Abstract

Rockburst accidents are highly likely to take place during the mining of coal seams in bifurcated area. A conventional triaxial testing machine and an acoustic emission (AE) monitoring system are employed to investigate the failure and instability characteristics of coal-rock parting-coal structure (CRCS) and its influencing mechanism. The results show that: (1) The instability process of the composite structure under the conventional triaxial path represents a coupled instability process of contact surface slipping and coal/rock fracture. The penetration of tensile fractures into shear fractures serves as the primary cause of the overall instability of the composite structure. (2) Alterations in the main frequency and maximum amplitude, a sharp decrease in the radiant energy index, and a significant increase in the cumulative apparent volume can be utilized as precursor identification information of the slipping and overall instability of the composite structure. (3) The inclination angle of the contact surface, confining pressure, and loading speed have an impact on the instability of the composite structure. Effectively controlling these factors during production can contribute to reducing the risk of impact disasters. The research results can provide theoretical support for the early warning and prevention of rockburst accidents in the bifurcated area.

Similar content being viewed by others

Introduction

During the deposition of coal seams, one or more strata of rock parting are frequently formed, which can make the coal seam structure more complex. The existence of rock parting is often a crucial factor in triggering coal seam impact disasters1,2. In recent years, rockburst have occurred frequently in coal mines, resulting in substantial economic losses. An investigation has disclosed that rock parting are present in the vicinity of the sites of these impact accidents3,4. Therefore, exploring the instability characteristics and influencing factors of coal seam structure under the influence of rock parting of great significance for preventing coal mining accidents.

In recent years, numerous novel theories and remarkable achievements have emerged in the field of rockburst prevention. The mechanisms of rockburst triggered by the instability of complex coal and rock structures have been gradually elucidated and uncovered. Li et al.5 explored the mechanical properties and failure instability characteristics of "coal-rock", "rock-coal", and "rock-coal-rock" material combinations based on the combination of coal and rock. Fan et al.6 investigated the failure characteristics and conditions of the coal and rock composite structure under the combined action of dynamic and static stresses through experiments and numerical methods, and explored the interrelationship between slipping rockburst and strain rockburst. Liu et al.7,8 studied the slipping and fracture instability mechanism of composite coal and rock structures under uniaxial dynamic and static loading by using the particle flow code (PFC). Some scholars have introduced the theory of stick–slip instability9,10 to study the phenomenon of rockburst instability induced by the shear slipping of coal and rock. These previous studies have explored the damage instability mechanisms of complex coal and rock structures from the perspectives of coal and rock structures and stress action modes, providing theoretical basis for the prevention of impact disasters induced by deep coal mining. However, these studies do not consider the characteristics of the three-dimensional stress state in the deep levels surrounding rock. Additionally, the instability process of coal and rock structures also varies under the action of radial pressure11,12,13. Moreover, although some scholars have evaluated the impact of rockbursts on coal seams, their research has mainly concentrated on the analysis and processing of field data, without effectively summarizing, analyzing, and interpreting the generation mechanism of rockbursts. Therefore, exploring the failure and instability characteristics of CRCS under conventional triaxial path and its influencing factors can not only clarify the instability mechanism of coal seams in the bifurcated area, but also provide theoretical guidance for rockburst disaster prevention.

During the processes of rock deformation and failure, a large number of cracks initiate, expand, and penetrate. As these cracks progress, the energy stored in the rock is released in the form of elastic waves, a phenomenon referred to as Acoustic Emission (AE)14,15. The AE phenomena can be used to monitor and evaluate the instability states of coal and rock. Qin et al.16 measured the micro-acoustic emission activity related to the deformation and failure of combined coal-rock structure under hard articulation conditions. Chen et al.17 utilized laboratory experiments in combination with numerical simulation methods to study AE signals during the fracture of composite coal samples, and interpreted sudden drops or abnormal calmness in AE signals as precursor indicators of rockburst in composite samples. Spetzler et al.18 reported that when a rock sample experiences critical damage, its AE signal waveform shows characteristics of "low frequency and high amplitude". These studies have significantly enhanced our understanding of the coal-rock failure process and provided technical support for preventing rockburst disasters. However, these investigations mainly focused on crack initiation, expansion, and penetration from the perspective of source evolution, without directly demonstrating the internal stress and displacement evolution characteristics within coal or rock19. The AE phenomenon can be regarded as a type of micro-seismic activity. In seismology, apparent stress and apparent volume are two parameters used to estimate stress levels and displacement deformations at their sources. These parameters are calculated based on each fracture occurrence within the rock matrix and can reflect internal stress information and displacement dynamics throughout the failure process20,21. Therefore, by analyzing the variations in apparent stress and relative displacement characteristics, we can explore dynamic evolution processes of stress distribution and deformation within the CRCS while studying the precursor signal attributes indicating instability.

