Abstract

Due to technological advancements and an increase in population growth, the need for freshwater has escalated. Several techniques have been developed to produce fresh water, and one of the promising techniques is using the solar thermal desalination process. This study conducts experimental analysis on a single slope solar still employing porous rubber sheet thermal energy storage. Various experiments were performed with water masses ranging from 10 to 25 kg within the basin, comparing these to a similar setup lacking sensible heat energy storage. The results showed that the increased water mass in the basin reduced the distilled water produced from the Solar still (SS) with and without sensible thermal energy storage. The highest distilled water produced from the SS in both cases was at the lowest mass of water. The SS with porous rubber sheet produced maximum distilled water of 0.85 kg/m2, whereas the SS without rubber sheet was found to be 0.75 kg/m2 at the lowest water mass. Similarly, the highest distilled water collected occurred at different time intervals, and the mass of water in the basin as the stored energy is liberated to the water at different times of the day. The augmentation in the distilled water produced from the SS with a porous rubber sheet may be due to the higher absorption of heat and improved surface area of water with solar radiance. Furthermore, at the lowest water mass, the average daily efficiency of the modified SS with porous is higher, reaching about 55.6%, which is higher compared to the SS without porous rubber sheet as thermal energy storage, and the average daily efficiency decreases with increased water mass inside the basin on both the cases. The exergy analysis revealed that the average exergy efficiency improved to about 4.69% from 3.54% using a porous rubber sheet in the basin for the lowest water mass of 10 kg as compared to the SS without any material.

Similar content being viewed by others

Introduction

The global demand for freshwater is escalating rapidly, contributing to a crucial water crisis around the world. Besides ground and surface water sources, the largest reservoir exists in seawater within the oceans. Addressing this demand primarily involves water filtration techniques. Various methods exist to purify water, including the treatment of seawater and collecting rainwater before its release into the environment1,2,3,4,5,6,7,8. However, desalination systems present a significant drawback due to their high energy requirements for operation. Solar stills are basically thermal desalination processes that involves heat energy to get fresh drinking water. However, compared to the other existing desalination systems, the thermal performance and freshwater generation are much lower. Moreover, solar still makes it easy to fabricate and produce fresh water in remote locations where conventional energy sources are unavailable. Solar stills (SS) stand out as a promising solution for freshwater generation9,10,11. Yet, they confront two main challenges: limited production capacity and dependence on an intermittent power source, namely solar energy. Recognizing the global shift toward renewable energy sources, leveraging their availability at no cost and minimal environmental impact, there’s a growing trend towards employing these resources in power production and various thermal applications.

Sathyamurthy4 used silver nanoparticles on paraffin wax and used as a latent heat energy storage on stepped SS for thermal performance augmentation. The maximum concentration of Nanoparticles (NP’s) in paraffin wax was limited to 2%, which augmented the thermal properties of nano-infused paraffin wax. Results concluded that potable water generation using nanoenhanced paraffin wax in stepped SS was improved by 74.89% than conventional stepped SS without thermal energy storage. Hammoodi et al.12 performed a detailed review of various factors that impact the thermal performance of pyramid solar still. Several factors, such as meteorological, operations, and design parameters, are more crucial in solar still performance. Meteorological parameters include solar intensity, ambient temperature, and wind velocity, which affect the driving factors of evaporation and condensation mechanisms. Operational factors include feed water, salinity level, water depth, and maintenance. Design parameters include multiple trays, thermal energy storage, reflectors, and nanomaterial, which improves the freshwater output and efficiency. It was concluded that with the proposed techniques, the thermal efficiency can be improved to 88%. Furthermore, it was recommended to explore the integration of advanced material and hybrid design, which maximizes the potential of pyramid solar still in producing clean water for drinking purposes.

