Abstract

Escalating global plastic pollution and the depletion of fossil-based resources underscore the urgent need for innovative end-of-life plastic management strategies in the context of a circular economy. Thermolysis is capable of upcycling end-of-life plastics to intermediate molecules suitable for downstream conversion to eventually high-value chemicals, but tuning the molar mass distribution of the products is challenging. Here we report a temperature-gradient thermolysis strategy for the conversion of polyethylene and polypropylene into hydrocarbons with tunable molar mass distributions. The whole thermolysis process is catalyst- and hydrogen-free. The thermolysis of polyethylene and polyethylene/polypropylene mixtures with tailored temperature gradients generated oil with an average chain length of ~C14. The oil featured a high concentration of synthetically useful α-olefins. Computational fluid dynamics simulations revealed that regulating the reactor wall temperature was the key to tuning the hydrocarbon distributions. Subsequent oxidation of the obtained α-olefins by sulfuric acid and neutralization by potassium hydroxide afforded sulfate detergents with excellent foaming behaviour and emulsifying capacity and low critical micelle concentration. Overall, this work provides a viable approach to producing value-added chemicals from end-of-life plastics, improving the circularity of the anthropogenic carbon cycle.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$32.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on SpringerLink

- Instant access to the full article PDF.

USD 39.95

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

Additional data are provided in the Supplementary Information, and all the raw files are available via Dryad at https://doi.org/10.5061/dryad.41ns1rnq0 (ref. 51). Source data are provided with this paper.

References

Celik, G. et al. Upcycling single-use polyethylene into high-quality liquid products. ACS Cent. Sci. 5, 1795–1803 (2019).

Butler, E., Devlin, G. & McDonnell, K. Waste polyolefins to liquid fuels via pyrolysis: review of commercial state-of-the-art and recent laboratory research. Waste Biomass Valor. 2, 227–255 (2011).

Schleussner, C.-F., Ganti, G., Rogelj, J. & Gidden, M. J. An emission pathway classification reflecting the Paris Agreement climate objectives. Commun. Earth Environ. 3, 135 (2022).

Ellis, L. D. et al. Chemical and biological catalysis for plastics recycling and upcycling. Nat. Catal. 4, 539–556 (2021).

Zhang, F. et al. Polyethylene upcycling to long-chain alkylaromatics by tandem hydrogenolysis/aromatization. Science 370, 437–441 (2020).

Liu, S., Kots, P. A., Vance, B. C., Danielson, A. & Vlachos, D. G. Plastic waste to fuels by hydrocracking at mild conditions. Sci. Adv. 7, eabf8283 (2021).

Dong, Q. et al. Depolymerization of plastics by means of electrified spatiotemporal heating. Nature 616, 488–494 (2023).

Thiounn, T. & Smith, R. C. Advances and approaches for chemical recycling of plastic waste. J. Polym. Sci. 58, 1347–1364 (2020).

Lv, H., Huang, F. & Zhang, F. Upcycling waste plastics with a C–C backbone by heterogeneous catalysis. Langmuir 40, 5077–5089 (2024).

Bezergianni, S., Dimitriadis, A., Faussone, G.-C. & Karonis, D. Alternative diesel from waste plastics. Energies 10, 1750 (2017).

Dobó, Z. et al. Characterization of gasoline-like transportation fuels obtained by distillation of pyrolysis oils from plastic waste mixtures. Energy Fuels 35, 2347–2356 (2021).

Kots, P. A., Doika, P. A., Vance, B. C., Najmi, S. & Vlachos, D. G. Tuning high-density polyethylene hydrocracking through mordenite zeolite crystal engineering. ACS Sustain. Chem. Eng. 11, 9000–9009 (2023).

Tennakoon, A. et al. Catalytic upcycling of high-density polyethylene via a processive mechanism. Nat. Catal. 3, 893–901 (2020).

Vance, B. C. et al. Single pot catalyst strategy to branched products via adhesive isomerization and hydrocracking of polyethylene over platinum tungstated zirconia. Appl. Catal. B 299, 120483 (2021).

Jia, X., Qin, C., Friedberger, T., Guan, Z. & Huang, Z. Efficient and selective degradation of polyethylenes into liquid fuels and waxes under mild conditions. Sci. Adv. 2, e1501591 (2016).

Gan, L. et al. Beyond conventional degradation: catalytic solutions for polyolefin upcycling. CCS Chem. 6, 313–333 (2023).

Xu, Z. et al. Chemical upcycling of polyethylene, polypropylene, and mixtures to high-value surfactants. Science 381, 666–671 (2023).

Cox, M. F. Effect of alkyl carbon chain length and ethylene oxide content on the performance of linear alcohol ether sulfates. J. Am. Oil Chem. Soc. 66, 1637–1646 (1989).

Soaps & Detergents (Eastman, 2024); https://www.eastman.com/Markets/cleaners/Household-Cleaners/Pages/Soaps-Detergents.aspx

Chupa, J., Misner, S., Sachdev, A., Wisniewski, P. & Smith, G. A. in Handbook of Industrial Chemistry and Biotechnology (ed. Kent, J. A.) 1431–1471 (Springer US, 2012).

