Abstract

In seasonal frozen regions, asphalt pavements face accelerated degradation due to extreme environmental stressors-including cyclic freeze-thaw transitions and intense ultraviolet radiation-that induce severe thermo-oxidative and UV aging effects. These compounded aging mechanisms lead to premature cracking, raveling, and functional failure of road surfaces, imposing significant economic burdens on infrastructure maintenance. To address this critical challenge, this study systematically investigates the alterations in the rheological properties of AH-90 base asphalt, SBR-modified asphalt, and SBS-modified asphalt under natural aging conditions over varying time intervals using temperature sweep tests, bending beam rheometer tests, and multi-stress creep recovery tests. The influence of natural weather conditions on the microstructure of asphalt binders was examined by Fourier transform infrared spectroscopy and fluorescence microscopy before and after different nature aging conditions. The findings demonstrate that the use of modifiers can modify the natural aging characteristics of asphalt binders. Compared to BA, SBS demonstrates superior resilience to natural aging, while SBR is more susceptible to aging. After natural aging, the stiffness modulus of BA, SBS, and SBR increased by 21%, 10%, and 39% respectively. T30 (The temperature at which the limiting phase angles grades reaches 30°) exhibits a robust association with the intrinsic aging features of asphalt binders, facilitating the assessment of natural aging impacts on asphalt qualities. Throughout natural aging, the modifier deteriorates due to the oxidation of the unsaturated polybutadiene component by chain scission, while SBS exhibits a more stable phase structure than SBR during the aging process.

Similar content being viewed by others

Introduction

Nowadays, asphalt has become a commonly used highways construction materials, due to its unique technical advantages (such as driving comfort, low noise, etc.)1. Nevertheless, Asphalt is highly sensitive to temperature, leading to rutting at high temperatures and cracking at low temperatures2. In addition, during service, asphalt undergoes oxidation, UV irradiation aging, and physical hardening, leading to increased brittleness and stiffness3. This subsequently leads to various forms of damage, such as stripping, pothole formation, and raveling4,5. Improving pavement performance and extending service life requires an understanding of how aging processes affect the physical, rheological, and microstructural properties of asphalt6. A significant amount of research has been dedicated to examining the alterations in asphalt properties resulting from aging7,8,9,10. The field aging process of asphalt pavement is slow and continuous, from a mechanistic perspective, asphalt aging involves a series of oxidation reactions, resulting in the volatilization of lighter components and an increase in asphaltene content11. Therefore, to simulate the aging process, researchers have employed accelerated aging tests, such as the Rolling Thin Film Oven Test (RTFOT) and the Pressure Aging Vessel (PAV)12. For instance, short-term aging occurring during paving and compaction can be simulated using the rolling thin film oven test (RTFOT), while long-term aging is simulated with the pressure aging vessel (PAV)13. At same time, many time-extended aging tests also were pointed out based on standard RTFOT and PAV test, such as 180, 360 min RTFOT test and 40, 100, 120 h PAV test14,15. Li et al.16, found that extended RTFOT can effectively replicate the long-term aging of asphalt used in pavements, with approximately 60 min of prolonged RTFOT aging corresponding to one year of field aging. Research has shown that RTFO durations of 5 h 20 min and 6 h can serve as alternatives to the PAV test17. Liu et al.15, demonstrated that extracted asphalt can be simulated in the laboratory using standard RTFO conditions and a 26-hour PAV test. These efforts allow researchers to grasp the degradation of asphalt properties during pavement service period, and provide a reference for asphalt recycling and regeneration, which is meaningful for improving the quality of pavements. Although artificial aging simulation tests have been widely used in existing research and have proven their effectiveness18. During service periods, the aging of asphalt is a complex process encompassing several chemical and physical changes19. For example, asphalt may surfer a thermal and ultraviolet oxygen aging and in summer20, and in winter, a long period of low temperature environment will make the asphalt ap-pears a physical hardening phenomenon21,22,23. In the repeated alternation of the above process, the asphalt aging may be a certain difference with the expected condition. Due to the artificial simulation of aging may ignore these processes24. As found by Zhang et al., Accelerated aging may replicate the initial behaviors observed during the early phases of field aging; however, as the aging process progresses, it becomes less effective at mimicking the aging characteristics present in more intricate scenarios. Consequently, the extent of aging observed through accelerated methods is less pronounced compared to that experienced in the mid to late stages of field aging25. Consequently, there are some studies to carry out the relevant field aging test based on the local condition, to establish relationship between field aging and artificial aging tests26,27,28. Hu et al.29, assessed the impact of weathering and aging on high viscosity modified asphalt under defined environmental conditions. Their findings demonstrate that, in contrast to PAV aging, high viscosity modified asphalt undergoes more pronounced chemical alterations during weather aging, chiefly attributable to the synergistic effects of solar radiation and temperature. As discussed above, the changes in properties associated with the microstructure of asphalt under natural weather conditions are different from the artificial simulated aging test. Under natural weather conditions, the effect of freeze-thaw cycles, rain, sunlight, and other factors cannot be ignored. Despite numerous natural weather-aging studies that have been carried out using asphalt, it is crucial to acknowledge that the weathering-aging characteristics of asphalt might differ considerably across different locales. Especially in some areas with harsh cold weather and high-temperature gradients, such as seasonal frozen regions. Premature cracking is a common distress on asphalt pavements in seasonal frozen regions, which will further aggravate the pavement conditions. To enhance the quality and prolong the lifespan of pavements, it is essential to study how this type of climatic environment influences the performance and microstructural features of asphalt.

