Abstract

This study investigates an innovative approach by utilizing biodiesel derived from Waste Cooking Oil (WCO) to evaluate its impact on engine performance, combustion dynamics, and emissions characteristics. It examines the effects of blending Pentanol with WCO-based biodiesel in a Common Rail Direct Injection engine, maintaining a constant injection timing of 23° before Top Dead Center and a compression ratio of 17.5:1. The analysis covers various fuel compositions, including pure diesel (D100), 30% WCO-biodiesel (B30), 30% WCO-biodiesel with 10% Pentanol (B30 + P10), 30% WCO-biodiesel with 20% Pentanol (B30 + P20), 40% WCO-biodiesel (B40), 40% WCO-biodiesel with 10% Pentanol (B40 + P10), and 40% WCO-biodiesel with 20% Pentanol (B40 + P20), under varying load conditions. The results reveal that WCO-derived biodiesel blends demonstrate notable improvements in combustion and emission metrics. The B30 + P20 blend stands out, delivering a 9.9% increase in brake thermal efficiency, a 10.5% reduction in brake-specific fuel consumption (BSFC), and a 12.6% improvement in volumetric efficiency compared to pure diesel. Additionally, this blend enhances the heat release rate and cylinder pressure by 4.8% and 3.1%, respectively. Emission reductions are substantial, with CO, HC, and NOX emissions decreasing by 31.75%, 20.28%, and 14.82%, respectively, when compared to other biodiesel blends. This research underscores Pentanol-enhanced WCO-biodiesel blends as a sustainable and efficient alternative for automotive applications.

Similar content being viewed by others

Introduction

Energy is required in every area of the economy, including agriculture, manufacturing, transportation, commerce, and home sectors. Natural gas, coal, and other fossil fuel-based fuels like petroleum have long been the world’s main energy sources. Due to the extensive use of fossil fuels in the industrialized world and the residential sector, the rising energy demand has resulted in environmental damage. Consuming fossil fuels entails several hazards for the environment and human health and large and potentially long-lasting effects on global warming1. As a result, academics are looking into alternative energy sources due to rising environmental concerns. Wind, hydropower, solar, biomass, and biofuels are a few examples of renewable energy sources. Due to economic and environmental issues, all of these resources must participate; one potential solution is biodiesel2.

Biodiesel is an alternative to diesel fuel manufactured from the triglycerides of plant and animal fats. Using different catalysts, biodiesel can be produced from various vegetable oils, including castor oil, palm oil, sunflower oil, soybean oil, and rapeseed oil3. The term “waste cooking oil” in this article refers to edible oil formerly used for frying in hotels and restaurants but is no longer used. Most impoverished nations, including those in Africa, throw leftover cooking oil into the environment4. This significantly impacts society’s ecological, social, economic, and health problems. Unsafe or ineffective waste cooking oil discharged into bodies of water increases the number of organic pollutants in the water5. This significantly lowers water quality, harming fish stocks, other aquatic life, and the neighbourhood6. Chemical reactions, transesterification, and esterification are the process which is used to make biodiesel. Transesterification is the most beneficial and cost-effective technology for producing biodiesel7. In the presence of a few catalytic reagents and alcohol, the transesterification process converts oil to biodiesel8. The triglycerides in the oil are converted to esters and glycerol compounds during the process. Glycerol and esters may both be used to make biodiesel and soap. Methanol or ethanol can be used in the process; however, methanol is more commonly employed since it produces a greater yield (polar and short-chain) than ethanol9.

