Abstract

This study explores the innovative use of polymer plate anchors in geotechnical engineering, addressing some of the limitations of traditional steel plate anchors. We investigated the performance of polymer vertical anchor plates in multi-layered cohesionless soils, focusing on the pullout capacity under various conditions. The research evaluated the effects of soil density, number of layers, and anchor embedment depth on the pullout performance. Experiments were conducted in a container filled with sand at two different densities (dense and loose) up to a height of 80 cm. A total of 12 tests were performed with varying embedment depths. Results indicated that increasing the distance of the polymer anchor from the soil wall significantly enhanced the pullout force, with a threefold increase observed at greater depths. The study concludes that soil parameters and anchor embedment geometry are critical factors influencing the pullout behavior of polymer anchors, highlighting the potential of polymer materials in anchor plate design.

Similar content being viewed by others

Introduction

It’s becoming increasingly clear that the environmental impact of waste disposal, particularly plastic waste, is a pressing issue that cannot be ignored. As a result, many scientists are now exploring ways to recycle and reuse waste in various fields. In the construction industry, researchers have been working to reduce environmental pollution by using recycled materials in different sectors, especially in concrete production1. However, while there have been significant improvements in this area, there has been little exploration of the potential for using recycled materials in other sub-branches of civil engineering, such as geotechnical engineering. Using recycled materials in areas like soil stabilization, piles, shields, and anchors could go a long way in preventing pollution caused by the disposal of these materials in the environment2,3.

Literature review

Engineers have been using vertical plate anchors for a long time to strengthen geotechnical structures. These anchors are usually made of steel, concrete, or wood and have different shapes, such as rectangular, square, or circular, depending on the site of application. The main purpose of these anchors is to resist the lateral movement of soil and the horizontal tensile force on structures such as retaining walls, bridge supports, and piles. The pullout capacity of these anchors is crucial for the overall performance of the structures they reinforce4,5. Much research has been done on the pullout capacity of these anchors, considering various factors that can affect it, such as the shape of the anchor, the type of soil, and the embedment depth.

A study by Choudhary and Dash explored the behavior of vertical plate anchors in granular soil. Their findings showed that the load-carrying capacity and failure displacement of the anchor depend on the embedment depth and soil density. The study also emphasized that increasing the embedment depth can change the failure mechanism from the general state to the localized failure around the anchor6. Similar results were obtained by Das et al. (1977)7 and Dickin and Leung (1985)8 in their respective studies. Studies on horizontal anchors, such as those by Kumar (2003) and Bhattacharya and Kumar (2015, 2016), emphasizing the unique challenges and advantages of vertical anchors in layered soils9,10,11,12. Bhattacharya and Kumar (2011) investigated the horizontal pullout capacity of vertical strip anchors in sand, highlighting the influence of vertical spacing between anchors13. Bhattacharya and Kumar (2014) examined the vertical pullout capacity of horizontal anchor plates under seismic and seepage forces, providing insights into the complex interactions in such conditions14. Bhattacharya and Roy (2016) explored the variation of horizontal pullout capacity with the width of vertical anchor plates, emphasizing the impact of anchor dimensions on performance12. Giampa et al. (2016) studied the effect of shape on the pullout capacity of shallow plate anchors in sand, offering valuable data on how different anchor geometries affect pullout resistance15. These studies collectively enhance the understanding of vertical anchor plate behavior in various soil conditions and loading scenarios.

Moreover, Yue et al. found in their research that the anchor embedment ratio has a significant role in the anchor load-carrying capacity under lateral loading in the sand. Their study concluded that increasing the anchor embedment depth can increase the anchor’s load-carrying capacity16. Overall, previous studies on the pullout capacity of vertical plate anchors have suggested a direct relationship between the failure surface and the embedment depth. Shallow anchors, due to general shear failure, have a failure surface that reaches the soil surface, while deeper anchors with increased embedment depth lead to local failure around the anchor17,18,19,20,21,22.

The challenge of finding homogeneous soil in nature necessitates the investigation of vertical plate anchors in multi-layered soils. Previous studies have extensively explored the behavior of vertical plate anchors in homogeneous soils, providing valuable insights into their load-carrying capacity and failure mechanisms4,5. However, these studies often do not account for the complexities of real-world soil conditions, which are rarely uniform.