The main objective of this study is to (1) evaluate the combined effects of thermo-oxidative and ultraviolet (UV) aging on asphalt degradation in seasonal frozen regions, (2) characterize the divergent aging mechanisms of SBS and SBR modifiers through rheological-microstructural correlations, and (3) develop a phase angle-derived evaluation criterion to quantify aging resistance. At first, the asphalt binder was stored in small aluminum boxes and exposed outdoors in June 2023. Subsequently, the samples were taken at a specific time to follow experiments protocol. The asphalt binders were eventually assessed by temperature sweep tests, frequency sweep tests, MSCR, FTIR, and FM to determine the variation in asphalt properties under natural settings.

Materials and methods

Materials

The asphalt used in this study was AH-90 (BA), supplied by a petroleum company in Liaoning, China. The SBS used is a thermoplastic elastomer with excellent thermoplastic, high elasticity, and compatibility, significantly enhancing the fatigue resistance of asphalt. The SBR used is a synthetic rubber copolymerized from styrene and butadiene, offering superior resistance to ultraviolet radiation and oxidation. In related research30,31, the typical dosage of SBS and SBR ranges from 2 to 4% and 3–5%, respectively, excessive amounts of modifiers may lead to segregation and insufficient storage stability, whereas an insufficient dosage may result in an inconspicuous modification effect. Considering these factors, this study adopted 3% SBS and 4% SBR as the optimal dosages32,33. The parameters of the modifier are shown in Tables 1 and 2 below.

Preparation of modified asphalt

The BA was heated in a constant-temperature oil bath at 150 ± 1 °C until it reached a fully fluid state. Then, 3% SBS (or 4% SBR) gradually added while stirring at 2000 rpm for 20 min at 150 °C using a mechanical mixer. Subsequently, the temperature was increased to 160 °C, and the mixture was subjected to high-speed shearing at 5000 rpm for 40 min using an emulsifying shear device. Finally, the mixture was allowed to expand and develop in a constant-temperature oven at 160 ± 1 °C for 30 min, yielding the SBS (or SBR) modified asphalt. The physical properties of used asphalt binder are shown in Table 3. Subsequently, a 48-hour segregation test was conducted, and the results are presented in Fig. 1. The softening point differences were determined to be 0.6 °C and 0.4 °C, respectively, meeting the standard requirements and indicating good storage stability.

Methods

Natural weather aging protocol

The asphalt binder analyzed and evaluated in this study was obtained after 12 months of weathering and multiple seasonal freeze-thaw cycles. Previous research indicates34,35that UV radiation and thermo-oxidative aging typically occur on the pavement surface. To accurately assess the impact of natural aging on asphalt binders, the sample thickness was standardized to 1 mm36. Initially, BA, SBS, and SBR were heated to a molten condition and subsequently put into aluminum molds measuring 50 mm in diameter, 25 mm in height, and 1 mm in thickness. The samples were then exposed to the natural weather conditions in Harbin, China, which experiences a seasonal freeze-thaw climate, from June 2023 to May 2024. Finally, the samples were collected for subsequent experimental procedures in October 2023, February 2024, and June 2024, and were labeled as 1 st aged, 2nd aged, and 3rd aged, respectively. During the experiment, the highest and lowest monthly temperatures are presented in Fig. 2, the aging sample container is shown in Fig. 3.

Temperature sweep test (TS)

The effect of natural weather conditions on the rheological properties of asphalt binders at both high and low temperatures was evaluated using a dynamic shear rheometer (MCR302, Anton Paar, Graz, Austria)37during a temperature sweep test. Several criteria were acquired and computed, including complex moduli (G*), phase angles (δ), and the temperatures T30, T45, and T60 corresponding to the limiting phase angles of 30°, 45°, and 60° respectively38. The rheological test protocols are as follows: (1) The test temperature ranges from 52 °C to 82 °C, with a 6 °C increment, while the controlled strain was maintained at 12% and the loading frequency set to 10 rad/s (1.59 Hz). (2) The test temperature ranges from − 12 °C to 30 °C, with a 6 °C increment, while the controlled strain was set at 1% and the loading frequency at 10 rad/s (1.59 Hz).

To assess the changes in asphalt performance before and after aging, two types of aging indices were calculated from the obtained G* and δ data at different aging stages, using Eq. (1) and Eq. (2), respectively.

Multiple stress creep recovery test (MSCR)

MSCR tests were performed using a dynamic shear rheometer (MCR302, Anton Paar, Graz, Austria) across a temperature range of 52 °C to 76 °C, with a 6 °C increment39. The non-recoverable creep compliance (Jnr) and average percent recovery (R) were measured at 0.1 kPa and 3.2 kPa, respectively, to assess the high-temperature deformation resistance of the asphalt binders.

Bending beam rheometer test (BBR)

The low-temperature properties of asphalt binders were evaluated using creep stiffness (S) and the m-value, determined via the BBR test. In accordance with the ASTM D6648 protocol, the test temperatures ranged from − 12 °C to −24 °C, with intervals of 6 °C, three replicate samples were tested for each condition.