A comprehensive review of solar still with the magnetic field was carried out by Hammoodi et al.13. The review on solar still is based on passive and active methods and explores modifications such as ferrite magnetic rings, which could increase the distillate output up to 49.22%. other configurations demonstrated that the freshwater enhancement ranges from 15.78 to 31.33%, which completely depends on the orientation and size of the magnets used. It was also reported that the energy and exergy efficiencies can be further improved by integrating permanent magnets with graphite plate fins. Thakur et al.5 introduced carbon soot nanoparticles in paraffin wax and used as thermal energy storage for augmented output from tubular solar still. Their results revealed that the incorporation of 0.3 wt% of carbon soot particles in paraffin wax improved the thermal conductivity by 40.59%. Their results revealed that paraffin wax in cylindrical tubes improved the freshwater yield by 42.4%, whereas using nano-enhanced paraffin wax in cylindrical tubes improved the freshwater yield by 87.82%. The utilization of Phase Change Materials (PCMs) and Carbon Nanoparticles (CSNPs) combined with Phase Change Materials (PCM-CSNP) led to substantial improvements in energy efficiency. Specifically, when comparing the energy efficiency enhancements achieved by PCM alone versus PCM combined with CSNPs (PCM-CSNP), there was a remarkable increase observed. The introduction of PCM resulted in a notable 59.26% boost in energy efficiency. However, the incorporation of CSNPs alongside PCM in the PCM-CSNP configuration showcased an even more significant enhancement, demonstrating a remarkable surge of 109.94% in energy efficiency. This considerable improvement in energy efficiency with the PCM-CSNP combination highlights the synergistic effect and heightened performance achieved by the integration of Carbon Nanoparticles (CSNPs) with Phase Change Materials (PCMs). Such advancements are pivotal in various applications, particularly in thermal energy storage systems, wherein the combination of PCM and CSNPs contributes substantially to optimizing energy utilization and enhancing overall system efficacy.

Sathyamurthy et al.14 used different thicknesses of porous sponges as an interfacial material for augmenting the potable water generation from the hemispherical SS. Results indicated that the rate of evaporation through the porous sponge improved to about 73% using 3 cm thickness. On increasing the sponge layer thickness from 3 to 4 cm, there was a drastic decrease in the daily fresh water generation, thermal efficiency, and exergy efficiency. The impact of pumice stones as a heat storage material on solar still performance was experimentally investigated by Bilal et al.15. Their study revealed that with the increased water mass of pumice stones in the basin, the daytime yield decreased, whereas overnight fresh water increased, and this might be due to the accumulation of heat with the heat storage material. Sathyamurthy et al.16 conducted an experimental analysis on conventional SS by adding waste soda cans filled with paraffin wax as a thermal energy storage medium. Furthermore, the waste soda cans were coated using carbon soot NPs from the tailpipe of automobile exhaust to augment the heat absorption capacity and improve the surface. Results concluded that the daily yield of potable water generation and thermal efficiency were augmented using the surface coating of soda cans using carbon-based NPs.

Kabeel et al.17 experimentally investigated the enhancement of thermal performance in traditional solar stills (SS) by incorporating graphite, a high thermal conductivity material. Their findings demonstrated that utilizing graphite as a thermal energy storage medium in the basin significantly improved the system’s thermal efficiency and potable water yield, achieving increases of 79.48% and 75.11%, respectively, compared to conventional solar stills without thermal energy storage. The influence of energy storage on solar still performance was experimentally investigated by Deshmukh and Thombre18. Solar still with passive storage (sand and SM oil) has higher overnight productivity. Overnight productivity increases with an increase in storage and water mass. The results also indicated that productivity is higher with low relative humidity. Daily productivity on potable water generation decreases with an increase in water depth. Dhasan et al.19 examined the thermal performance of iron oxide NPs in the substrate and used as thermal energy storage in conventional SS and compared the thermal performance from the SS without nanocoating by optimizing the water thickness. Experimental results revealed that by adding the nano-coating of the substrate (absorber) of the SS, the thermal performance and the freshwater yield increase. Similarly, the salt deposition of the substrate is lowered when compared to the substrate without surface coating. The optimized water thickness for augmented yield, exergy efficiencies, and daily efficiencies (thermal performance) was found to be 10 mm.