By maintaining a 3:1 molar ratio of triglycerides to alcohol, the transesterification process can be completed stoichiometrically. While transesterification can be acid or base-catalyzed, base-catalyzed transesterification is more frequently used to produce biodiesel. Sodium hydroxide (NaOH) and potassium hydroxide (KOH) are the basic catalysts10. Transesterification is used in the current work to turn WCO into biodiesel with high free fatty acid content. With different loads, blends of WCO biodiesel (30%), Pentanol (20%), and Diesel (70%) were used with constant injection timing. The combustion, performance, and exhaust gas emission properties of a modified common rail direct injection (CRDI) engine was evaluated through experiments using the engine connected to a gas analyzer and a smoke meter9. The performance (BTE and BSFC) and emission (CO, HC, NOx, and smoke) characteristics of WCO biodiesel blends at various loads were examined using a single-cylinder CRDI engine. Increased load causes a rise in BTE and a fall in BSFC at concentrations up to 30%. Heavy loads result in a rise in HC and CO, a decrease in NOx, and CO with a diesel-equivalent concentration of CO8.

According to Literature reviews, Among the several fuel mixes used in engines, B30 (30% biodiesel and 70% diesel) is said to be the most effective10 because it performs as biodiesel the best, The B10 and B20 blend deliver comparable performance and emissions since they share many characteristics with Diesel. The WCO-biodiesel blend B100 cannot be attained to a greater proportion since it damages the engine and increases NOx emissions. The B30 blend delivers a balanced NOx emission while also increasing engine performance. It also reduces CO and HC emissions to a significant extent, So In this research, Blending Pentanol with WCO-Biodiesel in various ratios increases engine Performance and also decreases NOx emissions11 It also reduces CO and HC emissions to a significant extent.

The novelty of this study lies in its pioneering exploration of Pentanol-enhanced biodiesel derived from Waste Cooking Oil (WCO) as a sustainable alternative fuel for Common Rail Direct Injection (CRDI) engines. By systematically blending Pentanol with WCO-based biodiesel in varying compositions and load conditions, the research uncovers substantial enhancements in engine performance, combustion dynamics, and emissions reduction. This innovative approach not only highlights the synergistic effects of Pentanol in improving thermal efficiency, fuel consumption, and emission profiles but also positions Pentanol-enhanced WCO-biodiesel blends as a promising solution for advancing eco-friendly automotive technologies.

Materials and methods

Fuel production

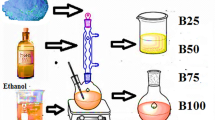

Transesterification method is the most promising for producing biodiesel. Figure 1 shows the Transesterification process of WCO-biodiesel. It is adding methanol and converting triglycerides to glycerol and biodiesel in the presence of a catalyst. To separate the fatty acids from the triglycerides, methanol is utilized as the reaction agent. KOH and NaOH are the most common catalysts employed in this process, and they help to boost yield rates. Given that it is more affordable than other feedstocks and is readily available in Indian restaurants, used cooking oil is thought to be a promising source11. As depicted in Fig. 2, the proper technique easily collects and extracts the oil. In a glass jar, 1,000 ml of used cooking oil is heated to 60 °C. For the desperation of methanol, 0.5–1% volume of oil containing KOH is utilized as a catalyst; the predicted ratio is 0.2:1. The extraction results in the optimum reaction temperature of 50 to 60 ℃.

As a result, the stirring will occur between 300 and 700 times per minute for 90 min. Triglycerides are now separated from oil to allow glycerol to set. The glycerol is then divided by turning the funnel’s bottom valve screw, and it is kept in a separate compartment. From the funnel, the WCO biodiesel is transferred to the glass container. The product’s maximum WCO-biodiesel yield was observed to be 95.3%12. However, compared to the water treatment used to remove particles from the WCO-biodiesel, it includes a higher level of contamination of contaminants. The ratio of water to WCO-biodiesel is 0.2:1, and after the water is heated to saturation, swirled with a magnetic stirrer for 15 min, and collected for around 8 h inside a separate funnel, the process is repeated. At the bottom of the funnel, soap, and water agglomerate throughout this time. The aggregate is milky white and contains a small amount of glycerol. Moving the funnel to a glass beaker and heating it above the saturation temperature between 100 °C and 120 °C separates the water from the WCO-biodiesel and evaporates. As a result, pure WCO-biodiesel is produced13. Figure 3 shows that Pentanol is added to WCO-biodiesel in various ratios to boost the fuel’s ability to burn. The ASTM fuel standard is used to test and compare the fuel properties of all fuel samples, as indicated in Table 1.