Fourier transform infrared (FTIR) spectroscopy

The changes in the chemical bonds of asphalt binders were investigated using a Nicolet IS50 FTIR instrument. The analysis was conducted using wavelengths from 4000 cm⁻¹ to 400 cm⁻¹, the binder was dissolved in carbon disulfide at a concentration of 5 wt% and applied to KBr plates for FTIR analysis.

Fluorescence microscopy (FM)

The morphology of asphalt binders was examined using an Axioskop2plusFL optical microscope. Small quantities of heated samples were placed between microscope slides and observed at a magnification of 400×. The research flowchart is shown in Fig. 4.

Results and discussion

High- and low-temperature rheological properties

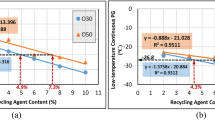

Figures 5, 6 and 7 demonstrates the effect of weathering aging on the rheological characteristics of asphalt binders at elevated and reduced temperatures during different aging phases.

Figure 5(a), 6(a) and 7(a) distinctly illustrates that the effects of aging and temperature on the complex shear modulus (G*) vary across different asphalt binders. The G* of all the asphalt binders decreased by various magnitudes with increasing test temperature, while the effect of aging on the complex shear modulus is quite different. This variation is mainly due to the differences in temperature sensitivity and aging resistance between base and modified asphalts, the effect of aging ratio on the complex shear modulus (G*) of base asphalt becomes more pronounced as natural aging progress, especially during the early stages of aging. Natural aging also has a considerable effect on the properties of modified asphalt. As the duration of natural aging progressed from 1 to 3, the G* initially rose and then declined. This phenomenon is primarily attributed to early-stage aging, during which natural light and oxidation reactions promote the crosslinking of asphalt molecular chains, thereby increasing stiffness and consequently raising the G* value. However, as aging progresses, excessive oxidation induces the scission and degradation of macromolecular chains, leading to the breakdown of the asphalt molecular structure and a subsequent reduction in stiffness. Moreover, the effect of natural aging on SBR was more obvious than on SBS. Compared with base asphalt and SBR, SBS showed higher aging resistance, resulting in slight performance changes under the same aging conditions. Previous research has indicated that the aging resistance of SBR is less favorable, leading to significant changes in G* following the first aging protocol. Furthermore, natural aging results in oxidative stiffening and polymer degradation in asphalt binders, the G* of modified asphalt declines with further aging cycles.

As illustrated in Fig. 5(b), 6(b) and 7(b), the effects of natural aging and temperature on the δ is different with G*. Specifically, the asphalt binder increases with rising temperatures, whereas it decreases with prolonged aging times. Generally, the conclusions drawn regarding the changes in phase angle (δ) with respect to aging time are consistent with G*, with only quantitative differences observed. For instance, in the case of base asphalt, the G* increased by approximately 0 to 40% as the degree of aging progressed from one to three times, while the δ changed by only about 3%. Additionally, by analyzing the variation of the G* value of asphalt at different testing temperatures, it was found that, when the aging degree indicator is kept constant, the aging rate of G* increases with rising temperature. Based on this phenomenon, G* can be considered as a significant evaluation parameter when investigating the degree of aging in asphalt binders. Moreover, this parameter provides higher precision and accuracy at elevated testing temperatures.

The temperature corresponding to the limit phase angle exhibits high sensitivity, accuracy, and precision, requiring only a small amount of material and enabling rapid testing. Furthermore, thermoreversible aging processes are less of a confounding factor when binders are tested at higher temperatures, where equilibration typically occurs more quickly than at lower temperatures. Therefore, the temperature at which the limit phase angle reaches 30° is an ideal parameter for assessing the low-temperature performance of asphalt. The phase angle (δ) derived from rheological principles is commonly used to characterize the viscoelastic properties of asphalt materials. Studies suggest that when δ = 0°, the asphalt binder is in an elastic state, whereas when δ = 90°, the asphalt binder is in a viscous state. When the δ is 45°, the asphalt binder is considered in a viscoelastic equilibrium state40. Consequently, calculating the temperatures where δ reached a particular value can help to study the viscoelastic properties of the asphalt binder further. Previous studies have demonstrated that T60, T45, and T30 are reliable indicators for assessing asphalt performance under both high and low temperature conditions39. Significantly, according to relevant studies, the temperature corresponding to the limit phase angle of 30°, denoted as T30, shows a strong correlation with results obtained from critical crack tip opening displacement tests, double edge notched tensile tests, and extended bending beam rheometer tests. Furthermore, T30 demonstrates superior accuracy in evaluating the performance grade loss compared to T45 and BBR tests41,42. The low-temperature cracking resistance of asphalt is directly related to its elastic recovery ability. When the phase angle of asphalt is low, it indicates that the material maintains better elasticity at low temperatures, allowing it to resist stress concentrations induced by temperature variations and reduce the occurrence of cracks. Therefore, asphalt with a lower T30 phase angle exhibits stronger crack resistance and can effectively withstand thermal stress at low temperatures.

