Abstract

Oil spills pose a major environmental challenge, highlighting the urgent need for effective materials capable of achieving efficient oil-water separation to mitigate their detrimental impacts. While various bio-based and synthetic adsorbents have been explored for this purpose, existing materials often suffer from low adsorption capacity, poor reusability, limited hydrophobicity, or environmental concerns. In particular, natural bio-based materials frequently exhibit inherent hydrophilicity, limiting their effectiveness in selective oil adsorption. To address this gap, we developed a novel bio-based oil adsorbent derived from sphagnum moss, modified via sequential pretreatment with hydrogen peroxide and sodium hydroxide, followed by chemical functionalization with silane. This modification enhanced hydrophobicity and structural stability, overcoming the limitations of unmodified bio-based adsorbents. Characterization using SEM, XPS, FTIR, and TGA confirmed the successful grafting of hydrophobic functional groups and the formation of a uniformly rough surface, leading to a water contact angle of 157°. Comparative analysis demonstrated that the modified sphagnum moss exhibited a significantly enhanced adsorption capacity of 22.756 g/g for motor oil, outperforming conventional bio-based adsorbents, including currently prevalent biological adsorbents (1.69–12.8 g/g) and biochar (8.1–18.2 g/g). Furthermore, the adsorption kinetics conformed to a pseudo-second-order model, indicating chemisorption as the dominant mechanism. This suggests strong interactions between oil molecules and the functionalized surface, contributing to enhanced efficiency and selectivity. These findings highlight the novelty, superior performance, and environmental compatibility of modified sphagnum moss as an effective and sustainable solution for oil spill remediation. Its high adsorption capacity, selective oil affinity, and reusability make it a promising alternative to existing bio-based adsorbents, providing an eco-friendly approach to oil spill management and environmental restoration.

Similar content being viewed by others

Introduction

In recent decades, the rapid acceleration of industrialization has led to substantial advancements in the petrochemical industry. However, oil and organic chemical spills have become a growing concern, threatening human health, aquatic ecosystems, and the sustainability of ecological systems. This challenge has drawn significant global attention and spurred extensive research1. Currently, the commonly used methods for addressing oil and organic pollutant spills include combustion, mechanical recovery, chemical treatment, and adsorption2,3. Among these approaches, adsorption is considered a highly promising solution due to its accessibility and its ability to selectively absorb and retain oil and organic solvents from water4. However, current adsorbent materials are often hindered by high costs, poor biodegradability, and complex synthesis processes, limiting their practical use. Thus, the development of cost-effective, environmentally friendly, and highly efficient oil-absorbing materials has become an urgent priority.

Oil-absorbing materials can be classified into inorganic mineral adsorbents, synthetic organic adsorbents, and natural organic adsorbents based on their constituent materials5. Ideal adsorbent materials should exhibit high adsorption capacity, strong hydrophobic and oleophilic characteristics, fast adsorption rates, and low cost. Traditional inorganic adsorbents, such as sepiolite, kaolin, red mud, and fly ash, are extensively utilized owing to their low cost, easy availability, and fast adsorption rates6,7. However, their limited oil adsorption capacity, poor oil-water selectivity, and challenges in regeneration restrict their broader application8. Novel inorganic adsorbents, such as carbon nanotubes, demonstrate excellent superhydrophobic properties9. However, their complex synthesis processes and high costs limit their application in large-scale organic water pollution treatment. Additionally, synthetic polymer adsorbents, including polypropylene fibers10, melamine sponges11,12, polymer foams13 and bio-based gelators14,15, demonstrate good adsorption performance for organic pollution treatment. However, their intricate synthesis processes, poor biodegradability, high costs, and potential for secondary pollution make their environmental impact difficult to fully control16,17. Recently, bio-based adsorbents derived from agricultural sources have garnered significant attention owing to their low cost, high efficiency, environmental friendliness, and the potential for improved performance through modification. Natural bio-based adsorbents, including wheat bran18, corncobs17, pomelo peels19, cotton2, durian shells20, plantain21, orange peel22, and lemon grass3, have demonstrated significant potential for the remediation of oil spills and other organic pollutants.

However, these materials often face limitations, including high water adsorption, poor selectivity, slow adsorption rates, and difficulty in recovery after adsorption, restricting their practical applications. Thus, enhancing selective adsorption of oil-water mixtures and simplifying post-adsorption recovery are key challenges in designing efficient adsorbents17. Surface modification provides effective solutions to improve natural adsorbent performance, particularly by introducing hydrophobic functional groups to significantly improve their oleophilic and hydrophobic properties, boosting oil-water separation efficiency23,24. This study used natural porous sphagnum moss as a raw material to develop a novel, economical, efficient, and easily recoverable adsorbent via surface modification.

