Abstract

This research investigated the effect of hexamethylenediamine (HMDA) on the fine migration phenomenon in sandstones containing kaolinite clay. Fine migration, which refers to the movement of fine particles during oil and gas extraction, can lead to decreased production efficiency and severe problems in hydrocarbon reservoirs. Therefore, understanding and controlling this phenomenon is of great importance. In this study, zeta potential (ζ) values were measured for clay and sand in different fluids with different concentrations of HMDA. The results showed that HMDA effectively reduces the ζ of both materials. This reduction is due to hydrogen bonds and electrostatic interactions between HMDA and the surface of clay and sand particles. Considering that the ζ is a measure of the tendency of particles to accumulate or disperse, its reduction can lead to an increase in the system’s stability and a decrease in the possibility of fine migration. Wettability measurement and clay-rich core flooding tests were performed to verify the results. These experiments showed that HMDA at an optimal concentration of 1 wt% alters the wettability of sandstones from oil-wet to neutral and significantly reduces fine migration. Wettability alteration is caused by the neutralization of surface charges of particles and the increase of interactions between particles and fluid. XRD analyses also showed that the concentration of kaolin particles in the studied sandstone is 3.2%, with an original permeability of about 62 md. Conducting five core flooding experiments on these sandstone plugs confirmed that HMDA, due to ζ compensation, prevents fine migration and inhibits pressure from increasing during the core flooding experiment. Under controlled fine migration conditions (HMDA solution), the magnitude of core permeability remained almost constant at the level between 50 and 60 md. However, low salinity water reduced it to below 10, while pressure increased and fluctuated.

Similar content being viewed by others

Introduction

As one of the most essential energy sources in the world, the oil industry always faces many challenges1,2,3,4. One of these challenges is the phenomenon of fine migration5,6,7, which refers to the movement of fine particles in oil reservoirs8. This phenomenon can reduce the performance and efficiency of oil extraction and block pores in oil formations. Especially in sandstone reservoirs, the accumulation of fine particles can significantly decrease permeability and, ultimately, a drop in oil production9,10,11,12,13.

The salinity and composition of fluids in reservoirs play an essential role, especially in particle behavior and movement14,15,16,17,18. Studies have shown that an increase in salinity can lead to an increase in the electric charge on the surface of particles and a decrease in the repulsion between them19,20,21,22. This can quickly help the movement of fine particles and the occurrence of fine migration. In contrast, water with low salinity can significantly increase fine migration23,24,25,26. The reason for this is related to the electric charge of the particle surface. In low salinity conditions, the particle surface’s electric charge decreases, reducing the repulsive force between the particles27,28,29,30. In other words, in low salinity conditions, fine particles can be closer to each other, and their movement becomes more accessible, which ultimately leads to fine migration and pore blockage31,32,33,34.

Several methods and techniques are used to prevent the phenomenon of fine migration. One of these methods is the use of surfactants. Surfactants can help reduce the surface tension of fluids and thus control the behavior of fine particles. By changing the surface characteristics of particles, these materials can increase the repulsion between them and prevent the accumulation and movement of fine particles35,36,37,38.

Another method is using clay stabilizers, which improve the stability of fine particles during the oil extraction process39,40,41,42,43,44. These materials can help strengthen the structure of minerals and prevent fine migration. In addition, additives such as HMDA have been considered an effective option in controlling the behavior of particles in different salinity conditions. HMDA can change the electrical charge of the particle surface by creating appropriate chemical bonds and helping to increase their stability. In recent years, research has been done on using nanoparticles and new technologies to control fine migration. For example, nanoparticles can be used as catalysts or additives in fluids to help improve oil recovery performance45,46,47,48,49,50.

The phenomenon of fine migration, as one of the most critical challenges of the oil industry, has attracted the attention of researchers in recent years. Studies have shown that fine migration can significantly affect oil extraction performance. Many researchers investigated the effect of the movement of fine particles on the permeability of oil reservoirs and showed that the movement of fine particles can lead to a significant decrease in permeability51,52,53,54. The salinity and composition of fluids are also known as influential factors in the behavior of particles in oil reservoirs. This can help to increase the movement of fine particles and the occurrence of fine migration55,56,57,58.

This research aims to investigate salinity and HMDA’s effect on the behavior of kaolinite and quartz particles in oil extraction processes. Core flooding, Brunauer-Emmett-Teller (BET), and zeta potential tests have been performed on different samples. The results of this research can help to understand the phenomenon of fine migration better and provide practical solutions in the management of oil resources.

