Abstract

To address the issues of poor strength and low efficiency in traditional clay-cement composite gas-sealing materials (CCC), a method was proposed to prepare a new type of sealing material by utilizing multi-walled carbon nanotubes (MWCNTs) along with xanthan gum (XG) and magnesium oxide (MgO) to modify CCC. Through controlled experiments of water extraction rate testing, the optimal water-to-solid ratio for the multi-component system material has been determined to be 0.6. Mechanical performance testing reveals that when 1.5% xanthan gum, 5% magnesium oxide, and 1.39% multi-walled carbon nanotubes are added, the compressive strength of the multi-walled carbon nanotube-xanthan gum-magnesium oxide-clay-cement composite (MXM-CCC) reaches 18.60 MPa, with a flexural strength of 3.89 MPa. Pore integration analysis reveals that MXM-CCC has a porosity of 17.29%, with pore sizes ranging from 2.00 nm to 50 nm accounting for 71.46% of the total. The proportion of larger pores has decreased, resulting in a more optimal distribution of pore sizes. The formation mechanism and sealing mechanism of MXM-CCC were explored using characterization techniques such as XRD, FTIR, SEM, and thermogravimetric analysis. The hydroxyl and carboxyl groups in konjac gum undergo chelation with Ca²⁺ in CCC, forming a chelate structure. This causes the hydration products of the clay and cement to adhere together, improving the pore structure and mechanical properties of MXM-CCC. The addition of multi-walled carbon nanotubes accelerates the hydration reaction, increasing the content of substances such as C-(A)-S-H gel, ettringite, and Mg(OH)2 in the MXM-CCC. These chemicals act as a framework, providing support within the pores and inhibiting the shrinkage of MXM-CCC, and improving the adhesion between various hydration products. Additionally, multi-walled carbon nanotubes perform a nano-filling role, filling the pores and improving the density of the multi-component material, thereby enhancing its mechanical properties.

Similar content being viewed by others

Introduction

In 2023, China produced 47.1 billion tonnes of raw coal1. The expanded mining of coal has led to an increasing area of mined-out regions, a rise in the number of ventilation channels, and a larger probability of spontaneous combustion, creating safety hazards for underground workers and production equipment2. Therefore, preventing the spontaneous combustion of coal is essential to underground safety work3.

Fires caused by spontaneous combustion of coal account for over 90% of all mine fires, and the primary means of controlling these fires is to reduce or eliminate the supply of oxygen. Sealing gas leaks is a critical technology in preventing coal spontaneous combustion4,5. The spray sealing technology for gas leakage prevention is widely used in mining gob areas due to its convenient material sourcing, simple production process, lower cost, and flexibility6,7. Currently, the commonly used spraying materials of gas sealing in coal mines consist of organic and inorganic materials. The organic spraying materials of gas sealing primarily include phenolic foam, urea-formaldehyde foam, and polyurethane foam8. Yu et al.9 used phenol, urea, and paraformaldehyde as raw materials, curing agent, surfactant, and foaming agent as additives, and polyvinyl alcohol (PVA) and cashew nut shell oil as toughening agents into the resin to produce a novel polyurethane foam (PUF). This foam exhibited several advantages in terms of expansion performance, dimensional stability, compressive strength, and construction safety. Xi et al.10 studied the surfactants’ effects on the performance of composite foam slurry for mine sealing (CFSM). The foam gel sealing material developed can effectively prevent the spontaneous combustion of coal. Dong et al.11 found that urethane-modified phenolic foam (PF) could effectively reduce CO concentration and provide good sealing for gas leaks. Organic spraying materials of gas sealing are characterized by simple application, high expansion rates, good adhesion, and effective sealing. However, due to the flammable nature of some varieties and cost limitations, their more comprehensive application is challenging.

