corrosion, lower maintenance costs, and improved safety. This innovation aligns with sustainable industry practices, minimizing environmental impact while maintaining high efficiency8.

Mohammadi and Alemi (2021) explored the use of single-walled carbon nanotubes (SWCNTs) to simultaneously control the formation and growth of asphaltene solids and wax crystals under real oilfield conditions. The study showed that adding 100 ppm SWCNTs significantly reduced asphaltene onset pressure and delayed wax formation and gelation points. Wax crystal size decreased from 756 to 86 nm, with notable morphological changes. These effects were attributed to strong π–π interactions between SWCNTs and asphaltenes, as well as their ability to inhibit wax crystal aggregation. This innovative approach highlights SWCNTs as a promising solution for mitigating flow assurance issues in petroleum production9.

Silin et al. (2022) investigated various problems that may arise in the acidification of oil reservoirs due to the incompatibility of acid with reservoir rocks and fluids. One of these problems is the formation of acid emulsions in the oil, which leads to the blocking of pores and prevents the interaction between the surface of the acid and the stone. The conventional "bottle test" method lacks comprehensive characterization of these emulsions and is only used for rapid reagent selection. Silin et al. (2022) introduced a new method to evaluate emulsion formation and possible damage during acid treatment using visual observation, viscosity measurement, surface tension, and voltage stability analysis. While HCl-based emulsions are usually more viscous, thinner, and more stable, high acid strength can lead to emulsion breakdown. Emulsions stable under static conditions may disintegrate under mechanical stress; this feature is observed in emulsions based on sulfamic acid. Although the emulsions can be separated visually, an emulsion column may exhibit a water content gradient. These findings highlight the relationship between acid and oil parameters in emulsion formation10.

Liu et al. (2024) reviewed the challenges of asphaltene deposition during CO2-enhanced oil recovery (CO2-EOR) and evaluated various inhibitors to address this issue. They highlighted how asphaltene destabilization by CO2 leads to deposition, causing pore plugging and reduced permeability. Inhibitors such as surfactants, polymers, ionic liquids, and nanoparticles, particularly carbon quantum dots (CQDs), were shown to stabilize asphaltenes and prevent aggregation through strong π–π interactions. The authors emphasized optimizing inhibitor concentrations and strategies for cost-effective and environmentally friendly applications, recommending further field-scale studies to validate laboratory findings11.

In reservoirs with low permeability and heat transfer, electromagnetic (EM) methods are more effective in reducing viscosity and enhancing oil mobility than other techniques. Electromagnetic waves with frequencies ranging from 300 MHz to 300 GHz, known as microwaves, create a field from which materials with a high dielectric coefficient absorb energy. In the oil industry, microwaves are primarily used in oil shale reservoirs.. Microwave heating is achieved using an antenna near the production zone. To utilize microwaves as an Enhanced Oil Recovery (EOR) method, an antenna is placed in a drilled hole close to the producing well12. Microwave-absorbing materials play a significant role in various applications that involve the attenuation of electromagnetic radiation13.

The microwave energy heats the oil in the reservoir, moving toward the producing well. As a result, microwaves are used for oil upgrading, viscosity alteration, temperature increase, wettability enhancement, and enhanced oil recovery (EOR). The absorption of energy varies depending on the sample composition and dielectric properties. Consequently, certain components within the oil begin to heat up because of microwave radiation. Elements in crude oil with a high dielectric coefficient, such as sulfur, nitrogen, and oxygen, exhibit better microwave absorption. The dielectric properties of the materials cause them to align with the microwave field pole in a manner similar to polarity. Sulfoxides, amines, ketones, and aldehydes are the most common functional groups found in asphaltene structures14,15,16,17,18,19,20,21,22.

Taheri-Shakib et al. (2021) explored the impact of using microwaves for heating on asphaltene deposits in heavy oil. They found that microwave radiation duration plays a crucial role in comparison to conventional heating methods, leading to unpredictable changes at different time intervals. In addition, their research highlighted that compounds with sulfur, nitrogen, and oxygen elements exhibit better microwave absorption properties because of their high dielectric coefficient. As a result, asphaltene particles were observed to undergo cracking under microwave treatment, transforming into lighter hydrocarbons23.

Microwaves increased the temperature of oil parts containing asphaltene particles more than other parts. Asphaltene, one of the heaviest components in crude oil, poses challenges in production and transportation in the oil industry. Understanding the behavior of asphaltene is crucial. Asphaltene precipitation is characterized by high polarity properties, including sulfur, nitrogen, and oxygen. Microwaves can crack these particles, causing them to turn into lighter hydrocarbons24.

Karim et al. investigated the effect of microwave irradiation on the acid hydrolysis of faba bean starch, focusing on the resulting physicochemical changes in starch granules. The study revealed that microwave treatment significantly reduced hydrolysis time and enhanced the efficiency of the process. It also altered the granule structure, increasing its susceptibility to hydrolysis and improving its functionality for industrial applications25.

The ATR-FTIR analysis provides valuable insights into the molecular interactions occurring at the rock-fluid interface during acid treatment. The data reveal that microwave radiation enhances the desorption of various organic compounds from the rock surface, including aromatic compounds, long-chain alkanes, and polar functional groups such as hydroxyl (O–H) and amine (N–H) bonds, as well as carbonyl (C=O) functional groups.The enhanced efficiency of desorption observed with microwave radiation suggests that this treatment facilitates the breakdown of complex hydrocarbon structures, promoting the removal of precipitated asphaltene sludge that often accumulates during acid treatment. Asphaltenes, being high molecular weight compounds, can significantly hinder fluid flow and reduce overall recovery efficiency. The ability of microwave radiation to assist in their desorption indicates a potential pathway for improving the effectiveness of acidizing operations. Moreover, the simultaneous application of microwave radiation during acid treatment appears to create a more favorable environment for the interaction between the acid and the rock surface. This environment may enhance the dissolution of minerals and organic compounds, further contributing to improved fluid mobility. The findings suggest that microwave treatment could serve as a complementary approach to traditional acidizing methods, potentially leading to increased oil recovery rates and more efficient reservoir management26.

Le et al. introduced an innovative microwave-assisted method for synthesizing zeolite 4A, achieving enhanced porosity and reduced crystallization time compared to conventional hydrothermal methods. The synthesized zeolite 4A exhibited high crystallinity, uniform cubic morphology, and increased surface area, as confirmed by XRD and SEM analyses. The approach also demonstrated significant energy efficiency by utilizing a domestic microwave oven, highlighting its potential for industrial scalability. This method offers a sustainable and efficient alternative for zeolite 4A production with improved adsorption properties27.

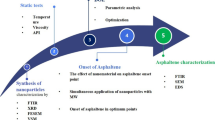

In this Research, the combined effects of microwaves and acid on heavy crude oil were investigated, focusing on changes in asphaltene concentration and the cracking of asphaltene hydrocarbons. Various basic petroleum and chemistry engineering tests were conducted, including changes in pH, interfacial tension and viscometry tests, asphaltene extraction, densitometry, temperature changes, sludge amount, and optical tests such as Fourier transform infrared spectroscopy and Nuclear Magnetic Resonance. This comprehensive approach provides valuable insights into the behavior of heavy crude oil under these experimental conditions.