Therefore, this study focuses on coal seam in the bifurcation area as its research background. A ternary series structure model of the CRCS has been established. By conducting conventional triaxial loading tests and employing an AE monitoring system, we investigate the failure instability characteristics and influencing factors of the CRCS. This research is aimed at discerning the precursor signals associated with the instability processes, such as the dominant frequency, maximum amplitude, cumulative apparent volume, and radiation energy index. The results of this paper not only enrich the theoretical comprehension of the deformation and failure mechanisms in the surrounding rocks of roadways and working faces but also offer novel perspectives for early warning and prevention strategies of rockburst accident in the bifurcated area of coal seams.

Test scheme and design

Experimental system

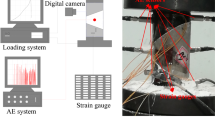

The experiments were conducted with an MTS815 electro-hydraulic servo rock mechanics testing machine and an AE testing and analysis system. The MTS815 machine is composed of three parts: the loading system, the control system, and the testing system. It has a maximum axial load capacity of 1700 kN and a maximum confining pressure of 50 MPa, fully meeting the loading requirements of the experiment. The AE testing and analysis system utilizes six Nano30 AE receivers with a resonant frequency of 300 kHz for signal acquisition. The experimental setup is shown in Fig. 1.

Sample design

Based on the geological structural characteristics of coal seam in the bifurcated area, a ternary composite sample consisting of CRCS was designed. The sample has dimensions of 50 mm × 100 mm, taking the form of a standard cylindrical shape composed of upper coal, middle rock parting, and lower coal, as shown in Fig. 2. The ends and contact surfaces of the samples were cut in a single operation using a cutting machine. During this cutting process, the integrity of each structural block was carefully monitored. Any samples with joints, cracks, or damage caused by human factors were rejected. Subsequently, fine sandpaper with a grit size of 2000 was used to polish the end faces. This ensured smooth contact with the testing machine and also guaranteed that the contact surfaces between the coal and the rock fit seamlessly, without any observable discontinuities. The overall height deviation of the samples should not exceed 0.2 mm, while the diameter deviation must be maintained within 0.1 mm. In accordance with the experimental requirements, the qualified composite samples were labeled and wrapped with cling film for protection them from weathering.

Test scheme

A total of 7 groups were designed to assess the combined model under diverse confining pressures, inclination angles, and loading speeds. The detailed testing scheme is shown in Table 1. The loading process is divided into three stages:

-

(1)

With the combined sample firmly secured, the initial system pressure is established by setting a pressure differential of 2 kN.

-

(2)

Employing stress control, both the axial pressure and confining pressure are loaded at a rate of 0.05 MPa/s. The loading of these two pressures is always synchronized until the pre—determined confining pressure strength is attained.

-

(3)

Once the confining pressure reaches the set value, it remains constant. Axial compression loading is then carried out through displacement control at a speed of 0.003 mm/s until the rock sample fails.

Failure and instability characteristics

Stress–strain curve, ring count and RA value

The waveform data of the AE signal contain basic information such as duration, rise time, ring count, amplitude, and energy. Among these, the ring count is a commonly used characteristic parameter in AE experiments. It represents the number of times the signal amplitude surpasses the set threshold (45dB). For a crack, the larger the ring count, the greater the overall amplitude of the vibration waveform generated by the crack, the stronger the signal strength, and the higher the crack energy22,23. The waveform of the AE signal is shown in Fig. 3.

The RA value represents the ratio of the AE rise time to the amplitude, with the unit is ms/mV, which can reflect the failure form of rock to a certain extent. Research shows that high RA values are associated with tensile failure, while low RA values are linked to shear failure24,25. To explore the fracture evolution characteristics related to the failure and instability of the CRCS, AE data were retrieved from experimental results of the combined sample R-5. Subsequently, the relationship curves of axial stress, ring count, and RA value with time were plotted, as shown in Fig. 4.