Methodology

Materials

This section presents the materials required for the experiments performed in this research. The materials utilized include HMDA, sandstone core plugs rich in clays, and salts such as NaCl, CaCl2, and MgCl2 purchased from Merck.

HMDA

Hexamethylenediamine (HMDA), the primary chemical used in this study, was sourced from Merck, a reputable supplier known for high-quality chemicals. The HMDA utilized in this study was of 98% purity, ensuring high consistency in its chemical properties. Its chemical composition comprises a primary diamine functional group with the molecular formula C6H12N2. The material is highly soluble in water, and its structure allows it to interact effectively with the clay particles in the sandstone samples, thus preventing fine migration.

Clay particles

The kaolinite needed in this research was obtained from Pars Ore Company. Kaolinite is one of the essential minerals in sandstone oil formations, primarily found in clay-rich sandstones. Due to its unique characteristics, such as crystalline structure and water absorption, this clay can significantly affect the lubrication behavior and fluid flow in these formations. As a tecto silicate mineral, kaolinite has solid and stable bonds that can lead to dense structures resistant to fluid flow59,60,61.

Sand particles

Quartz is one of the most common and stable tectonic minerals, widely occurring in petroleum formations and sandstone sediments. This mineral is known by the chemical formula SiO₂, and due to its unique physical and chemical properties, it plays a vital role in geological and petroleum engineering processes62. Quartz was used as a reference material in batch experiments in this work. The quartz used in this work had a purity of 99%.

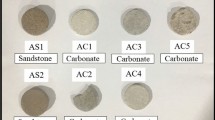

Core plugs

In this research, core plugs taken from outcrop formations of oil fields related to southeast Iraq were used to perform core flooding tests, which contained 5% by weight of kaolinite. This combination has been chosen to simulate natural conditions in sandstone oil formations. XRD (X-ray Diffraction) and XRF (X-ray Fluorescence) tests effectively confirmed the presence of 5% by weight of kaolinite and showed that this mineral is significantly present in the structure of the samples. The results of these analyses are shown in Table 1.

Flooding of six core plug samples was used to study the effect of HMDA on fine migration in clay-rich sandstones, the specifications of which are given in Table 2. These studies provide the possibility to accurately evaluate the effect of kaolinite on the behavior of fluids and oil extraction processes.

Salts

In this experiment, different salts, including NaCl, CaCl₂, and MgCl₂•6 H₂O, were prepared with high concentrations from Merck. These salts were used to investigate the effect of salinity and ionic composition on fluid behavior in different conditions of oil formations. These salts were selected due to their particular characteristics in creating simulated conditions for core flooding experiments and evaluating their effects on fluid displacement and fine migration in kaolinite and quartz in sandstone formations.

Experimental procedure

Zeta potential measurement

Quartz and kaolinite particles were ground separately to reach micro sizes in this experiment. Then, two brine samples were prepared for ζ measurement: one with high salinity with a salt concentration of 250,000 mg/L and the other with low salinity with a concentration of 1,000 mg/L. This selection of different salinity conditions was done to investigate salinity’s effect on ζ and particles’ behavior in different environments.

In the test process, the milled particles were first suspended in both types of brines and stirred well to create a uniform distribution for 24 h. Then, the zeta electrophoresis device was used to measure the ζ. By applying an electric field, the movement of particles in the measuring liquid and the ζ were calculated, which indicated the electric charge of the surface of the particles and their interaction with the environment.

In addition, the particle size was also investigated using Dynamic Light Scattering (DLS). This device determines their size and distribution by analyzing the pattern of light scattered by suspended particles63,64. The results of these tests can help better understand the behavior of quartz and kaolinite particles in different salinity conditions and their effect on oil extraction processes.

Brunauer-Emmett-Teller (BET) test

In this experiment, the BET method was used to investigate the adsorption of HMDA on clays and quartz. This experiment was designed to determine this material’s specific surface and absorption capacity on two different types of minerals. At first, kaolinite and quartz samples were prepared separately and then treated with HMDA at a particular concentration under control conditions.

The BET method is specifically used to measure the specific surface area of solids and allows us to investigate the extent of HMDA adsorption on minerals. In this experiment, the changes in strain and the volume of absorbed gas were measured after exposing the samples to nitrogen gas. These data allow us to calculate the specific surface area and adsorption capacity of HMDA on clays and quartz.

The results obtained from this experiment can help to understand better the interaction of HMDA with minerals and its effect on the physical and chemical properties of kaolinite and quartz soils. This information is precious in preventing fine migration and optimizing oil extraction processes.