Inorganic spraying materials of gas sealing mainly include various modified cement mortar and composite slurry spraying materials of gas sealing. Xi et al.12 developed a new form of cement-based foam material (CBFM) with good sealing properties and impact resistance by selecting different types of surfactants and organic polymer (OP). Xue et al.13 synthesized a Janus-type composite solidify foam (JCSF) using non-combustible inorganic materials such as cement and fly ash as the matrix, with organic materials serving as the reinforcing component. The foam exhibited high sealing efficiency and excellent fire prevention and extinguishing performance. Li et al.14 used ordinary Portland cement as the base material and modified it with fly ash and other additives to develop a novel underground sealing material that had good rheological properties. Zhang et al.15 have developed a new spray sealing material by mixing cement with fly ash, silica fume, sand, water, and polypropylene fiber as spraying additives in appropriate proportions. Han et al.16 analyzed the characteristics of modified cement mortar spraying materials of gas sealing, exploring the effects of powder additives, water-reducing agents, and quick-setting agents through experimentation. He et al.17 conducted a study on the microstructural characteristics of hydrated clay-cement slurry, discovering that a significant amount of clay-cement gel clusters and C-S-H gel formed during the hydration of the clay-cement slurry. The clay-cement gel clusters were adsorbed onto each other and linked together, while C-S-H filled the gaps and connected to form a network.

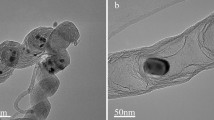

Researchers have found that clay-cement-based mortar spraying materials are inexpensive and offer relatively excellent performance. However, most modified cement mortar spraying materials of gas sealing have problems such as excessive additives, complex production processes, long setting times, easy detachment, shrinkage and cracking after setting, which are not conducive to sealing gas leakage channels18,19. Therefore, enhancing the mechanical properties and crack resistance of clay-cement-based materials is crucial for optimizing spray sealing materials. Li et al.20 found that Xanthan gum could serve as a dispersing agent for cement hydration products, increasing the resistance of sodium silicate to dynamic dispersion. Cao et al.21 used magnesium oxide as a concrete expansion agent to reduce the water demand for concrete. The new material was stable in expansion and met the expected assumptions. Zhang et al.22 proposed using xanthan gum an magnesium oxide modification to prepare a new clay-cement-based spray sealing material. The new material exhibited strong stability and reduced porosity. Shi et al.23 utilized multi-walled carbon nanotubes, which were incorporated into a cement matrix after ultrasonic dispersion for modification purposes. Liu et al.24 used nanoindentation techniques to analyze the mechanical properties of cement-based materials containing multi-walled carbon nanotubes at the nanoscale. Liu et al.25 found that incorporating 0.06% graphene resulted in a certain improvement in the compressive and flexural strengths of cement-based materials. Wang et al.26 found that incorporating carbon nanotubes helped reduce the total porosity within cement-based materials. Liao et al.27 employed a chemical co-deposition method to prepare magnesium oxide-coated carbon nanotube samples, concluding that there was good interfacial compatibility between the magnesium oxide nanoparticles and the carbon nanotubes.

In summary, existing organic solidified foams generally have low durability, crumbling tendency, and high cost, making them unsuitable for large-scale application. Although modified cement mortar materials are more suitable for mass application, they suffer from poor adhesion and low strength, and tend to crack, creating gas leakage channels. Xanthan gum (XG) and magnesium oxide (MgO) can improve the pore structure of the material, enhancing its toughness and strength. Multi-walled carbon nanotubes (MWCNTs) contribute to the mechanical properties of cement mortar and exhibit good interfacial compatibility with MgO. As a result, this study utilizes MWCNTs, along with MgO and XG, to modify clay-cement-based composites (CCC). Through controlled experiments, samples were prepared with varying mass fractions of MWCNTs. Various properties of the samples were analyzed, enabling the selection of a sample that exhibits excellent mechanical performance, high strength, and good durability as a novel spray sealing material, namely, multi-walled carbon nanotubes-xanthan gum-magnesium oxide-clay-cement composite sealing materials (MXM-CCC).

