Abstract

The pitch deviation, non-parallel end face, and middle diameter deviation generated during the machining process of connecting rod bolts will lead to changes in bolt preload and stress distribution under ideal conditions, and their effects under individual or interaction are not fully understood. The finite element simulation model of connecting rod bolt tightening was established by Abaqus finite element simulation analysis software. The Yamamoto analysis method verified the finite element model of connecting rod bolts. The effects of pitch deviation, non-parallel end face, and middle diameter deviation on the preload, stress distribution, and fatigue safety factor of connecting rod bolts under tightening load were studied. The results show that increasing pitch deviation and middle diameter deviation or decreasing non-parallel end face will increase the bolt preload under the same torque. When the pitch is 1 mm, the middle diameter is 8.3505 mm, and the non-parallel end face is 0.5°, the fatigue safety factor of the bolt failure area is the largest, and the fatigue failure does not quickly occur during the working process. The bolt connection structure of a U-shaped cutting groove can significantly improve the fatigue strength of the joint between the bolt head and the screw, and its average fatigue safety factor is 1.71.

Similar content being viewed by others

Introduction

The connecting rod bolt is essential to the engine’s connecting rod. Its function is to connect the connecting rod body and the connecting rod end cover. The reliability of the connecting rod bolt connection is directly related to the stability and reliability of the engine1. However, in the processing of connecting rod bolts, the mold and tool will cause certain wear after long-term use, which will inevitably lead to uncontrollable factors, such as pitch deviation, non-parallel end face and middle diameter deviation, which will have a great impact on the preload and stress distribution of connecting rod bolts.

The bolt structure strength and tightening process research account for most existing research. In the research of bolt structure strength, three methods are mainly used: analytical, finite element, and experimental inquiry. In the analytical method, Motosh2 gave the calculation method of load distribution on the contact thread of bolts and nuts made of different materials and concluded that using softer materials for nuts can make the thread load evenly distributed. Based on many assumptions, by reducing the bolt construction to a cantilever beam structure, Yamamoto et al.3,4 created a theoretical bolt model, examined the thread load, and determined the cause of the thread load’s unequal distribution. After conducting a theoretical analysis of the axial load distribution of thread pairs, Through the analysis of single-turn threaded bolts, GOODIER5 found out the type of deformation where the load is concentrated in different parts of the thread.Nassar6 examined the fatigue performance of bolts during operation and examined the impact of several parameters on bolt fatigue performance. This was integrated with the cumulative fatigue damage criteria. Fukuoka7 proposed an effective method for mesh generation of an accurate screw thread model and analyzed the variation law of thread root stress and contact pressure along the axial direction of the spiral line and nut-bearing surface. Using the connecting rod bolt as the study object, Jia8 investigated the effects of pitch, preload, and thread connection length on the thread’s axial force distribution and suggested that the Spiralock anti-loosening thread might improve the thread’s uniformity in axial stress distribution. Chen Haiping9 established a parametric finite element model of the load distribution of thread pairs based on ANSYS and verified the model’s reliability. On this basis, the effects of thread type, pitch, radial dimension coefficient of thread pairs, number of meshing teeth, friction coefficient, and elastic modulus ratio of materials on the load distribution of thread pairs were studied. Fan Tongbai10 established a finite element model of the wheel structure of the wheel-mounted brake disc and simulated the force of the screw under high-speed rotation, which laid a foundation for further research on the structural reliability of the bolt. In the experiment, Kazemi et al.11 conducted fatigue tests on bolts subjected to cyclic tensile shear loads. Based on the stress amplitude of bolts, a new high-cycle fatigue model was proposed, and a multi-axial S-N curve was established. The difference in fatigue life of bolts under different combined cyclic loads was studied. The results show that multi-axial loading will reduce the fatigue life of bolts. Wu Xiufeng12 studied the feasibility of high-strength bolt connections of glass structures through experiments. The results show that using adhesive-bonded stainless steel plate and aluminum gasket with less hardness after curing can avoid stress concentration damage of glass. Regarding the tightening process, Ganeshmurthy et al.13 simulated the tightening process of bolt assembly by establishing a finite element bolt model with thread angle. Two tightening processes, the torque method and torque angle method, were used, respectively. The difference in bolt axial tensile force was compared and analyzed. The effect of bolt thread friction coefficient and aperture gap on bolt preload in two tightening processes was studied. Liu14 proposed a simple and easy experimental method for the variation of friction coefficient. The tightening conditions were analyzed by repeated tightening tests. The results showed that repeated tightening would increase the friction coefficient without lubrication. When lubricant was used, the friction coefficient in the repeated tightening process was relatively stable. Deng et al.15 first established and verified the theoretical formula of the torsional tension relationship in the tightening process of wedge-shaped locking nut and then established an accurate finite element model of wedge-shaped thread connection. The influence of bolt nut material, tightening times, and friction coefficient on the torque coefficient and repeated tightening performance of wedge-shaped locking nuts was systematically studied. Li Xiaoqiang16 analyzed the influence of tightening methods such as torque, torque angle, and tightening speed on the pre-tightening force by taking a single bolt as the research object. The results show that distributed tightening and increasing tightening speed can improve the control accuracy of pre-tightening force and reduce the dispersion of pre-tightening force. Wanpeng et al.17 Established a semi-analytical model of composite double-lap joint structure considering clearance, and described the influence of geometric deviation on bolt load and stress distribution. The results show that a reasonable setting of bolt clearance can obtain a more uniform stress distribution. Nao-Aki Noda et al.18 found that appropriate pitch deviation not only has good anti-loosening performance, but also can improve its fatigue reliability to a certain extent. Longfei Tan19 studied the tightening process of a certain type of bolt when the clamped part has a non-parallel end face, and analyzed its influence on the bolt stress. The results show that when the clamped part has a non-parallel end face, it will have a certain effect on the bolt preload. In order to study the influence of the position error of the bolt hole on the mechanical properties of the assembly, Jiao Junjie et al.20 established a finite element model considering the position error, and studied the influence of the position error on the connection stiffness and the hole edge stress of the bolt connection structure. The results show that the position error has little effect on the axial stiffness and has a significant effect on the tangential stiffness. The hole edge stress of the bolt hole reaches the maximum at 180 °. Hao GONG21 proposed the radial slip theory of bolts, and verified the expansion process of the slip region on the thread surface by finite element analysis. On this basis, a new type of bolt connection method is proposed to improve the anti-loosening and anti-fatigue performance of bolts, but the influence of deviation is not considered. Bin Yang et al.22 studied the influence of non-parallel end faces on the loosening of bolted joints when the clamped parts have non-parallel end faces, and found that non-parallel end faces bring additional contact pressure and contact friction torque. In a certain range, with the increase of the non-parallel end face inclination angle, the contact pressure and contact friction torque increase, and the thread anti-loosening performance is improved to a certain extent. Kai Jiang et al.23 proposed an accurate thread mesh modeling method, which takes into account the thread contact conditions in the actual working conditions, that is, the thread clearance. On this basis, the influence of different friction coefficients on the tightening process of bolted joints was studied. Existing scholars have carried out a series of studies on bolts’ tightening process and structural strength. However, in practical applications, uncontrollable factors, such as pitch deviation, end face unevenness, and mid-diameter deviation, will inevitably occur in manufacturing. There is no clear conclusion on the influence of single or interaction on bolt preload and stress distribution, and the reliability of connecting rod bolt connection has a great influence on the stability of the engine. Therefore, it is necessary to study the connecting rod bolts with pitch deviation, end face unevenness, and mid-diameter deviation to increase the connecting rod bolt connection’s dependability.