Core flooding test

The primary test in this research was core flooding, which was done using the Vinci device. The schematic of this device is given in Fig. 1. This experiment is designed to investigate the phenomenon of fine migration in sandstone oil formations containing clay. In this process, samples of core plugs containing 5% by weight of kaolinite were used to investigate the behavior of fluids and interactions between particles in different conditions.

At first, the samples of core plugs were prepared in certain conditions and accurately placed in the core holder of the Vinci machine. These samples included a mixture of quartz and kaolinite, which have essential characteristics in the behavior of fluids in petroleum formations. The Vinci device was prepared with precise pressure and temperature settings, and the initial pressure or confining pressure was applied to the samples to create suitable simulation conditions of the actual situation in oil tanks.

In the next step, fluid with a specific salinity (high or low salinity) was continuously injected into the samples. This experiment used different fluids, including high-salinity and low-salinity brine samples, to investigate different effects on the fine migration phenomenon. At the same time as the fluid was injected, the pressure was continuously measured along the length of the samples. These measurements allow researchers to observe changes in pressure over time in response to fluid injection.

In addition, the output fluid from the samples was collected and analyzed to investigate its composition and characteristics. This analysis includes measuring the concentration of fine particles and the chemical changes in the fluid. After the experiment, the collected data, including pressure, flow rate, and composition of the outlet fluid, were analyzed in detail. These analyses help to identify the flow patterns and behavior of particles in response to pressure and salinity changes and can lead to the identification and investigation of the fine migration phenomenon.

The results obtained from the core flooding test can provide valuable information about the interactions between minerals and fluids and help better understand particles’ behavior in petroleum formations65. This information is especially critical in optimizing oil extraction processes and resource management in sandstone formations. With a more detailed understanding of fine migration, it is possible to provide solutions to control and improve oil extraction performance.

Results and discussion

In this section, the results of the experiments are fully presented, and points obtained from experiments are thoroughly discussed. The composition of brines used in ζ and core flooding experiments is presented in Table 3.

In Table 3, HS denotes high salinity, LS is low salinity, and LSH is shortened to low salinity with HMDA.

Zeta potential test

A zeta potential experiment in the first phase was conducted to find the optimal concentration of HMDA to manipulate clay particles’ surface charge in distilled water. As presented in Table 4, increasing HMDA concentration to 1 wt% strongly affects the surface charge of clay particles; however, further increments have no more impact on this parameter.

The ζ measurement test results show the effect of salinity and the addition of HMDA on kaolinite and quartz particles. As illustrated in Table 5, ζ for kaolinite particles in LS reached − 40 mV and quartz − 27 mV. These values indicate a high negative charge on the surface of the particles in LS conditions, which can lead to the repulsion between particles and thus increase the probability of movement of fine particles.

As the salinity increased to 250,000 mg/L, the ζ for both minerals decreased significantly to − 3 mV for kaolinite and − 1 mV for quartz. This decrease indicates a decrease in the electric charge of the surface of the particles, by which the repulsive force between the particles decreases. In HS, kaolinite and quartz particles can quickly get closer to each other, increasing the possibility of fine migration. These findings indicate that an increase in salinity can lead to an increase in the movement of fine particles in oil formations.

By adding HMDA to the samples at a concentration of 1%, the ζ for kaolinite and quartz decreased to − 8 and − 2 mV in brine. This significant decrease in ζ indicates the positive effect of HMDA in reducing the repulsion between particles. By reducing the repulsion, the particles can come closer together and form stable aggregates or flocs, which can help prevent fine particles from moving under certain conditions.

These results are significant for controlling fine migration in oil formations because fine particles in extraction fluids can decrease the efficiency and performance of oil extraction processes. Using HMDA makes it possible to effectively reduce particle repulsion and provide conditions where fine particles move less, thus creating more stability in the extraction process.

Finally, these investigations show that understanding the effect of salinity and additives such as HMDA on ζ and particle behavior in petroleum formations can help optimize oil extraction processes and resource management. Researchers and engineers can use this information to design effective strategies to control fine migration and improve oil extraction performance.

BET test results

BET test was performed to investigate kaolinite and quartz’s surface area and pore characteristics, focusing on nitrogen adsorption as the adsorbed material. BET results related to kaolinite, quartz, and their modifications with HMDA are presented in Fig. 2A and B. The results of this experiment show that adsorption of HMDA alters the surface characteristics in kaolinite and quartz particles.