The performance analysis of a stepped absorber pyramid-shaped condensing cover integrated into a solar parabolic dish collector to augment freshwater was experimentally analyzed by Ahmed et al.20. It was reported that through the hybrid approach, the freshwater output was enhanced, reaching a maximum of 6038 ml/m2 with an enhancement of about 131% compared to the conventional pyramid shaped solar still. Similarly, the energy and exergy efficiencies of the hybrid approach were found to be 56 and 4.26%, whereas, for a stand-alone approach, the efficiencies were found to be 24 and 3.79%, respectively. The augmentation in freshwater output and thermal efficiencies (energy and exergy) in a hybrid approach was due to the excellent heat absorption and distribution, which results in higher evaporation rates. It was also suggested that future enhancements, such as thermal energy storage and tracking systems, may be incorporated to improve the efficiency of the system and freshwater output. Ahmed et al.21 performed an experimental analysis on a single slope SS equipped with local clay and PCM as thermal energy storage to compare the freshwater output and thermal efficiency. Experimental results revealed that the highest productivity was achieved using local clay as thermal energy storage as compared to PCM and SS without any storage. The increase in freshwater output using local clay as thermal energy storage compared to traditional SS was found at 38.7%, whereas the productivity rise was found to be 21% compared to PCM as energy storage. The enhancement of freshwater output was due to the higher water temperature. Similarly, the water temperature of local clay as thermal energy storage was due to the higher absorption of solar energy as compared to the SS with PCM storage. Moreover, the PCM undergoes a phase change during the charging, which tends to lower water temperature. Furthermore, the average thermal efficiency of traditional SS, SS with PCM, and SS with local clay was found to be 34, 41.2, and 47%, respectively. The impact of the mass of PCM on the thermal performance of single slope SS was analyzed experimentally by Ahmed et al.22. The mass of PCM in the SS was varied from 0 to 6 kg. the experimental findings reveal that the optimized mass of PCM was 4 kg, which resulted in an improved productivity of 29.7% and an average thermal efficiency of 68% compared to SS without PCM. The improvement in thermal efficiency and freshwater output was due to the higher water temperature maintained during the lower solar radiation period, which resulted in efficient evaporation. The average thermal efficiency of 2 and 6 kg PCM in the SS was estimated as 57.2 and 53.6%, respectively.

Hammoodi et al.23 performed experiments on a pyramid shaped solar still by introducing magnetic field intensity at different levels to enhance the freshwater output and thermal efficiency under various operating parameters. The water depth in the SS was varied from 1.5 to 3 cm while the intensity of the magnetic field was varied in 136, 175, and 220 mT and the location of the magnet. Similarly, the solar still was fabricated using acrylic and sheet metal with the above modification, and the comparison was made. Results revealed that with magnetic field intensity of 220 and 136 mT, the energy efficiency was found to be 41.1 and 39.6%, with freshwater output rising by 34 and 24%, respectively, at an optimized water depth of 1.5 cm compared to the non-magnetic field in the SS. The experimental findings with respect to the material, acrylic-based SS, along with the magnets, produced a maximum cumulative freshwater output of 3300 ml/m2, which is 10% higher as compared to the non-magnetic field SS.

A computational analysis on a half-cylindrical container with copper rods filled with PCM was analyzed by Basem et al.24. Three different configurations, namely container without rod, with 3 rods, and with 5 rods, and the numerical analysis was carried out with ANSYS FLUENT 16 using the enthalpy-porosity model. The melting process completely relies on the natural convection theory, which prolonged the melting time to 400 minutes from the container without copper rods, whereas, with 3 and 5 copper rods, the melting time was reduced to 220 and 190 minutes, which was 40 and 52% improvement in respect to the time respectively compared to the baseline reading. Also, results revealed that the thermal performance improvement is directly proportional to the number of rods attached.

Remote arid communities and disaster relief operations will benefit from this low-maintenance, high-efficiency solar still, reducing freshwater costs by 40% compared to conventional designs. This study introduces porous rubber sheets-a recycled, low-cost material-as a novel sensible heat storage medium, addressing the scarcity of sustainable and efficient thermal storage solutions in solar desalination. In the present experimental study, single slope solar still thermal performance, daily energy, and exergy performances are analyzed under different water masses in the absorber. Along with the single slope solar still, a porous rubber sheet from recycled materials is used as a low-cost sustainable thermal energy storage medium in the solar still under different water masses are analyzed to study the impact to optimize the water mass in the solar still.