Materials and method

Analytical techniques and rheological measurements were used to investigate the combined effects of microwave radiation and acid treatment on asphaltene concentration and fluid-fluid interactions. Heavy crude oil samples underwent treatment with microwaves and acid, followed by a series of tests including measurements of pH changes, interfacial tension, viscosity, asphaltene extraction, density, temperature variations, and sludge formation. Fourier Transform Infrared Spectroscopy (FTIR) was employed to analyze the samples. After assessing the changes in asphaltene concentration, the treated asphaltenes were further characterized using Nuclear Magnetic Resonance (NMR) and FTIR techniques.

Materials

Oil sample

The oil sample was obtained from an oil field in the south of Iran. The API, viscosity, acid number, and asphaltene content of the oil sample are shown in Table 1. The oil sample was obtained from an oil field located in the southern region of Iran, a region known for its significant oil reserves and operational importance. While we did not disclose the specific oil field and depth for confidentiality reasons, we provided a general description of the field's geological and operational characteristics to justify the sample's representativeness. The oil extracted from this region typically exhibits characteristics that are common in many other fields in the region, including the presence of high-asphaltene content and other crude oil properties, making it a suitable representative sample.

Acid solution

Acidic solutions at a concentration of 15% were prepared to mimic the crude oil-acid interaction at the beginning of the injection. Distilled water, sea water, and formation water were used to synthesize acidic solutions. The composition of seawater shown in Table 2 is taken from Persian Gulf seawater. In addition, the formation water was designed according to the chemistry of water produced from the same field where crude oil was sampled.

Methods

Microwave treatment

According to Fig. 1, the microwave oven operates at a frequency of 2.45 GHz with adjustable radiation power from 260 to 130026. We selected two power levels, 780 W and 1300 W, to investigate the effects of both low and high microwave radiation intensities on asphaltene behavior and sludge formation. These power levels were chosen based on a combination of preliminary experiments and literature review, which indicated that power levels within this range are commonly used in similar studies to explore the effect of microwave radiation on oil properties. The lower power level (780 W) was used to examine the minimal effect of microwave radiation, while the higher power level (1300 W) was selected to observe the maximal impact, allowing us to compare the results and determine the threshold at which significant changes in asphaltene structure and sludge formation occur. The range was limited to these two points to focus on the most impactful extremes of the microwave power spectrum and avoid the complexity of exploring intermediate power levels that might not provide additional meaningful data.

Schematics of microwave radiations22.

The internal dimensions of the microwave oven are 10 * 17 * 20 cm. In this study, we ensured uniform microwave treatment by carefully positioning the sample inside the microwave oven to avoid hot spots or uneven radiation exposure. To approximate uniform heating, the samples were centrally placed within the microwave chamber, minimizing potential gradients in the microwave field strength. Additionally, preliminary temperature measurements were conducted using thermocouples at various positions within the sample before and after microwave exposure. These measurements confirmed a relatively uniform temperature distribution across the sample. Heavy crude oil was placed in the vicinity of different acid solutions and then treated with microwave radiation at 780 and 1300 watts for 1,2 and 3 min. The surface temperature of the heavy crude oil under treatment was measured using a digital thermometer with an accuracy of ± 1 °C. The temperature of the untreated crude oil is approximately 26 °C26.

Asphaltene extraction

To study the changes in the molecular structure of the asphaltenes, the asphaltenes were extracted using the IP-143 standard method. To do this, the oil mixtures were combined with normal heptane (Merck, Germany) to separate the asphaltene, wax, and other heavy fractions. The mixture was then heated to 80 ℃ for 30 min and left to stand in the dark for 24 h. Subsequently, the mixture underwent filtration using Whatman filter paper #42 to separate the solid precipitates. The filter paper was rinsed with normal heptane in a soxhlet setup to isolate the wax and saturated hydrocarbons. Subsequently, the paper was washed with toluene in the soxhlet setup, causing the asphaltene fraction to dissolve. Finally, the asphaltenes were obtained by evaporating the toluene.

To determine the amount of asphaltene in oil samples, an IP-143 test was performed. As mentioned in the sample preparation phase, after the samples were prepared, the IP-143 test was performed on them after a few days. We will explain the working method below:

First step: First, for every 1 cc of the oil sample taken in the previous step, 30 cc of normal heptane was poured into the round-bottomed balloon, placed on the heater, and refluxed for 1 h. Close the lid of the balloon and place it in a cool, dry, and dark place for 24 h. After 24 h, it was observed that some asphaltene had been deposited and stuck to the balloon wall. Then, using Whatman #42 filter paper with 0.7-micron holes, we filtered the sample in the balloon. It can be seen that particles higher than 0.7 microns do not pass through the paper and remain on the paper.

Liquids passing through the filter paper cannot be used. We kept this balloon in place because there was some asphaltene deposit stuck to the wall of the balloon, which we will need in the next step. The materials deposited on the filter paper are asphaltene and wax.

The second step: the filter paper was placed inside the sale, and the reflux operation was repeated with normal heptane. Normal heptane was used because of its saturation, which caused the waxes to wash off the filter paper. We continued the reflux operation until the solution returned to the balloon and became colorless. The filter paper will be with asphaltene and some sulfur or impurity.

Third step: We placed the filter paper with asphaltene inside the saxule, poured some toluene into the primary balloon, and repeated the reflux operation. Note that the smaller the amount of toluene used, the easier it will be to proceed, because all the toluene present must be evaporated after the reflux operation; It should also be noted that due to the volatility of toluene and the presence of heat, the asphaltene may burn at the bottom of the balloon, in which case the test will not be acceptable. We continued the reflux operation as in the previous step until the liquid returned to the balloon and became colorless. Then, we placed the balloon under the laboratory hood to evaporate the toluene.

After the complete evaporation of toluene, the substances in the balloon are asphaltene. We then weighed the balloon containing asphaltene. This weight indicates the amount of asphaltene. Note that before starting the test, we should also have the weight of the balloon used. Using the following relationship, we can determine the percentage of asphaltene.

FTIR spectroscopy

FTIR spectroscopy was employed to analyze changes in the concentration of functional groups in the asphaltene molecular structure. In this study (Tables 4, 5), we initially employed FTIR spectroscopy as a quantitative method to analyze molecular changes, particularly the evolution of functional groups in the asphaltene samples. FTIR is a well-established technique for identifying the presence of functional groups and observing qualitative trends in molecular interactions. However, given the complexity of asphaltene chemistry and the need for high sensitivity in detecting small changes, we opted for integral area calculations of FTIR peaks as a proxy for quantifying the extent of changes in functional group content.