In the test results, the adsorption rate of nitrogen on virgin kaolinite was higher than that of quartz. In the test conditions, nitrogen adsorption on kaolinite reached 120 mg/g, and on quartz reached 80 mg/g. This difference indicates the higher surface area of kaolinite particles. This phenomenon can be attributed to kaolinite’s surface structure and chemical characteristics.

In addition, the desorption test results also provide interesting information. In the desorption test, it was observed that 90% of nitrogen adsorbed on kaolinite was not quickly released after pressure reduction. However, only 60% of nitrogen adsorbed on quartz was released under these conditions.

After modifying the surface of kaolinite and quartz particles with HMDA, the surface characteristics for both particles were changed. The adsorption capacity for nitrogen gas in kaolinite particles dropped from 120 to 61 mg/gr-rock. However, it was reduced from 80 to 65 in quartz particles, indicating that HMDA reduces the specific surface capacity of kaolinite particles filling its pores.

These findings are significant in the field of management and control of the fine migration phenomenon. Considering that HMDA can act as an effective additive in oil extraction processes, its use in appropriate conditions can help to increase extraction efficiency and reduce the problems caused by the displacement of fine particles. As a result, understanding the adsorption and desorption behavior of HMDA on kaolinite and quartz can help optimize oil extraction methods and natural resource management.

Furthermore, the wettability study of sand slice surfaces in a water/oil system showed that adsorption of HMDA alters the sandstone surface from oil-wet to neutral status, presented in Fig. 3.

Results of core flooding tests

In this part, six core flooding tests were performed in the following order, and the graphs and explanations of each test are explained separately and in detail.

First experiment: injection of HS Brine and low injection rate

This experiment injected HS brine of 250,000 mg/L into the plug at a low injection rate of 0.1 mL/min, which resembles 1.3 ft/day, simulating areas far from the wellbore. As illustrated in the obtained data in Fig. 4, one of the key results of this experiment was that the injection pressure remained constant from the beginning to the end, and no significant increase was observed. This pressure stability indicates the absence of fine migration, which means that the fine particles did not move under these conditions, and the pore structure in the plug was maintained.

This situation can be due to the high electric charge on the surface of kaolinite and quartz particles in HS brine. In HS conditions, the particle surface’s negative charge increases significantly, leading to repulsion between particles and preventing their movement. This phenomenon shows that, under appropriate conditions, HS can be used to control the behavior of particles in oil formations, and it is especially effective in preventing the accumulation of fine particles.

The second experiment: injection of HS Brine and a high injection rate

This experiment injected HS brine into the plug at an injection rate of 3 mL/min, equal to 40 ft/day, simulating near-wellbore areas. Based on data illustrated in Fig. 5, the injection pressure started to increase, and the permeability of the plug reached 31 mD, while in the previous experiment, this value was 60 mD. This significant decrease in permeability indicates the positive effect of a higher injection rate on the movement of particles and their behavior in HS.

This phenomenon can be because, with the increase of the injection rate, the drag force on the particles increases, which can lead to the movement of fine particles. However, at the same time, due to the HS, the electric charge of the surface of the particles is such that it limits their movement. As a result, the balance between drag force and electrical repulsion in these conditions can decrease permeability.

Third experiment: injection of LS Brine and low injection rate

LS was injected into the plug, and in this condition, fine migration occurred, and the permeability decreased to 13 mD. According to Fig. 6, due to the lower electric charge on the surface of the particles, the repulsion between them is reduced, and this causes the tiny particles to move quickly and create blockages in the pores.

These findings show insufficient repulsive force between particles in LS, which can lead to particle accumulation and permeability reduction. Additionally, these results point to the importance of salinity control in petroleum formations, as LS can significantly affect oil recovery efficiency.

Fourth experiment: injection of LS Brine and high injection rate

In this experiment, LS brine was injected into plug#4 at a high injection rate, and the permeability drop was strongly noticeable and reached seven mD. Based on Fig. 7, the sharp decrease in permeability indicates the negative effect of LS and high injection rate on particle movement and fine migration.

In this case, due to insufficient repulsion between particles in LS, the drag force caused by the high injection rate can lead to the displacement of fine particles and severe blockage of pores. These findings point to the importance of paying attention to the environmental conditions and the behavior of particles in oil extraction processes and show the necessity of controlling the injection rate in LS.