Experimental materials and methods

Experimental materials

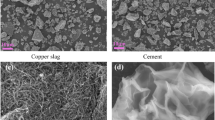

Cement (PO42.5), clay (kaolin, natural moisture content of 3%), MgO (analytical grade, calcined), XG (11138-66-2, McLean), sodium silicate (analytical grade), defoamer (organic silicon defoamer) and MWCNTs (carboxylated, industrial grade) were used in this study. Properties of experimental materials are shown in Table 1.

Experimental methods

Referring to the literature [22] for the optimization of clay to cement ratio and water-solid ratio, several groups of CCC samples were prepared, and the water-solid ratios were selected as 0.6, 1.0, and 1.5, and the clay accounted for 0, 10%, 20%, 30%, and 40% of the mass of the cement, respectively, in order to determine the water-solid ratios and the clay to cement ratios. The specific ratios are shown in Table 2.

Water separation rate test of the slurry

After mixing the slurry of clay and cement with water, it was poured into a 50mL test tube, and the initial height of the suspended liquid h0 was recorded. After 2 h, the height of the suspended liquid h1 was measured. The water separation rate of the slurry was calculated using Eq. (1)28. The water separation rate under each water-to-solid ratio are shown in Fig. 1.

Figure 1 shows that as the mass ratio of clay to cement increases, the water separation rate from the slurry decreases under all water-to-solid ratios. However, it is evident that, at a constant mass ratio, increasing the water-to-solid ratio leads to a gradual rise in the water separation rate, which becomes significantly apparent when the water-to-solid ratio exceeds 1. When the solid-to-water ratio is 0.6, and the mass ratio of clay to cement is 0.2, the water separation rate of the slurry after 2 h can drop to below 5%.

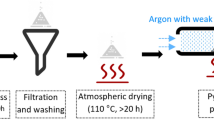

On the basis of the experiments in Table 2, combined with the analysis of water precipitation rate, a water-solid ratio of 0.6 and a clay to cement ratio of 0.2 were selected. Referring to the literature22, the CCC system was supplemented with XG accounting for 0% (0 g), 0.5% (4.5 g), 1% (9 g), and 1.5% (13.5 g) of the mass of the cement, and with 0% (0 g), 2.5% (22.5 g), 5% (45 g), 7.5% (67.5 g) and 7.5% (67.5 g) of MgO, assisted by the addition of sodium silicate and defoamer for the experiment, in order to determine the optimum mixing ratio in the CCC system. The specific design is shown in Table 3.

Mechanical performance analysis

According to GB /T 17,671—1999, after curing the specimens under standard conditions for 7 days, their mechanical properties were assessed using an electronic universal testing machine. Each group of specimens was tested three times, and the flexural and compressive strengths were calculated using Eqs. (2) and (3), respectively, and the average values were taken29.

In the formula, Rf represents the flexural strength, Ff denotes the flexural failure load, L indicates the distance between supporting cylinders, b refers to the edge length of the square cross-section of the prism, Rc signifies the compressive strength, Fc represents the compressive failure load and A denotes the area of the compressed section.

From Figs. 2 and 3, it can be observed that in the XG/MgO composite system, XG has a significant impact on the compressive strength of CCC, whereas MgO greatly influences its flexural strength. When the MgO content is 5% (45 g) and the XG content is 1.5% (13.5 g), the compressive strength reaches 14.60 MPa, and the flexural strength reaches 2.80 MPa.

Combined with the results of mechanical property analysis, 1.5% XG and 5% MgO were selected as the experimental groups in Table 3, and MWCNTs accounting for 0% (0 g), 0.56% (5 g), 1.11% (10 g), 1.67% (15 g), and 2.22% (20 g) of the mass of cement were added, respectively. This is used to preliminarily determine the reasonable range of MWCNTs, as shown in Table 4.

