Abstract

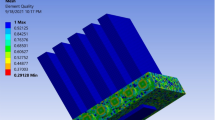

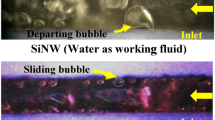

The miniaturization of advanced electronics can lead to high heat fluxes, which must be dissipated before they cause device degradation or failure. Embedded microfluidic cooling is of potential value in such systems, but devices are typically limited to heat fluxes below 2,000 W cm−2. Here we report a microfluidic cooling strategy that can dissipate heat fluxes up to 3,000 W cm−2 at a pumping power of only 0.9 W cm−2 using single-phase water as the coolant. Our approach is based on a three-tier structure that consists of a tapered manifold layer on the top, a microjet layer in the middle and a microchannel layer with sawtooth-shaped sidewalls at the bottom. The structures are etched directly into the backside of the silicon substrate using standard microelectromechanical system technology. Moreover, the coefficient of performance can reach 13,000 and dissipate a heat flux of 1,000 W cm−2 at a maximum chip temperature rise of 65 K.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$32.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on SpringerLink

- Instant access to the full article PDF.

USD 39.95

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

Source data are provided with this paper. Further data that support the findings of this study are available from the corresponding author upon reasonable request.

References

Amano, H. et al. The 2018 GaN power electronics roadmap. J. Phys. D 51, 163001 (2018).

Lee, H., Smet, V. & Tummala, R. A review of SiC power module packaging technologies: challenges, advances, and emerging issues. IEEE J. Emerg. Sel. Topics Power Electron. 8, 239–255 (2020).

Qin, Y. et al. Thermal management and packaging of wide and ultra-wide bandgap power devices: a review and perspective. J.Phys. D 56, 093001 (2023).

Bar-Cohen, A., Maurer, J. J. & Altman, D. H. Embedded cooling for wide bandgap power amplifiers: a review. J. Electron. Packag. 141, 040803 (2019).

Bar-Cohen, A. et al. The ICECool fundamentals effort on evaporative cooling of microelectronics. IEEE Trans. Compon. Packag. Manuf. Technol. 11, 1546–1564 (2021).

Darwish, A. M., Huebschman, B. D., Viveiros, E. & Hung, H. A. Dependence of GaN HEMT millimeter-wave performance on temperature. IEEE Trans. Microw. Theory Techn. 57, 3205–3211 (2009).

Pomeroy, J. W., Uren, M. J., Lambert, B. & Kuball, M. Operating channel temperature in GaN HEMTs: d.c. versus RF accelerated life testing. Microelectron. Reliab. 55, 2505–2510 (2015).

Technologies for Heat Removal in Electronics at the Device Scale (THREADS) HR001123S0013 (US DARPA Microsystems Technology Office, 2022); https://www.highergov.com/document/hr001123s0013-pdf-c849d5

Jones, N. The information factories. Data centres are chewing up vast amounts of energy. Nature 561, 163–166 (2018).

Nadjahi, C., Louahlia, H. & Lemasson, S. A review of thermal management and innovative cooling strategies for data center. Sustain. Comput. Inform. Syst. 19, 14–28 (2018).

Agostini, B. et al. State of the art of high heat flux cooling technologies. Heat Transf. Eng. 28, 258–281 (2007).

Moreno, G. et al. Electric-drive vehicle power electronics thermal management: current status, challenges, and future directions. J. Electron. Packag. 144, 011004 (2022).

Tuckerman, D. B. & Pease, R. F. W. High-performance heat sinking for VLSI. IEEE Electron Device Lett. 2, 126–129 (1981).

Wu, C. J. et al. Ultra high power cooling solution for 3D-ICs. In Proc. 2021 Symposium on VLSI Technology 1–2 (IEEE, 2021).