Choudhary and Dash (2018) highlighted the influence of embedment depth and soil density on the performance of vertical plate anchors in granular soils, emphasizing the need for more nuanced studies that consider varying soil layers6. Similarly, Yue (2020)16 demonstrated the significant role of anchor embedment ratio in load-carrying capacity under lateral loading, suggesting that deeper anchors in layered soils might exhibit different failure mechanisms compared to those in homogeneous soils.

Despite these advancements, there remains a gap in understanding the behavior of vertical plate anchors in multi-layered cohesionless soils, particularly when using alternative materials such as polymers. Polymeric anchors offer several advantages over traditional metallic or concrete anchors, including resistance to corrosion, flexibility, and potentially lower weight. These properties could lead to different performance characteristics, especially in multi-layered cohesionless soils where the interaction between the anchor and the soil layers can be more complex.

This research aims to fill this gap by evaluating the performance of vertical polymer anchors in double-layer sand. This study seeks to provide a more comprehensive understanding of how polymeric anchors behave in diverse geotechnical applications. The goal is to determine whether polymeric anchors can offer a viable and potentially superior alternative to conventional materials in terms of load-carrying capacity, failure mechanisms, and overall effectiveness in multi-layered cohesionless soils.

Materials and methods

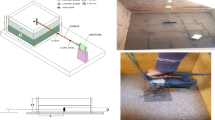

Figure 1 shows the schematic shape of the instrument used to study the pullout behavior of horizontal anchors. This instrument consisted of a wooden box, a loading system, a monitoring system, and a plate anchor. The built wooden box had dimensions of 1 × 1 × 1 m, secured with steel corners around the box. The box’s dimensions matched those chosen by other researchers and the ASTM D6706-1 (2013) standard23,24. To avoid the effect of the sample’s dimensions on the test results, the test box’s dimensions should not be smaller than 610 × 460 × 610 mm25,26. According to this standard, the minimum width of the recommended box is twenty times the diameter of 85 mm or six times the largest diameter of the soil aggregate. To eliminate friction between the soil and the box wall, the minimum distance between the anchor and the wall should be 150 mm. If this distance is not met, it is necessary to reduce the friction between the box and the soil by lubricating the box wall or using appropriate covers23,24. In most research on the physical modeling of anchors, the minimum dimensions of the model are considered one-tenth of the actual dimensions to minimize the effects of boundary conditions on the results. Therefore, it can be said that the dimensions selected in this research are fully consistent with real conditions27 (Moghadam et al. 2018).

The loading system consists of a winch motor, which connects to a plate anchor using a steel cable with a diameter of 10 mm, and applies the pullout force to the anchor. The monitoring system includes a load cell and a linear variable displacement transducer (LVDT) to measure force and displacement, respectively. The load cell is an S-shaped tool with a capacity of 2 tons, and the LVDT can measure with an accuracy of 0.1 mm. A digital data logger was used in this research to record and collect the force and displacement data from the experiments. The data logger is a 24-bit Advantech 4704 type with a sampling rate of 1000 samples per second, which has a sensor and stores the measured data in its internal memory. The data is connected to the computer through the USB interface. Moreover, strain gauges with an accuracy of 0.03 mm were used to evaluate the soil surface deformations when applying pullout force. To account for the soil heterogeneity in nature, an attempt was made to use two-layer soil with different relative densities. For this purpose, the first and second layers were prepared using dense and loose sands, respectively. The ASTM D4253 (2006) standard was used to make the dense layer23,24. The sand was poured into the box in four stages, each of which was compacted using an electric vibrating compactor to prepare a dense layer with a height of 40 cm and a relative density of 95%. The loose layer (Dr < 35%) was placed on the dense layer in four stages to a total height of 40 cm, so that the sample’s total height reached 80 cm. To prepare a loose layer, sand was poured from a very close height to avoid compaction due to the soil’s weight. The sand used in this research was river sand, with a grain size distribution between 0.075 and 4.75 mm (according to the grain size analysis test), and D10 = 0.42 mm, D60 = 2.1 mm, and D30 = 2.1 mm. Figure 2 shows the gradation diagram of sand. As observed, the uniformity coefficient (Cu) and coefficient of curvature (Cc) are 5 and 2.25, respectively. The internal friction angle (ϕ) of loose sand is approximately 32°, and for dense sand, it is approximately 38°.