Fifth experiment: injection of LSH Brine at a low injection rate

In this experiment, LS brine containing one wt% HMDA was injected into the plug at a low injection rate. Based on data illustrated in Fig. 8, permeability decreased to only 52 mD, which does not indicate a noticeable decrease. These results indicate that HMDA, as an effective additive, can increase the stability of particles and prevent the displacement of fine particles.

By creating chemical and physical bonds with kaolinite and quartz particles, HMDA can change their surface’s electric charge and help increase the repulsion between particles. These findings show that adding HMDA can be an effective strategy to control fine migration in oil formations.

Experiment six: injection of LSH at a high injection rate

LSH was injected at a high injection rate in this experiment, and the obtained data are plotted in Fig. 9. In this state, permeability decreased from 60 mD to 27 mD. This sharp decrease in permeability was caused by fine detachment due to the high drag force.

The results of this experiment show the challenges that can arise in low salinity conditions and high injection rates. In this situation, the drag force can overcome the electrical repulsion and lead to the separation of fine particles. These findings emphasize that the use of HMDA should be carefully controlled, and environmental conditions should be considered to prevent problems caused by fine detachment.

In general, the results of these tests show the significant effect of salinity and injection rate on particle behavior and fine migration phenomenon in oil formations. Also, using HMDA as an additive can help improve permeability performance and stability in different conditions. As a result, a detailed understanding of particle behavior under different salinity conditions and injection rates helps to optimize oil extraction processes and natural resource management.

Limitations of the study

While the findings presented in this study offer valuable insights into the effect of hexamethylenediamine (HMDA) on fine migration in sandstone reservoirs, several limitations must be acknowledged:

-

1.

Single Fluid System: The study primarily focuses on a single fluid system to investigate the effects of HMDA on zeta potential, wettability alteration, and fine migration. However, multiple fluids are present in real-world reservoir conditions, and their interactions with the additive may differ. The effects of HMDA on fine migration in more complex fluid environments, such as those containing varying salinity or different surfactants, have not been explored in this study.

-

2.

Environmental and Economic Considerations: Although HMDA shows promise in controlling fine migration, the potential environmental impact and economic feasibility of using HMDA as an additive in large-scale operations remains to be assessed. Future studies should consider the environmental safety and cost-effectiveness of HMDA to ensure its practicality in real-world applications.

-

3.

Scale-Up: While laboratory-scale experiments provide valuable insights, there are significant differences between laboratory-scale and field-scale operations. The results observed in core flooding tests may not directly translate to large-scale reservoir conditions due to factors such as heterogeneity of the reservoir, fluid flow dynamics, and the scale of fine migration. Future studies should aim to validate these findings in larger-scale field tests to ensure their applicability in real-world scenarios.

Conclusion

This research investigated the effect of salinity and additives on the behavior of kaolinite and quartz particles in oil extraction processes using core flooding, BET, and zeta potential tests. The results clearly show the significant effects of salinity conditions and injection rate on oil formations’ fine migration and permeability performance.

The results of core flooding tests showed that in HS and low injection rate, the magnitude of permeability barely reduced from 60 to 50 md, which indicated that fine migration did not occur. In conditions of low salinity and high injection rate, fine migration led to a sharp decrease in permeability from 60 to 4 mD, while pressure increased with fluctuation. However, adding HMDA to LS brine and the injection rate prevented fine migration and reduced the permeability from 60 to 52 mD.

In the BET test, it was also observed that HMDA is effectively adsorbed on kaolinite and quartz, which can help improve the performance of extraction processes and control particle behavior. These findings suggest that HMDA can act as an effective additive in various salinity conditions and help prevent fine particle migration and pore plugging in petroleum formations.

This research shows the importance of understanding the behavior of particles in different conditions in oil extraction processes. The obtained results can help engineers and researchers design and optimize extraction processes and provide solutions for better control and management of oil resources. Considering the challenges in the oil industry, this information can be used as a basis for future research and the development of new solutions for managing and exploiting energy resources.

Data availability

Data will be made available on academic request from the corresponding author.Khaled HeratiHarat University, AfghanistanKh.h1992huni@gmail.com.

Abbreviations

- BET:

-

Brunauer-Emmett-Teller

- DLS:

-

Dynamic Light Scattering

- HMDA:

-

Hexamethylenediamine

- HS:

-

High salinity

- LS:

-

Low salinity

- LSH:

-

Low salinity-HMDA

- MMT:

-

montmorillonite

- XRD:

-

X-ray diffraction

- XRF:

-

X-ray Fluorescence

References

Struchkov, I. A. & Rogachev, M. K. The challenges of waxy oil production in a Russian oil field and laboratory investigations. J. Petrol. Sci. Eng. 163, 91–99 (2018).