The calculated values of T60, T45, and T30 for asphalt binders are presented in Fig. 5(c), 6(c) and 7(c). A noticeable increase in T60, T45, and T30 values of asphalt binders is observed as aging progresses. Compared to base asphalt, both modified asphalts exhibit relatively higher T45 and T60, along with lower T30 at the same age43degree. The findings indicate that altered44asphalt possesses a higher percentage of elastic materials at identical temperatures, which in turn improves its resistance to deformation. Furthermore, compared to T45 and T60, the variation in T30 with aging is particularly obvious, demonstrating a strong positive correlation. This suggests that with increasing aging, asphalt binders exhibit greater brittleness, particularly in terms of their resistance to physical hardening45,46. Consequently, this may explain why asphalt binders exhibit good performance occurring premature cracking after paving.

Multiple stress creep recovery test

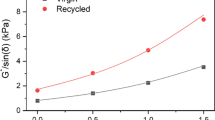

Figures 8, 9 and 10 shows the anti-deformation ability of different kinds of asphalt materials at different temperatures after real aging service of pavement in seasonal frozen areas.

Generally, the nonrecoverable creep compliance (Jnr) of asphalt binders increases with increasing temperature, while the average percent recovery (R) gradually decreases. Additionally, both Jnr and R of asphalt binders decreased with increasing load level. Notably, SBS exhibits a lower Jnr, and a higher R compared to SBR. It indicates that both temperature and loading levels significantly influence the de-formation resistance and recovery of asphalt binders. Additionally, incorporating SBS significantly improves the permanent deformation resistance of base asphalt, whereas the effect of the SBR modifier is less pronounced.

With increasing aging, the Jnr and R values of different asphalt binders show significant variations. Specifically, as the aging degree progresses from the 1 st to the 3 rd stage, the Jnr of BA at different temperatures decreases, while the R value increases. The extent of property changes in BA also varies significantly across different ageing periods. Notably, the performance changes observed between the 1 st and 3 rd aging stages are more obvious, whereas the 2 nd aging stage has a relatively slight impact on BA performance. This indicates that the aging of asphalt binder is more pronounced under elevated ambient temperatures and increased UV radiation in summer (1 st aging), while the aging behavior is mitigated under conditions characterized by lower average ambient temperatures and UV radiation (2 nd aging). During the freeze-thaw cycle (3 rd aging), moisture exposure accelerates the aging process of asphalt binder.

With the progression of aging, the Jnr value of SBR decreases initially and then rises, while the R value follows the opposite pattern. This is consistent with the mechanisms of asphalt aging described in the literature32,33, this behavior can be primarily attributed to the mild oxidation of the asphalt matrix and the volatilization of light components during the early aging stage, which result in increased viscosity and a denser internal structure. Additionally, the uniform dispersion of the SBR phase contributes to the enhancement of the polymer network stability. However, with further aging, molecular chain scission and the degradation of SBR occur, leading to the deterioration of the elastic network structure. Consequently, the asphalt becomes more brittle and susceptible to cracking, the recovery capacity is significantly reduced, and the extent of non-recoverable creep deformation increases. However, as aging progresses, natural aging results in oxidative stiffening and polymer degradation in asphalt binders, which reduces its modifying effect. A comparable pattern is seen in SBS-modified asphalt, though the effect of aging on SBS is less pronounced compared to SBR. Notably, SBS maintains a higher resistance to permanent deformation even after two aging cycles. With increases in aging degree, the Jnr of SBS also presents an increasing trend. This implies that SBS exhibits superior aging resistance compared to SBR, and under comparable conditions, SBS undergoes less degradation and aging than SBR. The main reason for this difference is that SBS, as a triblock copolymer, forms a stable three-dimensional network structure through crosslinking with the asphalt molecules, whereas SBR is a diblock copolymer. During aging, the risk of molecular chain scission is higher for SBR. Under prolonged thermal-oxidative coupling in natural environments, SBR exhibits earlier hardening, and performance degradation compared to SBS. In the laboratory aging experiments35,36, the aging levels of SBS and SBR were similar in the short term, while SBS performed better than SBR after long-term aging. Based on the observations in this study, it can be concluded that under natural aging conditions in cold regions with large temperature fluctuations, the long-term aging resistance, component stability, and molecular chain strength of SBS are all significantly superior to the base asphalt and SBR.

BBR test

The results of the BBR test for asphalt binders, conducted at various aging levels and temperatures, are presented in Figs. 11 and 12.

As illustrated in Figs. 11 and 12, with the gradual decrease in testing temperature, the S value of the asphalt binder continues to increase, while the m value decreases. This signifies that the deformation resistance and stress relaxation characteristics of the asphalt binder decline because of low temperatures. Furthermore, in comparison to the unaltered asphalt at the same temperatures, the modified asphalt binder demonstrates a reduced S value and an elevated m value, indicating that the modification method substantially enhances the low-temperature performance of the asphalt binder. Among them, SBR has the smallest S and the highest m-value before aging, followed by SBS. It proves that the low temperature improvement of BA by SBR modifier is more significant compared to SBS modifier.