Harpole, G. M. & Eninger, J. E. Micro-channel heat exchanger optimization. In Proc. Seventh Annual IEEE Semiconductor Thermal Measurement and Management Symposium (SEMI-THERM VII) 59–63 (IEEE, 1991).

Escher, W., Brunschwiler, T., Michel, B. & Poulikakos, D. Experimental investigation of an ultrathin manifold microchannel heat sink for liquid-cooled chips. J. Heat Transf. 132, 081402 (2010).

Lin, Y. et al. Single-phase and two-phase flow and heat transfer in microchannel heat sink with various manifold arrangements. Int. J. Heat Mass Transf. 171, 121118 (2021).

Jung, K. W. et al. Embedded cooling with 3D manifold for vehicle power electronics application: single-phase thermal-fluid performance. Int. J. Heat Mass Transf. 130, 1108–1119 (2019).

Wu, Z., Xiao, W. & Song, B. Efficient thermal management of high-power electronics via jet-enhanced HU-type manifold microchannel. Int. J. Heat Mass Transf. 221, 125113 (2024).

Altman, D. H., Gupta, A. & Tyhach, M. Development of a diamond microfluidics-based intra-chip cooling technology for GaN. In ASME 2015 International Technical Conference and Exhibition on Packaging and Integration of Electronic and Photonic Microsystems (InterPACK 2015) 1–6 (ASME, 2015).

Gambin, V. et al. Impingement cooled embedded diamond multiphysics co‑design. In 2016 15th IEEE Intersociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems (ITherm) 1518–1529 (IEEE, 2016).

Zhang, H. & Guo, Z. Near-junction microfluidic cooling for GaN HEMT with capped diamond heat spreader. Int. J. Heat Mass Transf. 186, 122476 (2022).

Mandel, R. K., Bae, D. G. & Ohadi, M. M. Embedded two-phase cooling of high flux electronics via press-fit and bonded FEEDS coolers. J. Electron. Packag. 140, 031003 (2018).

Drummond, K. P. et al. Characterization of hierarchical manifold microchannel heat sink arrays under simultaneous background and hotspot heating conditions. Int. J. Heat Mass Transf. 126, 1289–1301 (2018).

Drummond, K. P., Weibel, J. A. & Garimella, S. V. Two-phase flow morphology and local wall temperatures in high-aspect-ratio manifold microchannels. Int. J. Heat Mass Transf. 153, 119551 (2020).

van Erp, R., Soleimanzadeh, R., Nela, L., Kampitsis, G. & Matioli, E. Co-designing electronics with microfluidics for more sustainable cooling. Nature 585, 211–216 (2020).

Wei, T. et al. High-efficiency polymer-based direct multi-jet impingement cooling solution for high-power devices. IEEE Trans. Power Electron. 34, 6601–6612 (2019).

Walsh, S. M. et al. Embedded microjets for thermal management of high power-density electronic devices. IEEE Trans. Compon. Packag. Manuf. Technol. 9, 269–278 (2019).

Jones-Jackson, S., Rodriguez, R. & Emadi, A. Jet impingement cooling in power electronics for electrified automotive transportation: current status and future trends. IEEE Trans. Power Electron. 36, 10420–10435 (2021).

Wu, Z. et al. Jet microchannel with sawtooth wall for efficient cooling of high-power electronics. Int. J. Heat Mass Transf. 206, 123955 (2023).

Gilmore, N., Timchenko, V. & Menictas, C. Open manifold microchannel heat sink for high heat flux electronic cooling with a reduced pressure drop. Int. J. Heat Mass Transf. 163, 120395 (2020).

Escher, W., Michel, B. & Poulikakos, D. A novel high performance, ultra thin heat sink for electronics. Int. J. Heat Fluid Flow. 31, 586–598 (2010).

van Erp, R., Kampitsis, G. & Matioli, E. Efficient microchannel cooling of multiple power devices with compact flow distribution for high power-density converters. IEEE Trans. Power Electron. 35, 7235–7245 (2020).