Asphaltene powders were combined with Potassium bromide at a ratio of 1:40 to create a pellet for testing. The FTIR spectrum of the resulting pellet was examined in the 400–4000 cm−1 range with a resolution of 1cm−1 using the PerkinElmer Frontier21. The choice of a spectral range from 400 to 4000 cm⁻1 with a resolution of 1 cm⁻1 was made based on the need to capture the full spectrum of functional group vibrations present in the asphaltene samples. The 400–4000 cm⁻1 range is typical for FTIR analysis of organic materials, as it encompasses the most relevant vibrational modes for functional groups such as C–H, O–H, and C=O, which are key to understanding changes in asphaltene composition. The 1 cm⁻1 resolution was selected to provide sufficient detail while maintaining reasonable measurement time. This resolution strikes a balance between sensitivity to functional group vibrations and experimental efficiency, allowing for clear identification of spectral features without excessive noise. By calculating the integral areas of the absorbance spectra, measured from valley to valley, we could determine the concentration of functional groups present in the heavy crude oil and asphaltene structures. Although these comparisons, represented as indexes, do not provide quantitative concentration data, they do indicate changes in functional group concentrations. Unlike FTIR spectroscopy, NMR spectroscopy directly correlates the integral area of chemical shifts with the concentration of specific functional groups. Therefore, the asphaltene structural data were derived from NMR spectroscopic analysis. The deconvoluted FTIR peaks, obtained through a Gaussian form using "residual after 1st derivative," displayed consistent indices.

NMR spectroscopy

The molecular structure of asphaltene was analyzed using NMR spectroscopy. To verify the complete dissolution of asphaltenes in deuterated chloroform (CDCl3), we performed visual inspection under a microscope to ensure that no solid particles remained. Additionally, the solubility of asphaltenes was confirmed through spectroscopic techniques, including NMR, where a homogenous solution should show sharp, well-resolved peaks without signs of aggregation. Solvent blank controls were used to ensure that the solvent did not interfere with the measurement or introduce any artifacts. By comparing the NMR spectra of the solution to known standards, we confirmed that the dissolution was complete.

For the HNMR test, 5 mg of asphaltene powder was dissolved in 0.7 ml of deuterated chloroform, whereas 40 mg of asphaltene powder was used for the CNMR test. A Bruker spectrometer operating at a wave frequency of 500 MHz was utilized, with the pulse width and recycle delay set at 128 and 16μs respectively21.

The pulse width (128 μs) and recycle delay (16 μs) parameters were selected based on standard NMR experimental protocols optimized for signal resolution and sensitivity. The 128 μs pulse width is long enough to ensure sufficient excitation of the nuclei in the asphaltene sample without causing broadening or distortion of the peaks. The 16 μs recycle delay was chosen to allow enough time for the magnetization to relax fully between pulses, ensuring accurate and reproducible signal measurements. These parameters were optimized based on initial experiments to achieve a good signal-to-noise ratio and avoid saturation effects in the NMR spectra. Mestrenova software was employed to analyze the data, including identifying shifts, applying corrections, and calculating the spectrum integral areas. The aromaticity and shape factors were determined on the basis of the integral areas of aromatic, aliphatic, and peripheral carbons in the CNMR spectra. In addition, the average carbon number of the alkyl chains was calculated using the integral areas of α, β, and γ alkyl hydrogen and the Dickson equation. Based on the NMR data, a hypothetical molecular structure of asphaltene was proposed21.

Rheological tests

The Anton Par rheometer is a device used for conducting viscometric tests that employs a CC27 spindle to measure viscosity. The machine has a maximum spindle rotation speed of 1200 rpm and can calculate viscosity up to a cutting rate of 1400 s−1. Its components include a spindle connected to an internal motor, a chamber for holding the fluid, mechanical sensors for detecting force, a thermometer linked to the fluid chamber’s temperature, and a monitor for data collection. As the motor spins, the spindle interacts with the fluid, experiencing resistance that is translated into data by the sensors. By recording the force parameters of the fluid, the rheometer can determine the viscosity of the fluid in the chamber. In an experiment studying the combined effects of acid and microwaves on treated crude oil viscosity, 18 cc of the oil was placed in the chamber, and its viscosity was measured by adjusting the temperature.

Interfacial tension

Interfacial tension (IFT) is the energy between two immiscible fluids. This parameter is an important factor in any harvesting process. The materials used in the processes of increased extraction, such as surfactants, alkalis, and polymers, tend to reduce the interfacial tension between oil and water. As a result, capillary forces are reduced and more residual oil is produced. Drop shape analysis (hanging drop method) is a suitable method for measuring surface tension. Hanging drop surface tension by image analysis, has been considered a very accurate method for measuring IFT for various values. In this method, video images of hanging drops are analyzed and the IFT is measured by solving the Young–Laplace equation. The wettability of the reservoir rock and the interfacial tensions between the reservoir fluids play a vital role in oil recovery efficiency.

Density measurement

Density measurement is a crucial aspect of material analysis in various industries, and one of the commonly used methods for determining the density of a substance is through the use of a pycnometer. A pycnometer is a specialized glassware that is designed to measure the density of liquids and solids accurately. The process of density measurement with a pycnometer involves several steps to ensure precision and accuracy. Firstly, the pycnometer is thoroughly cleaned and dried to eliminate any potential contaminants that could affect the measurement. Once cleaned, the pycnometer is weighed to obtain its empty weight, which serves as a reference for the subsequent measurements.

To measure the density of a liquid, the pycnometer is filled with the liquid of interest, ensuring that no air bubbles are trapped inside. The filled pycnometer is then weighed again to determine the combined weight of the pycnometer and the liquid. The difference between the combined weight and the empty weight of the pycnometer provides the mass of the liquid. By knowing the volume of the pycnometer (10 cc), the density of the liquid can be calculated using the formula density = mass / volume.

It is important to note that temperature plays a significant role in density measurements, as the density of a substance can vary with temperature changes. Therefore, it is essential to conduct density measurements at a consistent and controlled temperature (@ 26 °C) to ensure accurate results.

Sludge measurement

To measure the amount of sludge, we pour the created third phase (emulsion) on the mesh 300 and then after passing the acid solution, we measure the weight remaining on the mesh.

Sample preparation

The acidic solutions used are acidic formation water, acidic sea water, and acidic distilled water, which are denoted by the abbreviations AFW, ASW, and ADW, respectively. Acidic water is the water used to dilute the mother hydrochloric acid.

After preparing the acid solutions, the desired oil and acid solution were poured into Blue Cap containers with a capacity of 100 cc and a ratio of 1:1 and were rotated by hand for 5 min to form the third phase (coagulated asphaltene emulsion). From the preparation of acidic solutions, oil and the desired acidic solution were poured into Blue Cap containers with a capacity of 100 cc and rotated by hand for 5 min to form the third phase (coagulated asphaltene emulsion). (asphaltene coagulated emulsion). Then, to better combine the materials and create a water–oil emulsion phase between the water phase and the oil phase, the emulsion was heated on a magnetic stirrer for 3 h at a temperature of 26 °C. After performing these steps, in addition to the oil and water phases, a third phase was formed on the surface of the water–oil joint (asphaltic sludge). This is the first step to check the state of the working acid in the vicinity of the fluid alone and without the presence of microwaves. In the second neighborhood, the acid solutions made in the above-mentioned order are first placed in the vicinity of crude oil with the same stated percentage, and then they are directed to the microwave (MW) chamber. At this stage, by applying 1300 W(100% microwave) and 780 W(60% microwave) for 1, 2 and 3 min, the crude oil is simultaneously placed in the vicinity of the acid solution and microwaves. Finally, to check the changes, the oil sample was taken from the top of the test tube, and tests of viscosity, interfacial tension, FTIR, densitometry, pH meter, IP-143 asphaltene deposition extraction, and NMR were performed on the oil/asphaltene. In addition, the amount of asphaltic sludge resulting from the mixing of two phases was investigated.All connections between test types have been considered by incorporating the properties of acid and microwave radiation so that the simultaneous effects of the two stimulation methods can be applied.