After natural aging, the S of asphalt binder increases while m-value decreases, this indicates that the asphalt binder exhibits increased brittleness and hardness at low temperatures, while both its toughness and strength are reduced. Consistent with the results obtained from previous tests, the low-temperature performance of the base asphalt showed a significant change after 1 st aging, and then gradually weakened. In addition, compared with the BA, the aging effect on modified asphalt is relatively limited, as even after the third cycle of natural aging, the low-temperature grading temperatures of both modified asphalts remained unchanged. At the − 18 °C test, both the S and m values meet the regulatory requirements. However, as the test temperature decreases, particularly at −24 ℃, the effect of aging becomes significant. Following natural aging, the stiffness modulus of BA, SBS, and SBR increased by 21%, 10%, and 39% respectively, while the m-values decreased by 17%, 6%, and 24% correspondingly.

In summary, under natural aging conditions, asphalt shows significantly different aging behaviors before and after modification. In the seasonal frozen region, the aging of asphalt binders is more obvious during higher average ambition temperatures and UV radiation, as well as during the freeze-thaw periods. The incorporation of modifiers can enhance both high and low-temperature performance, as well as the aging resistance of asphalt binder; however, the effectiveness of the modification is influenced by the type of modifier used. Following aging, the asphalt binder exhibits an increase in its elastic component, which results in a higher modulus and improved resistance to deformation. However, because of the degradation of the modifier, the performance of modified asphalt can undergo considerable changes following specific natural aging periods. Although the low-temperature grading temperature of the asphalt remains unchanged after one year of natural aging, The increase in the T30 value shows a strong positive correlation with the extent of natural aging. This indicates that relying solely on performance grading methods to assess the impact of aging on asphalt properties may neglect important changes occurring throughout the aging process. It may result in the early fracturing of asphalt pavements, T30 can be considered a dependable measure for evaluating the effects of natural aging on asphalt performance.

FTIR analysis

FTIR spectral analysis was performed on asphalt binders at different stages of aging to clarify the changes in functional groups throughout the natural aging process. The test findings are illustrated in Figs. 13, 14 and 15, while the principal bond assignments of the asphalt in the FTIR spectrum are detailed in Table 447.

The aging of asphalt binder is widely recognized to involve intricate oxidative reactions, which include the evaporation of lighter components and the transformation of resins into asphaltenes, along with changes in the colloidal structure12. Consequently, changes in the carbonyl (C = O, spectral bands at 1700 cm−1) and sulfoxide (S = O, spectral bands at 1030 cm−1) are frequently employed to assess the degree of aging in asphalt binders48.

Figures 13, 14 and 15 demonstrate that the FTIR spectra of the asphalt binders undergo noticeable alterations throughout the natural aging process. Generally, with increasing aging, the characteristic peaks of the asphalt binders remain relatively consistent; instead, there are only variations in the intensity and broadening of certain characteristic peaks. It is noteworthy that prior to aging, both SBR- and SBS-modified asphalts show higher absorption at 1030 cm−1 compared to base asphalt, probably resulting from the bending vibration of the sulfoxide group. It may be due to the higher preparation temperature and extended shearing time during the modification process, which a certain degree of oxidation reaction of asphalt binder can be induced.

As aging progresses, the absorption peak areas at 1030 cm−1for all three asphalt binders increase, indicating that an oxidation reaction occurs during aging, and the sulfur turned into sulfoxide. This phenomenon is also documented in prior research7,49,50. Additionally, under identical aging conditions, both modified asphalt binders demonstrate reduced absorbance at 1030 cm−1. The results suggest that modified asphalt binders might act as antioxidants to sulfoxide formation. However, it is noteworthy that the absorption peak at 1700 cm−1 does not exhibit significant changes during the aging process, suggesting that sulfur oxidation is more likely to occur in the early stages of natural aging and produce sulfoxide in asphalt compared to carbon-oxygen reactions. Nonetheless, the extent of aging and the limited sample numbers necessitate further investigation and discussion. Previous studies have also indicated that the variation of the carbonyl group at 1700 cm−1 is not particularly noticeable for SBS and SBR modified asphalt binders during aging. This suggests that a possible degradation mechanism for the polymer is the oxidation of the unsaturated polybutadiene segment through chain scission.

In comparison to the BA, SBR and SBS exhibit distinct absorption peaks at 966 cm−1 and 748 cm−1, respectively, this due to the bending vibrations of both styrene and butadiene. These peaks represent the primary characteristic features of SBR and SBS modified asphalt. As the natural aging state progresses from the 1 st to the 3rd stage, the intensity of the peaks at 966 cm−1 and 748 cm−1 for SBR and SBS modified asphalt binders gradually decreases. It is noteworthy that the absorption peak area of SBR-modified asphalt at 966 cm−1 diminished after the first aging stage, whereas the intensity of the absorbance peak at 748 cm−1 for SBS remained largely stable until the second aging stage. It means that SBS has better natural aging resistance with lower rates of polymer degradation and oxidation than SBR.

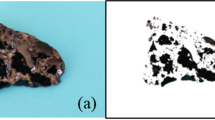

Morphology

The microstructure of asphalt treated by different modification processes in seasonal frozen areas is analyzed. The process of structural evolution with natural weathering is shown on Figs. 16 and 17.

