Abstract

The impact tendency of coal is a necessary condition for the occurrence of pressure bumping and a measure of the degree of damage. Through the combination of self-made lateral restraint device and high-speed camera, the variation law and failure mode of burst tendency index of coal samples under real-time drilling and pressure relief of lateral restraint under different loads were studied. The results show that: (1) With the increase of real-time drilling load under lateral constraints, the burst tendency index of coal samples changes. (2) The failure order of coal samples is as follows: the corner coal flakes peel off and pulverized coal is sprayed out, cracks and deformations are generated around the borehole, and finally the coal flakes peel off and the cracks penetrate to cause large-area damage of the coal samples. At the same time, the internal energy of the coal samples is released through borehole, which significantly reduces the damage of the coal samples. (3) The lateral restraint device makes the coal samples always in a stable state before and after drilling, resulting in the weakening effect of the burst tendency of the coal sample is not significant, and the pressure relief effect is not obvious. The research results can provide new ideas and methods for drilling and pressure relief test, and also provide basis and guidance for the prevention of pressure bumping in coal mines.

Similar content being viewed by others

Introduction

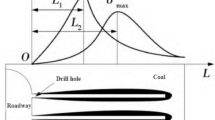

In recent years, with the increasing mining intensity of coal resources, resulting in the gradual depletion of shallow coal resources, coal mining has to advance deeper1,2. At the same time, due to the significant increase of deep original rock stress, the dynamic disasters of coal and rock such as pressure bumping and rock burst have the characteristics of high strength, wide damage range and more sudden and frequent occurrence3,4,5,6. As the main dynamic disaster in the process of coal mining, pressure bumping has seriously threatened the safe and efficient mining of coal resources in China7,8,9. Pressure bumping refers to the phenomenon of explosive release of accumulated energy caused by sudden instability of internal stress state of coal and rock with high brittleness and elasticity under the action of high ground stress and mining disturbance stress, which is often accompanied by sudden and rapid ejection of coal and rock10,11,12. The drilling and pressure relief technology can effectively reduce the energy accumulation inside the coal rock by drilling on the coal rock mass with stress concentration. It has the advantages of simple and fast construction and strong adaptability, and has been widely used to prevent and control pressure bumping5,13,14.

The selection of drilling and pressure relief design parameters is closely related to the pressure relief effect. Unreasonable drilling parameters may not be able to achieve effective pressure release, and even introduce additional problems. Therefore, people have conducted extensive analysis and research on the influencing factors of drilling and pressure relief15. In order to study the influence of drilling parameters on the pressure relief effect, Tai et al.7 prefabricated the rock with holes and carried out a series of uniaxial compression tests. It is found that the diameter of the borehole has the most significant effect on the pressure relief effect, followed by the depth of the borehole. Zhang et al.16 prepared borehole gypsum samples with different numbers and configurations to study their uniaxial mechanical properties, by analyzing the evolution of the strength and energy dissipation index of the samples after drilling and pressure relief, it is found that higher drilling density can improve the fracture development around the borehole and enhance the energy release effect to a certain extent. Gu et al.17 studied the influence of the number of boreholes on the energy of coal samples, and found that the elastic energy of coal samples decreased with the increase of the number of boreholes, while the energy consumption showed an increasing trend. Zhang et al.18 studied the energy dissipation and mechanical behavior of drilling and pressure relief under high stress by means of the combination of theoretical analysis and numerical simulation. It is revealed that the larger the pressure relief range of large diameter borehole is, the higher the efficiency is, and the evaluation system of pressure relief effect is established. Wu.et al.11 conducted uniaxial compression tests on sandstone with prefabricated circular and rectangular holes using digital image correlation (DIC) and acoustic emission (AE) techniques, revealing that the shape of the borehole has a significant effect on the mechanical properties and crack evolution of the rock. Liu et al.19 conducted uniaxial compression tests on sandstone with prefabricated elliptical holes and cracks. It is believed that the strength and deformation of the samples are obviously affected by the ligament angle, and the prominent part of strain localization is the precursor of crack. Zeng et al.20 studied the uniaxial compression and numerical simulation of rock samples with different openings, and found that the shape of the hole had a great influence on the mechanical properties and failure modes of the samples.