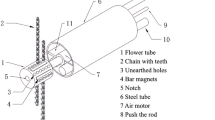

In this research, polymer plate anchors with equal dimensions of 150 × 50 × 8 mm were used. Figure 3 shows a schematic of the polymer plate anchors. The polymer plate anchors were fabricated from Polycaprolactone (PCL), which is a synthetic, semi-crystalline, biodegradable polyester. The anchor plates were fabricated with a smooth surface, similar to that of steel plates. This smooth surface was chosen to ensure consistency in the comparison of performance characteristics between polymeric and traditional steel anchors. It has a bending strength of approximately 10–15 MPa and a tensile strength of around 21–23 MPa. The modulus of elasticity (Young’s Modulus) for PCL typically ranges from 0.21 to 0.44 GPa, and it has a Poisson’s ratio of approximately 0.40. These characteristics make PCL suitable for applications requiring flexibility, strength, and biodegradability. To evaluate the effect of the depth and height of the anchor embedment in the soil, the anchors were placed at three different depths and three different heights in the soil. Since the embankment process is related to the plate anchor embedment process, these anchors were installed inside the box during the embankment so that the anchors were placed at the predetermined embedment depths and then the embankment process continued. Due to the sensitivity of loading and the effect of changes in the load direction angle on the anchor pullout force, any eccentricity in relation to the loading direction was checked during the embedding of the anchor and before continuing the embankment process, and the anchor was installed vertically without any angle in the center of the loading area in the soil. Furthermore, the anchors were installed at four depths of 150, 300, 450, and 600 mm from the box side wall and at three heights of 200, 400, and 600 mm from the soil surface, which were the middle of the loose layer, the border of the loose and dense layer, and the middle of the dense layer, respectively. Therefore, the effect of the distance of the anchor from the wall and the ground surface and the change in soil density on the anchor pullout force could be evaluated.

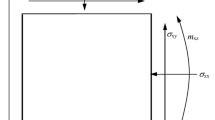

The anchor pullout operation was performed by a winch motor that could adjust the loading speed. After the anchor was installed and embedded at the expected depth, it was connected to a load cell by a hook. Then, the anchor was loaded at an average speed of 15 mm/min, and the load and displacement were recorded by a displacement gauge and a load cell. Additionally, a series of strain gauges were installed on the samples’ finished surface to evaluate the soil surface displacements when applying pullout force. This study aimed to evaluate the pullout capacity of polymer plate anchors in different states. Moreover, the changes in the anchors’ pullout force coefficients were studied as an important parameter in the anchors’ pullout topic. The pullout force coefficient of plate anchors was obtained using the theory of Neely et al., which was presented in 1973 for single vertical anchors under horizontal force4. Equation 1 shows how to calculate the pullout force coefficient of horizontal plate anchors.

\({M_{\gamma q}}=\frac{{{Q_u}}}{{\gamma B{h^2}}}\)

where Mγq represents the pullout force coefficient, Qu indicates the ultimate pullout load, γ shows the unit weight of the soil, B is the width of the anchor, and h is the height of the anchor. No deflection or bending was observed in the polymer anchor plates during our experiments. This observation is crucial as it indicates the mechanical stability and robustness of the polymeric anchors under the applied loads. The absence of deflection or bending suggests that the polymeric material used, Polycaprolactone (PCL), maintains its structural integrity and performs effectively in resisting the applied forces. This finding supports the potential use of polymeric anchors in geotechnical applications where maintaining shape and strength under load is essential.

