Abstract

This paper proposes an ultra-broadband flexible conductor backed coplanar waveguide with triangular edges (FCBCPW-TE), comprising a conductor-backed coplanar waveguide (CBCPW) and triangular arrays arranged periodically along the edges. The simulation results show that the periodically arranged edge triangles could effectively block leaky waves in the DC-70 GHz frequency range. The design of this flexible transmission line, which propagates TEM mode, is straightforward. Through the optimized design, theoretical analysis, and experimental validation, the measured results show that it has good transmission performance in flat, bent, and twisted states. The measured results show that the insertion loss is less than 0.19 dB/mm from 10 MHz to 70 GHz, and the reflection coefficient is less than − 10 dB. Additionally, the measured group delay per unit length is 4.79 ps-6.18 ps, with a group velocity dispersion less than 1.13 ps2/mm. The proposed FCBCPW-TE, characterized by high frequency, miniaturization, and ultra-thin flexibility, holds promising potential for application in ultra-miniature high-speed communication systems.

Similar content being viewed by others

Introduction

Transmission line constitutes the foundation of high-speed communication networks and radio frequency (RF) microwave engineering. With the rapid advancement in electronics and integrated circuit technologies, the potential for development in high-speed digital circuit interconnection transmission, picosecond interconnection, and chip interconnection is substantial. To ensure energy can be transmitted at low loss and high speed during communication, designing a well-performing transmission line is crucial. Thus, the concept of broadband transmission lines ranging from direct current (DC) to millimeter-wave/terahertz (THz) frequency has been introduced1,2,3,4.

As conformal and wearable devices become more prevalent, there is an increasing demand for efficient, flexible circuits. Broadband transmission lines rapidly evolve towards flexible, conformal, giving high-frequency, high-speed transmission circuits the characteristics of foldable/bendable deformation5,6. By integrating various functional devices on a flexible substrate, one can construct foldable/bendable high-frequency, high-speed novel flexible interconnection structures. These can alter the rigid physical state of traditional information devices/systems and achieve efficient integration with information and communication systems. Consequently, the design of a flexible broadband transmission line carries profound research significance5,7.

Traditional flexible transmission lines could be categorized into three types based on operational modes. The first type includes microstrip, coaxial, and coplanar waveguides that transmit in Quasi-TEM modes8. While these TEM-based transmission lines do not have a cutoff frequency, they suffer from significant attenuation and loss at high frequencies, making them unsuitable for Millimeter wave (mmW) applications. The second category comprises rectangular waveguides and substrate-integrated waveguides (SIWs), which transmit in the TE10 mode and exhibit low-loss characteristics8,9. However, these transmission lines have a cutoff frequency and cannot propagate signals starting from DC. In reference10, M.S. Mahani proposed a flexible substrate-integrated waveguide, achieving a flexible interconnection structure operating in the 16–40 GHz range. Nevertheless, the bandwidth of SIWs is limited to only 40% due to their cutoff frequency. A third approach involves the design based on spoof surface plasmon polaritons (SSPP) principles, which exhibit a field confinement effect that significantly restricts electromagnetic energy near the metal/dielectric interface11,12,13. However, SSP flexible transmission lines suffer noticeable radiation loss under bending, folding, and twisting conditions. Additionally, SPP transmission lines require conversion structures, which add to the design complexity. In summary, traditional flexible transmission lines struggle to achieve ultra-broadband transmission from DC to mmW range.

This paper designs and fabricates a flexible, low-loss, broadband transmission line based on deformable CBCPW, and verifies its excellent transmission performance in flat, bent, and twisted states within the DC–70 Hz operating frequency range. The measured return loss is less than − 10 dB from DC to 7 GHz, and the insertion loss is less than 0.19 dB/mm.

Results

Working principle

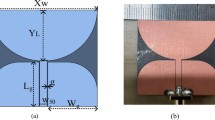

Figure 1 illustrates the structure of FCBCPW-TE, which is composed of a periodic triangular CBCPW, with specific configurations and dimensions as indicated in the caption. By adjusting the geometric parameters of the periodic triangular stubs, such as the period p, height l, and width n, the propagation characteristics of the transmission line could be controlled. The FCBCPW-TE utilizes a flexible substrate composed of a 0.1 mm-thick polyimide (PI) substrate with a dielectric constant of 4 and a loss tangent of 0.002. Polyimide exhibits exceptional tensile strength and remarkable electrical properties. The port impedance of FCBCPW-TE is 50 ohms, eliminating the need for any additional transition.

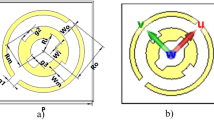

The periodic triangular stubs along the edge of the CBCPW serve to block wave leakage, operating on the following principles. Figure 2a and b depict the configuration and equivalent circuit of the periodic triangular cell, respectively.