Materials and methods

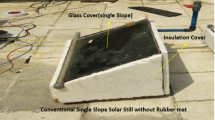

The experimental setup consists of a flat absorber with dimensions of 500 \(\times\) 500 mm in length and breadth, respectively. The height at one end of the solar still is maintained at 300 mm, and at the lower end, it is maintained at 200 mm. The condensing glass cover has a thickness of 3 mm with dimensions of 500 mm \(\times\) 500 mm with a transmissivity of 90%. The glass cover is inclined at an angle of 14° with the horizontal surface while the condensed water droplets inside the closed chamber glide through the inclined glass surface and get collected as fresh water. Hose connections are provided in the distillate collector, and the freshwater is measured every hour using a graduated flask. The brackish water placed inside the solar still evaporates using the radiation from the sun as the solar radiation acts as the primary energy source. The temperature of each element in the solar still, such as water and glass, is measured using PT100-type RTD sensors, and the other parameters, solar radiation, wind velocity, and relative humidity, are measured using a solar power meter, vane-type anemometer, and hygrometer, respectively. In addition to the conventional SS, another SS with a similar dimension is fabricated where the porous rubber medium is placed in the flat absorber of the conventional SS for thermal energy storage. The experiments are carried out during the summer conditions of the Coimbatore region, India, at different water masses of brackish water placed in the basin, and the effect of thermal energy storage using rubber material is experimentally analyzed. The photograph of the experimental setup and the rubber sheet used in the present experimental study are shown in Figs. 1 and 2, respectively. The physical properties of the porous rubber sheet is tabulated in Table 1.

Experimental uncertainty

Uncertainty plays a significant role in solar still experiments or any scientific experimentation involving instruments. Instrument uncertainty refers to the potential variation or margin of error associated with the measurements taken using those instruments. Reducing experimental uncertainty involves meticulous experimental design, calibration of instruments, controlling variables, repeated trials, and statistical analysis to account for variability. Documenting all procedures and providing error bars or confidence intervals in the results can help address and communicate the uncertainty associated with the findings. Likewise, Table 2 details the measurement uncertainties associated with the instruments utilized in this study. The uncertainty of the instruments is based on the errors that occurred, and it is mathematically expressed as25,

where, a is the accuracy of the instrument.

Daily energy and exergy efficiencies

Energy analysis

The daily thermal efficiency from the SS is mainly dependent on the amount of water produced from the SS with the product of latent heat of vaporization to the amount of incoming solar radiation received by the solar still per unit area. The empirical relation to estimating the daily thermal efficiency of the SS is given in Equation (2). This relationship is mathematically expressed as26:

Exergy analysis

Exergy is a thermodynamic property used to measure the maximum useful work that can be obtained from a system as it reaches equilibrium with its surroundings. It represents the available energy within a system that can be converted into mechanical work or other useful forms of energy. given as27,

However, the exergy for SS is expressed mathematically as27,

The input exergy from the solar radiation received to the basin is expressed mathematically as28,

where, I(t) is the amount of solar radiation recieved (W/m2), Ab is the area of basin, Ta is the ambient temperature (K), Ts is the sun temperature (K)

Similarly, the exergy due to the evaporation and condensation of water is expressed mathematically as29,

where, me is the amount of water collected (kg/m2), and h\(_fg\) is the Latent heat of vaporization (kJ/kg).

Moreover, the instantaneous exergy efficiency from the SS is evaluated as29,

Results and discussion

Variance of solar radiation, ambient temperature, wind velocity, and relative humidity during the experiments

The variations on hourly solar radiation, ambient temperature, relative humidity, and wind velocity are plotted in Fig. 3a–d. It is seen that the maximum solar radiation recorded during the experiment for different water masses of 10, 15, 20, and 25 kg are found as 1050, 1028, 1032, and 1025 W/m2 respectively, and the variations on the solar radiation are consistent throughout the experiments. Similarly, the average solar radiation on the horizontal surface is found as 713.6, 712.6, 713.1, and 710.8 W/m2 for water mass of 10, 15, 20, and 25 kg, respectively. Also, the average ambient temperatures are 31.6, 32.03, 32.3, and 32.5 °C for 10, 15, 20, and 25 kg of water mass, respectively. Relative humidity can influence temperature changes within the solar still. In higher-humidity environments, the ambient air temperature might be lower due to moisture. The variance in relative humidity during the experiments is plotted in Fig. 3c. The relative humidity during the experiments varied from 54 to 92%, while the average relative humidity with water mass of 10, 15, 20, and 25 kg are found as 70.6, 70.6, 69.73, and 70.2%, respectively. The variance in wind velocity recorded for the experiments conducted on conventional SS and modifications done to the SS for water mass of 10, 15, 20, and 25 kg is plotted in Fig. 3d. It is seen that the wind velocity fluctuates hugely, and it is an uncontrollable and unpredictable parameter. However, the average wind velocity measured during the experiments for water masses of 10, 15, 20, and 25 kg is measured as 2.52, 2.72, 2.68, and 2.63 m/s, respectively.