The burst tendency of coal is the internal mechanical properties and evaluation index of pressure bumping, it refers to the nature of impact damage caused by the accumulation of deformation energy of coal, which represents the ability of coal to produce pressure bumping12,21,22. Therefore, people have studied the burst tendency of coal rock. Liu et al.23 carried out grouting and crack arrest test on fractured rock mass, and analyzed the sensitivity of different crack arrest measures to its impact tendency. It was found that the grouting rock mass had a strong impact tendency and the amount of grouting and crack arrest was an important sensitive parameter of the impact energy index. Dai et al.24 proposed to use cyclic mechanics from the perspective of energy and combined with rock elastic energy index (WET) and impact energy index (KE) to determine the impact tendency of coal-rock combination. Uniaxial and triaxial tests under different strain rates were carried out by Zhang et al.25 and it was found that the impact tendency of coal rock increased first and then decreased with the increase of strain rate. Ouyang et al.26 studied the impact tendency of coal under different gas pressures, and found that with the increase of gas pressure, the four parameters for evaluating the impact tendency of coal showed a downward trend. Zhang et al.12 used a combination of laboratory tests and numerical simulations to study the impact tendency of coal-rock combination masses under different stress paths. It was found that the impact tendency during unloading was higher and more likely to cause pressure bumping disasters. Liu et al.21 studied the impact tendency of coal with different water content, and found that the greater the water content, the more obvious the change of impact tendency, and the elastic energy index of coal decreased with the increase of water content.

In summary, the study of drilling and pressure relief mainly focuses on the selection of different parameters and the influence of influencing factors on the effect of pressure relief. The study of impact tendency of coal- rock combination is aimed at the change of characteristic parameters of impact tendency under different loading paths and different occurrence conditions, there are few studies on the change of impact tendency of coal-rock combination after drilling and pressure relief. Therefore, this paper takes the coal body of Hulusu Coal Mine in Inner Mongolia, China as the research object. in order to approximately simulate the real occurrence state of coal body drilling and pressure relief underground, the steel fixture is processed to carry out the research on the impact tendency of coal body after real-time drilling and pressure relief under lateral constraints, aiming to provide some data theoretical support for the influencing factors of drilling and pressure relief and the prevention of pressure bumping.

Experimental schemes

Sample preparation

In this study, the 2–1 coal seam of Hulusu Coal Mine in Hujierte Mining Area, Dongsheng Coalfield, Inner Mongolia, China, was taken as the research object, and a large amount of raw coal was collected underground (as shown in Fig. 1a). According to the method recommended by ISRM, the large raw coal is cut and ground to prepare a standard cuboid coal sample of 50 mm × 50 mm × 100 mm that meets the rock mechanics test standard27. The surface of the coal sample is smooth without obvious defects such as crack bedding, and the two ends of the coal sample are polished to make its flatness less than 0.02 mm (as shown in Fig. 1b). In order to better monitor the digital image correlation (DIC) image data during the deformation and failure of the sample, white matte paint is sprayed on one side of the sample and black spots of different sizes and shapes are drawn (as shown in Fig. 1c). Finally, the physical parameters of the sample are measured, and the specific parameters are shown in Table 1.