Results and discussions

Measurement of the hydrogen potential

The pH is a quantitative measure of the acidity or basicity of an aqueous solution, defined as the negative logarithm of the activity of the hydrogen ion (H+) in the solution. The pH scale ranges from 0 to 14, with a pH of 7 being neutral, values below 7 being acidic, and values above 7 being basic or alkaline. The pH is mathematically defined as:

where [H+] is the equilibrium molar concentration (mol/L) of hydrogen ions in the solution. This logarithmic scale means that each unit change in pH corresponds to a ten-fold change in the hydrogen ion concentration. At 25 °C (77 °F), solutions with a pH less than 7 are considered acidic, as they have a higher concentration of H+ ions than hydroxide (OH−) ions. Solutions with a pH greater than 7 are basic or alkaline, as they have a higher concentration of OH− ions than H + ions. A pH of 7 at 25 °C indicates a neutral solution, where the concentrations of H+ and OH− ions are equal, as in pure water. It's important to note that the neutral pH value of 7 can shift depending on temperature. As the temperature increases above 25 °C, the neutral pH value decreases, as the dissociation of water (H2O ⇌ H+ + OH−) is favored towards the products at higher temperatures. The pH of the different solutions increased compared to the pure mother acid, but the increase was not significant, and the pH values remained relatively close to each other. This suggests that the application of different acid strength conditions did not dramatically affect the pH, and the acid strength was largely preserved. In the acidic solutions, the pH changes with temperature are negligible compared to basic and neutral solutions. This is because in acidic solutions, the concentration of H+ ions is much higher than the concentration of OH− ions, and the small changes in the water dissociation equilibrium due to temperature have a minimal impact on the overall H+ concentration and the resulting pH. The electromagnetic field can cause the dissociation of water molecules, leading to an increase in the concentration of hydroxide ions (OH−) and a corresponding decrease in the concentration of hydrogen ions (H+). This results in an increase in the pH of the solution, which is proportional to the flow rate of the solution through the electromagnetic field28.

Figure 2 shows initial fluctuations in pH levels, which may be attributed to the dynamic nature of chemical reactions during treatments. To assess the statistical significance of pH fluctuations, we conducted a series of experiments with control samples under identical conditions but without microwave treatment. The results showed that the fluctuations in pH were indeed statistically significant, indicating that microwave treatment had a measurable impact on the pH of the solution. Control experiments helped rule out potential artifacts, such as those from measurement drift or sample contamination, ensuring the validity of the observed changes. These fluctuations could indicate the breakdown of certain hydrocarbon fractions and the subsequent release of acidic compounds into the solution. Over time, the pH values appear to stabilize, suggesting that the treatments reach a state of chemical equilibrium. This stabilization is crucial as it indicates that the reactions have proceeded to a point where the acidity of the crude oil remains consistent under the given treatment conditions, allowing for predictable outcomes in oil recovery processes.

The mechanism behind this pH increase can be explained by the dipole nature of the water molecule. The electromagnetic field can interact with the dipole moment of water, causing the water molecules to dissociate more readily, releasing more OH− ions and absorbing more H+ ions. This shift in the water dissociation equilibrium leads to the observed increase in pH.

Microwave radiation serves as a powerful tool in enhancing the effectiveness of chemical treatments. The application of microwave energy can lead to localized heating, which facilitates chemical reactions and enhances mass transfer processes. The graph's inclusion of different microwave intensities (100% mw vs. 60% mw) allows for a comparative analysis of how energy input affects the chemical behavior of the crude oil. Higher microwave intensities typically result in increased thermal agitation, which can break down complex hydrocarbon structures and promote the release of acidic components within the oil. This thermal effect may lead to a more significant alteration in pH levels, reflecting the efficiency of the treatment.

The use of acidified water treatments is critical in modifying the chemical composition of heavy crude oil. Acids, such as hydrochloric acid, can help break down asphaltene and other high molecular weight hydrocarbons, which are known to contribute to the viscosity and stability of crude oil. By reducing the viscosity, these treatments can enhance the flow properties of the oil, making it easier to extract and process. The effectiveness of these acid treatments is reflected in the resulting pH changes observed in the graph. A significant reduction in pH after treatment indicates successful acidification, which can lead to improved oil recovery outcomes.

The influence of the electromagnetic field on the electrical conductivity is revealed and confirmed. This method has many applications, such as increasing the pH of the solution (to reduce the corrosiveness of the water flow), creating a local increase in the concentration of ions in the local volume of the solution, and improving the activity of the solution. For statistical studies, we conducted the necessary studies using minor changes in the numbers in the chart and data file.

Temperature changes

Polar/nonpolar molecules absorb microwave energy to accelerate the rate of chemical reaction, and microwave energy is considered nonionizing radiation. Molecular motion is affected by microwaves, but they cannot change the molecular structure. The spin effect of microwaves excites polar materials and therefore heats polar materials but not nonpolar materials. Permanent dipole (combined polar)—change of dipole occurs during rotation, thus interaction with radiation; therefore, heteronuclear diatomic molecules are microwave active. Microwaves only transfer energy to polar molecules Microwave energy is too low to activate or break molecular bonds directly. Therefore, microwaves cannot cause molecules to undergo chemical reactions by directly absorbing energy, as high energy visible and ultraviolet light can in photochemical reactions. Microwaves heat polar molecules because they can oscillate in response to a microwave electromagnetic field. These oscillations create thermal energy in the polar molecules and increase their temperature. On the other hand, nonpolar molecules do not have the same ability to oscillate and are therefore not easily heated in microwaves.

The temperature of crude oil in the vicinity of acid solutions and microwaves was recorded using a digital laser thermometer (GM-320, Benetech) with an accuracy of ± 1 °C. Considering that the digital thermometer measures the temperature of the material based on the beam reflected from the surface of the sample, it is not possible to continuously measure the temperature. To measure the temperature of the treated crude oil during microwave irradiation, it was necessary to stop the irradiation every 30 s. Because of the short treatment time (3 min), stopping the treatment even for a short time will disrupt the treatment. To avoid this problem, another batch of acid solutions was prepared to record the temperature characteristics. For example, to obtain a temperature curve with six data points, six acid solutions were treated at six time periods. It should be mentioned that to compare the increase in temperature between crude oil and treated crude oil, the crude oil sample has a temperature of approximately 26 °C and this temperature is defined at time 0. It is clear that the measured temperature is proportional to the irradiation time and gradually increases with increasing irradiation time based on the types of additions. The measured temperature of crude oil without addition is lower than that when using different types of H+ donors at both concentrations due to the weak microwave absorption characteristics of heavy crude oil, as noted by several researchers, and the measured temperature. According to Fig. 3 at 1 min, the irradiation time was 41 °C, and then the increase was continued until reaching 68 °C in 3 min. The separation reaction is strongly dependent on the irradiation time, and it was observed that only heavy oil with respect to the lower temperature, the percentage of viscosity reduction is lower and the viscosity is proportional to the asphaltene content due to the lower degree of fragmentation and hydrogenation saturation of the fragments to produce the lower temperature fraction. Percentage concentration of H+ donors At the beginning of microwave irradiation, all H+ donors had approximately temperature values. However, it increased very quickly to approximately 55 °C in only 2 min, and then each kind of trend was different during the irradiation time from 2 to 3 min. Therefore, the curves of formation water and sea water had almost similar trends such that the gradual increase in their temperature as a function of irradiation time had almost similar numerical values in this time interval (2–3 min). Percentage concentration of H+ donors at 1min irradiation time, all H+ donors had almost temperature values of 31–41 °C. During the irradiation time, it increased between 1 and 3 min, and each type had a different trend.