The failure and instability process of the combined sample R-5 can be divided into six stages. The OA stage represents the primary fracture pressure sealing stage, in which the number of AE events is small, the RA value is relatively small, the fracture type is shear fracture, and the axial stress exhibits “concave” growth. The AB stage represents the linear elastic stage, during which the axial stress increases linearly with minimal AE activity. The BC stage represents the precursor stage of slip, in which the internal axial stress produces a small stress drop, accompanied by a gradual increase in the number of AE events. However, the RA value is relatively small, and the fracture type is shear fracture. In general, the axial stress still tends to increase, but the slope of the curve decreases significantly. The micro-fractures reduce the accumulation rate of elastic energy inside the model. The CD stage represents the slip stage, in which the ring count increases rapidly, the RA value also reaches 9.44 ms /mV, and the axial stress clearly decreases. The overall slip phenomenon of the combined structure is caused by tensile fracture passing through micro-shear fracture on the coal-rock contact surface. The DE stage represents the precursor stage of global instability. As the stress continues to load, the axial stress gradually increases again, but the slope of the curve obviously decreases, and the ring count gradually decreases. At this time, the RA value of AE events is also significantly lower, because the coal-rock contact surface overcomes the static friction force and produces slip, which reduces the accumulation rate of the elastic energy within the model. The EF stage represents the stage of overall instability. With further loading of axial stress, the accumulated elastic energy reaches its bearing limit, the axial stress rapidly decreases after reaching its peak value, the RA value also rapidly increases and high values frequently appear, which indicates that tensile crack develop rapidly and that the model becomes overall unstable.

AE event

The axial stress, ring count, and RA value of the combined sample R-5 were statistically analyzed to determine the evolution forms of fractures. However, statistical analysis cannot directly reflect the spatial and temporal distribution characteristics of AE events. Therefore, to explore the spatiotemporal evolution features of AE events, the spatial evolution laws of AE event types and energies were derived based on the RA value and energy value of AE events, respectively. Specifically, the OA and AB stages, as well as the CD and DE stages, exhibit a relatively small number of AE events. These stages are combined for unified analysis, as presented in FigS. 5 and 6. The color and size of the spheres denote different crack types and source energy levels, which will not be repeated in the following.

In the OA and AB stages, discontinuous AE events occurred within the model. All the crack types were shear cracks, with a relatively small number of events and low energy levels (except for one high-energy event within the rock parting). The occurrence of these AE events was random, which was attributed to the inherent primary fractures in the coal and rock parting. In the BC stage, the AE events started to accumulate near the upper contact surface of the coal and rock parting, the number and energy of the events increased relatively, and tensile crack occur in the upper coal. Based on the spatial positioning of AE events, slip initially occurred at the contact surface. This was analyzed to be due to the large angle of the upper contact plane. In the CD and DE stages, the number of generated AE events decreased relatively reduced because of slip unloading. Notably, these events remained concentrated around the upper contact surface and were mainly shear cracks. This finding indicates that although slip unloading occurred on the upper contact surface at this stage, the energy released by slip was much less than the work done by external forces. Consequently, the axial stress continues to increase, which is also a precursor signal of the overall failure and instability of the model. In the EF stage, there was a rapid increase in the number of AE events, reaching a peak energy level of 4.78 × 106 ms·mV. These emissions gradually clustered together, with an increasing number of tension cracks, and emissions also initiated from the lower contact surfaces. This indicates that the overall instability of the combined model. Overall, in the model instability process, the temporal and spatial evolution of cracks is that shear cracks first promote the initiation and expansion of micro-cracks, and then tensile cracks eventually penetrate the shear cracks, leading to macroscopic failure and instability.

Apparent stress and relative displacement

To observe more clearly the evolution of the apparent stress and relative displacement of the combined sample R-5, the regions where the apparent stress exceeds 120 Pa and the relative displacement is greater than 9 × 10–4 m have been marked in red. Figures 7 and 8 show the temporal evolution patterns of the apparent stress and relative displacement of combined sample R-5, respectively.