Both Figs. 16 and 17 demonstrate that both modifiers display favorable compatibility with the base asphalt binder, leading to a homogeneous dispersion system. In the aging evolution of the seasonal frozen area, the average size of SBS in the asphalt system is larger than that of SBR, and the average size of the two is gradually decreasing with the intensification of weathering. Besides, certain modifiers display a larger particle size in SBR and SBS. As aging progresses, the dispersion size of both modifiers in asphalt binder decreases, indicating that the polymer undergoes degradation during this process. The microstructural changes are more obvious in SBR, where smaller particles are nearly completely degraded following the initial phase of natural aging. In contrast, SBS retains a considerable number of particles, with some of the larger particles degrading into smaller ones. As aging progresses, the particles in SBS exhibit a more uniform size distribution, along with a further size reduction. However, even after 3 rd of natural aging, a greater quantity of particles remains. Conversely, the microstructure of SBR exhibits more significant alterations with increased aging, which causes a notable decrease in the quantity of particles, with only a few remaining in the final stage of aging. This phenomenon further demonstrates that SBS exhibits superior resistance to natural aging compared to SBR, as it maintains the stability of its phase structure throughout the aging process, which contributes to the stabilization of the properties of SBS.

Conclusions

This study examines the alterations in asphalt performance due to the climatic conditions typical of seasonally frozen regions. Three types of asphalt binders were exposed to the natural environment, allowing them to undergo aging for one year. Subsequently, the rheological properties and crack resistance of asphalt samples were evaluated and analyzed, as well as microstructural analyses, at various aging states, and draw the following conclusions:

(1) The incorporation of polymers will alter the evolution patterns of complex shear modules (G*) and phase angle (δ) in asphalt during natural aging. Specifically, the BA demonstrates a continuous increase in G* with prolonged aging time, accompanied by a corresponding decrease in δ. In contrast, polymer-modified asphalts (SBS/SBR) exhibit biphasic behavior: both G* and δ initially increase before subsequent reduction during aging progression, with the primary distinction manifesting in their respective transition points.

(2) After natural aging, the stiffness modulus of BA, SBS-modified, and SBR-modified asphalt increased by 21%, 10%, and 39% respectively, while the m-values decreased by 17%, 6%, and 24% correspondingly. The findings demonstrate that SBS-modified asphalt exhibits superior natural aging resistance compared to base asphalt (BA), whereas SBR-modified asphalt shows greater susceptibility to aging degradation. This necessitates that modifier selection in seasonal frozen regions should not only account for conventional performance metrics (e.g., PG grading, ductility) but also carefully evaluate the binder’s durability against synergistic environmental aging factors, particularly ultraviolet radiation and thermo-oxidative degradation mechanisms.

(3) Additionally, T30 demonstrates a positive correlation with aging in seasonal frozen area characteristics of asphalt binders. In addition, asphalt binders may be more susceptible to physical hardening behavior after undergoing natural aging, which may shed light on the susceptibility of some asphalt pavements to early cracking. Consequently, binder selection protocols in seasonal frozen regions should comprehensive assessment on physical hardening effects of asphalt binder’s low temperature performance and T30 is a favorable critical for binder selection.

(4) In seasonal frozen regions, asphalt degradation mechanisms extend beyond conventional thermo-oxidative aging to include substantial ultraviolet radiation-induced deterioration, necessitating comprehensive consideration of these synergistic environmental stressors in material durability assessments. During natural aging, modified asphalt experiences degradation of the polymer due to oxidation of the unsaturated polybutadiene component through chain scission. Compared to SBR-modified asphalt, SBS-modified asphalt retains a more consistent phase structure during the entire aging process.

Data availability

The datasets used and analyzed during the current study are available from the corresponding author on reasonable request.

References

Li, Y., Jing, P., Zheng, C., Cheng, P. & Chen, Y. Effect of nano-modified EVA on the physical and rheological characteristics of SBR modified asphalt binder. Constr. Build. Mater. 444, 137843, ISSN 0950–0618. https://doi.org/10.1016/j.conbuildmat.2024.137843 (2024).

Li, Y., Abdelmagid, A. A. A., Qiu, Y., Yang, E. & Chen, Y. Study on the aging mechanism and microstructure analysis of Rice-Husk-Ash- and Crumb-Rubber-Powder-Modified asphalt. Polym. 14, 1969. https://doi.org/10.3390/polym14101969 (2022).

Miró, R., Martínez, A. H., del Moreno-Navarro, F. & Rubio-Gámez, M. Carmen Effect of ageing and temperature on the fatigue behaviour of bitumens. Materials & Design 86, 129–137. (2015).

Qin, Q., Schabron, J. F., Boysen, R. B. & Farrar, M. J. Field aging effect on chemistry and rheology of asphalt binders and rheological predictions for field aging. Fuel 121, 86–94 (2014).

Salehfard, R., Behbahani, H., Dalmazzo, D. & Santagata, E. Effect of colloidal instability on the rheological and fatigue properties of asphalt binders. Constr. Build. Mater. 281, 122563, ISSN 0950–0618. https://doi.org/10.1016/j.conbuildmat.2021.122563 (2021).

Tarsi, G., Varveri, A., Lantieri, C., Scarpas, A. & Sangiorgi, C. Effects of different aging methods on chemical and rheological properties of bitumen. J. Mater. Civ. Eng. 30(3), 04018009. https://doi.org/10.1061/(ASCE)MT.1943-5533.0002206 (2018).

Zhao, X., Wang, S., Wang, Q. & Yao, H. Rheological and structural evolution of SBS modified asphalts under natural weathering. Fuel 184, 242–247 (2016).