According to Fig. 3 all oil samples commence at a baseline temperature of approximately 26 °C. This uniform starting point establishes a controlled environment for assessing the impact of microwave treatment on each sample. The initial temperature serves as a reference for evaluating the effectiveness of the heating process.

As time progresses, all treatment conditions exhibit a consistent upward trend in temperature, indicative of the energy absorption characteristics of heavy crude oils when subjected to microwave irradiation. This trend is crucial for understanding how quickly the oils can be heated, which is vital for various applications in the oil industry. Notably, the rate of temperature increase varies significantly between the two power levels. The 100MW treatments consistently achieve higher temperatures compared to the 60MW treatments at equivalent time intervals. For example, at the 3-min mark, the temperature for the 100%MW-ADW oil reaches approximately 80 °C, while the 60%MW-ADW oil peaks around 60 °C. This difference highlights the relationship between microwave power and thermal efficiency.

Within each power category, the temperature responses of the different oil types (ADW, ASW, AFW) appear closely aligned, suggesting that the thermal conductivity and dielectric properties of these oils are similar under microwave treatment. This observation indicates that the inherent properties of the oils do not significantly alter the heating dynamics when subjected to microwave energy. The consistent temperature profiles across different oil types imply that the type of oil may not significantly influence the heating efficiency within the tested parameters. This characteristic allows for broader applicability of the microwave heating method across various heavy crude oils, simplifying operational protocols in industrial settings.

The observed temperature increases can be attributed to the dielectric heating mechanism inherent to microwave technology. Microwaves induce molecular agitation, primarily affecting polar molecules and leading to increased kinetic energy and, consequently, higher temperatures29. This phenomenon is essential for understanding how energy is transferred to the oil during treatment. The disparity in temperature rise between the two power levels suggests that higher microwave power not only accelerates the rate of heating but also enhances the penetration depth of microwaves into the oil matrix. This improved penetration depth results in more efficient energy transfer, which is critical for maximizing the effectiveness of the heating process30.

The results underscore the potential of microwave heating as an effective method for enhancing thermal recovery processes in heavy crude oil extraction. The ability to rapidly elevate temperatures could facilitate the reduction of oil viscosity, thereby improving flow characteristics and extraction efficiency. This reduction in viscosity is particularly important for heavy crude oils, which are often more challenging to extract due to their high density and viscosity. The findings advocate for further exploration into the optimization of microwave parameters, such as power levels and treatment durations, to maximize the benefits of this technology in real-world applications. Understanding how different parameters interact will be crucial for developing effective heating protocols tailored to specific operational needs.

As mentioned in the scope of these results, these results showed that the increase in concentration leads to an increase in temperature, especially the water temperature. The percentage of distilled water leads to an increase in the degree of temperature because of the polar nature of the solvent, which creates good absorption properties for microwave radiation. The use of H+ donors increases.

Interfacial tension

The resulting solution is a combination of acid with three types of polar water; therefore, this solution will have a positive effect on the polar compounds of crude oil and increase the polarity of the polar compounds of crude oil. The above will decrease for the polar compounds of crude oil. In general, according to the explanations given, microwaves in the presence of three types of water with acid, which are generally considered polar solutions, will cause changes in the amount of asphaltene with the help of acid solution and three types of water, which are generally considered polar. At high energies (1300 Watt) will cause the separation of light compounds and part of the asphaltene along with the polar solution will occur, which causes the interfacial tension to decrease due to the presence of some asphaltene and the polar solution, but this decrease will be less compared to the lower energy (780 W).

At low microwave energy (780 W), a small amount of asphaltene and polar solution will be destroyed, and therefore a large amount of asphaltene with polar solution remains in the composition of crude oil, which increases the surface tension according to the mentioned cases compared to high energy waves of 1300 W.

In the early times and with the effect of microwaves on polar materials and the intensification of the polarity of the polar compounds of crude oil by acid and formation water and sea and distilled water, the surface tension will decrease, but with the passage of time and the reduction of the effect of acid and various types of water, the polarity will be affected. The timing of the early effects of microwave exposure was determined through time-resolved measurements. We conducted experiments where the microwave exposure was applied for short intervals (1 min), and at each interval, the samples were analyzed for physical and chemical changes. Parameters such as temperature, viscosity, and pH were measured at each time point to track the immediate effects of microwave radiation. These early effects were characterized by rapid changes in the sample's physical properties, and their timings were recorded to provide insights into the mechanisms underlying microwave-induced modifications. These will decrease, and the effect of microwaves will cause the destruction of most of the polar compounds, and as a result, the interfacial tension will increase. It is necessary to explain that the decrease and increase due to different salinity in the three types of water will be different. In formation water, in a period of 2–3 min, we will experience a decrease in interfacial tension due to the recrystallization of sodium chloride salt, which will further intensify the effect of polarity. In some cases, due to the short time and the lack of full onset of the effects of microwaves and polar solvents, we will not observe a significant increase in the interfacial tension, but the trend of the graph will be toward stability and then increase. Note that the interfacial tension is measured between the tested oil and distilled water. In addition, the interfacial tension will decrease between two polar compounds and increase between polar and non-polar compounds. In summary, it can be said that, by mixing acidic solutions with crude oil, some of the polar compounds of crude oil will react with polar acidic solutions from the asphaltene coating. As a result, the polarity of crude oil will increase a bit, and finally, the tension of the interfacial area decreases.

According to Fig. 4, the IFT values for untreated crude oil (at 0 min) are significantly higher than those for treated samples, indicating that the treatments effectively reduce interfacial tension. This reduction is essential for improving the separation of oil and water phases, which can enhance oil recovery processes. The decrease in IFT can lead to a more efficient extraction process, as lower IFT values typically correlate with improved flow characteristics of the oil31.

Among the treated samples, ADW-mw100% and AFW-mw100%show the lowest IFT values, indicating that these treatment conditions are particularly effective at reducing interfacial tension. This suggests that higher microwave power combined with acidic solutions leads to more efficient emulsification and separation. The significant drop in IFT under these conditions indicates that the treatment effectively alters the physical properties of the oil, making it easier to separate from water. Conversely, the treatments at 60% power (e.g., AFW-mw60%, ADW-mw60%) generally exhibit higher IFT values compared to their 100% counterparts. This indicates that lower microwave power may not provide sufficient energy to effectively alter the interfacial properties of the oil. The insufficient energy at lower power levels may limit the effectiveness of the treatment, resulting in higher IFT values and potentially less efficient recovery processes.