Results and discussion

In this study, 12 series of tests were performed for polymer anchors with different embedment depths. In the presented diagrams, L represents the distance of the embedded anchor from the box wall, H indicates the embedment depth from the soil surface, and d represents the length of the anchor. Figures 4, 5 and 6 show force-displacement diagrams of the polymer plate anchor at three embedment depths (H) of 200, 400, and 600 mm and four distance ratios of (L/d) 1, 2, 3, and 4. As observed, the pullout force of the anchors increases with the distance of the anchors from the soil wall in all three embedment depths (H). The main reason is the increase in the soil mass available in front of the anchor by increasing the embedment depth, which causes more resistance during pullout. For instance, increasing the distance from the box wall by four times increases the pullout force in all three heights (H) by 2 to 3 times. Moreover, the highest pullout force was recorded at a depth of 600 mm from the soil surface. The increase in soil density and the frictional force between the soil and the anchor increase the anchor resistance against pullout and reach its maximum value. The anchor embedded at the boundary between the dense and loose layers has a lower pullout force than the anchor placed in the dense layer. Besides, the pullout force of the anchor reaches its minimum value in the loose layer because the soil’s internal friction angle is lower, and the space between the soil grains allows the anchor to move more easily in the soil. Similar results were obtained in the research of Choudhary and Dash (2018)6. They conducted experiments on plate anchors in three types of dense, semi-dense, and loose soils and observed that the increase in soil density increases the ultimate pullout force, and the rate of this force increase rises with the increase in the anchor embedment depth, which is attributed to the soil failure behavior. According to the experiments, the increase in soil density increases the size of the failure surface, which is more evident at a greater depth. Therefore, the performance of the system is improved due to the increased soil mass involved in the anchor force6. Ilamparuthi et al. (2002) achieved similar results by studying horizontal anchors embedded in sandy soil28. Figure 7 shows the diagram of polymer plate anchors’ pullout force coefficient versus the embedment depth ratio (H/d). As shown, the pullout force coefficient of the anchors increases with the distance between the anchors and the box wall. Furthermore, the pullout force coefficient of the anchors increases with the embedment depth ratio (H/d), which is due to the increase of surcharge on the anchor with the increase in depth. On the other hand, the increase in depth (H) raises the soil density, which is directly related to its internal friction angle. In this regard, the increase in density increases the internal friction angle, which causes more interactions between the soil and the anchor and ultimately leads to an increase in the pullout force and the pullout force coefficient of the anchor. Ansari et al. (2021) also obtained similar results in their research29.

The following presents the soil surface deformations caused by the pullout of different types of anchors. Figures 8, 9 and 10 show diagrams of the soil surface deformations caused by the pullout of polymer plate anchors at different distances and depths. As seen, the soil surface deformations change with the increase in distance ratio (L/d). This is mainly due to the soil accumulation in front of the anchor during pullout, which first causes soil settlement and then uplifts the soil. The soil surface deformations also change with the embedment depth, such that increasing the embedment depth reduces the soil surface deformations. This is related to the decrease of the anchor force transition to higher levels with the increase in the anchor embedment depth. Moreover, the higher soil density and the increase in surcharge are other factors that reduce the soil surface deformations due to the increase in the embedment depth. Choudhary and Dash (2018) obtained similar results6.

Conclusions

This research investigated the behavior of vertical plate anchors under horizontal pullout force using physical modeling in a laboratory setting. The anchor used in this research was made of polymer material. This study explores the innovative use of polymer plate anchors in geotechnical engineering, addressing some of the limitations of traditional steel plate anchors. Considering the heterogeneous nature of the soil, the research attempted to evaluate the anchor behavior in two layers with different densities. The experiment showed that various soil parameters and anchor embedment geometry could significantly affect the pullout behavior of the anchor. The main results obtained from this research are as follows.

-

The pullout force changes with the number of soil layers, such that embedding the anchor in the lower layer increases the surcharge and soil density, which leads to an increase in the pullout force of the anchor.

-

The pullout force of the anchor increases with the distance of the anchors from the wall, which is mainly due to the increase of soil mass in front of the anchor during the application of pullout force.

-

The pullout force of the polymer plate anchor is 250 kN in the closest location to the soil surface and wall (L/d = 1). In this regard, the pullout force increases with the increase in the embedment depth and distance from the wall. At L/d = 4, when the anchor is located in the second layer with higher density and depth, the pullout force of polymer anchors is 4.8 times higher than that of the shallow state, respectively. This result is useful and necessary for the design of retaining walls. In comparison, steel plate anchors typically exhibit pullout forces ranging from 200 kN to 300 kN under similar conditions.

-

The location of the anchor embedment, as well as its shape and material, directly affect the amount and mechanism of the soil surface deformation during the pullout process. In this regard, the surface displacements increase with the distance of the anchor from the wall, while the surface displacements decrease with the increase in the embedment depth.

-

In general, the pull-out results are almost close, but in polymer vertical anchor plate, it can be said that at greater burial depths, about 80–95% of the results are similar to steel anchors, and at shallower depths, similar results have been achieved. Although this is the beginning of a new generation of polymer vertical anchor plate and more tests are needed to achieve more results in the future for this type of anchor. The main goal of polymer vertical anchor plate is to reduce the damage caused by corrosion of steel anchors and to reduce the cost of construction and production compared to steel anchors.