Test equipment

In this experiment, the RMT-150-B electro-hydraulic servo test system (as shown in Fig. 2a) is used. The axial load of the system is measured by 1000KN mechanical sensor, and the load accuracy can reach 1.0 × 10−3 kN; the axial deformation of the sample is measured by a 5.0 mm displacement sensor, and the circumferential deformation is measured by two 2.5 mm displacement sensors, with an accuracy of 1.0 × 10–3 mm. The digital speckle image uses a high-speed camera to shoot the entire test process at a frequency of 8HZ (as shown in Fig. 2c), and a fill light is set on the side to prevent the light from being too dim and affecting the shooting effect. The maximum rotation speed of the hand drill is 3000 r/min, and the front end is equipped with a 10 mm drill bit (as shown in Fig. d), which is drilled manually. Under the background of roadway drilling and pressure relief, the coal sample is constrained in five directions, one of the faces is exposed. In order to simulate the real stress state of the coal body in the coal mine as much as possible, the lateral restraint device (as shown in Fig. 2e) is customized to achieve the above effect. Before the test, the sample is placed in the space of 50 mm × 50 mm × 100 mm reserved in front of the lateral restraint device. The four bolts on the left side are manually tightened to ensure that the sample can be completely fixed. Similarly, the rear steel block is completely fixed with the screw and the sample. A square steel block with an absolutely flat surface of 48 mm × 48 mm × 48 mm is arranged above to ensure that the loading force of the upper indenter can be normally transmitted to the coal sample. In summary, the coal sample can be approximately close to the real stress state under the condition of drilling and pressure relief underground coal mine during the test.

Test method

This test is divided into three groups: group I monitoring uniaxial compressive strength, dynamic failure duration; group II monitoring impact energy index; group III monitoring the elastic energy index (as shown in Table 1). The pre-loading stress is the key to complete the test. The pre-loading force is too low to simulate the real environment of the underground coal body, and too high may lead to failure without drilling and pressure relief or failure during drilling28. Therefore, in order to ensure the normal progress of the test, the pre-loading stress of 0.1σc, 0.2σc, 0.3σc and 0.4σc (σc is the uniaxial compressive strength of the sample) is set respectively, so as to study the impact tendency of coal body in advance drilling and pressure relief. According to the GB/T25217.2–2010 standard, the loading path and method are as follows:

-

(1)

Preloading stress: The uniaxial compression test of the displacement loading of the complete coal sample under the lateral constraint is carried out at a rate of 0.01 mm/s, when the test curve is obviously reduced to 0 or the sample is obviously damaged, the uniaxial compressive strength is obtained by unloading (as shown in Fig. 3a), so as to set the drilling load to ensure the normal operation of the test.

-

(2)

Monitoring uniaxial compressive strength and dynamic failure time: First, the test machine is loaded to the preset load level at a rate of 0.5 MPa/s and maintained for 5 min; then a circular hole with a diameter of 10 mm and a depth of 50 mm was drilled in the center of the coal sample surface by manual use of electric drill. Subsequently, the loading was continued at a rate of 0.5 MPa/s until the sample failed (as shown in Fig. 3-a).

-

(3)

Monitoring the impact energy index: firstly, the test machine is loaded to the preset load level at a rate of 0.01 mm/s and maintained for 5 min, then the pressure is released by manual drilling, and then the load is continued at a rate of 0.01 mm/s until the sample failed (as shown in Fig. 3b).

-

(4)

Monitoring the elastic energy index: First, the test machine is loaded to the preset load level at a rate of 0.5 MPa/s and maintained for 5 min; then the pressure is released by manual drilling, and then continue to load to 80%σc at a rate of 0.5 MPa/s, and finally unload to 0.5 MPa at a rate of 0.5 MPa/s (as shown in Fig. 3c).

Result and analysis

Classification of coal impact tendency

The impact tendency of coal body can use uniaxial compressive strength (RC), dynamic failure duration (DT), impact energy index (KE) and elastic energy index (WET) to evaluate the risk degree of coal mine12,29, each parameter is divided into strong, weak and no three levels, if there is a conflict between the parameters, the fuzzy comprehensive evaluation method can be used to evaluate26. The specific classification is shown in Table 2.

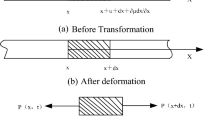

Uniaxial compressive strength

The stress–strain curves of coal samples with different drilling loads under lateral constraints are shown in Fig. 4. The stress–strain curves of coal samples under different drilling loads can be divided into four typical stages, including the initial compaction stage of crack closure, the linear elastic stage of stable expansion, the plastic stage of interaction between stable and unstable states, and the peak point and post-peak failure stage30,31 Combined with Fig. 4, the uniaxial compressive strength of coal samples is calculated. It refers to the ratio of the failure load to the compression area of the standard sample under uniaxial loading conditions, and it also reflects the ability of the sample to resist deformation. The greater the uniaxial compressive strength, the greater the deformation resistance, and the more severe the damage process of the sample26. The specific calculation formula is as follows:

In the formula: RC: uniaxial compressive strength of sample (MPa); P: sample failure load (KN); F: sample initial bearing area (cm2).