The edge of the FCBCPW-TE consists of an infinite repetition of periodic triangular units, where the admittance jb is separated by a distance d on the z-axis14,15,16. The performance of the unit can be represented by its equivalent ABCD matrix14. Therefore, the input and output of the nth unit are expressed as:

Where,

From reference14, the requirement for no electromagnetic wave propagation in a periodic triangular unit in the form of an infinitely cascaded cell is given by Eq. (2).

When the conditions of Eq. (2) are met, the periodic triangular unit is unable to propagate waves, defining a stopband. In these formulas, b represents admittance, θ = kd is the electrical length, k is the propagation constant, p is the period, and γ denotes the complex propagation constant.

When the condition 0.5|A + D|≥1 in Eq. (2) is met, it implies that the periodic structure cannot propagate waves, and the waves decay along the line. In this case, the stub exhibits band-stop characteristics. The dimensions of the simulated and optimized periodic stub unit are p = 0.3 mm, m = 0.1 mm, n = 0.2 mm, and l = 1 mm. The ABCD matrix parameters of the periodic unit are extracted from the S-parameter simulated by HFSS, demonstrating the existence of a bandgap from DC to 75 GHz (where 0.5|A + D|≥1), as shown in Fig. 3. This verifies that within the DC-70 GHz range, the periodic stub behaves similarly to a high-impedance surface, preventing wave leakage outside the stub. The S-parameters of the transmission lines are simulated, revealing significant insertion loss above 75 GHz, as shown in Fig. 4.

To further verify the bandgap characteristics of periodic stubs, equivalent to “metal sidewalls”, the following Fig. 5 presents the electric field distributions of CBCPW with and without stubs at different frequencies. As the frequency increases, the CBCPW occurs significant field leakage. For the FCBCPW-TE, the electric field is effectively confined within the periodic triangular stubs when the frequency increases from 20 GHz to 60 GHz (in increments of 20 GHz). At 80 GHz, the electric field leaks towards the edges, indicating that the periodic triangular structure is no longer effective in blocking wave propagation. Figure 5 also illustrates the electric field conditions of FCBCPW-TE in both flat and 90-degree bent statuses. The electric field characteristics of FCBCPW-TE remain consistent when bent at 90 degrees compared to its flat state. This indicates that the transmission line exhibits excellent flexibility and bending characteristics. Furthermore, the FCBCPW-TE propagates in a quasi-TEM mode.

The configuration of the FCBCPW-TE under study in which L = 100 mm, W = 18 mm, w1 = 0.28 mm, g = 0.13 mm, s = 0.3 mm, h = 0.1 mm, thickness of the polyimide (PI) substrate is 0.1 mm and thickness of the copper conductor is 0.018 mm. The geometry of the triangular unit cell in which P = 0.3 mm, m = 0.1 mm, n = 0.2 mm, l = 1 mm. (a) Top View. (b) 3D View. (c) Side View.

Method analysis. The simulated result of |0.5(A + D), where A and D are parameters of the ABCD matrix of the equivalent stub circuit, is shown in Fig. 2.

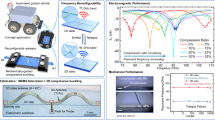

Fabrication and measurement process

The design and optimization of the FCBCPW-TE resulted in specific parameters for a flexible transmission line with excellent transmission performance. To validate the theory, a prototype of the FCBCPW-TE was fabricated using PCB technology, and its performance was measured using a vector network analyzer. Figure 6 shows the physical fabrication of the FCBCPW-TE, which utilized polyimide flexible substrate with a thickness of 0.1 mm, and two lengths of 100 mm and 140 mm were fabricated.

The S-parameters and group delay of the transmission lines, in both lengths (100 mm and 140 mm), were measured using the Anritsu MS4647B Vector Network Analyzer (VNA) across the operational frequency range of 10 MHz–70 GHz. The VNA was calibrated using the two-port method, which involved four steps: short, open, load, and thru. After calibration, the FCBCPW-TE was connected to the VNA to complete the measurement within the 10 MHz–70 GHz working frequency range.

The practical measurement process for the FCBCPW-TE was conducted on the measurement setup depicted in Fig. 7, which comprises a vector network analyzer, coaxial cables, spread spectrum modules, 1 mm coaxial connectors, and 1 mm End Launch test probes. Figure 7 is a schematic diagram of the test in the working frequency range of 10 MHz–70 GHz. Figure 8 demonstrates the testing process of the FCBCPW-TE in various configurations, including flat, bent, and twisted states, thereby verifying its bendability and conformability characteristics.