In summary, the finite element model of the connecting rod bolt is established, and the correctness of the finite element model is verified by comparing it with the calculation results of the Yamamoto method. The finite element model of standard thread connection structure considering pitch deviation, non-parallel end face, and middle diameter deviation is established by introducing pitch deviation, non-parallel end face, and middle diameter deviation. The influence of pitch deviation, non-parallel end face, and middle diameter deviation on the thread connection structure’s preload, contact stress, and the fatigue safety factor is studied, which has important engineering practical significance and theoretical research value for improving the reliability of connecting rod bolt structure.

Theoretical analysis of torque and preload

When the bolt is tightened, the tightening torque \(T\) applied to it can be decomposed into the end face friction torque \(TW\) between the nut (bolt) and the support surface of the connected part and thread torque \(TS\). The formula is as follows:

In the formula:\(F\) is the preload; \({\text{d}}2\) is the thread diameter; \(\mu_s\) is the friction coefficient between threads; \(\mu_w\) is the friction coefficient of the end face; \(\alpha\) is the tooth side angle; \(P\) is the pitch; \(D_w\) is the equivalent friction diameter, the formula is shown in(4):

In the formula, \(d_w\) is the contact outer diameter of the supporting surface; \(d_h\) is the contact inner diameter of the supporting surface.

The above Eq. (1)(2)(3)(4)is sorted out:

In the formula:\(K\)is the torque coefficient.

Generally speaking, the bolt preload operating on the cross-section after tightening is supposed to create stress that is between 60% and 70% of the bolt material’s yield strength. The recommended preload range for bolts made of carbon steel is displayed below.

The nominal stress cross-sectional area of the bolt\({A_s}\):

In the formula, \({A_s}\)is the nominal stress cross-sectional area of the bolt; \({\sigma _s}\)is the yield strength of bolt material. The formula (7) is selected to calculate the bolt preload.

Establishment of tightening simulation model of connecting rod bolt connection structure

Geometric modeling

The connecting rod assembly includes a piston pin, bushing, connecting rod body, cover, and bolt. To analyze the bolt-tightening process more precisely, the sub-model is the local three-dimensional model of a single bolt connection. Constrain the six degrees of freedom at both ends of the connecting rod nut in space. For the connecting rod end cover, constrain the five degrees of freedom at both ends in space, and release the displacement of the connecting rod end cover in the Z direction.Table 1 displays the structural properties of this model, which is seen in Fig. 1.

