Abstract

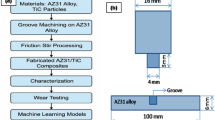

This study investigates the warm straight-groove incremental sheet forming (ISF) behavior of AZ31 magnesium alloy using an integrated experimental, statistical, and machine learning approach. To test the effect of forming temperature, step-down, spindle speed and feed rate, a Taguchi L27 design was used to study the effect of above variables on forming time and forming force. TOPSIS multi-response optimization was used to find the most balanced parameter combination to result in low force and high process efficiency. The statistical result showed that temperature and step-down were the most prevailing factors that controlled the deformation behaviour at warm forming conditions. A Random Forest regression model was constructed in order to increase the predictive ability, and it was able to successfully recreate the trends in the forming time, forming force, and performance index. The fractographic analysis of the fractured wall of the groove proved the presence of a ductile failure mechanism in which voids and localisation of shear dominate. The combined DOE-TOPSIS-ML-SEM analysis offers a very powerful procedure of comprehending and optimizing the warm incremental sheet forming of lightweight AZ31 magnesium alloy.

Similar content being viewed by others

Data availability

The datasets generated and analyzed during the current study are available from the corresponding author on reasonable request.

References

Park, J. J. & Kim, Y. H. Fundamental studies on incremental sheet metal forming process. J. Mater. Process. Technol. 140, 447–453 (2003).

Ambrogio, G., Filice, L. & Gagliardi, F. Warm incremental forming of magnesium alloy AZ31. CIRP Ann. 57, 257–260 (2008).

Ben, S. L. et al. Incremental sheet forming: Technology, modeling and formability. Proc. Inst. Mech. Eng. B J. Eng. Manuf. 236, 1916–1943 (2022).

Kumar, A. & Trzepieciński, T. Critical review of surface quality in incremental sheet forming. J. Manuf. Process. 98, 767–792 (2024).

Schreiber, R. G. & de Jesus, A. M. P. Review of ISF parameters and applications. Braz J. Dev. 8, 39536–39556 (2022).

Gandla, P. K. & Kumar, V. Formability in incremental sheet forming: A critical review. Results Eng. 16, 100615 (2022).

Vignesh, G., Narayanan, C. S. & Pandivelan, C. Review on incremental sheet forming process. J. Manuf. Process. 56, 325–348 (2020).

Magdum, R. A. & Chinnaiyan, P. A critical review of incremental sheet forming in view of process parameters and process output. Adv. Mater. Process. Technol. 8, 2039–2068 (2022).

An, Z., Yan, D., Qie, J., Lu, Z. & Gao, Z. Warm single-point incremental forming of AZ31 cylindrical parts. Front. Mater. 7, 151 (2020).

Ambrogio, G., Filice, L., Gagliardi, F. & Bruschi, S. Incremental sheet forming with local heating of A5083 and AZ31. Int. J. Mod. Phys. B. 22, 5601–5607 (2008).

Mohanraj, R., Deepak, C. R. & Gokul, V. Warm incremental sheet forming of AZ31 and AA6061. Proc. Inst. Mech. Eng. B J. Eng. Manuf. 237, 1515–1528 (2023).

Zhang, H. et al. Influence of temperature in warm incremental sheet forming of AZ31B. Metals 11, 316 (2021).

Wang, N. T. et al. Robot-assisted cold and warm incremental sheet forming of AZ31. J. Manuf. Process. 92, 654–667 (2023).

Qin, Z., Gatea, S. & Ou, H. Friction and heat partition coefficients in incremental sheet forming process. J. Manuf. Process. 124, 503–523 (2024).

Trzepieciński, T. & Oleksik, V. Surface finish in single point incremental forming. Materials 14, 1640 (2021).

Deokar, S., Shinde, S. & Kumar, S. Incremental sheet forming of non-axisymmetric components. Procedia Manuf. 30, 207–214 (2019).

Magdum, R. A. & Chinnaiyan, P. Experimental investigation and optimization of AZ31 magnesium alloy during warm incremental sheet forming. Coatings 13, 68 (2023).

Parida, A. K. & Behera, A. Multi-response optimization using TOPSIS. Int. J. Ind. Eng. Comput. 5, 535–546 (2014).

Khan, A. A. et al. TOPSIS-based multi-objective optimization in hard turning. Mater. Today Proc. 46, 5800–5807 (2021).

Kamalizadeh, S. & Karimi, S. TOPSIS approach for milling optimization. Metals 12, 1796 (2022).

Kazeem, R. A. et al. Multi-process optimization using TOPSIS. Int. J. Adv. Manuf. Technol. 130, 3157–3175 (2024).