Data availability

The datasets generated during and/or analysed during the current study are available from the corresponding author on reasonable request.

Abbreviations

- B:

-

Anchor width

- Cc:

-

Uniformity coefficient

- Cu:

-

Curvature coefficient

- Dr :

-

Soil relative density

- D10 :

-

Diameter of soil particles finer than 10% of the soil

- D30 :

-

Diameter of soil particles finer than 30% of the soil

- D60 :

-

Diameter of soil particles finer than 60% of the soil

- D85 :

-

Diameter of soil particles finer than 85% of the soil

- d or h:

-

Anchor height

- H:

-

Anchor embedment depth from the soil surface

- L:

-

Distance of the embedded anchor from the box wall

- Mγq :

-

Pullout force coefficient

- Qu :

-

Ultimate pullout load

- γ:

-

Unit weight of the soil

References

Fazeli, G., Lotfollahi, S., Bakhtiari, P. & Farrokhi, F. Bearing capacity and geotechnical properties of sandy soil substrate contaminated with oil derivatives (diesel fuel and kerosene). Q. J. Eng. Geol.Hydrogeol. 54 (4), qjegh2020–qjegh2134. https://doi.org/10.1144/qjegh2020-134 (2021).

Lotfollahi, S., Jaidari, A., Bakhtiari, P., Hosseini, M. & Ghorbani, M. Effect of wollastonite microfibers and waste tire rubber on mechanical properties of concrete. Int. J. Concrete Struct. Mater. 17 (1), 33. https://doi.org/10.1186/s40069-023-00595-3 (2023).

Reddy, N. G., Vidya, A. & Sri Mullapudi, R. Review of the utilization of plastic wastes as a resource material in civil engineering infrastructure applications. J. Hazard. Toxic. Radioactive Waste. 26 (4), 03122004. https://doi.org/10.1061/(ASCE)HZ.2153-5515.0000717 (2022).

Das, B. M. & Shukla, S. K. Earth Anchors (J. Ross Publishing, 2013).

Evans, T. M. & Zhang, N. Three-dimensional simulations of plate anchor pullout in granular materials. Int. J. Geomech. 19 (4), 04019004. https://doi.org/10.1061/(ASCE)GM.1943-5622.0001367 (2019).

Choudhary, A. K. & Dash, S. K. Pull-out behaviour of vertical plate anchor in granular soil. Proc. Inst. Civ. Eng. Geotech. Eng., 171 (5), 379–390. https://doi.org/10.1680/jgeen.17.00174 (2018).

Das, B. M., Seeley, G. R. & DAs, S. C. Ultimate resistance of deep vertical anchor in sand. Soils Found. 17 (2), 52–56. https://doi.org/10.3208/sandf1972.17.2_52 (1977).

Dickin, E. A. & Leung, C. F. Evaluation of design methods for vertical anchor plates. J. Geotech. Eng. 111 (4), 500–520. https://doi.org/10.1061/(ASCE)0733- (1985). 9410(1985)111:4(500).

Kumar, J. Uplift capacity of horizontal strip anchors in layered sands. Indian Geotech. J. 33 (2), 145–163 (2003).

Bhattacharya, P. & Kumar, J. Effects of heterogeneity and nonlinearity on uplift characteristics of shallow horizontal anchor plates. Geotech. Geol. Eng. 41, 1615–1634 (2015).

Bhattacharya, P. & Kumar, J. Uplift capacity of anchors in layered sand using Finite-Element limit analysis: formulation and results. Int. J. Geomech. 16 (3), 04015078 (2016).

Bhattacharya, P. & Roy, A. Variation of horizontal pullout capacity with width of vertical anchor plate. Int. J. Geomech. 16 (5), 06016002 (2016).

Bhattacharya, P. & Kumar, J. Horizontal pullout capacity of a group of two vertical strip anchors plates embedded in sand. Geotech. Geol. Eng. 30, 513–521 (2011).

Bhattacharya, P. & Kumar, J. Vertical pullout capacity of horizontal anchor plates in presence of seismic and seepage forces. Geomech. Geoeng. 9 (4), 294–302 (2014).