Epelle, E. I. & Gerogiorgis, D. I. A review of technological advances and open challenges for oil and gas drilling systems engineering. AIChE J. 66 (4), e16842 (2020).

Parizad, A., Shahbazi, K., Ayatizadeh, A. & Tanha Enhancement of polymeric water-based drilling fluid properties using nanoparticles. J. Petrol. Sci. Eng. 170, 813–828 (2018).

Zhou, Y. et al. Effect of multi-scale rough surfaces on oil-phase trapping in fractures: Pore-scale modeling accelerated by wavelet decomposition. Comput. Geotech. 179, 106951 (2025).

Byrne, M. et al. Fines Migration in Oil and Gas Reservoirs: Quantification and Qualification Through Detailed Study. In SPE International Symposium and Exhibition on Formation Damage Control. (2014).

Miri, R., Haftani, M. & Nouri, A. A review of fines migration around steam assisted gravity drainage wellbores. J. Petrol. Sci. Eng. 205, 108868 (2021).

Bedrikovetsky, P. et al. Fines-Migration-Assisted Low-Salinity Waterflooding: Field Case Analysis. In SPE Russian Petroleum Technology Conference. p. SPE-176721-MS. (2015).

Shan, Y. et al. Effect of Plastic Fine Particles on Shear Strength at the Critical State of sand-clay Mixture. Can. Geotech. J.

Gabriel, G. A. & Inamdar, G. R. An Experimental Investigation of Fines Migration in Porous Media. In SPE Annual Technical Conference and Exhibition. (1983).

Oyeneyin, M. B. et al. Factors to Consider in the Effective Management and Control of Fines Migration in High Permeability Sands. In SPE European Formation Damage Conference. (1995).

Mosalman Haghighi, O., Mohsenatabar, A. & Firozjaii An experimental investigation into enhancing oil recovery using combination of new green surfactant with smart water in oil-wet carbonate reservoir. J. Petroleum Explor. Prod. Technol. 10 (3), 893–901 (2020).

Niu, Q. et al. Explosive fracturing mechanism in low-permeability sandstone-type uranium deposits considering different acidification reactions. Energy 312, 133676 (2024).

Yu, J. et al. Stress relaxation behaviour of marble under Cyclic weak disturbance and confining pressures. Measurement 182, 109777 (2021).

Aghdam, S. K., Kazemi & Ahmadi, M. Studying the effect of various surfactants on the possibility and intensity of fine migration during low-salinity water flooding in clay-rich sandstones. Results Eng. 18, 101149 (2023).

Khezerloo-ye Aghdam, S., Kazemi, A. & Ahmadi, M. Performance evaluation of different types of surfactants to inhibit clay swelling during chemical enhanced oil recovery. Can. J. Chem. Eng. 102 (1), 481–494 (2024).

Khayati, H. et al. An experimental investigation on the use of saponin as a non-ionic surfactant for chemical enhanced oil recovery (EOR) in sandstone and carbonate oil reservoirs: IFT, wettability alteration, and oil recovery. Chem. Eng. Res. Des. 160, 417–425 (2020).

Kazemi, A., Khezerloo-ye, S., Aghdam & Ahmadi, M. Theoretical and experimental investigation of the impact of oil functional groups on the performance of smart water in clay-rich sandstones. Sci. Rep. 14 (1), 20172 (2024).

Wang, S. et al. Comparative laboratory wettability study of sandstone, tuff, and shale using 12-MHz NMR T1-T2 fluid typing: insight of shale. SPE J. 29 (09), 4781–4803 (2024).

Kia, S. F., Fogler, H. S. & Reed, M. G. Effect of pH on colloidally induced fines migration. J. Colloid Interface Sci. 118 (1), 158–168 (1987).

Haftani, M. et al. An Investigation into the Effect of Brine Salinity on Fines Migration in SAGD Operations. In SPE Western Regional Meeting. (2019).

Khilar, K. C. & Fogler, H. S. Colloidally induced fines migration in porous media. Rev. Chem. Eng. 4 (1–2), 41–108 (1987).

Fathima, A. et al. Polymer nanocomposites for water shutoff application- A review. Mater. Res. Express. 6 (3), 032001 (2019).

Borazjani, S. et al. Effects of fines migration on Low-Salinity waterflooding: analytical modelling. Transp. Porous Media. 116 (1), 213–249 (2017).