When the loading time t = 1254 s, high stress is predominantly concentrated in the upper part of the coal and rock parting, with obvious stress concentration near the upper and lower contact surfaces. This indicates that the contact surface can impede stress transfer, thereby resulting in localized stress concentrations. From the relative displacement evolution cloud map, there is a distinct relative displacement difference between the upper and lower contact surfaces, particularly at the upper contact surface, which indicates that there is a slipping phenomenon along the contact surface of coal and rock parting, and the degree of slipping at the upper contact surface is greater than that at the lower contact surface. When t = 1342 s, the high stress zone gradually expands downward from the upper coal. Simultaneously, a low stress zone emerges in the middle of the rock parting, and the high stress zone migrates to both sides of the rock parting, which indicates that a fracture phenomenon occurs in the middle of the rock parting. This phenomenon is also show in Fig. 8. When t = 1380 s, the high stress zone in the rock parting is significantly reduced, and the range of the low stress zone gradually expands, indicating that the combined model experiences a failure phenomenon. Additionally, the apparent stress and relative displacement exhibit obvious stress and displacement differences on both sides of the contact surface, indicating that the model experiences the slipping of the contact surface during the fracture instability process. When t = 1414 s, the high stress region expands rapidly, while the high and low stress regions produce “scatter” distribution characteristics, and the relative displacement also produces “scatter” distribution characteristics, indicating that the combined model experiences overall instability.

In summary, the failure and instability process of the combined model represents a damage evolution in terms of apparent stress and relative displacement. The concentration of the high stress region facilitates the generation, expansion, and interconnection of cracks within the model, and then causes displacement changes in the internal block of the model and slip dislocation within the structure. Concurrently, the slip dislocation within the composite structure can trigger the migration of the high stress zone inside the model, thereby further intensifying the degree of fracture of the coal and rock parting. Therefore, the failure and instability process of the CRCS is also a coupling instability involving contact surface slipping and coal/rock parting fracture.

Energy dissipation

To investigate the energy dissipation characteristics during the failure and instability processes of the CRCS, the AE monitoring data of composite model R-5 were statistically analyzed, and curves of the axial stress, total released energy and absolute energy over time were drawn, as shown in Fig. 9.

The energy dissipation process of the combined sample R-5 under triaxial compression can be categorized into three stages: the slip dissipation stage, the energy accumulation stage, and the failure dissipation stage. During the initial loading process, the phenomenon of slip energy release occurs, with a relatively small contribution to the total dissipated energy, accounting for only 2.97%. In this stage, the majority of the work performed by the loading system is released through structural slipping. As loading progresses, the model transitions into the energy accumulation stage, where the work done by the loading system is greater than the sum of structural slipping and AE energy release, and the accumulated elastic energy gradually increases. In this stage, essentially silent AE events occur, and the total energy released is essentially 0. With increasing degree of stress loading, the accumulated energy inside the model reaches its bearing limit until the model finally experiences overall instability, which is the failure dissipation stage. The accumulated elastic energy is released rapidly, and both the absolute energy and the total energy released reach a peak.

Instability precursor

Based on the above analysis, it can be concluded that the slipping of contact surfaces and the fracture of coal-rock parting are direct causes of the overall structural failure and instability in the CRCS. Therefore, it is very important to identify some precursory characteristics of these activities for the prevention of rockburst in bifurcated area.

-

(1) Main frequency and maximum amplitude

The variation curves of the main frequency and maximum amplitude of the combined sample R-5 are shown in Fig. 10. The main frequency and maximum amplitude of AE events are obviously different in the process of slipping and overall instability. When t = 1243 s and 1278 s, the combined model is in the slip stage, and AE event amplitude produces two peaks (A and B), the peak amplitude reaches 0.044 mV and 0.043 mV, and the main frequency is relatively high. When t = 1382 s and t = 1413 s, the combined model is in the overall instability stage, the maximum amplitude of AE events increases significantly (C and D), and the maximum amplitudes are 0.16 mV and 0.79 mV, respectively, but the main frequency is concentrated in the relatively low frequency region. Therefore, the variation in the main frequency and maximum amplitude can be used to predict contact surface slipping and the overall instability of the composite structure.