Safety and compatibility of pentanol

Pentanol, particularly as a biofuel, presents promising safety and compatibility benefits when used as an alternative fuel in internal combustion engines. It is a higher alcohol with a longer carbon chain than ethanol or methanol, providing better energy density and improved combustion characteristics. Pentanol is less volatile than shorter-chain alcohols, which makes it safer to handle, store, and transport, as it has a lower risk of evaporation and flammability. Its high flash point enhances safety in storage compared to conventional gasoline and even ethanol. Furthermore, pentanol blends well with gasoline, which allows it to be used in existing engine infrastructures with minor modifications. This compatibility reduces the need for extensive changes to fuel systems, making it a viable drop-in fuel for immediate adoption.

Despite its potential, pentanol has some challenges in compatibility with materials commonly used in fuel systems. Its relatively high viscosity and corrosive properties can cause wear and degradation in components like seals, gaskets, and fuel lines if the system is not designed for alcohol-based fuels. However, these issues can be mitigated through the use of advanced materials in engine parts. Additionally, pentanol’s higher oxygen content compared to gasoline results in cleaner combustion, reducing harmful emissions like carbon monoxide and unburned hydrocarbons. This makes pentanol a safer and more environmentally friendly option, aligning with global efforts to lower emissions and move towards greener energy sources.

Experimental setup and engine specification

CRDI engine

A single-cylinder, four-stroke CRDIVCR (Common Rail Direct Injection Variable Compression Ratio) engine is connected to an eddy current dynamometer. The signals are interfaced with the computer through a fast data acquisition device. The system consists of a standalone panel box with an air box, two fuel tanks, a manometer, a fuel measuring device, transmitters for air and fuel flow measurement process indicators, and a piezo powering unit. Rotameters are offered for measuring the flow of engine cooling water. The CRDI VCR engine is equipped with a programmable Open ECU for Diesel Injection, a fuel injector, a common rail with a rail pressure sensor and pressure regulating valve, a crank position sensor, a fuel pump, and a wiring harness. Figure 4 depicts the experimental configuration of the CRDI engine, and Table 2 lists the details. The AVL DI gas 444 N (five-gas analyzer) measures and records the engine’s emissions. Table 3 shows the technical specifications of the Five-gas analyzer and smoke meter. The experiments were performed at partial load due to operational stability considerations, and the manuscript now discusses why full engine load tests were not conducted.

Uncertainty analysis

where BP-Brake power, BTE-Brake thermal efficiency, BSFC- Brake specific fuel consumption, HC-Hydrovarbon, CO-Carbon monoxide, NOx-Nitrogen oxide, and EGT-Exhaust gas temperature.

Long-term effects of using waste cooking oil biodiesel and Pentanol blends

The long-term use of waste cooking oil (WCO) biodiesel and pentanol blends in engines can affect engine wear, residue buildup, and lubricant degradation. WCO biodiesel typically contains higher levels of oxygen and certain contaminants, which can increase the formation of combustion residues, such as carbon deposits, on engine components like injectors, pistons, and valves. When blended with pentanol, the oxygen-rich nature of the fuel may improve combustion efficiency, potentially reducing soot and residue buildup compared to pure biodiesel. However, the higher viscosity and acidity of WCO biodiesel, combined with pentanol’s alcohol properties, can still lead to increased wear on engine parts, especially those in direct contact with the fuel. Over time, this could result in higher rates of corrosion and degradation of metal surfaces unless addressed through material upgrades or engine design adjustments.