Figure 5 is the curve of uniaxial compressive strength and drilling load of coal samples under lateral constraints. It is found that the uniaxial compressive strength of boreholes under different axial stresses is quite different from that of complete coal samples. The data show that with the increase of drilling stress load, the uniaxial compressive strength decreases first and then increases, and there is a sudden increase under 30% drilling load compared to complete coal samples. From the classification of impact tendency (as shown in Table 2), when RC ≥ 14 uniaxial compressive strength belongs to strong impact tendency, it can be seen that the uniaxial compressive strength of drilling and pressure relief coal samples under different loads shows strong impact tendency. The reason is as follows: Stage I is in the initial compaction stage, and the internal crack closure of the coal sample gradually forms a whole. At this time, the borehole will break the compaction state of the coal sample and cause new crack damage. The re-applied load will re-enter the compaction stage. At this time, due to the loss of the important bearing part in the middle of the sample, it cannot withstand greater load, which ultimately leads to the uniaxial compressive strength lower than the complete coal sample. Stage II is in the basically stable linear elastic stage, and micro-crack damage is occasionally generated inside the coal sample and accompanied by energy release. At this time, the borehole will enter the compaction stage again, and the sample needs a long time to reclose the original crack and the newly generated crack damage of the drilling, which provides more opportunities for the coal sample to adapt to the external load to achieve a longer equilibrium state (see Fig. 9). The uniaxial compressive strength of the final coal sample is higher than that of the complete sample. In summary, drilling under different load conditions is essentially different from the deformation and failure stage of coal rock.

Dynamic failure duration

The dynamic failure duration of the coal sample is the time difference between the peak strength and the residual strength, which can reflect the ability of the sample to resist damage when subjected to external forces to a certain extent. The specific calculation formula is as follows:

In the formula: DT: dynamic failure duration (ms); Tσr: the time required to reach the peak strength (ms); Tσc: the time required to reach the residual strength (ms).

Figure 6 is the time-load curves of different load drilling under lateral constraint. According to the observation, the dynamic failure duration of real-time drilling and pressure relief under the peak intensity of 10%, 20%, 30% and 40% is 401 ms, 832 ms, 863 ms and 1971 ms, respectively. Refer to Table 2, when 50 < DT ≤ 500, the dynamic failure duration belongs to weak impact tendency, when DT > 500, the dynamic failure duration belongs to no impact tendency. Figure 7 is the dynamic failure duration and drilling load evolution curve under lateral constraints. It is found that compared with the dynamic failure duration 874.5 ms of the complete coal sample under the lateral constraint condition, the dynamic failure time of the 10% peak strength real-time drilling and pressure relief is weak impact tendency, and the real-time drilling under the other loads is non-impact tendency. From the perspective of dynamic failure time alone, drilling and pressure relief under low stress can improve the impact tendency of coal to a certain extent, while drilling and pressure relief under medium and high stress makes the impact tendency of coal samples equal to or lower than that of samples without drilling and pressure relief. In general, the dynamic failure duration of coal samples after drilling is generally higher than that before drilling, while the impact tendency is reduced.

Impact energy index

The impact energy index (KE) of coal sample refers to the ratio of the deformation energy accumulated before the peak to the deformation energy lost after the peak, which is the ratio of the pre-peak area to the post-peak area of the displacement-load curve of the sample. It can reflect the residual energy after the coal sample is completely failed and judge whether it has impact tendency5,21,26. The specific calculation formula is as follows:

In the formula: KE: impact energy index; AS: deformation energy accumulated before the peak; AX: deformation energy accumulated after the peak.