The type of acidic solution used plays a significant role in the effectiveness of the treatment. For instance, ADW consistently shows lower IFT values compared to AFW and ASW across both power levels. This suggests that the ionic composition and pH of the acidic distilled water may enhance its ability to reduce interfacial tension more effectively than the other solutions. The unique properties of distilled water, such as its purity and specific ion content, likely contribute to its superior performance in this context. The differences in IFT can be attributed to the varying chemical compositions of the acidic solutions. Distilled water may contain fewer impurities and a different ionic strength than fresh or sea water, leading to more favorable interactions with the oil. The presence of specific ions in the acidic solutions can significantly influence the emulsification process, impacting the overall effectiveness of the treatment.

The IFT values tend to decrease with longer treatment durations, particularly for the 100% microwave treatments. For example, treatments at 3 min generally yield lower IFT values than those at 1 min. This trend indicates that prolonged exposure to microwave energy enhances the interaction between the oil and the acidic solutions, leading to greater reductions in interfacial tension and brings about better mixing.

Viscosity

In the analysis of the above results, it should be said that in the first few minutes, because the acid has still maintained its pH at the beginning of the test, and the microwave waves will just start working, so at this stage, the effect of the acid will be greater than that of the microwave waves, and as a result, because The time is low and the pH is lower and more acidic, so the thickness of the emulsion layer will increase and the resulting emulsion will be stable, so it will not be able to separate into water and oil phase, and as a result, by taking an oil sample from the oil layer, which will be accompanied by some emulsion to The reason for the high thickness and the error in removing the oil from the oil layer (which will increase the viscosity of the oil compared to the oil before the test), with the passage of time and the reduction of the effect of acid and the increase of R, as well as the reduction of the emulsion layer and the beginning of the effect of microwave waves and microwave heat, which directly It will affect the composition of crude oil. The viscosity of the oil layer, which has some emulsion, will decrease because both the increase in pH and the start of the effect of microwave waves and the concentrated heat of the waves on the composition of the oil layer, which also has some emulsion, will make the emulsion easier to The water and oil phases are transformed and broken in some way, and as a result, the viscosity of the oil layer decreases. Over time, in the next stage, the effect of acid and microwave waves will reach a balance, which causes the viscosity of the oil layer to remain almost constant. However, over time, the effect of pH and acidity will completely disappear, and microwave waves will overcome the acid and the property of acidic pH. The concentrated heat of microwave waves with a direct effect on the composition of the oil layer, which also has a negligible amount of emulsion, will increase the viscosity of the oil layer compared with the previous oil tested. The above compounds and molecules will cause the movement of these molecules and atoms and will have very little loss compared to normal heat because normal heat starts from heating the container and then heat transfer, but microwave heat is concentrated on molecules and compounds. By focusing on the molecules and increasing the movement of the molecules, the microwave waves make it easier for the lighter components to be separated from the oil layer and also reduce the amount of sulfur in the oil, thus causing the heavier components to remain, and as a result, the viscosity of the oil layer increases. The effect of microwave waves on increasing the viscosity of crude oil is greater than that of acid with a lower pH. Over long periods of time, microwave waves will overcome the acid.

The presence of acid and salt will increase the efficiency of microwave waves; however, if both salt and acid factors are involved, this efficiency will not increase to a great extent; however, if each factor is present separately, the efficiency of microwave waves will increase. Regarding the distilled water that was used to dilute the acid and was placed in the vicinity of the microwave waves (780 and 1300 watts) along with the crude oil, it should be said that in this mixing, due to the absence of salt and solutes in the water and the mixing of the acid with only the distilled water in the vicinity of the oil Crude in low times due to the onset of acidity and low pH, oil viscosity increase will be higher compared to formation water (acid dilution) and sea water (acid dilution) in the vicinity of crude oil32. This increase in viscosity at low times and high acidity with lower pH will be more at low power (780 watts) and the reason for this is because at lower powers of microwave waves at low times with a fresh start of effect and focus of heat on the molecules And the compounds cause the properties of each substance to change slowly, that is, at low powers and short times, microwave waves cause the acid to lose its properties step by step, and in the early times, the acidic effect is still maintained and the waves cause changes to begin, if in the waves with a percentage Above, at the beginning of the work, when we are dealing with distilled water and acid, it causes the acidic property to immediately change and increase, and as a result, the oil zone becomes more viscous and decreases. Therefore, at the initial stage of work, regarding distilled water and acid in the vicinity of crude oil, the final analysis is It will be the case that at the power of 780 W, because the microwave waves are at low times, so they will not immediately affect the acid, and the acid will still maintain its acid strength and increase the viscosity of the oil layer. However, at a power of 1300 W, with the greater effect of microwave waves, the acid will lose its acidic property, and as a result, with a lower amount of acid power, it will increase the viscosity of the oil layer, and this increase in viscosity will be less compared to the power of 780 W.

According to Fig. 5, the viscosity of crude oil treated under different conditions shows significant variations. In general, the viscosity tends to increase with the application of microwave treatment, particularly at 100% power. This implies that the microwave energy facilitates the interaction between the oil and the acidic solutions, potentially leading to changes in the oil's molecular structure and flow properties. Higher microwave power likely enhances the thermal energy available to the system, promoting more effective mixing and interaction. For example, the highest viscosities are observed for treatments at ADW-MW100% and AFW-MW100%, indicating that higher microwave power combined with acidic solutions leads to a more substantial increase in viscosity compared to lower power settings. This trend suggests that the treatment is more effective at higher energy levels, possibly due to increased molecular agitation and interaction33,34,35.

The type of acidic solution used has a noticeable effect on the viscosity of the treated oil. Treatments with ADW (Acidic Distilled Water) generally result in higher viscosity values compared to those with AFW (Acidic Fresh Water) and ASW (Acidic Sea Water). This suggests that the chemical composition of the acidic solution plays a crucial role in modifying the oil's properties. The presence of different ions and compounds in the solutions can significantly influence the emulsification and stability of oil–water mixtures, affecting the overall viscosity. The differences in viscosity can be attributed to factors such as pH, ionic strength, and the presence of specific ions or organic compounds in the acidic solutions. For instance, distilled water may have a different ionic composition compared to fresh or sea water, which can lead to varying interactions with the oil.

The viscosity values tend to increase with longer treatment durations. For instance, treatments at 3 min generally yield higher viscosity than those at 1 min. This trend indicates that prolonged exposure to microwave energy enhances the interaction between the oil and the acidic solutions, leading to greater changes in viscosity. The increase in viscosity over time suggests that the microwave treatment promotes the coalescence of oil droplets and the breakdown of emulsions, resulting in a thicker oil phase. The longer treatment times allow for more extensive molecular interactions, which can lead to increased viscosity as the oil becomes more concentrated with heavier components. This is particularly important for optimizing oil recovery processes, as higher viscosity can impede flow but may also indicate a more concentrated oil phase that could enhance recovery efficiency.