Bolt material properties

The bolt is made of 28B2. The bolt sample is depicted in Fig. 2, and Table 2 displays its chemical makeup. GB / T 13298 − 2015 ‘Metal Microstructure Inspection Method’ standard24 states that the bolt material is subjected to microscopic metallographic analysis, as Fig. 3 illustrates. Solubite is the material’s microstructure. The figure shows that the microstructure satisfies the performance criteria since it is delicate, uniformly distributed, and devoid of defects.

In order to obtain the key mechanical performance parameters of the bolt material, the bolt test tensile bar sample was processed, as shown in Fig. 4.

According to the GB/T228.1-2010 Metallic Materials Tensile Test Method at Room Temperature standard, the tensile test of 28B2 bolt test rod was carried out on the UTM5105 universal electronic tensile testing machine. The installation diagram of the bolt tensile test sample is shown in Fig. 5.

As shown in Fig. 6, after the bolt test rod is broken and the tensile test is completed, the stress-strain curve can be drawn from the obtained data, which mainly reflects the process of elastic deformation to plastic deformation of the material with the increase of external load. Among them, the yield strength is 1082.5 MPa and the tensile strength is 1281.7 MPa.

In order to measure the friction coefficient of the key contact surface of the bolt, the bolt tightening test was carried out. Firstly, the relevant fixture was designed according to the manual sleeve wrench standard. Figure 7 is the adapter, Table 3 is the structural parameters of the adapter, and Fig. 8 is the bearing sleeve. Figure 9 is the installation diagram of bolt tightening test.

Table 4 is the friction coefficient of the key contact surface of the bolt. After calculating the average value of the five sets of test data, it can be concluded that the friction coefficient µs of the key contact surface of the connecting rod bolt is 0.205, and µw is 0.132.

Establishment of finite element model of connecting rod bolt

In order to simulate the actual contact between the inner thread and the outer thread when the connecting rod bolt is tightened, the bolt is meshed by R-trails in Hypermesh, and the bolt tightening process is simulated and analyzed by the display dynamics analysis module in the finite element software Abaqus. Three pairs of contact pairs are set up, which are the lower surface of the bolt and the upper surface of the connecting rod body, the upper surface of the bolt head and the lower surface of the connecting rod end cover, the upper surface of the connecting rod end cover and the lower surface of the connecting rod body. As shown in Fig. 10, Fig.(a) is the finite element model of the connecting rod bolt and the contact of the thread meshing, and Fig.(b) is the application of the bolt load constraint.

Model verification

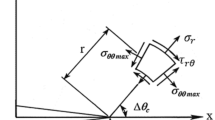

The validity of the bolted joint structure model is critical to the accuracy of the analysis results25. In the method of calculating the bearing capacity distribution of the thread pair, the Yamamoto method reflects the bearing distribution of the thread pair by the\(\frac{{{F_0}}}{{{F_b}}}=\frac{{\sinh \lambda x}}{{\sinh \lambda L}}\) distribution of the axial load of the thread and has a wide range of applications. Figure 11 is the force diagram of the thread meshing part. In the figure\({F_b}\)is the tensile force on the bolt rod. Taking the top surface of the nut as the starting point, the axial force acting on the vertical section of the bolt at the \(x\) position is\({F_0}\).

The axial load at any section of the Yamamoto method is shown in (9)

In the formula, \(x\) is the distance from the top surface of the nut; \(\lambda\) is the characteristic parameter of the axial force distribution, \(L\) is the total length of the thread engagement.

Table 5 is the finite element solution of different thread load ratios and Yamamoto’s analytical solution. From Fig. 12, it can be seen that the error between the finite element solution of different thread load ratios and the Yamamoto analytical solution is small, and the fitting is good. Therefore, the established finite element model of thread load distribution is considered accurate and reliable.

Tightening simulation analysis of connecting rod bolt connection structure

Effect of pitch deviation on bolt preload and stress

Effect of pitch deviation on bolt preload force

Based on the 28B2 connecting rod bolt connection structure, four-bolt connection schemes with bolt external pitch of 1 mm, 1.001 mm, 1.003 mm, and 1.005 mm are taken. The structure scheme is shown in Fig. 13. The tightening loading method is the torque method, the input torque \(T\) = 80 N·m, and then the curve of the relationship between the input torque \(T\) and the preload \(F\) during the tightening process is drawn as shown in Fig. 14. It can be observed from the diagram that the slope of the torque preload curve increases with the increase of the pitch deviation, indicating that the efficiency of the tightening torque into the preload is improved.