-

(2) Cumulative apparent volume and radiant energy index

The variation curves of the cumulative apparent volume and radiant energy index of combined sample R-5 with loading time during failure and instability are shown in Fig. 11. Before the slip occurred (1270 ~ 1271 s), the radiant energy index exhibited a downward trend, whereas the increase in cumulative apparent volume accelerated, indicating that local strain softening within the model exacerbated the instability of the CRCS. As shown in Fig. 7, there was an apparent stress concentration near the contact surface of the coal and rock parting, and it can be concluded that instability occurred near the contact surface. Concurrently, based on fracture evolution characteristics such as main frequency and maximum amplitude, slipping can be concluded to have occurred at the contact surface of the coal and rock parting. When t = 1286 ~ 1370 s, the radiation energy index showed an increasing trend, and the cumulative apparent volume remained essentially unchanged. At this time, the model was in the strain hardening stage, and the elastic energy gradually accumulated. Before the overall instability of the model (1270 ~ 1371 s), the radiant energy index decreased rapidly and the cumulative apparent volume increased sharply. At this time, the model was in strain softening state again and was about to reach the final instability state. After 1371 s, the radiant energy index fluctuated abnormally, the cumulative apparent volume continued to increase, the strain softening of the model was obvious, and the model reached the overall instability. In summary, the sharp decline in the radiant energy index and the sharp increase in the cumulative apparent volume can be considered the precursory characteristics of structural slipping and overall instability of the CRCS.

Analysis of influence factors

Inclination angle of contact surface

To investigate the influence of the inclination angle of the contact surface on the failure and instability of the combined samples, comparative tests were conducted using combined models R-1, R-2, and R-3 with varying inclination angles. The stress–strain curves for these models are shown in Fig. 12. The peak instability strength for the combined models at different inclination angles are 93.9 MPa, 89.7 MPa and 77.116 MPa, respectively. With increasing inclination angle of the contact surface, the bearing capacity of the model decreases gradually. However, the axial strain increases gradually when the model is unstable, which indicates that the accumulated elastic energy may be gradually released with the slipping of coal and rock parting, leading to a reduction in peak instability strength while simultaneously increasing axial strain.

To further investigate the instability characteristics of the combined model attributed to the slip at the contact surface, the macro and micro-failure and instability characteristics of the combined models R-1, R-2 and R-3 are drawn, as shown in Figs. 13 and 14.

Model R-1 exhibits significant fracture phenomenon of coal and rock parting, and macroscopic fractures traverse the whole model. In contrast, Model R-2 shows that the fracture phenomenon is relatively weakened, and obvious slip dislocation occurs on the lower contact surface. Slip dislocation occurs on both the upper and lower contact surfaces of model R-3, and there is no macroscopic fracture in the coal and rock parting. This finding indicates that with increasing inclination angle of the contact surface, the instability form of the combined sample gradually changes from fracture instability to slipping instability. From the perspective of the AE energy, the degree of energy release of model R-1 is obviously large, and there are more large energy events, especially in the rock parting. The AE location of model R-2 is concentrated in the middle of the model, and the energy of a single AE event is greater, especially the source density in the upper coal, which is obviously greater. Model R-3 AE events are evenly distributed, and the AE density and energy peaks are significantly smaller (with only two events exceeding 104 ms·mV). The stress‒strain curves of the three models, indicate that a change in the inclination angle of the contact surface can cause a change in the failure and instability of the model.

Figure 15 shows the evolution of AE energy and ring count with time for the combined model R-5. At the initial stage of loading, no AE signal was detected from the combined sample, indicating that the stress intensity at this stage was relatively low and insufficient to cause damage to the coal and rock parting. When the loading time reaches 719 s, the number of AE suddenly increases and the energy is high, with a maximum energy of 154 ms·mV. Concurrently, the small and medium energy ring counts continue to increase within the model. The shear stress of the contact surface of coal and rock parting overcomes the static friction resistance, leading to unstable slipping at these interfaces. With a further increase in axial stress, stable slipping occurred along these contact surfaces. Consequently, the number of small energy events increases gradually, and the accumulated elastic energy is released quickly.

Confining pressure

The original rock stress field is a three-dimensional stress field, and the magnitude of the original rock stress is influenced by factors such as the burial depth of coal seams, faults, and folds in geological structures. To investigate the influence of the confining pressure on the failure and instability of the CRCS, three model samples were designed to study the influence of the confining pressure. The stress–strain curves of models R-4, R-3 and R-5 under different confining pressures are shown in Fig. 16.