In order to find out the doping amount of MWCNTs at the optimum mechanical properties of the samples, referring to the literature [22], the dosages of XG, MgO and MWCNTS were redesigned based on Table 4. The design is shown in Table 5.

Figures 4 and 5 indicate that the addition of MWCNTs enhances both the compressive and flexural strengths of the XG-MgO-CCC material. As more MWCNTs are added, the compressive and flexural strengths increase first and then decrease, attributed to excessive MWCNTs causing agglomeration within the material. When the MWCNTs content is 10 g, both strengths are maximized. Consequently, the MWCNTs/XG/MgO composite system is further refined, achieving maximum compressive strength of 18.60 MPa and flexural strength of 3.89 MPa when XG is 13.5 g (1.5%), MgO is 45 g (5%), and MWCNTs are 12.5 g (1.39%).

Microstructure analysis

This study focuses on the compressive and flexural strengths as well as the pore properties of the materials. The compressive and flexural strengths of the samples with 1.39% of multi-walled carbon nanotubes (MWCNTs) were optimal among the tested samples, so the experimental group with 1.39% of MWCNTs was selected microanalysis (Pore Structure Analysis, XRD, SEM, FTIR) to investigate the micro-mechanism. At the same time, to verify the effect of the addition of MWCNTs, a control group with 0% MWCNTs was selected for simultaneous analysis.

Pore structure analysis

Based on the mechanical performance analysis results of each sample group, 1.39% MWCNTs from the superior performance group and 0% MWCNTs from the sample group were selected. A liquid nitrogen adsorption test was conducted using specific surface area and pore size analyzers to obtain the pore structure parameters for both sample groups, as shown in Tables 6 and 7.

From Tables 6 and 7, it can be observed that in the 0% MWCNTs sample group, the proportion of pore sizes between 2.00 nm and 10.00 nm is 16.89%. In comparison, the proportion of pore sizes between 10.00 nm and 50.00 nm is 47.42%, and the proportion for pore sizes larger than 50.00 nm is 35.69%, resulting in a porosity of 19.12%. In the 1.39% MWCNTs sample group, the proportion of pore sizes between 2.00 nm and 10.00 nm increases to 18.2%, the proportion between 10.00 nm and 50.00 nm rises to 53.26%, and the proportion larger than 50.00 nm decreases to 28.54%, with a porosity of 17.29%. Compared to the 0% MWCNTs sample group, the sample group with added MWCNTs has a lower porosity, a reduced proportion of larger pores, and a more favorable pore size distribution.

XRD analysis

X-ray diffraction (XRD) analysis was conducted on the sample group with 1.39% MWCNTs, and the sample group with 0% MWCNTs. The XRD spectra are presented in Fig. 6.

The diffraction peaks of both sample groups clearly correspond to phases including quartz, CaCO3, Mg(OH)2, and MgO, as shown in Fig. 6. However, compared to the 0% MWCNTs sample group, the diffraction peak of quartz in the 1.39% MWCNTs sample group decreases, while the peak for CaCO3 increases and sharpens. It indicates a reduction in the content of quartz and a significant increase in the content of CaCO3, which also has a higher crystallinity. The diffraction peaks of MgO and Mg(OH)2 are clearly visible in both sample groups, however, the 1.39% MWCNTs sample group contains lower levels of MgO and higher levels of Mg(OH)2. Therefore, it can be concluded that incorporating MWCNTs significantly facilitates the reactions between various raw materials, leading to more complete transformations.

FTIR analysis

Fourier-transform infrared spectroscopy (FTIR) was used to analyze the mechanical properties of the sample group with 1.39% MWCNTs and the sample group with 0% MWCNTs. The results are shown in Fig. 7.