Effect of pitch deviation on bolt contact stress

In order to further study the influence of pitch deviation on the stress distribution of bolt connection structure during tightening, the stress nephograms of torque at = 0.8 N · m, = 40 N · m and = 80 N · m were extracted respectively. From the stress cloud diagram of Fig. 15, it can be seen that in the case of no pitch deviation, that is, when the bolt pitch is 1 mm, when the torque increases from 0.8 N · m to 80 N · m, the stress on the thread gradually moves down, and the farther away from the first thread position, the smaller the stress. The stress concentration area is mainly in the lower part, and the effective meshing section is close to the top surface of the nut. When the bolt is tightened, a large stress is generated at the bottom of the thread under the influence of the pre-tightening force in the unmeshed section of the bolt. For the meshing thread area of the bolt, the first thread meshing position is the main stress concentration area of the bolt, and the stress value exceeds the yield strength of the bolt material. The closer the distance from the top surface of the nut, the smaller the stress, and the overall distribution is stepped. In the case of bolt pitch deviation, at the time of T = 0.8 N · m, compared with the bolt with pitch of 1 mm, the stress at the first thread of meshing increases with the increase of pitch deviation, and the stress on the thread decreases with the increase of pitch deviation, but the difference is not obvious. At the time of T = 40 N · m, with the increase of pitch deviation, the stress at the first thread of meshing increases more obviously, and the difference of stress downward displacement on the thread is more obvious. At the time of T = 80 N · m, that is, when the bolt tightening is completed, for the unmeshed area of the thread, as the pitch deviation increases, the stress at the bottom of the thread also increases, and the stress gradually spreads to the center of the bolt rod. For the thread meshing area, the stress at the first thread increases with the increase of the pitch deviation. This is mainly because when there is a pitch deviation, the screws at each position under ideal conditions are not closely meshed, and only the screws at the first thread position are meshed. Therefore, the first thread meshing of the thread pair is the initial meshing position, and with the increase of torque and the deformation of the thread, other teeth begin to contact gradually. Therefore, the stress concentration area of the thread pair mainly occurs at the first thread meshing of the initial meshing. As the pitch deviation increases, the effective meshing section of the thread gradually moves up.

The contact stress of each tooth of the thread is extracted, as shown in Fig. 16.In the absence of pitch deviation, the stress concentration area of the thread is mainly concentrated at the first thread meshing, and the overall distribution is stepped. The closer to the tooth root, the greater the stress. In the case of external pitch deviation, with the increase of external pitch deviation, the distribution of thread contact stress is highly uneven, the effective contact section of thread is significantly reduced, and the closer to the top surface of the nut, the smaller the stress, and even the last few turns of thread are almost uncontacted. This will lead to more concentrated stress at the first meshing point of the thread, and the bolt is more prone to fatigue failure in the working state.

In summary, when there is a pitch deviation of the bolt, with the increase of the pitch deviation of the bolt, when the pitch is 1.005 mm, the stress at the first thread of the meshing is more concentrated, and the effective contact section of the thread is significantly reduced. During the bolt’s working process, the meshing’s first thread is prone to fatigue fracture.

Effect of non-parallel end faces on bolt preload and stress

Effect of non-parallel end face on bolt preload

Based on the 28B2 connecting rod bolt connection structure as the basic model, take the bolt non-parallel end face\(\theta\)as 0°,0.5°,1°,1.25°, pitch \(P\) = 1 mm, and the other four-bolt connection schemes; the structure scheme diagram is shown in Fig. 17. The tightening loading method is the torque method, and the input torque \(T\) = 80 N·m. The tightening curve under the condition of a non-parallel end face is shown in Fig. 18. From the diagram; it can be observed that the slope of the torque preload curve gradually decreases with the increase of the non-parallel end face\(\theta\), indicating that the efficiency of the tightening torque into the preload is reduced, and the preload generated by the bolt joint when the tightening torque is \(T\) = 80 N·m is reduced.

Effect of non-parallel end face on bolt contact stress

According to the above analysis, the non-parallel end face mainly influences the preload. In order to further study its influence on the stress distribution of the bolt connection structure during the tightening process, the stress diagram of torque at the moments at \(T\) = 12 N·m, \(T\) =32 N·m, \(T\) =60 N·m, and \(T\) = 80 N·m and the point-line diagrams with A and B as the path are extracted respectively, as shown in Figs. 19 and 20.

The stress cloud diagram of the bolt at different torque moments during the tightening process is shown in Fig. 19.It can be seen that when the non-parallel end face\(\theta\) = 0°, at the moment of torque \(T\) = 12 N·m, the stress of the contact part between the inner side of the bolt end face and the support surface of the connecting rod end cover is large. With the increase of torque, the stress of the contact part between the inner side of the bolt end face and the support surface of the connecting rod end cover also increases, and the overall step gradually spreads outward. Comparing the stress cloud diagrams under different conditions, at the time of \(T\) = 12 N·m, the stress of the contact part between the outer side of the bolt end face and the support surface of the connecting rod end cover is 0.52 MPa when\(\theta\) = 0°.At other angles, the stress of the contact part between the outer side of the bolt end face and the support surface of the connecting rod end cover increases with the increase \(\theta\), and the maximum is 240 MPa. At the time of \(T\) = 32 N·m, \(T\) =60 N·m, and \(T\) = 80 N·m, with the increase of\(\theta\), the stress of the contact part between the outer side of the bolt and the support surface of the connecting rod end cover increases from 293.7 MPa to 888.33 MPa. The stress concentration area of the inner side of the bolt and the support surface of the connecting rod end cover is slightly reduced.

The stress cloud diagram of the bolt end face at \(T\) = 80 N·m is extracted, as shown in Fig. 21. After the tightening process of the bolt, in the x-axis direction, when the non-parallel end face\(\theta\) = 0°, the stress value decreases with the increase of the distance from the inner diameter of the support surface; compared with different non-parallel end face structure schemes, the stress value of the outer diameter of the support surface increases with the increase of the end face angle, and when the end face angle is 0.5°, the end face stress is more uniform.