Rawat, S. & Singh, R. Enhanced TOPSIS for multi-objective optimization. Expert Syst. Appl. 244, 123116 (2024).

La, N. T. et al. Hybrid Taguchi–TOPSIS optimization in ultrasonic incremental forming. Materials 17, 2152 (2024).

Chinnaiyan, P. & Jeevanantham, A. K. Multi-objective optimization of single point incremental sheet forming of AA5052 using Taguchi based grey relational analysis coupled with principal component analysis. Int. J. Precis Eng. Manuf. 15, 2309–2316 (2014).

Patel, D. M. & Gandhi, A. H. Experimental investigation and optimization of forming parameters in single point incremental forming of AZ31 magnesium alloy. Int. J. Exp. Res. Rev. 46, 240–252 (2024).

Maji, K. & Kumar, G. Inverse analysis and multi-objective optimization of single-point incremental forming of AA5083 aluminum alloy sheet. Soft Comput. 24, 4505–4521 (2019).

Xiao, X. et al. RSM and BPNN modeling in incremental sheet forming process for AA5052 sheet: Multi-objective optimization using genetic algorithm. Metals 10, 1003 (2020).

Xie, Z. D. et al. Effects of ultrasonic vibration on performance and microstructure of AZ31 magnesium alloy under tensile deformation. J. Cent. South. Univ. 25, 1545–1559 (2018).

Van Sy, L. & Thanh Nam, N. Hot incremental forming of magnesium and aluminum alloy sheets by using direct heating system. Proc. Inst. Mech. Eng. B J. Eng. Manuf. 227, 1099–1110 (2013).

Zhang, W. et al. Microstructure evolution and mechanical properties of AZ31 magnesium alloy sheets prepared by low-speed extrusion with different temperature. Crystals 10, 644 (2020).

Guo, J. et al. Wire Arc additive manufacturing of AZ31 magnesium alloy: grain refinement by adjusting pulse frequency. Materials 9, 823 (2016).

Xu, J. et al. Microhardness, microstructure and tensile behaviour of an AZ31 magnesium alloy processed by high-pressure torsion. J. Mater. Sci. 50, 7424–7436 (2015).

Ostasevicius, V. et al. Machine learning methods for single point incremental forming process monitoring. Sensors 21, 18 (2021).

Sevšek, L. et al. Soft computing for SPIF process parameter correlation. Appl. Soft Comput. 141, 110497 (2023).

Harfoush, A., Vanhoucke, B. & Duflou, J. R. Artificial intelligence in incremental sheet forming. Proc. Manuf. 54, 21–28 (2021).

Möllensiep, D., Liu, S. & Tekkaya, A. E. ANN-based prediction of geometric accuracy in incremental sheet forming. Int. J. Adv. Manuf. Technol. 135, 4021–4035 (2024).

Wang, C. et al. Learning-based model predictive control for incremental sheet forming. J. Manuf. Syst. 69, 315–329 (2023).

Kurra, S., Regalla, S. P. & Gupta, A. K. Prediction of surface roughness using machine learning technique for incremental sheet forming process. J. Mater. Eng. Perform. 31, 4512–4525 (2022).

Mittal, A. et al. Machine learning enabled estimation of formability for anisotropic sheet metals. Int. J. Mech. Sci. 265, 108845 (2024).

Liu, Z. et al. Study on incremental sheet forming performance of aluminum alloy based on adaptive fuzzy PID temperature control. Metals 12, 852 (2022).

Li, W. et al. Application of machine learning on tool path optimisation and cooling lubricant in induction heating-assisted single point incremental sheet forming of Ti-6Al-4V sheets. Int. J. Adv. Manuf. Technol. 123, 821–838 (2022).

Li, H. et al. Machine learning for predicting fracture strain in sheet metal forming. Metals 12, 1799 (2022).

Do, V. C. et al. Enhancing forming limit curve and fracture height predictions in single-point incremental sheet forming of sheet material. Materials 16, 7306 (2023).

Funding

The authors received no funding for this work.

Author information

Authors and Affiliations

Contributions

A.A.K., R.A.M., A.R.M. **–** Design and conduct the experiment, draft manuscript preparation, data collection and analysis of results. A.W.K., P.C. **–** reviewing and editing. All authors reviewed the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Khot, A.A., Magdum, R.A., Magdum, A.R. et al. Multi-response optimization and machine learning-based prediction of straight-groove warm incremental sheet forming of AZ31 magnesium alloy. Sci Rep (2026). https://doi.org/10.1038/s41598-026-37761-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-026-37761-y