Figure 8 is the displacement-load curve of different drilling loads under lateral constraints. At this time, the area enclosed by the envelope after the peak of the curve is larger, that is, the loss of deformation energy increases. After calculation, the impact energy indexes of real-time drilling and pressure relief under axial stress of 10%, 20%, 30% and 40% of peak strength are 0.965, 2.621, 0.754 and 0.935, respectively. According to the impact tendency classification of coal in Table 2, the impact energy index KE ≥ 5; when 1.5 ≤ KE < 5, it is a weak impact tendency; when KE < 1.5, there is no impact tendency. Figure 9 shows the variation trend of the impact energy index with the drilling load. It can be seen that the impact energy index of drilling and pressure relief increases sharply at 20% peak strength, and the impact energy index of the remaining peak strength drilling is equal to or slightly lower than that of the complete coal sample. The reason is that due to the large amount of deformation energy accumulated before the peak value, resulting in a sudden increase in the impact energy index. However, in general, real-time drilling and pressure relief will lead to a decrease in the impact energy index of coal samples.

Elastic energy index

As early as 1981, the Polish scholar Kidybinski proposed to use the elastic energy index (WET) as an index to evaluate the trend of pressure bumping24. It refers to the ratio of elastic strain energy to plastic strain energy released before the peak strength of the sample under cyclic action, and it can also reflect the ability of coal samples to store elastic energy before failure26. The specific calculation of the elastic energy index is shown in Fig. 10, and the calculation formula is as follows:

In the formula: WET-elastic energy index; ΦSE: elastic strain energy (area under unloading curve); ΦC: total strain energy (area under the loading curve); ΦSO: plastic strain energy, (area surrounded by loading curve and unloading curve).

Figure 11 is the displacement-load curve of different loads drilling under lateral constraint. After integral calculation, the elastic energy indexes of real-time drilling and pressure relief under peak strength of 10%, 20%, 30% and 40% were 0.756, 1.231, 2.888 and 2.107, respectively, which increased by 8.37%, 76.33%, 313.69% and 201.89% respectively compared with the elastic energy index of intact coal sample of 0.698. According to the impact tendency classification of coal in Table 2, the elastic energy index of real-time drilling and pressure relief under 10% and 20% loads is no impact tendency, while the elastic energy index of real-time drilling and pressure relief under 30% and 40% loads is weak impact tendency and the elastic strain energy on the curve becomes larger and the plastic strain energy becomes smaller.

Figure 12 shows the trend of elastic energy index of real-time drilling and pressure relief with the increase of load under lateral constraints, it is found that the overall trend of elastic energy index (WET) is increasing with the increase of real-time drilling and pressure relief stress state, but the elastic energy index decreases in stage II, but it does not affect the overall trend. According to Table 2, under the lateral constraint condition, the elastic energy index increases from no impact tendency to weak impact tendency after drilling and pressure relief, which also explains the failure of pressure bumping prevention and control after the implementation of drilling and pressure relief, the inability to solve the problem of pressure bumping prevention or the large deformation of roadway surrounding rock caused by the excessive pressure relief from the energy point of view.

Mode of failure

The high-speed camera was used to capture the whole process of failure and damage of coal samples after lateral restraint of different loads and real-time drilling and pressure relief, and the crack evolution and damage mechanism of coal samples were analyzed in depth. Figure 13 is the uniaxial compression failure evolution diagram of complete coal samples under lateral constraints. It is found that coal flake spalling and pulverized coal ejection appear in the corner part of the coal sample at first. With the continuous loading, the spalling area of the coal flake gradually increases and shear cracks are generated at the same time. Finally, the crack and spalling are connected to cause the overall spalling of the coal near the free surface. Compared with the coal sample after drilling unloading, the coal spalling area of the complete coal sample is the largest. It shows that under the action of the lateral restraint device, the complete coal sample can only release energy through the free surface when the lateral deformation is completely restrained. When the internal energy of the coal sample accumulates to a certain extent, the free surface will be peeled off as a whole. This is consistent with the phenomenon of pressure bumping in coal mine, which shows that the lateral restraint device can approximately simulate the occurrence state of underground coal body.