Dong, F. et al. Influence of base asphalt aging levels on the foaming characteristics and rheological properties of foamed asphalt. Constr. Build. Mater. 177, 43–50 (2018).

Hofko, B. et al. Effect of short-term ageing temperature on bitumen properties. Road. Mater. Pavement Des. 18 (sup2), 108–117 (2017).

Lu, X., Soenen, H., Sjövall, P. & Pipintakos, G. Analysis of asphaltenes and maltenes before and after long-term aging of bitumen. Fuel. 304, 121426, ISSN 0016–2361. https://doi.org/10.1016/j.fuel.2021.121426 (2021).

Tauste, R., Moreno-Navarro, F., Sol-Sánchez, M. & Rubio-Gámez, M. C. Understanding the bitumen ageing phenomenon: A review. Constr. Build. Mater. 192, 593–609 (2018).

Lin, J., Hong, J., Liu, J. & Wu, S. Investigation on physical and chemical parameters to predict long-term aging of asphalt binder. Constr. Build. Mater. 122, 753–759 (2016).

Wang, Y., Sun, L. & Qin, Y. Aging mechanism of SBS modified asphalt based on chemical reaction kinetics. Constr. Build. Mater. 91, 47–56 (2015).

Ogbon, W. A. et al. Comparative Analysis of Several short-term Aging Simulation Methods and their Impact on long-term Aging Performance of Asphalt Binders437 (CONSTRUCTION AND BUILDING MATERIALS, 2024).

Liu, H. L. et al. Laboratory Aging Method for Simulating the Extracted Aged Asphalt from Reclaimed Asphalt Pavement21 (CASE STUDIES IN CONSTRUCTION MATERIALS, 2024).

Li, P. L., Ding, Z., Zhang, Z. Q. & Zhang, D. Y. Comparative evaluation of laboratory and field ageing of asphalt binder using a non-linear differential model. ROAD. Mater. PAVEMENT Des. 17 (2), 434–445 (2016).

Nagabhushanarao, S. S. & Vijayakumar, A. S. Chemical and Rheological Characteristics of Accelerate Aged Asphalt Binders Using Rolling Thin Film Oven272 (CONSTRUCTION AND BUILDING MATERIALS, 2021).

Xing, C. W. et al. Effect of Salt Solution Environment on the Aging of Styrene-Butadiene-Styrene (SBS)-Modified Asphalt. POLYMERS 16, (12). (2024).

Chen, H., Li, C., Sun, J. & He, Q. Effect of interactive aging considering ultraviolet on rheological properties of SBR modified asphalt and analysis of the aging mechanism. J. Chongqing Univ. 42 (7), 54–62 (2019).

Wang, Q., Li, S., Wu, X., Wang, S. & Ouyang, C. Weather aging resistance of different rubber modified asphalts. Constr. Build. Mater. 106, 443–448 (2016).

Ding, H., Qiu, Y. & Rahman, A. Low-Temperature reversible aging properties of selected asphalt binders based on thermal analysis. J. Mater. Civ. Eng. 31(3), 04018402. https://doi.org/10.1061/(ASCE)MT.1943-5533.0002625 (2019).

Ding, H., Zhang, H., Liu, H. & Qiu, Y. Thermoreversible aging in model asphalt binders. Constr. Build. Mater. 303, 124355, ISSN 0950–0618. https://doi.org/10.1016/j.conbuildmat.2021.124355 (2021).

Xu, J. et al. Study on the effects of reversible aging on the low temperature performance of asphalt binders. Constr. Build. Mater. 295, 123604, ISSN 0950–0618. https://doi.org/10.1016/j.conbuildmat.2021.123604 (2021).

Ma, Y. T. et al. Weather Aging Effects on Modified Asphalt with rubber- Polyethylene Composites865 (SCIENCE OF THE TOTAL ENVIRONMENT, 2023).

Zhang, D. et al. Comparative analysis of rheological and microscopic performance of SBS modified asphalt based on field aging and laboratory aging. Fuel. 352, 128933, ISSN 0016–2361. https://doi.org/10.1016/j.fuel.2023.128933 (2023).

Han, S., Zhang, Z., Zhang, Y. C., Cheng, X. P. & Ren, W. Y. Changes in rheological properties during asphalt aging. Pet. Sci. Technol. 37 (13), 1539–1547 (2019).

Gholami, M., Khodaii, A. & Hajikarimi, P. Long-term Aging Simulation of Asphalt Mixture: A Comparative Experimental Study435 (CONSTRUCTION AND BUILDING MATERIALS, 2024).

Song, S. L. et al. Analysis of Natural Aging Behavior of Asphalt Binder in Cold and Arid Region. ADVANCES IN MATERIALS SCIENCE AND ENGINEERING 2022. (2022).

Hu, M. J. et al. Quantifying Weathering-Aging Test Parameters of High Viscosity-Modified Asphalt by Establishing a Conversion Relationship with Standard PAV Aging. JOURNAL OF MATERIALS IN CIVIL ENGINEERING 34, (6). (2022).

Guopeng Zeng, A. et al. Research on anti-aging properties of POE/SBS compound-modified asphalt in high-altitude regions. Constr. Build. Mater. 376 (131060), 0950–0618 (2023).