Yang, Y. et al. Embedded microfluidic cooling with compact double H type manifold microchannels for large-area high-power chips. Int. J. Heat Mass Transf. 197, 123340 (2022).

Rajan, S. K. et al. Integrated silicon microfluidic cooling of a high-power overclocked CPU for efficient thermal management. IEEE Access 10, 59259–59269 (2022).

Drummond, K. P. et al. A hierarchical manifold microchannel heat sink array for high-heat-flux two-phase cooling of electronics. Int. J. Heat Mass Transf. 117, 319–330 (2018).

Moffat, R. J. Describing the uncertainties in experimental results. Exp. Therm. Fluid Sci. 1, 3–17 (1988).

Ditri, J., Hahn, J., Cadotte, R., McNulty, M. & Luppa, D. Embedded cooling of high heat flux electronics utilizing distributed microfluidic impingement jets. In Proc. ASME 2015 International Technical Conference and Exhibition on Packaging and Integration of Electronic and Photonic Microsystems (InterPACK 2015) 1–10 (ASME, 2015).

Kempers, R., Colenbrander, J., Tan, W., Chen, R. & Robinson, A. J. Experimental characterization of a hybrid impinging microjet-microchannel heat sink fabricated using high-volume metal additive manufacturing. Int. J. Thermofluids 5–6, 100029 (2020).

Everhart, L. et al. Manifold microchannel cooler for direct backside liquid cooling of SiC power devices. In Proc. ASME 2007 5th International Conference on Nanochannels, Microchannels, and Minichannels 285–292 (ASME, 2007).

Yang, S., Li, J., Cao, B., Wu, Z. & Sheng, K. Investigation of Z-type manifold microchannel cooling for ultra-high heat flux dissipation in power electronic devices. Int. J. Heat Mass Transf. 218, 124792 (2024).

Lee, Y. J. & Kim, S. J. Experimental investigation on thermal-hydraulic performance of manifold microchannel with pin-fins for ultra-high heat flux cooling. Int. J. Heat Mass Transf. 224, 125336 (2024).

Palko, J. W. et al. Extreme two‐phase cooling from laser‐etched diamond and conformal, template‐fabricated microporous copper. Adv. Funct. Mater. 27, 1703265 (2017).

Acknowledgements

This work was supported by the National Key R&D Program of China (grant number 2023YFB4404100, W.W.), the Scientific Research Innovation Capability Support Project for Young Faculty (grant number ZYGXQNJSKYCXNLZCXM-E1, B.S.) from the Ministry of Education of China, the National Natural Science Foundation of China (grant number 52076002, B.S.), the National Key Laboratory of Advanced Micro and Nano Manufacture Technology, the Molecular Materials and Nanofabrication Laboratory, and the High-Performance Computing Platform of Peking University. B.S. acknowledges support from the New Cornerstone Science Foundation through the XPLORER PRIZE.

Author information

Authors and Affiliations

Contributions

B.S. and Z.W. conceived the research. B.S. and W.W. supervised the research. Z.W. and H.H. fabricated the devices. Z.W. and W.X. conducted the thermo-hydraulic measurements and analyses. Z.W. and B.S. prepared the paper.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Electronics thanks Junrui Lyu and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Figs. 1–6, Tables 1–3 and references.

Source data

Source Data Fig. 3

Statistical source data for Fig. 3.

Source Data Fig. 4

Statistical source data for Fig. 4.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wu, Z., Xiao, W., He, H. et al. Jet-enhanced manifold microchannels for cooling electronics up to a heat flux of 3,000 W cm−2. Nat Electron 8, 810–817 (2025). https://doi.org/10.1038/s41928-025-01449-4

Received:

Accepted:

Published:

Version of record:

Issue date:

DOI: https://doi.org/10.1038/s41928-025-01449-4

This article is cited by

-

Advancing cooling limits with 3D embedded microchannels

Nature Electronics (2025)