The untreated crude oil serves as a baseline for comparison, showing significantly lower viscosity values than those observed with treated samples. This indicates that the treatment process effectively alters the viscosity of the oil, likely enhancing its properties for separation and recovery. The untreated crude oil’s viscosity is substantially lower than that of all treated samples, highlighting the impact of the microwave treatment and acidic solutions on the oil's physical characteristics. The untreated crude oil's viscosity being lower suggests that the treatment process not only modifies the viscosity but may also improve the oil's separation characteristics. Understanding how these treatments affect viscosity can help refine extraction techniques and improve overall recovery rates.

The changes in viscosity due to microwave treatment are significant for oil recovery processes. Higher viscosity values may indicate a greater concentration of heavier hydrocarbons or emulsified solids, affecting the efficiency of separation and transport. Understanding these dynamics can inform better operational strategies for oil extraction and processing. For instance, knowing the optimal viscosity range can help in designing equipment and processes that maximize flow rates and minimize energy consumption. The relationship between microwave treatment and viscosity changes underscores the potential for using microwave technology as a method for enhancing oil recovery. This could lead to more efficient processes that minimize waste and maximize yield. The ability to control viscosity through treatment parameters can provide operators with a powerful tool for optimizing extraction.

The findings suggest that both the microwave power level and the type of acidic solution should be carefully optimized to enhance the viscosity reduction process, which can contribute to improved oil recovery rates. Identifying the most effective combinations of treatment conditions will allow operators to streamline their processes and improve overall efficiency. This optimization can lead to cost savings and reduced environmental impacts by minimizing the need for additional processing steps. Additionally, the results indicate that the treatment duration plays a significant role in achieving the desired viscosity outcomes. Future studies could focus on determining the optimal treatment times for various combinations of microwave power and acidic solutions. This will help establish guidelines for industrial applications, ensuring that operators can achieve the best results with minimal energy expenditure.

Density

In general, there was no decrease in the density of oil due to changes in the composition. In the samples that showed a decrease in viscosity, the density remained unchanged or increased. In the samples where the oil viscosity increased, the density also increased. The highest measured density was at a power of 780 W and in a period of 2 min in the vicinity of the acid solution and distilled water, which is compatible with viscometric tests because we do not have salt in distilled water and only acid, which is the absence of all kinds of salts. The low energy of microwaves causes the heavy compounds of crude oil to be placed next to other compounds, and because the absence of salt and solutes does not increase microwave heating, so in this power and in this type of solution, with the loss of light components, heavy compounds even A much smaller amount does not change.

It can be said that the effect of removing light gasses by microwaves is greater than the effect of breaking heavy particles such as asphaltene, because in cases where we saw a decrease in viscosity, the density did not change. Of course, the breaking of molecules and heavy particles changes (reduces) the density of oil, but according to the tests performed, the pycnometer is not a precise tool for observing the decrease in density caused by the breaking of heavy particles suspended in oil.

According to Fig. 6, The graph indicates that the density of the treated oil generally increases with the application of microwave treatment, particularly at higher power settings (100%) compared to lower settings (60%). This suggests that higher microwave energy facilitates better separation of oil from water and solids, leading to a denser product. The increase in density could be attributed to the effective breakdown of emulsions and the aggregation of solid particles, which are critical processes in oil recovery. The density values for oil treated with acidic solutions show variation based on both the type of acidic solution and the duration of treatment. For instance, treatments using acidic distilled water (ADW) at 100% power appear to produce higher density values than those using acidic fresh water (AFW) or acidic sea water (ASW). This difference highlights the influence of the chemical composition of the acidic solutions on the treatment's effectiveness.

The density of the oil tends to increase with longer treatment durations. For example, the bars representing 3 min of treatment generally show higher density values compared to those for 1 min, indicating that prolonged exposure to microwave energy enhances the separation process. This trend underscores the importance of optimizing treatment time to achieve desired density characteristics in oil recovery. It suggests that longer treatment times allow for more complete emulsification breakdown and solid separation. Different types of acidic solutions yield varying density results, suggesting that the chemical composition of the water plays a significant role in the treatment's effectiveness. For example, the use of acidic distilled water (ADW) consistently leads to higher density values across different treatment times compared to acidic sea water (ASW) and acidic fresh water (AFW). This may be attributed to the purity and specific ionic properties of distilled water, which can enhance the separation of oil from impurities. The presence of specific ions or organic compounds in ASW and AFW may hinder the separation process, leading to lower density outcomes. The graph also includes a reference point for the density of oil at 0 min, which serves as a baseline for evaluating the effects of the treatments. This initial density value provides context for understanding how much the density changes as a result of the treatments.

The results imply that microwave treatment is an effective method for enhancing oil separation from water and solids. The increase in density suggests that the process may effectively reduce the volume of emulsified water and solids in the oil, which is critical for improving oil recovery rates. The ability to manipulate microwave settings and treatment duration opens avenues for optimizing the separation process in real-world applications.The findings highlight the potential of microwave-assisted separation techniques in the oil industry, particularly in enhancing the efficiency of operations where oil–water emulsions are prevalent. This technology could lead to reduced operational costs and improved recovery rates, making it a valuable tool for petroleum engineers and operators.

The differences observed between the types of acidic solutions suggest that their chemical properties significantly impact the behavior of oil–water emulsions. Understanding how various acidic solutions interact with crude oil can inform the development of more effective treatments tailored to specific oil types and recovery scenarios. This knowledge is essential for designing processes that maximize oil recovery while minimizing waste and environmental impact.

Amount of sludge

Regarding the sludge resulting from the waves in the presence of acid and acid solution, it should be said that in the presence of distilled water and acid solution, the waves will increase with the passage of time as well as the increase in power, with the loss of heavy and light compounds of crude oil and the creation of new compounds that have They are also of high density, the possibility of sludge formation increases over a long time36. It should be noted that this increase in sludge is greater in lower capacities because the heavy components of crude oil are still stored and new compounds are created at the same time.

The proximity of formation water due to high salinity and the effect on microwave heating of the resulting sludge will be less than that of other solutions, and at 780 watts of power, it will generally be in a decreasing manner regarding the reductions of acid solution and sea water and distilled water and acid solution in time. These reductions occur due to the increase in microwave power and the effect of temperature on the heavy compounds of crude oil.

The data suggest that treatments conducted at 100% microwave power generally produce more sludge than those at 60% power. This indicates that higher microwave intensity enhances the breakdown of oil–water emulsions, leading to more effective separation and increased sludge formation. The increased energy input from the higher power setting likely facilitates more vigorous agitation and heating of the mixture. This phenomenon can be attributed to the enhanced thermal and mechanical effects of microwave radiation, which promotes better interaction between the oil and the acidic solution. The higher energy levels may lead to increased molecular agitation, resulting in more effective emulsification and subsequent separation of sludge from the liquid phase.