In order to analyze the stress distribution of the bolt end face under different\(\theta\)angles more accurately, the stress at the time of \(T\) = 80 N·m is extracted by A and B as the path. The polar coordinate diagram is drawn as shown in Fig. 22. It can be seen from Fig. 22(a) that when = 0°, the stress of the contact part between the inner side of the bolt end face and the support surface of the connecting rod end cover is generally larger, but the stress is smaller at 218° and 243°. The stress corresponding to\(\theta\) = 0° is 990.57 MPa and 1009.56 MPa, the stress corresponding to \(\theta\) = 0.5° is 1015.98 MPa and 1121.02 MPa, the stress corresponding to \(\theta\) = 1° is 1047.65 MPa and 1030.17 MPa, and the stress corresponding to \(\theta\) = 1.25° is 1058.42 MPa and 1040.94 MPa. With the increase of \(\theta\)angle, the stress difference between the contact part of the inner side of the bolt end face and the support surface of the connecting rod end cover is small. Figure 22(b) is the stress distribution diagram of the contact part between the outer side of the bolt end face and the support surface of the connecting rod end cover. It can be seen from the diagram that with the increase of\(\theta\)angle, the stress of the contact part between the outer side of the bolt end face and the support surface of the connecting rod end cover also increases, and its growth rate increases first and then decreases.

During the tightening process of the connecting rod bolt, the support shoulder of the bolt head produces a certain compressive stress and shear tensile stress on the end cover of the connecting rod. If this part is crushed, it will inevitably lead to the attenuation of the preload of the connecting rod bolt, which will not guarantee that the tightening preload of the connecting rod bolt meets the use requirements26. The stress cloud diagram of the end face of the connecting rod end cover at \(T\) = 80 N·m is extracted, as shown in Fig. 23.After the bolt tightening process is completed, the stress of the end cover shows a trend of decreasing first and then increasing with the increase of the \(\theta\)angle of the non-parallel end face. When the end face angle is 0.5°, the stress of the end cover is the smallest, and fatigue damage is not easy to occur during the working process. In summary, when the bolt has a non-parallel end face\(\theta\), as the non-parallel end face\(\theta\)of the bolt increases, the stress value of the outer diameter of the support surface increases, and when the end face angle is 0.5°, the stress of the bolt end face is more uniform, the end cover stress is small, and the bolt is not prone to fatigue damage during operation.

Effect of middle diameter deviation on bolt preload and stress

Effect of middle diameter deviation on bolt preload

Based on the 28B2 connecting rod bolt connection structure, the non-parallel end face of the bolt\(\theta\) = 0.5 °, the bolt diameter is 8.3505 mm, 8.3245 mm, 8.2725 mm and 8.2125 mm, and the pitch \(P\) = 1 mm. The structure scheme diagram is shown in Fig. 24. The tightening loading method is the torque method, and the input torque \(T\) = 80 N·m. The tightening curve under the condition of middle diameter deviation is shown in Fig. 25. It can be observed from the figure that as the diameter deviation increases, the slope of the torque preload curve also increases, indicating that the efficiency of the tightening torque into the preload is improved. The preload generated by the bolt node when the tightening torque is \(T\) = 80 N·m increases.

The stress diagram of the bolt connection structure under various middle diameter deviations is generated by placing the Von Mises stress of the finite element calculation results of different middle diameter deviation connection structures under the same scale. The impact of various middle diameter variations on the bolt connection structure’s stress distribution is contrasted and examined, as seen in Fig. 26. Figure 26 illustrates how, in the absence of a middle diameter deviation, the bolt’s stress concentration area is primarily at the lower fillet of the connecting rod bolt head and the first thread of the bolt meshing after the bolt tightening process. In these locations, the stress value of the bolt surpasses the bolt material’s yield strength. The stress distribution of the bolt is stepped in the bolt’s meshing thread area when it is distant from the first meshing thread. The stress value decreases with proximity to the bolt’s top. When there is a centre diameter deviation, the value of stress at the first thread of the bolt increases as the centre diameter deviation increases.

Fatigue safety factor evaluation and optimization of bolts

Working load analysis of connecting rod bolt

The piston is positioned close to the upper dead point of the work stroke, and there is gas pressure on the connecting rod’s tiny end aperture when the connecting rod is at its maximum compression condition, as seen in Fig. 27. The connecting rod bolt is solely subjected to the preload force, the crankshaft exerts an upward push on the big end aperture of the connecting rod, and the connecting rod retains its motion state owing to inertia27,28 The connecting rod bolt is preloaded, and the connecting rod end cover exerts a downward strain on the bolt when the connecting rod is at its maximum tensile condition29. The connecting rod bolt is currently under the most significant amount of stress.