Sphagnum moss is a widely available and renewable plant material composed mainly of cellulose, lignin, and other components. It is characterized by excellent biodegradability, a porous structure, and a high specific surface area25. The oxygen-containing functional groups and aromatic structures of sphagnum moss provide abundant active sites for organic compound adsorption, indicating strong potential for water pollution remediation26. Sphagnum moss has been widely investigated for its adsorption capacity toward heavy metals and organic dyes in aquatic systems27,28,29,30. Nevertheless, the abundant hydrophilic hydroxyl groups on the surface of sphagnum moss limit its application in oil-water separation, particularly due to poor selectivity for oil pollutant adsorption on water surfaces. This limitation has resulted in slow progress in research on their adsorption of organic pollutants on water surfaces. This study addresses water surface organic pollution by enhancing the hydrophobic and oleophilic properties of sphagnum moss through surface pretreatment and silanization. The adsorption performance of the modified sphagnum moss for various organic compounds was systematically evaluated, and the mechanisms underlying its gel adsorption capacity and selective adsorption were thoroughly investigated. These findings bridge the research gap in using sphagnum moss adsorbents for oil spill remediation and establish a theoretical foundation for developing efficient, low-cost, and biodegradable adsorbents.

Experimental procedure

Raw materials

The bio-based oil adsorbent was prepared using raw sphagnum moss (Raw-SM) as the base material, which was sourced from a local supplier in Guizhou, China. Sodium hydroxide (NaOH) and hydrogen peroxide (H2O2), sourced from Shandong Xuchen Chemical Technology Co., Ltd., China, were used as pretreatment reagents for sphagnum moss. Vinyltriethoxysilane (VTES), ethanol, and hydrochloric acid, procured from Chongqing Chuandong Chemical Co., Ltd., China, along with silicon dioxide (SiO2) particles sourced from Hubei Kandis Chemical Co., Ltd., China, were used as surface modification agents for the preparation of the materials. Crude oil, motor oil, and vacuum pump oil were sourced from a local service station. Petroleum ether, toluene, and xylene, used as probe liquids to evaluate the adsorption properties of the materials, were procured from Weifang Huabo Chemical Co., Ltd., China. All chemicals used were of analytical grade and applied without additional purification.

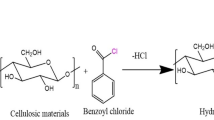

Preparation of bio-based oil gelling agent materials

The bio-based oil adsorbent was synthesized through a two-step surface modification process: alkaline-oxidation pretreatment followed by silane-based hydrophobic functionalization. The entire synthesis was performed under atmospheric pressure, without requiring external electrical input. The detailed procedure is depicted in Fig. 1.

Alkaline-oxidation pretreatment of sphagnum moss

In the pretreatment stage, 10.00 g of raw sphagnum moss was immersed in 1.00 L of NaOH solution (2.00 g/L) and stirred at 500 rpm for 30 min at room temperature to remove surface impurities and increase porosity. Subsequently, 2.00 mL of 30% hydrogen peroxide (H2O2) was gradually added under continuous stirring at 600 rpm to facilitate oxidative modification, while the temperature was raised to 95 °C using a digital hotplate. The reaction proceeded for 60 min to ensure the complete removal of residual organic matter. After the reaction, the pH of the treated sphagnum moss was adjusted to neutral (pH 7.0) by gradually adding 0.1 mol/L hydrochloric acid (HCl), with pH continuously monitored using a pH meter. The neutralized sample was vacuum-filtered through a Büchner funnel with a 0.45 μm membrane filter, then thoroughly rinsed with deionized water to eliminate residual reagents. Finally, the pretreated sphagnum moss was dried at 105 °C in a laboratory oven for 60 min to achieve complete moisture removal before subsequent modification.

Surface functionalization via silane modification

The surface functionalization process involved silane grafting to impart hydrophobicity to the pretreated sphagnum moss. A silane solution was prepared by combining 3.00 g of dried, pretreated sphagnum moss, 2.00 mL of vinyltriethoxysilane (VTES), 0.10 g of nano-silica (SiO₂) particles, 3.00 mL of 0.1 mol/L NaOH solution, and 40.00 mL of anhydrous ethanol. The mixture was stirred at 600 rpm for 15 min at room temperature, then subjected to ultrasonic treatment at 40 kHz and 200 W for 30 min to enhance silane penetration into the porous structure of the moss. The solution was transferred to a PTFE-lined stainless-steel autoclave and hydrothermally treated at 110 °C in a muffle furnace for 2 h to promote the condensation reaction between silane molecules and the moss surface. After cooling to room temperature, the modified sphagnum moss was vacuum-filtered and extensively rinsed with ethanol to eliminate unreacted silane. Finally, the sample was dried in a vacuum oven at 80 °C for 6 h to obtain the hydrophobic bio-based oil adsorbent. It was then stored in a desiccator with anhydrous silica gel to prevent moisture adsorption before characterization and adsorption testing.

Schematic illustration of the synthesis process of bio-based oil adsorbent (Created using ChemDraw 3D (version: 2022; URL link:https://revvitysignals.com/products/research/chemdraw) and Cinema 4D (version: 2024; URL link: https://www.maxon.net/cinema-4d)).