The results of Fig. 7 show a clear trend where longer treatment durations (3 min) yield more sludge compared to shorter durations (1 min). This suggests that extended exposure to microwave energy allows for greater emulsification or breakdown of crude oil, resulting in increased sludge generation. The time-dependent nature of sludge production highlights the importance of optimizing treatment duration to maximize efficiency while minimizing energy consumption. The correlation between treatment time and sludge production underscores the necessity for careful timing in operational protocols. Longer treatment times may allow for more complete reactions and interactions within the emulsion, leading to improved separation outcomes. However, there is a balance to be struck, as excessively long treatment times may not yield proportionately higher sludge production and could lead to diminishing returns.

The type of acidic solution used significantly impacts the amount of sludge produced. For instance, different solutions (AFW, ADW, ASW) may yield varying sludge quantities due to their distinct chemical compositions. The presence of different ions, organic compounds, or impurities in these acidic solutions can influence the emulsification process, affecting the interaction between the oil and water37,38,39.

Acidic Sea Water (ASW) may contain salts and minerals that alter the physical properties of the emulsion compared to Acidic Distilled Water (ADW), which is more purified. This variation in chemical composition can lead to differences in how effectively the oil is broken down and separated, resulting in varying amounts of sludge production. Understanding these differences is crucial for optimizing treatment processes based on the specific characteristics of the water being used.

Asphaltene extraction

The content of asphaltenes during acid treatment has various responses. In this case, the asphaltene content is increased, which is caused by the loss of light hydrocarbons (less than C5) produced by fragmentation, which leads to the concentration of high molecular weight hydrocarbons (asphaltenes)40. This increase is evidence of fragmentation of asphaltene molecules into condensable aromatics, which leads to the recombination reaction. In the vicinity of microwave waves, the amount of asphaltene will decrease drastically. The reason for this is the direct effect of the waves on the polar compounds of crude oil. Thus, the crude oil will be fragmented and reduced by the radiation of asphaltene waves.

In the vicinity of acidic solutions and waves, the amount of asphaltene will be slightly reduced, which is due to the reaction of the acidic solution with the polar components of crude oil and the loss of light components of crude oil due to microwave heating, as well as the direct effect of microwave heating on It is a polar compound, in this way that with the reaction of acid solutions with crude oil asphaltene and the radiation of waves, the resulting polar components will begin to break under the direct influence of microwaves, but due to the presence of acid solutions with high polarities and helping to maintain Crude oil asphaltene will be lower because of crude oil asphaltene reduction41,42. Acidic solutions will help maintain the polarity of crude oil asphaltene and it will be partially preserved, and as a result, the amount of asphaltene will increase in the vicinity of constant temperature and acidic solution, which is due to maintaining the amount of asphaltene by acidic solutions. One side is the effect of temperature on the creation of new compound reactions or the fragmentation of heavy compounds and the creation of new polar heavy bonds. In general, it can be said that because the concentration decreases with increasing temperature, by applying microwaves without the presence of acidic solutions, the heating will break the polar components and reduce the asphaltene. Regarding microwaves in the vicinity of acidic solutions, acidic substances react with oil and polar components of crude oil, and when the effect of microwaves begins, polar compounds and new bonds are broken again, and asphaltene is partially reduced, but only in the presence of crude oil next to acidic solutions. The reaction of acidic solutions with polar compounds, such as crude oil asphaltene, increases the amount (falseness) of asphaltene.

The Fig. 8 displays a clear downward trend in asphaltene content from crude oil to the treated samples. This suggests that the treatments applied to the oils effectively reduce the concentration of asphaltenes. Crude Oil has the highest asphaltene content at 16.0%. This indicates that the raw crude oil contains a significant amount of heavy fractions, which can complicate its processing and transport.

ADW-100%mw-1min shows a reduction to 15.7%, indicating that the treatment with Acidic Distilled Water (ADW) and microwave energy for one minute has a minor but noticeable effect.

ASW-100%mw-1min, further reduces the asphaltene content to 14.7%, suggesting that the treatment with Acidic Sea Water (ASW) is slightly more effective.

AFW-100%mw-1min, treated with Acidic Fresh Water (AFW), exhibits the lowest asphaltene content at 14.5%. This indicates that the specific conditions of this treatment were most effective in reducing asphaltenes.

Asphaltenes are large, complex molecules composed of carbon, hydrogen, sulfur, nitrogen, and oxygen. They are typically characterized by their solubility in toluene but insolubility in lighter alkanes43. Their presence in crude oil can lead to several challenges, including increased viscosity, instability, and potential clogging of pipelines. High asphaltene content can also complicate refining processes, leading to lower yields and increased operational costs44,45.

The reduction in asphaltene content as observed in the graph suggests that the treatments (ADW, ASW, and AFW) are effective methods for improving oil quality. These treatments may involve various physical and chemical processes, including solvent extraction, thermal treatment, or the application of microwave energy, which can enhance the separation of lighter fractions from heavier asphaltenes. The effectiveness of these treatments can be attributed to the specific interactions between the acidic solutions and the asphaltenes, which may alter the solubility and stability of these compounds.

FTIR spectra

Use of Fourier-Transform Infrared (FTIR) spectroscopy discusses to analyze the structural changes in the functional groups of a treated asphaltene sample46. Asphaltene is a complex, high molecular weight fraction of petroleum that is known to contain a variety of functional groups, such as alkanes, aromatics, alcohols, and carbonyls. FTIR spectroscopy is a widely used analytical technique in chemistry and materials science that provides information about the molecular structure of a sample by detecting the characteristic vibrational frequencies of the chemical bonds within the molecules. Each functional group or chemical compound exhibits unique vibrational modes that appear as distinct peaks in the FTIR spectrum.

The key findings from the FTIR analysis of the treated asphaltene sample are:

-

1.

Absence of new peaks: The lack of any new peaks in the FTIR spectrum of the treated asphaltene indicates that the treatment did not result in the formation of new functional groups or chemical compounds within the asphaltene structure.

-

2.

Identification of functional groups:

-

a.

Alkane compounds: The peaks at 2962, 2921, 2851, 1455, 1374, and 727 cm−1 correspond to the asymmetric and symmetric stretching vibrations of the C–H bonds in the methyl (CH3) and methylene (CH2) groups, as well as the C–H bending and rocking modes. These are characteristic of the aliphatic hydrocarbon chains present in the asphaltene structure.

-

b.

Aromatic compounds: The peaks in the range of 3000–3100, 1601, 864, 801, and 750 cm−1 are associated with the C–H stretching and bending vibrations of the aromatic rings within the asphaltene structure.

-

c.

Amine and alcoholic groups: The broad peak observed in the range of 3100–3500 cm−1 is attributed to the N–H and O–H stretching vibrations of amine and alcoholic functional groups, respectively.

-

d.

Carbonyl group (C=O): The peak at 1700 cm−1 corresponds to the C=O stretching vibration, which is characteristic of carbonyl-containing functional groups, such as ketones, aldehydes, or carboxylic acids.

-

e.

C–O stretching: The peaks at 1262 and 1096 cm−1 are associated with the C–O stretching vibrations, which are common in various oxygen-containing functional groups, such as alcohols, ethers, or esters.

-

f.

Sulfoxide functional group: The peak at 1022 cm−1 is characteristic of the S=O stretching vibration of the sulfoxide functional group.

-

a.