In the formula, \({F_B}\)is the rotational inertia force and reciprocating inertia force borne by the extensive head cover of the connecting rod; \(n\) is the number of connecting rod bolts; \(mH\)is the mass of the piston group; is the equivalent mass of the connecting rod small end; \(r\) is the crank pin rotation radius; \(\omega\)is the rotation angular velocity of crankshaft; \(\lambda\)is the connecting rod ratio; \({m_3}\)is the mass of the extensive head cover of the connecting rod; \(m1\)is the equivalent mass of the big end of the connecting rod.

According to the engine working condition parameter in Table 6, the working load\({F_0}\)is calculated to be 7858.6 N.

For the allowable safety factor of connecting rod bolts, Dai Chunxiang of Sichuan University used the standard of the fatigue safety factor of connecting rod bolts [n] ≥ 1.0 in the analysis of the fatigue life of connecting rod components30. Teng Shuai et al. of China National Heavy Duty Truck Group used the standard of fatigue safety factor [n] ≥ 1.3 in the study of fatigue test of connecting rod bolts of diesel engines31. This paper selects [n] ≥ 1.3 as the evaluation standard. Calculation of safety coefficients for bolts with geometrical deviations by using the FEMFAT software.

Evaluation of fatigue safety factor of connecting rod bolts

Safety factor analysis of bolt connection structure under pitch deviation

Figure 28 is the distribution of the fatigue safety coefficients of the initial thread of the bolt under the pitch deviation; it can be seen from the figure, with the increase of the pitch deviation, the fatigue safety factor of the initial thread of the bolt shows a downward trend when the pitch is 1 mm, n is 1.31 when the pitch is 1.005 mm, n is 1.25.

The failure-prone areas of the bolt during operation are shown in the Fig. 29, and are denoted by I, II, III for ease of analysis32.

Distribution of safety coefficients for deviations of bolts with different pitches on the same scale, as shown in Fig. 30.

The safety coefficients at the three positions of the extracted bolts A、B、C are shown in Table 7 and their corresponding histograms are shown in Fig. 31.

As can be seen from Fig. 31, the safety coefficient at position C is the smallest, and the safety coefficients at the three positions A、B、C become smaller with the increase of pitch deviation, and the safety coefficient at position C is greater than 1.3 when the pitch is 1 mm, which is not easy to fatigue fracture.

Safety factor analysis of bolt connection structure under non-parallel end face

At the bolt’s initial meshing thread, under the non-parallel end face, Fig. 32 displays the distribution of the fatigue safety factor. The figure shows that the fatigue safety factor at the bolt’s first meshing thread increases initially before decreasing as the non-parallel end face\(\theta\) grows. When\(\theta\) = 0°, n is 1.31. When\(\theta\) = 0.5°, n is 1.35.

Taking Fig. 33 as the path, the safety factor of the joint between the bolt head and the screw is extracted. It can be seen from Fig. 34 that with the\(\theta\)angle of the non-parallel end face, the distribution curve of the fatigue safety factor increases greatly at first and then decreases slightly.

The safety coefficients at the three positions of the extracted bolts A、B、C are shown in Table 8 and their corresponding histograms are shown in Fig. 35.

Figure 35 illustrates that the bolt failure region’s weakest fatigue safety factor is found at area C. As the non-parallel end face\(\theta\)rises, the fatigue safety factor at the initial thread of contact increases and eventually falls. When\(\theta\) = 0°, n is 1.31. When\(\theta\) = 0.5°, n is 1.35. When\(\theta\) = 1.25°, n is 1.29.

Analysis of safety factor of bolted connection structure under middle diameter deviation

Figure 36 shows the distribution of the fatigue safety factor at the first few teeth of the bolt under the mid-diameter deviation. with the increase of the deviation of the middle diameter, the fatigue safety factor of the initial thread of the bolt shows a downward trend. When the middle diameter is 8.3505 mm, n is 1.35. When the middle diameter is 8.2125 mm, n is 1.25.

As illustrated in Fig. 37, the fatigue safety factor distribution cloud map of the bolted joint structure’s failure-prone region under the middle diameter deviation is positioned under the same scale for examination.

The bolt’s accessible failure area’s fatigue safety factor is retrieved (see Table 9), and Fig. 37 displays the related fatigue safety factor histogram.

According to Fig. 38, the bolt failure region’s most minor fatigue safety factor is found at the area C. As the diameter deviation increases, the fatigue safety factor in the failure area drops. Fatigue fracture is not likely to occur at this time when the diameter is 8.3505 mm since the fatigue safety factor at area C is more significant than 1.3.

In conclusion, bolt preload, structural stress, and fatigue safety factor assessment are considered when analyzing the structural strength of connecting rod bolts under geometric deviation. The fatigue safety factor at the initial thread is 1.35 when the pitch of the connecting rod bolts is 1 mm, the non-parallel end face is 0.5 °, and the middle diameter is 8.3505 mm. This value satisfies the allowable safety factor design standard and makes it difficult for fatigue fracture to occur during operation. Consequently, the center diameter is 8.3505 mm, the pitch is 1 mm, and the non-parallel end face is 0.5°. The preferable construction is the bolt connection structure.