Characterization

The microstructures and structure of sphagnum moss were examined before and after modification using a scanning electron microscope (SEM; Gemini 300) equipped with an energy-dispersive spectrometer (EDS; Smart EDX). To improve the SEM image quality, the samples were sputter-coated with gold to form a conductive layer. Functional groups of the materials were characterized using Fourier-transform infrared spectroscopy (FT-IR; Bruker TENSOR 27). The FT-IR spectra of each sample were recorded in the range of 4000 –400 cm− 1. Thermal stability of the samples was assessed using a NETZSCH 209F1 thermogravimetric analyzer, operated at a constant heating rate of 10 ℃/min from room temperature to 900 ℃ under a nitrogen (N₂) atmosphere. Elemental analysis and surface structure characterization were analyzed using X-ray photoelectron spectroscopy (XPS; Thermo Scientific K-Alpha). The static contact angle between sphagnum moss and water was measured at ambient temperature using a YIKE-360 optical contact angle goniometer. The measurements were performed at three different positions for each value.

The adsorption performance of the material was assessed based on its capacity to adsorb various organic pollutants, including crude oil, motor oil, vacuum oil, toluene, and xylene. Both modified and unmodified sphagnum moss samples were weighed and immersed in various organic compounds for 20 min to reach adsorption equilibrium. The adsorption efficiency was calculated by measuring the mass difference before and after immersion. To ensure reproducibility, three to five replicate tests were conducted for each experiment. The adsorption efficiency was determined using the formula provided below:

The weight of sphagnum moss at adsorption equilibrium is denoted as W2, while W1 represents the initial weight before adsorption. Adsorption-desorption experiments were performed to evaluate the reusability of the modified sphagnum moss. The regeneration capability of the modified sphagnum moss adsorbent for organic solvent adsorption was evaluated using a rotary evaporator at 80 °C under a negative pressure of 0.05 MPa18,31. The recyclability of the adsorbent was determined by measuring its xylene adsorption capacity over multiple cycles. Each experiment was performed in triplicate, and the results are presented as mean values with standard deviations.

Results and discussion

Analyses of morphologies

The surface morphologies of both the original and modified sphagnum moss are presented in Fig. 2. The original sphagnum moss (Fig. 2a, b) displays a highly porous surface structure, making it highly suitable for adsorption applications. Upon comparison with the original material, the modified sphagnum moss exhibits increased surface roughness, the deposition of insoluble silica particles, and encapsulation by a distinct polysiloxane-derived layer resulting from silane hydrolysis (Fig. 2d, e). Additionally, EDS spectrum analysis (Fig. 2c, f) confirmed the presence of Si, along with C and O elements, on the surface of the modified sphagnum moss, signifying a modification in its surface composition. As shown in Fig. 3, SEM imaging combined with the corresponding elemental mapping of C, O, and Si, confirms the presence of a uniform and intact layer on the surface of the modified sphagnum moss.

XPS analysis before and after modification

High-resolution X-ray photoelectron spectroscopy (XPS) analysis was performed to investigate the sphagnum moss before and after surface modification, as shown in Fig. 4. The survey spectrum (Fig. 4a) demonstrates a significant increase in Si elemental content following the surface modification of sphagnum moss. In the C 1s spectrum (Fig. 4b), changes in the bonding state of C elements are evident post-modification, with an enhanced presence of C = C bonds at 284.8 eV indicating successful attachment of hydrophobic groups onto the surface of sphagnum moss32. Moreover, bonding configurations involving C elements such as O-C = O, C = O, and C-O exhibit decreased binding energies and reduced peak areas after modification, suggesting altered bonding arrangements. Additionally, notable changes in silicon bonding modes are observed in the Si 2p spectrum (Fig. 4c). Following surface modification, binding energies for Si-O and Si-C bonds significantly increase from 102.3 eV to 103.4 eV and from 101.4 eV to 102.8 eV respectively33,34. Furthermore, a new bond involving Si-O-C appears at around 102.3 eV35. The enhanced peak areas corresponding to Si-C, Si-O and Si-O-C bonds indicate successful attachment of silicon-containing groups onto the surface of sphagnum moss after modification which also influences the bonding configurations involving C elements. These bonds impact both atomic arrangement and the active sites on the sphagnum moss surface, as further supported by analysis presented in Fig. 4d depicting O 1s spectrum.

FT-IR analysis

To elucidate the alterations in the microstructure of sphagnum moss following surface modification, infrared spectroscopy was utilized to analyze samples subjected to various treatment protocols, as shown in Fig. 5. The spectrum in Fig. 5 exhibits prominent absorption peaks at 3342 cm-1, which are primarily attributed to the bending vibration of hydroxyl groups (-OH)36. Pretreatments using sodium hydroxide and hydrogen peroxide resulted in the degradation of the sphagnum moss’s surface fibrous layer, significantly exposing the internal hydrophilic groups, particularly hydroxyl groups. This exposure increased the number of surface hydrophilic groups (-OH), thereby providing more reactive sites for subsequent surface modification grafting reactions, enhancing the reactivity and accessibility of the moss surface. After surface modification, a notable reduction in peak intensity in the hydroxyl region was observed, accompanied by the appearance of new absorption peaks at 3066 cm⁻¹ and 1412 cm-1, attributed to the stretching vibration and in-plane deformation of vinyl groups (-CH = CH2), respectively.