Figure 14 is the real-time uniaxial compression failure evolution diagram of drilling and pressure relief under lateral restraint at 10% load. Firstly, the coal sample will peel off and pulverized coal will be ejected from the corner. Then, under the action of axial load, a certain number of micro-crack damage will appear in the borehole and accompanied by pulverized coal ejecting, which will quickly cause the overall large-area spalling of the free face. However, there is still a certain residual strength in the coal sample at this time. Continued loading will cause shear cracks in the corners until the sample loses its bearing capacity, forming the final macroscopic fracture surface.

Figure 15 is the real-time uniaxial compression failure evolution diagram of drilling and pressure relief under lateral restraint at 20% load. It is found that the macroscopic damage still occurs first at the corner, rather than first along the borehole. The phenomenon of coal flake spalling and pulverized coal ejection occurred around the borehole, and then the spalling expanded along the oblique direction around the hole, and the circular hole became elliptical under uniaxial compression (a sign of failure). When the loading continues, the spalling area of the free surface of the coal sample is expanded and shear failure occurs. Finally, the coal sample presents a shear failure mode and a certain area of coal remains.

Figure 16 is the real-time uniaxial compression failure evolution diagram of drilling and pressure relief under lateral restraint at 30% load. a is the last picture before the failure of the coal sample, the borehole becomes oblate and macroscopic cracks appear around it, at the same time, macroscopic shear failure also appears in the corner of the macroscopic crack, the coal sample is destroyed around the hole along the direction parallel to the macroscopic failure of the missing angle. The failure rate is much larger than the drilling and pressure relief failure at 20% peak stress.

Figure 17 is the real-time uniaxial compression failure evolution diagram of drilling and pressure relief under lateral restraint at 40% load. Coal flake spalling and crack damage occurred in a, The borehole in b was obviously elliptical and a large number of surrounding coal flakes were peeled off and accompanied by pulverized coal ejection. The corner of c was connected with the coal flakes around the borehole, which eventually caused large-scale spalling damage.

In summary, compared with the complete coal sample, the coal sample after the real-time drilling and pressure relief under the lateral constraint will still remain a certain area of coal after the final damage, indicating that the drilling and pressure relief can effectively reduce the energy accumulated inside the coal sample to reduce the final damage degree.

Conclusion

In this paper, through the combination of the self-developed lateral restraint device and the loading platform of the testing machine, the drilling and pressure relief test under different loads of lateral restraint is carried out, so as to approximately simulate the drilling and pressure relief process underground coal mine. By obtaining the relevant data in the loading process of the testing machine, the uniaxial compressive strength (RC), elastic energy index (WET), dynamic failure duration DT and impact energy index KE of the coal sample after drilling and pressure relief are calculated to analyze the impact tendency of the coal sample, the crack evolution and damage process of coal samples after drilling and pressure relief were analyzed by high-speed camera. The main conclusions and rules are as follows:

-

(1)

The uniaxial compression test of real-time drilling and pressure relief under different loads of lateral restraint shows that the uniaxial compressive strength (RC) and dynamic failure duration (DT) after drilling are generally shows an downward first and then upward trend than those of undrilled coal samples. The impact energy index (KE) is generally shows an downward trend than that before drilling, but there are also individual points that have surged. The elastic energy index (WET) generally shows an upward trend with the increase of the axial load of the real-time drilling; it can be seen that the real-time drilling and pressure relief under different loads has a certain influence on the impact tendency of the coal sample itself.

-

(2)

Real-time drilling and pressure relief of coal samples under uniaxial compression of lateral restraint, the coal samples first appear coal flake spalling and powder injection at the corners, then cracks appear around the borehole and produce approximate elliptical deformation. Finally, the crack and coal flake spalling and penetration cause large-area coal body collapse damage. Due to the existence of the borehole, the internal energy of the coal sample can be released, so that the coal sample after the drilling and pressure relief will eventually destroy, the free surface still retain a certain area of coal flake, while the free surface of the complete coal sample is completely destroyed.