Optimization design of bolted connection structure

Most scholars start from the thread pair and change the distribution of thread contact stress to improve the fatigue strength at the first thread of meshing but do not consider improving the fatigue strength at the joint between the thread head and the screw. Therefore, based on the preferred structure obtained from the previous analysis, the research object is proposed to optimize the connecting rod bolt connection structure with the hexagonal flange bolt with the cutting groove. According to GB / T16674.2-2016, the design standard is established. The plane diagram of the connecting rod bolt structure with the U-shaped cutting groove is shown in Fig. 39, the structural parameters in Table 10, and Fig. 40 is a three-dimensional section view.

As shown in Fig. 41, under the same load constraints, the preload of the U-shaped cutting groove bolt connection structure is greater than that of the structural optimization model, and the reliability of the U-shaped cutting groove bolt connection structure is higher.

The stress cloud diagram of each model is extracted as shown in Fig. 42. To facilitate the comparison of the stress distribution of each model under the same load, the stress scale is set to 4.91 ~ 1320 MPa.It is not difficult to see that the stress of the bolt connection structure of the U-shaped cutting groove at the joint of the bolt head and the screw joint is significantly lower than that of the structural optimization model.

Taking Fig. 33 as the path, the fatigue safety factor of the joint between the bolt head and the screw joint of each model is extracted. Figure 43 shows that the fatigue safety factor of the U-shaped cutting groove bolt connection structure model is significantly improved compared with the structural optimization model. The average fatigue safety factor is increased from 1.58 to 1.71, which greatly reduces the possibility of fatigue failure of the bolt head and the screw joint during the working process.

Conclusion

In this paper, a finite element model of standard threaded connection structure considering pitch deviation, non-parallel end face and middle diameter deviation is established, and its influence on preload, contact stress and fatigue safety factor of threaded connection structure is studied. It has important engineering practical significance and theoretical research value for improving the reliability of connecting rod bolt structure.

(1) From the aspects of bolt preload, structural stress and fatigue safety factor evaluation, the pitch deviation has the greatest influence on it, followed by the middle diameter deviation, and finally the non-parallel end face.

(2) In order to reduce the influence of pitch deviation, middle diameter deviation and non-parallel end face on the bolt connection structure, when the pitch is 1 mm, the middle diameter is 8.3505 mm, and the non-parallel end face is 0.5 °, the fatigue safety factor of the bolt failure area is the largest, and the fatigue failure is not easy to occur during the working process.

(3) The bolt connection structure of a U-shaped cutting groove can greatly improve the fatigue strength of the bolt head and the screw joint. Compared with the bolt without the cutting groove structure, the average fatigue safety factor is increased from 1.58 to 1.71.

Data availability

The data that support the findings of this study are available from the corresponding author upon reasonable request.

References

Zhu, X. et al. Failure analysis of a failed connecting rod cap and connecting bolts of a reciprocating compressor. Eng. Fail. Anal. 100 (74), 218–227 (2017).

Motosh, N. Load distribution on threads of titanium tension nuts and steel bolts. ASME J. Eng. Ind. 97 (1), 162–166. https://doi.org/10.1115/1.3438531 (1975).

Yamamoto, A. Screw Connection Theory and Calculation (Shanghai Science and Technology, 1982).

SopwithDG The distribution of load in screw threads. Proc. Institution Mech. Eng. 159 (1), 373–383. https://doi.org/10.1243/PIME_PROC_1948_159_030_02 (1948).

Goodier, J. N. The distribution of load on the threads of screws. ASME. J. Appl. Mech. 7 (1), A10–A16. https://doi.org/10.1115/1.4008988 (1940).

Nassar, S. A. & Ali, R. A. An improved cumulative damage criterion for preloaded threaded fasteners. ASME J. Mech. Des. 136 (7), 074502. https://doi.org/10.1115/1.4027511 (2014).

Fukuoka, T. & Nomura, M. Proposition of helical thread modeling with accurate geometry and finite element analysis. ASME J. Press. Vessel Technol. 130 (1), 011204. https://doi.org/10.1115/1.2826433 (2008).

Jia, D. et al. Research on optimizing the axial force of thread connection of engine connecting rod. Eng. Fail. Anal. 130, 105771. https://doi.org/10.1016/j.engfailanal.2021.105771 (2021).

Haiping, C. H. E. N. & Pan, Z. E. N. G. FANG gang & LEI liping. Load distribution of bolted joint. J. Mech. Eng. 46 (9), 171–178 (2010).

Tongbai, F. A. N. & Zunsong, R. E. N. ZHA Hao & XU Ning. Distribution and variation of bolt bending moment of brake discs under High-speed rotation. J. Mech. Eng. 56 (22), 159–166 (2020).

Kazemi, A. & Nassar, S. A. Principal Stress-Based equation for Multi-Axial fatigue analysis of preloaded threaded fasteners. ASME J. Press. Vessel Technol. 140 (2), 021405. https://doi.org/10.1115/1.4039124 (2018).

Wu, X. Shao Qing-hao, Han Wei-chi, Li Yong-chun. Experimental research and feasibility analysis of high strength bolt connection of glass structure. J. Lanzhou University:Natural Sci. 56 (2), 279–284 (2020).