Additionally, a distinct peak at 756 cm⁻¹ was detected, corresponding to Si-C vibrations37. These infrared spectral changes confirm the successful silane modification of the sphagnum moss surface, reducing its hydrophilic nature while introducing a substantial number of hydrophobic groups. Vinyl triethoxysilane undergoes a silanization reaction in water, polymerizes spontaneously, and subsequently grafts onto the pre-treated sphagnum moss surface, which contains a large number of hydroxyl groups. This process results in the formation of a thin polysiloxane layer, which decreases the abundance of surface hydrophilic groups. Simultaneously, the terminal group of the surface modifier bonds with the hydrophobic and lipophilic vinyl group, enhancing the material’s hydrophobic and lipophilic properties. Following surface modification, the characteristic peak at 967 cm-1 in the spectrum is attributed to the stretching vibration of the -Si-O-Si- bonds grafted onto the modified sphagnum moss surface, in agreement with prior energy spectrum and XPS analyses38. Additionally, hydroxyl groups on SiO₂ particles react with the silane to form short polymer chains, promoting particle aggregation and deposition on the sphagnum moss surface. This observation aligns with the SEM results presented in Fig. 2. The characteristic peak at 1601 cm-1 appears in both the modified and unmodified sphagnum moss, originating from the -C = O bond in the cellulose and lignin. However, this peak persists after surface modification, primarily originating from the hydrophobic -CH = CH₂ groups grafted onto the modified sphagnum moss surface3. The presence of this characteristic peak, along with the surface microstructure and energy spectrum analyses, confirms the success of the surface silanization modification.

Thermogravimetric analyses

Native and modified sphagnum moss samples were analyzed using thermogravimetric analysis (TGA) under a nitrogen (N2) atmosphere to evaluate their thermal properties. As illustrated in Fig. 6, the TGA curves show an initial mass loss below 200 °C, which is attributed to the evaporation of volatile components, including water, hydrocarbons, and hydroxyl groups36,39. The mass losses at 200 °C for the native and modified samples were 3.9% and 4.8%, respectively. At the 10% weight loss point (T10), the decomposition temperature of the native samples occurred at 231.9 °C, while the modified sphagnum moss decomposed at 292.2 °C.

To evaluate the thermal stability of sphagnum moss before and after modification, the temperature at 10% mass loss (T10) and the temperature corresponding to the maximum decomposition rate (Tdm) were analyzed and compared. The TG and DTG results revealed that surface modification increased T10 from 231.9 °C to 292.2 °C and shifted Tdm from 256.5 °C to 359.9 °C. These findings suggest that surface modification significantly enhanced the thermal stability of the sphagnum moss. At 900 °C, the mass remained relatively stable, leaving some residual material. The residue at 900 °C (M900) for native and modified sphagnum moss was 7.98% and 13.67%, respectively. This observation may be attributed to the presence of minerals in the sphagnum moss and silicon-containing compounds, such as polysiloxane, formed during the silanization process.

Wettability analyses

The analysis of the microstructure of sphagnum moss before and after modification clearly shows that surface silanization treatment significantly decreases the abundance of hydrophilic groups while increasing the presence of hydrophobic groups on the surface.

To further investigate the wetting properties of the modified sphagnum moss material on water and organic pollutants, both macroscopic wetting performance and microscopic contact angles were analyzed, as illustrated in Fig. 7. In the macroscopic wetting performance measurement, water and xylene were dyed with blue ink and Sudan Red dye, respectively, to better characterize the material’s wetting behavior. Figures 7a,b display the wetting angles of the original sphagnum moss material with water. Due to its porous surface structure, the sphagnum moss absorbs water rapidly, almost completely upon contact, with an initial wetting angle of 25.3°. After 30 s, the water is fully absorbed, and the material expands, indicating the original material’s excellent wettability and hydrophilic performance. To compare the material’s selective adsorption of water and xylene, tablets were prepared and macroscopic adsorption experiments were conducted, as shown in Fig. 7c. The original sphagnum moss material exhibits good adsorption properties for both water and xylene. The modified sphagnum moss material has a water wetting angle of 157°, which remains unchanged after 30 s, demonstrating excellent hydrophobic performance (Figs. 7d, e). The macroscopic adsorption of water and xylene (Fig. 7f) shows that the modified sphagnum moss material exhibits strong adsorption capacity for xylene, while water stained with blue ink forms spherical droplets on the material surface, demonstrating excellent hydrophobicity. This is consistent with the earlier microstructural analysis. After modification, the sphagnum moss material exhibits strong oil affinity and hydrophobicity, enabling selective adsorption of water and organic pollutants.

Adsorption capacity of sphagnum moss samples

After surface modification, the sphagnum moss exhibited both hydrophobicity and lipophilicity. To evaluate its selective adsorption capability for removing organic pollutants from water, a specified quantity of modified sphagnum moss was applied to adsorb organic compounds from the water surface, as shown in Fig. 8. The modified sphagnum moss was uniformly distributed across the surface of oil-contaminated water. Upon gentle stirring, it efficiently adsorbed the oil, gradually accumulating and reducing its presence on the water surface, as depicted in Fig. 8c. After the adsorbed sphagnum moss aggregated, the organic pollutant was efficiently absorbed and subsequently collected using a mesh net, as illustrated in Figs. 8d, e. demonstrating its high-efficiency selective adsorption capability.