-

(3)

From the perspective of impact tendency, comparison of real-time drilling and pressure relief of laterally constrained coal samples with complete coal samples without drilling and pressure relief, the weakening effect of impact tendency of coal sample after drilling and pressure relief is not significant, and the effect of pressure relief is not obvious. Analyzing the reasons might be that the lateral constraint stiffness is large, which is equivalent to that the coal body is in a relatively stable rock layer. After real-time drilling and pressure relief, the coal body remains stable state, and the influence of drilling and pressure relief on the change of coal impact tendency is not obvious.

Data availability

All data generated or analysed during this study are available from the corresponding author on reasonable request.

References

Konicek, P., Soucek, K., Stas, L. & Singh, R. Long-hole destress blasting for rockburst control during deep underground coal mining. Int. J. Rock Mech. Min. Sci. 61, 141 (2013).

Kang, H., Gao, F., Xu, G. & Ren, H. Mechanical behaviors of coal measures and ground control technologies for China’s deep coal mines—A review. J. Rock. Mech. Geotech. 15, 37 (2023).

Xueqiu, H., Wenxue, C., Baisheng, N. & Mitri, H. Electromagnetic emission theory and its application to dynamic phenomena in coal-rock. Int. J. Rock Mech. Min. Sci. 48, 1352 (2011).

Xie, H., Ju, Y., Gao, F., Gao, M. & Zhang, R. Groundbreaking theoretical and technical conceptualization of fluidized mining of deep underground solid mineral resources. Tunn. Undergr. Sp. Tech. 67, 68 (2017).

Li, Y. et al. Experimental study on pressure relief mechanism of variable-diameter borehole and energy evolution characteristics of the surrounding rock. Energies 15, 6596 (2022).

Du, S. et al. Measurement and prediction of granite damage evolution in deep mine seams using acoustic emission. Meas. Sci. Technol. 30, 114002 (2019).

Tai, L. et al. Experimental study on the significance of pressure relief effect and crack extension law under uniaxial compression of rock-like materials containing drill holes. Sci. Rep. UK 14, 1104 (2024).

Zhang, H. et al. Study on complex theory solution and numerical simulation of fracture mechanics of surrounding rock stress and energy field in fault type rock burst stope. Adv. Mater. Sci. Eng. 2022, 1 (2022).

Zhang, G. et al. The failure characteristics and energy evolution pattern of compound coal-rock under the action of cyclic loading. Sustainability-Basel 15, 4133 (2023).

Li, C. C., Tongbin, Z., Yubao, Z. & Wan, W. A study on the energy sources and the role of the surrounding rock mass in strain burst. Int. J. Rock Mech. Min. Sci. 154, 105114 (2022).

Wu, H., Zhao, G. & Liang, W. Investigation of cracking behavior and mechanism of sandstone specimens with a hole under compression. Int. J. Mech. Sci. 163, 105084 (2019).

Wu, S. et al. Study on impact tendency of coal and rock mass based on different stress paths. Adv. Civ. Eng. 2020, 1 (2020).

Kang, H. et al. A new ground control measure for double-use entries in underground coal mines. Int. J. Rock Mech. Min. Sci. 160, 105266 (2022).

Song, D., Wang, E., Liu, Z., Liu, X. & Shen, R. Numerical simulation of rock-burst relief and prevention by water-jet cutting. Int. J. Rock Mech. Min. Sci. 70, 318 (2014).

Ma, J. et al. Numerical simulation analysis of acoustic emission characteristics during the drilling pressure relief process in coal seams under different influencing factors. Processes 11, 3277 (2023).

Zhang, S., Li, Y., Shen, B., Sun, X. & Gao, L. Effective evaluation of pressure relief drilling for reducing rock bursts and its application in underground coal mines. Int. J. Rock Mech Min. Sci. 114, 7 (2019).

Gu, X. et al. Drilled-hole number effects on energy and acoustic emission characteristics of brittle coal. J. Market. Res. 23, 3892 (2023).