Lubricant degradation is another significant concern with long-term use of WCO biodiesel and pentanol blends. Biodiesel is more prone to diluting engine oil than conventional diesel due to its higher polarity and lower volatility. Additionally, pentanol, as an alcohol, can contribute to lubricant breakdown if it mixes with engine oil. This can reduce lubrication effectiveness, increase friction, and lead to the formation of acidic byproducts, potentially accelerating wear in critical engine components like bearings, pistons, and cylinders. To address these issues, it is essential to perform frequent oil changes, use high-quality lubricants specifically formulated for biodiesel-alcohol blends, and maintain fuel injection systems regularly. These measures are critical for ensuring engine durability and consistent performance when using these alternative fuel blends.

Results and discussion

Engine performance characteristics

Brake thermal efficiency

Brake Thermal Efficiency is the portion of the fuel’s heat contribution corresponding to a powerful engine’s braking capacity14. It evaluates how effectively an engine converts fuel heat into mechanical energy. In Fig. 5, it is clearly shown that B30 + P20 has More BTE 36.67% than other fuels, including Diesel, with 30.09% at full load and 1.22% at no load. But the B40 + P20 are slightly higher, with 34.96% at full load and 1.29% at no load compared to Diesel. The B30 + P20 carries out better results than a Diesel (D100) with increases by 9.9%, for the reason that WCO-biodiesel and pentanol mixture contains more oxygen compared to Diesel and another sample so that combustion rate and brake thermal efficiency will be considerably increased15.

Specific fuel consumption

Any prime mover that burns fuel and produces rotational, or shaft, control has its fuel productivity determined by how much fuel is used specifically for the brake power16. It is widely employed to determine how effective an internal compression ignition engine is with a pole yield. It is calculated by dividing the fuel consumption rate by the energy produced. Therefore, it might also be referred to as fuel usage, particularly for power. In Fig. 6, it is demonstrated that the fuel consumption for producing one unit of electricity is very high, with B40 blends using 0.37 kg/kWh more fuel than other blends at a full load. But on the Other end, B30 + P20 is comparatively nearer to the SFC of D100 and reduced by 10.5% Lower than the Other Fuel blends with 0.28 kg/kWh in a full load. But the SFC of B40 + P20 is 0.34 kg/kWh in a full load. Finally, the sample of B30 + P20 is superior to specific fuel consumption to produce high power17. Due to the reason of decreasing viscosity leads to an increased spray cone angle and spray penetration, which results in very small droplets and increases the fuel injection characteristics for fine atomization18.

Air-fuel ratio

In an ignition procedure, the air-fuel ratio (AFR) is the mass ratio of air to a strong fluid or vaporous fuel19. A detonation can occur due to combustion, which can occur in controlled environments such as internal combustion engines or mechanical heaters. The air-fuel ratio regulates the amount of energy produced, the emission of hazardous pollutants during the reaction, and whether a mixture becomes volatile20. In Fig. 7, it has been shown that the Air-fuel for production is very high in B40 than in other blends with 41.59%. In B40 + P20, the Air-fuel Ratio is 34.72%, But on the Other end, B30 + P20 is comparatively nearer to the AFR of D100 and Lower than the Other Fuel blends, so The B30 + P20 Blend is good in AFR with 30.88%.

Volumetric efficiency

The ratio of the mass thickness of the air-fuel mix forced into the cylinder at air weight (during the admission stroke) to the mass thickness of a corresponding air volume in the admission complex is known as volumetric efficiency21. The phrase is also used in various construction contexts, such as with electrical and water-powered pumps. B30 + P20 has a higher Volumetric Efficiency (82.66%) than other fuels, including Diesel (80.66%), as shown in Fig. 8. Compared to other fuel mixes, the B30 + 20 will sweep a larger fuel volume while simultaneously lowering the SFC22.