To evaluate the organic matter adsorption capacity of modified sphagnum moss, crude oil, motor oil, vacuum oil, toluene, and xylene were selected as test materials. Both silanized and untreated sphagnum moss samples were immersed in organic pollutants, and the adsorption rates were determined after equilibrium was achieved, as shown in Fig. 9a. Surface modification substantially improved the adsorption capacity of sphagnum moss, doubling the saturated adsorption capacity compared to the untreated material. The modified sphagnum moss exhibited an oil adsorption capacity of 22.756 g/g, marking a significant improvement compared to the original material. A literature review was performed to compare the adsorption performance of the modified sphagnum moss with previously reported bio-based adsorbents (see Fig. 9b)3,4,18,19,22,40,41,42,43,44,45,46. The modified sphagnum moss adsorbent demonstrated a significantly higher adsorption capacity than conventional biological adsorbents and outperformed most biochar-based oil adsorbents. Additionally, the material exhibited strong hydrophobicity, high adsorption capacity, and selective adsorption properties, effectively overcoming the limitations of low efficiency and inadequate hydrophobicity in bio-based adsorbents. Moreover, the fabrication process is simple and cost-effective, with biodegradable sphagnum moss as the primary component, making it environmentally friendly and highly promising for oil spill management and ecological restoration.

Recyclability is a key factor that affects the practical performance of oil-water separation materials47. After adsorption, the volatile organic compounds retained by the modified sphagnum moss can be effectively recovered via evaporation. Figure 10 illustrates the cyclic adsorption performance of the modified sphagnum moss for organic compounds over multiple cycles. The adsorption capacity exhibits slight fluctuations during the recycling process. After 10 adsorption-evaporation cycles, the modified sphagnum moss retains over 90% of its initial capacity, demonstrating excellent recyclability.

Adsorption kinetics

Adsorption experiments were conducted to evaluate the time-dependent adsorption capacities of both original and modified sphagnum moss using organic matter. Figure 11 presents the adsorption capacity curves for both original and modified sphagnum moss over a time range of 2–105 min. The modified sphagnum moss demonstrated markedly higher adsorption efficiency compared to the original moss. The curves further revealed that the adsorption of motor oil by the modified sphagnum moss increased rapidly during the initial 15 min. Subsequently, the adsorbed amount stabilized, indicating that the adsorption rate was rapid, with equilibrium achieved within 15 min, making the material highly suitable for treating organic water pollutants. The modified sphagnum moss demonstrated a maximum adsorption capacity of 22.756 g/g, maintaining stability with minor fluctuations thereafter. The porous structure of sphagnum moss facilitates rapid contact between motor oil and the adsorbent. Surface modification increases the availability of adsorption sites, enhancing both adsorption capacity and efficiency, thereby quickly reaching adsorption equilibrium.

To analyze the adsorption rate and mechanisms of the modified sphagnum moss, the adsorption data were fitted using two kinetic models: the pseudo-first-order and pseudo-second-order models. The fitted curves are presented in Fig. 11. The Lagrange pseudo-first-order kinetic model (Eq. (1)) is widely employed for solid‒liquid adsorption systems48, emphasizing a linear relationship between the adsorption rate and the concentration of reactants, as expressed in:

The pseudo-second-order kinetic model (Eq. (2)), on the other hand, describes chemisorption, involving electron sharing or exchange between the adsorbent and the adsorbate49, as follows:

Here, t represents the adsorption time in minutes, \(\:{q}_{e}\) is the amount adsorbed at equilibrium (g/g), and \(\:{q}_{t}\) is the amount adsorbed at time t (g/g). From the fitted slope and intercept, the values of \(\:{q}_{e}\), \(\:{k}_{1}\), and \(\:{k}_{2}\) were calculated. The fitted curves for \(\:\text{ln}({\text{q}}_{\text{e}}-{\text{q}}_{\text{t}})\) and \(\:\frac{\text{t}}{{\text{q}}_{\text{t}}}\) are presented in Fig. 11.

The adsorption fitting curves showed that the pseudo-first-order kinetic model provided a fitting equation of y = -0.04773x + 1.36578 with an R2 value of 0.82916. In contrast, the pseudo-second-order kinetic model yielded a fitting equation of y = 0.0435x + 0.0946 with an R2 value of 0.99991. Table 1 summarizes the results of fitting the experimental adsorption data of modified sphagnum moss over time (depicted in Fig. 11) using the pseudo-first-order and pseudo-second-order kinetic models.

The fitting results demonstrated that the pseudo-second-order kinetic model provided a superior linear fit compared to the pseudo-first-order model, as evidenced by an R2 value of 0.99991. Additionally, the theoretical saturated adsorption capacity \(\:{q}_{e}\) predicted by the pseudo-second-order model closely aligned with the experimentally measured value, outperforming the predictions of the pseudo-first-order model. These findings indicate that the pseudo-second-order kinetic model more accurately represents the adsorption behavior of organic compounds by modified sphagnum moss, suggesting that the process is predominantly governed by chemical adsorption50,51.

Mechanism for the surface modification

The surface-modified sphagnum moss demonstrates good hydrophobicity and oleophilicity, with the modification mechanism shown in Fig. 12. The surface of sphagnum moss is rich in components such as hemicellulose, lignin, and also contains a certain amount of hydrophilic groups, such as hydroxyl groups (—OH), which exhibit adsorption capabilities for both water and organic compounds.