With increasing confining pressure, the peak instability strength of the model gradually increases. However, the peak strain first increases and then decreases with increasing confining pressure. This analysis indicates that the axial stress required for coal and rock parting fractures changes due to changes in the confining pressure. Concurrently, the axial stress required for slipping along the contact plane of coal and rock parting is also affected. Furthermore, the failure and instability characteristics of the combined model are altered under the influence of contact surface slipping and coal /rock parting fractures.

Figures 17 and 18 show the macro and micro-failure and instability characteristics of the combined models R-4, R-3, and R-5 under different confining pressures. When the confining pressure is 10 MPa, from the perspective of macroscopic fracture characteristics, the lower coal of model R-4 has obvious plastic failure and slipping dislocation occurs on the lower contact surface. From the perspective of mesoscopic fracture characteristics, only two minor energy events are detected in the upper coal far from the contact surface of coal and rock parting, while there are more AE events in the lower coal, and the accumulation of minor energy events occurs in the lower contact surface, indicating that the combined model has a slipping instability phenomenon along the lower contact surface. When the confining pressure is 20 MPa, from the perspective of the macroscopic fracture characteristics, there is no obvious macroscopic fracture, but there are obvious slipping dislocations on both contact surfaces. From the perspective of mesoscopic fracture characteristics, minor energy events are generated in coal and rock parting, but the events are relatively dispersed, which indicates that the mesoscopic cracks have not been connected to form macroscopic cracks. Additionally, it is evident that energy events are generated on both the upper and lower contact surfaces of coal and rock parting. When the confining pressure is 30 MPa, from the perspective of the macroscopic fracture characteristics, an obvious macroscopic shear fracture occurs in the middle of the model, and no obvious slipping dislocation occurs on the contact surface of the coal and rock parting. From the perspective of mesoscopic fracture characteristics, the density of energy events increases, the number of large energy events increases significantly, and energy events are also generated at the contact surface, which indicates that the failure and instability characteristics of model R-5 also include the slipping instability of the upper and lower contact surfaces. However, compared with those of model R-3, the fracture and instability characteristics of the coal and rock parting are more obvious.

Based on the analysis of the experimental phenomena of different confining pressures, the failure and instability characteristics of the combined model can be divided into three types. First, when the axial stress required for coal and rock parting fracture is less than that required for slipping along the two contact planes, the combined model will produce fracture instability. Second, when the axial stress required for the contact surface slipping with a larger inclination angle is less than that required for coal and rock parting fracture, the combined model will produce single contact surface slipping and fracture instability. Third, when the axial stress required for coal and rock parting fracture exceeds that required for slip along both surfaces, the combined model will produce double contact surface slipping and fracture instability.

Loading speed

In engineering practice, the process of stress redistribution around roadways is influenced by the excavation speed. When the excavation speed is relatively high, the rate of increase in axial pressure surrounding the roadway also tends to be faster. Therefore, it is highly important to study the influence of loading speed on the failure and instability of the CRCS. To explore the influence of loading speed, the combined models R-3, R-6 and R-7 were designed for comparative analysis. The stress–strain curves for models R-3, R-6, and R-7 under different loading speeds are shown in Fig. 19.

The peak instability strength of the combined model under different loading speeds are 77.116 MPa, 78.5 MPa and 81.374 MPa, respectively. With increasing axial stress loading speed, the peak instability strength of the combined model gradually increases. This finding indicates that the bearing capacity of the combined model can be enhanced with increasing loading speed. The axial strain of the three models are R-7, R-6 and R-3 in descending order. These findings indicate that increasing the loading speed can enhance the brittle failure characteristics of the combined model.

The macro and micro failure and instability characteristics of the combined models R-3, R-6 and R-7 under different loading speeds are shown in Figs. 20 and 21. With increasing loading speed, the macro and micro failure characteristics of the model also change. In model R-3, there is no macroscopic damage to the coal and rock parting, and the two contact surfaces have obvious slipping dislocations. The distribution of AE sources is uniform with relatively low energy levels. In model R-6, the upper coal of model R-6 has obvious macroscopic damage, the source events are concentrated in the upper part of the model and the energy is relatively high. Slip displacement occurs at the upper contact surface, whereas there are essentially no cracks or slip movements are detected in the lower coal. In model R-7, obvious macroscopic damage occurs in the upper coal, slipping dislocation occurs at the upper contact surface, and AE events are evenly distributed. However, both the quantity and energy of AE sources significantly exceed those found in the lower section of the model. Although some AE sources appear on the lower contact surface, their numbers are minimal, indicating that there is no observable slipping phenomenon macroscopically. According to the macro and micro fracture instability characteristics of the combined sample, the local stress concentration obviously increases with increasing loading speed, and the concentrated stress causes local failure and instability of the model. Consequently, the instability characteristics of the model also change from overall slipping instability to local fracture and slipping instability.