Emission characteristics

CO emission

Figure 9 shows that the CO emissions are decreased by shortening the injection times in various loading circumstances. The CO emissions display a linearly changing curve when the load varies while the main injection remains constant. Carbon monoxide (CO) emissions are generated due to insufficient oxygen, improper air-fuel equivalence ratio, and incomplete combustion during combustion.CO23 emissions from Biodiesel with Pentanol Blends are much less than D100. Diesel fuel has a very low level of oxygen, which reduces complete combustion. The B30 + P20 produces less CO emissions, with 0.039% at low load and 0.193% at full load. B40 + P20 Produces less than B30 + P20, with 0.037% in no load and 0.188% in a full load. Because Pentanol is an additional supporter for increasing combustion rate and reducing CO emission24.

HC emission

Figure 10 shows at no load, the HC emission of the B30 + P20 and B40 + P20 is the same at 24 ppm, but when adding the load, there is a rise in HC of 88 ppm and 90 ppm, respectively. Due to the cause of increasing engine load, more fuel is consumed throughout combustion, so excess fuel is produced in incomplete combustion and increased HC emissions25. This is essentially the same as the component load criteria. At full load, HC emission is highest for D100 and in no load with 30 ppm and full load at 109 ppm, greater than B30 + P20 and B40 + P20. WCO-biodiesel and pentanol mixture produced high turbulence combustion in the pre-phase combustion stage. For this reason, the excess oxygen molecule in this fuel mixture is released for better combustion26.

NOX emission

Figure 11 shows that the NOX emission graph depicts the NOX emission rates. This figure clearly shows that Using biodiesel will increase the NOx emissions more than Diesel. For B30, it will give an emission of 1691ppm, and For B40, it will give an emission of 1698ppm, which is much higher than that of D100, having only 1509ppm. But it clearly shows that biodiesel blending with Pentanol will reduce NOX emissions27. The B30 + P20 Has a Lower NOX of 1469ppm, which is better than the D100. But In B40 + P20, it will increase again due to the higher amount of biodiesel added28.

Smoke opacity

The smoke emission result is between the smoke and the load, as shown in Fig. 12. Diesel has more smoke emission than other fuels, with 4.2% without loads and 41.5% in a full load. The smoke emission is reduced in all Biodiesel blends compared to Diesel. B30 has 39.1% with a full load, but when we add Pentanol further, it will be reduced to 34.8% for B30 + P20. But in B40 + P20, it slightly decreases due to the greater amounts of Pentanol and Biodiesel29.

Combustion characteristics

Cylinder pressure

Figure 13 shows that the cylinder pressure at 70.43 bar for the blend of B30 and constant injection timing of 23° before TDC shows increased cylinder pressure. When Pentanol is added to the biodiesel, the in-cylinder pressure increases drastically for B30 + P20 with 75.18 bar and B40 + P20 with 73.43 bar, less than the B30 + P20. Because the percentage of biodiesel increases in Diesel, the engine’s cylinder pressure will decrease during combustion30. Because of this, the WCO-biodiesel range has higher density and viscosity than Diesel31. The optimum percentage of WCO- biodiesel and 20% Pentanol mixture released greater performance during combustion and produced higher cylinder pressure.

The net heat release rate

From Fig. 14, it is shown that the net release rate for the blends of B30 + P20 and constant injection timing at 23° before TDC shows higher heat release rate results like 54.84 kJ/m3 deg compared to other blends of B30 and B40. The relationship between the cylinder pressure and the rate of heat emission is directly proportional31. Net Heat Release Rate and Cylindric Pressure are increased when Pentanol is added to the biodiesel in B30 + P20 with 4.8% and 3.1% compared to D100. Pentanol is a suitable blend of the WCO-biodiesel blends for effective combustion.