The long-chain molecules in the cellulose and intermolecular hydrogen bonds in sphagnum moss form a highly crystalline, supramolecular structure, with hemicellulose and lignin tightly embedded, further improving its stability and structural integrity. This complex structure hinders the effective interaction between vinyltriethoxysilane and the active hydroxyl groups on the sphagnum moss surface, reducing accessibility for surface modification and thereby affecting the modification efficiency21,22. Therefore, surface pretreatment of sphagnum moss is necessary before silanization to expose numerous hydrophilic groups. Sodium hydroxide and hydrogen peroxide are commonly employed to treat the highly crystalline supramolecular structure of cellulose on the surface23. Following treatment, the sphagnum moss surface exhibits a significant increase in hydrophilic groups, thereby providing more active sites for subsequent silanization reactions. During surface modification, vinyltriethoxysilane undergoes a silanization reaction in aqueous solution, forming a polymeric structure of polysiloxane24, which then grafts onto the pretreated sphagnum moss, rich in hydrophilic hydroxyl groups (—OH). This process significantly reduces the number of exposed hydrophilic groups, while the hydrophobic vinyl groups (—CH = CH2) on the polysiloxane surface increase its affinity for organic compounds, improving selective adsorption of organic pollutants. Additionally, during the surface modification process, certain hydroxyl groups (—OH) on the silica particles graft with the silane, successfully attaching the silica particles to the surface of sphagnum moss. The unreacted hydroxyl groups (—OH) on the sphagnum moss surface and the remaining hydroxyl groups (—OH) on the silica particles form hydrogen bonds with water molecules18, preventing scattering on the water surface during oil adsorption and promoting aggregation, which facilitates subsequent recovery and reuse.

Conclusions

In summary, a novel bio-based oil absorbent was successfully synthesized via the silane modification of biodegradable sphagnum moss. The modified sphagnum moss demonstrated exceptional hydrophobicity, with a water contact angle of 157°, notably surpassing that of most conventional bio-based oil absorbents. The exceptional hydrophobicity of this material results from the elimination of hydrophilic groups, the successful grafting of hydrophobic functional groups, and increased surface roughness, all of which synergistically enhance oil adsorption performance.

The modified sphagnum moss exhibited a high adsorption capacity for various organic compounds, with a maximum adsorption of 22.756 g/g for motor oil, markedly outperforming conventional biological adsorbents and biochar-based materials. Oil-water separation experiments under environmental conditions further validated its strong phase selectivity and practical feasibility. Alongside its superior adsorption performance, the material displayed remarkable reusability, maintaining over 90% of its initial adsorption capacity after 10 cycles, indicating excellent durability and recyclability. The modified sphagnum moss exhibited enhanced hydrophobicity, high adsorption capacity, and selective adsorption properties, effectively addressing the limitations of low adsorption efficiency and inadequate hydrophobicity in conventional bio-based adsorbents.

Although the modified sphagnum moss exhibits excellent adsorption and selective adsorption properties, its scalability and long-term mechanical stability in practical applications require further improvement. Future studies should prioritize enhancing structural stability, refining large-scale fabrication techniques, and developing advanced functionalization strategies to broaden its applicability in diverse environmental conditions. Overall, this material presents an efficient and sustainable approach to oil spill remediation, offering promising potential for practical applications.

Data availability

Data is provided within the manuscript. Data is available on request from Yu Wang (wangyugeu @126.com).

References

Chen, Y. et al. Superhydrophobic hierarchically porous polymer modified by epoxidized soybean oil and stearic acid synergy for highly efficient sustainable oil-water separation. J. Environ. Chem. Eng. 12, 113529 (2024).

Liu, F., Ma, M., Zang, D., Gao, Z. & Wang, C. Fabrication of superhydrophobic/superoleophilic cotton for application in the field of water/oil separation. Carbohydr. Polym. 103, 480–487 (2014).

A, A. R., Jagadeesan, A. K., Deivasigamani, P. & Sundararaman, S. Balakrishna Pillai Sankari, N. P. The bio-adsorption competence of tailor-made lemon grass adsorbents on oils: an in-vitro approach. Environ. Res. 222, 115332 (2023).

Riyal, I., Sharma, H. & Dwivedi, C. Arising hydrophobic wettable materials for oil spill clean-up: A review. Groundw. Sustain. Dev. 26, 101274 (2024).

Zamparas, M., Tzivras, D., Dracopoulos, V. & Ioannides, T. Application of sorbents for oil spill cleanup focusing on natural-based modified materials: A review. Molecules 25, 4522 (2020).

Zadaka-Amir, D., Bleiman, N. & Mishael, Y. G. Sepiolite as an effective natural porous adsorbent for surface oil-spill. Microporous Mesoporous Mater. 169, 153–159 (2013).

Liu, G., Li, Y., Hou, J., Wang, Y. & Lin, D. A review on the industrial waste based adsorbents for the removal of pollutants from water: modification methods and adsorption study. Resour. Environ. Sustain. 19, 100183 (2025).

Ahamad, T., Naushad, M., Alshehri, S. M. & Ruksana & Ultra-fast spill oil recovery using a mesoporous lignin-based nanocomposite prepared from date palm pits (Phoenix dactylifera L). Int. J. Biol. Macromol. 130, 139–147 (2019).