Giampa, J. R. et al. The effect of shape on the Pull-out capacity of shallow plate anchors in sand. Géotechnique 69 (4), 355–363 (2016).

Yue, H., Zhuang, P., Zhang, H. & Song, X. Failure and deformation mechanisms of vertical plate anchors subjected to lateral loading in sand. Int. J. Geomech. 20 (11), 04020210. https://doi.org/10.1061/(ASCE)GM.1943-5622.0001859 (2020).

Al Hakeem, N. & Aubeny, C. Numerical investigation of uplift behavior of circular plate anchors in uniform sand. J. Geotech. GeoEnviron. Eng. 145 (9), 04019039. https://doi.org/10.1061/(ASCE)GT.1943-5606.0002083 (2019).

Niroumand, H. & Kassim, K. A. Design and Construction of Soil Anchor Plates (Elsevier, 2016).

Shahriar, A. R., Islam, M. S. & Jadid, R. Ultimate pullout capacity of vertical anchors in frictional soils. Int. J. Geomech. 20 (2), 04019153. https://doi.org/10.1061/(ASCE)GM.1943-5622.0001576 (2020).

Yoshida, S., Xiong, X. & Matsumoto, T. Experimental and numerical study on reinforcement effect of plate anchors or flip anchors on model slopes. Soils Found. 63 (2), 101285. https://doi.org/10.1016/j.sandf.2023.101285 (2023).

Zhuang, P. et al. Ultimate pullout capacity of single vertical plate anchors in sand. Mar. Georesources Geotechnology. 40 (8), 1004–1022. https://doi.org/10.1080/1064119X.2021.1950247 (2022a).

Zhuang, P. Z. et al. Pullout behaviour of inclined shallow plate anchors in sand. Can. Geotech. J. 59 (2), 239–253. https://doi.org/10.1139/cgj-2020-0495 (2022b).

ASTM (American Society for Testing and Materials). Standard Test Methods for Maximum Index Density and Unit Weight of Soils Using a Vibratory Table. ASTM Standard D4253-00 (ASTM International, 2006).

ASTM (American Society for Testing and Materials). Standard test Method for Measuring Geosynthetic Pullout Resistance in Soil. ASTM Standard D6706-01. (ASTM International, 2013).

Chu, L. M. & Yin, J. H. Comparison of interface shear strength of soil nails measured by both direct shear box tests and pullout tests. J. Geotech. Geoenviron. Eng. 131 (9), 1097–1107. https://doi.org/10.1061/(ASCE)1090-0241 (2005).

Su, L. J., Chan, T. C., Yin, J. H., Shiu, Y. K. & Chiu, S. L. Influence of overburden pressure on soil–nail pullout resistance in a compacted fill. J. Geotech. GeoEnviron. Eng. 134 (9), 1339–1347. https://doi.org/10.1061/(ASCE)1090-0241(2008)134:9(1339) (2008).

Jalali Moghaddam, M., Zad, A. & Mehrannia, N. Failure mechanism evaluation of plate anchor retaining walls containing crumb rubbers by using PIV technique. Amirkabir J. Civil Eng. 50 (5), 937–948. https://doi.org/10.22060/ceej.2017.12719.5254 (2018).

Ilamparuthi, K., Dickin, E. A. & Muthukrisnaiah, K. Experimental investigation of the uplift behaviour of circular plate anchors embedded in sand. Can. Geotech. J. 39 (3), 648–664. https://doi.org/10.1139/t02-005 (2002).

Ansari, Y., Kouretzis, G. & Sloan, S. W. Physical modelling of lateral sand–pipe interaction. Géotechnique, 71 (1), 60–75. https://doi.org/10.1680/jgeot.18.P.119 (2021).

Author information

Authors and Affiliations

Contributions

A.P. wrote the main manuscript text and L.B. prepared figures. H.N. prepared the idea, methodology, and supervision. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Parsa, A., Niroumand, H. & Balachowski, L. Pullout performance of innovative polymer vertical anchor plates in layered soils. Sci Rep 15, 10561 (2025). https://doi.org/10.1038/s41598-025-94125-8

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-94125-8

Keywords

This article is cited by

-

Effect of Anchor Plate on Prestressed Anchor Cable Performance in Soft Rock Tunnels

Geotechnical and Geological Engineering (2025)