Effect of water mass on water temperature from conventional and proposed solar still

The influence of water mass on water temperature from conventional and proposed solar still by employing rubber material as thermal energy storage is plotted in Figs. 4 and 5 respectively. It can be clearly seen from both the plots that a higher mass of water on the basin exhibited lower temperature during the start of experiments, and the temperatures reached a maximum of 59 and 60 °C for water mass of 25 kg in the basin of conventional and proposed solar still by employing rubber material as thermal energy storage respectively. However, for a lower water mass of 10 kg in the basin, the water temperature is recorded as 62 and 66 °C for conventional and proposed solar still by employing rubber material as thermal energy storage, respectively. During the lower water mass, the thin layer of water from the surface absorbs the heat and evaporates, which improves the temperature of the water, whereas, with increased water mass in the basin, the heat absorbed is stored in the form of sensible heat, which is later discharged during the lower solar radiation period. Moreover, the availability of rubber as a thermal energy storage medium improved the water temperature even during the absence of solar radiation, especially during the night hours, for augmented evaporation rate from the top surface of the water. From Figs. 4 and 5, it is also seen that the water temperature is higher from the solar still by employing rubber material as thermal energy storage as sensible heat storing material during the lower solar radiation period. The experimental results also revealed that the average temperature of water from the conventional SS for mass of water as 10, 15, 20 and 25 kg are found as 42.4, 42.4, 43.2 and 45.6 °C respectively during the solar radiation absence whereas, for the proposed solar still by employing rubber material as thermal energy storage it is found as 40.6, 45.2, 47.2 and 50 °C respectively.

Effect of water mass on glass temperature from conventional and proposed solar still

The influence of water mass on water temperature from conventional and proposed solar still by employing rubber material as thermal energy storage is plotted in Figs. 6 and 7 respectively. The maximum recorded glass temperature for 10, 15, 20, and 25 kg water mass are 47, 51, 51, and 47 °C, respectively, from the conventional SS. Similarly, the recorded maximum glass temperature of SS using the proposed technique is 51, 51, 46, and 45 °C for 10, 15, 20, and 25 kg, respectively. The possible increase in the glass temperature of the proposed modification in the SS may be due to the higher evaporation of water inside the chamber and the interaction of vapor with the inclined surface for heat rejection for effective condensation. Similarly, the mean temperature of glass cover from the traditional SS for water mass of 10, 15, 20, and 25 kg are found as 40, 41.7, 41.1 and 41.2 °C, whereas, for the SS using material storage, it is found as 39.5, 41, 39.4 and 41.4 °C respectively.

Effect of water mass on potable water generation from conventional and proposed solar still

The variance in the mass of water on potable water generation from the conventional and proposed solar still by employing rubber material as thermal energy storage is plotted in Figs. 8 and 9 respectively. Increasing water mass reduces freshwater yield due to higher thermal inertia. The maximum fresh water produced from the SS using a conventional absorber is recorded as 0.74, 0.65, 0.50, and 0.52 kg/m2 for 10, 15, 20, and 25 kg, respectively. Similarly, the average nighttime fresh water produced from the SS is found to be 0.15, 0.16, 0.18, and 0.22 kg/m2 for 10, 15, 20, and 25 kg, respectively. The nighttime freshwater yield from the conventional SS is recorded as 0.52, 0.54, 0.65, and 0.79 kg/m2 for 10, 15, 20, and 25 kg, respectively.

From the results of Fig. 9, it is seen that the maximum freshwater yield is obtained for the lowest water mass of 10 kg and recorded as 0.84 kg/m2 by employing rubber material as thermal energy storage. Similarly, for the water mass of 15, 20, and 25 kg inside the basin using the proposed modification, the maximum freshwater measured are 0.73, 0.61, and 0.59 kg/m2 respectively, and it is higher compared to the conventional SS and the yield of potable water decreases with increased water mass. However, the average nighttime yield for water mass of 10, 15, 20, and 25 kg are found as 0.15, 0.19, 0.26, and 0.27 kg/m2 respectively. This is due to the energy absorbed by the rubber sheet, which has an improved surface area. The nighttime fresh water produced from the SS using the proposed modification is found to be 0.79, 0.99, 1.33, and 1.38 kg/m2 for 10, 15, 20, and 25 kg, respectively.