Thannimalay, L. & Yusoff, S. Comparative analysis of environmental evaluation of LAS and MES in detergent—a Malaysian case study. World Appl. Sci. J. 31, 1635–1647 (2014).

Lucchetti, M. G., Paolotti, L., Rocchi, L. & Boggia, A. The role of environmental evaluation within circular economy: an application of life cycle assessment (LCA) method in the detergents sector. Environ. Clim. Technol. 23, 238–257 (2019).

Liu, B. et al. Corncob cellulose nanosphere as an eco-friendly detergent. Nat. Sustain. 3, 448–458 (2020).

Farias, C. B. B. et al. Production of green surfactants: market prospects. Electron. J. Biotechnol. 51, 28–39 (2021).

Aguado, J., Serrano, D. & Escola, J. in Feedstock Recycling and Pyrolysis of Waste Plastics: Converting Waste Plastics into Diesel and Other Fuels—Catalytic Upgrading of Plastic Wastes (eds John Scheirs, J. & Kaminsky, W.) Ch. 3, 73–110 (Wiley, 2006).

Mazloum, S. et al. Modelling plastic heating and melting in a semi-batch pyrolysis reactor. Appl. Energy 283, 116375 (2021).

De la Flor-Barriga, L. A. & Rodríguez-Zúñiga, U. F. Numerical analysis on a catalytic pyrolysis reactor design for plastic waste upcycling using CFD modelling. RSC Adv. 12, 12436–12445 (2022).

Shan, T. et al. Simulation of the two-stage pyrolysis process of mixed waste plastics. Energy Fuels 37, 16771–16780 (2023).

Ahmad, I. et al. Pyrolysis study of polypropylene and polyethylene into premium oil products. Int. J. Green. Energy 12, 663–671 (2015).

De Amorim, M. T. S. P., Comel, C. & Vermande, P. Pyrolysis of polypropylene: I. Identification of compounds and degradation reactions. J. Anal. Appl. Pyrolysis 4, 73–81 (1982).

Ballice, L. & Reimert, R. Classification of volatile products from the temperature-programmed pyrolysis of polypropylene (PP), atactic-polypropylene (APP) and thermogravimetrically derived kinetics of pyrolysis. Chem. Eng. Process. Process Intensif. 41, 289–296 (2002).

Das, P. & Tiwari, P. Valorization of packaging plastic waste by slow pyrolysis. Resour. Conserv. Recycl. 128, 69–77 (2018).

Serranti, S., Luciani, V., Bonifazi, G., Hu, B. & Rem, P. C. An innovative recycling process to obtain pure polyethylene and polypropylene from household waste. Waste Manage. (Oxf.) 35, 12–20 (2015).

Bauer, M. et al. Sink–float density separation of post-consumer plastics for feedstock recycling. J. Mater. Cycles Waste Manage. 20, 1781–1791 (2018).

Kanbur, U. et al. Catalytic carbon–carbon bond cleavage and carbon-element bond formation give new life for polyolefins as biodegradable surfactants. Chem 7, 1347–1362 (2021).

Li, H. et al. Hydroformylation of pyrolysis oils to aldehydes and alcohols from polyolefin waste. Science 381, 660–666 (2023).

Prieto Vidal, N. et al. The effects of cold saponification on the unsaponified fatty acid composition and sensory perception of commercial natural herbal soaps. Molecules 23, 2356 (2018).

Wilkinson, K. M., Bain, C. D., Matsubara, H. & Aratono, M. Wetting of surfactant solutions by alkanes. ChemPhysChem 6, 547–555 (2005).

Yang, L., Li, X. & Dong, J. Renewable branched-chain sulfonate surfactants by addition of sodium hydrogensulfite to alkyl oleate. Colloids Surf. A 641, 128513 (2022).

Ju, Y., Hua, J., Niu, H. & Chen, H. Multibranched molecule defoamers based on methyl gallate for highly effective defoaming and antifoaming. Langmuir 39, 12497–12509 (2023).

Li, J., Li, Y., Song, Y., Wang, Z. & Zhang, Q. Properties of quaternary ammonium surfactant with hydroxyethyl group and anionic surfactant mixed systems. J. Mol. Liq. 271, 373–379 (2018).

Bijma, K. et al. Classification of calorimetric titration plots for alkyltrimethylammonium and alkylpyridinium cationic surfactants in aqueous solutions. J. Chem. Soc. Faraday Trans. 93, 1579–1584 (1997).

Markarian, S. A., Harutyunyan, L. R. & Harutyunyan, R. S. The properties of mixtures of sodium dodecylsulfate and diethylsulfoxide in water. J. Solut. Chem. 34, 361–368 (2005).