Qu, F., Lv, S., Gao, J. & Liu, C. Performance and mechanism of asphalt modified by Buton-Rock asphalt and different types of Styrene-Butadiene-Rubber. Appl. Sci. 10, 3077 (2020).

Li, G. et al. Ultraviolet aging behavior of asphalt based on principal component analysis and the Least-Squares method. J. Mater. Civ. Eng. 37, 1 (2025 ).

Zhang, Q., Cui, Y. & Qiu, H. Microstructure, fatigue, and Self-Healing properties of SBS-Modified asphalt under ultraviolet radiation. J. Mater. Civ. Eng. 35, 7, 04023163 (2023).

Omairey, E. L., Zhang, Y., Soenen, H. & Carbonneau, X. Parametric analysis and field validations of oxidative ageing in asphalt pavements using multiphysics modelling approaches. Int. J. Pavement Eng., 24(2). (2022).

Yuan, J., Li, H., Li, T., Huang, J. & Sun, W. Evolution of asphalt performance under the coupled aging of ultraviolet, high temperature and water. Case Stud. Constr. Mater. 20 (e03220), 2214–5095 (2024).

Chen, Z., Zhang, H. & Duan, H. Investigation of ultraviolet radiation aging gradient in asphalt binder. Constr. Build. Mater. 246, 118501 (2020).

American Association of State Highway and Transportation Officials (AASHTO). Standard Method of Test for Determining the Rheological Properties of Asphalt Binder Using a Dynamic Shear Rheometer (DSR) (AASHTO, 2020).

Li, Y. & Hesp, S. A. M. On the use of empirical phase angle limits for the grading of asphalt binder. Constr. Build. Mater. 346, 128413, ISSN 0950–0618. https://doi.org/10.1016/j.conbuildmat.2022.128413 (2022).

American Association of State Highway and Transportation Officials (AASHTO). Standard Method of Test for Multiple Stress Creep and Recovery (MSCR) Test of Asphalt Binder Using a Dynamic Shear Rheometer (DSR) (AASHTO, 2019).

Cheng, P., Li, Y. & Zhang, Z. Effect of phenolic resin on the rheological and morphological characteristics of Styrene-Butadiene Rubber-Modified asphalt. Materials 13, 5836. https://doi.org/10.3390/ma13245836 (2020).

Ding, H. et al. Performance grading of extracted and recovered asphalt cements. Constr. Build. Mater. 187, 996–1003 (2018).

Angius, E., Ding, H. & Hesp, S. A. Durability assessment of asphalt binder. Constr. Build. Mater. 165, 264–271 (2018).

Lill, K., Kontson, K. & Aavik, A. Determining asphalt binder aging by using limiting phase angle temperature. Baltic J. Road. Bridge Eng. 19 (4), 28–49 (2024).

Khusainov, E. Use of phase angle in lieu of critical crack tip opening displacement for asphalt binder specification. (2021).

Ding, H., Tetteh, N. & Hesp, S. A. Preliminary experience with improved asphalt cement specifications in the City of Kingston, Ontario, Canada. Constr. Build. Mater. 157, 467–475 (2017).

Li, Y., Ding, H., Nie, Y. & Hesp, S. A. Effective control of flexible asphalt pavement cracking through quality assurance testing of extracted and recovered binders. Constr. Build. Mater. 273, 121769 (2021).

Zhang, F. & Yu, J. The research for high-performance SBR compound modified asphalt. Constr. Build. Mater. 24 (3), 410–418 (2010).

Li, Y., Cheng, P., Siddig, E. A. A. & Han, C. Investigation on thermal aging stability of crosslinked styrene butadiene rubber modified asphalt binder. Road. Mater. Pavement Des. 21 (7), 1902–1917 (2019).

Hangtian Ni, M. et al. Degradation characteristics of SBS polymer and its contribution to weathering aging of modified asphalt. Constr. Build. Mater. 369, 130549 (2023).

Ahmed Eltwati, M. R., Hainin, F., Tarhuni, E., Jusli, M. & Alamri Effect of waste engine oil and warm mix additive on the physical, rheological, and short-term aging attributes of Styrene–Butadiene Rubber-modified asphalt binders. Case Stud. Constr. Mater. 21, 2214–5095 (2024).

Acknowledgements

Yiming Li wishes to thank the financial support provided by the Longjian Road and Bridge Co., Ltd.

Funding

This research was funded by the independent research and development project of Longjian Road and Bridge Co., Ltd. (Grant number: 230000100004258240011), Science and Technology Program of Department of Transportation Heilongjiang Province (Grant number: HJK 2024Z0012, HJK2024B003), and the Fundamental Research Funds for the Central Universities (Grant number: 2572022BJ01).

Author information

Authors and Affiliations

Contributions

Feng Wang and Yiming Li: conceptualization, methodology, writing—original draft preparation; Rui Ma: review and editing; Minggang Sun, Yongqian Wang and Yunhui Sun: software, validation, formal analysis; Peifeng Cheng: funding acquisition, methodology. All authors have read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Wang, F., Ma, R., Li, Y. et al. Weathering aging resistance in seasonal frozen regions: A comparative study of SBS- and SBR-modified asphalt binders through rheological and morphological characterization. Sci Rep 15, 13625 (2025). https://doi.org/10.1038/s41598-025-98396-z

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-98396-z