Conclusions

In the current experiment, CRDI engines operating at constant injection pressure showed improved engine performance, combustion characteristics, and pollutant emissions when using a mixture of biodiesel and pentanol derived from waste cooking oil. The experimental results were compared with diesel fuel (D100) and other blends such as B30, B30 + P20, and B40 + P20. It was observed that specific fuel consumption (SFC) increased with increasing load for WCO-biodiesel. However, the B30 + P20 sample exhibited a 10.5% decrease in specific fuel consumption compared to other fuel samples, making it comparable to D100 and significantly better than other blends. The brake thermal efficiency was 36.97% for B30 + P20, which is higher than the 30.09% observed for neat diesel. The air-fuel ratio (A/F ratio) for B30 + P20 was 30.88, closer to that of diesel (29.65) and better than other fuel blends. The volumetric efficiency of B30 + P20 was 85.33%, higher than diesel. The cylinder pressure and net heat release rate of B30 + P20 were increased by 4.8% and 3.1% compared to diesel. Emissions were drastically reduced by using biodiesel blended with pentanol. The CO emission for biodiesel blends with pentanol was reduced by 31.75% compared to D100.

At no load condition, the CO2 was at 2.31%, increasing to 8.33% at full load for B30 + P20, which was better than diesel and other fuel blends. The HC emission for B30 + P20 was 20.28% lower than D100 at full load. NOx emission in B30 and B40 increased with an increase in loads, but biodiesel blended with pentanol reduced NOx by 14.82% compared to D100. The smoke opacity was also 39.8% at full load for B30 + P20, lower than diesel. Different blends of waste cooking oil were used for different loads of biodiesel, pentanol, and diesel. The findings suggest that the inclusion of pentanol in biodiesel blends reduced pollutants at every stage. The examined sample fuel of B30 + P20 was found to be the most suitable due to the balance of performance and exhaust gas emissions. The B30 + P20 blend holds potential as a superior substitute for neat diesel.

Data availability

The datasets used and/or analysed during the current study are available from the corresponding author on reasonable request.

References

Sakthimurugan, V. & Madhu, S. Novel Scenedesmus obliquus algae biofuel emission and performance characterise in Si-DLC coated diesel engine. Mater. Today Proc., 77, 490–496. (2023). https://doi.org/10.1016/j.matpr.2022.11.304

Yaramati, S. & Sakthimurugan, V. Effect of Tio2 nanoparticles in spirulina biodiesel-diesel blends at various injection strategies: Performance, combustion and emission characteristics. IOP Conf. Ser. Mater. Sci. Eng. 574 (1), 012016. https://doi.org/10.1088/1757-899x/574/1/012016 (2019).

Rajak, U. et al. A numerical investigation on a diesel engine characteristic fuelled using 3D CFD approach. Fuel 368, 131488. https://doi.org/10.1016/j.fuel.2024.131488 (2024).

Banga, S. & Pathak, V. V. Biodiesel production from waste cooking oil: A comprehensive review on the application of heterogenous catalysts. Energy Nexus. 100209. https://doi.org/10.1016/j.nexus.2023.100209 (2023).

Selvam, M., Palani, S. K., Harish, K. A. K. & Pragadish, N. Investigation on the effect of nanocatalyst (Ceo2 + Zro2) blended biodiesel in CRDI-VCR engine for reducing emissions and fuel consumption. Environ. Eng. Manag J. (EEMJ). 22 (2). https://doi.org/10.30638/eemj.2023.024 (2023).

Echaroj, S., Pannucharoenwong, N., Duanguppama, K., Rattanadecho, P. & Hemathulin, S. High throughput biodiesel production from waste cooking oil over metal oxide binded with Fe2O3. Energy Rep. 9, 205–215. https://doi.org/10.1016/j.egyr.2023.05.271 (2023).

Rajak, U., Ağbulut, U., Dasore, A. & Verma, T. N. Artificial intelligence based-prediction of energy efficiency and tailpipe emissions of soybean Methyl ester fuelled CI engine under variable compression ratios. Energy 294, 130861. https://doi.org/10.1016/j.energy.2024.130861 (2024).