Ye, X., Shao, C., Fan, Q., Shang, L. & Ye, F. Porous carbon nanotube microspheres with tailorable surface wettability areas for oil adsorption. J. Colloid Interface Sci. 604, 737–745 (2021).

Li, Z. et al. C-shaped porous polypropylene fibers for rapid oil absorption and effective on-line oil spillage monitoring. J. Hazard. Mater. 452, 131332 (2023).

He, L. et al. Research progress in hydrophobic modification of melamine sponge and its application in oil-water separation field. J. Environ. Chem. Eng. 12, 112536 (2024).

Zhang, B. et al. Facile fabrication of silane modified melamine sponge for highly efficient oil absorption properties. J. Water Process. Eng. 63, 105407 (2024).

Li, Y. et al. Superhydrophobic, electrically conductive and multifunctional polymer foam composite for chemical vapor detection and crude oil cleanup. J. Hazard. Mater. 424, 127697 (2022).

Tomon, T. R. B. et al. A novel naturally superoleophilic coconut oil-based foam with inherent hydrophobic properties for oil and grease sorption. Sci. Rep. -UK 14, (2024).

Fazel, S. Enhancing the oil adsorption properties of cellulose nanofiber aerogels through chemical modification. J. Polym. Environ. 32, 3 (2024).

Cuong, T. D. & Hoang, P. H. Preparation of bio-based porous material with high oil adsorption capacity from bio-polyurethane and sugarcane Bagasse. RSC Adv. 14, 6938–6947 (2024).

Rezaei, F. & Hassanajili, S. Facile fabrication of superhydrophobic magnetic bio-waste for oil spill cleanup. Ind. Crop Prod. 201, 116848 (2023).

Lv, P., Yang, S. & Ma, P. Bio-based oil gelling agent for effective removal of oil spills from the surface of water. Mater. Chem. Front. 2, 1784–1790 (2018).

Xu, J., Yang, L., Zhou, Y., Yuan, M. & Yuan, B. One-step fabrication of hydrophobic photothermal pomelo Peel Biochar via copper-catalyzed carbonization for efficient viscous oil and organic solvents absorption. Surf. Interfaces. 56, 105607 (2025).

Liu, T. A natural armor-protected absorbent from discarded Durian peel with rapid and recyclable absorption, high oil retention and self-cleaning ability. Colloids Surf. Physicochem Eng. Asp. 666, 131294 (2023).

Eboibi, B. E. et al. Bio-sorptive remediation of crude oil polluted sea water using plantain (Musa parasidiaca) leaves as bio-based sorbent: parametric optimization by Taguchi technique, equilibrium isotherm and kinetic modelling studies. Heliyon 9, e21413 (2023).

El Gheriany, I. A., Saqa, A. E., Abd El Razek Amer, F., Hussein, M. & A. & Oil spill sorption capacity of raw and thermally modified orange Peel waste. Alex Eng. J. 59, 925–932 (2020).

Wei, D. W. et al. Superhydrophobic modification of cellulose and cotton textiles: methodologies and applications. J. Bioresour Bioprod. 5, 1–15 (2020).

Meng, J. et al. Sm-MOF decorated cotton for efficient on-demand oil-water separation and organic pollutants removal. Sep. Purif. Technol. 358, 130248 (2025).

Sarbisheh, F. et al. Application of response surface methodology for modeling and optimization of malachite green adsorption by modified sphagnum peat moss as a low-cost biosorbent. Desalin. Water Treat. 59, 230–242 (2017).

Zhang, R., Leiviskä, T., Taskila, S. & Tanskanen, J. Iron-loaded sphagnum moss extract residue for phosphate removal. J. Environ. Manage. 218, 271–279 (2018).

Aldmour, S. T. Utilization of organic-rich materials for the adsorption of copper ions from aqueous environments. Results Eng. 22, 102216 (2024).

Phaenark, C., Nasuansujit, S., Somprasong, N. & Sawangproh, W. Moss biomass as effective biosorbents for heavy metals in contaminated water. Heliyon 10, e33097 (2024).

Abu-Saqer, K. K. & Lubbad, S. H. Assessment of various treatment methods and reagents for cleanup and conditioning of sphagnum peat moss as sorbents in removal of malachite green as a cationic organic dye probe from water. SN Appl. Sci. 1, (2019).

Secrain, S., Pannu, A., Dogra, N., Sabharwal, H. & Kapila, S. Assessment of biomass of moss thuidium cymbifolium Dozy & Molk. for removal of eriochrome black T and Auramine-O dyes from aqueous solutions: kinetics, isotherms, thermodynamics, and microtoxicity studies . Biomass Convers Bior. 2024.

Wang, X. et al. Facile fabrication of superhydrophobic and eco-friendly poly(lactic acid) foam for oil–water separation via skin peeling. ACS Appl. Mater. Interfaces. 11, 14362–14367 (2019).

Chen, L. et al. Comparison of hydrophobic cellulose nanofibrils modified with different diisocyanates for circulating oil absorption. Int. J. Biol. Macromol. 258, 129107 (2024).