As shown in Fig. 7, the FTIR spectra of the 0% MWCNTs sample group and the 1.39% MWCNTs sample group do not exhibit significant differences in peak values. Characteristic peaks for carbon compounds were not detected, indicating that MWCNTs did not undergo other chemical reactions that would compromise the structure of the original XG-MgO-CCC material. The absorption peak at 3469 cm− 1 corresponds to the stretching vibration of –OH, the peak at 1650 cm− 1 is associated with the O–H stretching vibration in H2O, the absorption peak at 1456 cm− 1 relates to the Ca–O stretching vibration, and the peak at 544 cm− 1 represents the Mg–O stretching vibrations in MgO and Mg(OH)2. Figure 7 shows that the –OH stretching vibration peak in the 1.39% MWCNTs sample group intensifies while the O–H stretching vibration peak diminishes, alongside a reduction in the Ca–O stretching vibration peak. It suggests that the reaction involving the raw materials in the new material is more thorough, leading to an increased content of products such as Mg(OH)2 and ettringite, consistent with the observations made in the XRD analysis.

Thermogravimetric analysis

Thermogravimetric tests were conducted on the 1.39% MWCNTs sample group with excellent mechanical properties and the 0% MWCNTs sample group using a simultaneous thermal analyzer, as illustrated in Figs. 8 and 9.

Both groups of samples underwent continuous mass loss over the temperature range of 0–700 ℃. From Fig. 8, the 0% MWCNTs samples exhibited three primary weight loss ranges. In the TG curve, the first range from 50 to 180 ℃ with a mass loss of 4.24%, a large mass loss occurred in a short period ot time, and the corresponding DTG curve had a sharp peak and a relatively large peak area. The second range of the TG curve was slowly decreasing from 380℃ to 480℃ with a mass loss of 1.08%, and the corresponding DTG curve was relatively flat. The third range was from 500℃ to 700℃ with a mass loss of 1.98%, and the corresponding DTG curve had a small peak. As seen in Fig. 9, the 1.39% MWCNTs samples revealed three major weight loss ranges. A mass loss of 7.33% from 50℃ to 180℃, and the DTG curve had the largest peak and an inflection point, corresponding to the speed of mass loss from fast to slow. The mass loss from 380℃ to 480℃ was 0.53%. The mass loss from 500℃ to 700℃ was 1.77%, showed a peak in the DTG curve, and the rate of the variation was larger than that in the temperature range of 380℃ to 480℃. Considering the weight loss across these ranges, the first range corresponds to the loss of bound water in the hydrated products C-(A)-S-H, the second range primarily involves the decomposition of Ca(OH)2 and Mg(OH)2, while the third range is mainly due to the decomposition of carbonates present in the samples.

Microstructural analysis

Microstructural analysis of the 1.39% MWCNTs sample group was conducted using a scanning electron microscope, as depicted in Fig. 10.

As shown in Fig. 10a and b, layered hydrated calcium oxide and needle-like ettringite can be observed. Figure 10c and d reveal flaky magnesium hydroxide and needle-like ettringite, which provide significant structural support, effectively suppressing the shrinkage of the MXM-CCC and enhancing the stability of the matrix structure. As illustrated in Fig. 10e and f, a network and honeycomb structure of C-(A)-S-H gel can be seen, with a large amount of gel encapsulating substances such as magnesium hydroxide and ettringite. This gel exhibits excellent binding properties, reinforcing the connectivity between materials, resulting in an enhanced pore structure, greater density, and overall integrity of the new material. As shown in Fig. 10g and h, it can be found that compared to the experimental groups, the control group has more pronounced pores in the cementitious materials with more connectivity, resulting in a less dense structure. Therefore, the compressive and flexural strengths of the control group are lower than those of the experimental group.