Effect of water mass on daily energy and exergy efficiency from conventional and proposed solar still

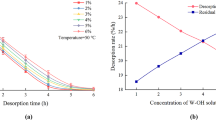

The daily thermal efficiency of both conventional and modified single-slope solar stills (SS), incorporating a rubber sheet for thermal energy storage, is shown in Fig. 10a. The data indicates a consistent decline in daily thermal efficiency as the water mass in the basin increases for both configurations. This reduction can be explained by the impact of higher water mass on the system’s thermal inertia. With greater water mass, the system requires more energy to heat the water to optimal evaporation temperatures, thereby slowing the heating process. Similarly, during the cooling phase, the retained thermal energy takes longer to dissipate, reducing the overall system efficiency. For the conventional SS, the daily thermal efficiency values at water masses of 10, 15, 20, and 25 kg were observed to be 41.6%, 39%, 36.7%, and 35.4%, respectively. In contrast, the modified SS, enhanced with a rubber sheet as a thermal energy storage medium, achieved significantly higher efficiencies of 55.6%, 51.1%, 50.3%, and 48.2% for the same water masses.

It may be inferred that due to the excellent heat energy stored by absorption in the rubber sheet available in the modified SS, higher thermal efficiencies are attained even at higher water mass while comparing it with the traditional SS. The addition of the rubber sheet in the basin acts as a thermal buffer, mitigating the adverse effects of increased water mass by maintaining a more stable thermal environment. This modification enhances evaporation efficiency and ensures better utilization of solar energy. These findings underscore the importance of thermal energy storage materials in improving the performance of solar stills, particularly in scenarios with varying water loads. By optimizing the heat storage and release processes, the modified SS provides a more efficient and reliable solution for freshwater production compared to its conventional counterpart.

The variation in daily exergy efficiency for traditional and modified single-slope solar stills (SS) with a porous rubber sheet as thermal energy storage is depicted in Fig. 10b. The results indicate that as the water mass in the basin increases from 10 to 25 kg, the daily exergy efficiency of the traditional SS decreases from 3.54% to 2.8%. In contrast, the modified SS with thermal energy storage demonstrates improved exergy efficiency, achieving 4.69% and 3.76% for 10 and 25 kg of water, respectively. The enhancement in daily exergy efficiency for the modified SS is calculated as 32.4%, 27.8%, 34.04%, and 34.28% for water masses of 10, 15, 20, and 25 kg, respectively, compared to the traditional SS. Dhasan et al.30 reported that the average daily exergy efficiency of conventional solar stills ranged between 2.1% and 1.7% with increasing water thickness in the basin. However, the current study, conducted under summer conditions, shows a notably higher daily exergy efficiency. Similarly, research by Rajaseenivasan et al.19 on single-basin double-slope solar stills found the average exergy efficiency to vary between 1.4% and 1.8% for water thicknesses of 2 to 8 cm. These findings highlight that the use of a porous rubber sheet as thermal energy storage in the basin of solar still significantly enhances daily exergy efficiency. This improvement is attributed to the porous rubber sheet’s ability to store heat during sunshine hours and release it during non-sunny periods, maintaining optimal evaporation conditions compared to a flat absorber.

The daily exergy efficiency is likely to be improved in the case of a modified SS, and it is attributed to the porous rubber sheet properties. The rubber sheets in the SS effectively absorb the direct solar radiation and store the thermal energy during the high solar radiation period, releasing the heat gradually during the lower and fluctuating solar radiation period, which enables a stable water temperature inside the basin. However, in the case of a traditional SS, solar radiation is used to heat the water to make it evaporate, whereas, in the case of the modified SS, the rubber sheets store the heat, which acts as a thermal energy storage mechanism to evaporate the water even under fluctuating solar intensity. Moreover, this energy storage mechanism not only enhances the evaporation rate but also maximizes the freshwater output and overall efficiency of the system. Furthermore, the heat loss from the modified SS is reduced by the rubber sheets, which act as insulation, thereby improving the thermal management within the solar still. This enhancement allows for more efficient heat distribution and supports continuous evaporation, even when solar intensity declines. By integrating the rubber sheet, the modified SS demonstrates its potential as an effective and scalable solution for improving solar still performance, particularly in regions with high solar availability.