Wei, C. et al. A novel bio-aerogel based on agroforestry waste chestnut shell for enhanced oil-water separation performance. Colloids Surf. Physicochem Eng. Asp. 705, 135701 (2025).

Qu, W. et al. Synthesis and characterization of UIO-66-NH2 incorporated PVA/cellulose nanofibers composite aerogel for enhanced oil-water separation and formaldehyde adsorption. Sep. Purif. Technol. 325, 124673 (2023).

Liu, J. et al. Adsorption properties and mechanisms of methylene blue and Tetracycline by nano-silica Biochar composites activated by KOH. Chemosphere 337, 139395 (2023).

Zhai, Y., Yuan, X., Cheng, L. & Wu, H. Superhydrophobic cellulose-based aerogel derived from phormium tenax (Harakeke) for efficient oil sorption. Ind. Crop Prod. 202, 116981 (2023).

Wu, Y. et al. A versatile and efficient method to fabricate durable superhydrophobic surfaces on wood, lignocellulosic fiber, glass, and metal substrates. J. Mater. Chem. A 4, (2016).

Yu, X., Wu, Q. & Gu, L. Bioinspired surface silicification of cellulose-mediated PVDF membranes for significantly enhancing superhydrophilicity and anti-oil adhesion toward ultrafast oil/water emulsion separation. Ind. Crop Prod. 222, 119634 (2024).

Hu, C., Zhuang, J., Xia, Y., Zhang, J. & Zhang, X. Facile fabrication of sulfonated bacterial cellulose-silane composite aerogels via in situ polymerization for enhanced oil/water separation performance. Int. J. Biol. Macromol. 283, 137650 (2024).

Gundu, S., Sahi, A. K., Kumari, P., Vishwakarma, N. K. & Mahto, S. K. Assessment of various forms of cellulose-based Luffa cylindrica (mat, flakes, and powder) reinforced polydimethylsiloxane composites for oil sorption and organic solvents absorption. Int. J. Biol. Macromol. 240, 124416 (2023).

Ren, J., Wang, Y., Zhou, J. & Hu, L. Preparation and performance of surface-modified adsorbent materials from discarded traditional Chinese medicine residues. Mater. Res. Express. 10, 115508 (2023).

Montazeri, M. & Norouzbeigi, R. Ambient-dried, natural palm tree trunk–based hydrophobic foam for efficient oil sorption. Ind. Crops Prod. 225, 120551 (2025).

Zeng, G. et al. Solar-assisted efficient cleanup of high-viscosity oil spills using magnetic porous biochar. J. Alloys Compd. 924, 166474 (2022).

Kovačević, A., Marković, D., Radoičić, M., Šaponjić, Z. & Radetić, M. Sustainable non-woven sorbents based on jute post-industrial waste for cleaning oil spills. J. Clean. Prod. 386, 135811 (2023).

Pan, X., Kuang, S. & Wang, X. Effective strategy for alleviation of oil contamination in marine via the superhydrophobic biochar: performances, mechanisms and environmental recalcitrance. J. Clean. Prod. 462, 142695 (2024).

Huang, X., Jiang, Y. & Yu, R. Popped rice biochar and superhydrophobic SiO₂ / popped rice Biochar for oil adsorption. Silicon 13, 2661–2669 (2020).

Chen, Y. et al. Several birds with one stone strategy of pH/thermoresponsive flame-retardant/photothermal bactericidal oil-absorbing material for recovering complex spilled oil. J. Mater. Sci. Technol. 128, 82–97 (2022).

Debnath, S. & Das, R. Strong adsorption of CV dye by Ni ferrite nanoparticles for wastewater purification: fits well the pseudo-second-order kinetic and Freundlich isotherm model. Ceram. Int. 49, 16199–16215 (2023).

Zhao, S. et al. Efficient adsorption of methylene blue in water by nitro-functionalized metal-organic skeleton-calcium alginate composite aerogel. Int. J. Biol. Macromol. 253, 126458 (2023).

Yang, Z. et al. Development and application of metal–organic frameworks and spherical carbon particles for efficient recovery of phenols and oils from coal chemical wastewater: A new full-process adsorption treatment mode. Chem. Eng. J. 498, 155219 (2024).

Mao, Y. et al. Cotton fiber-anchored binary PANI and LDH composite for removal of ketoprofen in environmental water samples. Microchem J. 178, 107324 (2022).

Acknowledgements

This work was supported by the Scientific Research Foundation of Guizhou Education University (Project No: 2025ZD005), the Science and Technology Foundation of Guizhou Province (Project No: QKHJC-ZK[2021]254) and the Youth Science and Technology Talent Development Program of Guizhou Provincial Department of Education (Project No: QJH-KY[2022]299).

Author information

Authors and Affiliations

Contributions

Yu Wang and Junpeng Ren conceived the experiment(s), Junpeng Ren and Xiuheng Yang conducted the experiment(s), Junpeng Ren wrote the main manuscript text; Junpeng Ren, Yu Wang, Shijiang Zhang analysed the results. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Ren, J., Yang, X., Wang, Y. et al. Sustainable hydrophobic bio-based adsorbent from modified sphagnum moss for efficient oil-water separation. Sci Rep 15, 11792 (2025). https://doi.org/10.1038/s41598-025-96059-7

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-96059-7