Figure 22 shows the number of events, peak energy and total energy of models R-3, R-6 and R-7 under different loading speeds. With increasing loading speed, the peak energy and total energy of AE events gradually increase. This indicates that the higher the loading speed is, the more energy is released, and the more obvious the rockburst phenomenon. The number of AE events first increases but then decreases, which is attributed to the abnormal fracture of the upper coal caused by the local stress concentration. In general, with increasing loading speed, the number of AE events tends to increase.

Conclusion

-

(1)

The failure and instability process of the CRCS is characterized by a coupled instability mechanism involving contact surface slip and coal/rock parting fractures. During this process, shear crack initially promotes the initiation and propagation of micro-crack within the model. Subsequently, tensile crack ultimately connects with these shear crack, resulting in macro failure and instability.

-

(2)

When slip occurs in the combined samples, the maximum amplitude of AE sources is relatively low, accompanied by a relatively high fundamental frequency. Conversely, when the overall instability occurs, the maximum amplitude is relatively high and the main frequency is relatively low. The variations in the main frequency and maximum amplitude can be used to predict contact surface slipping and the overall instability of the combined structure. The sharp decrease in the radiant energy index and the sharp increase of cumulative apparent volume can be used as precursory characteristics of contact surface slipping and overall instability of the composite samples.

-

(3)

With increasing inclination angle of the contact surface, the instability form of the CRCS changes from fracture to slipping, and the instability strength of the model decreases gradually. With increasing confining pressure, the axial stress required for failure and instability of the CRCS increases. The influence of the confining pressure on the failure and instability characteristics mainly focuses on the fracture of coal and rock parting, but has little effect on the slipping instability of the contact surface. With increasing loading speed, the instability form changes from overall slipping instability to local fracture and slipping instability, the energy released gradually increases, and the rockburst phenomenon is significantly enhanced.

Data availability

The datasets used and analyzed during the current study are available from the corresponding author on reasonable request.

References

Liu, G. J., Mu, Z. L. & Karakus, M. Coal burst induced by rock wedge parting slip: A case study in Zhaolou coal mine. Int. J. Min. Reclam. Environ. 32(5), 297–311 (2018).

Wang, J. C. et al. Mechanism of rock burst occurrence in specially thick coal seam with rock parting. Rock Mech Rock Eng. 49, 1953–1965 (2016).

Zhang, H. et al. Numerical study on the characteristics of roadway failure and instability in coal seam with rock parting. Sci. Rep. 14, 1587 (2024).

Liu, Y., Cai-Ping, Lu., Xiao, Z.-Y. & Guo, Y. Mechanisms underlying the slip and failure of coal-rock parting-coal structures under unloading conditions. Rock Mech. Rock Eng. 55(8), 4913–4928 (2022).

Li, F. X., Yin, D. W., Wang, F., Jiang, N. & Li, X. L. Effects of combination mode on mechanical properties of bi-material samples consisting of rock and coal. J. Market. Res. 19, 2156–2170 (2022).

Fan, Y. F. et al. Failure characteristics and conditions of rock-coal combination structure with weak layer under dynamic and static stresses. Sci. Rep. 13(1), 12410 (2023).

Liu, Y. et al. Numerical investigation of slip and fracture instability mechanism of coal-rock parting-coal structure(CRCS). J. Struct. Geol. 118, 265–278 (2019).

Lu, C. P. et al. Mechanisms of rockburst triggered by slip and fracture of coal-parting-coal structure discontinuities. Rock Mech. Rock Eng. 52, 3279–3292 (2019).

Babanouri, N., Asadizadeh, M. & Hasan-Alizade, Z. Modeling shear behavior of rock joints: A focus on the interaction of influencing parameters. Int. J. Rock Mech. Min. Sci. 134, 104449 (2020).