Yu, M. et al. Effects of fines migration on oil displacement by low-salinity water. J. Petrol. Sci. Eng. 175, 665–680 (2019).

Khezerloo-ye Aghdam, S., Kazemi, A. & Ahmadi, M. Studying the effect of surfactant assisted low-salinity water flooding on clay-rich sandstones. Petroleum, (2023).

Fang, T. et al. Multi-scale mechanics of submerged particle impact drilling. Int. J. Mech. Sci. 285, 109838 (2025).

Bazyari, A. et al. Performance of Smart Water in Clay-Rich Sandstones: Experimental and Theoretical Analysis3210354–10366 (Energy & Fuels, 2018). 10.

Al-Sarihi, A. et al. Fines Migration as an EOR Method During Low Salinity Waterflooding. In SPE Asia Pacific Oil and Gas Conference and Exhibition. p. D021S008R004. (2018).

Chequer, L., Vaz, A. & Bedrikovetsky, P. Injectivity decline during low-salinity waterflooding due to fines migration. J. Petrol. Sci. Eng. 165, 1054–1072 (2018).

Dai, Z. et al. Identification of Relative Conductivity Models for Water Flow and Solute Transport in Unsaturated Bentonite33S177–S185 (Physics and Chemistry of the Earth, 2008).

Han, G. et al. Fines migration and pore clogging induced by single- and two-phase fluid flows in porous media: from the perspectives of particle detachment and particle-level forces. Geomech. Energy Environ. 23, 100131 (2020).

Maghsoudian, A. et al. Applying the synergistic effect of chemically low salinity water flooding assisted fines migration in coated micromodel. 2021 1, 1–5 (2021).

Yue, L. et al. Insights into mechanism of low salinity water flooding in sandstone reservoir from interfacial features of oil/brine/rock via intermolecular forces. J. Mol. Liq. 313, 113435 (2020).

Sun, X. et al. Genesis of Pb–Zn-Ag-Sb mineralization in the Tethys Himalaya, China: early magmatic-hydrothermal Pb–Zn(-Ag) mineralization overprinted by Sb-rich fluids. Miner. Deposita. 59 (7), 1275–1293 (2024).

Songire, S., Uppuluri, R. & Rama, M. S. Aqueous-Based Surface Modifying Agent for Mitigation of Fines Migration. In SPE Annual Caspian Technical Conference and Exhibition. (2014).

Huang, T., Crews, J. B. & Willingham, J. R. Nanopart. Formation Fines Fixation Improving Perform. Surfactant Struct. Fluids (2008).

Muneer, R., Hashmet, M. R. & Pourafshary, P. Fine migration control in sandstones: surface force analysis and application of DLVO theory. ACS Omega. 5 (49), 31624–31639 (2020).

Hu, M. et al. Evolution characteristic and mechanism of microstructure, hydraulic and mechanical behaviors of sandstone treated by acid-rock reaction: application of in-situ leaching of uranium deposits. J. Hydrol. 643, 131948 (2024).

Hibbeler, J., Garcia, T. & Chavez, N. An Integrated Long-Term Solution for Migratory Fines Damage. In SPE Latin American and Caribbean Petroleum Engineering Conference. (2003).

AlMubarak, T., AlDajani, O. & AlMubarak., M. A Collective Clay Stabilizers Review. In International Petroleum Technology Conference. (2015).

Zhou, Z. J., Gunter, W. O. & Jonasson, R. G. Controlling Formation Damage Using Clay Stabilizers: A Review. In Annual Technical Meeting. (1995).

El-Monier, I. A. & Nasr-El-Din, H. A. Mitigation of Fines Migration Using a New Clay Stabilizer: A Mechanistic Study. In SPE European Formation Damage Conference. (2011).

Mikhienkova, E. I. et al. Experimental study on the influence of nanoparticles on oil-based drilling fluid properties. J. Petrol. Sci. Eng. 208, 109452 (2022).

Rafati, R. et al. Effect of nanoparticles on the modifications of drilling fluids properties: A review of recent advances. J. Petrol. Sci. Eng. 161, 61–76 (2018).

Hasannejad, R. et al. Application of silica nanofluid to control initiation of fines migration. Pet. Explor. Dev. 44 (5), 850–859 (2017).

Yuan, B., Moghanloo, R. G. & Wang, W. Using nanofluids to control fines migration for oil recovery: nanofluids co-injection or nanofluids pre-flush? -A comprehensive answer. Fuel 215, 474–483 (2018).