Suzihaque, M. U. H., Alwi, H., Ibrahim, U. K., Abdullah, S. & Haron, N. Biodiesel production from waste cooking oil: A brief review. Mater. Today Proc., 63, pp.S490-S495. (2022). https://doi.org/10.1016/j.matpr.2022.04.527

Venu, H. et al. A comprehensive combustion, performance, and environmental analyses of algae biofuel, hydrogen gas, and nano-sized particles (liquid-gas-solid mix) in agricultural CRDI engines. Int. J. Hydrogen Energy. 73, 839–855. https://doi.org/10.1016/j.ijhydene.2024.05.209 (2024).

Ban, S. et al. Process simulation and economic analysis of dolomite catalyst based biodiesel production from Nepalese Jatropha Curcas. Clean. Chem. Eng., 2, p.100029. (2022). https://doi.org/10.1016/j.clce.2022.100029

Amenaghawon, A. N., Obahiagbon, K., Isesele, V. & Usman, F. Optimized biodiesel production from waste cooking oil using a functionalized bio-based heterogeneous catalyst. Clean. Eng. Technol. 8, 100501. https://doi.org/10.1016/j.clet.2022.100501 (2022).

Rajak, U. et al. Effects of different biofuels and their mixtures with diesel fuel on diesel engine performance and exhausts. Sci. Total Environ. 903, 166501. https://doi.org/10.1016/j.scitotenv.2023.166501 (2023).

Pangestu, T. et al. The synthesis of biodiesel using copper based metal-organic framework as a catalyst. J. Environ. Chem. Eng. 7 (4). https://doi.org/10.1016/j.jece.2019.103277 (2019).

Rajak, U. et al. Sustainability evaluation of green microalgae biofuel production and reducing the engine emissions in a common rail direct engine. Fuel 350, 128687. https://doi.org/10.1016/j.fuel.2023.128687 (2023).

Veeraraghavan, S., Madhu, S., De Poures, M. V. & Palani, K. Influence of exhaust gas recirculation on emission metrics in a diesel engine operated with hydrogen induction and cassia fistula biodiesel. SAE Techn Paper. https://doi.org/10.4271/2024-01-5221 (2024).

Soudagar, M. E. M. et al. Organic municipal solid waste derived hydrogen production through supercritical water gasification process configured with K2CO3/SiO2: Performance study. Biomass Bioenergy. 190, 107379. https://doi.org/10.1016/j.biombioe.2024.107379 (2024).

Jume, B. H., Gabris, M. A., Nodeh, H. R., Rezania, S. & Cho, J. Biodiesel production from waste cooking oil using a novel heterogeneous catalyst based on graphene oxide doped metal oxide nanoparticles. Renew. Energy. 162, 2182–2189. https://doi.org/10.1016/j.renene.2020.10.046 (2020).

Soudagar, M. E. M. et al. Optimizing IC engine efficiency: A comprehensive review on biodiesel, nanofluid, and the role of artificial intelligence and machine learning. Energy Conv Manag. 307, 118337. https://doi.org/10.1016/j.enconman.2024.1183 (2024).

Mohamed, M. et al. Diesel engine performance, emissions and combustion characteristics of biodiesel and its blends derived from catalytic pyrolysis of waste cooking oil. Energies, 13(21), p.5708. (2020). https://doi.org/10.3390/en13215708

Makareviciene, V., Santaraite, M. & Sendzikiene, E. Analysis of biological degradation and life cycle indicators of mineral diesel fuel mixtures, containing 10% biodiesel, obtained by simultaneous oil extraction and transesterification. Energies 14 (24). https://doi.org/10.3390/en14248367 (2021).

Abishek, M. S. et al. Alumina and titanium nanoparticles to diesel–Guizotia abyssinica (L.) biodiesel blends on MFVCR engine performance and emissions. Sustain. Energy Technol. Assess. 61, 103580. https://doi.org/10.1016/j.seta.2023.103580 (2024).