Simulation and measurement results

Figure 8 illustrates the measuring process for the 100 mm and 140 mm FCBCPW-TE in various states (flat, upward bent, downward bent, and twisted). Differential calculations are required to measure the insertion loss and group delay (Measure |140 mm–100 mm|). During the fabrication, surface roughness in the metal is inevitable. This factor has been considered in the simulation, and the Huray model has been employed to simulate the impact of surface roughness17,18. The Huray model, characterized by a nodule radius of 1.8 micrometers (µm) and a hall-huray surface ratio of 0.5, is utilized to simulate the effects of surface roughness on the system17. The simulation results of the S-parameters, which take into account the surface roughness of the metal, are shown in Fig. 9.

Figure 9a and b compare the measured and simulated results for the FCBCPW-TE. Figure 9a exhibits the differential insertion loss (Measure |140 mm–100 mm|) from both simulated and measured results, indicating that the insertion loss is less than 0.19 dB/mm in the 10 MHz-70 GHz range. Additionally, Fig. 9b shows the reflection coefficient of the FCBCPW-TE, indicating that the simulated and measured reflection coefficients are below − 10 dB. The small discrepancies between the simulated and measured insertion losses across the entire frequency range can primarily be attributed to measurement and fabrication errors. Furthermore, the inevitable introduction of metal surface roughness during the PCB fabrication may also contribute to these differences. However, the insertion loss of the flexible transmission line under different measuring states (flat, upward bent, downward bent, and twisted) is less than 0.19 dB/mm, validating its excellent flexible transmission performance.

To further elucidate the group delay and dispersion characteristics of FCBCPW-TE, an analysis was conducted on the group delay and Group Velocity Dispersion (GVD) of both simulated and measured results. Figure 9c depicts the group delay outcomes from the simulations and measurements. The test results indicate that the group delay remains relatively flat within the operational frequency range, suggesting the absence of phase distortion in the transmission line. Moreover, as illustrated in Fig. 9c, the group delay per unit length is less than 6.18 ps/mm. Notably, the measured group delay slightly outperforms the simulated results.

Figure 9d presents the simulated and measured Group Velocity Dispersion (GVD) for the FCBCPW-TE. The simulated and measured GVD values are less than 1.13 ps2/mm within the frequency band of 10 MHz to 70 GHz, indicating that this flexible transmission line has extremely low dispersion.

To further highlight the advantages of the proposed FCBCPW-TE, Table 1 provides a comparison of the working bandwidth, integration, power handling capability, and insertion loss of conventional microstrip lines(MLs), coplanar waveguides(CPWs), and Surface plasmon polaritons (SSPPs)11,19,20,21,22,23. From the perspective of bandwidth, the FCBCPW-TE operates from DC and has a bandwidth comparable to that of CPW, but it outperforms both SSPPs and MLs. From the perspective of integration, FCBCPW-TE, MLs, and CPWs are all easy to integrate. However, SSPPs require additional transition structures, making them more difficult to integrate. Regarding power handling capability, MLs have a low quality factor and low power handling capability due to their open structure and high losses. The power handling capability of FCBCPW-TE is comparable to that of CPWs and better than that of MLs. SSPPs could highly confine the electromagnetic field at the metal-dielectric interface, resulting in significant field enhancement. This allows for higher energy density in the localized area under the same input power. The power handling capability of SSPPs is slightly higher than that of CPW and FCBCPW-TE, but it is still relatively low. From the perspective of insertion loss, the FCBCPW-TE has lower losses than the conventional ML and CPW reported in references20,22. In summary, the proposed FCBCPW-TE demonstrates significant advantages in terms of bandwidth, integration, and loss.

Discussion

This paper presents a flexible transmission line based on CBCPW, featuring a periodically triangular structure along its edges that confines electromagnetic waves within the DC to 70 GHz range. The periodic stubs exhibit an effect similar to a high-impedance surface, creating a stopband within their operational frequency range. This prevents wave leakage towards the outer sides, like the transmission line possessing two rows of metallic sidewalls. The prototype of the FCBCPW-TE underwent optimized design, fabrication, and measuring in various states. The measured results indicate that the insertion loss from 10 MHz to 70 GHz is less than 0.19 dB/mm, with an S11 below − 10 dB. The measured group delay per unit length ranges from 4.79 to 6.18 ps, exhibiting a flat profile that suggests minimal phase distortion. Furthermore, the measured Group Velocity Dispersion (GVD) is below 1.13 ps2/mm, indicating extremely low dispersion. The consistent electromagnetic performance of the FCBCPW-TE in both flat and deformed states demonstrates its suitability for high-frequency, low-loss, and miniaturized flexible circuit applications.

Methods

Numerical simulations were conducted using the electromagnetic simulation software ANSYS HFSS. For the transmission line structure, two prototypes of varying lengths were fabricated using the PCB technology (100 mm and 140 mm), with a polyimide substrate exhibiting a dielectric constant of 4 and a loss tangent of 0.002. The metal copper cladding had a thickness of 0.018 mm and an electrical conductivity of 5.8 × 107 S/m. The Anritsu MS4647B Vector Network Analyzer measured the S-parameters and group delay.