Huang, T. & Clark, D. E. Enhancing oil recovery with specialized nanoparticles by controlling Formation-Fines migration at their sources in waterflooding reservoirs. SPE J. 20 (04), 743–746 (2015).

Saw, R. K. et al. A mechanistic study of low salinity water-based nanoparticle-polymer complex fluid for improved oil recovery in sandstone reservoirs. Colloids Surf., A. 666, 131308 (2023).

Al-Anssari, S. et al. Impact of nanoparticles on the CO2-brine interfacial tension at high pressure and temperature. J. Colloid Interface Sci. 532, 136–142 (2018).

Al-Anssari, S. et al. Effect of Nanoparticles on the Interfacial Tension of CO2-Oil System at High Pressure and Temperature: An Experimental Approach. In SPE Asia Pacific Oil & Gas Conference and Exhibition. p. D013S101R009. (2020).

Zeinijahromi, A. & Bedrikovetsky, P. Fines-Migration-Assisted Oil and Gas Recovery (Low Salinity Water Injection). In SPE Russian Petroleum Technology Conference. (2015).

Russell, T. et al. Effects of delayed particle detachment on injectivity decline due to fines migration. J. Hydrol. 564, 1099–1109 (2018).

Russell, T. et al. Effects of kaolinite in rocks on fines migration. J. Nat. Gas Sci. Eng. 45, 243–255 (2017).

Zi, J. et al. Quantitatively characterizing sandy soil structure altered by MICP using multi-level thresholding segmentation algorithm. J. Rock Mech. Geotech. Eng. 16 (10), 4285–4299 (2024).

Aghdam, S. K., Kazemi & Ahmadi, M. Theoretical and experimental study of fine migration during Low-Salinity water flooding: effect of Brine composition on interparticle forces. SPE Reservoir Eval. Eng. 1–16. (2022).

Rosenbrand, E. et al. Different effects of temperature and salinity on permeability reduction by fines migration in Berea sandstone. Geothermics 53, 225–235 (2015).

Sarkar, A. K. & Sharma, M. M. Fines migration in Two-Phase flow. J. Petrol. Technol. 42 (05), 646–652 (1990).

Zou, B. et al. Transient rock breaking characteristics by successive impact of shield disc cutters under confining pressure conditions. Tunn. Undergr. Space Technol. 150, 105861 (2024).

Bish, D. L. Rietveld refinement of the kaolinite structure at 1.5 K. Clays Clay Miner. 41 (6), 738–744 (1993).

Miranda-Trevino, J. C. & Coles, C. A. Kaolinite properties, structure and influence of metal retention on pH. Appl. Clay Sci. 23 (1), 133–139 (2003).

Wang, H. et al. Non-monotonic Effect of Differential Stress and Temperature on Mechanical Property and Rockburst Proneness of Granite Under high-temperature True Triaxial Compression10162 (Geomechanics and Geophysics for Geo-Energy and Geo-Resources, 2024). 1.

Zhou, H. et al. Anisotropic strength, deformation and failure of gneiss granite under high stress and temperature coupled true triaxial compression. J. Rock Mech. Geotech. Eng. 16 (3), 860–876 (2024).

Souza, T. G. F., Ciminelli, V. S. T. & Mohallem, N. D. S. A comparison of TEM and DLS methods to characterize size distribution of ceramic nanoparticles.J. Phys. Conf. Ser. 733(1), 012039. (2016).

Bhattacharjee, S. DLS and zeta potential – What they are and what they are not? J. Controlled Release. 235, 337–351 (2016).

Du, C. et al. Electroosmosis of gold tailings under multiple electrokinetic geosynthetics electrodes. Geotext. Geomembr. 52 (4), 585–597 (2024).

Author information

Authors and Affiliations

Contributions

Zahraa Sabah GhnimTheory, WritingAyat Hussein AdhabExperimentalSubhash Chandra*SupervisionJayanti MakasanaExperimentalSubbulakshmi GanesanTheoryAman Shankhyan ExperimentalM Ravi KumarExperimentalGirish Chandra SharmaTheoryMorug Salih Mahdi FiguresAseel Salah MansoorWritingUsama Kadem RadiExperimentalNasr Saadoun AbdTheoryKhaled HaratiSupervision.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Ghnim, Z.S., Adhab, A.H., Chandra, S. et al. Experimental investigation of the role of hexamethylenediamine in controlling fine migration in clay-rich sandstones. Sci Rep 15, 11784 (2025). https://doi.org/10.1038/s41598-025-92167-6

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-92167-6