Conclusions

An experimental study was conducted on a single-slope solar still under the climatic conditions of Coimbatore, Tamil Nadu, India, utilizing a porous rubber sheet as an SHSM. The investigation led to the following conclusions:

-

The modified solar still, designed with a basin water mass of just 10 kg, achieved a maximum potable water yield of 0.85 kg/m2, surpassing the performance of the conventional solar still under identical conditions, which produced approximately 0.75 kg/m2. This improvement highlights the effectiveness of the modifications in enhancing water production efficiency. However, it was observed that as the basin water mass increased, the total potable water production decreased for both the modified and traditional solar stills. This decline can be attributed to the higher thermal inertia associated with larger water volumes, which require more energy to heat and maintain optimal evaporation rates. These findings emphasize the importance of maintaining lower basin water masses to maximize productivity in solar still systems.

-

The experimental analysis revealed that the daily energy efficiency of a single-slope solar still equipped with a porous rubber sheet as a sensible heat storage material was 55.6% when operating with the lowest water mass. In contrast, the conventional solar still, without the energy storage enhancement, achieved a thermal efficiency of only 41.6%, indicating a notable improvement of 33.6% with the use of the porous rubber sheet. This enhancement is attributed to the material’s ability to absorb and retain heat during peak solar radiation, which the material gradually releases to maintain consistent water evaporation rates. However, it was observed that the efficiency of the modified solar still decreased with an increase in water mass, likely due to the greater thermal inertia associated with larger water volumes, which slows the heating process. Furthermore, conventional solar still consistently exhibited lower performance than modified systems, highlighting the significant role of incorporating thermal energy storage materials like porous rubber sheets in improving overall productivity and efficiency. This study underscores the importance of material selection and water depth optimization in maximizing the thermal performance of solar desalination systems.

-

Upon examining the exergy analysis of the modified solar still, a noteworthy enhancement in the average exergy efficiency of approximately 32.4% is observed compared to the traditional solar still for the lowest water mass.

Future work

It is suggested that the use of the synergetic effect of PCM and rubber sheet as thermal energy storage could optimize the day-night efficiency. Furthermore, field testing in the coastal regions and desert climates would be recommended.

Data availability

The datasets used and/or analyzed during the current study are available from the corresponding author upon reasonable request.

References

Kumar, P. et al. Exploring the photo-thermal conversion behavior and extinction coefficient of activated carbon nanofluids for direct absorption solar collector applications. Environ. Sci. Pollut. Res. 1–13 (2022).

Saleque, A. et al. MXene/MnO2 nanocomposite coated superior salt-rejecting biodegradable luffa sponge for efficient solar steam generation. Desalination 554, 116488–116488 (2023).

Balachandran, G. et al. Investigation on the performance enhancement of single-slope solar still using green fibre insulation derived from Artocarpus heterophyllus rags reinforced with Azadirachta indica gum. Environ. Sci. Pollut. Res. 28, 32879–32890 (2021).

Sathyamurthy, R. Silver (Ag) based nanoparticles in paraffin wax as thermal energy storage for stepped solar still-An experimental approach. Sol. Energy 262, 111808–111808 (2023).

Thakur, A. K., Sathyamurthy, R. & Velraj, R. Development of candle soot dispersed phase change material for improving water generation potential of tubular solar distillation unit. Sol. Energy Mater. Sol. Cells 241, 111748–111748 (2022).

Sathyamurthy, R. Combined sensible heat and nano-enhanced latent heat energy storage for solar thermal evaporation: an experimental approach. J. Therm. Anal. Calorim. 1–15 (2023).

Sharshir, S. W. et al. Improving the solar still performance by using thermal energy storage materials: A review of recent developments. Desalin. Water Treat. 165, 1–15 (2019).

Kabeel, A. E., Arunkumar, T., Denkenberger, D. C. & Sathyamurthy, R. Performance enhancement of solar still through efficient heat exchange mechanism-a review. Appl. Therm. Eng. 114, 815–836 (2017).

Hammoodi, K. A. et al. Improving the performance of a pyramid solar still using different wick materials and reflectors in Iraq. Desalin. Water Treat. 285, 1–10 (2023).

Hammoodi, K. A., Dhahad, H. A., Alawee, W. H., Omara, Z. & Yusaf, T. Pyramid solar distillers: A comprehensive review of recent techniques. Results Eng. 18, 101157 (2023).

Shanmugan, S. et al. A technical appraisal of solar photovoltaic-integrated single slope single basin solar still for simultaneous energy and water generation. Case Stud. Therm. Eng. 54, 104032 (2024).

Alawee, W. H. et al. Effects of magnetic field on the performance of solar distillers: A review study. Eng. Technol. J. 41, 121–131 (2023).