Zhang, H. et al. Research on optimization of coal pressure relief borehole parameters under high-stress conditions. Geofluids 2021, 1 (2021).

Liu, X., Yang, S., Huang, Y. & Cheng, J. Experimental study on the strength and fracture mechanism of sandstone containing elliptical holes and fissures under uniaxial compression. Eng. Fract. Mech. 205, 205 (2019).

Zeng, W., Yang, S. & Tian, W. Experimental and numerical investigation of brittle sandstone specimens containing different shapes of holes under uniaxial compression. Eng. Fract. Mech. 200, 430 (2018).

Liu, F., Han, Y., Liang, X. & Xin, L. Mechanical behavior and impact resistance tendency of coal mass with different water content. Geofluids 2022, 1 (2022).

Zhiguo, L., Wenjun, J., Gao, F. & Du, T. Numerical analysis on the factors afecting post peak characteristics of coal under uniaxial compression. Int. J. Coal Sci. Techn. https://doi.org/10.1007/s40789-023-00626-0 (2024).

Liu, S., Xiao, F., Li, T. & Zhang, B. Analysis of impact tendency and sensitivity of fractured rock with different crack arrest measures. Sustainability-Basel 14, 13833 (2022).

Dai, J., Zhao, M., Wang, Z., Gao, H. & Cheng, X. Investigation into the mechanical properties and impact tendency of coal-rock composite structures with peridynamics: A study on predicting the occurrence tendency of dynamic pressure in coal-rock structures. PLoS ONE 19, e0314927 (2024).

Kun Zhang, Y. Z. S. Z. & Cui, Y. Study on the energy evolution mechanism of coal and rock with impact tendency under diferent strain rates. Sci. Rep. https://doi.org/10.1038/s41598-023-41094-5 (2023).

Ouyang, Z. et al. Study on the rock burst tendentiousness of coal under different gas pressures. Arab. J. Geosci. https://doi.org/10.1007/s12517-019-4991-y (2020).

Xiating, F. et al. ISRM Suggested Method; determining deformation and failure characteristics of rocks subjected to true triaxial compression. Rock Mech. Rock Eng. 52, 2011 (2019).

Lu, X., Jiang, J., Wang, W., Cao, X. & Hong, L. Laboratory experimental study on the pressure relief effect of boreholes in sandstone under high-stress conditions. Sustainability-Basel 15, 15557 (2023).

Dai, L. et al. Impact tendency characteristics of borehole coal samples under real-time and uniaxial loading conditions: insights from physical experiments. Processes 12, 2189 (2024).

Liu, H. D., Liu, J. J., Zhang, S. Y., Feng, L. Y. & Qiu, L. Stress-strain and acoustic emission characteristics of cement-based materials used to simulate soft rock with fractures. Sci. Rep. UK 12, 7903 (2022).

Hou, P. Y. & Cai, M. Post-peak stress-strain curves of brittle hard rocks under different loading environment system stiffness. Rock Mech. Rock Eng. 55, 3837 (2022).

Acknowledgements

The authors acknowledge the financial support provided by National Natural Science Foundation of China (52404119, 52274186), Natural Science Foundation of Henan (242300421451), Opening Foundation of State Key Laboratory of Coking Coal Resources Green Exploitation in China PingMei ShenMa Group (4104020211205z), Opening Foundation of Hubei Key Laboratory for Efficient Utilization and Agglomeration of Metallurgic Mineral Resources (2024zy001).

Author information

Authors and Affiliations

Contributions

JM: Conceptualization, Methodology, Software, Investigation, Formal Analysis, Writing Original Draft. DL: Conducting a research and investigation process. MY: Project administration, Formal analysis.SZ: Resources, Supervision. XD: Investigation, Data Curation, Formal Analysis.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Consent to publish

All the authors agree to publish this paper.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Ma, J., Liu, D., Yang, M. et al. A novel experimental study on impact tendency of real time borehole coal samples under lateral constrained compression. Sci Rep 15, 12894 (2025). https://doi.org/10.1038/s41598-025-97898-0

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-97898-0