Formation mechanism of materials

The formation mechanism of MXM-CCC is illustrated in Fig. 11. Combined with the results of XRD, FTIR, SEM and TG-DTG analysis, it is known that the raw materials contained CaCO3, Mg(OH)2, and MgO. After the hydration reaction started, MgO and Ca-containing substances in the MXM-CCC complex group underwent a hydrolysis reaction in the reaction system to form Mg2+, Ca2+. The remaining raw materials formed various ingredients such as -OH, -COOH, etc22. After the beginning of the hydration reaction, the products of gel C-S-H, C-A-S-H gradually increased. In particular, the addition of MWCNTs further promoted the hydration reaction, the pore size decreased significantly, the pore connectivity weakened, and the microstructure denser, which increased the compressive and flexural strength of the samples to some extent30,31,32,33. Through the mass loss in the three temperature ranges of the TG-DTG curves, it can also be revealed that the addition of MWCNTs, which promotes the hydration reaction, increased the gel material and significantly improved the mechanical properties34,35.

Conclusion

In this paper, MWCNTs, supplemented by MgO and XG, were utilized to modify CCC. Based on the experimental results, the following conclusions can be made:

-

(1)

Analysis of the compressive and flexural strengths of various sample groups shows that XG has a significant effect on the compressive strength of the material, while MgO provides a certain enhancement to the flexural strength. When the MgO content is 5%, and the XG content is 1.5%, the compressive strength reaches 14.60 MPa, and the flexural strength reaches 2.80 MPa. The addition of MWCNTs to the XG-MgO-CCC material significantly improves both compressive and flexural strengths. When the MWCNTs content is 1.39%, the 7-day compressive strength of MXM-CCC reaches 18.60 MPa, and the flexural strength reaches 3.89 MPa.

-

(2)

Combining pore structure and micromorphology analysis, the proportion of pore sizes in MXM-CCC within the range of 2.00 nm to 10.00 nm is 18.2%, while that of pore sizes between 10.00 nm and 50.00 nm is 53.26%, and for pore sizes greater than 50.00 nm, it accounts for 28.54%. The porosity is measured at 17.29%. According to thermogravimetric analysis, the new material shows an increased formation of ettringite and calcium silicate hydrate, with the addition of MWCNTs significantly enhancing the hydration reaction of the material, resulting in a more thorough reaction.

-

(3)

The characterization results of MXM-CCC indicate that the incorporation of MWCNTs facilitates the progress of the hydration reaction, acting as a “bridge” that connects hydration products and performs its role as a nano-filler, further optimizing the pore size of MXM-CCC. The addition of XG encourages the formation of dense chelates of Ca2+ within MXM-CCC, filling in some of the larger pores and connecting clay surface particles with hydration products. The hydration reaction of MgO produces Mg(OH)2 crystals that fill the pores within the material. Consequently, MXM-CCC exhibits reduced porosity and a more excellent pore size distribution, resulting in a denser material structure and superior mechanical properties.

Data availability

All data generated or analysed during this study are included in this published article.

References

National Bureau of Statistics. Energy production situation in December 2022. http://www.stats.gov.cn/sj/zxfb/202302/t20230203_1901714.html, 2023-01-17.

Xu, Y. et al. Potential coupled harzard zone of coal spontaneous combustion and gas in goaf under mining condition. J. China Coal Soc. 44(S2), 585–592. https://doi.org/10.13225/j.cnki.jccs.2019.0596 (2019).

Wang, Z. Research on ventilation mode selection and fire prevention and extinguishing technology of 52305 working face with gob-side entry retaining in Yujialiang Coal Mine. China Coal 49(S2), 140–144. https://doi.org/10.19880/j.cnki.ccm.2023.S2.023 (2023).

Zhang, J. et al. Experimental study and application of new polymer foam plugging material. J. China Coal Soc. 43(S1), 158–166. https://doi.org/10.13225/j.cnki.jccs.2017.1367 (2018).

Kai, C. A. O. Research on fire area management technology in fully mechanized top coal backout caving face. Coal Technol. 39(11), 109–111. https://doi.org/10.13301/j.cnki.ct.2020.11.031 (2020).