Hammoodi, K. A., Dhahad, H. A., Alawee, W. H. & Omara, Z. A detailed review of the factors impacting pyramid type solar still performance. Alex. Eng. J. 66, 123–154 (2023).

Sathyamurthy, R. et al. Influence of high porous sponges for improving the interfacial evaporation from hemispherical solar distillers. Sci. Rep. 13, 17210–17210 (2023).

Bilal, A. & Jamil, B. Investigating the effect of pumice stones sensible heat storage on the performance of a solar still. Groundw. Sustain. Dev. 9, 100228–100228 (2019).

Sathyamurthy, R. et al. Enhancing solar still thermal performance: The role of surface coating and thermal energy storage in repurposed soda cans. J. Energy Storage 77, 109807–109807 (2024).

Kabeel, A. E. Enhancing the performance of single basin solar still using high thermal conductivity sensible storage materials. J. Clean. Prod. 183, 20–25 (2018).

Deshmukh, H. S. & Thombre, S. B. Solar distillation with single basin solar still using sensible heat storage materials. Desalination 410, 91–98 (2017).

Rajaseenivasan, T., Murugavel, K. K. & Elango, T. Performance and exergy analysis of a double-basin solar still with different materials in basin. Desalin. Water Treat. 55, 1786–1794 (2015).

Mohammed, A. H., Shmroukh, A. N., Ghazaly, N. M. & Kabeel, A. E. Performance analysis of an SPD integrated with a stepped pyramid solar still: Experimental study. Environ. Dev. Sustain. 1–20 (2024).

Mohammed, A. H., Attalla, M. & Shmroukh, A. N. Comparative study on the performance of solar still equipped with local clay as an energy storage material. Environ. Sci. Pollut. Res. 29, 74998–75012 (2022).

Mohammed, A. H., Attalla, M. & Shmroukh, A. N. Performance enhancement of single-slope solar still using phase change materials. Environ. Sci. Pollut. Res. 28, 17098–17108 (2021).

Hammoodi, K. A. et al. Experimental study on pyramid solar distiller performance with applying magnet field under various operating conditions. Energy Sources Part A Recov. Utili. Environ. Eff. 45, 11410–11423 (2023).

Basem, A., Hammoodi, K. A., Al-Tajer, A. M., Mohsen, A. & Omar, I. A numerical investigation of the increase in heat transfer in a half-cylindrical container filled with phase change copper rods. Case Stud. Therm. Eng. 40, 102512 (2022).

Abernethy, R. B., Benedict, R. P. & Dowdell, R. B. ASME measurement uncertainty. ASME J. Fluids Eng. 161–164 (1985).

El-Sebaii, A. A. Thermal performance of a triple-basin solar still. Desalination 174, 23–37 (2005).

Hepbasli, A. A key review on exergetic analysis and assessment of renewable energy resources for a sustainable future. Renew. Sustain. Energy Rev. 12, 593–661 (2008).

Petela, R. Exergy of undiluted thermal radiation. Sol. Energy 74, 469–488 (2003).

Tiwari, G. N., Dimri, V. & Chel, A. Parametric study of an active and passive solar distillation system: Energy and exergy analysis. Desalination 242, 1–18 (2009).

Dhasan, K. S., Sathyamurthy, R., Mohanasundaram, K. & Sudalaimuthu, P. Performance analysis on single slope solar still with absorber coated using iron oxide nanoparticles at different water thickness. Sol. Energy 264, 112083–112083 (2023).

Acknowledgements

The author would like to thank the Deanship of Research and Oversight Coordination (D-ROC) for providing financial assistance through project reference number EC231013. The corresponding author would also like to thank Mrs. Abarna Ravishankar and Mrs. Santharani Sathyamurthy for their moral support.

Funding

This research received no external funding.

Author information

Authors and Affiliations

Contributions

Ravishankar Sathyamurthy - conceived the experiment(s), conducted the experiment(s) and analyzed the results. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The corresponding author declares that there is no competing interest exists.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Sathyamurthy, R. Experimental analysis of solar still equipped with porous rubber sheet as energy storage material. Sci Rep 15, 8156 (2025). https://doi.org/10.1038/s41598-025-93148-5

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-93148-5

Keywords

This article is cited by

-

Artificial intelligence: a ray of hope for solar still desalination reinforcement—a review

Journal of Thermal Analysis and Calorimetry (2025)

-

Impact of surface coating on freshwater generation from solar stills: a comprehensive review

Discover Applied Sciences (2025)