Gopinathan, M., Fielza, F. & Kumaran, P. Pre-treatment of waste cooking oil using continuous microwave-assisted glycerolysis reaction. Int. J. Adv. Res. Technol. Innov. 2 (4), 10–19. https://doi.org/10.1016/myjms.2020.15.31 (2020).

Onuh, E. I., Inambao, F. & Awogbemi, O. Performance and emission evaluation of biodiesel derived from waste restaurant oil and Moringa oleifera: A comparative study. Int. J. Ambient Energy. 42 (8), 912–919. https://doi.org/10.1080/01430750.2019.1594377 (2021).

Suzihaque, M. U. H. et al. A sustainability study of the processing of kitchen waste as a potential source of biofuel: Biodiesel production from waste cooking oil (WCO). Mater. Today Proc. 63, pp.S484-S489. (2022). https://doi.org/10.1016/j.matpr.2022.04.526

Soudagar, M. E. M. et al. Utilization of non-edible bio-feedstock Pongamia Pinnata-diethyl ether ternary fuel blend supplemented with graphene oxide nanoparticles on CRDi engine characteristics. J. Ther. Anal. Calorim. 149 (17), 10165–10165. https://doi.org/10.1007/s10973-024-13373-4 (2024).

Chinglenthoiba, C., Das, A. & Vandana, S. Enhanced biodiesel production from waste cooking palm oil, with NaOH-loaded calcined fish bones as the catalyst. Environ. Sci. Pollut Res. 27, 15925–15930. https://doi.org/10.1007/s11356-020-08249-7 (2020).

Petchsoongsakul, N., Ngaosuwan, K., Kiatkittipong, W., Wongsawaeng, D. & Assabumrungrat, S. Different water removal methods for facilitating biodiesel production from low-cost waste cooking oil containing high water content in hybridized reactive distillation. Renew. Energy. 162, 1906–1918. https://doi.org/10.1016/j.renene.2020.09.115 (2020).

Liu, J. & Tao, B. Fractionation of fatty acid Methyl esters via Urea inclusion and its application to improve the low-temperature performance of biodiesel. Biofuel Res. J. 9 (2), 1617–1629. https://doi.org/10.18331/BR2022.9.2.3 (2022).

Vellaiyan, S. Optimization of water and 1-pentanol concentrations in biodiesel-diesel blends for enhanced engine performance and environmental sustainability. Results Eng. 102953. https://doi.org/10.1016/j.rineng.2024.102953 (2024).

Salguero, H. S. & Leon, A. T. Aracel iLucio Quintana, Favian Bayas Morejon., 2017. Recovery of waste cooking oil used in the biodiesel production in Ecuador. Int. J. Sci. Eng. Res. 8: 123–127 .https://doi.org/10.1016/rwcbpe.2017.29.14

Vardhan, M. G., Yuvarajan, D. & Alexander, C. H. C. Study on reducing smoke emission from diesel engines through innovative blends of phoenix sylvestris seed oil and diesel. In Proceedings of 5th International Conference on Sustainable Innovation in Engineering and Technology Vol. 3161, 020260. https://doi.org/10.1063/5.0229663 (2024).

Author information

Authors and Affiliations

Contributions

All Authors have equally contributed to the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Selvam, M., Pragadish, N., Harish, K.A. et al. Investigating emission characteristics and combustion performance of a CRDI engine utilizing novel biodiesel derived from waste cooking oil and pentanol blends. Sci Rep 15, 14742 (2025). https://doi.org/10.1038/s41598-025-98462-6

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-98462-6

Keywords

This article is cited by

-

Impact of biodiesel concentration and temperature on fuel properties: a comprehensive analysis of diesel and biodiesel mixtures

International Journal of Energy and Water Resources (2025)

-

Synergistic effect of biogas and waste Annona seed biodiesel on dual fuel engine performance and emissions

Discover Sustainability (2025)