Jinlin, Q. I. A. O. et al. Study on sealing performance of mine polymer plastic sealing material. China Coal 48(11), 34–40. https://doi.org/10.19880/j.cnki.ccm.2022.11.006 (2022).

Bin, X. U. et al. Stability of cement-based grouting slurry and test of its bleeding law. Coal Geol. Explor. 47(5), 24–31. https://doi.org/10.3969/j.issn.1001-1986.2019.05.004 (2019).

Liang, Z. et al. Development and application of ordinary portland sulphoaluminate cement composite thin spray material. China Min. Magaz. 32(7), 158–164. https://doi.org/10.12075/j.issn.1004-4051.20220893 (2023).

Yu, Chuang. Study on the preparation and characteristics of new mine leak-sealing materials. Taiyuan University of Technology. (2021). https://doi.org/10.27352/d.cnki.gylgu.2020.000950.

Xi, X. & Tao, Y. F. Study on the formation mechanism and mechanical properties of composite foam slurry material for mine plugging. Energy https://doi.org/10.1016/j.energy.2023.128295 (2023).

Dong, H. & Hu, X. M. Study of preparation and properties of environmentally friendly phenolic resin for mining. J. Appl. Polym. Sci. 140 (23). https://doi.org/10.1002/app.53932 (2023).

Xi, X. & Jiang, S. Experimental investigation on cement-based foam developed to prevent spontaneous combustion of coal by plugging air leakage. Fuel https://doi.org/10.1016/J.FUEL.2021.121091 (2021).

Xue, D. & Hu, X. M. A study on a Janus-type composite solidified foam and its characteristics for preventing and controlling spontaneous combustion of coal. Energy https://doi.org/10.1016/j.energy.2023.127433 (2023).

Li, R. Study on preparation and properties of cement-fly ash composite materials for leakage blocking in mine. China University of Mining and Technology. https://doi.org/10.27623/d.cnki.gzkyu.2021.001791. (2022).

Zhang, X. Experimental study on the properties of composite toughened air leakage plugging materials. Taiyuan University of Technology. https://doi.org/10.27352/d.cnki.gylgu.2022.002232. (2022).

Han, J., Wang, F. & Yu, C. Study on characteristics of new modified cement mortar spraying material. China Min. Magaz. 30(09), 114–119. https://doi.org/10.12075/j.issn.1004-4051.2021.09.010 (2021).

He, X., Pu, Z. & Duan, D. Microscopic characteristics of hydration and consolidation ofday cement slurry. J. Xi’an Univ. Sci. Technol. 43(6), 1168–1175. https://doi.org/10.13800/j.cnki.xakjdxxb.2023.0615 (2023).

Zhang, C. et al. Clay dosage and water/cement ratio of clay-cement grout for optimal engineering performance. Appl. Clay Sci. 163, 312–318. https://doi.org/10.1016/j.clay.2018.07.035 (2018).

Lei, X., Song, H. & Li, H et al. Influence of different chemical activators on CFB ultrafine fly ash based spraying materials. Fly Ash Comprehen. Util. (6), 13–17,27. https://doi.org/10.3969/j.issn.1005-8249.2018.06.004.

Li, Z.-F. et al. Experimental study of water-soluble vegetable gum-modified cement-sodium silicate plugging materials. Chin. J. Geotech. Eng. 42(7), 1312–1321. https://doi.org/10.11779/CJGE202007015 (2020).

Fengze, C. A. O. & Peiyu, Y. A. N. Effect of water-binder ratio on hydration degree and expansive characteristics of magnesium oxide expansive agents. J. Chin. Ceramic Soc. 47(2), 171–177. https://doi.org/10.14062/j.issn.0454-5648.2019.02.03 (2019).

Hang, H. et al. Preparation and characteristics of xanthan gum and MgO modified clay-cement based new spraying material of gas sealing. J. China Coal Soc. 46(06), 1768–1780. https://doi.org/10.13225/j.cnki.jccs.hz21.0181 (2021).