Ganeshmurthy, S. & Nassar, S. A. Finite Element Simulation of Process Control of Bolt Tightening for Joints With Non-Parallel Contact. Proceedings of the ASME 2012 Pressure Vessels and Piping Conference. Volume 2: Computer Technology and Bolted Joints. Toronto, Ontario, Canada. July 15–19, 2012. pp. 343–351. ASME. https://doi.org/10.1115/PVP2012-78508

Liu, Z. et al. Changing behavior of friction coefficient for high strength bolts during repeated tightening. Tribol. Int. 151, 106486. https://doi.org/10.1016/j.triboint.2020.106486 (2020).

Xinjian, D. E. N. G., Jianhua, L. I. U. & GONG Hao. Theoretical analysis on Torque-tension relationship and tightening characteristics of wedge threaded connection. J. Mech. Eng. 57 (19), 180–191 (2021).

Xiaoqiang, L. I., Qingkuo, M. E. N. G., Yifan, D. U. & Feiyu, C. H. E. N. ZHAO Bing. Influence of tightening strategy on Pre-tightening force of Aero-engine Single-bolt connection. J. Mech. Eng. 56 (13), 231–241 (2020).

Peng, W. A. N., Zhimin, L. I., Cheng, Z. H. E. N. G. & lirui, Y. A. N. G. LIU Tao. Effects of geometrical variation on bolt load and stress distributions in multi⁃bolt composite joints. Chin. Q. Mech. 45 (01), 187–199 (2024).

Noda, N. A. et al. Effect of pitch difference between the bolt–nut connections upon the anti-loosening performance and fatigue life. Mater. Design. 96, 476–489. https://doi.org/10.1016/j.matdes.2016.01.128 (2016).

Tan, L., Wang, C., Liu, Y., Sun, W. & Zhang, W. Study on hysteresis and threaded fitting behavior of bolted joint with non-parallel bearing surface. Mech. Syst. Signal Process. 168, 108655. https://doi.org/10.1016/j.ymssp.2021.108655 (2022).

Junjie, J. I. A. O., Rong, M. O., Guangqing, X. U. & Xuan, F. U. CHANG Zhiyong. Influence of position error of bolt hole on assembly mechanical characteristics of short precision bolted connection structure. Jouranl Aerosp. Power. 36 (5), 935–947 (2021).

Gong, H., Liu, J., Feng, H. & Huang, J. Concept of radial slippage propagation triggering self-loosening and optimisation design of novel anti-loosening structures. Friction 11 (6), 865–880. https://doi.org/10.1007/s40544-022-0618-5 (2023).

Yang, B. et al. Influence mechanism of bolted joint with geometric irregularity bearing surface on anti-loosening performance. Int. J. Press. Vessels Pip. 191, 104364. https://doi.org/10.1016/j.ijpvp.2021.104364 (2021).

Jiang, K. et al. Effects of different friction coefficients on input torque distribution in the bolt tightening process based on the energy method. J. Tribol. 144 (7), 071203. https://doi.org/10.1115/1.4052638 (2022).

General Administration of Quality Supervision. Inspection and Quarantine of the People’s Republic of China, Standardization Administration of China. GB/T 13298 – 2015:Inspection methods of microstructure for metals (Standards Press of China, 2020).

Jiuyi, L. I., Fengjun1, Z. H. O. U. & Ao, Z. H. A. N. G. SUN Yunhou,LEI Zhigang & ZHU Jingzhong. Accurate finite element modeling and validity analysis of thread structure. Adv. Eng. Sci. 54 (3), 220–229 (2022).

Chen Zhanshan. Research on Reliability Design and Tightening Technology of Engine Connecting Rod Bolt (Jilin:Jilin University, 2016).

Jia, D. et al. Design research on the unmeshed thread section structure of engine Conrod bolts. Structures 57, 105187. https://doi.org/10.1016/j.istruc.2023.105187 (2023).

Research on Structure Optimization and Tightening Technology of Connecting Rod Bolts for Passenger Cars. Kunming: Kunming University of Science and Technology, (2019).

Pan & Qiongyao Chen Kai. Strength analysis and structural improvement for engine connecting rod. Veh. Engine, (S1)140–142 (2008).

Dai Chunxiang, H., Zeyin & Lv Hesheng. Analysis on fatigue life of the linkage component. Mech. Res. Application 2016, 29(06):35–36 .

Shuai, T. et al. Study on fatigue test of diesel engine connecting rod bolts. Heavy Truck (4):10–11 (2015).

Bu, Y. Design and Calculation of Threaded Joints (Higher Education Press, 1995).

Acknowledgements

This study was supported by Major Science and Technology Planning Projects of Yunnan Provincial Science and Technology Department (No. 202202AC080006).

Author information

Authors and Affiliations

Contributions

Dewen Jia: Writing - Review & Editing Xiaofan Song: Writing - Original DraftWei Deng: Supervision Xiwen Deng: Validation Huiping J: Visualization Jilin Lei: Software.

Corresponding author

Ethics declarations

Competing interests

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Jia, D., Song, X., Deng, W. et al. Analysis of the influence of geometric accuracy on the preload and stress of engine connecting rod bolts. Sci Rep 15, 8606 (2025). https://doi.org/10.1038/s41598-025-92013-9

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-92013-9