Data availability

All data generated or analysed during this study are included in this published article.

References

Tonouchi, M. Cutting-edge terahertz technology. Nat. Photon. 1(2), 97–105 (2007).

Wang, D. & Ke, W. Propagation characteristics of mode-selective transmission line. In 2018 IEEE/MTT-S International Microwave Symposium-IMS (IEEE, 2018).

Fesharaki, F. et al. Low-loss and low-dispersion transmission line over DC-to-THz spectrum. IEEE Trans. Terahertz Sci. Technol. 6(4), 611–618 (2016).

Fesharaki, F. et al. Guided-wave properties of mode-selective transmission line. IEEE Access. 6, 5379–5392 (2017).

Cherukhin, I., Si-Ping, G. & Yongxin, G. Fully flexible polymer-based microwave devices: materials, fabrication technique, and application to transmission lines. IEEE Trans. Antennas Propag. 69(12), 8763–8777 (2021).

Lin, X. et al. Ultrawideband textile antenna for wearable microwave medical imaging applications. IEEE Trans. Antennas Propag. 68(6), 4238–4249 (2020).

Peyrot, A. H. & Alain, M. G. Analysis of flexible transmission lines. J. Struct. Div. 104(5), 763–779 (1978).

Wu, K. E., Maurizio, B. & Nelson, J. G. F. Substrate integrated transmission lines: review and applications. IEEE J. Microwaves 1(1), 345–363 (2021).

Marcuvitz, N. Waveguide Handbook. No. 21 (Iet, 1951).

Mahani, M. S. & Abhari, R. Experimental evaluation of flexible high-speed interconnect system using substrate integrated waveguide technology. Electron. Lett. 48, 1500–1501 (2012).

Wei, J. et al. A flexible transmission line of spoof surface plasmon polaritons at microwave frequencies. In 2022 IEEE 10th Asia-Pacific Conference on Antennas and Propagation (APCAP) (IEEE, 2022).

Pan, B. C., Zhao, J., Liao, Z., Zhang, H. C. & Cui, T. J. Multi-layer topological transmissions of spoof surface plasmon polaritons. Sci. Rep. 6, 22702 (2016).

Shen, X. & Tie, J. C. Planar plasmonic metamaterial on a thin film with nearly zero thickness. Appl. Phys. Lett. 102, 21 (2013).

Pozar, D. M. Microwave Engineering (Wiley, 2012).

Fan, F. et al. Bandwidth investigation on half-height pin in ridge gap waveguide. IEEE Trans. Microwave Theory Tech. 66(1), 100–108 (2017).

Safwat, A. M. E. & Sergei, A. T. High-impedance wire. IEEE Antennas Wirel. Propag. Lett. 6, 631–634 (2007).

Méndez-J, Gabriela, S. C., S-G & Reydezel, T-T. Modeling and parameter extraction for the metal surface roughness loss effect on substrate integrated waveguides from S-parameters. IEEE Trans. Microwave Theory Tech. 66(2), 875–882 (2017).

Yi, M. et al. etal. Surface roughness modeling of substrate integrated waveguide in d-band. IEEE Trans. Microw. Theory Tech. 64(4), 1209–1216.

Shi, Y. et al. Multi-GHz microstrip transmission lines realised by screen printing on flexible substrates. In 2017 IEEE Electrical Design of Advanced Packaging and Systems Symposium (EDAPS) (IEEE, 2017).

Hernandez, G. A. et al. Microwave performance of Niobium/kapton superconducting flexible cables. IEEE Trans. Appl. Supercond. 27(4), 1–4 (2016).

Belhaj, M. M. et al. Inkjet printed flexible transmission lines for high frequency applications up to 67 GHz. In 2014 44th European Microwave Conference (IEEE, 2014).

Choi, J. H., Sebastian, L. & Martin, K. Flexible RF substrate and interconnection technology for > 100 GHz applications. In 2022 14th Global Symposium on Millimeter-Waves & Terahertz (GSMM) (IEEE, 2022).

Abt, M. et al. Aerosol-printed highly conductive ag transmission lines for flexible electronic devices. IEEE Trans. Compon. Packag. Manuf. Technol. 8(10), 1838–1844 (2018).

Author information

Authors and Affiliations

Contributions

T.X designed the structure, and measured the structure. T.X, P. G, W.X., and J.C. wrote the manuscript. H. J and J.L. polished the paper. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Xie, T., Gong, P., Xie, W. et al. An ultra-broadband flexible conductor backed coplanar waveguide with triangular edges. Sci Rep 15, 13152 (2025). https://doi.org/10.1038/s41598-025-96805-x

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-96805-x