Tao, S. H. I., Zexin, L. I. & Shanshan, L. I. Autogenous shrinkage and crack resistance of carbon nanotubes reinforced cement based composites. Acta Mater. Compos. Sinica 36(06), 1528–1535. https://doi.org/10.13801/j.cnki.fhclxb.20181210.002 (2019).

Liu, Q. et al. Nanomechanical properties of multi-wall carbon nanotubes/cementitious composites. Acta Mater. Compos. Sinica 37(04), 952–961. https://doi.org/10.13801/j.cnki.fhclxb.20190730.004 (2020).

Liu, Y. et al. Mechanical and shrinkage resistance of graphene-modified cement-based materials. J. Mater. Sci. Eng. 40(01), 28–33. https://doi.org/10.14136/j.cnki.issn1673-2812.2022.01.005 (2022).

Wang, X. & Feng, D. Research progress on carbon nanomaterials modified cementitious composites. Mater. Rep. 2023(21):1-29[2023-05-12]. http://kns.cnki.net/kcms/detail/50.1078.TB.20221130.1558.009.html.

Liao, L. et al. Stability of interface between MgO and carbon nanotubes. J. Aeronaut. Mater. 41(05), 94–102. https://doi.org/10.11868/j.issn.1005-5053.2021.000069 (2021).

Liu, W., Wu, H., & Shen, J. Based on box-behnken method superfine cement grouting material ratio andperformance optimization model. Coal Sci. Technol. 1–13. http://kns.cnki.net/kcms/detail/11.2402.TD.20240228.1131.008.html. (2024).

Li, Shuangchen. Study on mechanical properties and apparent characterization of road concrete using drilling solid waste. Northeast Petroleum University. https://doi.org/10.26995/d.cnki.gdqsc.2023.000685. (2023).

Wang, Y. G. Micro structure evolution and composite synergistic effect of new cementitious materials of red mud, fly ash and desulfurization gypsum. University of Science &Technology Beijing, (2022).

Tang, W. C., Wang, Z., Donne, S. W., Forghani, M. & Liu, Y. Influence of red mud on mechanical and durability performance of self-compacting concrete. J. Hazard. Mater. 379 12802. https://doi.org/10.1016/j.jhazmat.2019.120802.

Alkali activation of blast furnace slag using Bayer red mud as an alternative activator to prepare cemented paste backfill. Constr. Build. Mater. https://doi.org/10.1016/j.conbuildmat.2024.139061.

An, Q., Pan, H., Zhao, Q. & Wang, D. Strength development and microstructure of sustainable geopolymers made from alkali-activated ground granulated blast furnace slag, calcium carbide residue, and red mud. Constr. Build. Mater. 356, 129279. https://doi.org/10.1016/j.conbuildmat.2022.129279 (2022).

Liu, J., Li, X., Lu, Y., Bai, X. Effects of Na/Al ratio on mechanical properties and microstructure of red mud-coal metakaolin geopolymer. Constr. Build. Mater. 263 (2020). https://doi.org/10.1016/j.conbuildmat.2020.120653.)

Hu, W., Nie, Q., Huang, B., Shu, X. & He, Q. Mechanical and microstructural characterization of geopolymers derived from red mud and fly ashes. J. Cleaner Prod. 186, 799–806. https://doi.org/10.1016/j.jclepro.2018.03.086 (2018).

Author information

Authors and Affiliations

Contributions

M.F. and M.W. wrote the main manuscript text and H.Z. prepared figures . L.C translated the entire text. All authors reviewed the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Fu, M., Wang, M., Qin, X. et al. Research on the performance of MXMCCC materials for gas leakage sealing. Sci Rep 15, 9561 (2025). https://doi.org/10.1038/s41598-025-94048-4

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-94048-4