Bäckström, E., Odelius, K. & Hakkarainen, M. Trash to treasure: microwave-assisted conversion of polyethylene to functional chemicals. Ind. Eng. Chem. Res. 56, 14814–14821 (2017).

Chen, L. et al. Selective, catalytic oxidations of C–H bonds in polyethylenes produce functional materials with enhanced adhesion. Chem 7, 137–145 (2021).

Onwudili, J. A., Insura, N. & Williams, P. T. Composition of products from the pyrolysis of polyethylene and polystyrene in a closed batch reactor: effects of temperature and residence time. J. Anal. Appl. Pyrolysis 86, 293–303 (2009).

Albonetti, S., Cavani, F. & TrifirÒ, F. Key aspects of catalyst design for the selective oxidation of paraffins. Catal. Rev. 38, 413–438 (1996).

Raymond, R. L. Microbial oxidation of n-paraffinic hydrocarbons (volume 2). J. Ind. Microbiol. Biotechnol. 22, 206–215 (1999).

Ardiyanti, A. R., Khromova, S. A., Venderbosch, R. H., Yakovlev, V. A. & Heeres, H. J. Catalytic hydrotreatment of fast-pyrolysis oil using non-sulfided bimetallic Ni–Cu catalysts on a δ-Al2O3 support. Appl. Catal. B 117–118, 105–117 (2012).

Clothier, P. Q. E., Aguda, B. D., Moise, A. & Pritchard, H. O. How do diesel-fuel ignition improvers work? Chem. Soc. Rev. 22, 101–108 (1993).

Munyaneza, N. E. et al. Chain-length-controllable upcycling of polyolefins to sulfate detergents. Dryad https://doi.org/10.5061/dryad.c866t1gc5 (2024).

U.S. Soap and Detergent Market: Analysis and Forecast to 2030 (IndexBox, 2022).

Price of High-Density Polyethylene Worldwide from 2017 to 2022 (Statista, 2023).

Price of Polypropylene Worldwide from 2017 to 2022 (Statista, 2023).

U.S.—Sulphuric Acid and Oleum—Market Analysis, Forecast, Size, Trends and Insights (IndexBox 2023).

Markets/Energy-Refined Products (Bloomberg, 2024); https://www.bloomberg.com/energy

Acknowledgements

This work is based on the project supported by NSF Award No. DMR-2411680. We acknowledge the Chemistry Chromatography Center at Virginia Tech and M. Ashraf-Khorassani for providing assistance with the GC–MS experiments.

Author information

Authors and Affiliations

Contributions

G.L. conceived and supervised the project. G.L. and N.E.M. designed the research. N.E.M. performed the thermolysis and sulfation experiments. J.M., L.S. and N.R. evaluated the molar masses of the plastic feedstocks and thermolysis products. N.E.M. and A.D. conducted materials characterization of plastic waste-based detergents. R.Q. and R.J. performed the computational fluid dynamics studies. G.L. and N.E.M. wrote the original manuscript. All authors contributed to manuscript proofreading and editing.

Corresponding authors

Ethics declarations

Competing interests

G.L. and N.E.M. have filed a patent based on this work: PCT/US2024/026720. The remaining authors declare no competing interests.

Peer review

Peer review information

Nature Sustainability thanks Yue Liu, Fan Zhang and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary information

Supplementary Figs. 1–30, Scheme 1, Tables 1–10, Results, Discussion and computational fluid dynamics simulations.

Source data

Source Data Fig. 1

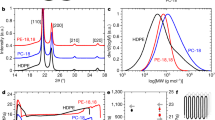

GC chromatograms of PE-oil and PE-wax.

Source Data Fig. 2a

Bar graphs of wax, oil and gas yield from plastics.

Source Data Fig. 2b

Pie charts of acyclic and naphthene product breakdown.

Source Data Fig. 2c

GC chromatograms of PP-oil and PP-wax.

Source Data Fig. 2d

GC chromatograms of PE/PP mixture oil and wax.

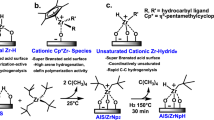

Source Data Fig. 3b

Proton NMR of PE thermolysis oil.

Source Data Fig. 3b

Proton NMR of PE-oil-derived AHS.

Source Data Fig. 3c

13C NMR of PE-oil-derived AHS.

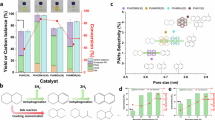

Source Data Fig. 4c

Contact angle measurements of plastic-waste-based detergent solutions and SDS.

Source Data Fig. 5b

Drainage time experiments of detergents and paraffin oil mixtures.

Source Data Fig. 5c and 5d

Effect of detergent concentration on surface tension.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Munyaneza, N.E., Ji, R., DiMarco, A. et al. Chain-length-controllable upcycling of polyolefins to sulfate detergents. Nat Sustain 7, 1681–1690 (2024). https://doi.org/10.1038/s41893-024-01464-x

Received:

Accepted:

Published:

Version of record:

Issue date:

DOI: https://doi.org/10.1038/s41893-024-01464-x