Dieterich, J. H. Time-dependent friction and the mechanics of stick-slip. Pure Appl. Geophys. 116(4/5), 790–806 (1978).

Ma, B., Wang, F., Liu, H. Y., Yin, D. W. & Xia, Z. G. Mechanical properties of rock-coal-rock composites at different inclined coal seam thicknesses. Front. Phys. 9, 806055 (2022).

Guo, W. Y. et al. Mechanical behavior of rock-coal-rock specimens with different coal thicknesses. Geomech. Eng. 15(4), 1017–1027 (2018).

Ma, C., Zhu, C. J., Zhou, J. X., Ren, J. & Yu, Q. Dynamic response and failure characteristics of combined rocks under confining pressure. Sci. Rep. 12(1), 12187 (2022).

Tham, L. G., Liu, H., Tang, C. A., Lee, P. K. K. & Tsui, Y. On tension failure of 2-D rock specimens and associated acoustic emission. Rock Mech. Rock Eng. 38(1), 1–19 (2005).

Tan, Y. L., Zhang, Z. & Zhao, T. B. AE pattern of rock burst disaster induced by strata activation in coal mine. Disaster Adv. 4(4), 29–33 (2011).

Qin, S. Q. et al. Instability leading to coal bumps and nonlinear evolutionary mechanisms for a coal-pillar-and-roof system. Int. J. Solids Struct. 43, 7407–7423 (2006).

Chen, Z. H., Tang, C. A. & Huang, R. Q. A double rock sample model for rockbursts. Int. J. Rock Mech. Min. Sci. 34(6), 991–1000 (1997).

Spetzler, H. et al. Seismic and strain studies on large laboratory rock samples being stressed to failure. Tectonophysics 1444, 55–68 (1987).

He Zhilong, Lu. et al. Research on mechanisms and precursors of slip and fracture of coal-rock parting–coal structure. Rock Mech. Rock Eng. 55, 1343–1359 (2022).

Hardy, H. R. Geotechnical field applications of AE/MS techniques at the Pennsylvania State University: A historical review. NDT E Int. 27, 191–200 (1994).

Senatorski, P. Apparent stress scaling and statistical trends. Phys. Earth Planet. Inter. 160(3–4), 230–244 (2007).

Manthei. G., Zang, A. & Grosse, C. U. Laboratory acoustic emission in study of rock mechanics. Acoustic Emission Testing, 2 Edn. 477–527 (2022).

Liu, W. R., Liu, J. K. & Zhu, C. Multi-scale effect of acoustic emission characteristics of 3D rock damage. Arab. J. Geosci. 12(22), 668 (2019).

Shahidan, S., Pullin, R., Bunnori, N. M. & Zuki, S. S. M. Active crack evaluation in concrete beams using statistical analysis of acoustic emission data. Insight 59(1), 24–31 (2017).

Yilei, Gu., Wang, Z., Qingmiao Li, Ju. & Fang, S. L. Laboratory study on RA value fractal of shale acoustic emission under conventional triaxial compression. J. Chongqing Univ. 41(2), 78–86 (2018) ((In Chinese)).

Acknowledgements

We gratefully wish to acknowledge The Sponsored by Natural Science Foundation of Henan (242300420353) and Research Project on Science and Technology of Nanyang City (24KJGG018, 24KJGG066), Basic and Frontier Technology Research Project of Nanyang City (23JCQY2014) and Doctoral Research Start-up Fund Project, Nanyang Institute of Technology (NGBJ-2022-37).

Author information

Authors and Affiliations

Contributions

Y.-Y.P.: Conceptualization, methodology, software, visualization, data curation, formal analysis, writing—origi nal draft preparation, funding acquisition; H.Z.: Conceptualization, investigation, validation, methodology, supervision, writing—original draft preparation; D.-Y.Y.: Project administration, methodology, formal analysis, writing-review and editing, funding acquisition; X.W.: Formal analysis, visualization, validation; Y.-W.Z.: Vali dation, supervision; J.-Q.W.: Validation, formal analysis.

Corresponding authors

Ethics declarations

Competing interest

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Pi, Y., Zhang, H., Yao, D. et al. Study on the instability characteristics and influencing mechanism of coal-rock parting-coal structure under triaxial loading. Sci Rep 15, 12404 (2025). https://doi.org/10.1038/s41598-025-96584-5

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-96584-5